Page 1

For OEM Applications

ES-P777

Job Name

Job Location

Engineer

Approval

LEAD FREE

–––––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––––––

*

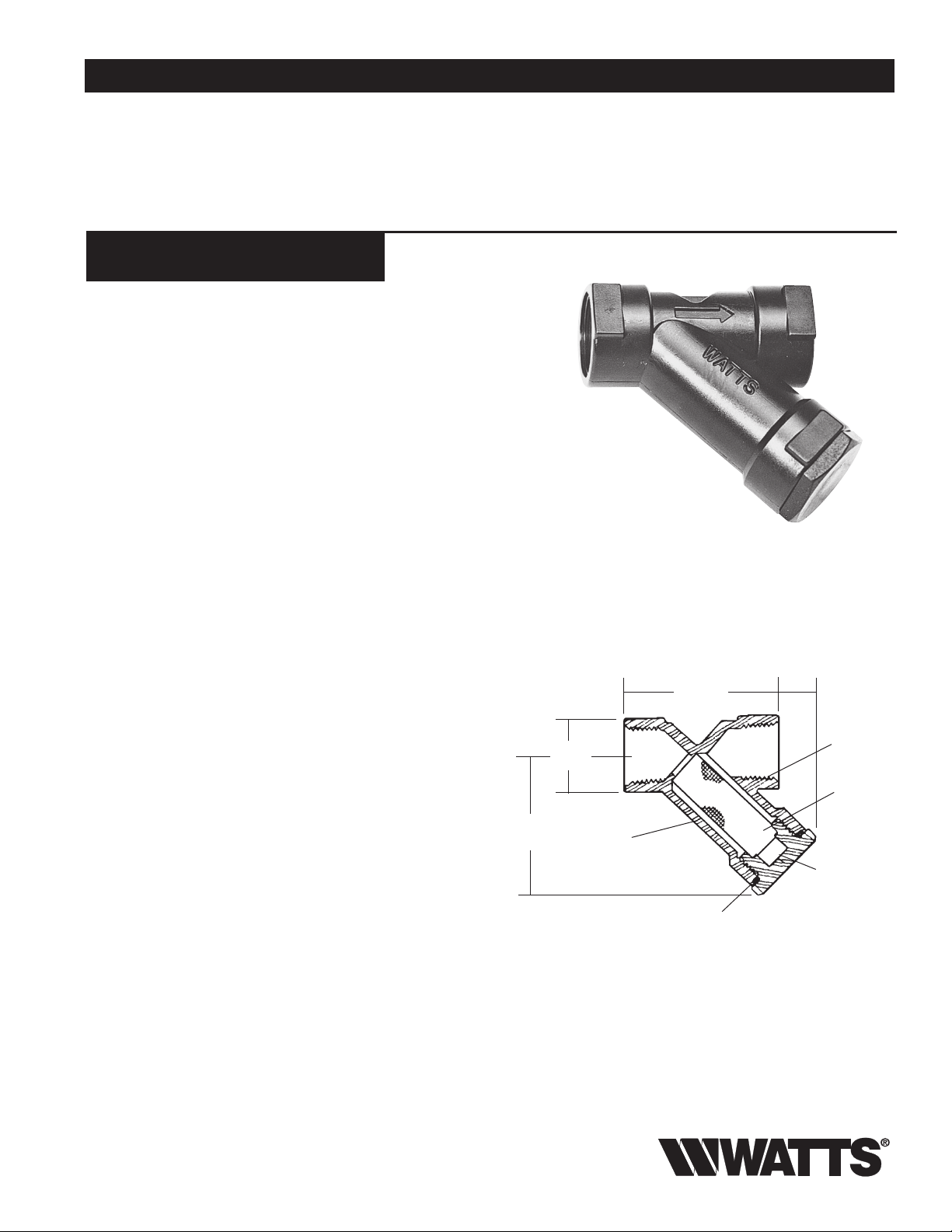

Series P777

Plastic Wye-Pattern Strainers

Sizes: 1⁄4" – 3⁄8" (8 – 10mm)

Series P777 Plastic Wye-Pattern Strainers are designed to

ensure protection to mechanical equipment from the destructive effects of dirt, scale and foreign objects. These 45˚

wye-pattern strainers are for OEM applications where space

requirements are limited.

Features

• Very compact

• Corrosion-resistant

• O-ring sealed, quick clean out plug

• Standard 100 mesh stainless steel screen

• Optional screens available, consult local Watts Agent

Contractor

Approval

Contractor’s P.O. No.

Representative

––––––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––––––

––––––––––––––––––––––––––––––––––––––––

––––––––––––––––––––––––––––––––––

P777

Specifications

A plastic wye-pattern strainer shall be installed to protect

mechanical equipment from dirt, scale and foreign objects

where indicated on the plans. Strainer shall be corrosionresistant and compact. Strainer shall be manufactured out

of NSF approved plastic and come standard with 100 mesh

stainless steel screen. Strainer shall be a Watts Series P777.

Pressure

Maximum Working Pressure: 300psi (21 bar) CWP

Materials

Body: NSF approved, glass-filled, Noryl® plastic

Cleanout Plug: NSF approved glass filled Noryl® plastic

Screen: 304 stainless steel

O-ring: Buna-N

Noryl® is registered trademark of SABIC Innovative Plastics™.

*The wetted surface of this product contacted by consumable

water contains less than one quarter of one percent (0.25%) of

lead by weight.

Dimensions

7

⁄8" D.

(22mm)

13⁄4"

(44mm)

Body

17⁄8"

(48mm)

O-ring

1

⁄2"

(13mm)

Cleanout Plug

Available in

1

⁄4" and 3⁄8"

NPT

Screen

304 SS

Watts product specifications in U.S. customary units and metric are approximate and are provided for reference only. For precise measurements,

please contact Watts Technical Service. Watts reserves the right to change or modify product design, construction, specifications, or materials without prior notice and without incurring any obligation to make such changes and modifications on Watts products previously or subsequently sold.

Page 2

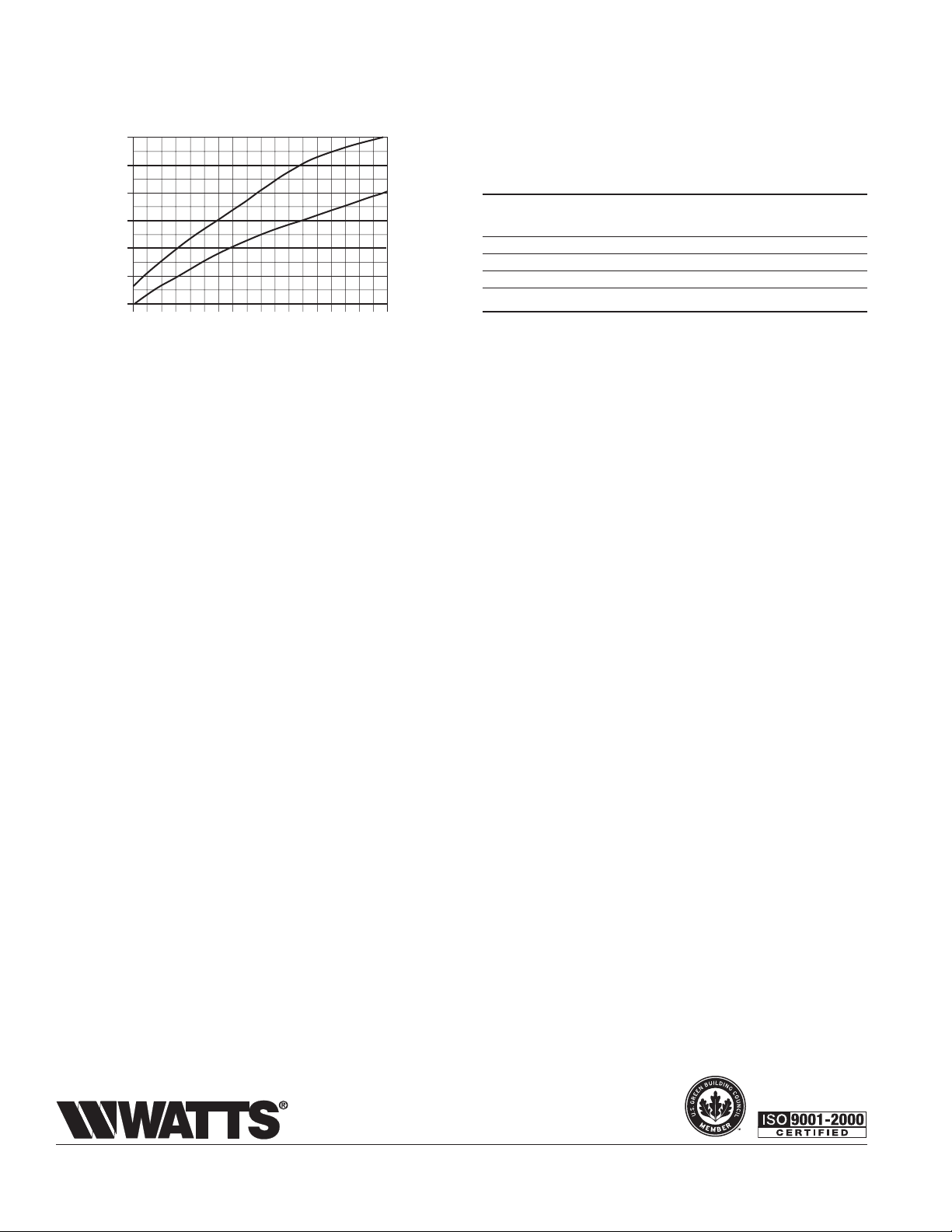

Performance

Flow rates using standard 100 mesh screen

lpm gpm

30 8

27 7

23 6

19 5

15 4

11 3

Flow Rate (water)

8 2

2 4 6 8 10 12 14 16 18 20 psi

.1 .3 .4 .6 .7 .8 1.0 1.1 1.2 1.4

Pressure Drop

3

(10mm)

1

(8mm)

bar

⁄8"

⁄4"

*Micronic Wire ø Width %

Model Retention Mesh (in.) Opening (in.) Open Area

P777-40 400 40 .010 .016 36.0

P777-60 230 60 .0075 .009 30.5

P777-80 180 80 .0055 .007 31.4

†P777-100 140 100 .0045 .0055 30.3

*Average particle retention for round particles.

†

Standard 100 mesh screen.

A Watts Water Technologies Company

Canada: 5435 North Service Rd., Burlington, ONT. L7L 5H7; www.wattscanada.ca

ES-P777 0933 © 2009 Watts

USA: 815 Chestnut St., No. Andover, MA 01845-6098; www.watts.com

Loading...

Loading...