Page 1

For Commercial, Residential and Food Service Applications

ES-OFTWH

Job Name

Job Location

Engineer

Approval

–––––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––––––

Model OFTWH

OneFlow® Anti-Scale System

Connection Sizes: 3⁄4" (20mm)

Flow Rates: From 0.5 gpm to 10 gpm (1.9 lpm to 38 lpm)

®

The OneFlow

scale formation on internal and external plumbing surfaces.

The OneFlow

that must be installed on a cold water line prior to a waterheating device (water heater or tankless water heater) for

single tankless heaters.

OneFlow

minerals into harmless, inactive microscopic crystal particles.

These crystals stay suspended in the water and are passed

to drain. The system requires very little maintenance, no backwashing, no salt and no electricity. Typical hardness problems,

especially build-up of scale in heating elements, pipes, water

heaters, boilers and on fixtures are no longer a concern.

OneFlow

It is a scale prevention device with proven third party laboratory test data and years of successful commercial, residential

and food service applications. OneFlow

scale solution and is a great alternative to water softening (ion

exchange) or scale sequestering devices.

Features

• Chemical-free scale prevention and protection - converts hardness minerals to harmless, inactive microscopic crystals making OneFlow

softener for the prevention of scale due to water hardness

• Virtually maintenance free - No salt bags or other chemicals

to constantly add or maintain

• No control valve, no electricity and no wastewater

• Uses environmentally friendly “green” technology

• Improves efficiency of all water heating devices and

downsream plumbing components.

• Simple sizing & installation – standard

• Perfect system for restaurants, cafeterias, coffee shops

and homes where multiple or single equipment protection

is desired for longer equipment life and reduced energy

consumption

• Inlet ball valve for easy isolation shutoff and filter changes

• OneFlow

change the cartridge once every two years

• Easily installed mounting bracket included w/filter wrench

to allow cartridge change-outs when necessary

* The wetted surface of this product contacted by consumable

water contains less than one quarter of one percent (0.25%) of

lead by weight.

For hot water applications where water temperature is

110°F - 150°F (43°C - 66°C), please consult ES-OneFlow-Hot Water.

Anti-Scale System provides protection from

®

system is a single cartridge-based system

®

prevents scale by transforming dissolved hardness

®

is not a water softener. It does not add chemicals.

®

is the intelligent

®

an effective alternative technology to a water

3

/4" connections

®

cartridge-based systems are easily maintained;

Contractor

Approval

Contractor’s P.O. No.

Representative

––––––––––––––––––––––––––––––––––––––––––––

––––––––––––––––––––––––––––––––––––––––––––––

––––––––––––––––––––––––––––––––––

––––––––––––––––––––––––––––––––––––––––

OFTWH

Models

Model Peak Flow Rate Connection Size

OFTWH 10 gpm (38 lpm)

3

⁄4" (20mm) FNPT

Replacement Cartridge

OFTWHRM Cartridge should be replaced every 2 YEARS.

Specifications

A OneFlow® scale prevention system shall be installed on the

cold water service line to condition the tap water just prior to

the service line feeding the equipment it is designed to protect.

The system will be sized for maximum or peak flow rate based

on the specification of said equipment. A OneFlow

may also be installed to protect multiple pieces of equipment

from the ill-effects of hard water scale provided the aggregate

peak flow rate for each piece of equipment it is protecting has

been considered. The system shall be plumbed with a bypass

valve to allow isolation of filter housing to allow the bypass of

untreated water in the event that service or cartridge replacement be necessary. The installation area should be suitable in

size for the housing to be serviced without encumbrance and

the system should be installed per the Installation, Operation &

Maintenance manual as provided with each system.

The OneFlow

to backwash, flush, or regenerate once put into service. The

system shall not require any chemical additives and shall not

require electricity for operation.

Note: Copper lines need to be passivized for a minimum

of 4 weeks before placing unit into service. Not for use on

closed loop systems.

®

system must not require additional waste water

®

system

Watts product specifications in U.S. customary units and metric are approximate and are provided for reference only. For precise measurements,

please contact Watts Technical Service. Watts reserves the right to change or modify product design, construction, specifications, or materials without prior notice and without incurring any obligation to make such changes and modifications on Watts products previously or subsequently sold.

Page 2

Water Chemistry & Limitations

PH 6.5 to 8.5

Hardness (maximum) 75 grains (1300 ppm CaCO3)

Temperature 41°F to 100°F (5° to 40°C)

Chlorine < 3 ppm

Iron (maximum) 0.3 mg/l

Manganese (maximum) 0.05 mg/l

Copper none allowed

Oil & H2S none allowed

Polyphosphate none allowed

Silica (maximum) 10 ppm

System Specifications

Maximum Pressure: 90psi/620.1 kPa

Maximum Temperature: 100°F/38°C

Min.: 35°F/2°C

Inlet/Outlet Connections:

3

/4" FNPT

Service Flow Rate: 0.5 gpm to 10 gpm (1.9 Ipm to 38 Ipm)

Gallon Rating: OFTWH: up to 6 gpm, 24/7/365 for 2 years

for the OFTWHRM.

Capacity: OFTWHRM cartridge does not have a grain removal

capacity, however, other contaminants present in the water will

gradually degrade the effectiveness of this cartridge. Change

the OFTWHRM cartridge at least once every two years.

Standards

Independent scientific testing has confirmed Template Assisted

Crystallization (TAC) technology provides scale reduction of

over 95+%. Testing was conducted under protocol based on

DVGW W512 test to access control of scale formation.

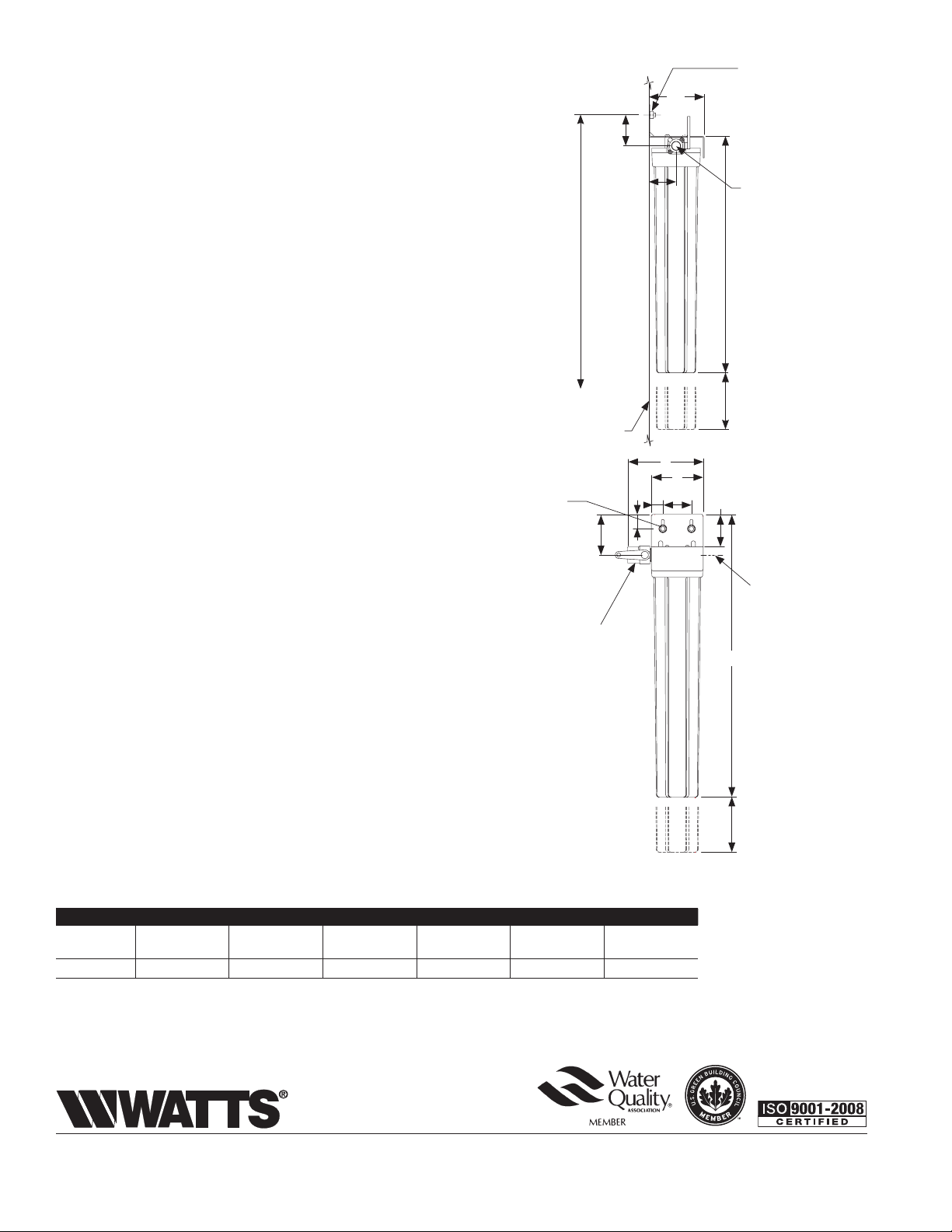

Mounted to

secure wall

on studs or

wall panel –

Do not mount

to unsupported

sheet-rock or

gypsum board.

3

/4" Full flow

ball valve w/ 3/4"

FPT inlet connection

from building

water supply

7

2

/8"

to inlet

3 1/2"

Installation Height

2'- 8" Min. — 5'- 0" A.F.F.

Wall

/4"

1

1

1

/2"

3

Mounted to secure wall

C

D

B

E

1'

on studs or wall panel –

Do not mount to unsupported

sheet-rock or gypsum board.

3

/4" Full flow

ball valve inlet

connection to

water supply

/8"

7

Max Pressure: 90psi

1'- 9

Max Temperature: 100ºF

Water treatment unit

must be installed on the

cold water supply only

3" Min.

Removal

Clearance

/16"

13

2

3

/4" FPT outlet

connection to

equipment

E

Max Pressure: 90psi

Max Temperature: 100ºF

Water filtration unit

must be installed on the

cold water supply only

3" Min.

Removal

Clearance

Dimensions — Weights

Model Dimensions Weight

A B C D E

in. mm in. mm in. mm in. mm in. mm lbs. kgs

OFTWH 26 66 7

The overall height and the height of the inlet fitting varies due to material variations and assembly

tolerances. Please allow additional clearance above the filter for making connections.

A Watts Water Technologies Company

ES-OFTWH 1140 © 2011 Watts

3

⁄4 20 85⁄8 23 913⁄16 25 53⁄4 15 19 8.6

USA: No. Andover, MA • Tel: (978) 688-1811 • Fax: (978) 794-1848 • www.watts.com

Canada: Burlington, ON • Tel: (905) 332-4090 • Fax: (905) 332-7068 • www.wattscanada.ca

Loading...

Loading...