Page 1

Installation, Operation and

Maintenance Manual

Model OF1465, OF1665

OneFlow

Chemical-Free, Salt-Free Scale Prevention

Introduction

The Watts OneFlow® Anti-Scale System provides protection from

scale formation on internal and external plumbing surfaces. The

OneFlow

ing to treat both hot and cold water, or it can be located directly

before a water heater, boiler, or other water using device that

requires protection from hard water.

OneFlow

hardness minerals into undissolved crystal microparticles. These

crystals stay suspended in the water and have a greatly reduced

ability to react and attach to surfaces like dissolved hardness

does. Therefore the problem of internal buildup of scale in pipes,

water heaters and on fixtures and glass is greatly reduced.

OneFlow

antiscalants, sequestrants, etc.. will most likely have to be changed

to be compatible with OneFlow

washing chemistry will likewise require adjustments.

®

®

®

®

Anti-Scale Systems

system can be installed at the point of entry to a build-

prevents scale by transforming the normal dissolved

is not a water softener – Water treatment chemistry (e.g.

®

treated water. Laundry and ware-

IOM-OF1465_1665

OneFlow® Benefits

• Chemical free scale prevention. Cost savings and environmental

benefits.

• Virtually maintenance free. No salt bags or other chemicals to

buy, transport and store.

• No electricity, no wastewater, completely self-contained.

• Improves the efficiency of water-using appliances.

• Simple installation – no electrical and drain hookup.

• Safe for landscaping and lawn watering. No need for costly

bypass plumbing.

• Compatible with all on-site and community wastewater treatment systems.

• Not subject to water softener restrictions and “bans”.

• OneFlow

drink and is well suited for use in food and beverage preparation.

®

treated water has no added sodium, is safe to

Page 2

!

Important note about iron,

manganese and copper in the

water supply

Iron and Manganese

Just as with conventional water softening media, OneFlow® needs

to be protected from excess levels of certain metals that can easily

coat the active surface, reducing its effectiveness over time. Public

water supplies rarely, if ever, present a problem, but if the water

supply is from a private well, confirm that the levels of iron (Fe) and

manganese (Mn) are less than 0.3 mg/L and 0.05 mg/L respectively. Copper should be less than 1.3 mg/L.

Copper

Copper usually originates from new copper plumbing upstream

of the OneFlow

waiting 3-4 weeks before placing the system in operation. This

will allow the copper surfaces to be fully flushed and develop a

natural protective surface. To further minimize any problem with

excess copper, avoid applying excess flux on the inner surfaces

of the pipe and to use a low-corrosivity water soluble flux listed

under the ASTM B813 standard. Once the plumbing connections are complete, place the OneFlow

to following the startup procedure and flush the plumbing for at

least 10 minutes.

®

system. If this condition exists, we recommend

®

system in bypass prior

!

Installation Precautions!

• Do NOT install system on line pressure above 125psi.

• Do NOT install the system backwards with the feed water

line connected to the outlet.

• Do NOT install system in direct sunlight or where system is

exposed to harsh chemicals or may be subjected to being

struck by moving equipment, carts, mops or any other item

that may cause damage.

• IF water hammer is evident, install water hammer arrestors

before the OneFlow

• Always back-up valves and fittings with a wrench when

installing a fitting to avoid turning the valve.

• Do NOT install the unit behind equipment where it may be

difficult to access the system for filter replacement.

Position the OneFlow

the OneFlow

stall the system near any device or area that would be adversely

effected by water.

®

system near any source of heat. Also, do not in-

®

unit.

®

unit in a suitable location. Do NOT install

System Overview

!

Cautions!

• Do not let the system freeze. Damage to the tank may result.

• System must be operated in a vertical position. Do not lay

it down during operation. The system may be placed in any

position for shipping and installation but must be operated in

the vertical position.

• Place the system on a smooth, level surface. Because the system operates in an upflow, fluidized bed mode, having a level

surface is more important than with a softener or media filter.

• A bypass valve should be installed on every system to facilitate installation and service.

• Observe all local plumbing and building codes when installing

the system.

Notes to the Installer

i

The OneFlow® system differs from a conventional softener or

media filter in a number of key respects.

• The system is light and only partially filled with media. This is

normal. The upflow operation of the system requires a lot of

freeboard to allow the bed to fully fluidize.

• The system has no underbed so you can tip the system over

without any fear of upsetting the media. This makes transportation and installation much easier than conventional systems.

• Because the OneFlow

the tank connections are opposite of what you’re used to.

• Please see the Important note about iron, manganese and

copper above.

• Please see the note about “Using OneFlow

treatment equipment” on the next page.

®

system operates in the Upflow mode,

®

with other water

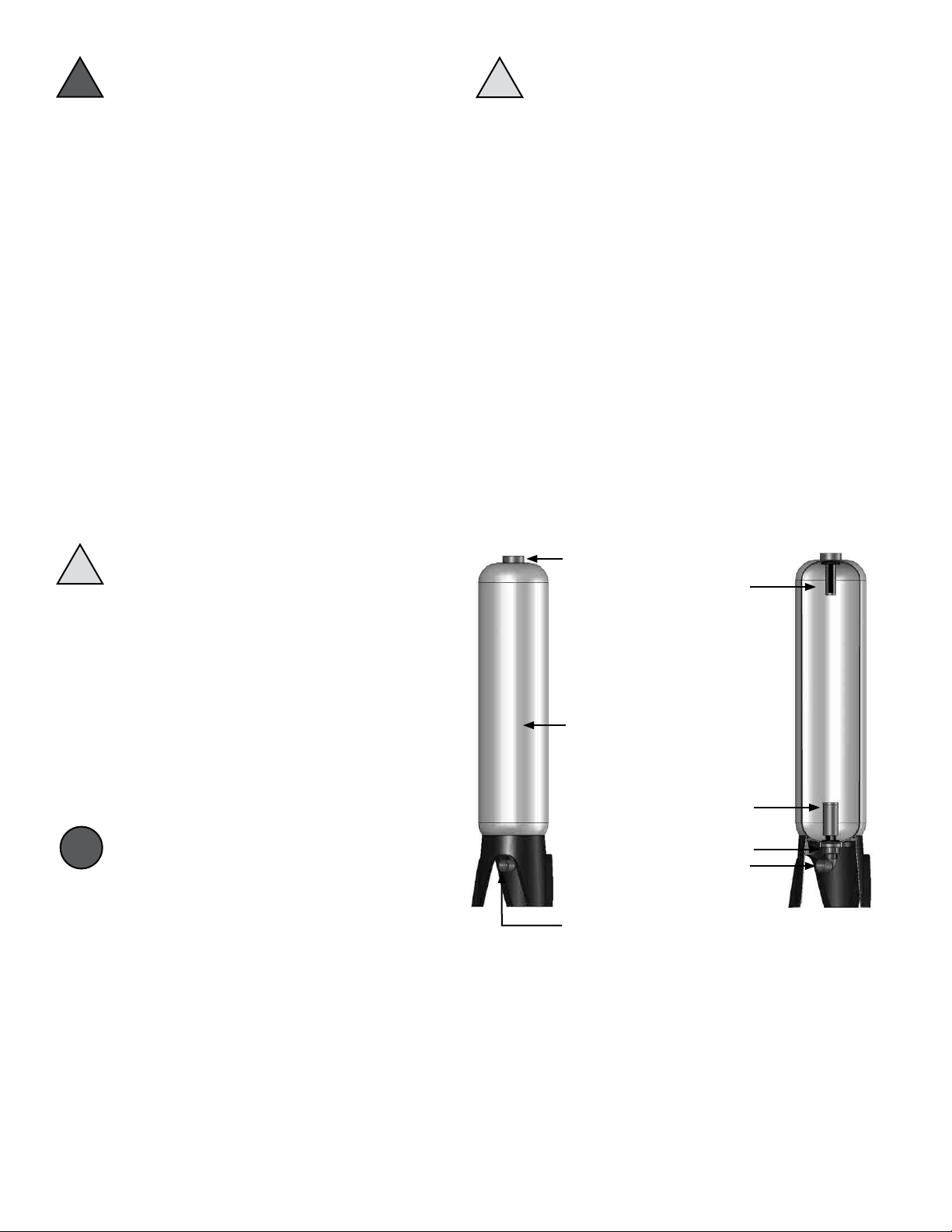

Outlet - 2” PVC socket

Outlet Screen

Media Tank

Inlet Screen/Difffuser

2” Union (socket)

2” Elbow (street)

Inlet - 2” PVC socket

Using OneFlow® with other water treatment

equipment.

Due to the unique properties of OneFlow®, there are some

unique requirements for using OneFlow

tion or other forms of water treatment.

1. OneFlow

not install any filters after OneFlow

which scale prevention is required. POU filters, e.g. carbon or

RO are exempt from this requirement.

2. Do not apply phosphate or any other antiscalant either before

or after OneFlow

®

must be the last stage in the treatment chain. Do

®

.

2

®

in conjunction with filtra-

®

or before any devices for

Page 3

Equipment Specifications

OneFlow® systems are complete, self-contained,

loaded with media, and ready to use. A simple

inlet and outlet connection is all that is required

for installation. Please review operating pressures,

temperatures and water chemistry limitations to

ensure compatibility.

b

c d

Important Notes!

i

NOTE: We recommend the installation of a dual-union ball-valve

on the inlet and outlet to isolate the tank for servicing.

NOTE: A full bypass should be installed so that the full service

flow can be routed around the system as needed for servicing.

NOTE: The OneFlow

which is opposite of a conventional softener. The inlet is on the

bottom, the outlet on the top.

®

system operates in the Up-Flow mode

Specifications

Inlet Connection 2” PVC Union with Socket.

Outlet Connection 2” PVC Socket

Temperature 40° - 110°F

pH 6.5 to 8.5

Ferrous Iron, Max* 0.3 mg/L

Manganese, Max* 0.05 mg/L

Copper, Max* 1.3 mg/L

Water Pressure 15 min, 100 max (PSI)

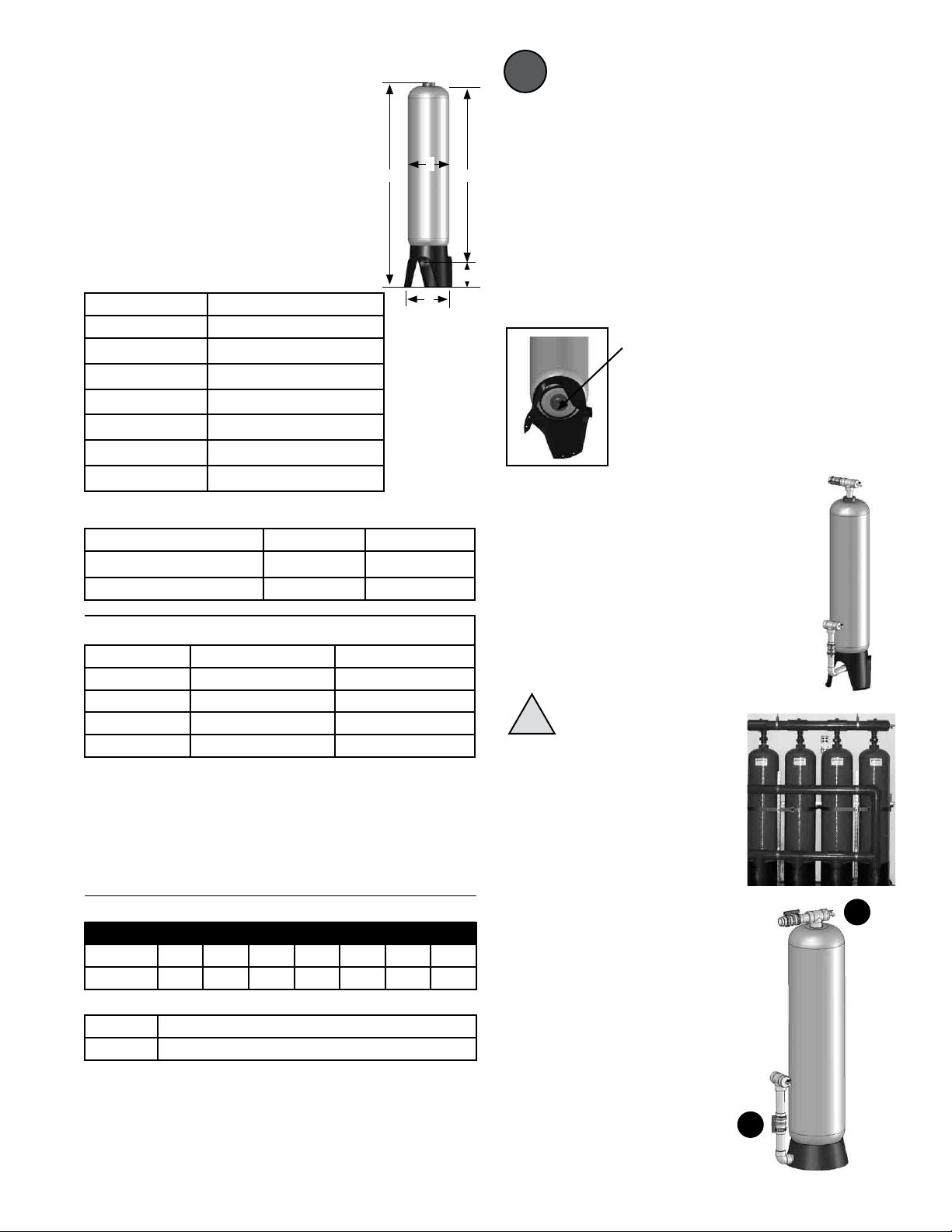

a

Mechanical Specifications

MODEL 1465 1665

Dry Weight (lbs) 54 68

Service Weight (lbs) 350 420

Dimensions (nominal - inches)

a 17 17

b 14 16

c* 79 79

d 65 65

e* 10.25 10.50

* The overall height and the height of the inlet fitting varies due

to material variations and assembly tolerances. Please allow additional clearance above the tank for making connections.

Maximum Service Flow (gpm) vs. Water

Temperature

Continuous Duty Systems:

System 40°F 45°F 50°F 55°F 60°F 65°F 70°F

14-65 40 44 48 50 50 50 50

16-65 45 51 56 59 63 69 75

Intermittent Duty Systems:

14-65 50 GPM at all temperatures

16-65 75 GPM at all temperatures

* Intermittent duty is defined as less than 2 hours of Maximum

Flow per 24 hour period. Higher Flow rates can be achieved by

combining systems in an array.

e

Installation

Tighten the Tank Bushings

Tank bushing.

Rotate Clockwise

to tighten.

Lay the tank down and check the bushings

on the inlet and outlet (bottom and top) of the

tank. It is common for them to loosen during

shipment. Tighten the bushings with a strap

wrench as needed

Install Piping

Connect the inlet and outlet plumbing according to

your preferences and any applicable local codes.

Include sample/drain ports with hose-bibb connections on the inlet and outlet piping to facilitate

startup and service.

!

Support the Piping

The full weight of the piping and

valves must be supported by unistrut, pipe hangers or other means.

The tank connections cannot support the weight of the piping. This

photo from a multi-tank system

installation shows properly supported

piping.

Start-Up

Connect a hose to the hose bibb on the

outlet of the tank. Run the hose to a drain.

Slowly / partially open the supply water

ball valve. Allow the tank to slowly fill with

water. When a steady stream of water appears at the drain, close the supply valve.

Open the inlet and outlet valves on the

system. Transfer the bypass valves from

Bypass to the Service position. Open

a nearby faucet downstream from the

OneFlow

Check for leaks. Repair as needed.

The system is now ready for service.

®

system to relieve any air.

1

2

3

Page 4

Limited Warranty

Watts Regulator Company warrants its OneFlow® tank systems as follows:

• The OneFlow

• The OneFlow

ated in accordance with the instructions in the corresponding Installation and Operation Manual.

Watts Regulator Company warrants its OneFlow

• The OneFlow

shipment.

• OneFlow

operated in accordance with the instructions in the corresponding Installation and Operation Manual.

• Carbon replacement filter cartridges are not warranted to perform for any period of time because the service life of replacement carbon

filter cartridges varies significantly with local water conditions and volume.

Conditions

1. The OneFlow® system must be installed in applications with municipally supplied water adhering to EPA guidelines.

2. Any component failure must not result from abuse, fire, freezing or other acts of nature, violence, or improper installation.

3. Equipment must be installed and operated in compliance with the local plumbing codes and on an approved water supply.

4. Equipment is limited to use at water pressures and temperatures that do not exceed our published specifications.

5. Water supply must not exceed 2.0 PPM chlorine. For water supply exceeding 2.0 PPM chlorine, pretreatment is required.

(Please contact your water treatment specialist.)

6. Information, including model number, serial number, and date of installation, must be provided for any claims pertaining to equipment in

warranty.

7. Defective parts are subject to inspection by either Watts Regulator Company or any authorized representative before final commitment of

warranty adjustment is made.

8. Watts Regulator Company reserves the right to make changes or substitutions in parts or equipment with material of equal quality or value

and of then current production.

®

tank system is warranted to be free of defects in materials and workmanship for 5 years from the date of original shipment.

®

media is warranted for performance for a period of 2 years from the date of the original installation when installed and oper-

®

cartridge systems as follows:

®

cartridge system is warranted to be free of defects in materials and workmanship for 1 year from the date of original

®

cartridges are warranted for performance for a period of one year from the date of original installation when installed and

Limitations

Our obligation under this warranty with respect to the tank or valve is limited to furnishing a replacement for, or at our option, repairing any

part or parts to our satisfaction that prove defective within the warranty period stated above. Such replacement parts will be delivered to the

owner F.O.B. nearest factory, at no cost, excluding freight and local labor charges, if any.

Our obligation under this warranty with respect to the OneFlow

years from date of original installation. Such replacement media will be delivered to the owner F.O.B. nearest factory, at no cost, excluding

freight and local labor charges, if any. Damage to the media due to chlorine, other oxidizers or fouling caused by local water conditions or

any other operation outside of the limits shown under Specifications, is not covered by this warranty.

THE WARRANTY SET FORTH HEREIN IS GIVEN EXPRESSLY AND IS THE ONLY WARRANTY GIVEN BY WATTS REGULATOR COMPANY

WITH RESPECT TO THE PRODUCT. WATTS REGULATOR COMPANY MAKES NO OTHER WARRANTIES, EXPRESS OR IMPLIED. WATTS

REGULATOR COMPANY HEREBY SPECIFICALLY DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT

LIMITED TO THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

The remedy described under this warranty shall constitute the sole and exclusive remedy for breach of warranty, and Watts Regulator

Company shall not be responsible for any incidental, special or consequential damages, including without limitation, freight, handling, lost

profits or the cost of repairing or replacing other property which is damaged if this product does not work properly, other costs resulting from

labor charges, delays, vandalism, negligence, fouling caused by foreign material, damage from adverse water conditions, chemical, or any

other circumstances over which Watts Regulator Company has no control. This warranty shall be invalidated by any abuse, misuse, misapplication or improper installation of the product.

Some states do not allow limitations on how long an implied warranty lasts, and some states do not allow the exclusion or limitation of incidental or consequential damages. Therefore the above limitations may not apply to you. This warranty gives you specific legal rights, and

you may have other rights that vary from state to state. You should consult applicable state laws to determine your rights. SO FAR AS IS

CONSISTENT WITH APPLICABLE STATE LAW, ANY IMPLIED WARRANTIES THAT MAY NOT BE DISCLAIMED, INCLUDING THE IMPLIED

WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, ARE LIMITED IN DURATION TO THE APPLICABLE

WARRANTY PERIODS STATED ABOVE.

®

media will be limited to furnishing a replacement for the media within two

A Watts Wa ter Technologies Company

Canada: 5435 North Service Rd., Burlington, ONT. L7L 5H7; www.wattscanada.ca

IOM-OF1465-1665 1017 EDP#1915996 © 2010 Watts

USA: 815 Chestnut St., No. Andover, MA 01845-6098; www.watts.com

Page 5

Manual de instalación,

funcionamiento y

mantenimiento

Modelo OF1465, OF1665

IOM-OF1465_1665

Sistemas antisarro OneFlow

®

Prevención de sarro sin sustancias

químicas, sin sal

Introducción

El sistema antisarro OneFlow® de Watts brinda protección contra

la formación de sarro en las superficies internas y externas de las

cañerías. El sistema OneFlow

entrada de un inmueble para tratar tanto el agua caliente como la

fría, o puede ser colocado directamente antes de un calentador,

caldera o cualquier otro artefacto que utilice agua y que requiera

protección contra el agua dura.

OneFlow

disueltos normales en micropartículas de cristal sin disolver. Estos

cristales se mantienen suspendidos en el agua y tienen una

capacidad muy reducida para reaccionar y adherirse a superficies

tal como lo hacen los de dureza disueltos. Por lo tanto, el problema

de la acumulación interna de sarro en las cañerías, calentadores de

agua y en artefactos y vidrios se reduce notablemente.

OneFlow

necesario cambiar los tratamientos químicos del agua (por ejemplo:

inhibidores de sarro, secuestrantes, etc.) para que sean compatibles

con el agua tratada con OneFlow

lavado de ropa y piezas también necesitarán ciertos ajustes.

®

previene el sarro al transformar los minerales de dureza

®

no es un ablandador de agua. Es muy probable que sea

®

puede instalarse en el punto de

®

. Los químicos utilizados para el

Ventajas de OneFlow®

• Prevención de sarro sin sustancias químicas. Permite ahorrar

costos y beneficiar al medio ambiente.

• Prácticamente no necesita mantenimiento. No se necesita

comprar, transportar ni almacenar bolsas de sal u otros químicos.

• Sin uso de electricidad, sin desperdicio de agua, completamente

autónomo.

• Mejora la eficacia de los artefactos que utilizan agua.

• Instalación simple: no se necesitan conexiones eléctricas ni de

desagüe.

• Seguro para el riego de céspedes y jardines. No requiere

costosas cañerías de derivación.

• Es compatible con todos los sistemas de tratamiento de agua

residual in situ y comunitarios.

• No está sujeto a las restricciones o “prohibiciones” de los

ablandadores de agua.

• El agua tratada con OneFlow

segura para beber y puede usarse en preparaciones de comidas

y bebidas.

®

no contiene sodio agregado, es

Page 6

!

Aviso importante acerca de la

presencia de hierro, manganeso y

cobre en el suministro de agua

Hierro y manganeso

Tal como los materiales convencionales para ablandar el agua,

OneFlow® necesita protección contra los niveles excesivos de ciertos

metales que pueden cubrir fácilmente la superficie activa y reducir

su eficacia con el paso del tiempo. El suministro de agua pública

raramente o nunca presenta problemas. Sin embargo, si el suministro

de agua proviene de un pozo privado, confirme que los niveles de

hierro (Fe) y manganeso (Mn) sean inferiores a 0,3 mg/L y 0,05 mg/L

respectivamente. El cobre deberá ser inferior a 1,3 mg/L.

Cobre

El cobre generalmente se origina de cañerías de cobre nuevas

corriente arriba del sistema

recomendamos esperar de 3 a 4 semanas antes de poner el sistema

en funcionamiento. Esto permitirá que las superficies de cobre sean

completamente purgadas y desarrollen una superficie protectora natural.

Para minimizar cualquier problema causado por un exceso de cobre,

evitar aplicar fundente en exceso en las superficies internas de la cañería

y usar uno de los fundentes de baja corrosión solubles en agua incluidos

en la norma ASTM B813. Una vez terminadas las conexiones de las

cañerías, colocar el sistema

el proceso de arranque y purgar la cañería durante al menos 10 minutos.

OneFlow®. Si se presenta esta situación,

OneFlow® en derivación antes de comenzar

!

Precauciones en la instalación

• NO instalar el sistema a una presión de línea superior a 125 psi.

• NO instalar el sistema al revés con la tubería de agua de

suministro conectada a la salida.

• NO instalar el sistema bajo la luz directa del sol o donde

quede expuesto a sustancias químicas agresivas o pueda

recibir golpes por el movimiento de equipos, carros, mopas o

cualquier otro elemento que pueda causar daños.

• SI se observa un golpe de ariete, instalar dispositivos anti-

golpe de ariete antes de la unidad OneFlow

• Siempre retroceder las válvulas y accesorios con una llave al

instalar un accesorio para evitar girar la válvula.

• NO instalar la unidad detrás de equipos de modo que se

dificulte el acceso al sistema para el reemplazo del filtro.

Colocar la unidad OneFlow

NO instalar el sistema OneFlow

calor. Tampoco instalar el sistema cerca de dispositivos o zonas

que puedan sufrir daños por los efectos del agua.

®

en un lugar adecuado.

®

cerca de ninguna fuente de

®

.

Descripción general del sistema

Salida - Toma de PVC 2"

!

¡Advertencias!

• No permitir que el sistema se congele. El depósito podría dañarse.

• El sistema debe funcionar en posición vertical. No colocarlo en

posición horizontal durante su funcionamiento. El sistema puede

ubicarse de cualquier posición para el transporte y la instalación, pero

durante su funcionamiento debe estar en posición vertical.

• Colocar el sistema en una superficie lisa y plana. Debido a que

el sistema funciona en un modo de lecho fluidificado y caudal

ascendente, el hecho de tener una superficie nivelada es más

importante que en el caso de los ablandadores o filtros de materiales.

• En cada sistema se deberá instalar una válvula de derivación para

facilitar la instalación y el mantenimiento.

• Al instalar el sistema, respetar todos los códigos locales relativos a las

cañerías y a la construcción.

Notas para el instalador

i

En varios aspectos fundamentales, el sistema OneFlow®

es diferente a los ablandadores o filtros de materiales

convencionales.

• El sistema es liviano y se llena sólo parcialmente con el

material. Esto es normal. El funcionamiento de caudal

ascendente del sistema requiere que haya mucho margen

libre para permitir que el lecho se fluidifique totalmente.

• El sistema no posee un lecho inferior, por lo tanto se puede

dar vuelta sin ningún temor de volcar los materiales. Esto

hace que el transporte y la instalación sean mucho más

simples que en los sistemas convencionales.

• Debido a que el sistema OneFlow

caudal ascendente, las conexiones del depósito son diferentes

a las que se acostumbra utilizar.

• Leer el Aviso importante acerca de la presencia de hierro,

manganeso y cobre antes detallado.

• Leer el aviso acerca del “Uso de OneFlow

para tratamiento del agua” que se encuentra enseguida.

®

funciona en el modo de

®

con otros equipos

Pantalla de salida

Depósito de materiales

Difusor/pantalla

de entrada

Unión 2" (toma)

Codo 2" (calle)

Entrada - Toma de PVC 2"

Uso de OneFlow® con otros equipos para

tratamiento del agua.

Debido a las propiedades únicas de OneFlow®, existen algunos

requisitos especiales para usar OneFlow

por filtración u otros métodos de tratamiento del agua.

1. OneFlow

No instalar ningún filtro luego de OneFlow

dispositivo para el que se requiera la prevención de sarro. Este

requisito no es necesario para los filtros en el punto de uso, como

por ejemplo de carbono u ósmosis inversa.

2. No aplicar fosfato ni cualquier otro inhibidor de sarro ya sea

antes o después de OneFlow

6

®

debe ser la última etapa en la cadena de tratamiento.

®

junto con tratamientos

®

o antes de cualquier

®

.

Page 7

Especificaciones del equipo

Los sistemas OneFlow® son completos,

autónomos, tienen material cargado y están

listos para usar. Para instalarlos sólo se necesita

una simple conexión de entrada y de salida.

Observar las limitaciones operativas acerca de las

presiones, temperaturas y composición química

del agua a fin de garantizar la compatibilidad.

c d

Avisos importantes

i

NOTA: Recomendamos instalar una válvula esférica de unión doble en

la entrada y la salida a fin de aislar el depósito para el mantenimiento.

b

NOTA: Deberá montarse una derivación total para que el caudal

de servicio total pueda dirigirse en el sistema del modo en que sea

necesario para el mantenimiento.

NOTA:El sistema

ascendente a diferencia de un ablandador convencional. La entrada se

encuentra en la parte inferior, la salida en la parte superior.

OneFlow® funciona en el modo de caudal

Especificaciones

Conexión de entrada Unión de PVC 2" con toma.

Conexión de salida Toma de PVC 2"

Temperatura 40 - 110 °F

pH 6,5 a 8,5

Hierro ferroso, máx.* 0,3 mg/L

Manganeso, máx.* 0,05 mg/L

Cobre, máx.* 1,3 mg/L

Presión del agua 15 mín., 100 máx. (PSI)

e

a

Especificaciones mecánicas

MODELO 1465 1665

Peso seco (libras) 54 68

Peso de servicio (libras) 350 420

Dimensiones (nominal - pulgadas)

a 17 17

b 14 16

c* 79 79

d 65 65

e* 10,25 10,50

* La altura total y la altura del accesorio de entrada varían según

las variaciones del material y las tolerancias de montaje. Dejar un

espacio adicional sobre el depósito para realizar las conexiones.

Caudal de servicio máx. (gpm) vs.

Temperatura del agua

Sistemas de funcionamiento continuo:

Sistema 40 °F 45 °F 50 °F 55 °F 60 °F 65 °F 70 °F

14-65 40 44 48 50 50 50 50

16-65 45 51 56 59 63 69 75

Sistemas de funcionamiento intermitente:

14-65 50 gpm en todas las temperaturas

16-65 75 gpm en todas las temperaturas

* Se considera funcionamiento intermitente al inferior a 2 horas

de caudal máximo durante un periodo de 24 horas. Se pueden

obtener índices de caudal superiores combinando los sistemas

en serie.

Instalación

Ajustar los casquillos del depósito

Casquillo del depósito.

Girar en sentido horario

para ajustar.

Colocar el depósito en posición horizontal y

revisar los casquillos en la entrada y salida

(parte superior e inferior) del depósito. Es

normal que se aflojen durante el envío. Ajustar

los casquillos con una llave de correa según

sea necesario.

Instalación de las cañerías

Conectar las cañerías de entrada y salida de

acuerdo a las preferencias del usuario y los

códigos locales aplicables. Incluir puertos de

desagüe/muestra con conexiones de grifos de

mangueras en los caños de entrada y salida para

facilitar el arranque y el mantenimiento.

!

Sujetar la cañería

El peso total de la cañería y las válvulas

debe estar sujeto mediante un tubo

de una sola pieza, soportes colgantes

para caños u otros medios. Las

conexiones del depósito no pueden

sostener el peso de las cañerías. Esta

imagen de la instalación de un sistema

con depósitos múltiples muestra cómo

sujetar las cañerías adecuadamente.

Arranque

Conectar una manguera al grifo en la salida del

depósito. Llevar la manguera hacia un desagüe.

Abrir lentamente en forma parcial la válvula

esférica de suministro de agua. Dejar que el

depósito se llene con agua lentamente. Cuando

salga un chorro de agua constante por el

desagüe, cerrar la válvula de suministro.

Abrir las válvulas de entrada y de salida en el

sistema. Transferir las válvulas de derivación de la

posición de Derivación a la posición de Servicio.

Abrir una llave cercana que vaya corriente abajo

del sistema OneFlow

Revisar en busca de fugas. Repararlas si es

necesario.

El sistema ahora está listo para ser utilizado.

7

®

para eliminar el aire.

2

1

Page 8

Garantía limitada

Watts Regulator Company garantiza sus sistemas de depósito OneFlow® como se describe a continuación:

• El sistema de depósito OneFlow

®

• El material OneFlow

está garantizado en cuanto a su rendimiento por un período de 2 años desde la fecha de la instalación original en tanto se haya

instalado y utilizado de acuerdo a las instrucciones del Manual de instalación y uso correspondiente.

Watts Regulator Company garantiza sus sistemas de cartuchos OneFlow® como se describe a continuación:

• El sistema de cartuchos OneFlow

• Los cartuchos OneFlow

hayan instalado y utilizado de acuerdo a las instrucciones del Manual de instalación y uso correspondiente.

• No se garantiza el funcionamiento de los cartuchos de repuesto para filtros de carbono por ningún período dado que la vida útil de los cartuchos de

repuesto para filtros de carbono varía significativamente de acuerdo a las condiciones y el volumen del agua local.

Condiciones

1. El sistema OneFlow® debe instalarse en aplicaciones con agua suministrada a nivel municipal que cumpla con las normas de la Agencia de Protección

Ambiental de Estados Unidos (U.S. Environmental Protection Agency, EPA).

2. Los fallos en los componentes no deben producirse como consecuencia de uso indebido, incendio, congelamiento u otros factores como fuerzas de

la naturaleza, actos de violencia o instalación incorrecta.

3. El equipo debe instalarse y utilizarse de conformidad con los códigos locales relativos a las cañerías y con un suministro de agua aprobado.

4. El uso del equipo está limitado a las temperaturas y presiones de agua que no excedan nuestras especificaciones publicadas.

5. El suministro de agua no debe exceder 2 ppm de cloro. En suministros de agua que excedan 2 ppm de cloro, se requiere tratamiento previo.

(Contactar al especialista en tratamiento de agua.)

6. Para cualquier reclamo en relación con los equipos en garantía, se debe proporcionar información incluyendo el número de modelo, el número de

serie y la fecha de instalación.

7. Las piezas defectuosas están sujetas a inspección por parte de Watts Regulator Company o cualquier representante autorizado antes de que se

asuma el compromiso final de ajuste de garantía.

8. Watts Regulator Company se reserva el derecho a realizar cambios o sustituciones en las piezas o el equipo por materiales de valor o calidad

equivalente y producción vigente en el momento.

®

está garantizado como libre de defectos en materiales y manufactura por 5 años desde la fecha del envío original.

®

®

están garantizados en cuanto a su rendimiento por un período de un año desde la fecha de la instalación original en tanto se

está garantizado como libre de defectos en materiales y manufactura por 1 año desde la fecha del envío original.

Limitaciones

Nuestra obligación bajo la presente garantía con respecto al depósito o la válvula está limitada al reemplazo o la reparación, a nuestra elección, de

cualquier pieza o piezas a nuestra satisfacción con defectos comprobados dentro del período de garantía antes estipulado. Tales piezas de repuesto

serán entregadas al propietario bajo condición Libre a bordo (Free on Board, FOB) en la fábrica más cercana, sin costo alguno, sin incluir gastos de flete y

mano de obra local, de corresponder.

Nuestra obligación bajo la presente garantía con respecto al material OneFlow

desde la fecha de la instalación original. Tales materiales de repuesto serán entregados al propietario bajo condición Libre a bordo (Free on Board, FOB)

en la fábrica más cercana, sin costo alguno, sin incluir gastos de flete y mano de obra local, de corresponder. Esta garantía no cubre los materiales

dañados a causa del cloro, otros oxidantes o la contaminación por las condiciones del agua local o cualquier otra operación fuera de los límites indicados

en la sección Especificaciones.

LA GARANTÍA AQUÍ ESTIPULADA SE OTORGA EN FORMA EXPRESA Y ES LA ÚNICA GARANTÍA OTORGADA POR WATTS REGULATOR COMPANY

EN RELACIÓN CON EL PRODUCTO. WATTS REGULATOR COMPANY NO OTORGA NINGUNA OTRA GARANTÍA, YA SEA EXPRESA O IMPLÍCITA.

WATTS REGULATOR COMPANY POR LA PRESENTE RENUNCIA ESPECÍFICAMENTE A TODAS LAS DEMÁS GARANTÍAS, EXPRESAS O IMPLÍCITAS,

INCLUYENDO SIN LIMITACIÓN, LAS GARANTÍAS IMPLÍCITAS DE APTITUD PARA LA COMERCIALIZACIÓN E IDONEIDAD PARA UN PROPÓSITO EN

PARTICULAR.

La reparación descrita en esta garantía constituirá el único y exclusivo resarcimiento por incumplimiento de garantía, y Watts Regulator Company no

se hará responsable por daños fortuitos, especiales o derivados, incluyendo sin limitación, los gastos de flete y manipuleo, la pérdida de ganancias o

el costo de reparación o reemplazo de otra propiedad que resulte dañada por el mal funcionamiento de este producto, otros costos resultantes por

mano de obra, retardos, vandalismo, negligencia, contaminación ocasionada por materiales extraños, daños a causa de condiciones adversas del agua,

sustancias químicas o cualquier otra circunstancia sobre la cual Watts Regulator Company no tenga control. Esta garantía no tendrá validez en cualquier

caso de abuso, uso indebido, aplicación incorrecta o instalación inadecuada del producto.

Algunos estados no permiten limitaciones en la duración de una garantía implícita y otros estados no permiten la exclusión o limitación de daños fortuitos

o derivados. Por lo tanto, es posible que las limitaciones anteriores no sean aplicables en su caso. Esta garantía le otorga derechos legales específicos.

Usted podría tener también otros derechos que varían según el Estado en cuestión. Usted debe consultar las leyes estatales aplicables para determinar

sus derechos. EN LA MEDIDA EN QUE SEA CONGRUENTE CON LAS LEYES ESTATALES APLICABLES, CUALQUIER GARANTÍA IMPLÍCITA QUE NO

SEA RECHAZADA, INCLUYENDO LAS GARANTÍAS IMPLÍCITAS DE APTITUD PARA LA COMERCIALIZACIÓN E IDONEIDAD PARA UN PROPÓSITO EN

PARTICULAR, SE LIMITA EN SU DURACIÓN A LOS PERÍODOS DE GARANTÍA APLICABLES ESTIPULADOS PRECEDENTEMENTE.

®

estará limitada a suministrar repuestos por el material durante dos años

Una co mpa ñía de Watts Wat er Technologies

EE.UU.: 815 Chestnut St., No. Andover, MA 01845-6098; www.watts.com

Canadá: 5435 North Service Rd., Burlington, ONT. L7L 5H7; www.wattscanada.ca

IOM-OF1465_1665 1017 EDP Nº 1915996 © 2010 Watts

Page 9

Manuel d’installation,

de fonctionnement

et d’entretien

Modèle OF1465, OF1665

Systèmes antitartre OneFlow

Prévention contre le tartre

sans produits chimiques ni sel

Introduction

Le système antitartre OneFlow® de Watts offre une protection

contre la formation de tartre sur les surfaces de plomberie internes et externes. Le système OneFlow

d’entrée d’un bâtiment pour traiter l’eau chaude et l’eau froide, ou

il peut être placé directement avant un chauffe-eau, une chaudière ou un autre appareil fonctionnant à l’eau nécessitant une

protection contre l’eau dure.

OneFlow

dissous de dureté normale en microparticules de cristal non dissoutes. Ces cristaux restent en suspension dans l’eau et leur capacité à réagir et à se fixer sur les surfaces est considérablement

réduite comparée aux minéraux durs dissous. En conséquence,

le problème d’accumulation de tartre interne dans les tuyaux, les

chauffe-eaux ainsi que sur les appareils et le verre est considérablement réduit.

OneFlow

de l’eau (par exemple antitartres, séquestrants, etc.) devra très probablement être modifiée pour être compatible avec l’eau traitée avec

le système OneFlow

vaisselle devra également être modifiée.

®

permet d’éviter le tartre en transformant les minéraux

®

n’est pas un adoucisseur d’eau. La chimie du traitement

®

. La chimie de lavage des vêtements et de la

®

peut être installé au point

®

IOM-OF1465_1665

Avantages du système OneFlow

• Prévention contre le tartre sans produits chimiques. Économies et

respect de l’environnement.

• Pratiquement sans entretien. Pas de sacs de sel ou d’autres produits

chimiques à acheter, transporter et stocker.

• Pas d’électricité et d’eau usée, entièrement autonome.

• Améliore l’efficacité des appareils fonctionnant à l’eau.

• Installation simple, sans connexion électrique ni évacuation requise.

• Convient au paysagisme et à l’arrosage des gazons. Aucun besoin de

plomberie de dérivation coûteuse.

• Compatible avec tous les systèmes de traitement des eaux usées

collectifs et sur site.

• Non soumis aux restrictions et interdictions concernant les adoucisseurs d’eau.

• L’eau traitée avec le système OneFlow

peut être bue et convient parfaitement à une utilisation pour la

préparation d’aliments et de boissons.

®

®

n’a pas de sodium ajouté,

Page 10

!

Remarque importante

concernant la présence de fer,

de manganèse et de cuivre dans

l’alimentation en eau

Fer et manganèse

Comme avec les médias d’adoucissement de l’eau conventionnels, le système

OneFlow® doit être protégé des niveaux excessifs de certains métaux pouvant

recouvrir la surface active, réduisant son efficacité avec le temps. L’eau du

service public présente très rarement un problème. Cependant, si l’alimentation

en eau provient d’un puits privé, confirmer que les niveaux de fer (Fe) et de

manganèse (Mn) sont inférieurs à 0,3 mg/l et 0,05mg/l respectivement. La

teneur en cuivre doit être inférieure à 1,3 mg/l.

Cuivre

Le cuivre provient généralement d’un système de plomberie neuf en amont

du système OneFlow

d’attendre 3 à 4 semaines avant de mettre le système en service. Ceci

permettra aux surfaces en cuivre d’être bien rincées et de développer une

surface protective naturelle. Pour minimiser encore plus les problèmes dus

à un excès de cuivre, éviter d’appliquer un flux excessif sur les surfaces internes du tuyau et utiliser un flux soluble à l’eau à faible corrosion conforme

à la norme ASTM B813. Une fois les raccords de plomberie effectués, placer le système OneFlow

de démarrage et rincer la plomberie pendant au moins 10 minutes.

®

. Si cette condition est présente, il est recommandé

®

en dérivation avant de commencer la procédure

!

Précautions d’installation!

• NE PAS installer le système sur une pression de conduite

supérieure à 125 psi.

• NE PAS installer le système à l’envers avec la conduite d’eau

d’alimentation raccordée à la sortie.

• NE PAS installer le système directement à la lumière du soleil

et ne pas l’exposer à des produits chimiques corrosifs ou à

des impacts causés par des équipements mobiles, des chariots, des balais ou tout autre article pouvant provoquer des

dommages.

• SI un coup de bélier est évident, installer des antibéliers

devant l’unité OneFlow

• Toujours tenir les robinets et les raccords avec une clé lors

de l’installation d’un raccord pour éviter de tourner le robinet.

• NE PAS installer l’unité derrière un équipement où il serait

difficile d’accéder au système pour le remplacement du filtre.

Placer l’unité OneFlow

taller le système OneFlow

même, ne pas installer le système près d’un appareil ou d’une

zone qui pourraient être endommagés par de l’eau.

®

.

®

dans un endroit adapté. NE PAS ins-

®

près d’une source de chaleur. De

Présentation du système

Attention!

!

• Ne pas laisser le système geler. Ceci pourrait endommager le réservoir.

• Le système doit être utilisé à la verticale. Ne pas l’allonger durant le

fonctionnement. Le système peut être placé dans n’importe quelle

position pour l’expédition et l’installation mais il doit être utilisé en position verticale.

• Placer le système sur une surface lisse et plate. Puisque le système

fonctionne en mode de débit ascendant à lit fluidisé, l’installation sur

une surface plate est encore plus importante qu’avec un adoucisseur

ou un filtre à média filtrant.

• Un robinet de dérivation doit être installé sur chaque système pour faciliter l’installation et l’entretien.

• Respecter tous les codes de plomberie et de construction locaux lors

de l’installation du système.

Avis à l’installateur

i

Le système OneFlow® diffère des adoucisseurs conventionnels ou des

filtres à média filtrant sur plusieurs points clés.

• Le système est léger et partiellement rempli de média filtrant uniquement. Ceci est normal. Le fonctionnement en débit ascendant du

système nécessite un grand espace libre pour que le lit puisse complètement se fluidiser.

• Le système n’est pas muni d’un sous-lit de sorte qu’il peut être incliné

sans crainte de renverser le média filtrant. Ceci facilite considérablement le transport et l’installation, comparé aux systèmes conventionnels.

• Le système OneFlow

raccords du réservoir sont à l’opposé des installations traditionnelles.

• Consulter la remarque importante concernant la présence de fer, de

manganèse et de cuivre ci-dessus.

• Consulter également la remarque concernant l’utilisation du système

®

OneFlow

mentionnée ci-aprés.

avec un autre équipement de traitement de l’eau à

®

fonctionnant en mode de débit ascendant, les

Sortie - Douille en PVC de 2 po

Grille de sortie

Réservoir de média filtrant

Grille d’entrée/

diffuseur

Raccord de 2 po (douille)

Coude de 2 po (mâle-femelle)

Entrée - Douille en PVC de 2 po

Utilisation du système OneFlow® avec un

autre équipement de traitement de l’eau.

En raison des propriétés uniques du système OneFlow®, certaines exigences uniques sont à respecter lors de l’utilisation du système OneFlow

avec un système de filtration ou d’autres formes de traitement de l’eau.

1. Le système OneFlow

de traitement. Ne pas installer de filtre après le système OneFlow

ou avant tout appareil nécessitant une prévention contre le tartre. Les

filtres au point d’utilisation, tels que les filtres au charbon ou à osmose

inverse, ne sont pas concernés par cette exigence.

2. Ne pas appliquer de phosphate ou d’autre produit antitartre avant ou

après le système OneFlow

10

®

doit être situé en dernière place sur la chaîne

®

.

®

®

Page 11

Spécifications de l’équipement

Les systèmes OneFlow® sont complets, autonomes, chargés de média filtrant et prêts à l’emploi. Un simple raccord d’entrée et de sortie est

requis pour l’installation. Consulter les pressions,

températures et limites chimiques de l’eau pour le

fonctionnement afin d’assurer la compatibilité.

b

c d

Remarques importantes!

i

REMARQUE: Il est recommandé d’installer un robinet à bille à

double raccord sur l’entrée et la sortie pour isoler le réservoir lors

de l’entretien.

REMARQUE: Une dérivation complète devrait être installée

pour que la totalité du débit de service puisse être acheminée

autour du système selon les exigences de l’entretien.

REMARQUE: Le système OneFlow

débit ascendant, à l’opposé d’un adoucisseur conventionnel.

L’entrée est situé en bas, la sortie en haut.

®

fonctionne en mode de

Spécifications

Raccord d’entrée Raccord en PVC de 2 po avec

douille

Raccord de sortie Douille en PVC de 2 po

Température 4 °C - 43 °C (40° F - 110 °F)

pH 6,5 à 8,5

Fer ferreux, max.* 0,3 mg/l

Manganèse, max.* 0,05 mg/l

Cuivre, max.* 1,3 mg/l

Pression de l’eau 15 min., 100 max. (PSI)

a

Spécifications mécaniques

MODÈLE 1465 1665

Poids sec (livres) 54 68

Poids de fonctionnement

(livres)

350 420

Dimensions (nominales - pouces)

a 17 17

b 14 16

c* 79 79

d 65 65

e* 10,25 10,50

* La hauteur hors tout et la hauteur du raccord d’entrée varient

en fonction des matériaux et des tolérances d’assemblage.

Prévoir un dégagement supplémentaire au-dessus du réservoir

pour les raccordements.

Débit de service maximum (gal./min) par

rapport à la température de l’eau

Systèmes en service continu:

4 °C

7 °C

10 °C

13 °C

16 °C

18 °C

Système

14-65 40 44 48 50 50 50 50

16-65 45 51 56 59 63 69 75

(40 °F)

(45 °F)

(50 °F)

(55 °F)

(60 °F)

(65 °F)

21 °C

(70 °F)

Systèmes en service intermittents :

14-65 189 L/min (50 gpm) à toutes les températures

16-65 284 L/min (75 gpm) à toutes les températures

* Le service intermittent est défini comme moins de 2 heures

de débit maximum par période de 24 heures. Les taux de haut

débit peuvent être obtenus en combinant les systèmes dans un

réseau.

e

Installation

Serrer les douilles du réservoir

Douille du réservoir. Tourner dans

le sens horaire

pour serrer.

Allonger le résevoir au sol et vérifier les douilles

sur l’entrée et la sortie (en haut et en bas) du

réservoir. Elles se desserrent généralement

lors du transport. Serrer les douilles avec une

clé à sangle selon le besoin.

Installation de la tuyauterie

Raccorder la plomberie d’entrée et de sortie selon

ses préférences et en respectant les codes locaux

en vigueur. Inclure des ports d’échantillonnage/

d’évacuation avec des embouts de raccordement

sur la tuyauterie d’entrée et de sortie pour faciliter

la mise en route et l’entretien.

Support de

!

la tuyauterie

Le poids total de la tuyauterie et des robinets doit être supporté par des attaches

de tuyaux Unistrut ou d’autres moyens.

Les raccords du réservoir ne peuvent pas

supporter le poids de la tuyauterie. Cette

photo illustre une installation à plusieurs

réservoirs avec une tuyauterie adéquatement supportée.

Mise en route

Raccorder une conduite sur l’embout de la

sortie du réservoir. Acheminer la conduite vers

une évacuation.

Ouvrir lentement/partiellement le robinet à bille

de l’eau d’alimentation. Laisser le réservoir se

remplir d’eau lentement. Lorsqu’un filet d’eau

régulier apparaît au niveau de l’évacuation,

fermer le robinet d’alimentation en eau.

Ouvrir les robinets d’alimentation et de sortie

du système. Mettre les robinets de dérivation

de la position de dérivation à la position de

service. Ouvrir un robinet proche en aval du

système OneFlow

Inspecter pour toute fuite éventuelle.

Effectuer les réparations nécessaires.

Le système est maintenant prêt à être utilisé.

11

®

pour dissiper l’air.

1

2

Page 12

Garantie limitée

Watts Regulator Company garantit le système du réservoir OneFlow® de la façon suivante:

• Le système du réservoir OneFlow

date d’expédition d’origine.

• Le média filtrant OneFlow

conformément aux instructions du manuel d’installation et de fonctionnement.

Watts Regulator Company garantit le système de cartouche OneFlow

• Le système de cartouche OneFlow

date d’expédition d’origine.

• Les cartouches OneFlow

®

utilisées conformément aux instructions du manuel d’installation et de fonctionnement.

• Les cartouches de filtre au charbon de rechange ne sont pas garanties car la durée de vie des cartouches au charbon varie grandement

en fonction des conditions et du volume de l’eau locale.

Conditions

1. Le système OneFlow® doit être installé dans des applications alimentées par l’eau municipale conformément au règlement de l’EPA.

2. Les défaillances de composant ne doivent pas être causées par un abus, un incendie, le gel ou d’autres phénomènes naturels, des actes

de violence ou une installation érronée.

3. L’équipement doit être installé et utilisé conformément au code de plomberie en vigueur et avec une alimentation en eau approuvée.

4. L’équipement doit être utilisé à des pressions et des températures d’eau ne dépassant les spécifications indiquées.

5. La teneur en chlore de l’eau ne doit pas dépasser 2,0 ppm. Pour une eau présentant une teneur en chlore supérieure à 2,0 ppm, un prétraitement de l’eau est requis. (Merci de contacter le spécialiste de traitement de l’eau.)

6. Les informations, incluant le numéro de modèle, le numéro de série et la date d’installation, doivent être fournies pour toute réclamation

dans le cadre de la garantie.

7. Les pièces défectueuses seront soumises à une inspection par Watts Regulator Company ou par un représentant agréé avant que le

recours en garantie final ne soit accepté.

8. Watts Regulator Company se réserve le droit de remplacer ou de changer les pièces ou l’équipement par un matériau de qualité et de

valeur égales et en cours de production.

®

est garanti exempt de vices de matériau et de main d’œuvre pour une durée de 5 ans à compter de la

®

est garanti pour une période de 2 ans à compter de la date d’installation initiale lorsqu’il est installé et utilisé

®

de la façon suivante:

®

est garanti exempt de vices de matériau et de main d’œuvre pour une durée d’un an à compter de la

sont garanties pour une période d’un an à compter de la date d’installation initiale lorsqu’elles sont installées et

Limitations

Notre obligation dans le cadre de cette garantie et concernant la cuve ou le robinet est limitée au remplacement ou à la réparation, à notre

choix, de toute pièce jugée défectueuse dans la période de garantie indiquée ci-dessus. Ces pièces de rechange seront fournies gratuitement

au propriétaire FAB à l’usine la plus proche à l’exception des frais de transport et de main d’œuvre locale, le cas échéant.

Notre obligation dans le cadre de cette garantie par rapport au média filtrant OneFlow

années suivant la date d’installation d’origine. Le média filtrant de rechange sera fourni gratuitement au propriétaire FAB à l’usine la plus

proche à l’exception des frais de transport et de main d’œuvre locale, le cas échéant. Les dommages du média filtrant dus au chlore, aux

oxydants et à l’encrassement provoqués par les conditions de l’eau ou une utilisation en dehors des limites spécifiées ne sont pas couverts

par cette garantie.

LA PRÉSENTE GARANTIE EST EXPRESSE ET REPRÉSENTE LA SEULE GARANTIE OFFERTE PAR WATTS REGULATOR COMPANY POUR

CE PRODUIT. WATTS REGULATOR COMPANY N’OFFRE AUCUNE AUTRE GARANTIE EXPRESSE OU IMPLICITE. PAR LA PRÉSENTE,

WATTS REGULATOR COMPANY REJETTE SPÉCIFIQUEMENT TOUTE AUTRE GARANTIE, EXPRESSE OU IMPLICITE, NOTAMMENT TOUTE

GARANTIE IMPLICITE DE QUALITÉ MARCHANDE OU D’ADAPTATION À UN BUT PARTICULIER.

Le remède décrit dans cette garantie constitue le seul recours à toute rupture de la présente garantie et Watts Regulator Company ne saurait

être tenue responsable de tout dommage spécial, accessoire ou consécutif, y compris, mais non exclusivement : le transport, la manutention,

la perte de profits ou le coût afférent à la réparation ou au remplacement d’autres biens qui seraient endommagés par suite du fonctionnement incorrect dudit produit; d’autres coûts afférents aux frais de main-d’œuvre; délais, vandalisme, négligence, encrassement occasionné

par la présence de matériau étranger; dommages résultant d’une eau impropre, de produits chimiques ou de tout autre événement sur lequel

Watts Regulator Company ne saurait exercer le moindre contrôle. La présente garantie est déclarée nulle et non avenue en cas d’abus, de

mésusage, d’application ou d’installation erronée de ce produit.

Certains États ou certaines Provinces n’autorisent pas la limite de durée d’une garantie

implicite ou l’exclusion ou limite de dommages directs ou indirects. C’est pourquoi les limites ou exclusions susmentionnées peuvent ne pas s’appliquer à vous. Cette garantie vous

donne des droits légaux précis et il se peut que vous ayez aussi d’autres droits qui varient

d’une province, d’un état ou d’une juridiction à l’autre. Veuillez vous référer aux lois d’état

ou de province applicables pour déterminer vos droits en la matière. DANS LA MESURE

PERMISE PAR LA LOI, TOUTE GARANTIE IMPLICITE NE POUVANT PAS ÊTRE REJETÉE,

Y COMPRIS LES GARANTIES IMPLICITES DE QUALITÉ MARCHANDE ET D’ADAPTATION

À UN BUT PARTICULIER, SONT LIMITÉES AUX DURÉES DE GARANTIE APPLICABLES

INDIQUÉES CI-DESSUS.

®

sera limitée à son remplacement dans les deux

Une en tre pri se de Watts Wate r Technologies

IOM-OF1465_1665 1017 Réf. EDP 1915996 © 2010 Watts

États-Unis : 815 Chestnut St., No. Andover, MA 01845-6098; www.watts.com

Canada : 5435 North Service Rd., Burlington, ONT. L7L 5H7; www.wattscanada.ca

Loading...

Loading...