Page 1

Installation, Operation and

Maintenance Manual

Model OF140-4

OneFlow

Chemical-Free, Salt-Free Scale Prevention

Introduction

The OneFlow® Anti-Scale System will condition the tap water providing optimum water characteristics for their specified applications.

The result is reduced equipment maintenance requirements, longer

equipment life and improved quality & consistency of your products.

The OneFlow

materials and each system is quality inspected and pressure tested

prior to shipment. With proper installation and routine maintenance,

you will have years of trouble-free operation.

Please refer to this manual when performing routine filter changes.

The instructions make periodic maintenance quick and easy and

ensure you will receive maximum benefit from your system.

®

Anti-Scale System

®

system is built with the finest and most advanced

IOM-OF140-4

System Specifications

Maximum Pressure: 125psi/8.6 bar

Maximum Temperature: 100°F/38°C

Min.: 35°F/2°C

Inlet/Outlet Connections:

Service Flow Rate: 1-4 gpm

Gallon Rating: OF140-4: up to 4 gpm, 24/7/365 for 1 year for the

OF140RM.

Capacity: OF140RM cartridge does not have a grain removal

capacity, however, other contaminants present in the water will

gradually degrade the effectiveness of this cartridge. Change the

OF140RM cartridge at least once a year.

3

/4" FNPT

Page 2

Notice to Installer

i

• Do not discard this manual after installation. This manual

contains important operation, maintenance and precautionary information. Please present this manual to user/operator/

owner after installation.

• It is strongly encouraged that you read this manual before

installing the system to ensure the best possible installation.

• Installation must conform to all local and state plumbing codes

and regulations.

• Connect system to cold water supply only. Water temperature

cannot exceed 100°F/28°C.

• System must be installed in a vertical, upright and level

!

position.

• OneFlow

®

systems must not be used in conjunction with

polyphosphate or any other scale inhibitor.

• Do not use with water that is microbiologically unsafe or of

unknown quality without adequate disinfection before or after

the system.

• Notice to user/operator/owner: Please retain this manual for

future reference for parts, maintenance or troubleshooting.

• It is recommended that all personnel responsible for operation

and maintenance of this product read the precautions, operation

and maintenance sections of this manual.

!

Installation Precautions!

• Do NOT install system on line pressure above 125psi.

• Do NOT install system on HOT water line. Failure to limit line

temperature to 100°F may result in housing failure and damage.

• Do NOT install the system backwards with the feed water line

connected to the outlet.

• Do NOT use liquid pipe compounds for fitting connections.

USE two to three wraps of Teflon

®

tape.

• Do NOT solder plumbing connections attached to filter housing

or inlet valve. Inlet valve and filter housing will be damaged by

high temperature.

• Do NOT allow system to freeze. Turn off water supply to housing

and drain housing if temperature falls below 32°F.

• Do NOT install system in direct sunlight or where system is

exposed to harsh chemicals or may be subjected to being

struck by moving equipment, carts, mops or any other item

that may cause damage.

• ALLOW a minimum of 3” under the housing to allow for filter

replacement.

• IF water hammer is evident, install water hammer arrestors

before the OneFlow

®

unit.

• Do NOT overtighten fitting connections into inlet valve or

housing outlet.

• Always back-up valves and fittings with a wrench when

installing a fitting to avoid turning the valve.

• Do NOT install the unit behind equipment where it may be

difficult to access the system for filter replacement.

®

Position the OneFlow

through the OneFlow

when determining installation location. Do NOT mount the OneFlow

unit in a suitable location. The direction of flow

®

unit is always left to right; keep this in mind

®

system near any source of heat. Also, do not mount the system above

any device or area that would be adversely effected by water.

Installation

1. Turn off all equipment to be fed by the OneFlow® System,

locate water supply shutoff valve and turn OFF

2. Determine if the water line has an existing water treatment

system. If so, examine system for use of polyphosphate or

other scale inhibitors. OneFlow

in conjunction with other scale inhibitors. Remove the scale

inhibitors from the water line or discontinue installation.

3. Install a

1

/2” full-flow ball valve on the water supply side that

will feed the water system.

4. Anchor the OneFlow

®

system on a wall stud or suitable

mounting material spanning wall studs. System must be vertical and upright.

5. Run a suitable line from the

water source to the inlet ball valve on the left side of the

OneFlow

®

system. Use 2-3 wraps of Teflon® tape and brace

the inlet ball valve on the system with a wrench when connecting the feed water line. NOTE: DO NOT OVERTIGHTEN

CONNECTION FITTING INTO BALL VALVE.

6. Select the appropriate size tubing for the equipment being fed

and connect it to the outlet of the OneFlow

DO NOT connect the tubing to the equipment at this time. Prior

to making connection to the equipment, this line will be used to

facilitate flushing the system. As an option, a drain valve in a tee

on the outlet side of the OneFlow

the line to facilitate flushing when changing filters.

®

will not be effective if used

1

/2” full-flow ball valve at the tap

®

System. NOTE:

®

system could be provided in

7. With OneFlow

®

inlet valve closed, slowly open the 1/2” full-

flow ball valve at the tap water source. Check for leaks.

8. If a drain valve was not installed on the outlet side of the system,

hold the tubing that will connect to equipment in a clean bucket

or over sink or drain. Open the system inlet feed valve and allow

water to flush through system for 2 minutes at the specified

system flow rate to allow air bubbles to escape. NOTE: NO

ACTIVATION IS REQUIRED FOR THE OneFlow

®

SYSTEM TO

PERFORM PROPERLY. FLUSHING IS RECOMMENDED TO

ALLOW AIR TO ESCAPE THE SYSTEM.

9. Make certain that the end of the tubing to be connected to

the equipment is clean and sanitary.

10. Connect tubing to equipment. Open all water supply valves

and check for leaks.

11. If no leaks, turn on equipment and check for normal operation.

12. Attach the Service Log to the installed OneFlow

®

System and

fill in install date.

Teflon® is a registered trademark of the E.I. Dupont de Nemours & Company.

2

2

Page 3

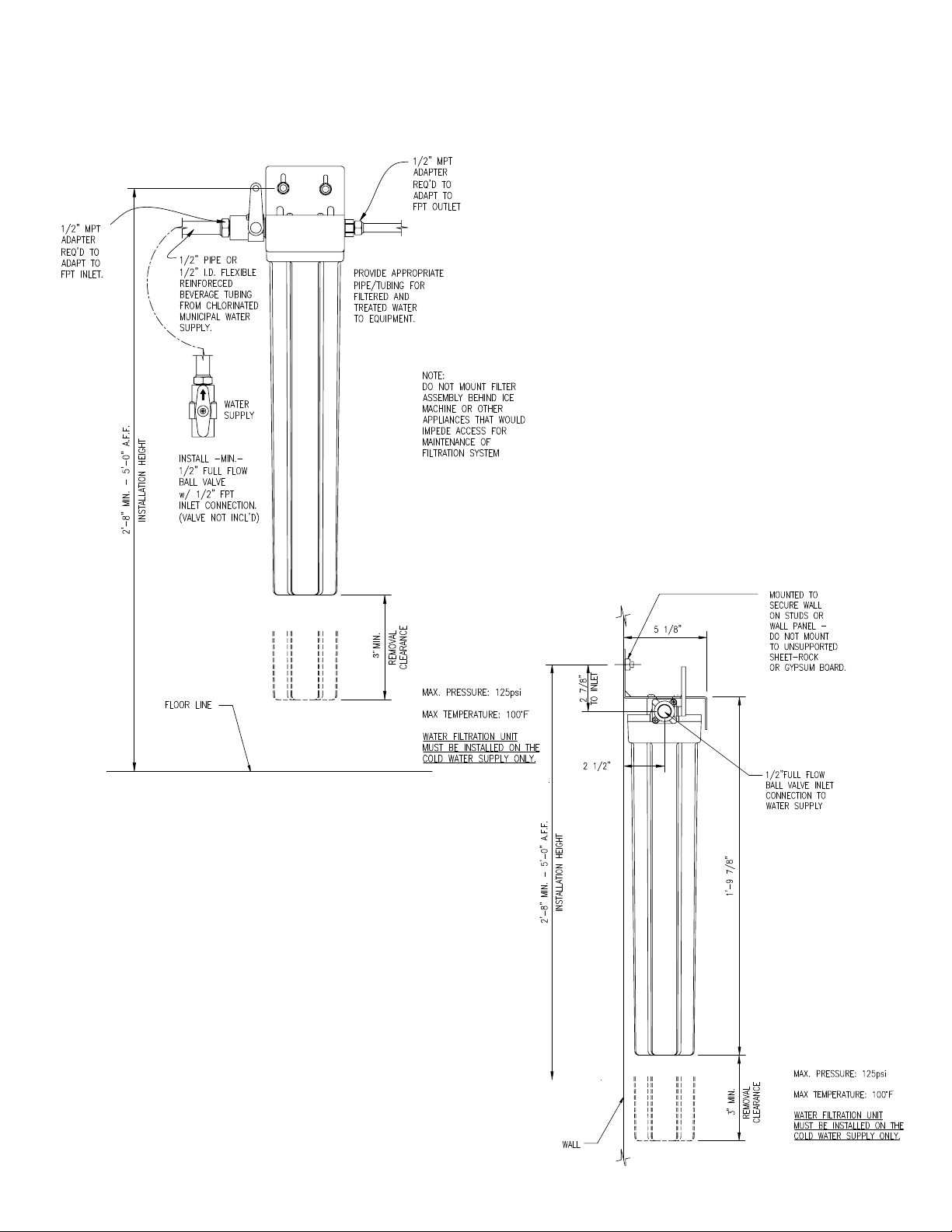

Installation Drawings & Dimensions

3

Page 4

Operation

With sufficient pressure, operation of the Watts OneFlow® System is completely automatic. Dependable operation involves only

periodic filter changes and service documentation.

Maintenance

Routine maintenance of your OneFlow® System involves periodic

filter cartridge changes and/or replacement of sump O-rings. If the

system sizing recommendations have been followed, the OneFlow

Cartridge should last one year.

Filter Change Frequency

The filters should be changed in response to the following conditions.

OF140RM • 12 months since installation or last filter change.

Replacement Filter Cartridges

OneFlow® systems can only be used with OneFlow® filter car-

®

tridges. Use of replacement cartridges other than those specified

will void warranties, certifications and may compromise equipment protection, water quality and equipment life.

2.

3.

4.

8.

6.

7.

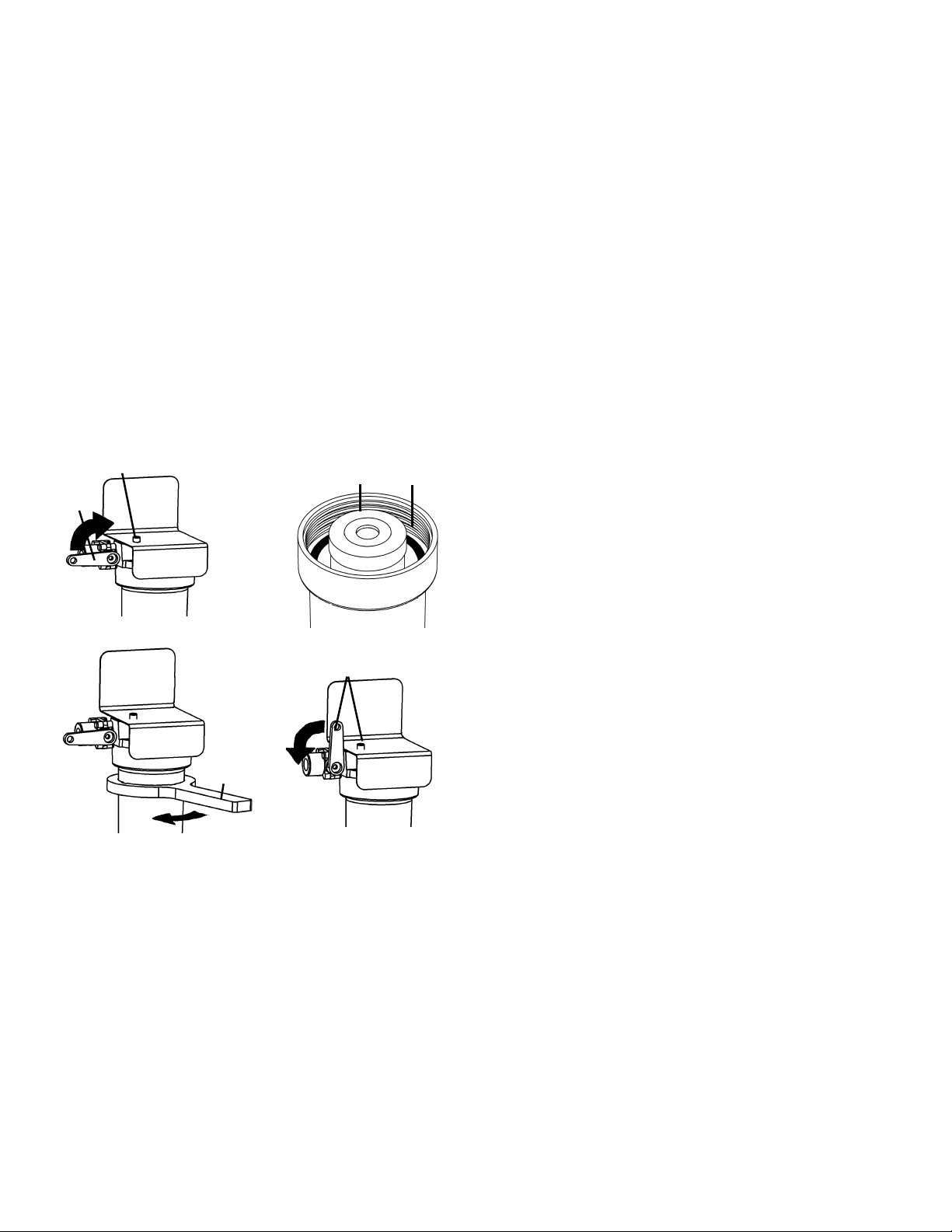

Filter Cartridge Replacement Procedure

IMPORTANT: Determine whether all equipment connected to

the OneFlow

water supply from filters.

1. If required, turn off equipment.

2. Turn OFF water to OneFlow

3. Press the red button to release pressure.

4. Remove housing(s) - use filter wrench if necessary.

5. Clean inside of housing sumps with warm water. If desired,

disinfect housings using a teaspoon of household bleach.

Add to filter bowl and add water. Let stand 5 minutes and

discard.

6. Insert new cartridges into filter housings. Match cartridge

model numbers to model numbers on bracket.

7. Make certain the O-ring is properly positioned and reinstall

filter housings (hand tighten only). Check O-ring for damage

and replace if damaged or distorted.

8. Slightly open the inlet ball valve; push the red pressure relief

button to release trapped air until a small amount of water

comes out - release the red button and fully open the ball valve.

9. Open the flush valve downline from the filter housing (if

equipped) and flush the new cartridges to drain or bucket for

two (2) minutes or until water runs clear. If no flush valve is

present, disconnect line from equipment to flush to drain.

10. VERY IMPORTANT: With water supply inlet valve OPEN and

water flow confirmed, turn on connected equipment. Failure

to supply water to equipment may cause serious damage.

11. Record filter change on the service log.

®

system must be turned off prior to shutting off

®

system by closing Inlet Ball Valve.

4

Page 5

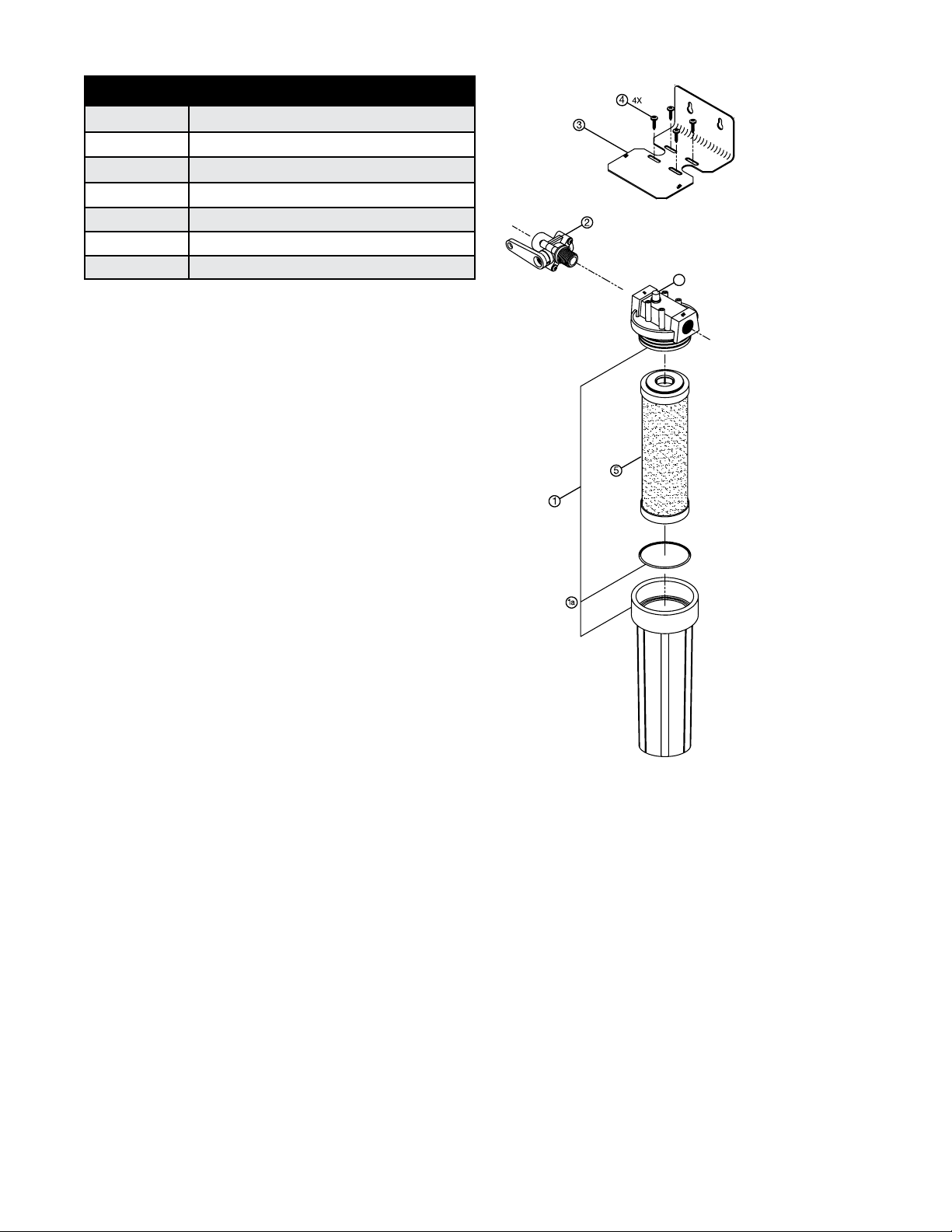

Replacement Parts for: OneFlow® OF140-4

Drawing ID # Description

1 Housing, w/PR

1a O-Ring

3

2 Valve,

3 Bracket, Single Housing

4 Screw

5 OF140RM Replacement Cartridge

6 Pressure Relief Button

/4" FxM Ball

t

e

l

n

i

t

e

l

t

u

o

6

N

I

T

U

O

5

Page 6

Limited Warranty

• The OneFlow® tank system is warranted to be free of defects in materials and workmanship for 5 years from the date of original shipment.

• The OneFlow

ated in accordance with the instructions in the corresponding Installation and Operation Manual.

Watts Regulator Company warrants its OneFlow

• The OneFlow

shipment.

• OneFlow

operated in accordance with the instructions in the corresponding Installation and Operation Manual.

• Carbon replacement filter cartridges are not warranted to perform for any period of time because the service life of replacement carbon

filter cartridges varies significantly with local water conditions and volume.

Conditions

1. The OneFlow® system must be installed in applications with municipally supplied water adhering to EPA guidelines.

2. Any component failure must not result from abuse, fire, freezing or other acts of nature, violence, or improper installation.

3. Equipment must be installed and operated in compliance with the local plumbing codes and on an approved water supply.

4. Equipment is limited to use at water pressures and temperatures that do not exceed our published specifications.

5. Water supply must not exceed 2.0 PPM chlorine. For water supply exceeding 2.0 PPM chlorine, pretreatment is required.

(Please contact your water treatment specialist.)

6. Information, including model number, serial number, and date of installation, must be provided for any claims pertaining to equipment in

warranty.

7. Defective parts are subject to inspection by either Watts Regulator Company or any authorized representative before final commitment of

warranty adjustment is made.

8. Watts Regulator Company reserves the right to make changes or substitutions in parts or equipment with material of equal quality or value

and of then current production.

®

media is warranted for performance for a period of 2 years from the date of the original installation when installed and oper-

®

cartridge systems as follows:

®

cartridge system is warranted to be free of defects in materials and workmanship for 1 year from the date of original

®

cartridges are warranted for performance for a period of one year from the date of original installation when installed and

Limitations

Our obligation under this warranty with respect to the tank or valve is limited to furnishing a replacement for, or at our option, repairing any

part or parts to our satisfaction that prove defective within the warranty period stated above. Such replacement parts will be delivered to the

owner F.O.B. nearest factory, at no cost, excluding freight and local labor charges, if any.

Our obligation under this warranty with respect to the OneFlow

years from date of original installation. Such replacement media will be delivered to the owner F.O.B. nearest factory, at no cost, excluding

freight and local labor charges, if any. Damage to the media due to chlorine, other oxidizers or fouling caused by local water conditions or

any other operation outside of the limits shown under Specifications, is not covered by this warranty.

THE WARRANTY SET FORTH HEREIN IS GIVEN EXPRESSLY AND IS THE ONLY WARRANTY GIVEN BY WATTS REGULATOR COMPANY

WITH RESPECT TO THE PRODUCT. WATTS REGULATOR COMPANY MAKES NO OTHER WARRANTIES, EXPRESS OR IMPLIED. WATTS

REGULATOR COMPANY HEREBY SPECIFICALLY DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT

LIMITED TO THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

The remedy described under this warranty shall constitute the sole and exclusive remedy for breach of warranty, and Watts Regulator

Company shall not be responsible for any incidental, special or consequential damages, including without limitation, freight, handling, lost

profits or the cost of repairing or replacing other property which is damaged if this product does not work properly, other costs resulting from

labor charges, delays, vandalism, negligence, fouling caused by foreign material, damage from adverse water conditions, chemical, or any

other circumstances over which Watts Regulator Company has no control. This warranty shall be invalidated by any abuse, misuse, misapplication or improper installation of the product.

Some states do not allow limitations on how long an implied warranty lasts, and some states do not allow the exclusion or limitation of incidental or consequential damages. Therefore the above limitations may not apply to you. This warranty gives you specific legal rights, and

you may have other rights that vary from state to state. You should consult applicable state laws to determine your rights. SO FAR AS IS

CONSISTENT WITH APPLICABLE STATE LAW, ANY IMPLIED WARRANTIES THAT MAY NOT BE DISCLAIMED, INCLUDING THE IMPLIED

WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, ARE LIMITED IN DURATION TO THE APPLICABLE

WARRANTY PERIODS STATED ABOVE.

®

media will be limited to furnishing a replacement for the media within two

A Watts Wa ter Technol ogi es Com pan y

Canada: 5435 North Service Rd., Burlington, ONT. L7L 5H7; www.wattscanada.ca

IOM-OF140-4 1017 EDP#2915002 © 2010 Watts

USA: 815 Chestnut St., No. Andover, MA 01845-6098; www.watts.com

Page 7

Manual de instalación,

funcionamiento y

mantenimiento

Modelo OF140-4

Sistema antisarro OneFlow

Prevención de sarro sin sustancias

químicas, sin sal

®

IOM-OF140-4

Introducción

El Sistema antisarro OneFlow® acondicionará el agua corriente

brindándole características óptimas para sus aplicaciones

específicas. Como resultado se reducen los requisitos de

mantenimiento del equipo, se prolonga su duración y se mejora la

calidad y consistencia de sus productos.

El sistema OneFlow

materiales y cada sistema es sometido a un control de calidad y

a una prueba de presión antes de su envío. Mediante la correcta

instalación y el mantenimiento periódico, usted contará con años de

uso sin problemas.

Consulte este manual al realizar los cambios de filtro periódicos. Las

instrucciones facilitan y agilizan el mantenimiento periódico, lo que le

permitirá aprovechar su sistema al máximo.

®

se fabrica con los mejores y más avanzados

Especificaciones del sistema

Presión máxima: 125 psi/8,6 bar

Temperatura máxima: 100 °F/38 °C

Mín.: 35 °F/2 °C

Conexiones de entrada/salida:

Caudal de servicio: 1-4 gpm

Clasificación de galón: OF140-4: hasta 4 gpm,

24/7/365por1año para el OF140RM.

Capacidad: el cartucho OF140RM no tiene capacidad de

eliminación de granos. Sin embargo, otros contaminantes

presentes en el agua degradarán la eficacia de este cartucho en

forma gradual. Cambiar el cartucho OF140RM al menos una vez

por año.

3

/4" FNPT

Page 8

Aviso para el instalador

i

• No desechar este manual después de la instalación.

Este manual contiene información importante acerca del

funcionamiento, mantenimiento y medidas de precaución.

Entregar este manual al usuario, operador o propietario luego

de la instalación.

• Se recomienda firmemente leer este manual antes de instalar

el sistema para garantizar la mejor instalación posible.

• La instalación debe cumplir con todos los códigos y

reglamentos locales y estatales relativos a las cañerías.

• Conectar el sistema únicamente al suministro de agua fría.

La temperatura del agua no puede exceder los 100 °F/28 °C.

• El sistema debe instalarse en posición vertical, recta y

!

nivelada.

• Los sistemas OneFlow

®

no deben utilizarse junto con

polifosfatos ni con otros inhibidores de sarro.

• No utilizar con agua microbiológicamente insegura o de

calidad desconocida sin una desinfección adecuada antes o

después del sistema.

• Aviso para el usuario, operador o propietario: Conservar

este manual para futuras consultas acerca de piezas,

mantenimiento o resolución de problemas.

• Se recomienda que todo el personal responsable por el

uso y mantenimiento de este producto lea las secciones de

precauciones, funcionamiento y mantenimiento de este manual.

Instalación

1. Apagar todos los equipos que se abastecerán del sistema

OneFlow

y CERRARLA.

2. Determinar si la tubería de agua ya cuenta con un sistema

de tratamiento de agua. De ser así, examinar el sistema para

determinar si utiliza polifosfato u otros inhibidores de sarro.

OneFlow

otros inhibidores de sarro. Retirar los inhibidores de sarro de

la tubería de agua o suspender la instalación.

3. Instalar una válvula esférica de

lado de suministro de agua para el sistema de agua.

4. Fijar el sistema OneFlow

material de montaje con entramados de pared. El sistema

debe estar en posición vertical y recta.

5. Conectar una tubería adecuada desde la válvula esférica de

1

/2" para caudal total en la fuente de agua corriente hasta

la válvula esférica de entrada del lado izquierdo del sistema

OneFlow

la válvula esférica de entrada del sistema con una llave

al conectar la tubería de agua de suministro. NOTA: NO

AJUSTAR EN EXCESO EL ACCESORIO DE CONEXIÓN EN

LA VÁLVULA ESFÉRICA.

6. Seleccionar la tubería del tamaño adecuado para el equipo al

que se dirige el suministro y conectarlo a la salida del sistema

OneFlow

de realizar la conexión al equipo, esta tubería se utilizará para

ayudar a purgar el sistema. Como pieza opcional, se puede

proporcionar para la tubería una válvula de drenaje en una

conexión en T en el lado de salida del sistema OneFlow

poder realizar la purga al cambiar filtros.

®

, localizar la válvula de corte del suministro de agua

®

no funcionará con eficacia si se utiliza junto con

1

/2" para caudal total en el

®

a un entramado de pared o a un

®

. Utilizar 2 a 3 vueltas de cinta de Teflon® y ajustar

®

. NOTA: NO conectar la tubería al equipo aún. Antes

®

para

!

Precauciones en la instalación

• NO instalar el sistema a una presión de línea superior a 125 psi.

• NO instalar el sistema en una tubería de agua CALIENTE. Si la

temperatura de la tubería no se limita a 100 °F, el alojamiento

puede averiarse o dañarse.

• NO instalar el sistema al revés con la tubería de agua de

suministro conectada a la salida.

• NO utilizar compuestos líquidos para cañerías en las conexiones

de instalación. UTILIZAR dos a tres vueltas de cinta de Teflon

• NO soldar conexiones de cañerías conectadas al alojamiento

del filtro o a la válvula de entrada. La válvula de entrada y el

alojamiento del filtro se dañarán debido a la alta temperatura.

• NO permitir que el sistema se congele. Cerrar el suministro de

agua al alojamiento y drenar el alojamiento si la temperatura

desciende por debajo de 32 °F.

• NO instalar el sistema bajo la luz directa del sol o donde

quede expuesto a sustancias químicas agresivas o pueda

recibir golpes por el movimiento de equipos, carros, mopas o

cualquier otro elemento que pueda causar daños.

• DEJAR un mínimo de 3" debajo del alojamiento para que se

pueda reemplazar el filtro.

• SI se observa un golpe de ariete, instalar dispositivos anti-

golpe de ariete antes de la unidad OneFlow

®

.

• NO ajustar en exceso las conexiones de instalación en la

válvula de entrada o la salida del alojamiento.

• Siempre retroceder las válvulas y accesorios con una llave al

instalar un accesorio para evitar girar la válvula.

• NO instalar la unidad detrás de equipos de modo que se dificulte

el acceso al sistema para el reemplazo del filtro.

Colocar la unidad

caudal que pasa por la unidad

OneFlow® en un lugar adecuado. La dirección del

OneFlow® siempre es de izquierda

a derecha. Tener en cuenta este factor al determinar el lugar de

instalación. NO montar el sistema

OneFlow® cerca de ninguna fuente

de calor. Tampoco montar el sistema sobre dispositivos o zonas que

puedan sufrir daños por los efectos del agua.

®

7. Con una válvula de entrada del sistema OneFlow

abrir lentamente la válvula esférica de

1

/2" para caudal total

cerrada,

en la fuente de agua corriente. Revisar en busca de fugas.

8. Si no se instaló una válvula de drenaje en el lado de salida del

sistema, colocar la tubería que se conectará al equipo en un

cubo limpio o sobre el fregadero o desagüe. Abrir la válvula de

suministro de entrada del sistema y dejar que el agua circule

por el sistema durante 2 minutos a la velocidad de caudal

especificada para el sistema para permitir que salgan las

burbujas de aire. NOTA: NO SE REQUIERE ACTIVACIÓN PARA

QUE EL SISTEMA OneFlow

®

FUNCIONE CORRECTAMENTE.

SE RECOMIENDA PURGAR PARA PERMITIR LA ELIMINACIÓN

DEL AIRE DEL SISTEMA.

9. Asegurarse de que el extremo de la tubería que se va a

conectar al equipo esté limpio e higienizado.

10. Conectar la tubería al equipo. Abrir todas las válvulas de

suministro de agua y verificar si hay fugas.

11. Si no hay fugas, encender el equipo y verificar si funciona

normalmente.

12. Adherir la Hoja de registro de mantenimiento al sistema

OneFlow

Teflon® es una marca comercial registrada de E.I. Dupont de Nemours & Company.

®

instalado y completar la fecha de instalación.

8

®

.

Page 9

Diagramas y dimensiones de instalación

ADAPTADOR

DE 1/2" MPT

NECESARIO PARA

ADAPTAR LA

ENTRADA FPT.

CAÑO DE 1/2" O TUBERÍA PARA

BEBIDAS REFORZADA FLEXIBLE

DE 1/2" DE D.I. PROVENIENTE

DEL SUMINISTRO DE AGUA

CLORADA MUNICIPAL.

INSTALAR (MÍN.) VÁLVULA

ESFÉRICA DE 1/2" PARA CAUDAL

TOTAL CON CONEXIÓN DE

ENTRADA DE 1/2" FPT. (VÁLVULA

NO INCLUIDA)

ALTURA DE INSTALACIÓN

SUMINISTRO

DE AGUA

PROPORCIONAR CAÑERÍA/TUBERÍA

ADECUADA AL EQUIPO PARA EL AGUA

FILTRADA Y TRATADA.

ADAPTADOR DE 1/2"

MPT NECESARIO

PARA ADAPTAR A LA

SALIDA FPT.

NOTA:

NO MONTAR EL CONJUNTO DEL FILTRO

DETRÁS DE UNA MÁQUINA DE HIELO U

OTROS ARTEFACTOS QUE DIFICULTEN EL

ACCESO PARA EL MANTENIMIENTO DEL

SISTEMA DE FILTRACIÓN.

2'-8" MÍN. - 5'-0" SOBRE EL PISO TERMINADO

NIVEL DEL SUELO

3" MÍN.

PRESIÓN MÁX.: 125 psi

ESPACIO PARA EXTRACCIÓN

TEMPERATURA MÁX.: 100 °F

LA UNIDAD DE FILTRACIÓN DE AGUA DEBE

INSTALARSE ÚNICAMENTE EN EL SUMINISTRO

DE AGUA FRÍA.

A LA ENTRADA

ALTURA DE INSTALACIÓN

2'-8" MÍN. - 5'-0" SOBRE EL PISO TERMINADO

MONTAR A UNA PARED FIRME

EN ENTRAMADOS O PANEL

PARA PARED. NO MONTAR A

TABLAROCA NI PLACA DE YESO

SIN SOPORTE.

CONEXIÓN DE ENTRADA DE

LA VÁLVULA ESFÉRICA DE

1/2" PARA CAUDAL TOTAL AL

SUMINISTRO DE AGUA FRÍA

PRESIÓN MÁX.: 125 psi

TEMPERATURA MÁX.: 100 °F

3" MÍN.

PARED

LA UNIDAD DE FILTRACIÓN DE AGUA

DEBE INSTALARSE ÚNICAMENTE EN EL

EXTRACCIÓN

ESPACIO PARA

SUMINISTRO DE AGUA FRÍA.

9

Page 10

Funcionamiento

Si la presión es suficiente, el funcionamiento del sistema

OneFlow

funcionamiento sea confiable sólo se requieren cambios

periódicos de los filtros y el registro del mantenimiento.

®

de Watts es totalmente automático. Para que el

Mantenimiento

El mantenimiento rutinario de su sistema OneFlow® implica cambios

periódicos de los cartuchos del filtro y/o reemplazo de las juntas

tóricas del sumidero. Si se han seguido las recomendaciones de

dimensiones del sistema, el cartucho OneFlow

un año.

Frecuencia de cambio de filtros

Los filtros deben cambiarse como consecuencia de las siguientes

condiciones.

OF140RM • 12 meses desde la instalación o desde el último

cambio de filtro.

®

debe durar

Cartuchos de filtro de repuesto

Los sistemas OneFlow® sólo pueden utilizarse con cartuchos

para filtros OneFlow

a los especificados anulará las garantías y certificaciones y

puede poner en peligro la protección del equipo, su duración

y la calidad del agua.

®

. El uso de cartuchos de repuesto distintos

2.

3.

4.

8.

6.

7.

Procedimiento de reemplazo del cartucho del filtro

IMPORTANTE: Determinar si se deben apagar todos los

equipos conectados al sistema OneFlow

suministro de agua desde los filtros.

1. De ser necesario, apagar el equipo.

2. CERRAR el agua al sistema OneFlow

esférica de entrada.

3. Presionar el botón rojo para aliviar la presión.

4. Extraer el/los alojamiento(s); utilizar la llave para filtros si es

necesario.

5. Limpiar el interior de los sumideros de los alojamientos con

agua tibia. Si se desea, desinfectar los alojamientos con

una cucharadita de lejía de uso doméstico. Colocarla en el

recipiente del filtro y añadir agua. Dejar reposar durante

5 minutos y desechar el líquido.

6. Insertar los cartuchos nuevos en los alojamientos del filtro.

Hacer coincidir los números de modelo de los cartuchos

con los números de modelo en el soporte.

7. Asegurarse de que la junta tórica esté en la posición

correcta y reinstalar los alojamientos del filtro (ajustar

únicamente a mano). Revisar la junta tórica en busca de

daños y reemplazarla si está dañada o deformada.

8. Abrir ligeramente la válvula esférica de entrada. Presionar el

botón rojo de alivio de presión para liberar el aire atrapado

hasta que salga un poco de agua. Soltar el botón rojo y abrir

por completo la válvula esférica.

9. Abrir la válvula de purga en línea descendente desde el

alojamiento del filtro (si corresponde) y purgar los cartuchos

nuevos al desagüe o a un cubo durante dos (2) minutos o

hasta que el agua salga transparente. Si no hay una válvula

de purga, desconectar la tubería proveniente del equipo

para purgar al desagüe.

10. MUY IMPORTANTE: Con la válvula de entrada de suministro

de agua ABIERTA y el caudal de agua confirmado, encender

el equipo conectado. La falta de suministro de agua al equipo

puede ocasionar daños graves.

11. Registrar el cambio de filtro en la hoja de registro de

mantenimiento.

®

antes de cerrar el

®

cerrando una válvula

10

Page 11

Piezas de repuesto para: OneFlow® OF140-4

Nº de

referencia del

diagrama

1 Alojamiento, con PR

1a Junta tórica

2 Válvula, esférica de

3 Soporte, alojamiento simple

4 Tornillo

5 Cartucho de repuesto OF140RM

6 Botón de alivio de presión

Descripción

3

/4" FxM

t

e

l

n

i

t

e

l

t

u

o

6

N

I

T

U

O

11

Page 12

Garantía limitada

• El sistema de depósito OneFlow® está garantizado como libre de defectos en materiales y manufactura por 5 años desde la fecha del envío original.

• El material OneFlow

instalado y utilizado de acuerdo a las instrucciones del Manual de instalación y uso correspondiente.

Watts Regulator Company garantiza sus sistemas de cartuchos OneFlow® como se describe a continuación:

• El sistema de cartuchos OneFlow

• Los cartuchos OneFlow

hayan instalado y utilizado de acuerdo a las instrucciones del Manual de instalación y uso correspondiente.

• No se garantiza el funcionamiento de los cartuchos de repuesto para filtros de carbono por ningún período dado que la vida útil de los cartuchos de

repuesto para filtros de carbono varía significativamente de acuerdo a las condiciones y el volumen del agua local.

Condiciones

1. El sistema OneFlow® debe instalarse en aplicaciones con agua suministrada a nivel municipal que cumpla con las normas de la Agencia de Protección

Ambiental de Estados Unidos (U.S. Environmental Protection Agency, EPA).

2. Los fallos en los componentes no deben producirse como consecuencia de uso indebido, incendio, congelamiento u otros factores como fuerzas de

la naturaleza, actos de violencia o instalación incorrecta.

3. El equipo debe instalarse y utilizarse de conformidad con los códigos locales relativos a las cañerías y con un suministro de agua aprobado.

4. El uso del equipo está limitado a las temperaturas y presiones de agua que no excedan nuestras especificaciones publicadas.

5. El suministro de agua no debe exceder 2 ppm de cloro. En suministros de agua que excedan 2 ppm de cloro, se requiere tratamiento previo.

(Contactar al especialista en tratamiento de agua.)

6. Para cualquier reclamo en relación con los equipos en garantía, se debe proporcionar información incluyendo el número de modelo, el número de

serie y la fecha de instalación.

7. Las piezas defectuosas están sujetas a inspección por parte de Watts Regulator Company o cualquier representante autorizado antes de que se

asuma el compromiso final de ajuste de garantía.

8. Watts Regulator Company se reserva el derecho a realizar cambios o sustituciones en las piezas o el equipo por materiales de valor o calidad

equivalente y producción vigente en el momento.

Limitaciones

Nuestra obligación bajo la presente garantía con respecto al depósito o la válvula está limitada al reemplazo o la reparación, a nuestra elección, de

cualquier pieza o piezas a nuestra satisfacción con defectos comprobados dentro del período de garantía antes estipulado. Tales piezas de repuesto

serán entregadas al propietario bajo condición Libre a bordo (Free on Board, FOB) en la fábrica más cercana, sin costo alguno, sin incluir gastos de flete y

mano de obra local, de corresponder.

Nuestra obligación bajo la presente garantía con respecto al material OneFlow

desde la fecha de la instalación original. Tales materiales de repuesto serán entregados al propietario bajo condición Libre a bordo (Free on Board, FOB)

en la fábrica más cercana, sin costo alguno, sin incluir gastos de flete y mano de obra local, de corresponder. Esta garantía no cubre los materiales

dañados a causa del cloro, otros oxidantes o la contaminación por las condiciones del agua local o cualquier otra operación fuera de los límites indicados

en la sección Especificaciones.

LA GARANTÍA AQUÍ ESTIPULADA SE OTORGA EN FORMA EXPRESA Y ES LA ÚNICA GARANTÍA OTORGADA POR WATTS REGULATOR COMPANY

EN RELACIÓN CON EL PRODUCTO. WATTS REGULATOR COMPANY NO OTORGA NINGUNA OTRA GARANTÍA, YA SEA EXPRESA O IMPLÍCITA.

WATTS REGULATOR COMPANY POR LA PRESENTE RENUNCIA ESPECÍFICAMENTE A TODAS LAS DEMÁS GARANTÍAS, EXPRESAS O IMPLÍCITAS,

INCLUYENDO SIN LIMITACIÓN, LAS GARANTÍAS IMPLÍCITAS DE APTITUD PARA LA COMERCIALIZACIÓN E IDONEIDAD PARA UN PROPÓSITO EN

PARTICULAR.

La reparación descrita en esta garantía constituirá el único y exclusivo resarcimiento por incumplimiento de garantía, y Watts Regulator Company no

se hará responsable por daños fortuitos, especiales o derivados, incluyendo sin limitación, los gastos de flete y manipuleo, la pérdida de ganancias o

el costo de reparación o reemplazo de otra propiedad que resulte dañada por el mal funcionamiento de este producto, otros costos resultantes por

mano de obra, retardos, vandalismo, negligencia, contaminación ocasionada por materiales extraños, daños a causa de condiciones adversas del agua,

sustancias químicas o cualquier otra circunstancia sobre la cual Watts Regulator Company no tenga control. Esta garantía no tendrá validez en cualquier

caso de abuso, uso indebido, aplicación incorrecta o instalación inadecuada del producto.

Algunos estados no permiten limitaciones en la duración de una garantía implícita y otros estados no permiten la exclusión o limitación de daños fortuitos

o derivados. Por lo tanto, es posible que las limitaciones anteriores no sean aplicables en su caso. Esta garantía le otorga derechos legales específicos.

Usted podría tener también otros derechos que varían según el Estado en cuestión. Usted debe consultar las leyes estatales aplicables para determinar

sus derechos. EN LA MEDIDA EN QUE SEA CONGRUENTE CON LAS LEYES ESTATALES APLICABLES, CUALQUIER GARANTÍA IMPLÍCITA QUE NO

SEA RECHAZADA, INCLUYENDO LAS GARANTÍAS IMPLÍCITAS DE APTITUD PARA LA COMERCIALIZACIÓN E IDONEIDAD PARA UN PROPÓSITO EN

PARTICULAR, SE LIMITA EN SU DURACIÓN A LOS PERÍODOS DE GARANTÍA APLICABLES ESTIPULADOS PRECEDENTEMENTE.

®

está garantizado en cuanto a su rendimiento por un período de 2 años desde la fecha de la instalación original en tanto se haya

®

®

están garantizados en cuanto a su rendimiento por un período de un año desde la fecha de la instalación original en tanto se

está garantizado como libre de defectos en materiales y manufactura por 1 año desde la fecha del envío original.

®

estará limitada a suministrar repuestos por el material durante dos años

Una co mpa ñía de Watts Water Techn olo gie s

EE.UU.: 815 Chestnut St., No. Andover, MA 01845-6098; www.watts.com

Canadá: 5435 North Service Rd., Burlington, ONT. L7L 5H7; www.wattscanada.ca

IOM-OF140-4 1017 EDP Nº 2915002 © 2010 Watts

Page 13

Manuel d’installation,

de fonctionnement

et d’entretien

Model OF140-4

Système antitartre OneFlow

Prévention contre le tartre

sans produits chimiques ni sel

Introduction

Le système antitartre OneFlow® permet de conditionner l’eau du

robinet et d’obtenir des caractéristiques d’eau optimales pour leurs

applications spécifiques. Le résultat produit peu d’exigences d’entretien et une durée de vie plus longue de l’équipement, ainsi qu’une

qualité et une uniformité améliorées des produits.

Le système OneFlow

avancés et de première qualité. Chaque système est soumis à une

inspection de la qualité et à un test de pression avant d’être expédié. Une installation et un entretien de routine adéquats assureront

un fonctionnement sans problème pendant plusieurs années.

Consulter ce manuel pour le remplacement de routine du filtre. Les

instructions permettent d’effectuer l’entretien périodique facilement

et rapidement et garantissent de tirer le meilleur parti des avantages

du système.

®

est construit avec les matériaux les plus

®

IOM-OF140-4

Spécifications du système

Pression maximale : 8,6 bar (125 psi)

Température maximale : 38 °C (100°F)

Min. : 2 °C (35 °F)

Raccords d’entrée et de sortie :

Débit de service : 4 - 15 L/min (1-4 gpm)

Gallonage: OF140-4 : jusqu’à 15 L/min (4 gpm), 24/7/365 pendant

1 an avec le modèle OF140RM.

Capacité: La cartouche OF140RM n’offre pas une capacité de retrait des

grains. De plus, d’autres contaminants présents dans l’eau réduiront petit à

petit l’efficacité de la cartouche. Remplacer la cartouche OF140RM au moins

une fois par an.

3

/4 po FNPT

Page 14

Avis à l’installateur

i

• Ne pas jeter ce manuel après l’installation. Ce manuel contient des

informations importantes concernant le fonctionnement, l’entretien et

les précautions à prendre. Merci de présenter ce manuel à l’utilisateur/

l’opérateur/le propriétaire après l’installation.

• Il est fortement recommandé de lire ce manuel avant d’installer le sys-

tème pour garantir la meilleure installation possible.

• L’installation doit être conforme aux normes et codes de plomberie

locaux et nationaux.

• Raccorder le système à l’alimentation d’eau froide uniquement. Le tem-

pérature de l’eau ne doit pas dépasser 38 °C (100 °F).

• Le système doit être installé d’aplomb, à la verticale et à niveau.

• Le système OneFlow® ne doit pas être utilisé avec du polyphosphate

!

ou tout autre inhibiteur de tartre.

• Ne pas utiliser avec de l’eau présentant des risques microbiologiques

ou de qualité inconnue sans l’avoir correctement désinfectée avant ou

après son passage dans le système.

• Avis à l’utilisateur/l’opérateur/le propriétaire: Conserver ce manuel pour

référence ultérieure concernant les pièces de rechange, l’entretien et

le dépannage.

• Il est recommandé que tout le personnel responsable du fonction-

nement et de l’entretien de ce produit lise les sections Précautions,

Fonctionnement et Entretien de ce manuel.

Précautions d’installation!

!

• NE PAS installer le système sur une pression de conduite supérieure à 125 psi.

• NE PAS installer le système sur une conduite d’eau CHAUDE. Si la

température de conduite n’est pas limitée à 38 °C (100 °F), le boîtier

peut être endommagé ou connaître des défaillances.

• NE PAS installer le système à l’envers avec la conduite d’eau d’alimen-

tation raccordée à la sortie.

• NE PAS utiliser de produits pour tuyauterie liquides sur les raccords.

UTILISER deux ou trois tours de ruban Teflon

• NE PAS effectuer le brasage aux raccords de plomberie attachés au

boîtier du filtre ou au robinet d’alimentation. Le robinet d’alimentation et

le boîtier du filtre seront endommagés par des températures élevées.

• NE PAS laisser le système geler. Couper l’alimentation en eau vers le boîtier et la

chambre de vidange si la température descend en dessous de 0 °C (32 °F).

• NE PAS installer le système directement à la lumière du soleil et ne pas

l’exposer à des produits chimiques corrosifs ou à des impacts causés

par des équipements mobiles, des chariots, des balais ou tout autre

article

pouvant provoquer des dommages.

• LAISSER au moins 3 pouces sous le boîtier pour permettre le rempla-

cement du filtre.

• SI un coup de bélier est évident, installer des antibéliers devant l’unité

• NE PAS trop serrer les raccords du robinet d’alimentation ou de la sor-

• Toujours tenir les robinets et les raccords avec une clé lors de

• NE PAS installer l’unité derrière un équipement où il serait difficile

Placer l’unité OneFlow

ment par l’unité OneFlow® se fait toujours de gauche à droite; garder ceci

à l’esprit lors de la sélection de l’emplacement. NE PAS monter le système

OneFlow® près d’une source de chaleur. De même, ne pas monter le système au-dessus d’un appareil ou d’une zone qui pourrait être endommagé par

de l’eau.

®

OneFlow

tie

du boîtier.

l’installation d’un raccord pour éviter de tourner le robinet.

d’accéder au système pour le remplacement du filtre.

.

®

dans un endroit adapté. La direction de l’écoule-

®

.

Installation

1. Éteindre tout l’équipement devant être alimenté par le système

OneFlow®. Repérer le robinet d’arrêt et le fermer.

2. Déterminer si la conduite d’eau est équipée d’un système de traite-

ment de l’eau. Le cas échéant, examiner le système pour détecter

l’utilisation de polyphosphate ou d’inhibiteurs de tartre. Le système

OneFlow® ne fonctionnera pas efficacement s’il est utilisé avec

d’autres inhibiteurs de tartre. Les retirer de la conduite d’eau ou arrêter

l’installation.

3. Installer un robinet à bille à passage intégral d’1/2 pouce sur l’alimenta-

tion en eau du système.

4. Ancrer le système OneFlow® sur un poteau de cloison ou un matériau

de montage adéquat. Le système doit être à la verticale et d’aplomb.

5. Installer une conduite adaptée entre le robinet à bille à passage intégral

d’1/2 pouce au niveau de la source d’eau du robinet et le robinet à

bille d’alimentation sur le côté gauche du système OneFlow®. Enrouler

2 à 3 tours de ruban Teflon® et maintenir le robinet à bille d’alimentation du système avec une clé lors du raccordement de la conduite

d’eau d’alimentation. REMARQUE: NE PAS TROP SERRER LE

RACCORD DANS LE ROBINET À BILLE.

6. Sélectionner une tuyauterie de taille appropriée à l’équipement

alimenté

et le raccorder dans la sortie du système OneFlow®. REMARQUE :

NE PAS raccorder la tuyauterie à l’équipement à ce stade. Avant

d’effectuer un raccordement à l’équipement, cette conduite sera

utilisée pour faciliter le rinçage du système. En option, un robinet de

vidange dans un té sur le côté sortie du système OneFlow® peut être

installé dans la conduite pour faciliter le rinçage lors du remplacement

des filtres.

7. Une fois le robinet d’alimentation OneFlow® fermé, ouvrir lentement le

robinet à bille à passage intégral d’1/2 pouce au niveau de la source

d’eau du robinet. Inspecter pour toute fuite éventuelle.

8. Si un robinet de vidange n’est pas installé sur le côté sortie du sytème,

tenir la tuyauterie qui sera raccordée à l’équipement au-dessus

d’un seau propre, d’un évier ou d’une évacuation. Ouvrir le robinet

d’alimentation

du système et laisser l’eau circuler dans le système pendant 2minutes

au débit spécifié pour permettre aux bulles d’air de s’échapper.

REMARQUE: AUCUNE ACTIVATION N’EST REQUISE POUR

QUE LE SYSTÈME OneFlow® FONCTIONNE CORRECTEMENT.

LE RINÇAGE EST RECOMMANDÉ POUR PERMETTRE À L’AIR DE

S’ÉVACUER.

9. S’assurer que l’extrémité de la tuyauterie à raccorder à l’équipement

est propre et sanitaire.

10. Raccorder la tuyauterie à l’équipement. Ouvrir tous les robinets d’alimentation en eau et inspecter pour toute fuite éventuelle.

11. S’il n’y a pas de fuites, mettre l’équipement en marche et vérifier qu’il

fonctionne normalement.

12. Attacher le journal d’entretien sur le système OneFlow® installé et y

noter la date d’installation.

Teflon® est une marque déposée de E.I. Dupont de Nemours & Company.

14

Page 15

Schémas d’installation et dimensions

ADAPTATEUR D’1/2 PO

MPT REQUIS POUR

L’ENTRÉE FPT.

HAUTEUR D’INSTALLATION

TUYAU D’1/2 PO OU

TUYAUTERIE À BOISSONS

RENFORCÉ FLEXIBLE

D’1/2 PO DE DIA. INT. À

PARTIR DE L’ARRIVÉE

D’EAU MUNICIPALE

CHLORÉE.

ALIMENTATION

EN EAU

INSTALLATION - MIN. ROBINET À BILLE À PASSAGE

INTÉGRAL D’1/2 PO AVEC

RACCORD

D’ENTRÉE D’1/2 PO FTP.

(ROBINET NON INCLUS)

ADAPTATEUR

D’1/2 PO MPT

REQUIS POUR LA

SORTIE FPT.

INSTALLER UNE TUYAUTERIE

APPROPRIÉE SUR L’ÉQUIPEMENT

POUR L’EAU FILTRÉE ET L’EAU

TRAITÉE.

REMARQUE: NE PAS MONTER LE

FILTRE DERRIÈRE LA MACHINE

À GLAÇONS OU D’AUTRES APPAREILS POUVANT BLOQUER

L’ACCÈS POUR L’ENTRETIEN DU

SYSTÈME DE FILTRATION.

2 PI ET 8 PO MIN. - 5 PI ET 0 PO AU-DESSUS DU SOL FINI

LIGNE DU SOL

3 PO MIN.

DÉGAGEMENT POUR

LE RETRAIT

PRESSION MAX. : 125 psi

TEMPÉRATURE MAX. : 38 °C (100 °F)

L’UNITÉ DE FILTRATION DE L’EAU

DOIT ÊTRE INSTALLÉE SUR

L’ALIMENTATION EN EAU FROIDE

UNIQUEMENT.

2 PI ET 8 PO MIN. - 5 PI ET 0 PO AU-DESSUS DU SOL FINI

HAUTEUR D’INSTALLATION

2 7/8"

VERS

L’ENTRÉE

MONTER SUR DES

POTEAUX DE CLOISON OU

DES PANNEAUX MURAUX

SOLIDES. NE PAS MONTER

SUR DES PANNEAUX DE

PLÂTRE OU DE GYPSE NON

SOUTENUS.

RACCORD D’ENTRÉE DU

ROBINET À BILLE À PASSAGE

INTÉGRAL D’1/2 PO VERS

ALIMENTATION EN

EAU FROIDE.

15

MUR

3 PO MIN.

DÉGAGEMENT

PRESSION MAX. : 125 psi

TEMPÉRATURE MAX. : 38 °C (100 °F)

POUR LE RETRAIT

L’UNITÉ DE FILTRATION DE L’EAU

DOIT ÊTRE INSTALLÉE SUR

L’ALIMENTATION EN EAU FROIDE

UNIQUEMENT.

Page 16

Fonctionnement

Avec une pression suffisante, le fonctionnement du système

OneFlow

nement fiable requiert uniquement un remplacement régulier des

filtres et l’enregistrement des dates d’entretien.

®

de Watts est complètement automatique. Un fonction-

Entretien

L’entretien de routine du sytème OneFlow® implique un remplacement régulier des cartouches de filtre et/ou un remplacement

des joints toriques de cuve. Si les recommandations concernant

le dimensionnement du système ont été respectées, la cartouche

OneFlow

Fréquence de remplacement des filtres

Les filtres doivent être remplacés en fonction des conditions suivantes.

OF140RM • 12 mois suite à l’installation ou au dernier remplace-

ment du filtre.

®

devrait durer un an.

Cartouches de filtre de rechange

Le système OneFlow® doit uniquement être utilisé avec les cartouches de

filtre OneFlow®. L’utilisation de cartouches de rechange autres que celles

indiquées annulera les garanties et les certifications et peut compromettre le

système de protection de l’équipement, la qualité de l’eau et la durée de vie

de l’équipement.

2.

3.

4.

8.

6.

7.

Procédure de remplacement de la cartouche du filtre

IMPORTANT: Vérifier que tout l’équipement raccordé au système

OneFlow® est éteint avant de couper l’alimentation en eau des filtres.

1. Si nécessaire, éteindre l’équipement.

2. Couper l’eau vers le système OneFlow® en fermant le robinet à bille

d’alimentation.

3. Appuyer sur le bouton rouge pour dissiper la pression.

4. Retirer le(s) boîtier(s) – utiliser une clé à filtre si nécessaire.

5. Nettoyer l’intérieur de la cuve du boîtier avec de l’eau chaude. Le cas

échéant, désinfecter le boîtier avec une cuillère à thé d’eau de Javel.

Mettre le produit dans la cuvette du filtre et remplir d’eau. Laisser

reposer 5 minutes et vider.

6. Insérer des cartouches neuves dans les logements de filtre. Faire

correspondre les numéros de modèle des cartouches avec les numéros de modèle indiqués sur le support.

7. S’assurer que le joint torique est bien placé et réinstaller les logements de filtre (serrer à la main uniquement). Vérifier que le joint

torique n’est pas endommagé et le remplacer s’il est endommagé ou

déformé.

8. Ouvrir légèrement le robinet à bille d’alimentation; pousser sur

le bouton rouge de dissipation de la pression pour dissiper l’air

emprisonné jusqu’à ce qu’un peu d’eau s’écoule, puis relâcher le

bouton rouge et ouvrir complètement le robinet à bille.

9. Ouvrir le robinet de rinçage en aval du logement du filtre (si présent)

et rincer les cartouches neuves au-dessus d’une évacuation ou d’un

seau pendant deux (2) minutes ou jusqu’à ce que l’eau qui s’écoule

soit

propre. S’il n’y a pas de robinet de rinçage, débrancher la conduite

de l’équipement pour effectuer le rinçage.

10. TRÈS IMPORTANT: Avec le robinet d’alimentation en eau OUVERT

et le débit d’eau confirmé, mettre l’équipement raccordé en marche.

Si l’équipement n’est pas alimenté en eau, des graves dommages

peuvent avoir lieu.

11. Noter la date de remplacement du filtre sur le journal d’entretien.

16

Page 17

Pièces de rechange pour : OneFlow® OF140-4

N° de schéma Description

1 Boîtier avec limiteur de pression

1a Joint torique

3

2 Robinet à bille d’

3 Support de boîtier unique

4 Vis

5 Cartouche de remplacement OF140RM

6 Bouton de dissipation de la pression

/4 po FxM

t

e

l

n

i

t

e

l

t

u

o

6

N

I

T

U

O

17

Page 18

Garantie limitée

• Le système du réservoir OneFlow® est garanti exempt de vices de matériau et de main d’œuvre pour une durée de 5 ans à compter de la

date d’expédition d’origine.

• Le média filtrant OneFlow

conformément aux instructions du manuel d’installation et de fonctionnement.

Watts Regulator Company garantit le système de cartouche OneFlow

• Le système de cartouche OneFlow

date d’expédition d’origine.

• Les cartouches OneFlow

utilisées conformément aux instructions du manuel d’installation et de fonctionnement.

• Les cartouches de filtre au charbon de rechange ne sont pas garanties car la durée de vie des cartouches au charbon varie grandement

en fonction des conditions et du volume de l’eau locale.

Conditions

1. Le système OneFlow® doit être installé dans des applications alimentées par l’eau municipale conformément au règlement de l’EPA.

2. Les défaillances de composant ne doivent pas être causées par un abus, un incendie, le gel ou d’autres phénomènes naturels, des actes

de violence ou une installation érronée.

3. L’équipement doit être installé et utilisé conformément au code de plomberie en vigueur et avec une alimentation en eau approuvée.

4. L’équipement doit être utilisé à des pressions et des températures d’eau ne dépassant les spécifications indiquées.

5. La teneur en chlore de l’eau ne doit pas dépasser 2,0 ppm. Pour une eau présentant une teneur en chlore supérieure à 2,0 ppm, un prétraitement de l’eau est requis. (Merci de contacter le spécialiste de traitement de l’eau.)

6. Les informations, incluant le numéro de modèle, le numéro de série et la date d’installation, doivent être fournies pour toute réclamation

dans le cadre de la garantie.

7. Les pièces défectueuses seront soumises à une inspection par Watts Regulator Company ou par un représentant agréé avant que le

recours en garantie final ne soit accepté.

8. Watts Regulator Company se réserve le droit de remplacer ou de changer les pièces ou l’équipement par un matériau de qualité et de

valeur égales et en cours de production.

®

est garanti pour une période de 2 ans à compter de la date d’installation initiale lorsqu’il est installé et utilisé

®

de la façon suivante:

®

est garanti exempt de vices de matériau et de main d’œuvre pour une durée d’un an à compter de la

®

sont garanties pour une période d’un an à compter de la date d’installation initiale lorsqu’elles sont installées et

Limitations

Notre obligation dans le cadre de cette garantie et concernant le réservoir ou le robinet est limitée au remplacement ou à la réparation, à

notre choix, de toute pièce jugée défectueuse dans la période de garantie indiquée ci-dessus. Ces pièces de rechange seront fournies gratuitement au propriétaire FAB à l’usine la plus proche à l’exception des frais de transport et de main d’œuvre locale, le cas échéant.

Notre obligation dans le cadre de cette garantie par rapport au média filtrant OneFlow

années suivant la date d’installation d’origine. Le média filtrant de rechange sera fourni gratuitement au propriétaire FAB à l’usine la plus proche à l’exception des frais de transport et de main d’œuvre locale, le cas échéant. Les dommages du média filtrant dus au chlore, aux oxydants et à l’encrassement provoqués par les conditions de l’eau ou une utilisation en dehors des limites spécifiées ne sont pas couverts par

cette garantie.

LA PRÉSENTE GARANTIE EST EXPRESSE ET REPRÉSENTE LA SEULE GARANTIE OFFERTE PAR WATTS REGULATOR COMPANY POUR

CE PRODUIT. WATTS REGULATOR COMPANY N’OFFRE AUCUNE AUTRE GARANTIE EXPRESSE OU IMPLICITE. PAR LA PRÉSENTE,

WATTS REGULATOR COMPANY REJETTE SPÉCIFIQUEMENT TOUTE AUTRE GARANTIE, EXPRESSE OU IMPLICITE, NOTAMMENT TOUTE

GARANTIE IMPLICITE DE QUALITÉ MARCHANDE OU D’ADAPTATION À UN BUT PARTICULIER.

Le remède décrit dans cette garantie constitue le seul recours à toute rupture de la présente garantie et Watts Regulator Company ne saurait

être tenue responsable de tout dommage spécial, accessoire ou consécutif, y compris, mais non exclusivement : le transport, la manutention,

la perte de profits ou le coût afférent à la réparation ou au remplacement d’autres biens qui seraient endommagés par suite du fonctionnement incorrect dudit produit; d’autres coûts afférents aux frais de main-d’œuvre; délais, vandalisme, négligence, encrassement occasionné

par la présence de matériau étranger; dommages résultant d’une eau impropre, de produits chimiques ou de tout autre événement sur lequel

Watts Regulator Company ne saurait exercer le moindre contrôle. La présente garantie est déclarée nulle et non avenue en cas d’abus, de

mésusage, d’application ou d’installation erronée de ce produit.

Certains États ou certaines Provinces n’autorisent pas la limite de durée d’une garantie implicite ou l’exclusion ou limite de dommages directs

ou indirects. C’est pourquoi les limites ou exclusions susmentionnées peuvent ne pas s’appliquer à vous. Cette garantie vous donne des

droits légaux précis et il se peut que vous ayez aussi d’autres droits qui varient d’une province, d’un état ou

d’une juridiction à l’autre. Veuillez vous référer aux lois d’état ou de province applicables pour

déterminer vos droits en la matière. DANS LA MESURE PERMISE PAR LA LOI, TOUTE

GARANTIE IMPLICITE NE POUVANT PAS ÊTRE REJETÉE, Y COMPRIS LES GARANTIES

IMPLICITES DE QUALITÉ MARCHANDE ET D’ADAPTATION À UN BUT PARTICULIER,

SONT LIMITÉES AUX DURÉES DE GARANTIE APPLICABLES INDIQUÉES CI-DESSUS.

®

sera limitée à son remplacement dans les deux

Page 19

Page 20

Une en tre pri se de Watts Water Techno log ies

États-Unis : 815 Chestnut St., No. Andover, MA 01845-6098; www.watts.com

Canada : 5435 North Service Rd., Burlington, ONT. L7L 5H7; www.wattscanada.ca

IOM-OF140-4 1017 Réf. EDP 2915002 © 2010 Watts

Loading...

Loading...