Page 1

For Health Hazard and Continuous Pressure Applications

ES-LF008PCQT

Job Name

Job Location

Engineer

Approval

LEAD FREE

–––––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––––––

*

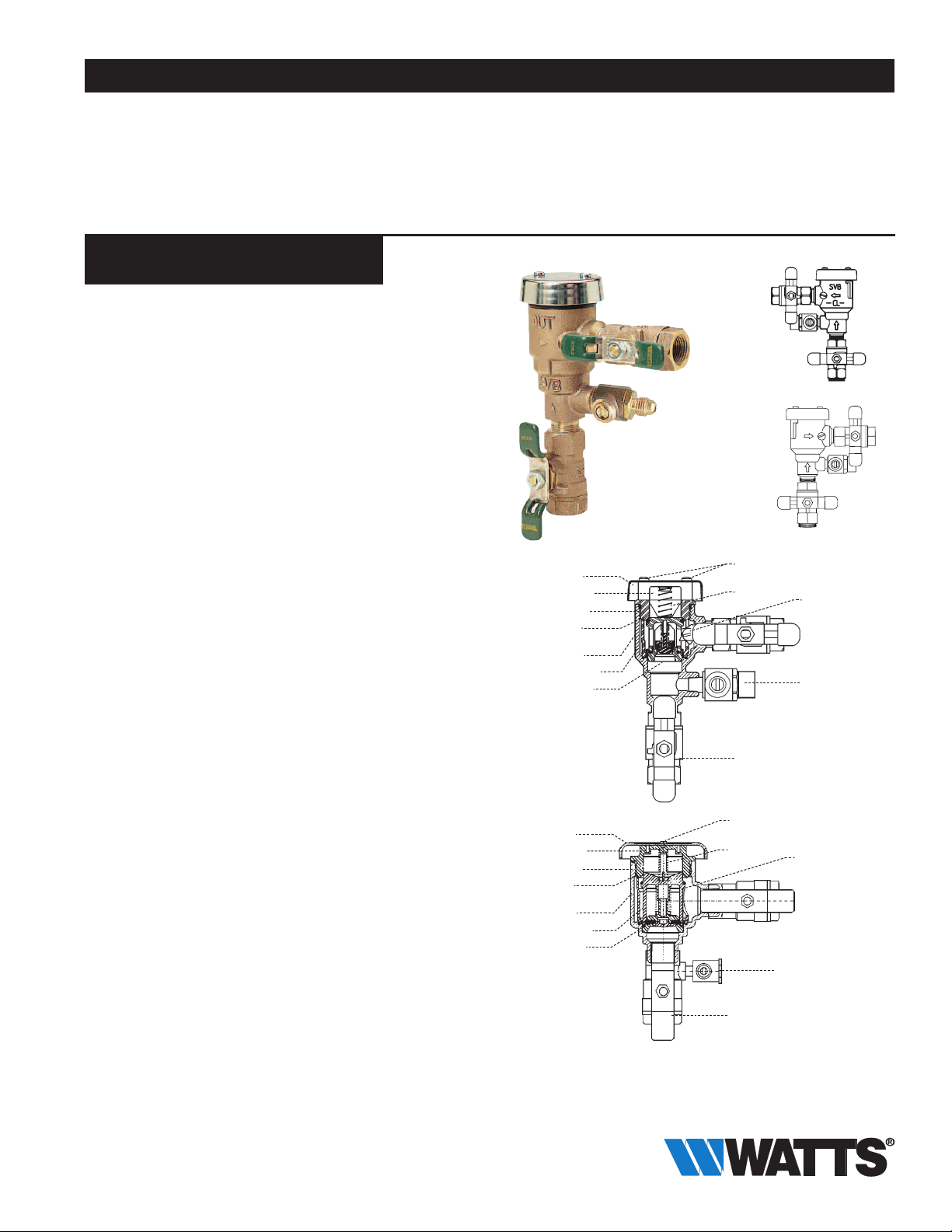

Series LF008PCQT

Health Hazard, Anti-Siphon,

Spill-Resistant Backflow Preventer

Sizes: 3⁄8", 1⁄2", 3⁄4" and 1" (10, 15, 20, 25mm)

Series LF008PCQT is designed for indoor point-of-use applications to prevent backsiphonage of contaminated water back

into the potable water supply. Separation of the water supply

from the air inlet is accomplished by means of a diaphragm

seal. This feature protects against any spillage during start-up

or operation. The LF008PCQT features Lead Free* construction to comply with Lead Free* installation requirements.

Features

• Standardly supplied with internal polymer coating

• Standardly supplied with Tee handles

• Available less Tee handle with stem wrench flats. For use

where space is limited

• Available in left-handed or right-handed outlet

• Spill-resistant design for indoor use

• Affordable design

• Modular cartridge for ease of service

• Vent uses an O-ring for reliable operation

• Lead Free* cast copper silicon alloy body for durability

• Compact space saving design

• Satin chrome finish available

Installation

The LF008PCQT is designed to be installed at the pointof-use. When factory installed deck/machine mounted on

machines or equipment, the critical level of the LF008PCQT

shall be not less than 1" (25mm) above the flood rim. If field

applied for general plumbing applications, the critical level of

the LF008PCQT shall be a minimum of 6" (150mm) above the

flood rim.

Specifications

A spill-resistant vacuum breaker (SVB) shall be installed, in

accordance with the manufacturer’s instructions, as noted

on the plans. The valve shall consist of a one-piece modular check and float assembly made of engineered thermoplastic and housed in a Lead Free* cast copper silicon alloy

body. Springs shall be stainless steel. The Health Hazard,

Anti-Siphon, Spill Resistant Backflow Preventer shall be constructed using Lead Free* materials. Lead Free* Health Hazard,

Anti-Siphon, Spill Resistant Backflow Preventer shall comply

with state codes and standards, where applicable, requiring

reduced lead content. The valve shall be constructed with a

molded diaphragm separating the air inlet from the potable

water supply to prevent spillage. The valve shall be a Watts

Series LF008PCQT.

Contractor

Approval

Contractor’s P.O. No.

Representative

Size: 3⁄8", 1⁄2" (10, 15mm)

Size: 3⁄4", 1" (20, 25mm)

* The wetted surface of this product contacted by consumable

water contains less than 0.25% of lead by weight.

––––––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––––––

––––––––––––––––––––––––––––––––––

––––––––––––––––––––––––––––––––––––––––

FOR INDOOR USE!

LF008PCQT-L (Left Handed)

LF008PCQT

LF008PCQT (Right Handed)

Hood Screws

Hood

Bonnet

O-ring

Vent

O-ring

Body

Retainer

Check

Assembly

Hood

Bonnet

O-ring

Vent

O-ring

Body

Retainer

Check

Assembly

(2 Required)

Vent

Spring

Shutoff

Valve Assembly

(2 Required)

Hood Screw

Vent

Spring

Shutoff

Valve Assembly

(2 Required)

Air Bleed Screw

Bleed O-ring

(not shown)

Test Cock

Air Bleed Screw

Bleed O-ring

(not shown)

Test Cock

Watts product specifications in U.S. customary units and metric are approximate and are provided for reference only. For precise measurements,

please contact Watts Technical Service. Watts reserves the right to change or modify product design, construction, specifications, or materials without prior notice and without incurring any obligation to make such changes and modifications on Watts products previously or subsequently sold.

Page 2

Materials

Springs: Stainless steel

Bonnet: PPO

Vent Disc: EPDM

Disc Holder: PPO

Check Disc: Silicone rubber

Body: Lead Free* cast copper silicon alloy

Standards

Meets requirements of IAPMO.

Approvals

1056

B64.1.2

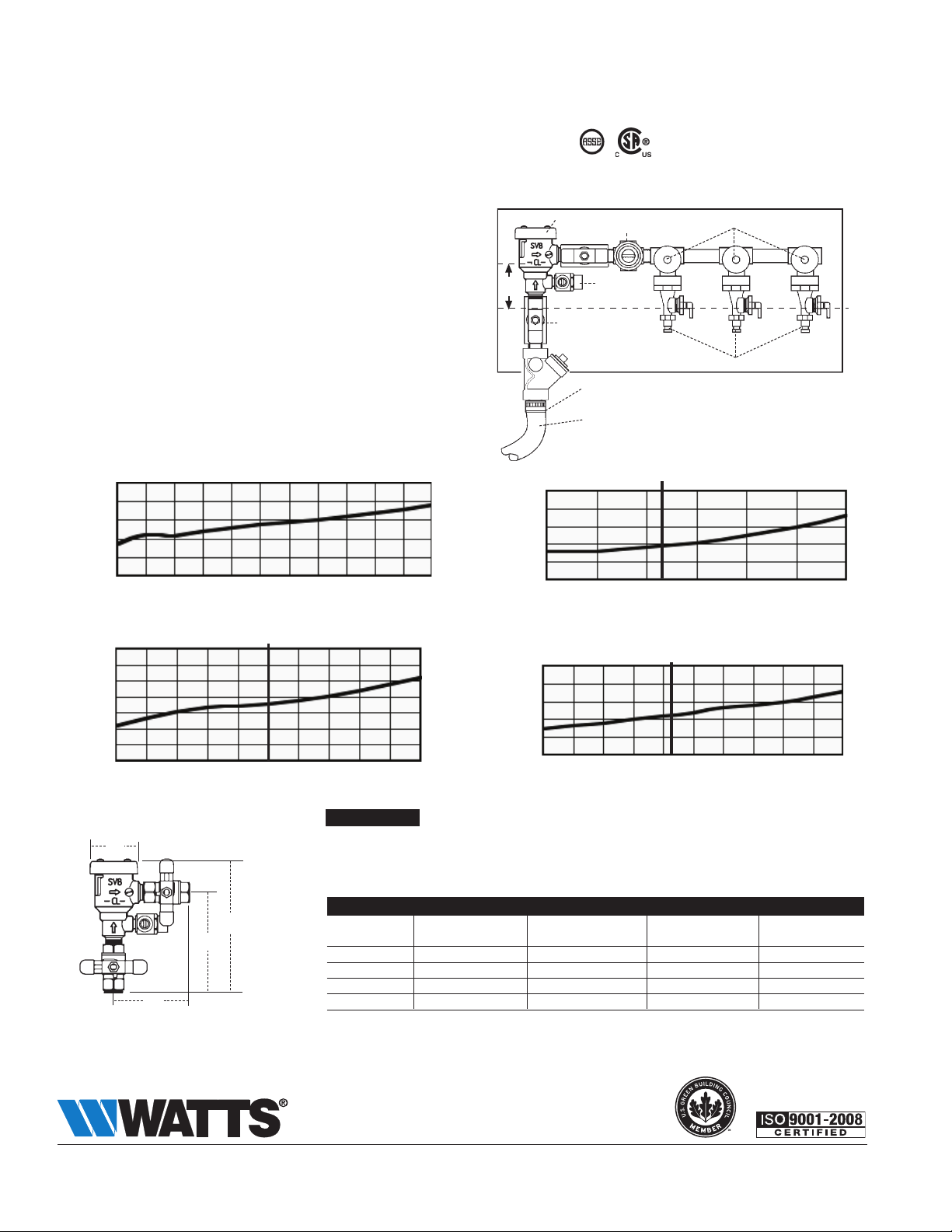

Pressure – Temperature

Temperature Range: 33°F – 180°F (0.5°C – 83°C)

Maximum Working Pressure: 150psi (10.3 bar)

End Connections

Female NPT - Ball Valve shutoffs

Capacity

As compiled from documented Foundation for Cross-Connection

Control and Hydraulic Research at the University of Southern

California lab tests.

==

Typical maximum system flow rate (7.5 feet/sec.)

3

D

⁄8" (10mm)

FLOW

1

⁄2" (15mm)

B

11.4 13.3 15.2 17.1

==

A strainer is recommended to be installed ahead of the backflow preventer to prevent the fouling of the check assembly

and resulting spillage from the valve during repressurization. Do not install in concealed locations or areas where water

leakage due to normal wear of the internal parts can cause damage.

LF008PCQT

in. mm in. mm in. mm in. mm lbs. kgs.

3

1

3

1 25 7

19 21 lpm

NOTICE

SIZE (DN) DIMENSIONS WEIGHT

B D E

⁄8 10 51⁄2 140 315⁄16 100 31⁄8 79 1.6 .73

⁄2 15 53⁄4 146 43⁄16 106 33⁄8 86 1.7 .77

⁄4 20 7 178 45⁄8 117 41⁄2 114 3.8 1.72

kPa psi

69 10

55 8

41 6

∆P

28 4

14 2

0 0

∆P

0 0.5 1 1.5 2 2.5 3 3.5 4 4.5 5 5.5 gpm

0 1.9 3.8 5.7 7.6 9.5

kPa psi

97 14

83 12

69 10

55 8

41 6

28 4

14 2

0 0

0 1 2 3 4 5 6 7 8 9 10 gpm

0 3.8 7.6 11.4 15.2 19 22.8 27 30 34 38 lpm

7.5 fps

2.3 mps

FLOW

Dimensions — Weights

2"

E

LF008PCQT-S

1" min.

(25mm)

Shutoff

kPa psi

69 10

55 8

41 6

∆P

28 4

14 2

0 0

0 5 10 15 20 25 30 gpm

0 19 38 57 76 95 114 lpm

7.5 fps

2.3 mps

kPa psi

69 10

55 8

41 6

∆P

28 4

14 2

0 0

0 5 10 15 20 25 30 35 40 45 50 gpm

0 19 38 57 76 95 114 135 152 171 190 lpm

7.5 fps

2.3 mps

1

⁄2 191 51⁄8 130 47⁄8 124 4.8 2.18

Watts P60-M1

Pressure Reducing Valve

Test cock

3

⁄4" (20mm) Hose

Adapter with

strainer washer

Supply Hose

FLOW

FLOW

3

⁄4" (20mm)

==

1" (25mm)

==

Solenoid Valves

Dispensing Inducers

Typical Installation

A Watts Water Technologies Company

USA: Tel: (978) 688-1811 • Fax: (978) 794-1848 • www.watts.com

Canada: Tel: (905) 332-4090 • Fax: (905) 332-7068 • www.watts.ca

ES-LF008PCQT 1318 © 2013 Watts

Loading...

Loading...