Page 1

20. WCC II TO WCC III

GLOBAL BRIDGE MANUAL

WCC III

20. WCC II TO WCC III

GLOBAL BRIDGE MANUAL

Page 2

T ABLE OF CONTENTS

SECTION 20: WCC II to WCC III

GLOBAL BRIDGE MANUAL

Overview ...................................................20-1

WccUtility.EXE Program Setup

Considerations and Limitations for

Global Bridge ............................................20-2

SET GLOBAL MAP VIEW ...........................20-3

SET BRIDGE MAP ......................................20-4

Troubleshooting the WCC III RS-485

Communications Loop ..............................20-5

Troubleshooting the WCC II Manchester

Communications Loop ..............................20-6

WCC II Manchester Communication

Boards .......................................................20-8

Page 3

20. GLOBAL BRIDGE BOARD INSTALLATION

SECTION 20:

WCC II to WCC III GL OBAL BRIDGE

MANUAL (SS5012)

__________________________________________

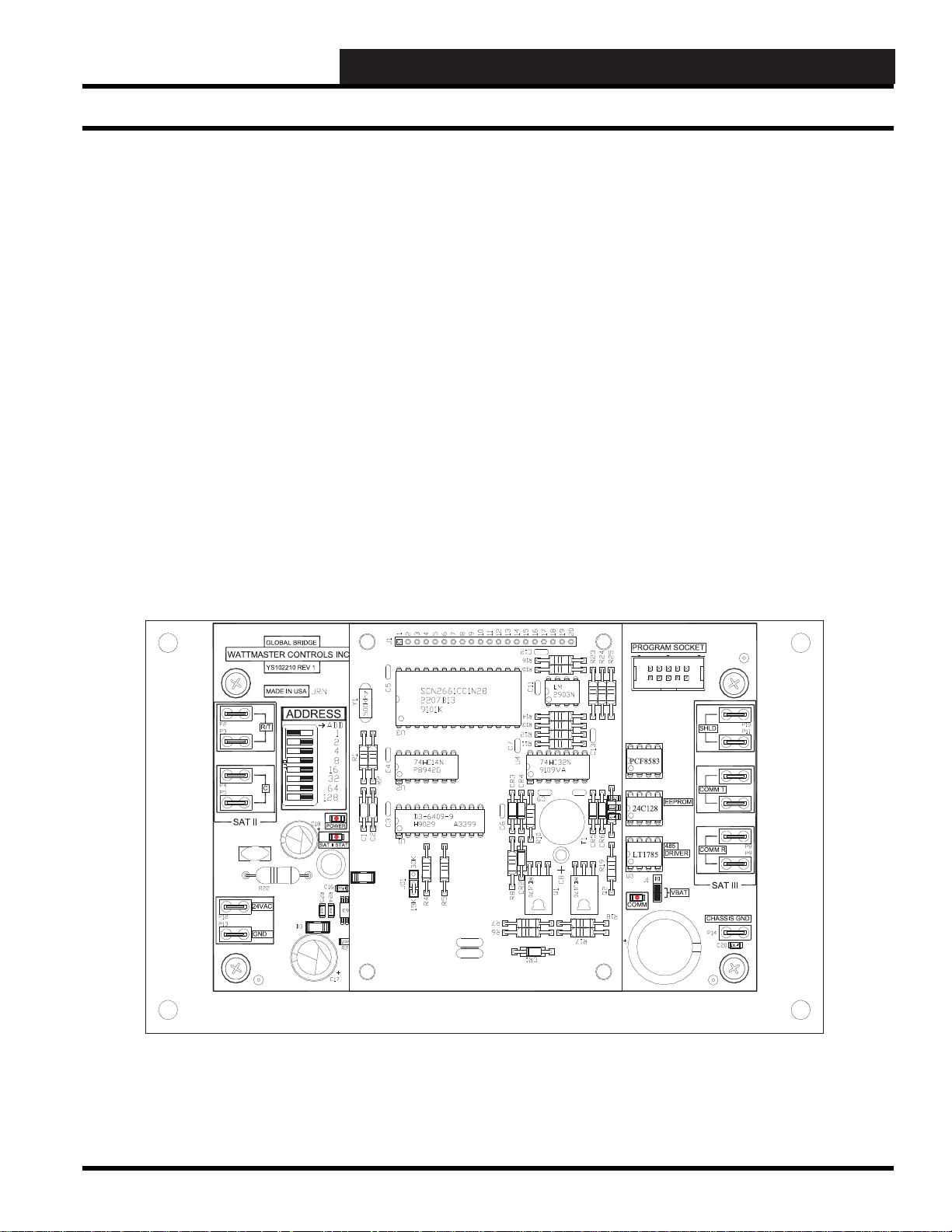

Overview

The “WCC II to WCC III Global Bridge” board provides a means

for the new WCC III system to pass information to and from the

old WCC II system. A single “WCC II to WCC III Global Bridge”

board can simulate (mirror) up to 8 WCC II SAT II Controllers. A

“WCC II to WCC III Global Bridge” can also share Global Binary

and Global Analog information from WCC II to WCC III and

current values of the simulated (mirrored) satellites from WCC III

to WCC II. But this is a one way data fl ow for the Global data, the

direction is from the WCC II system to the WCC III system.

Overview

Figure 20-1: Global Bridge Board

WCC III Technical Guide

20-1

Page 4

20. GLOBAL BRIDGE BOARD INSTALLATION

Setup Global Bridge

WccUtility .EXE Program Setup

Considerations and Limitations for

Global Bridge

To setup the Global Map for the “WCC II to WCC III Global Bridge”,

you only have to fi ll out the data in one “SetGlobalMapView”

window even if you have multiple “WCC II to WCC III Global

Bridges”. This is because all of the “WCC II to WCC III Global

Bridges” will have the same global analog/binary value that will

come from the WCC II front-end computer .

There are no limitations to the number of global analogs or global

binaries that you can setup from within the “SetGlobalMapView”

window. Of course, you cannot setup more than the WCC II limitations of 128 global analogs and 256 global binaries.

The BACKTASK.EXE program that is running on the WCC III

- MCD requires that the WccUtility.exe program be connected

(via an IP connection) to the WCC III - MCD, that the WccUtility.

exe program be opened and running at all times, and that the

“SetGlobalMapView” window also be opened at all times. This IP

connection must be made so that BACKT ASK.EXE can fetch and

retrieve the global values from the “old” WCC II system.

If you close the “SetGlobalMapView” window or the WccUtility.

exe program, the BACKTASK.EXE program will not be able to

retrieve any global values from the “old” WCC II system. This

means that the “SetGlobalMapView” window that does the global

analog and global binaries value transfers will not transfer these

global analog and global binaries values from the “WCC II to

WCC III Global Bridge” board to BACKTASK.EXE program of

WCC III - MCD.

20-2

WCC III Technical Guide

Page 5

20. GLOBAL BRIDGE BOARD INSTALLATION

Setup Global Map View Screen

SET GLOBAL MAP VIEW

Figure 20-2: Set Global Map View Window

From the WCCUtility.EXE program there are two choices for the

“WCC II to WCC III Global Bridge” board. The fi rst selection

choice is <Setup Global Map>. This is where global information

can be sent from the WCC II system to the WCC III - MCD.

Get Global Value From Satellite: Enter the address for the

“WCC II to WCC III Global Bridge” board. This value should be

higher than the last satellite number on your system. After entering

the address, press the <Set Satellite Number> button to lock in

the address. NOTE: The “WCCII to WCCIII Global Bridge” will

not show on the Satellite Summary Screen.

Set Update Speed: xxxx Milli-second: 1000 milliseconds is

entered for each “WCC II to WCC III Global Bridge” board on

the system. If you have three “WCC II to WCC III Global Bridge”

boards, then a value of 3000 milliseconds needs to be entered for

each “WCC II to WCC III Global Bridge” board. When desired

value is entered, press the <Set Update Speed> button to lock in

the “Set Update Speed” value.

<Add New Global Analog> Enter the number of the global

analog you wish to send from the WCCII to the WCCIII and press

the button. The global will be added to the Global Analog fi eld at

the bottom of the screen. There is no limitation to the number of

global analogs entered.

<Delete Global Analog> Enter the number of the global analog

you wish to delete from the Global Analog box and press the

button. The global analog will disappear from the list.

<Add New Global Binary> Enter the number of the global binary

you wish to send from the WCCII to the WCCIII and press the

button. The global will be added to the Global Binary fi eld at the

bottom of the screen. There is no limitation to the number of global

binaries entered.

<Delete Global Binary> Enter the number of the global binary

you wish to delete from the Global Binary box and press the button.

The global binary will disappear from the list.

NOTE: T o receive global analog and global binary values on

the WCC III system from the WCC II system, the mode for the

analog global and binary global on the WCC III system must

be set to external. See Section 3 for programming globals.

WCC III Technical Guide

20-3

Page 6

20. GLOBAL BRIDGE BOARD INSTALLATION

Set Bridge Map

SET BRIDGE MAP

Figure 20-3: The Set Bridge Map Window

From the WccUtility.exe program there are two choices for the

“WCC II to WCC III Global Bridge” board. The second selection

choice is <Set Bridge Map>. This is where satellite information

can be sent from the “new” WCC III - MCD to the old WCC II

system.

Bridge Satellite Number: Enter the address for the “WCC II to

WCC III Global Bridge” board. This value should be higher than

the last satellite number on your system.

<Load Map> After you type in the address Bridge Satellite (SAT

III) number, press the <Load Map> button to see your simulated

satellites (SAT II) that you have selected for simulation.

Simulate Satellites: Enter the satellite number(s) of which you

would like to simulate. There is a maximum of eight satellites per

“WCC II to WCC III Global Bridge” board. These are the SAT II

simulated addresses.

<Set Map> After entering (or adding) satellites to the “WCC II

to WCC III Global Bridge” board, you must press the <Set Map>

button to send the map information to the “WCC II to WCC

III Global Bridge” board. After the map information has been

received, the “WCC II to WCC III Global Bridge” board will

capture the current values from the satellites on the WCC III side

and provide them to the old BACKTASK program that is running

on the WCC II system side for use in the simulated SAT II satellite

logical address.

20-4

WCC III Technical Guide

Page 7

20. GLOBAL BRIDGE BOARD INSTALLATION

Troubleshooting Communication Loops

Troubleshooting the WCC III RS-485

Communications Loop

What is the WCC III RS-485 communications loop

voltage measurement on a SAT III controller or on a

WCC II to WCC III Global Bridge board?

There are two conditions for Voltage measurements of the WCC

III RS-485 communications loop.

1st Condition: The WCC III RS-485 communications loop

is plugged into a SAT III controller or on a WCC II to WCC

III Global Bridge board, and you are measuring the voltage

at the SAT III controller or on a WCC II to WCC III Global

Bridge board.

SAT II CONTROLLER

EACHCONTACT

ISRATED FOR

24VACORVDC

@.5AMPMAX

+V

SAT II

ATI

ON OFF

BATTON/ OFF

PULSE INPUT

L

LOCALSET DISABLE

O

A

D

LOCALSET

TEST

GND

ON OFF

L16

V

0-15VDC

OUTPUT

MINLOAD

IS1K OHM

RESISTIVE

VDCONLY

2134

5678

CHANNEL

2134

567

8

L15

L14

OUT

L13

L12

L11

L10

L9

ON OFF

L8

L7

L6

L5

L4

L3

L2

H

L1

ON OFF

COM

128

64

32

16

8

C

4

2

1

NUMBER

BINARY

INPUTS

BINARY

INPUTS

SAT

POWERCO NSUMPTION

WATTMASTER

CONTROLS GROUP

24 VAC ONLY

15VA / 625mA

GND

24VAC

24VAC

24VAC 120VAC

GROUND

POWER ---

WARNING: OBSERVE POLARITY B ETWEEN THE

SAT II AND THE WCC II TO WCC III GLOBAL

BRIDGE BOARD.

THE GROUND CONNECTIONS MUST BE THE

SAME. DAMAGE TO THE SAT II CONTROLLER

OR TO THE WCC II TO WCC III GLOBAL BRIDGE

BINARY BOARD CAN RESULT IN VOIDING THE

WARRANTY

120VAC WIRING IS BY OTHERS

THE VA RATING FOR THE S AT II CONTROLLER IS 15VA.

THE VA RATING FOR THE SAT III CONTROLLER IS 15VA.

THE VA RATING FOR THE WCC II TO WCC II GLOBAL BRIDGE

BOARD IS 7.5 VA.

TO OTHER

SAT II OR TO

THE WCC II

COMPUTER

WIRE NUT

On the RS-485 loop for a SAT III controller or on a WCC

II to WCC III Global Bridge board, the “T” (+) and ”R” (-)

terminals should measure “T”(+) @ 2.7VDC and “R”(-) @

3.0VDC voltages. These are approximate values, but should

be used as base line measurements.

SHLD

COMMT

COMMR

SATIII

CHASSISGND

TO HSS EXPANSION BOARDS.

UP TO TWO BINARY INPUT

BOARDS, AND UP TO TWO

BINARY OUTPUT BOARDS

MAY BE CONNECTED TO A

SAT III CONTROLLER.

TO OTHE R

SAT III O R TO

WCC III - MCD

SAT III CONTROLLER

ON OFF

BATTON/ OFF

PULSEINPUT

OPTION 3

OPTION 2

OPTION 1

LOCALSET DISABLE

LOCALSET

TEST

ON OFF

L16

L15

L14

BINARY

L13

L12

INPUTS

L11

L10

L9

ON OFF

L8

L7

L6

BINARY

L5

L4

INPUTS

L3

L2

L1

ON OFF

128

64

32

16

8

4

2

SATADDRESS

1

GND

GLOBALBRIDGE

WATTMASTE RCONTRO LSINC

YS102210REV1

MADEINUSA

ADDRESS

R/T

WIRE NUT

C

SATII

24VAC

GND

STATUS

SATREC

SAT III

PROGRAMMABLE CONTROLLER

SATXMIT

HSSREC

ANALOGINPUT

JUMPERSELECTION

HSSXMIT

THERM

STATUS1

STATUS 2

STATUS 3

0-10V

0-5V

0-1V

THERM

0-10V

0-5V

0-1V

THERM

0-10V

0-5V

0-1V

CH

THERM

0-10V

1

0-5V

0-1V

2

THERM

0-10V

3

0-5V

0-1V

4

A4TO 20mASENSOR WILLREQUIREA

50OHMLOAD RESISTORWHENSETFOR

A1VOLT INPUT,ORA 250OHMLOAD

5

RESISTORWHENSETFORA 5 VOLTINPUT.

A2WIRE ROOMSENSORWILLREQUIRE

6

A300OHMLOADRESISTORWHENSET

FORA1 VOLTINPUT.

A3WIREROOMSENSORWILLNOT

7

REQUIREALOAD RESISTORWHENSET

FORA1 VOLTINPUT.

WattMasterControls Inc.

8

LOCALSET

24VAC

WARNING: OBSERVE POLARITY

BETWEEN THE SAT III AND THE WCC II

TO WCC III GLOBAL BRIDGE BOARD GROUND CONNECTIONS MUST BE THE

SAME.

24VAC

24VAC 120VAC

GROUND

120VAC WIRING IS BY OTHERS

POWER

SATIISTAT

0TO1V

INPUT

0TO5V

INPUT

0TO10V

INPUT

THERMISTOR

INPUT

CURRENT

INPUT

PROGRAMSOCKET

PCF8583

24C128

LT1785

COMM

EEPROM

485

DRIVER

VBAT

TO OTHER SAT II

CONTROLLERS OR

TO THE WCC II

COMPUTER

WIRE "RT" TO "RT"

"C" TO "C"

TIE THE "SHIELD"

WIRES TOGETHER

WCC II TO WCC III

GLOBAL BRIDGE

TO OTHER SAT III

CONTROLLERS OR TO

WCC III - MCD

WIRE "T" TO "T"

"R" TO "R"

"SHD" TO "SHD"

Figure 20-4: Wiring diagram showing how to connect the WCC III to WCC II systems using the W CC II to WCC III

Global Bridge board.

WCC III Technical Guide

20-5

Page 8

20. GLOBAL BRIDGE BOARD INSTALLATION

Troubleshooting Communication Loops

2nd Condition: The WCC III RS-485 communications

loop is not plugged into a SAT III controller or on a WCC II

to WCC III Global Bridge board, and you are measuring the

voltage.

On the RS-485 loop for a SAT III controller or, on a WCC

II to WCC III Global Bridge board the “T” (+) and ”R” (-)

terminals should measure “T”(+) @ 3.25VDC and “R”(-) @

3.25VDC voltages. These are approximate values, but should

be used as base line measurement. More than half a volt either

way should be considered a suspected problem.

The RS-485 driver chip is a fi eld-replaceable part. It is W attMaster

Controls part #ID001785. It is the same RS-485 driver that

W attMaster Controls uses on all of its product lines.

The WCC II to WCC III Global Bridge board has 1000 Volts

of optical isolation for the RS-485 driver circuit. It should also

be resistant to having an external AC or DC voltage (up to 50

VAC/VDC) from being applied to the “R”, “T”, and “SHLD”

connections. There is no protection provided for 120 VAC or

greater line voltages for the “R”, “T”, and “SHLD” connections.

Troubleshooting the WCC II

Manchester Communications Loop

What is the WCC II Manchester communications loop

voltage measurement on a SAT II, SAT 2c, or SAT 2d?

It is not recommended to use a voltmeter to troubleshoot the WCC

II communications loop.

This is a really diffi cult voltage to measure. It really requires an

“Oscilloscope” to measure it correctly. But if you have a really

good digital hand held meter that can measure “AC Milli-Volts”

(the cost of such a meter is about $300 or more), you can measure

the voltage between the R/T and C connections (polarity doesn’t

matter). A fl uctuating AC voltage between 100mV AC to 200mVAC

should be present. Your meter should also have a frequency

counter on it, and the frequency should fl uctuate between 0 Hz

and 15.6KHz.

Bad or no WCC II Communications. Do the Resistance

Checks:

Step 1:

with the WCC II Communication loop disconnected and with the

power to the WCC II to WCC III Global Bridge off.

Step 2: SAT II / WCC II - Termination Resistors

Check the resistance between R/T and C on the SAT

a. The resistance should be about 120 ohms (+/- 15 ohms). If

it is, then it is probably OK and you should test the rest of the

WCC II communications loop. Each SAT II controller should

measure this resistance when the WCC II Communication

loop is disconnected and with the power to the SAT II

controller turned off.

b. If the reading is less than 100 ohms, the replacement of the

Manchester Communication board is required.

c. If the reading is more than 135 ohms, the replacement of

the Manchester Communication board is required.

a. Is there a Terminating Resistor on the loop? This may or

may not be a problem. Terminating resistors are connected

across the RT / C connections on the SAT, usually at the end of

the physical run of wire.

NOTE: If the WCC II communication loop splits into a “T”,

then there may be TWO or more of these terminating resistors.

The value of the terminating resistors may vary but should

be between 10 and 50 ohms. Also, if you are on a job that

has these terminating resistor(s ) , then you should realize that

this job has had a problem before in the past with this echoing

effect. Great care must be taken so that these terminating

resistor(s ) are put back on or that you note where they were in

case there is still a problem.

When troubleshooting the WCC II communications loop, the

following is the recommended procedure:

20-6

WCC III Technical Guide

Page 9

20. GLOBAL BRIDGE BOARD INSTALLATION

Troubleshooting Communication Loops

Step 3: SAT II controller Manchester boards’ impedance

mismatching problem:

a. When installing a new SAT II controller to your system,

the new SAT II controller appears to not work and/or other

previous working SAT II controllers now stop communicating.

This is a classic Manchester board impedance mismatching

problem. It is a diffi cult problem to fi x. The fi x involves

updating all of your SAT II controllers’ Manchester boards to

the current impedance.

b. Newer SA T II controllers Manchester boards have a

different R T to C resistance impedance than the much older

Manchester boards (more than 15 years old). The “New” R T

to C resistance should read about 120 ohms (+/-15 ohms).

c. Older Manchester boards have RT to C resistance

impedance’s of 18 (+/- 5) ohms or some even have

impedances of over 200 ohms. To guarantee the proper

operation of the WCC II communications loop, all SAT II

controllers Manchester boards should have the same RT to C

resistances. It has been WattMaster’s experience that when

the SAT II controllers’ Manchester boards’ impedances match,

the WCC II communications loop will work. Also, it is

recommended that the whole SAT II controller as a complete

assembly will need to be rebuilt and have all of the latest

upgrades preformed.

Step 4: Have you run the LOOPTEST diagnostics on the WCC

II computer?

a. The Looptest program must be run with 1000 passes

per SAT II controller in order to determine if a WCC II

communication problem exists with a particular SAT II

controller.

b. Make note of any failures of all of your SAT II controllers

on the loop as this will be useful in determining if a WCC II

communications problem exists.

c. If a SAT is failing a lot of passes (20 %), then disconnect

it from the communications loop. It could be causing an

intermittent communications problem with other SAT II

controllers that are on the WCC II communications loop.

d. It would be also helpful if you know how the

communications loop was ran - if it was split into multiple

loops converging into one at some point - because one of these

WCC II communications loops may be cut or disconnected,

and this may be the source of your problem.

NOTE: Before testing the Z-80 board for loop test diagnostics,

the clock chip on the WCC II front-end computer’s Z-80

board must be initialized. This is best done by setting the time

and date from within the WCC II program via the System

Parameters Screen. If the time and date are not initialized, this

could cause 3 or 4 failed passes per 1000 passes.

WCC III Technical Guide

20-7

Page 10

20. GLOBAL BRIDGE BOARD INSTALLATION

SAT II MANCHESTER BOARD

SAT II MANCHESTER BOARD

WITH BLUE POT - DO NOT USE

WCC II Manchester Boards

WCC II Manchester Communica tion

Boards

Figure 20-5: SAT II Manchester Boards

WattMaster Controls, Inc. in the past has produced two types

of Manchester Communication Boards - the early Manchester

Communication Board with an adjustable “Blue Potentiometer”

and the later Manchester Communication board without the “Blue

Potentiometer”. Use of the early Manchester Communication

Board with the “Blue Potentiometer” is not recommended for use

with the WCC II to WCC III Global Bridge board.

20-8

WCC III Technical Guide

Page 11

20. GLOBAL BRIDGE BOARD INSTALLATION

WCC II Manchester Boards

P

Figure 20-6: SAT II Manchester Board Jumpers

Please note the following:

• The later Manchester Communication Board will

need to have the 50 ohm load resistors installed on

it instead of the zero ohm jumper.

• Location R24 and R25 should have a 50 ohm load

resistor installed.

• A zero ohm jumper has a single Black band on it.

A 50 ohm resistor should have the color code of

“GREEN” “BROWN” “BLACK” “GOLD”.

P

WCC III Technical Guide

20-9

Page 12

20. GLOBAL BRIDGE BOARD INSTALLATION

20-10

WCC III Technical Guide

Loading...

Loading...