Page 1

13B. WCC III - MCD2

Installation Guide

WCC III

13B. WCC III - MCD2

Installation Guide

Page 2

T ABLE OF CONTENTS

SECTION 13B: WCC III - MCD2

INST ALLA TION GUIDE

__________________________________________

Main Differences Between the First Generation

WCCIII-MCD and the New WCCIII-MCD2

Computers ................................................................ 13B-2

The WCCIII-MCD2 Basic Operating Conditions ..... 13B-5

WCCIII-MCD2 Basic System Requirements ........... 13B-5

Front End Software Requirements

(Operator Console Software) .................................. 13B-5

Uninterruptable Power Supply ............................... 13B-6

Basic Operating Conditions of the MCD2 .............. 13B-6

Software Updates .................................................... 13B-6

WCCIII-MCD2 Internet Access ................................ 13B-6

RS-485 Communications Wiring ............................. 13B-7

WCCIII-MCD2 Mounting Requirements .................. 13B-8

Power Supply (24V A C) R equirements .....................13-10

Test DNS Settings (Choice #8) ........................ 13B-29

Update MCD2 via USB (Choice #9)..................13B-29

Update MCD2 via NET (Choice #10) ................ 13B-29

Reset MCD to Default IP Address

(Choice #11) ...................................................... 13B-30

Reset MCD to Default DNS Settings

(Choice #12) ...................................................... 13B-30

Restart LCD Driver (Choice #13) .....................13B-30

Restart LCD Display (Choice #14) ................... 13B-31

Shutdown MCD (Choice #15) ........................... 13B-31

Shutdown and Reboot the MCD

(Choice #16) ........................................................ 3B-31

How to Use the Initial Install and Reco v ery

Program on the WCCIII-MCD2 with the

install-menu program .......................................13B-32

Setup New CrystalFontz 635 Display

(Choice #1) ........................................................ 13B-33

Restore Backtask DAT Files from

CompactFlash (Choice #2) ............................... 13B-33

Initiating the System ............................................. 13B-11

WCCIII-MCD2 System Files ................................... 13B-11

Various I/O Connections ........................................ 13B-12

WCCIII-MCD2 LCD Screen ..................................... 13B-15

The LCD’s Keypad .................................................. 13B-15

WCCIII-MCD2 LCD Screens ................................... 13B-16

BIOS Confi guration for the WCCIII–MCD2.............13B-19

Linux Operating System Software Installation

Procedure ............................................................... 13B-19

WCCIII-MCD2 On/Off/Shut Down/Reset

Buttons ................................................................... 13B-19

Setup Time Zone (Choice #2) ............................... 13B-25

Copy the Backtask Data Files to USB Driv e

(Choice #3) ............................................................. 13B-26

Restore BackT ask data Files to USB Driv e

(Choice #4) ............................................................. 13B-27

Test APC UPS Connection (Choice #5) ................ 13B-28

Apply USB Over-Current HOTFIX and Reboot

(Choice #3) ........................................................ 13B-33

Reset {APCUPSD/Webmin/Firewall/LCDd}

to Default Settings (Choice # { 4/5/6/7 } ) ........ 13B-33

Create New SSH Server Keys

(Choice #8) ........................................................ 13B-33

Shutdown and Reboot the MCD

(Choice #9) ........................................................ 13B-33

How to Access the Linux-Based Functions

of the Operating System of the

WCCIII-MCD .......................................................13B-34

Common Linux Commands that would be

helpful to know for the WCCIII-MCD2 ..............13B-37

The WCC III – MCD Remote Serial Console .... 13B-40

Null Modem cable ............................................. 13B-41

WCCIII-MCD2 Backup/Restore Data to

and from USB Drives ........................................13B-43

WattMaster Controls - Ubuntu Linux

Installation ........................................................13B-44

Restart APC Monitor Server (Choice #6) ............. 13B-29

Test Internet Connection (Choice #7)...................13B-29

Page 3

13B. WCC III - MCD2 INSTALLATION GUIDE

System Requirements

SECTION 13B: WCC III - MCD2

INST ALLA TION GUIDE

__________________________________________

WCC III - MCD2 History Information

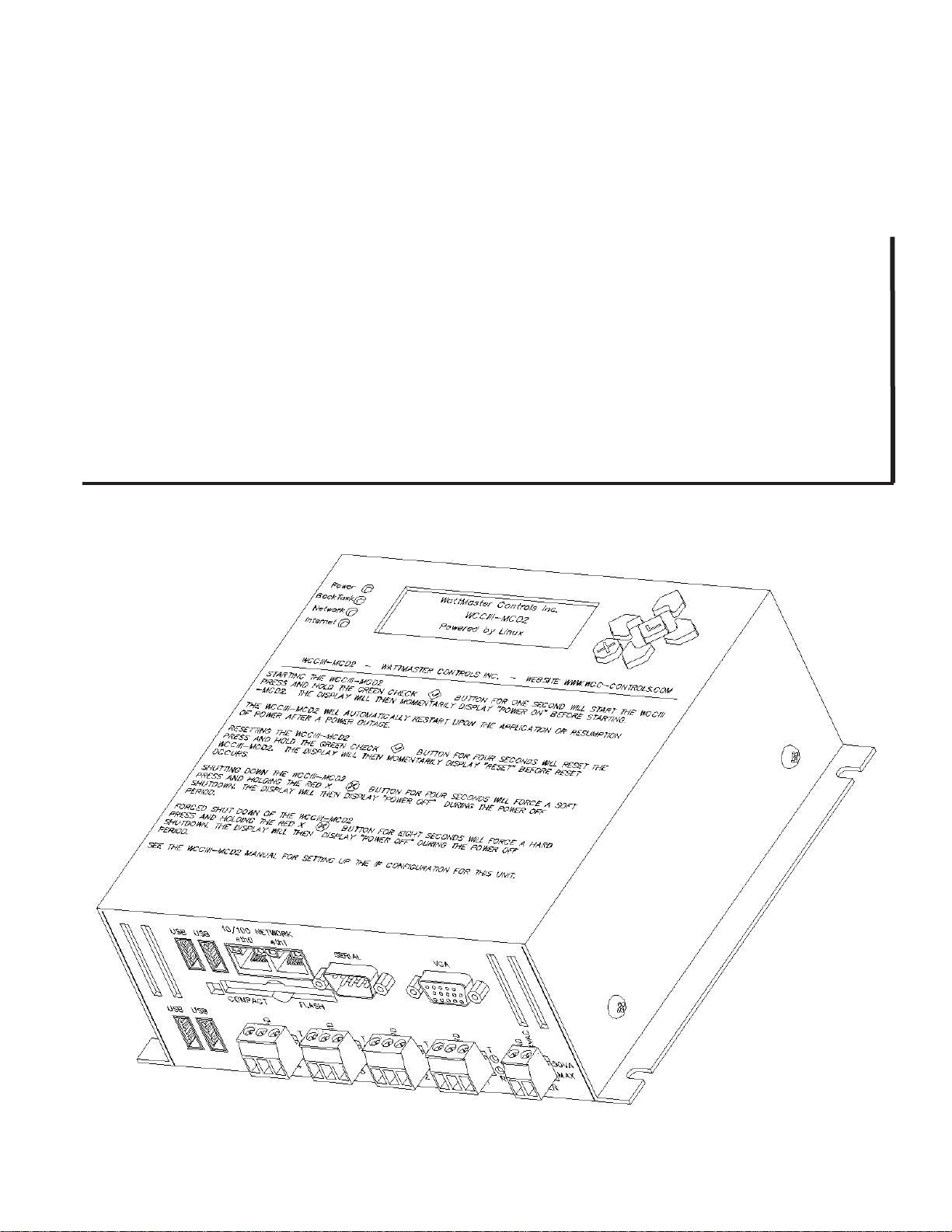

The WCCIII-MCD2 (WM part # OE405-02) was designed as

a product improvement of the older WCCIII-MCD (WM part #

OE405-01) and as such is a drop-in replacement unit for the older

WCC III-MCD computer product (WM Part # OE405-01). The

original WCCIII-MCD was designed as a product improvement

upgrade for the old WCCII type computer .

The heart of the WCCIII-MCD2 is an industrial-rated single board

computer that is within a custom-designed wrap-around sheet

metal computer enclosure that matches the look of the satellite type

3 controllers, and this makes the new WCCIII-MCD2 about one

quarter the size of the previous WCCIII-MCD. It has completely

quiet operation due to the fact that the new WCCIII-MCD2 is

completely fanless due to far less power requirements of the newer

generation of Intel

TM

processors.

The WCCIII-MCD2 is powered off of a single 24VAC @50VA

transformer (WM part # WP000050) – that is supplied with the

WCCIII-MCD2.

Also the new WCCIII-MCD2 uses a lot less separate individual

components in its construction than the old WCCIII-MCD

computer.

The old WCCIII-MCD used 7 separate cable assemblies to

interconnect the various circuit boards with in the WCCIII-MCD

case to each other. The new WCCIII-MCD2 uses a single cable

assembly called “SBC INTERNAL I/O CABLE” (WM part #

HZ00160) to interconnect the various circuit boards together.

There used to be a separate circuit board on the old WCCIII-MCD

that was used to control the power startup/shut down functions. On

the new WCCIII-MCD2, these power start up/shut down functions

are now handled by the CrystalFontz LCD controller. There was

also a passive backplane board on the old WCCIII-MCD, and this

was eliminated on the WCCIII-MCD2 design. The old WCCIIIMCD case used 17 separate pieces of steel sheet metal in its

design, whereas the new WCCIII-MCD2 has two simple pieces of

lightweight aluminum for its case design.

There are no physical moving parts within the WCCIII-MCD2.

WattMaster uses the start up and shut down operational control

of this new WCCIII-MCD2 design with the addition of a 4 line

by 20 character CrystalFontz LCD controller board. In addition,

WattMaster Controls has developed an additional circuit board

called the MCOMM board, which is a PIC32 based 4 channel –

Isolated RS-485 communication packetizer and unpacketizer for

the WCC III satellite type of communications loop.

The WCCIII-MCD2 will communicate to up to 240 of the

WattMaster Controls SAT 3 series of fi eld programmable

controllers. Also, a very specialized, small and compact power

supply module was designed to supply +12VDC @ 4 Amps

power to the MCOMM board, PCM-9362N CPU board, and the

CrystalFontz LCD controller, and this power supply module is

called “LTM8027 Power Supply Module”.

WCC III Technical Guide

13B-1

Page 4

13B. WCC III - MCD INSTALLATION GUIDE

Main Differences Between MCD and MCD2

Main Differences Between the First Generation WCCIII-MCD and the

New WCCIII-MCD2 Computers

First generation WCC III-MCD (See Note 1) New WCCIII-MCD2

120VAC power supply with Power Supply Fan 24VAC power supply (50VA transformer supplied) – Fanless operation.

(This dedicated 24VAC Transformer offers an extra layer of Electrical

Isolation that the fi rst generation WCC III-MCD did not have.)

Intel “M” processor

Wall mounted big bulky case with chassis mounted Fan W all mounted enclosure, Designed with the smallest possible foot print.

The three fans that were used on the fi rst generation of

WCC III-MCD, when combined made a lot of noise.

2 line by 20 character liquid crystal display that displayed 4 line by 20 character liquid crystal display Module with keypad and four

Linux Ubuntu (V8.04 LTS) operating system (See Note 2) Linux Ubuntu operating system (V12.04 L TS)

Main hard drive – Older T ech IDE solid state hard drive. Main Hard Drive - Newer T echnology “SATA” solid state hard drive.

Backup data hard drive - Compact Flash 2Gig Backup data hard drive - Compact Flash 4Gig

“BackTask” program running in windows emulation mode. The “BackTask” program is now running in native Linux.

RS-485 Communications:

Two Isolated RS-485 Communications loops - Standard (Two more

RS-485 Communications loops were optionally available for an

additional cost) (Limited to 60 Sats per Loop - 240 Sats Max)

One Ethernet port. (Referred to as “eth0”) Two Ethernet ports. (Referred to as “eth0” and “eth1”)

Four external USB ports. Four external USB ports.

UPS Backup power loss method

24VAC transformer used for detection of loss of power.

The onboard power switch board would detect loss of

power and then shutdown the WCCIII-MCD

TM

with CPU Fan Newer generation Intel “Atom Processor”TM Passive cooling – Fanless

Completely Fanless operation. Also this new WCCIII-MCD2 enclosure

intentionally matches the look and feel of the aluminum enclosures for

the SAT III, and Sat 3 C/D/E/F controllers

additional “Status” LEDs. This LCD Module also integrates all of the

necessary control signals for the ATX power supply functionality for the

WCCIII-MCD2.

RS-485 Communications:

Four Isolated RS-485 Communications loops are provided - Standard.

(Limited to 60 Sats per Loop - 240 Sats Max)

One of these two Ethernet ports (eth1) is used as a fi xed local IP address

for direct connection to a local on site computer, and or a setup Laptop/

Desktop computer for simplistic setup. The other Ethernet port “eth0” is

intended to be connected to the end customer’s network/internet/router.

USB connection to APC

shutdown. This feature adds important information about the exact time

date, and duration logging of the specifi c power outage. See Note 3.

TM

brand Smart UPS for automatic controlled

Table 13B-1: MCD vs. MCD2

13B-2

WCC III Technical Guide

Page 5

13B. WCC III - MCD2 INSTALLATION GUIDE

Main Differences Between MCD and MCD2

NOTE 1

The fi rst generation WCC III - MCD platform was by nature a work in progress, which due to unforeseen circumstances, the following was replaced and/or upgraded

over time: (Also See NOTE 2.)

Conventional spinning Hard Drive – W as replaced by a 4 gig solid state IDE hard Drive.

3 ½ inch Floppy Drive - W as replaced with a 2 by 20 line LCD display.

No data backup drive - W as replaced by a compact fl ash drive with nightly and monthly automatic data backups.

65 W att Power supply - Was Replaced with a 150W power supply. Original Power Supply was not enough.

This fi rst generation WCC III - MCD platform started out as a W indows XP based system, and then over time the fi rst generation WCC III - MCD has been upgraded to

the Linux Ubuntu operating system, which over time became the upgraded WCCIII-MCD. Windows XP operating system required that a keyboard/mouse emulation

box to be attached to the fi rst generation WCC III – MCD, or else certain errors could occur . Windows pretty much requires a Keyboard to function. (Mainly this had

to do with the “Auto-detect” of devices that are connected, and when a keyboard is not detected at some one of sacred fi les would get corrupted, and then cause failure

to boot up issues.) The Windows XP operating system was very susceptible to viruses, and required anti-virus software to be installed, but the antivirus software caused

almost as much problems with continual anti-virus updates, and yearly renewal issues. (The Linux operating system is much less prone to viruses) The Windows XP

operating system was obsoleted by Microsoft, and at this point there is no long term support for this Windows XP operating system anymore.

NOTE 2

The fi rst generation WCCIII-MCD (Referred to in this document as the old WCCIII-MCD) started life out as a Windows XP based system, and over time the fi rst

generation WCC III - MCD has been upgraded to the Linux Ubuntu operating system. At this time the “BackTask” program was written so that it required that it be

running under the Widows operating system, so the fi rst generation WCC III - MCD had the necessary Linux fi les installed so that the “BackTask” program could

be ran under the windows operating system in emulation mode from within the Linux operating system. This emulation mode also used up some 384 meg of main

hard drive space. The new WCCIII-MCD2 has the Linux Ubuntu operating system (V12.04 LTS), but without the windows emulation fi les, because the “Backtask”

program has now been rewritten so that it is running natively in Linux without having to run it in the Linux windows emulation mode.

Before starting the assembling of any WCC III-MCD2, please get the latest and greatest parts lists from Solomon (OE405-02).

All of the parts needed for the building to the required quantities of WCC III-MCD2 should be pulled fi rst, and then the shortages ordered, and then these shortages

should be fi lled before further proceeding in any assembling process.

NOTE 3

There is also a software provision within the WCCIII-MCD2 to control the shutdown of the WCCIII-MCD2 via USB commands that are sent from an APC

UPS (Uninterruptible Power Supply) upon detection of loss of power. When the battery in the UPS drops to 3 minutes of remaining power, the MCD will auto shut

down. A USB cable must be connected between the APC

be made to any of the four USB ports on the WCCIII-MCD2. This USB cable is supplied by APCTM in the box with the UPS.

WattMaster Controls recommends the following USB connected APCTM brand Uninterruptible Power Supplies:

The APC brand UPS must be a minimum of 500VA (300 Watts) and must have a USB connection. A short 1 foot extension cord may also be required to connect the

WCCIII-MCD2’s wall mounted transformer to the UPS in order to utilize all of the other UPS’s power plugs.

APCTM Back-UPS, Models 550/650/750 (550VA Part # BE550G), (650VA Part# BE650G1), (750VA Part # BE750G).

APC Power-Saving Back-UPS Pro 700 - Part # BR700G

APC Power-Saving Back-UPS Pro 1000 - APC Part # BR1000G

APC Smart-UPS 750VA LCD 120V – APC Part # SMT750

TM

APC

is a wholly own trademark of American Power Conversion.

TM

brand UPS and the WCCIII-MCD2 for this to occur. This USB connection cable from the APCTM UPS can

TM

brand

Table 13B-1, continued: MCD vs. MCD2

WCC III Technical Guide

13B-3

Page 6

13B. WCC III - MCD INSTALLATION GUIDE

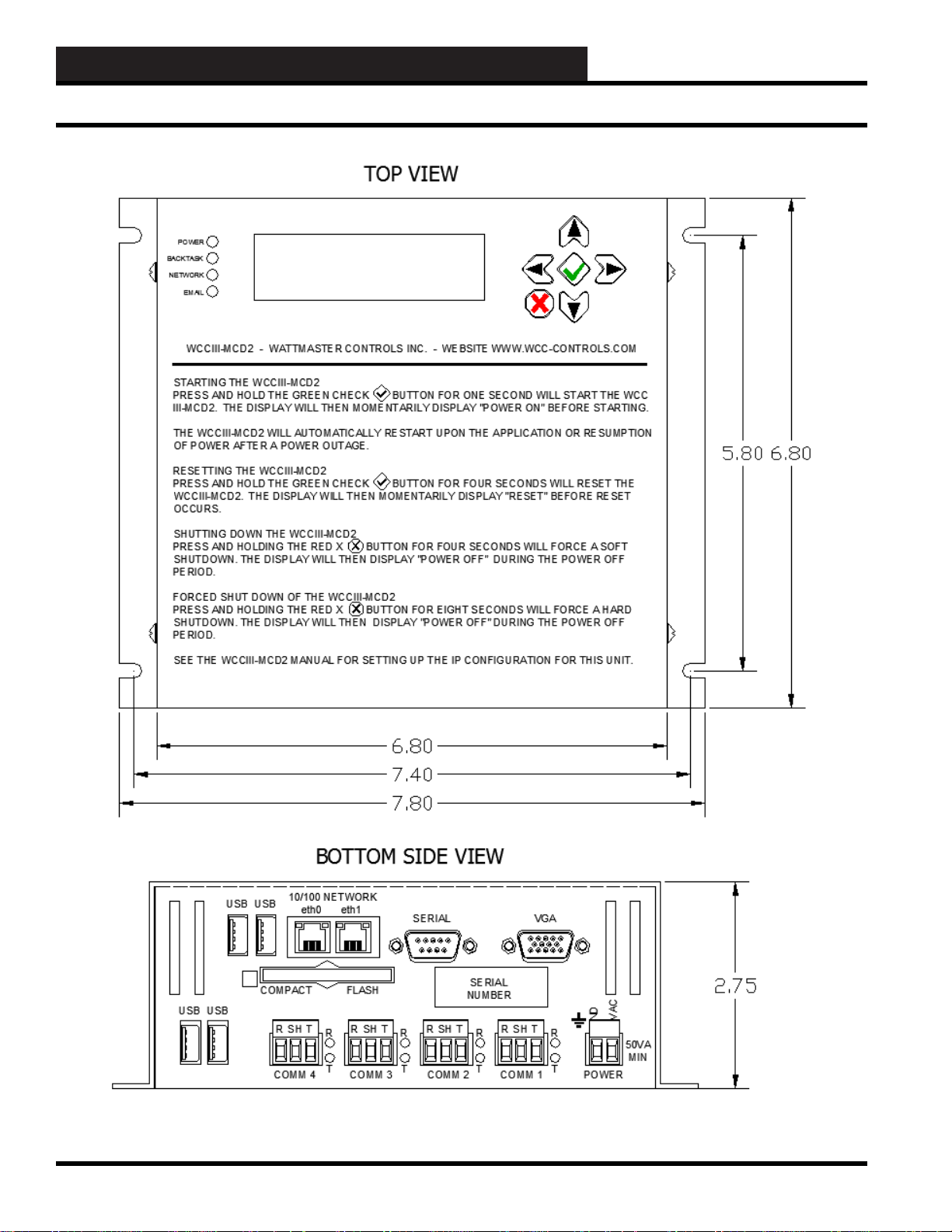

MCD2 Dimensions

Figure 1: MCD2 Dimensions In Inches

13B-4

WCC III Technical Guide

Page 7

13B. WCC III - MCD2 INSTALLATION GUIDE

System Requirements

To accomplish remote communications via the internet, the

following items are needed in addition to the WCC III system in

order to control the building mechanical systems:

WARNING: The WCC III-MCD2 system is not to be used in

any application where Fire/Life/Safety is an issue.

The WCCIII-MCD2 Basic Operating

Conditions

The WCCIII-MCD2 must be kept in a clean and dry area in the

building. The ambient temperature must be between 50 and 100

°F, and the relative humidity must be kept between 0 and 90%

(non-condensing).

The WCCIII-MCD2 is primarily designed to mount on a wall.

The WCCIII-MCD2 computer requires 115 VAC power and must

remain powered at all times for proper operation and control. The

115 VAC power circuit must be separate and dedicated exclusively

to the WCCIII-MCD2 computer. An APCTM brand UPS with an

USB connection must also be connected to the to the WCCIIIMCD2 for backup power.

A dedicated Network IP Address or Domain Name is required.

WCCIII-MCD2 Basic System

Requirements (On-Site WCCIII-MCD2

Computer)

• DSL or a Cable router/switch that connects to the

internet. Or, as an alternative, an internal jobsite

IP network that does not connect to the internet,

but when using this internal jobsite IP network, the

external internet Email of alarms from the WCCIIIMCD2 will not be possible. Also, external access

via the internet may not be possible. An Ethernet

crossover cable is supplied for standalone nonnetwork applications.

• A fi xed static IP address or a fi xed IP domain host

name from the ISP along with a provisioning sheet

that contains other pertinent IP setup information.

• Enabled port forwarding on the Firewall of the

router/switch. This is only if a Firewall is used.

• An Email address that supports a SMTP

server for SENDING with a pop server for

RECEIVING Emails, and it must have “authlogin”

authentication—TLS or SSL modes are supported.

W attMaster Controls can provide an Email address

with these requirements.

• An APC

Supply (UPS) – 700 Watt minimum with USB

communications.

TM

brand Uninterruptible Power

• A wall mounting surface is desirable, and preferred.

• A dedicated 120VAC power circuit is required.

Front End Software Requirements

(Operator Console Software)

• A Microsoft Windows XP /Vista/Windows 7/

Windows 8 -based computer.

• Minimum hardware specifi cation for the Microsoft

Windows XP / Vista based computer is a Pentium

IV running at 2.4 Giga Hertz with at least 1 GB

of RAM, and 10 GB of spare hard drive space. A

CDROM/DVD drive is also required for software

installation.

• WCC III software package – Provided on a

CDROM (W attMaster Part # DM1WC011-01X,

were “X” = revision level), or is available via a

download on the WCC Controls website: www .

wcc-controls.com. The installation CDROM

contains the following programs:

WCC III.exe (SS5021)

WCCUTILITY .exe (SS5023)

SCUSCR.exe (SS5026)

WCC3Trendlog.exe (SS5028)

TenantReport.exe (SS5025)

TenantOverride.exe*(SS5024)

WCC3Download.exe (SS5030)

WCC3Guest.exe (SS5022)

*NOTE: The TenantOverride.exe program is also

available as a single program installation for the

end users that are using the simplistic graphical

interface of the TenantOverride.exe screen to

locally turn on and off specifi c control points that

are applicable to the end user.

• A DSL or Cable router/switch that connects to the

internet, or access to the internet via some other

method. Or, as an alternative, an internal jobsite IP

network that does not connect to the internet, but

when using this internal jobsite IP network, the

external internet Email of alarms from the WCCIIIMCD2 may not be possible.

WCC III Technical Guide

13B-5

Page 8

13B. WCC III - MCD INSTALLATION GUIDE

System Requirements

Uninterruptable Power Supply

The WCCIII-MCD2 system is designed to automatically restart

after a power failure. However, the industrial computer which

acts as the WCC III-MCD2 Master Communications Device will

not automatically reboot unless the power is shut off cleanly and

then restored cleanly. During most power outages, the incoming

115 AC voltage could have great fl uctuations before the power

fi nally fails. In a like manner, brownouts will usually cause the

industrial computer to “lock-up.” That is to say, the screen will

continue to display on the monitor, but the cursor will not respond

to the keyboard commands. To prevent this “lock-up” issue from

happening to the WCC III-MCD2, an Uninterruptible Power

Supply (UPS) is required on each and every WCCIII-MCD2

computer.

An Uninterruptible Power Supply (UPS) provides emergency

power to keep the WCC III-MCD2 Master Communications

Device (personal computer) on-line for several minutes after a

primary power failure. The UPS regulates the incoming power

to the computer and shuts the power off cleanly several seconds

after the power outage, or brownout. When the primary power

is restored, the UPS brings the WCCIII-MCD2 back on-line

automatically. The WCC III system does not lose any information

since all of the programs and user entered data are stored on either

a disk in the MCD, on fi rmware, or on battery backed memory in

the satellite controllers.

Software Updates

WCC III-MCD2 program updates will be made available using

USB “jump” drives and/or internet downloading.

NOTE: As of September 1, 2009, all WCCIII-MCDs will only

be shipped with the Linux operating system installed. Older

Windows XP-based WCCIII-MCDs should be upgraded for

any future support issues from WattMaster. The Windows

XP operating system is at the end of long term support with

Microsoft. Microsoft’s main issues are with continuous

updates, and the multitude of viruses that are written for

Windows XP are also of concern. The Linux operating system

software on the WCCIII-MCD2 must be maintained and

updated periodically. W attMaster Controls, Inc. can do these

software updates and upgrades remotely via the internet only

if the WCCIII-MCD is connected to the internet. This is why

internet access to the WCCIII-MCD2 is so important. Failure

to keep the operating system updated could result in a WCC

III-MCD2 system malfunction. WattMaster Controls, Inc. is

not responsible for a system failure that is so generated due to

lack of upgrading or updating because the end customer does

not provide a static IP connection for the WCC III - MCD2 to

the internet for W attMaster Controls to connect to.

Basic Operating Conditions MCD2

(Master Communications Device)

The WCCIII-MCD has the following specifi cations:

• A Single Board Computer in a custom wall

mounted case

• Processor - Intel

Core

®

Atom™ processor N450 Single

• Memory – 1 GB SODIMM

• Hard Drive – Solid State SATA 8 GB Hard Drive.

Plus a 2 GIG COMPACT FLASH drive for secure

data backup.

• 4 line by 20 character Dot Matrix LCD display

with ATX shutdown control.

• Required I/O

1 - External RS232 port (9 Pin connector)

4 - External USB ports

2 - Internal USB ports

2 - Ethernet Port

WCCIII-MCD2 Internet Access

The most common question asked is: Why does the WCCIIIMCD2 computer need to have Internet access?

• If WattMaster Controls factory assistance or

troubleshooting is required for a WCC III system,

a representative from the factory can access the

system with a remote computer and view the same

WCC III Screens as the end user or contractor

in the building. This allows the end user or the

contractor for the building installation to talk to the

factory representative while they are both viewing

the same screens.

• The Emailing of important alarm notifi cations for

up to 60 Email Addresses is provided for from the

WCCIII-MCD2 device.

• The ability to send alarm notifi cation via a text

message to a cellular phone.

• Secure Remote communications package (WCC

III software) is provided for FREE. A CD-ROM is

supplied for installation.

• W orld-wide, multiple remote connections (up to

255 simultaneous connections possible)

• The ability for internet based tenant override

requires internet access.

13B-6

WCC III Technical Guide

Page 9

13B. WCC III - MCD2 INSTALLATION GUIDE

RS-485 Communications Wiring

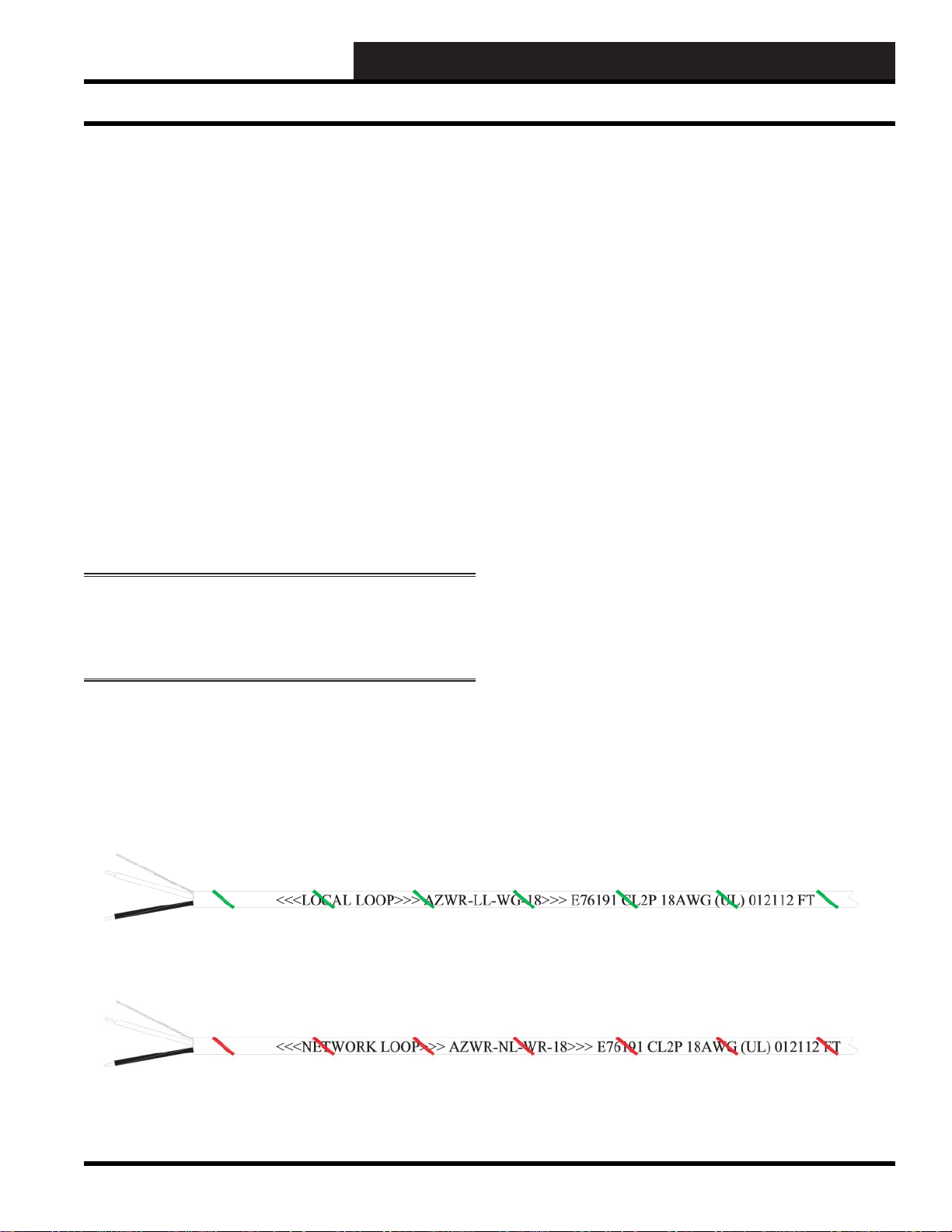

The WCC III System RS-485

Communications Wiring

The WCCIII-MCD2 can communicate with up to 239 satellite

controllers via a two-wire RS-485 communication loop. On

the bottom side of the WCCIII-MCD2 there are four RS-485

communication loop ports that come as standard. Each one of

these communications loop ports can communicate with up to 60

satellites for a total of 120 satellites.

The two-wire RS-485 communication loop should be stranded 2

wire twisted pair of 18-gauge wire with a shield wire, and it also

must be plenum rated were applicable. The use of stranded wire is

mandatory to ensure a good connection with the ¼ inch Sta-Con

connectors which are used to terminate the wires at the satellite

controllers. The RS-485 communication wire does not have to be

run from each satellite controller back to the WCCIII-MCD2, but

rather the RS-485 communication wire can be “daisy-chained,”

which means that only one twisted pair of wires is connected to

each of the WCCIII-MCD2 communications loops. The maximum

allowable length of wire from the WCCIII-MCD2 to the farthest

satellite is 4000 feet per RS-485 communications loop.

NOTE: A length greater than 4000 feet is allowed under

certain circumstances. Consult the factory for assistance if the

communications loop required for your application will exceed

4000 f eet.

The RS-485 wire specifi cations are generally a stranded 18-

gauge - 2 wire twisted pair with shield. 18-gauge stranded wire is

mandatory to ensure a good connection with the ¼ inch Sta-Con

connectors, which are used to terminate the wires at the WCC IIIMCD2 and at the satellite controllers. The old SAT II Manchester

communications loop was supposed to have used a 2-wire twisted

pair with shield, but this was not used in every installation. This

old SAT II communications loop should not be used for the new

SAT III communications loop. A new RS-485 communications

loop should be ran to each new replacement SAT III controller.

The shield wire must be used on the new SAT III controller, as

it provides a “ground” reference for the RS-485 communication

loop. WattMaster Controls sells two versions of 18-gauge - 2-wire

twisted pair with shield communications wire—(1) WattMaster

part #WR-NL-WR-18 which is marked “Network Loop” with

a red stripe for rapid identifi cation. This connection is intended

to run from the WCC III – MCD2 to the SAT III, SAT 3C/D/F,

SA T3P, and then to the next SA T 3 type controllers. (2) W attMaster

part# WR-LL-WG-18 which is marked “Local Loop” with a green

stripe for rapid identifi cation for the TUC loops that run from the

SAT 3C/D/F controllers out to the TUC controllers. “Wire Nuts”

on the RS-485 communications loop should be avoided at all costs.

As an alternative to the “Wire Nuts”, WattMaster Controls has a

Power and Switchable RS-485 communications board, and the

W attMaster part number is PL102224. This Power and Switchable

RS-485 communications board can be thought of as a 24-VAC

power and communication distribution system for the SAT III

communications loop, and this board will aid in initial startup

and future troubleshooting of the SAT III communications loop.

These boards should be used on a fl oor-by-fl oor basis. This Power

and Switchable RS-485 communications board is also available

in a small metal electrical enclosure. The wire that makes up the

communication loop should be shielded. Shielded cable has an

aluminum jacket over the wires that could act as an “antenna”

to carry away any “stray” electrical signals that could interfere

with the communication process. The shield should be grounded

throughout the SAT Loop.

Figure 2: WattMaster Local Loop Wire

Figure 3: WattMaster Network Loop Wire

WCC III Technical Guide

13B-7

Page 10

13B. WCC III - MCD INSTALLATION GUIDE

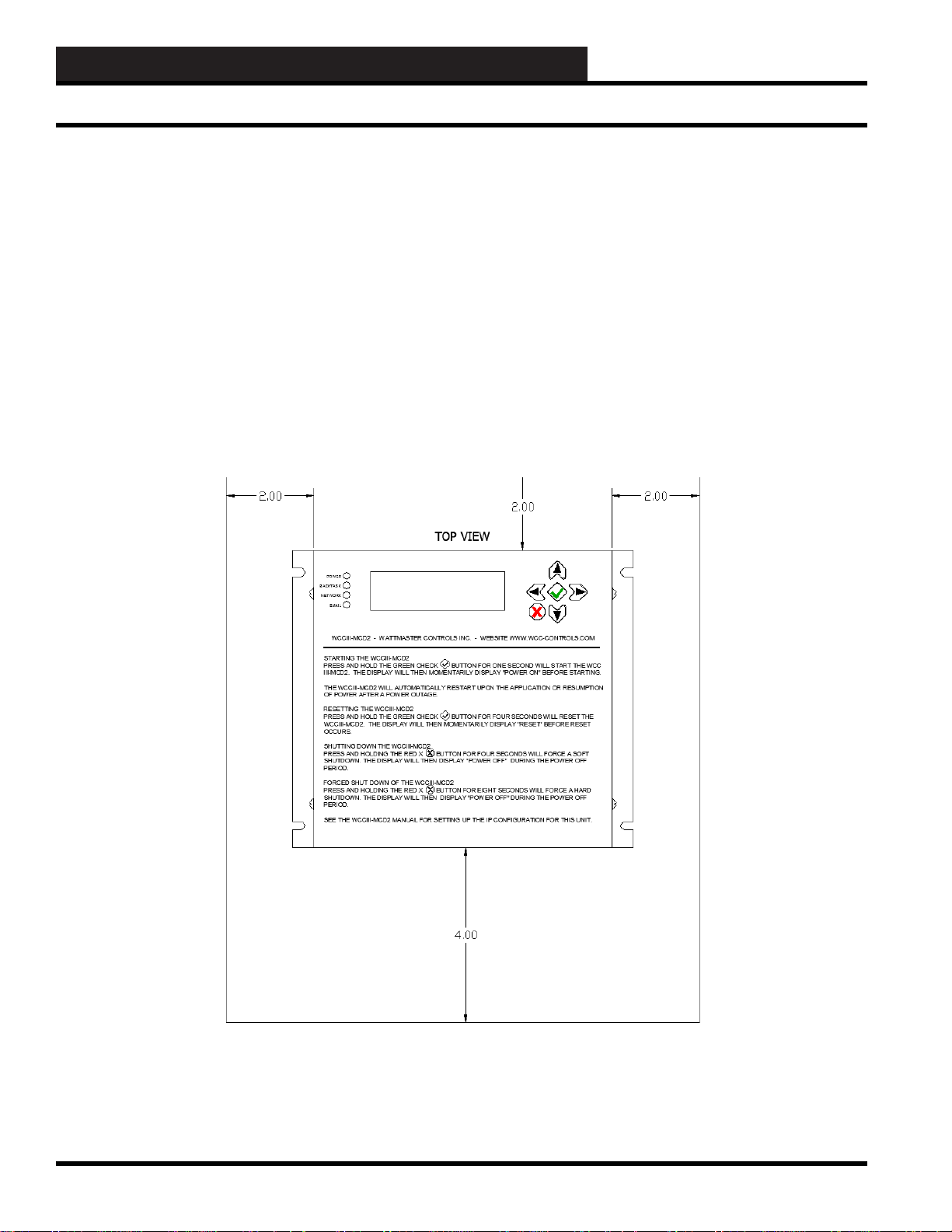

WCCIII-MCD2 Mounting Requirements

WCCIII-MCD2 Mounting Requirements:

The WCCIII-MCD2 was designed to be wall mounted, and

therefore should be mounted on a wall or in a NEMA 1 rated

electrical enclosure.

The WCCIII-MCD2 should be mounted in an air-conditioned

space (The ambient temperature must be between 50 and 100

°F, and the relative humidity must be kept between 0 and 90%

(non-condensing)). Setting the WCCIII-MCD2 on a desktop is

possible, but not recommended due to top and bottom ventilation

considerations.

Mounting in an NEMA type 1 electrical enclosure is possible

providing that there is enough ventilation and minimum clearance

for ventilation. The height of mounting the WCCIII-MCD2 should

be at eye level or with local codes on compliance with the ADA

act of 1990/2009. A minimum of two inches of clearance should

be maintained all around the WCCIII-MCD2, with the exception

of the bottom side of the WCCIII-MCD2 where four inches of

clearance is required for connector’s clearances.

When mounting the WCCIII-MCD2, proper minimum clearance

distances must be met and must be maintained. Space must be

allowed for proper ventilation. When mounting in an electrical

enclosure, be sure that you would avoid mounting the WCCIIIMCD2 above any heat generating sources such as transformers,

and energized contactors, etc. Some thought must be given to the

possibility of adding ventilation to the NEMA 1 rated enclosure

that the WCCIII-MCD could be mounted in if so mounted.

Figure 4: Top View - Minimum Mounting Distance Clearances

13B-8

WCC III Technical Guide

Page 11

13B. WCC III - MCD2 INSTALLATION GUIDE

WCCIII-MCD2 Mounting Requirements

Figure 5: Bottom View - Minimum Mounting Distance Clearance

WCC III Technical Guide

13B-9

Page 12

13B. WCC III - MCD INSTALLATION GUIDE

Pow er Supply Requirements

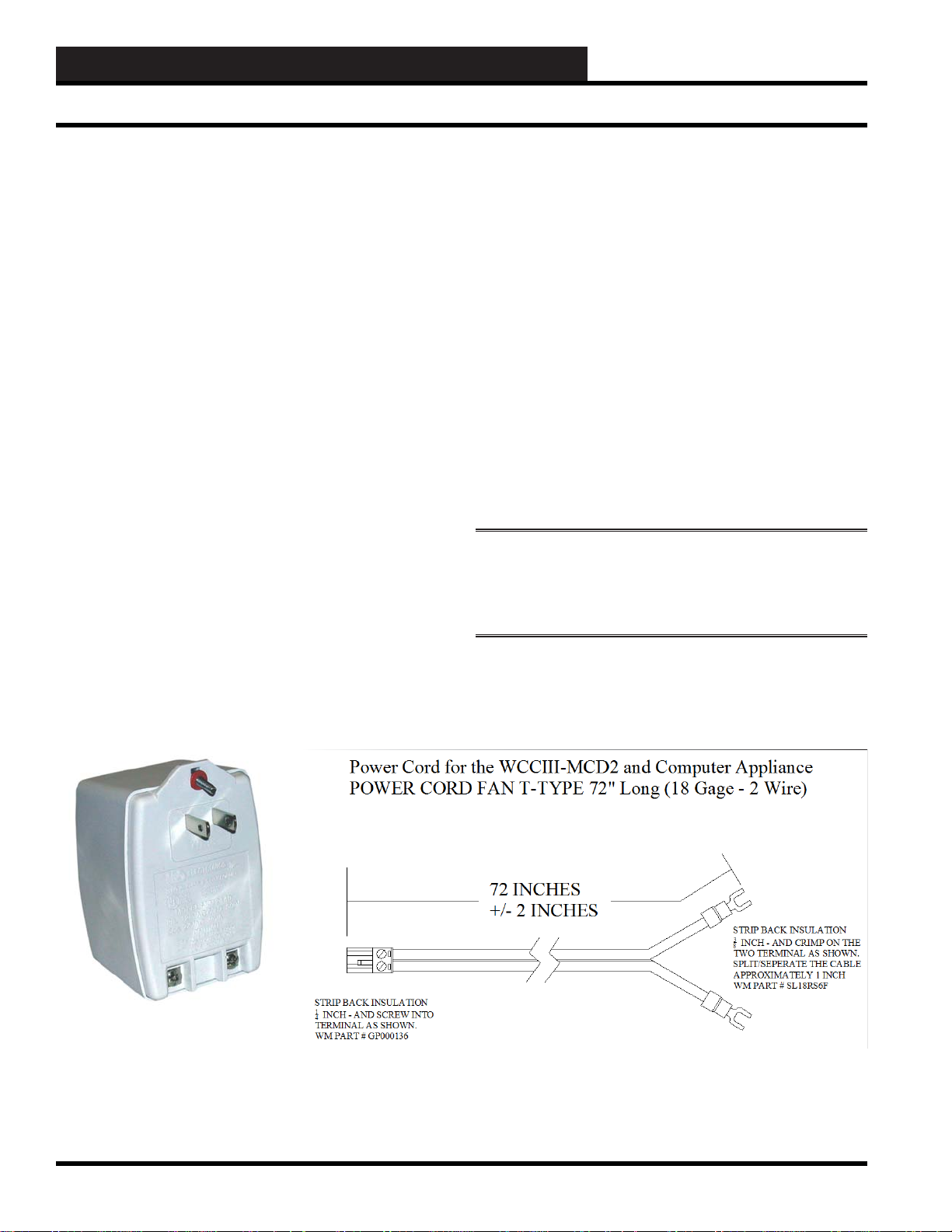

Power Supply (24VAC) Requirements

The WCCIII-MCD2 should only be powered by a dedicated

wall wort type 120VAC to 24VAC @50VA transformer, and this

transformer should only be used to power up the WCCIII-MCD2.

There should be no other devices/controllers that should be powered

off of this dedicated transformer . WattMaster Controls supplies the

WCCIII-MCD2 with such a transformer (WM Part # WP000050).

There is a modifi ed power cord (WM Part # HZ000161) that is

to be supplied with the WCCIII-MCD2’s transformer. There are

two fork terminals (WM Part # SL18RA6F – Fork Terminal,

#6 screw, 18 to 22 Gage) that are used to connect this modifi ed

cable to the 50VA transformer. The other end of this cable is a 2

position de-pluggable type connector (WM Part # GP000136 TERMINAL PLUG - 2 POSITION DEPLUGGABLE). Again

only the WCCIII-MCD2 should be powered from this dedicated

24VAC@50VA transformer. With the use of screw terminals on

the transformer that WattMaster Controls supplies you can easily

change the length of the power cord to up 100 feet. You must use

a minimum of 18 gauge wire (16 or 14 gage wire would be better)

to accomplish this.

If you choose not use the supplied dedicated wall wort type

120VAC to 24VAC @50VA transformer, then an isolation

transformer must be used. The only other option is to use a separate

dedicated transformer (only connected to the WCCIII-MCD2) that

can be connected to the WCCIII-MCD2 device. This transformer

must have an output that is rated for 24VAC @ 50 VA minimum

with appropriate fusing for its size.

The 24VAC@50VA power transformer for the WCCIII-MCD2 is

to be connected to a dedicated APCTM brand UPS ( Uninterruptible

Power Supply) outlet so that the WCCIII-MCD2 will keep

running during a minor power outage. The Cable/DSL modem/

router should also be plugged in to one of these dedicated UPS

(Uninterruptible Power Supply) outlets. Take note that the UPS

may have several outlets but not all are marked backup power.

Some are surge suppression only . Use the backed up power outlets.

The WCCIII-MCD2 has the ability to monitor power status of

the UPS to control the shutdown of the WCCIII-MCD2 via the

supplied APC USB cable. These commands that are sent from an

TM

APC

brand UPS (Uninterruptible Power Supply) upon detection

of loss of power will alert the WCCIII-MCD2 of power failure

that is then logged to the MCD’s SYSLOG fi le. The MCD will

monitor the UPS until there are 3 minutes of power remaining and

then initiate a shut-down of the WCCIII-MCD2. Upon resumption

of normal power, the WCCIII-MCD2 will power up on its own and

log the event in SYSLOG of the OS.

***WARNING*** If not using the supplied 24 V A C @ 5 0V

transformer, you must observe polarity if this other 24 V A C

transformer is connected to other devices. The use of another

transformer is NOT recommended.

Figure 6: Power Supply

13B-10

WCC III Technical Guide

Page 13

13B. WCC III - MCD2 INSTALLATION GUIDE

Initiating the System

Initiating the System

The SAT RS-485 communication loop wires are connected to the

“R” and “T” and shield terminals on the satellite controllers using

¼-inch Sta-Con connectors. Make sure the polarity is correct. That

is to say, the wire connected to the “R” and “T” terminal on the

WCCIII-MCD2 must be connected to the “R” and “T” terminal

on the satellite controllers. If the “R” and “T” and shield wires

are crossed, the WCC III system will not communicate. The shield

should be connected together when the cable is cut in order to

terminate the wires at the satellite controller. The communication

loop wire from the WCCIII-MCD2 is connected to one of the “R”

and one of the “T” terminals on the satellite controller, which is

physically located nearest the WCCIII-MCD2. The other “R”

and “T” terminals located on the satellite controller can be used

to extend the two-wire loop to the next satellite controller, or the

wires can branch off of a two-wire loop running through the center

of a building.

NOTE: The shield wire must be connected at each and every

Satelli te Con troller , also .

After the satellite controllers have been installed and powered

up, the WCCIII-MCD2 set up, and the 2-wire communications

line connected between all of the satellite controllers and also

connected to the WCCIII-MCD2, then the WCC III data fi les need

to be loaded into the WCC III - MCD. This is best accomplished by

using the WCC “mcd-menu” batch fi le, remotely with the Webmin

program, or by directly using the Linux command prompt on the

WCC III-MCD2 VGA monitor/USB Keyboard connections.

This “Webmin” program can be used over the internet/intranet or

locally with a network crossover cable. The “Webmin” program is

pre-installed on the Linux OS hard drive on the WCCIII-MCD2.

There are three password levels for the “Webmin” program, one

for the simple user, one for the contractor level, and one for the

W attMaster factory administrator.

WCCIII-MCD2 System Files

The Backtask program on the WCCIII-MCD2 is stored on the

solid state hard disk, so after boot-up, the system start up fi les will

cause the Backtask Program to run.

CAUTION: The WCCIII-MCD2 will not communicate

with the satellite controllers while it is going through the “reboot” process. If the satellite controllers do not communicate

with the WCCIII-MCD2 for approximately three minutes,

they will go into local set. The time it takes for the system to

“re-boot” should not cause the satellite controllers to go into

local set. The hard disk can hold a vast amount of data which

can accidentally be erased or lost due to system malfunction,

operator error, etc. Therefore it is extremely important to

make a back-up copy of the data on the hard disk. As you

program a system to control a building, information is written

on the disks. Therefore, back-up copi es of programming data

fi les on the hard disk should be made after the system has

been programmed to control the building. This can be done

remotely through the WCC Utility program.

NOTE: When converting the WCC II data fi les to WCC III

type d ata fi les, the WCC II data fi les have to be converted

to the new WCC III type data fi les using the WCCUtilities.

exe program. Then these new WCC III data fi les need to be

installed on the WCCIII-MCD2. This is best accomplished

by using the WCC “mcd-menu” batch fi le, remotely with the

Webmin program, or by directly using the Linux command

prompt on the WCCIII-MCD2.

The WCC III–MCD2 has two solid state hard drives, one that

has the Linux operating system along with the backtask program,

and one that has the daily/monthly WCC III backup data fi les

on it. A USB thumb drive can be used to shuffl e the data in and

out of the WCC III–MCD2. Another program called “Webmin”

is primarily used to administer the more advanced setup features

on the WCCIII–MCD2. This “Webmin” program requires an

internet browser, such as Mozilla, or Microsoft Internet Explorer

to function.

WCC III Technical Guide

13B-11

Page 14

13B. WCC III - MCD INSTALLATION GUIDE

Input/Output Connections

Various I/O connections tha t are on the

Bottom Side of the WCCIII-MCD2 De vice

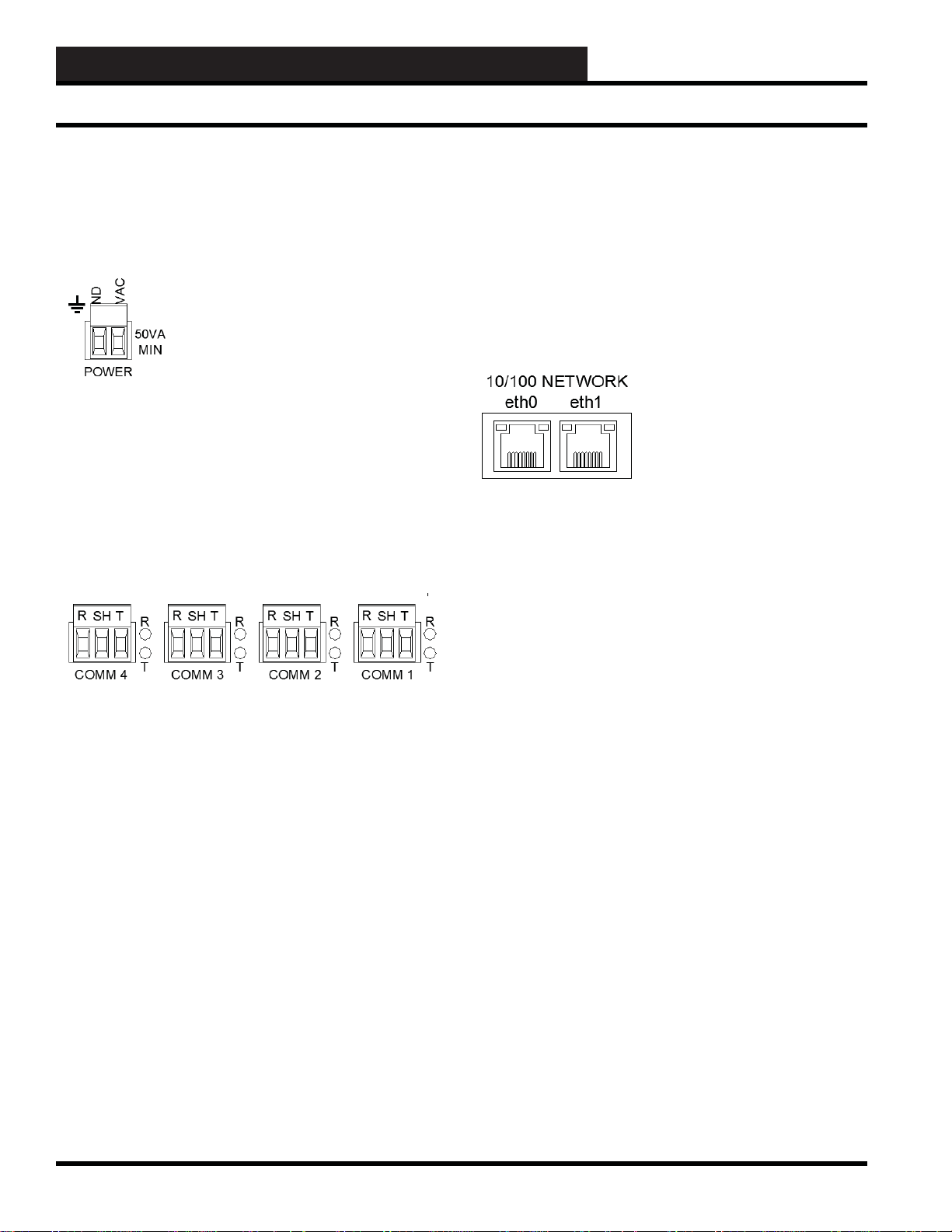

24VA C P ow er Connector

A two position de-pluggable connection is provided for power

connection to the WCCIII-MCD2 device. The WCCIII-MCD2 is

powered off of dedicated 120VAC to 24VAC@50VA transformer

that WattMaster Controls supplies with each WCCIII-MCD2

device. The 24VAC power de-pluggable connector is considered

to be “polarized” with a 24VAC side and a GND side. Correct

power polarity must be observed.

RS-485 Connectors

The WCCIII-MCD2 device provides four separate RS-485

connections. Each one of these three position de-pluggable

RS-485 connections are distance rated for up to 4000 feet of

communications loop cable when using approved communications

wire. (WM Part # or WM Part #). This communications cable is

described as 18 gauge single pair twisted, with a shield, and drain

wire. The Drain wire (Shield) must be connected between the

WCCIII-MCD2 device and all of the Satellite controllers.

R & T COMMUNICATIONS LEDs

There are simplistic communication diagnostic LEDs that are

provided next to each one of the RS-485 connectors. The LED

marked “R” stands for “Receive”, and this red LED will fl icker

when data is received from a specifi c satellite controller. The LED

marked “T” stands for “Transmit” and this red LED will LED will

fl icker when data is transmitted by the WCCIII-MCD2 to a specifi c

satellite controller).

10/100 Network ports eth0, and eth1

The main Ethernet port on the WCCIII-MCD2 is named and

labeled “eth0”. This is the primary I/P connection to the WCCIIIMCD2 device. See page XX for detailed instructions on how to

properly confi gure this network port for proper network access.

The auxiliary (second) Ethernet port on the WCCIII-MCD2 is

named and labeled “eth1”. This port confi guration should never

be changed or reconfi gured by the contractor or end user. It is

meant for direct connection (with a network cross-over cable) to

a Laptop that is to be used for setup, confi guration, updating, and

troubleshooting, or to a dedicated WCC3 computer that would be

set up to run the various WCC3 type programs that connect to the

WCCIII-MCD2 via a network connection.

Each port—etho0 and eth1—has two built in LEDs.

The Left LED is a bi-color Network Speed indicator:

LED Yellow on – Operating as a Gigabit connection (1000 Mbps)

LED Green on – Operating as a 100-Mbps connection.

LED Off – Operating as a 10-Mbps connection.

Wiring between the WCCIII-MCD2 and the satellite

controllers:

Basic rule of thumb when wiring communications from the

WCCIII-MCD2 to any and all Satellite connections: Wire “R”

connections to “R” connections, Wire “T” connections to “T”

connections, Wire “SH( SHLD)” connections to “SH (SHLD)”

connections, and there should not be an issue with communications

wiring.

13B-12

The Right LED is Link/Activity indicator:

LED Blinking – There is activity on this port.

LED Off – There is no network link established.

WCC III Technical Guide

Page 15

13B. WCC III - MCD2 INSTALLATION GUIDE

Input/Output Connections

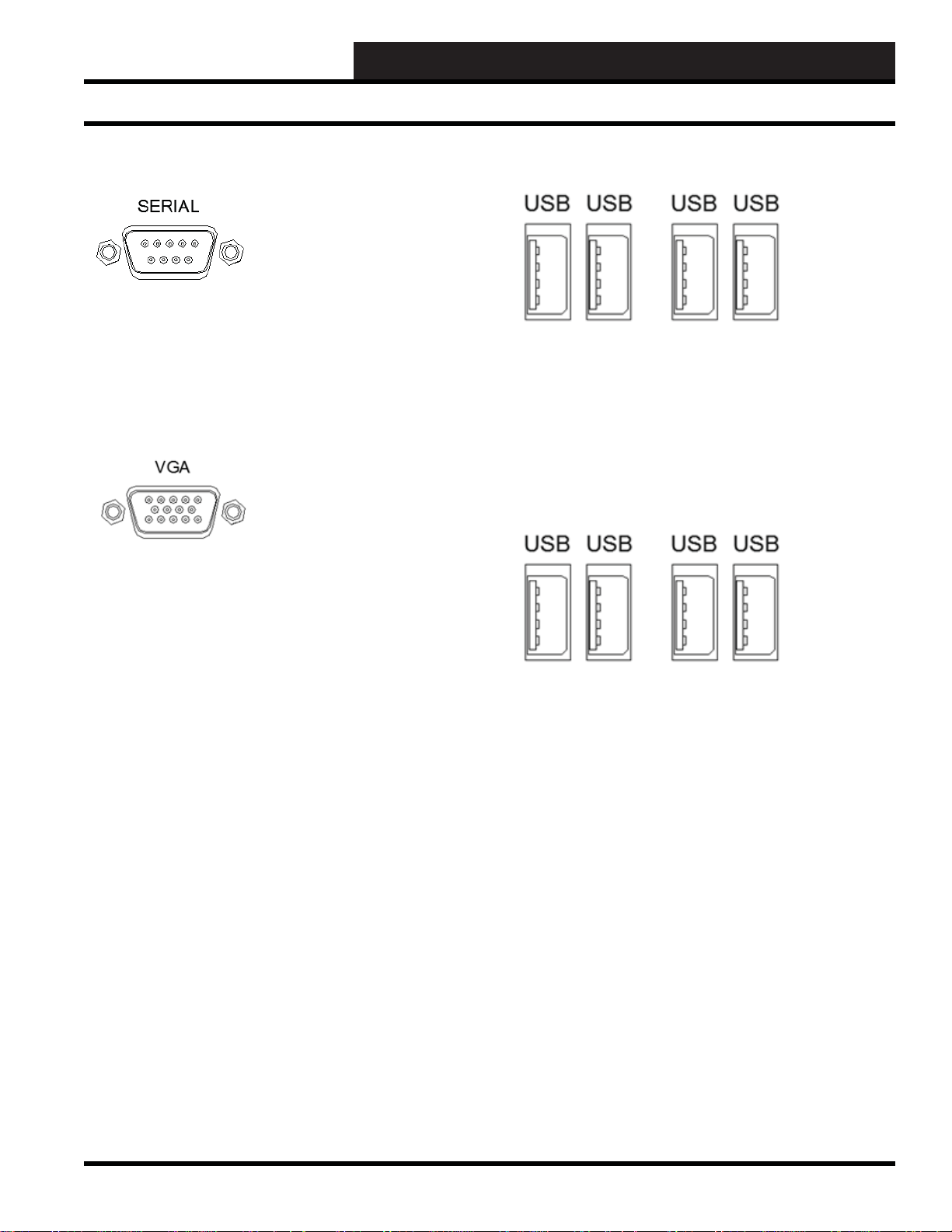

Serial Port

The Serial port is a 9 Pin “AT – Type” port that is now only used

for extreme cases as a point of access in case the Ethernet ports

and VGA are non-functional for some unknown reason. See page

43 for how to connect to a Windows based computer running

Hyper-Terminal for access.

VGA Monitor & USB Key Board

Normal operation of the WCCIII-MCD2 does not require the use

of a VGA monitor and USB Keyboard, but a VGA Monitor and

a USB Keyboard may be required only for initial setup and/or

software updating if you choose not to use a network cross-over

cable, and the putty.exe program to confi gure and or update the

WCCIII-MCD2 device. The Webmin access program should not

generally be used to initially confi gure or update the WCCIII-

MCD2 device.

VGA Monitor & USB Key Board Connections

You may use any of the four external USB connections for the

USB keyboard, and these external USB connectors are located on

the bottom side of the WCCIII-MCD device. A standard 15 pin

VGA monitor will plug into the clearly marked VGA port plug on

the bottom side of the WCCIII-MCD2 device.

USB ports

There are 4 four USB ports provided on the bottom side for

the WCCIII-MCD2 device. These USB ports are meant to be

connected to the following devices: USB Keyboard, USB APC

UPS, and USB Memory stick(s). The USB memory stick is used

for program data backup, data restore, system updates, and system

reloading.

TM

WCC III Technical Guide

13B-13

Page 16

13B. WCC III - MCD INSTALLATION GUIDE

Input/Output Connections

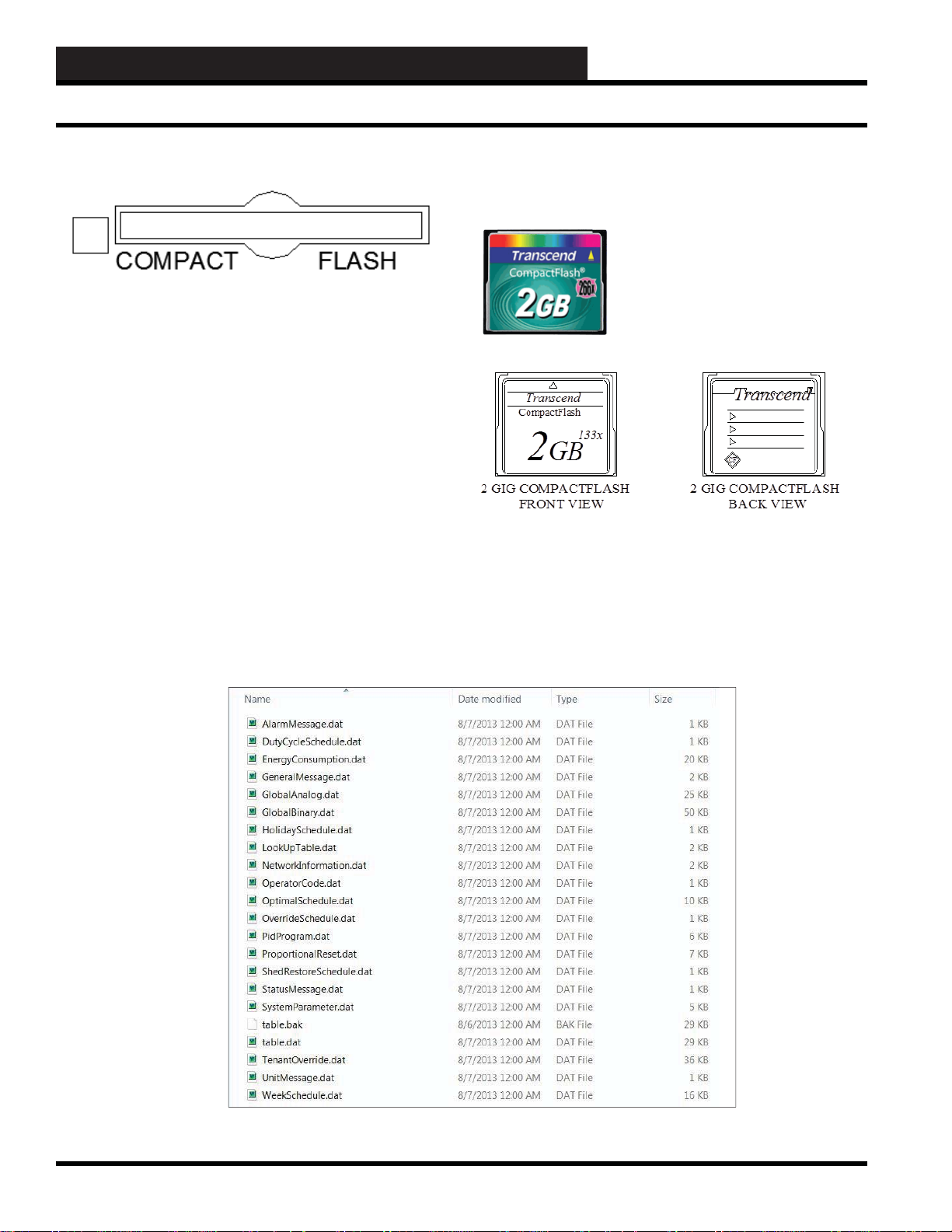

Compact Flash Port

The Compact Flash port on the WCCIII-MCD2 is utilized for

inserting a 2 Gig Memory module that plugs into the bottom side

of the WCCIII-MCD2 device. This Compact Flash connector

is polarized to prevent backwards insertion. This is where the

automatic daily/monthly backups of the WCC III / Backtask data

fi les are stored. This is done for customer backup data safety

purposes. The data is stored on root under an automatically

monthly created subdirectory system that is based on a year/

month.

Below is an example of the various data fi les that are stored on

the Compact Flash Card during the automatic safety backup that

the WCCIII-MCD2 automatically does at midnight every night.

This automatic safety backup occurs at midnight every night and

the previous day’s data is over written. The time listed for of all

of these fi les should be at 12:00 AM. This continually occurs until

the last day of the month when the WCCIII-MCD will automatically make a new subdirectory for the new month.

The WCC III-MCD2 Solid State CompactFlash

Module—2 GIG COMP A CT FLASH (WM Part #

ECC90052)

13B-14

WCC III Technical Guide

Page 17

13B. WCC III - MCD2 INSTALLATION GUIDE

LCD Display

The 4 Line by 20 Character LCD screen

on the WCCIII-MCD2

The CrystalFontz – 4 by 20 line LCD is an end user viewing

interface that is used to show the current status of the WCCIIIMCD2.

This 4 by 20 line LCD display will currently show the following

options:

• IP address (Current IP confi guration for eth0 of the

WCCIII-MCD2)

• System Time (Current time and date of the

WCCIII-MCD2)

• System Uptime WCCIII-MCD2 Uptime (Time

since last reboot)

• CPU Load Main processor CPU utilization (User

%, System%, Nice %, and Idle %)

• NetLoad IP packet processing utilization (RX

(Incoming), and TX (Outgoing) packet processing)

• POWER ON and POWER OFF status

The four status LEDs to the left of the LCD display the following:

• T op LED – Labeled “POWER” – Displays the On/

Off/Running condition of the WCCIII-MCD2.

LED stays “RED” during initial power up or when

manually powered down, then turns “YELLOW”

and then “GREEN” during the self-test boot

up sequence. When the SBC and BackTask

are functioning, the LED will turn “GREEN”

to indicate that the WCCIII-MCD2 is fully

functioning.

• 2nd from Top LED – Labeled “BACKTASK” –

This LED displays the On/Off Condition (Running

or not Running) of the Backtask program. If

the LED is RED – the Backtask program is not

running. If the LED is Green – the Backtask

program is running normally.

• 3rd from top LED – Labeled “Network” and

is bi-color. Red LED means no connectivity.

“YELLOW” LED means access to the local Intranet has been made. GREEN LED means that

connection to the Internet has been made.

• Bottom LED – Labeled “EMAIL” – Normal Status

for this LED is to Off, and this LED will turns

Green for fi ve seconds every time an EMAIL is

sent from the WCCIII-MCD2. On initial power up

this LED will turn “YELLOW” then “GREEN”

during the self-test boot up sequence

The CrystalFontz LCD module also used control the ATX (Power

Supply ON/OFF) type functionality of the PCM-9362N SBC

through the “H1” output connector which connects to the back

to inputs on the PCM-9362N SBC through the 50 pin “SBC

INTERNAL I/O CABLE” assembly.

The LCD’s Keypad

The LCD Keypad is used for the LCD screen navigation and to

control startup (power ON), Shutdown (power OFF), and reset of

the WCCIII-MCD2 device.

Starting the WCCIII-MCD2

Press and hold the Green Checkmark button for 1 second. The LCD

display will momentarily display, “Power On” before starting.

The WCCIII-MCD2 will automatically restart upon the application

or resumption of power after a power outage.

Resetting the WCCIII-MCD2

Press and hold the Green Checkmark button for 4 seconds. The

LCD display will momentarily display “Reset” before Reset

occurs.

Shutting Down the WCCIII-MCD2 - Soft Shut Down

Press and hold the Red X button for 4 seconds. The LCD display

will then display, “Power Of f” during the Power Of f period.

Forced Shut Down of the WCCIII-MCD2 - Hard Shut

Down

Press and hold the Red X button for 8 seconds. The LCD display

will then display, “Power Off” during the Power Off period. Files

are still open.

WCC III Technical Guide

13B-15

Page 18

13B. WCC III - MCD INSTALLATION GUIDE

WCCIII-MCD2 LCD Screens

WCCIII-MCD2 LCD Screens

System Time

The System Time Info screen displays information on the current

system time, week, day, and date. These times and dates can be

changed from the MCD-MENU (see page 25) or through the

W ebmin Access method (see page 35).

System Uptime

The System Uptime Info screen displays information on how

many days/hours/minutes since the last restart. It is often used as

a measure of computer operating system reliability and stability,

in that this time represents the time that a computer has been left

unattended without crashing or needing to be rebooted for any

administrative or maintenance purposes. This System Uptime

Info screen also displays the Backtask program running status

either as “ON” or “OFF”. Normal Status should be “ON”. The

“BACKTASK” LED should also be “GREEN” for “ON” and

“RED” for “OFF”.

CPU Load

The CPU Load Info screen displays the Total CPU load as a

percentage (17.4%), the WCCIII User CPU load (6.5%), and

the System CPU load (for the Linux Operating system), the total

system Idle time percentage (82.6%), and a 0-100% Bar Graph.

WCCIII User CPU Load: Percentage of the WCCIII-MCD2

CPU’s utilization that occurred while executing at the user level

(application). BackT ask/opt/Backtask/backtask is an application.

System CPU Load: Percentage of the WCCIII-MCD2 CPU’s

utilization that occurred while executing at the system level

(kernel). The Linux operating system is system level.

Idle Time: Percentage of the WCCIII-MCD2 CPU’s time that the

CPU was idle and the system did not do an outstanding disk I/O

request.

A computer processor is described as idle when it is not being

used by any program. Programs which make little use of the CPU

Idle Time mean that they run at a low priority so as not to impact

programs that run at normal priority like BackTask.exe. Many

programs that use the WCCIII-MCD2 CPU idle time can cause

the WCCIII-MCD2 CPU to always be 100% utilized, so that the

time spent when the WCCIII-MCD2 CPU would have been idle

is instead spent performing useful computations. This generally

causes the WCCIII-MCD2 CPU to consume more power as most

modern computer’s CPUs can enter power-save modes when they

are idle.

13B-16

WCC III Technical Guide

Page 19

13B. WCC III - MCD2 INSTALLATION GUIDE

WCCIII-MCD2 LCD Screens

NET Load

The NET Load info screen displays a real time Ethernet data

packet transmit and receive status in the fi rst column under total

KB/s and a total of Ethernet data packets transmitted and received

under the MB column.

An IP packet is the formatted unit of data that is carried by a

packet mode computer network. When the data is formatted into

IP packets, the bit rate of the communication medium (Ethernet)

can better be shared among users than if the network were circuit

switched.

Rx: Displays the number of IP Packets that are currently being

received on the network card right now.

Tx: Displays the number of IP Packets that are currently being

transmitted on the network card right now.

IP Address

The IP Address info screen displays the current Ethernet IP Address

of the network card labeled eth0. IP precedes the IP Address, NM

proceeds the Network Mask, and GW is the Gateway or Router

address to send IP packets outside of the local network. These IP

address confi gurations can be changed from the MCD-MENU (see

page 24).

The LED Labeled “Network” is a bi-color LED. When this

“NETWORK” LED is “RED” this means that there is no IP

connectivity. When the “NETWORK” LED is “YELLOW”

this means that access to the local intranet is made. When the

“NETWORK” LED is “GREEN” this means that there is a valid

connection to the Internet.

WCC III Technical Guide

13B-17

Page 20

13B. WCC III - MCD INSTALLATION GUIDE

BIOS Information For WCCIII-MC2 System Setup

13B-18

WCC III Technical Guide

Page 21

13B. WCC III - MCD2 INSTALLATION GUIDE

BIOS Information For WCCIII-MC2 System Setup

BIOS Confi guration for the

WCCIII–MCD2

The required setup information for the BIOS confi guration for the

WCCIII–MCD2 must match all of the WCCIII-MCD2 Operating

System Versions.

The initial software version of the WCCIII-MCD2 operating

system software was and is installed using a USB memory stick.

It is highly recommended that the WCC3 data be backed up

before attempting any WCCIII-MCD2 operating system reload or

upgrade. Using the initial install completely “wipes out” and in

other words “erases” all of this WCC3 data information.

Warning: The jumper labeled “J2” on the MCOMM board

(WM part # PL1 024 16-AT) should be removed during initial

software loading, but every effort must be used to ensure that

this jumper is put back “ON” after the software have been

loaded.

Linux Ubuntu Version 12.04 LTS (Long Term Support) for the

operating system will end on April 2017 for the WCCIII-MCD2.

Sometime before that date, WattMaster Controls, Inc. will force

an upgrade of the Linux Ubuntu operating system software for the

WCCIII-MCD2 to a more current supported version.

Linux Operating System Software

Installation Procedure for the

WCCIII-MCD2

Plug the VGA monitor and USB type keyboard into the WCCIIIMCD2. Then insert the USB memory stick that is preloaded with

the required WCCIII-MCD2 installation software (WM part

# SS50??) into one of the four bottom USB connectors that are

located on the bottom connector side of the WCCIII-MCD.

Warning: The jumper labeled “J2” on the MCOMM board

(WM part # PL1 024 16-AT) should be removed during initial

software loading, but put back “ON” after the software have

been loaded.

Once you have loaded the software successfully, press the “Delete”

or “Del” key on the USB style keyboard. This will cause the

WCCIII-MCD2 single board computer to go in to the BIOS setup

screens. The corresponding BIOS setup screen information must

exactly match what is printed here in this document. Then this

information must be saved by using the action command of Exit

and Save. See pages X for the installation screens.

WCCIII-MCD2 On/Off/Shut Down/Reset

Buttons

Starting the WCCIII-MCD2

Press and hold the Green Checkmark button for 1 second. The LCD

display will momentarily display, “Power On” before starting.

The WCCIII-MCD2 will automatically restart upon the application

or resumption of power after a power outage.

Resetting the WCCIII-MCD2

Press and hold the Green Checkmark button for 4 seconds. The

LCD display will momentarily display “Reset” before Reset

occurs.

Shutting Down the WCCIII-MCD2 - Soft Shut Down

Press and hold the Red X button for 4 seconds. The LCD display

will then display, “Power Of f” during the Power Of f period.

Forced Shut Down of the WCCIII-MCD2 - Hard Shut

Down

Press and hold the Red X button for 8 seconds. The LCD display

will then display, “Power Off” during the Power Off period. Files

are still open.

WCC III Technical Guide

13B-19

Page 22

13B. WCC III - MCD INSTALLATION GUIDE

Cov er Removal of the WCCIII-MCD2

13B-20

WCC III Technical Guide

Page 23

13B. WCC III - MCD2 INSTALLATION GUIDE

Functions of the WCCIII-MCD2

WCCIII-MCD2 Functions

The main function of the WCCIII-MCD2 is to provide a hardware

and software platform for a program that WattMaster Controls

has developed called “backtask”. The BACKTASK program is so

named because it is a multiple BACKground T ASKing application

program.

The BACKT ASK program does a lot of various functions such as:

USB communications to the internal MCOMM board, Time clock

functions, analog/binary global processing, overrides of control

points, Holiday scheduling, Optimal starts, PID programs, Shed /

Restore programs, Duty cycle programs, Proportional Programs,

Tenant Overrides, and Emailing of alarms. The BACKTASK

program also provides for remote IP connection to a set of

Windows-based programs generally referred to as the WCC III

programs.

If the BACKT ASK program is not running on the WCCIII-MCD2,

there is a watchdog circuit on the WCC3 MCOMM board that will

automatically restart/reset the WCCIII-MCD2 within 3 minutes.

This watchdog circuit may interfere with the installation of new

BACKTASK software. There is a way to disable this watchdog

circuit. Please contact WattMaster Controls for further important

information on temporally disabling this watchdog circuit. A two

pin berg jumper that is labeled “SBC RESET” on the WCC3

MCOMM board enables (ON) or disables (OFF) this watchdog

circuit, but this jumper must be “ON” for normal operation, and

if this “SBC RESET” jumper is left “OFF” then the automatic

restart/reset function of the WCCIII-MCD2 is then inoperable, and

may cause future undesirable operating issues. Manual reset from

the CrystalFontz LCD interface is also enabled/disabled with this

jumper, too.

This WCCIII-MCD2 also has hardware (WCC3 MCOMM board)

that interfaces to four isolated RS-485 communications loops

that then connects to various SAT III type controllers for building

automation controls.

The 24VAC@50VA power transformer for the WCCIII-MCD2 is

to be connected to a dedicated APC

Power Supply) outlet so that the MCD will keep running during a

minor power outage. The Cable/DSL modem/router should also be

plugged into one of these dedicated UPS (Uninterruptible Power

Supply) outlets. Take note that the UPS may have several outlets

but not all are marked backup power. Some are sur ge suppression

only. Use the backed up power outlets.

TheWCCIII-MCD2 has the ability to monitor power status of

the UPS to control the shutdown of the WCCIII-MCD2 via the

supplied APC USB cable. These commands that are sent from an

TM

APC

brand UPS (Uninterruptible Power Supply) upon detection

of loss of power will alert the WCCIII-MCD2 of power failure

that is then logged to the MCD’s SYSLOG fi le. The MCD will

monitor the UPS until there are 3 minutes of power remaining and

then initiate a shut-down of the WCCIII-MCD2. Upon resumption

of normal power, the WCCIII-MCD2 will power up on its own and

log the event in the SYSLOG of the OS.

TM

brand UPS ( Uninterruptible

Again, great caution must be used to ensure that this “SBC RESET”

jumper on the WCC3 MCOMM board is set back to enabled (ON)

if it is ever disabled for any and all software installations that occur

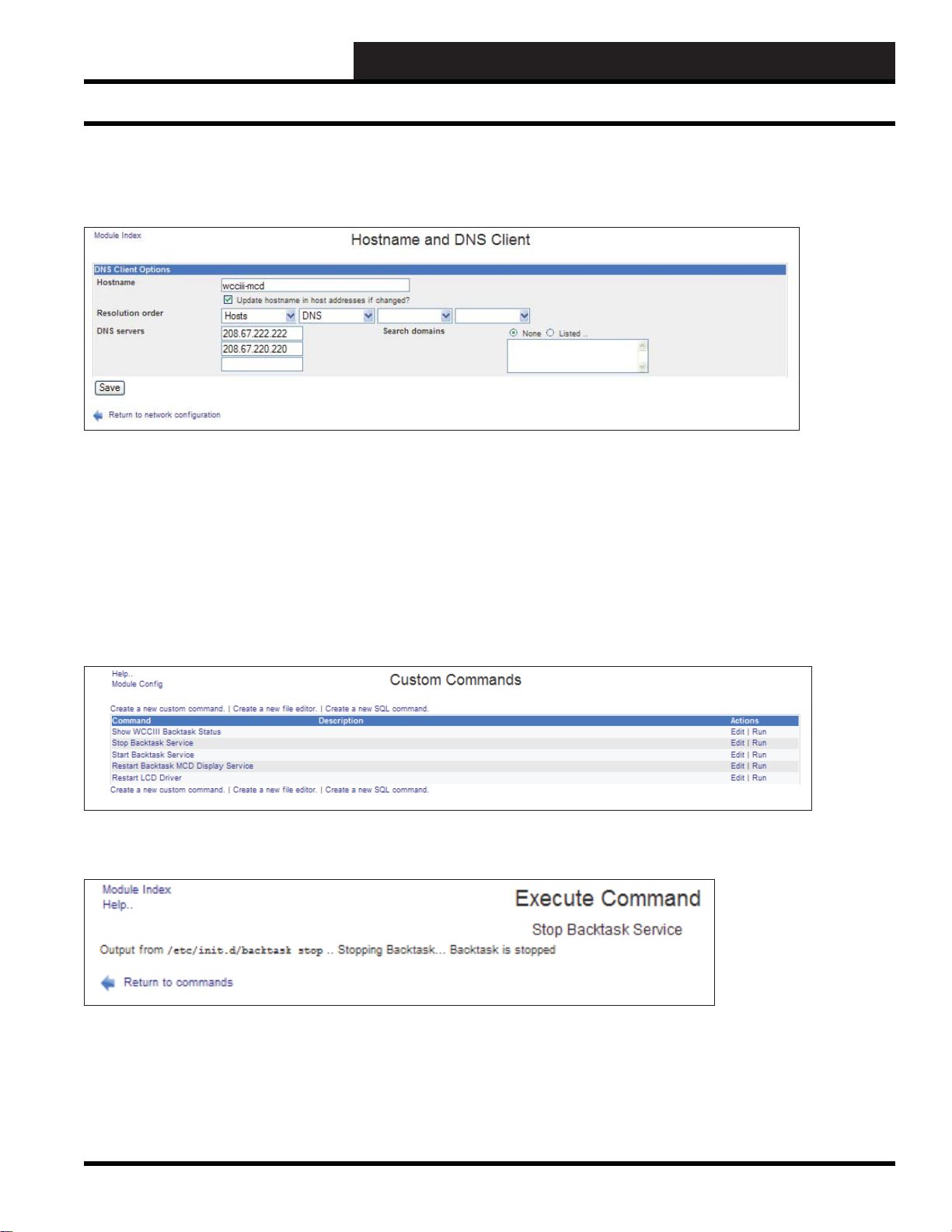

in the fi eld. This enabling/disabling of the “SBC RESET” jumper

is not normally done for simple setting of the IP addressing.

WCC III Technical Guide

13B-21

Page 24

13B. WCC III - MCD INSTALLATION GUIDE

MCD-Menu Program

How to Setup the IP Address on the

WCCIII –MCD2 with the mcd-menu

Program

Obtain a VGA monitor and a USB keyboard to connect to the

WCCIII-MCD2 device. There is a standard VGA monitor 15

pin connector on the bottom of the WCCIII-MCD2 device for

connection to a VGA type monitor. There are four external USB

connectors on the bottom of the WCCIII-MCD2 device, and

you can use any one of these external USB ports for a keyboard

connection.

Prior knowledge of Linux is not required, but would be helpful.

WattMaster Controls has developed a simple setup installation

program for the Linux command line interface, and this program is

called mcd-menu. This mcd-menu program has 16 functions that

are incorporated into it that will allow for the following operations

to be performed:

1. The setup the Network IP Confi guration of the WCCIII-

MCD2 network card interface.

2. The setup of the MCD’s Time Zone.

3. Copying of the BackT ask specifi c data fi les to the root

of the USB Drive.

4. Restoring of the BackT ask specifi c data fi les from the

root of the USB Drive.

5. The testing of APC Smart UPS connection via USB.

6. The restart of the APC Monitor server software.

7. The testing of the Internet Connection, from the

WCCIII-MCD2 to the Internet.

8. The testing of DNS Settings, from the WCCIII-MCD2

to the Internet.

9. Updating the WCCIII-MCD2 via USB Drive.

10. Updating the WCCIII-MCD2 via the Internet.

11. The resetting of the WCCIII-MCD2 IP address back to

the WattMaster factory Default IP Address settings.

12. The resetting of the WCCIII-MCD2 DNS settings back

to the WattMaster factory default DNS settings.

13. The restarting of the 4 by 20 line LCD Driver that is

located on the front of the WCCIII-MCD2.

14. The restarting of the 4 by 20 line LCD Display that is

located on the front of the WCCIII-MCD2.

15. The shutdown of the WCCIII-MCD2 – properly closing

down.

16. The shutdown and reboot of the WCCIII-MCD2.

The Webmin access method can also accomplish some of these

same tasks, but is a little bit harder to use and is meant to be more

of an “off-site” management tool for the WCCIII-MCD2. The

mcd-menu program is meant to be used as the initial IP setting,

time zone setting, and BACKTASK data fi le loading tool for the

WCCIII-MCD2. For this, a monitor and keyboard needs to be

connected temporally just for the initial IP setup and BACKTASK

data fi le loading.

The default administration username is wcciii and the password is

wt@@58.

This username and password are both CASE sensitive, and should

be entered in lower case letters only.

The administration username will time out after 15 minutes, and

you will be required to reenter the user name, and password again.

Type “mcd-menu” at the at the wcciii@wcciii-mcd:~$ prompt

(which is view only – restricted access). You can do very few

functions in View only restricted access, such as, copy/restore

WCCIII data fi les, check the IP Address, and check the UPS status.

Type “sudo mcd-menu” at the wcciii@wcciii-mcd:~$ prompt to

perform root level tasks like confi gure the IP address, shutdown the

WCC III - MCD, reboot the WCC III - MCD, reset the WCC III –

MCD IP addresses and DNS settings to DEF AULT confi gurations,

set time zones, restart the APC Monitor server, run updates from

USB or Internet, and copy/restore WCCIII data fi les.

Caution must be exercised with the sudo (super user) command

because it can render your WCCIII-MCD2 system unable to

communicate with the outside world if improperly used.

If you have selected a command requiring sudo (Super User)

access, the program will give you a warning message as listed

below:

****************************************************

* *

*

Warning: The program is not running as root. *

* Interface configurations or saving may fail! *

*

*

******************************************

13B-22

WCC III Technical Guide

Page 25

13B. WCC III - MCD2 INSTALLATION GUIDE

MCD-Menu Program

The mcd-menu is straight forward. You can select the desired

function by number (1 to 16) and hit the enter key to execute the

desire function. You can quit this mcd-menu program at any time

by typing “quit” and then pressing the enter key to quit. Then type

“exit” to return to the WCCIII-MCD2 Login: prompt.

Helpful hint: While at the wcciii@wcciii-mcd:~$ prompt, you

can select / toggle through previously entered commands with the

“UP” arrow key.

The new fi les are rolled into the installation fi les so they will be

available on new systems. They can also be pushed or updated

to older systems via secure ftp and then run from the shell.

Alternatively, they can also be uploaded to the WCCIII-MCD2

from inside the W ebMin program and then run from the command

line from within the browser. This mcd-menu program may be run

remotely from “Putty”, which is a terminal emulator application

program, provided that this program is installed and properly setup

on your computer.

NOTE: DO NOT run the mcd-menu program from inside

Web Min’ s Command Shell. It will not work there. This mcdmenu program is meant to work only from telnet/ssh session or

from the actual console (i. e. US B keyboard and VGA monitor that

is directly connected to the WCCIII-MCD2 ).

Press ENTER (or “d”) to scroll downward

OR “u” to scroll upward (T ype “quit” to quit)

PLEASE ENTER A CHOICE: ___

Helpful hint: You do not have to use the “u” or “d” keys and then

the “enter” to toggle between the fi rst and second menus. By using

just the “enter” key, you can toggle between the fi rst menu screen

with selections of 1 to 10 and the second menu screen that has

selection 11 only.

Please Pick a Function:

11. Reset MCD to Default IP Address

12. Reset MCD to Default DNS Settings

13. Restart LCD Driver

14. Restart LCD Display

15. Shutdown MCD

16. Shutdown and Reboot MCD

16 T otal Choices

Press ENTER (or “d”) to scroll downward

OR “u” to scroll upward (T ype “quit” to quit)

Using the default low level username wcciii and password

wt@@58, type mcd-menu at the prompt (view only – restricted

access)

Type sudo mcd-menu at the prompt (unrestricted access) (maybe

required to re-enter the password again).

The following fi rst main menu screen should appear:

Please Pick a Function:

1. Setup Network Confi guration

2. Setup Time Zone

3. Copy BackT ask Files to USB Drive

4. Restore BackT ask Files from USB Drive

5. T est APC UPS Connection

6. Restart APC Monitor Server

7. T est Internet Connection

8. T est DNS Settings

9. Update MCD2 via USB

10. Update MCD2 via NET

16 T otal Choices

PLEASE ENTER A CHOICE: ___

Helpful hint: You do not have to use the “u” or “d” keys and then

the “enter” to toggle between the fi rst and second menus. By using

just the “enter” key, you can toggle between the fi rst menu screen

with selections of 1 to 10 and the second menu screen that has

selection 11 only.

WCC III Technical Guide

13B-23

Page 26

13B. WCC III - MCD INSTALLATION GUIDE

MCD-Menu Program

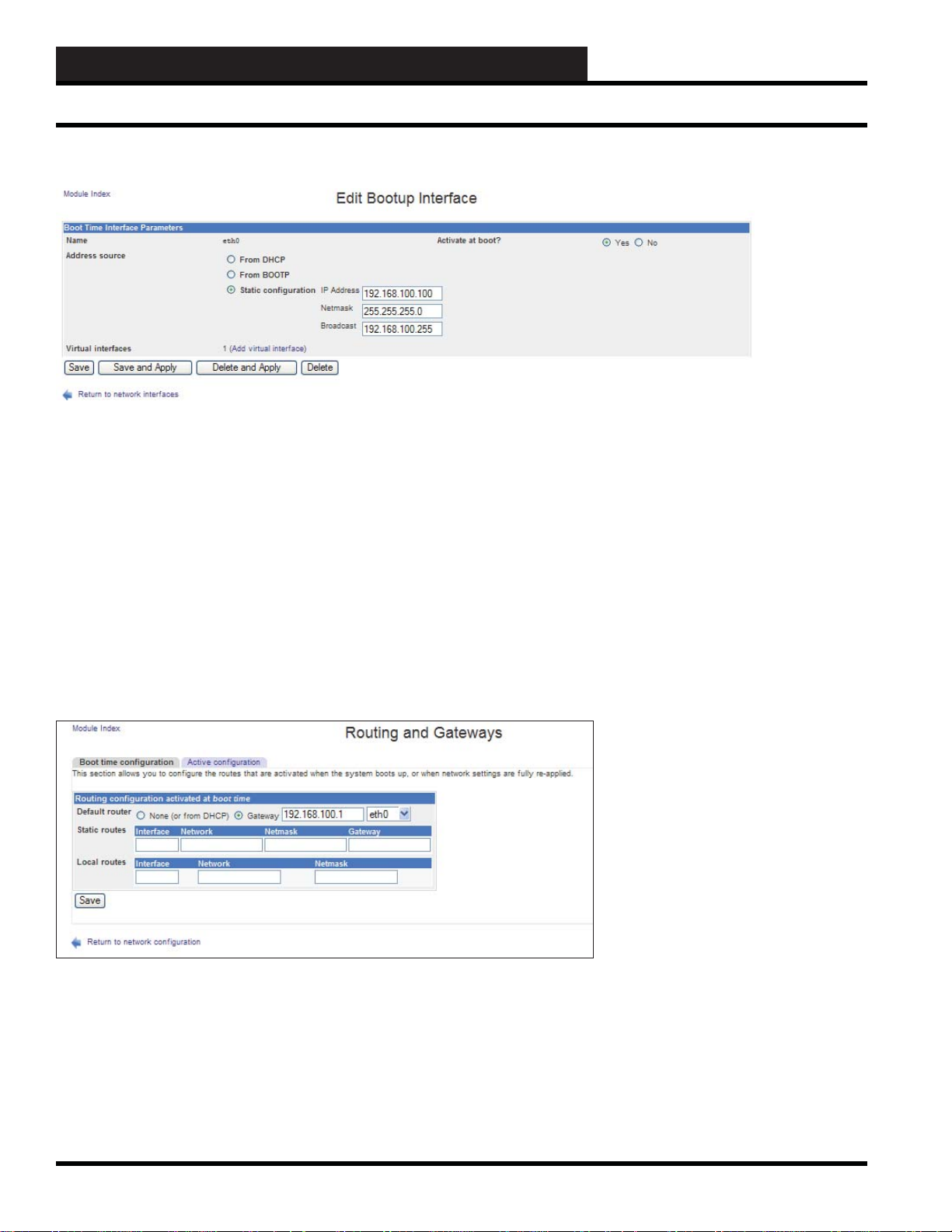

Setup Network Configuration

(Choice #1)

This sub program will allow you to set the IP confi guration of the

WCCIII-MCD2. You will be prompted to enter an IP Address in

the XXX.XXX.XXX.XXX format. If you do not have all of the

following information, then you should not proceed any further.

Fill in the blanks below for future reference.

Static IP address __ __ __ . __ __ __ . __ __ __ . __ __ __

Subnet Mask __ __ __ . __ __ __ . __ __ __ . __ __ __

Gateway __ __ __ . __ __ __ . __ __ __ . __ __ __

Nameserver __ __ __ . __ __ __ . __ __ __ . __ __ __

Nameserver __ __ __ . __ __ __ . __ __ __ . __ __ __ Optional

Nameserver __ __ __ . __ __ __ . __ __ __ . __ __ __ Optional

Y ou will be now be prompted to enter the following data, and if you

do not want to change the address listed within the listed brackets

[ ] then just press the enter key and the value in the brackets [ ]

will not change.

Enter interface confi guration data:

Interface to confi gure: [eth0] __

IP address: [192.168.100.101] __

Netmask: [255.255.255.0] __

Gateway (none for no gateway): [192.168.100.1] __

Nameservers (blank separate list): [8.8.8.8 8.8.4.4] __

Interface to confi gure: [eth0] __ There are two possible entries

here “eth0” and “eth1”

Some internet service providers do not have a static IP address.

They use what is called static host names, which correspond to an

actual static IP address. You can enter more than one IP address

here, a primary and a secondary, And please note that they must be

separated by a space.

For example, on the Internet, there exists a special case of

nameservers lookup sites, the so-called Domain Name System

(DNS) servers, which are used to translate a static hostname or

a domain name (for example, ‘WCC-CONTROLS.com’) to its

corresponding binary identifi er (the IP address 50.87.183.62), or

vice versa..

After you have entered in all of the required IP addresses, subnet

masks, Gateways, and or Nameservers, the program will now

change the internal IP network confi guration fi les within the Linux

operating system of the WCC III – MCD. It will take a few seconds

to do this function, and the following messages will display:

Confi guring interface:

/sbin/ifconfi g eth0 24.123.103.99 netmask 255.255.255.248

broadcast 24.123.103.103

Deleting old interface route:

/sbin/route del -net 24.123.103.96 netmask 255.255.255.248 eth0

Setting interface route:

/sbin/route add -net 24.123.103.96 netmask 255.255.255.248 eth0

Deleting old default route:

/sbin/route del default

Setting default route:

/sbin/route add default gw 24.123.103.97

Writing /etc/network/interfaces:

Writing /etc/resolv.conf:

eth0 is the default main IP address for the WCCIII-MCD2.

Eth1 is the secondary IP address for the WCCIII-MCD2 and it is

meant for direct connection from the WCCIII-MCD2 to a local

computer (Laptop) via an Ethernet crossover cable. Note: Do not

change this “eth1” IP address.

IP address: [24.123.103.99] __. This IP address must be supplied

by your Internet provider or by your network IT personnel. This IP

address must be a “static IP address” (fi xed), as in not dynamic –

which does change.

Netmask: [255.255.255.248] __. This IP address must be supplied

by your Internet provider or by your network IT personnel.

Gateway (none for no gateway): [24.123.103.97] __. This IP

address must be supplied by your Internet provider or by your

network IT personnel.

Nameservers (blank separate list): [8.8.8.8 8.8.4.4] __ . Is the

actual IP address for a DNS server.

13B-24

When completed the following information will be displayed:

New netstat settings:

24.123.103.96 0.0.0.0 255.255.255.248 U 0 0 0 eth0

192.168.200.0 0.0.0.0 255.255.255.0 U 0 0 0 eth0

0.0.0.0 24.123.103.97 0.0.0.0 UG 0 0 0 eth0

Network Confi guration Done.

*************************************************

* Warning: The program is not running as root. *

Interface configurations or saving may fail! *

*

******************************************

wcciii@wcciii-mcd:~$

NOTE: The mcd-menu program will close after the setup

process for the IP connections. This is done purposely and is

normal operation.

WCC III Technical Guide

Page 27

13B. WCC III - MCD2 INSTALLATION GUIDE

MCD-Menu Program

Setup Time Zone (Choice #2)

This function will call the Time Zone confi guration program

inside of Linux. The actual command is ‘sudo dpkg-reconfi gure

tzdata’ followed by a ‘sudo service cron restart’. This program

will bring up a menu of locations to set a time zone to. Not all

cities and localities will be listed, so select one from your time

zone. For ease of selections, US is listed towards the bottom of the

list and time zones are listed in a sub-menu as Eastern, Central,

Mountain, and Pacifi c.

Select US or Geographical Area and hit the Enter key.

Select the Time and hit the Enter key.

WCC III Technical Guide

13B-25

Page 28

13B. WCC III - MCD INSTALLATION GUIDE

MCD-Menu Program

Copy the Backtask Data Files to USB

Drive (Choice #3)

This sub-program will copy all of the useful WCC III data fi les to

a USB drive (User / Contractor provided), assuming that there is

a USB drive plugged into any of the USB ports on the WCCIIIMCD2. It will copy all of these fi les to the root of the USB drive.

This program assumes there is a USB fl ash drive inserted in the

bottom of the WCCIII-MCD2 even if it is not there. Therefore,

the program will not report that there is a drive reading or writing

error or any other errors. So when backing up the Backtask data

fi le, make sure that there is a USB fl ash drive in one of the USB

ports on the bottom of the WCCIII-MCD2. The LED on the USB

fl ash drive should light up when any data is written or read from

it. Please verify that this LED operates when backing up backtask

data to this USB fl ash drive.

All WCC III jobsites have multiple specifi c custom data fi les that

are the responsibility of the end user and/or mechanical contractor.

Any loss or the actual retention of these jobsite specifi c custom

data fi les are not within W attMaster Controls, Inc. liabilities.

The following will be displayed on the screen:

Selecting Copy Backtask Files to USB Drive.

Copying fi le: /opt/backtask/AlarmBits.dat

Copying fi le: /opt/backtask/AlarmMessage.dat

Copying fi le: /opt/backtask/EnergyConsumption.dat

Copying fi le: /opt/backtask/GeneralMessage.dat

Copying fi le: /opt/backtask/GlobalAnalog.dat

Copying fi le: /opt/backtask/GlobalBinary.dat

Copying fi le: /opt/backtask/HolidaySchedule.dat

Copying fi le: /opt/backtask/LookUpTable.dat

Copying fi le: /opt/backtask/Backtask/NetworkInformation.dat

Copying fi le: /opt/backtask/Backtask/OperatorCode.dat

Copying fi le: /opt/backtask/Backtask/OptimalSchedule.dat

Copying fi le: /opt/backtask/Backtask/OverrideSchedule.dat

Copying fi le: /opt/backtask/Backtask/PidProgram.dat

Copying fi le: /opt/backtask/Backtask/ProportionalReset.dat

Copying fi le: /opt/backtask/Backtask/ShedRestoreSchedule.dat

Copying fi le: /opt/backtask/Backtask/StatusMessage.dat

Copying fi le: /opt/backtask/Backtask/SystemParameter.dat

Copying fi le: /opt/backtask/Backtask/table.dat

Copying fi le: /opt/backtask/TenantEvent_001_2009_09.dat

Copying fi le: /opt/backtask/TenantEvent_004_2009_10.dat

Copying fi le: /opt/backtask/TenantOverride.dat

Copying fi le: /opt/backtask/TenantOverrideRecord.dat

Copying fi le: /opt/backtask/UnitMessage.dat

Copying fi le: /opt/backtask/WeekSchedule.dat

Done copying .dat fi les.

Copying SlideFiles.

Done copying SlideFiles.

Copying WGGC fi les.

Done copying WGGC fi les.

Returning to Main Menu.

The screen should now take you back to the mcd-menu main

screen after about a second or two.

13B-26

WCC III Technical Guide

Page 29

13B. WCC III - MCD2 INSTALLATION GUIDE

MCD-Menu Program

Restore BackT ask da ta Files to USB

Drive (Choice #4)

This subprogram will copy all of the useful WCC III data fi les from

a USB drive (User / Contractor provided), assuming that there is

a USB drive plugged into the USB port on the WCCIII-MCD2. It

will copy all of these fi les to the /opt/Backtask subdirectory of the

WCCIII-MCD2 solid state SATA hard drive.

If there is not a USB fl ash drive in the USB port on the bottom

of the WCCIII-MCD2, this program assumes that there is a USB

drive there even if it is not there. It will not report that there is

a drive reading or writing error, or any other errors. So when

restoring data fi les, make sure that there is a USB fl ash drive in the

USB socket port on the bottom of the WCCIII-MCD2. There is

an LED on this USB fl ash drive that should light up when data is

written or read from it. Please verify that this LED operates when

restoring data from this USB fl ash drive.

All WCC III jobsites have multiple specifi c custom data fi les that

are the responsibility of the end user and or mechanical contractor.

Any loss or the retention of these jobsite specifi c custom data fi les

are not within WattMaster Controls, Inc. liabilities.

The following will be displayed on the screen:

Copying fi le: /media/usb/OverrideSchedule.dat

Copying fi le: /media/usb/PidProgram.dat

Copying fi le: /media/usb/ProportionalReset.dat

Copying fi le: /media/usb/ShedRestoreSchedule.dat

Copying fi le: /media/usb/StatusMessage.dat

Copying fi le: /media/usb/SystemParameter.dat

Copying fi le: /media/usb/table.dat

Copying fi le: /media/usb/TenantEvent_001_2009_09.dat

Copying fi le: /media/usb/TenantEvent_004_2009_10.dat

Copying fi le: /media/usb/TenantOverride.dat

Copying fi le: /media/usb/TenantOverrideRecord.dat

Copying fi le: /media/usb/UnitMessage.dat

Copying fi le: /media/usb/WeekSchedule.dat

Done copying .dat fi les.