Page 1

12. WCC III Installation

Guide

WCC III

12. WCC III Installation

Guide

Page 2

T ABLE OF CONTENTS

SECTION 12:

WCC III INST ALLA TION GUIDE

WCC III System Requirements .................12-1

MCD Basic Operating Conditions .............12-2

Wall Mounting of the WCC III – MCD .........12-2

WCC III – MCD Internet Access ................12-4

Sending a Text Message to a

Cell Phone via an Email from

the WCC III System ................................... 12-6

WCC III System RS-485 Communication

Wiring ........................................................12-7

WCC III - MCD Typical System

Architecture ..............................................12-8

Mounting a Satellite Controller in an

Enclosure ................................................12-10

SAT 3C Controller ..................................12-49

Addressing the SAT 3C ........................... 12-51

Addressing (Numbering) of the

TUC/RTU Controllers that are

Connected to the SAT 3C .......................12-53

SAT 3D Controller ...................................12-57

Addressing the SAT 3D ........................... 12-58

Addressing (Numbering) of the TUC

Controllers that are Connected to the

SAT 3D .....................................................12-60

SAT 3F Controller ....................................12-62

Addressing the SAT 3F ...........................12-63

Addressing (Numbering) of the TUC

Controllers that are connected to

the SAT 3F ...............................................12-65

Satellite Controllers -

General Dimensions ...............................12-15

SAT III Controller - LED Information .......12-16

SAT III Controller - Connection Points ...12-17

Addressing (Numbering) of

SAT III Controllers ..................................12-19

SAT III Relay Outputs .............................12-21

Proportional-Integral (PI) Output

Board .......................................................12-24

Binary Input with Time Delay Board ......12-27

V-Out Binary/Relay Interface Board .......12-34

SAT III Analog Inputs .............................. 12-41

TUC-2R and Four Relay Expansion

Board ......................................................12-67

TUC-2R Three Relay Expansion Board

and Damper Actuator ..............................12-68

TUC-2R Velocity Sensor ......................... 12-69

Running the WCC3 Program ...................12-70

WCC III - MCD LCD Display .....................12-73

The WCC III - MCD ...................................12-78

Using the MCD-Menu Program ...............12-79

Page 3

12. WCC III INSTALLATION

GUIDE

System Requirements

SECTION 12:

WCC III INST ALLA TION GUIDE

__________________________________________

WCC III System Requirements

To accomplish remote communications via the internet, the

following items are needed in addition to the WCC III system in

order to control the building mechanical systems. The WCC III

system is not to be used in any application where Fire/Life/Safety

is an issue.

WCC III – MCD System Requirements

(On-Site WCC III – MCD Computer):

• DSL, or a Cable router/switch that connects to the

internet. Or, as an alternative, an internal jobsite

IP network that does not connect to the internet,

but when using this internal jobsite IP network, the

external internet Email of alarms from the WCC III

- MCD will not be possible. Also, external access

via the internet may not be possible.

• A fi xed static IP address or a fi xed IP domain host

name.

• Enabled port forwarding on the Firewall of the

router/switch. This is only if a fi rewall is used.

• On earlier versions, antivirus software is initially

provided by WattMaster Controls, with Norton

antivirus software for a period of 1 year. The

customer must maintain the antivirus software after

this 1-year period. Later versions are shipped with

Linux as the operating system and do not require

anti-virus software.

• An Email address that supports a SMTP

server for SENDING with a pop server for

RECEIVING Emails, and it must have “auth

login” authentication. TLS or SSL modes are not

supported. WattMaster Controls can provide an

Email address with these requirements.

• An Uninterruptible Power Supply (UPS) – 750-

Watt minimum

• A wall mounting surface is preferred.

• A dedicated 120VAC power circuit is required.

Front End Software Requirements

(Operator Console Software):

• A Microsoft Windows XP /Vista/Windows 7-based

computer.

• Minimum hardware specifi cation for the Microsoft

Windows XP / Vista based computer is a Pentium

IV running at 2.4 Giga Hertz with at least 1 GB

of RAM, and 10 GB of spare hard drive space. A

CDROM/DVD player is also required for software

installation.

• WCC III software package – Provided on a

CDROM, or is available via a download on the

WCC Controls website: www.wcc-controls.com.

The installation CDROM contains the following

programs:

WCC III.EXE (SS5021)

WCCUTILITY.EXE (SS5023)

SCUSCR.EXE (SS5026)

WCC3Trendlog.EXE (SS5028)

TenantReport.EXE (SS5025)

TenantOverride.EXE* (SS5024)

WGCC3.EXE (SS5029)

WCC3 Download (SS5030)

WCC3 Guest (SS5022)

• The CDROM part number (WattMaster Part #

DM1WC011-01X, were “X” = revision level)

• A DSL or Cable router/switch that connects to the

internet, or access to the internet via some other

method. Or, as an alternative, an internal jobsite

IP network that does not connect to the internet,

but when using this internal jobsite IP network, the

external internet Email of alarms from the WCC III

- MCD may not be possible.

* NOTE: The TenantOverride.exe program is also available

as a single program installation for the end users that are using

the simplistic graphical interface of the TenantOverride.exe

screen to locally turn on and off specifi c control points that are

applicable to the end user.

WCC III Technical Guide

12-1

Page 4

12. WCC III INSTALLATION

Basic Operating Conditions and Wall Mounting

The WCC III – MCD Basic Operating

Conditions

The WCC III - MCD must be kept in a clean and dry area in the

building. The ambient temperature must be between 50 and 100 °F,

and the relative humidity must be kept between 0 and 90% (noncondensing). The interior components are cooled by ventilation

fans within the WCC III – MCD unit, and therefore the unit should

not be kept in tightly confi ned or enclosed areas. The WCC III -

MCD is primarily designed to mount on a wall with the supplied

brackets.

The WCC III – MCD computer requires 115 VAC power and must

remain powered at all times for proper operation and control. The

115 VAC power circuit must be separate and dedicated exclusively

to the WCC III – MCD computer.

The WCC III - MCD system is designed to automatically restart

after a power failure. However, the industrial computer which

acts as the WCC III Master Communications Device will not

automatically reboot unless the power is shut off cleanly and

then restored cleanly. During most power outages, the incoming

115 AC voltage could have great fl uctuations before the power

fi nally fails. In a like manner, brownouts will usually cause the

industrial computer to “lock-up.” That is to say, the screen will

continue to display on the monitor, but the cursor will not respond

to the keyboard commands. To prevent this “lock-up” issue from

happening to the WCC III – MCD, an Uninterruptible Power

Supply (UPS) is required on each and every WCC III – MCD

computer.

An Uninterruptible Power Supply (UPS) provides emergency

power to keep the WCC III Master Communications Device

(personal computer) on-line for several minutes after a primary

power failure. The UPS regulates the incoming power to the

computer and shuts the power off cleanly several seconds after the

power outage, or brownout. When the primary power is restored,

the UPS brings the MCD back on-line automatically. The WCC

III system does not lose any information since all of the programs

and user entered data are stored on either a disk in the MCD, on

fi rmware, or on battery backed memory in the satellite controllers.

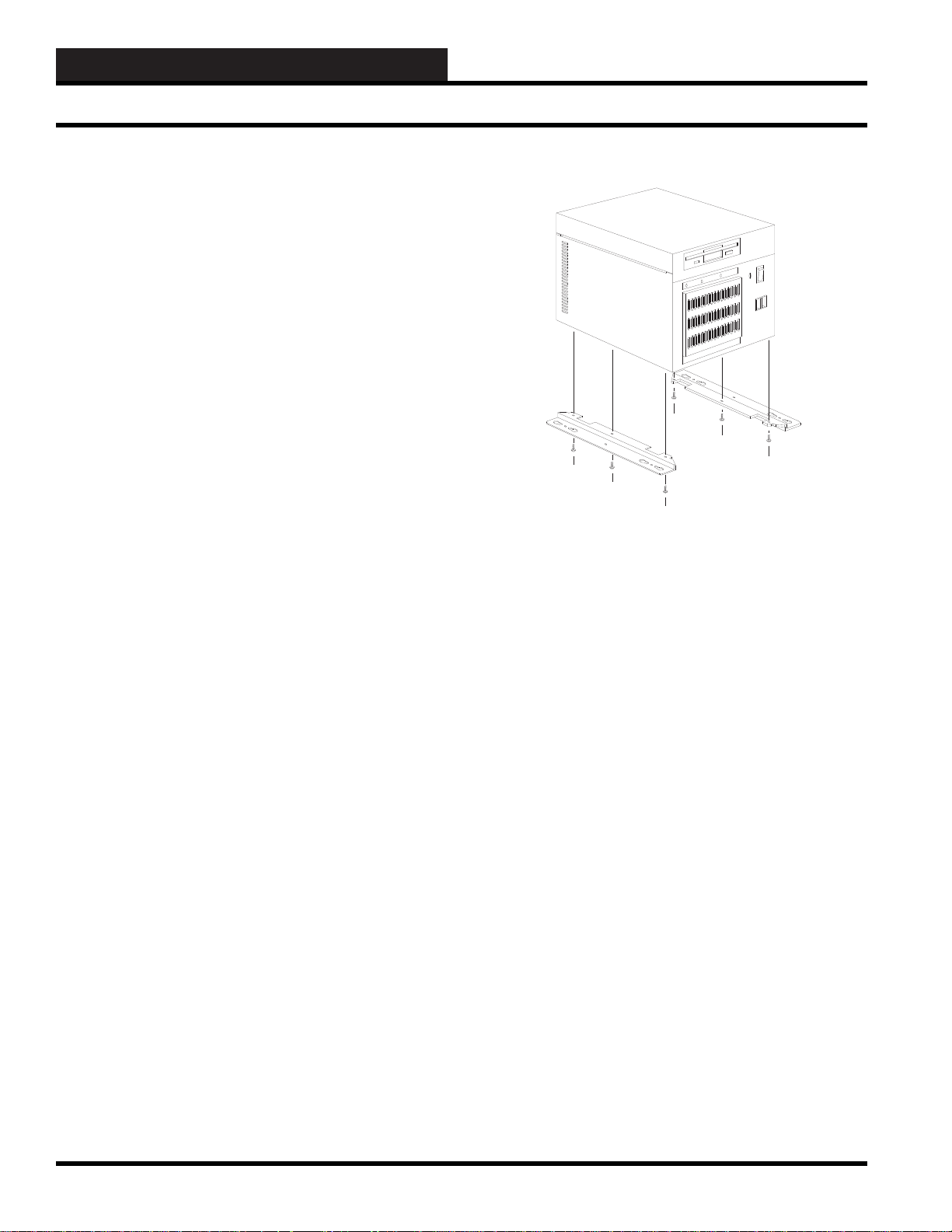

Figure 12-1: Installing the six screws for the two wall

mounting brackets of the WCC III – MCD Computer

Do not mount the WCC III – MCD computer straight into the

drywall. The use of a ¾-inch plywood “Backer Plate Board” is

required. You may want to paint this plywood “Backer Plate

Board” to match the color of the wall before mounting to the wall.

See Figure 12-2 for further application.

Backer Plate Mounting Notes:

Use correct type of wall mounting anchors for mounting on a

concrete wall for the mounting of the “Backer Plate Board” if and

when mounting the Backer Plate Board to a concrete wall. Use

at least 2-inch dry wall type screws if mounting the Backer Plate

Board to a “Dry-Wall” type wall. Mount the “Backer Plate Board”

so that the screws that are holding the “Backer Plate Board” are on

the 16-inch centers of the wall studs where applicable.

Mount the WCC III - MCD 4-½ to 5-½ feet off of the ground on a

suitable wall, in an air conditioned space. This area should not have

any radio transmitting or telephone switching gear in the space, or

near the space, or located on the back side of the adjacent wall.

Wall Mounting of the WCC III – MCD

It is strongly suggested that the WCC III – MCD is mounted on the

wall. General guidelines are as follows:

Always install the supplied six screws for the two supplied wall

mounting brackets for the WCC III – MCD Computer as shown in

Figure 12-1. Be sure to tighten the six screws so that they do not

loosen over time.

12-2

Do not block the airfl ow vents that are coming out of the WCC III-

MCD. Do not apply paint to the WCC III-MCD enclosure. Do not

cover the WCC III-MCD with any protective plastic while painting

with the WCC III-MCD turned on. The UPS battery backup unit

should be located within 3 or 4 feet of this WCC III – MCD.

WCC III Technical Guide

Page 5

12. WCC III INSTALLATION

Wall Mounting of the WCC III - MCD

Wall Mounting of the WCC III - MCD

Front view with wall mounting brackets

GUIDE

Use 3/4 inch plywood for the backer plate board

(supplied by others)

Figure 12-2: Wall mounting instructions for the WCC III – MCD

NOTES:

at least 2-inch dry wall type screws. Mount the backer plate board so that the screws that are holding the backer plate board are on the 16inch centers of the wall where applicable.

Mount the WCC III - MCD 4-½ to 5-½ feet off of the ground on a suitable wall in an air conditioned space. This space should not have any

radio transmitting or telephone switching gear in the space, or near the space, or located on the back-side of the adjacent wall.

Do not block the airfl ow vents that are coming out of the WCC III - MCD. Do not apply paint to the WCC III - MCD enclosure. Do not

cover the WCC III - MCD with any protective plastic while painting with the WCC III - MCD turned on.

The UPS should be located within 3 or 4 feet of this WCC III - MCD.

WCC III Technical Guide

Use approved anchors when mounting backer plate board on a concrete wall. If mounting backer plate board to dry wall, use

12-3

Page 6

12. WCC III INSTALLATION

WCC III - MCD Internet Access

WCC III – MCD Internet Access

The most common question asked is: Why does the WCC III –

MCD computer need to have Internet access?

If WattMaster Controls factory assistance or troubleshooting is

required for a WCC III system, a representative from the factory

can access the system with a remote computer and view the same

WCC III Screens as the end user or contractor in the building. This

allows the end user or the contractor for the building installation to

talk to the factory representative while they are both viewing the

same screens.

The Emailing of important alarm notifi cations for up to 60 Email

Addresses is provided for from the WCC III – MCD.

The ability to send alarm notifi cation via a text message to a

cellular phone.

Secure Remote communications package (WCC III software) is

provided for FREE. A CD-ROM is supplied for installation.

World-wide, multiple remote connections (up to 255 simultaneous

connections possible)

On earlier versions, antivirus software is initially provided by

WattMaster Controls, with Norton antivirus software for a period

of 1 year. The customer must maintain the antivirus software after

this 1-year period. Later versions are shipped with Linux as the

operating system and do not require anti-virus software.

The ability for internet based tenant override requires internet

access.

WCC III – MCD Cable Modem/Router

T echnical Considerations

The WCC III-MCD uses internet access to e-mail alarms and to

provide remote IP access for multiple remote WCC III operator

programs.

The DSL / Cable modem USB connection should not be connected

to any of the USB ports on the WCC III – MCD. The DSL / Cable

modem Ethernet connection should only be connected to the

Ethernet port on the WCC III – MCD if the DSL / Cable modem

has a built-in internal router with Ethernet switch.

The use of a DSL / Cable modem with an external router that is

then connected to the WCC III - MCD is also a recommended way

to connect the internet to the WCC III – MCD. The use of only a

plain DSL / Cable modem without an internal router with a built-in

switch is not currently recommended by WattMaster Controls.

It is recommended that the WCC III-MCD computer be connected

to the internet via a high-speed cable modem or NAT enabled

router.

This is best accomplished by what is called Port Forwarding (also

sometimes referred to as tunneling) and is the act of forwarding a

network port (located External on the internet) to another network

node (located Internal on the LAN). This technique can allow an

external user (The WCC III program) to reach a port that is on

a private LAN (Local Area Network) IP address (The WCC III MCD) from the outside via a NAT enabled router. This external

port number that is used for the WCC III – MCD computer is port

39289.

Custom remote WCC III system programming or analyzing of the

existing WCC III program is also available for a nominal charge.

Some cable modem devices may incorporate a router along with

the cable modem functionality, to provide the LAN with its own IP

network addressing. From a data forwarding and network topology

perspective, this router functionality is typically kept distinct from

the cable modem functionality (at least logically) even though

the two may share a single enclosure and appear as one unit. So,

the cable modem function will have its own IP address and MAC

address as will the router.

Figure 12-3: Typical small business type routers—a Broadband Firewall Router, and a Cable/DSL VPN Router

12-4

WCC III Technical Guide

Page 7

12. WCC III INSTALLATION

GUIDE

WCC III - MCD Internet Access

In a typical WCC III - MCD networking setup, internet access

is through a DSL or Cable modem. This modem may then be

connected to a router with a built in switch, (or typically the router

with switch is also built-in to the modem) which is then connected

to the internal LAN of networked computers by Ethernet cabling.

The NAT enabled router is the only device that the Internet sees

as it holds the public IP address. On the other hand, the WCC III

– MCD, located behind the NAT enabled router, is invisible to the

Internet as it holds a local IP address on the NAT enabled router.

Port forwarding is necessary in the NAT enabled router because

computers that are running the WCC III program will send

information that is directed to the public IP address and the NAT

enabled router needs to know where to send and then redirect that

information to the WCC III – MCD.

NOTE: A DSL modem is not recommended due to yet

another layer of setup complexity. DSL modem/routers also

have a maximum distance from the local telephone company’s

main central offi ce. That distance is 18,000 feet.

Step 1: You will need a high-speed cable or DSL modem/router

that is NAT enabled and it must be setup by the ISP, or by IT

(Information Technology) knowledgeable personnel, and it must

also be connected to the Internet.

The default IP addresses that the WCC III – MCD is shipped with

are:

WCC III-MCD IP Address: 192.168.100.100

WCC III-MCD Subnet Mask: 255.255.255.0

WCC III-MCD Default Gateway: 192.168.100.1

WCC III-MCD Preferred DNS Server: 208.67.222.222

WCC III-MCD Alternate DNS Server: 208.67.220.220

The external port number that is used for the WCC III – MCD

computer is port 39289.

For WCC III – MCD’s running windows set up the WCC III –

MCD BACKTASK.EXE Program

Com Port # ____________

External Port Range ____________

Default for the backtask.exe program is Comm port # 5 and port

# 39289.

Step 2: The following three items are needed from your ISP

(Internet Service Provider) in order to set up the Cable / DSL

modem/router for stand alone internet access. The ISP should

have already supplied a sheet of paper that has this important

information on it.

WCC III-MCD IP Address: _______._______._______._______

WCC III-MCD Subnet Mask: _______._______._______.______

WCC III-MCD Default Gateway: _______.______.______._____

WCC III-MCD Preferred DNS Server: _________._________.__

______._______

WCC III-MCD Alternate DNS Server: _________._________.__

______._______

WCC III Technical Guide

12-5

Page 8

12. WCC III INSTALLATION

WCC III - MCD Internet Access

Supported Networks

Only Microsoft based networks are currently supported by the

WCC III system. Any of the older 10 base T only networks are

not supported by the WCC III system, only 100 base T or faster

networks are supported. (10/100 base T are OK) The slower the

network, the slower the data returned from the WCC III-MCD will

be displayed, and the faster speed is always better.

Also, network “hub” devices are not recommended, because

“hub” devices divide the network’s bandwidth amongst the active

connections that are connected to the network hub. For example,

if you have a 16-port network hub on a 100 base T connection

with 10 active connections, then your effective network speed is

the same as a 10 base T connection.

A 10/100 base T network switch is the recommended connection

to the WCC III-MCD device. A network switch device has a full

100 base T connection to all active ports at the same time.

Benefi ts of Using a Separate DSL /

Cable Modem Internet connection for

the WCC III-MCD

1. It provides a layer of network isolation. A connection to the

building’s internal computer network may not be desirable to the IT

department. If the WCC III – MCD is connected to the building’s

internal computer network an additional fi rewall into the building’s

internal computer network may be required.

2. A dedicated high speed internet connection is a faster connection.

WCC III displayed data will be displayed quicker and updated

faster.

How to send a T e xt Message to a

Cellular phone via an Email from the

WCC III system

Most cellular telephone providers have as a free* option (Charges

may apply in some instances) an Email-to-TEXT service for their

cellular phone plans. *Usually the cellular telephone providers

will have an unlimited text messaging option in one or more of

their plans.

When using Verizon cellular service, the text messaging email

address for your phone is your 10-digit phone number followed

by @VTEXT.com. For example, if your phone number is 1-555555-5555, your email address (for TEXT MESSAGING) would

be 5555555555@VTEXT.com

When using Sprint cellular service, the text messaging email

address for your phone is your 10-digit phone number followed by

@messaging.sprintpcs.com. For example, if your phone number

is 1-555-555-5555, your email address (for TEXT MESSAGING)

would be 5555555555@messaging.sprintpcs.com.

When using AT&T cellular service, the text messaging email

address for your phone is your 10-digit phone number followed

by @txt.att.net. For example, if your phone number is 1-555-5555555, your email address (for TEXT MESSAGING) would be

5555555555@txt.att.net.

Example: 5555555555@VTEXT.com, 5555555555@messaging.

sprintpcs.com, or 5555555555@txt.att.net would be programmed

into the WCC III System parameters screen as an Email address.

Any alarm type level that is generated would be sent to that cellular

telephone number as a text message.

3. Network outages should be less frequent, due to the fact that

there is no overhead of a pre-existing internal computer network.

A pre-existing internal computer network will always require

periodic “downing of the network servers” to do maintenance

work to the existing computer network regardless of having the

WCC III-MCD connected to the pre-existing internal computer

network.

4. The need for having an onsite IT person to setup, and then

administer the WCC III-MCD will be reduced.

5. Setup and maintenance of e-mail accounts would be easier,

because they would be automatically provided by the Internet

Service Provider.

12-6

WCC III Technical Guide

Page 9

12. WCC III INSTALLATION

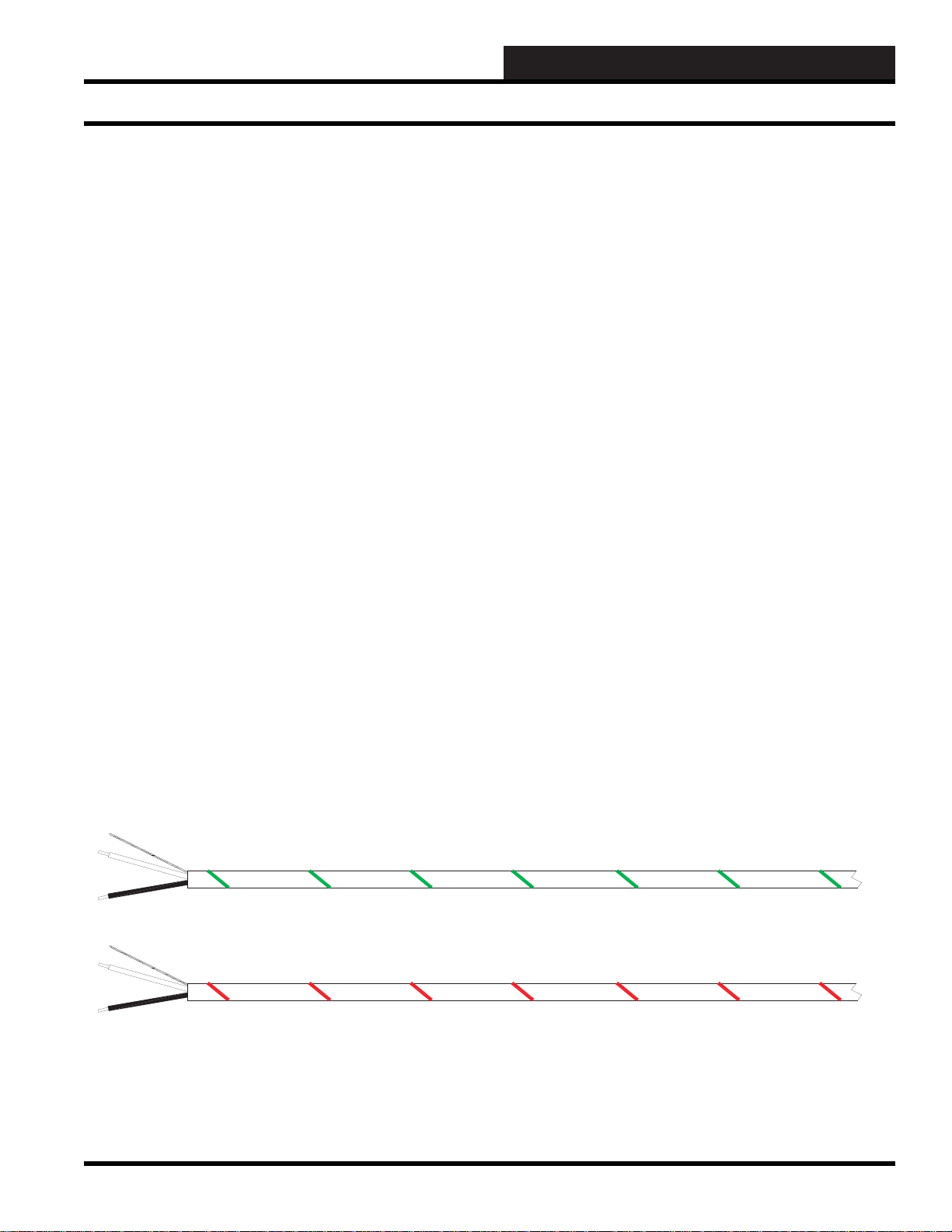

<<<LOCAL LOOP>>> AZWR-LL-WG-18>>> E76191 CL2P 18AWG (UL) 012112 FT

<<<NETWORK LOOP>>> AZWR-NL-WR-18>>> E76191 CL2P 18AWG (UL) 012112 FT

WATTMASTER LOCAL LOOP WIRE

WATTMASTER NETWORK LOOP WIRE

GUIDE

RS-485 Communication Wiring

The WCC III System RS-485

Communication Wiring

The WCC III - MCD can communicate with up to 239 satellite

controllers via a two-wire RS-485 communication loop. On the

back of the WCC III – MCD there are two RS-485 communication

loop ports that come as standard. Each one of these communications

loop ports can communicate with up to 60 satellites for a total of

120 satellites.

Two more additional RS-485 communication loop ports can be

added at an additional cost for any WCC III system that has more

than 120 satellites. The two-wire RS-485 communication loop

should be stranded 2 wire twisted pair of 18-gauge wire with a

shield wire, and it also must be plenum rated were applicable.

The use of stranded wire is mandatory to ensure a good connection

with the ¼ inch Sta-Con connectors which are used to terminate

the wires at the satellite controllers. The RS-485 communication

wire does not have to be run from each satellite controller back to

the WCC III – MCD, but rather the RS-485 communication wire

can be “daisy-chained,” which means that only one twisted pair of

wires is connected to each of the WCC III - MCD communications

loops. The maximum allowable length of wire from the WCC

III - MCD to the farthest satellite is 4000 feet per RS-485

communications loop.

The RS-485 wire specifi cations are generally a stranded 18-

gauge - 2 wire twisted pair with shield. 18-gauge stranded wire is

mandatory to ensure a good connection with the ¼ inch Sta-Con

connectors, which are used to terminate the wires at the WCC III

- MCD and at the satellite controllers. The old SAT II Manchester

communications loop was supposed to have used a 2-wire twisted

pair with shield, but this was not used in every installation. This

old SAT II communications loop should not be used for the new

SAT III communications loop. A new RS-485 communications

loop should be ran to each new replacement SAT III controller.

The shield wire must be used on the new SAT III controller, as

it provides a “ground” reference for the RS-485 communication

loop. WattMaster Controls sells two versions of 18-gauge - 2-wire

twisted pair with shield communications wire— (1) WattMaster

part #WR-NL-WR-18 which is marked “Network Loop” with a

red stripe for rapid identifi cation. This connection is intended to

run from the WCC III – MCD to the SAT III, SAT 3C/D/F, SAT

3P, and then to the next SAT 3 type controllers. (2) WattMaster part

# WR-LL-WG-18 which is marked “Local Loop” with a green

stripe for rapid identifi cation for the TUC loops that run from the

SAT 3C/D/F controllers out to the TUC controllers.

“Wire Nuts” on the RS-485 communications loop should be avoided

at all costs. As an alternative to the “Wire Nuts”, WattMaster

Controls has a Power and Switchable RS-485 communications

board, and the WattMaster part number is PL102224. This Power

and Switchable RS-485 communications board can be thought of

as a 24-VAC power and communication distribution system for

the SAT III communications loop, and this board will aid in initial

startup and future troubleshooting of the SAT III communications

loop. These boards should be used on a fl oor-by-fl oor basis. This

Power and Switchable RS-485 communications board is also

available in a small metal electrical enclosure.

Figure 12-4 WattMaster Controls various communications loop wire

WCC III Technical Guide

12-7

Page 10

12. WCC III INSTALLATION

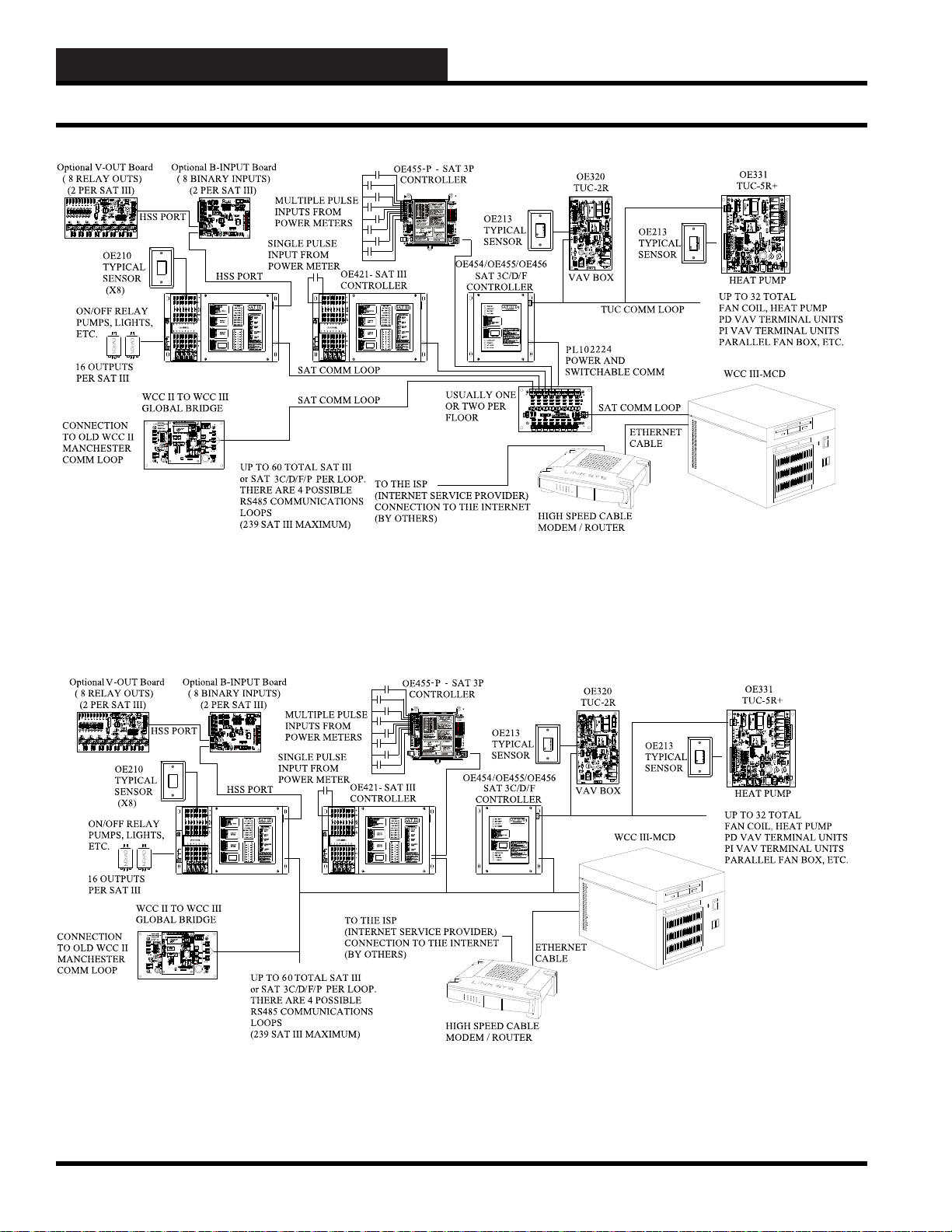

WCC III - MCD Typical System Architecture

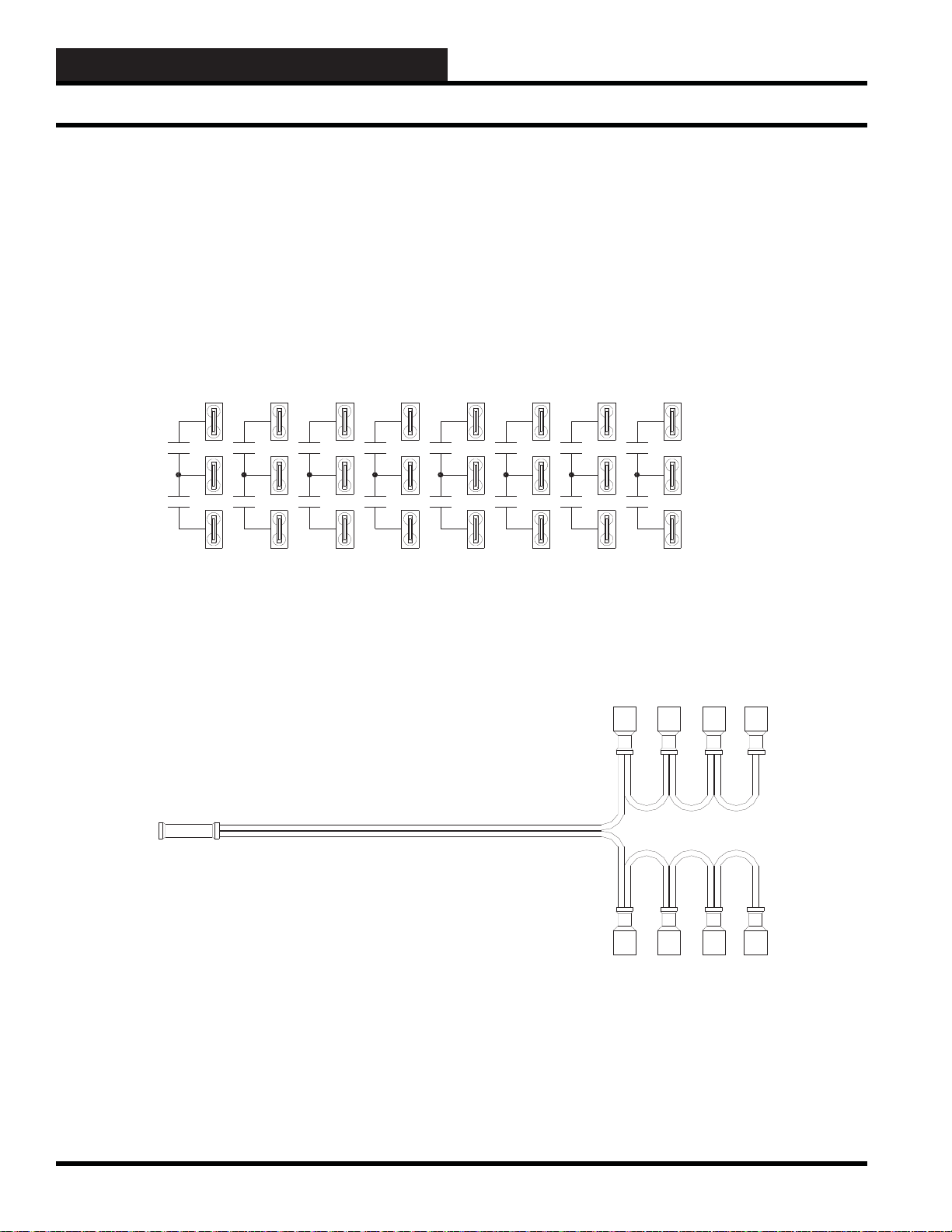

Figure 12-5: The WCC III typical system architecture with POWER and SWITCHABLE COMM boards

Figure 12-6: WCC III typical system architecture without the POWER and SWITCHABLE COMM boards

12-8

WCC III Technical Guide

Page 11

12. WCC III INSTALLATION

GUIDE

WCC III - MCD Typical System Architecture

The wire that makes up the communication loop should be

shielded. Shielded cable has an aluminum jacket over the wires

that could act as an “antenna” to carry away any “stray” electrical

signals that could interfere with the communication process. The

shield should be grounded throughout the SAT Loop.

The SAT RS-485 communication loop wires are connected to the

“R” and “T” and shield terminals on the satellite controllers using

¼-inch Sta-Con connectors. Make sure the polarity is correct.

That is to say, the wire connected to the “R” and “T” terminal on

the MCD must be connected to the “R” and “T” terminal on the

satellite controllers. If the “R” and “T” and shield wires are crossed,

the WCC III system will not communicate. The shield should be

connected together when the cable is cut in order to terminate the

wires at the satellite controller.

The communication loop wire from the WCC III - MCD is

connected to one of the “R” and one of the “T” terminals on the

satellite controller, which is physically located nearest the WCC

III - MCD. The other “R” and “T” terminals located on the satellite

controller can be used to extend the two-wire loop to the next

satellite controller, or the wires can branch off of a two-wire loop

running through the center of a building as shown in Figure 12-6.

NOTE: The shield wire must be connected at each and every

Satellite Controller also.

WCC III Technical Guide

12-9

Page 12

12. WCC III INSTALLATION

8

7

SATADDRESS

2

1

4

8

A3WIREROOM SENSORWILLNOT

REQUIREALOAD RESISTOR WHEN SET

FORA1 VOLT INPUT .

WattMasterControlsInc.

BINARY

INPUTS

BINARY

INPUTS

L8

ON OFF

128

32

16

64

L4

L3

L2

L1

L6

L5

L7

L11

L12

ON OFF

L10

L9

ON OFF

L15

L16

L14

L13

CH

4

3

5

6

2

1

LOCALSET

STATUS2

STATUS3

STATUS1

HSSXMIT

LOCALSET

LOCALSETDISABLE

BATTON/OFF

PULSEINPUT

OPTION1

TEST

OPTION3

OPTION2

ON OFF

STATUS

HSSREC

SATXMIT

SATREC

ANALOGINPUT

JUMPERSELECTION

A2WIREROOM SENSORWILLREQUIRE

A300OHM LOAD RESI STOR WHEN SET

FORA1 VOLT INPUT .

A4TO2 0 mA SENSOR WILLREQUIREA

50OHMLOAD RES ISTOR WHEN SE T FOR

A1VOLTINPUT, ORA 250 OHM LOAD

RESISTORWHENSETFO R A 5 VOLT INPUT.

CURRENT

INPUT

THERMISTOR

INPUT

0-1V

0-5V

0-10V

THERM

0-1V

0-5V

0-10V

THERM

0TO10V

INPUT

0TO5V

INPUT

0TO1V

INPUT

0-10V

0-1V

0-5V

0-10V

THERM

0-1V

0-5V

THERM

0-1V

0-5V

0-10V

THERM

PROGRAMMABLE CO NTROLL ER

SAT III

H

C

COM

CHANNEL

2134

2134

567

8

5678

V

OUT

GND

L

O

A

D

+V

ATI

10A250VAC~

5A30VDC

SA

VDE

G5Q-1A4

OMRON

DC24V

CHINA

10A250VAC~

5A30VDC

SA

VDE

G5Q-1A4

OMRON

DC24V

CHINA

10A250VAC~

5A30VDC

SA

VDE

G5Q-1A4

OMRON

DC24V

CHINA

10A250VAC~

5A30VDC

SA

VDE

G5Q-1A4

OMRON

DC24V

CHINA

EACHCONTACT

ISRATEDFOR

24VACOR VDC

@.5AMPMAX

0-15VDC

OUTPUT

MINLOAD

IS1KOHM

RESISTIVE

VDCONLY

100VA

TRANSFORMER

SWITCH

DISCONNECT

INTER PANEL

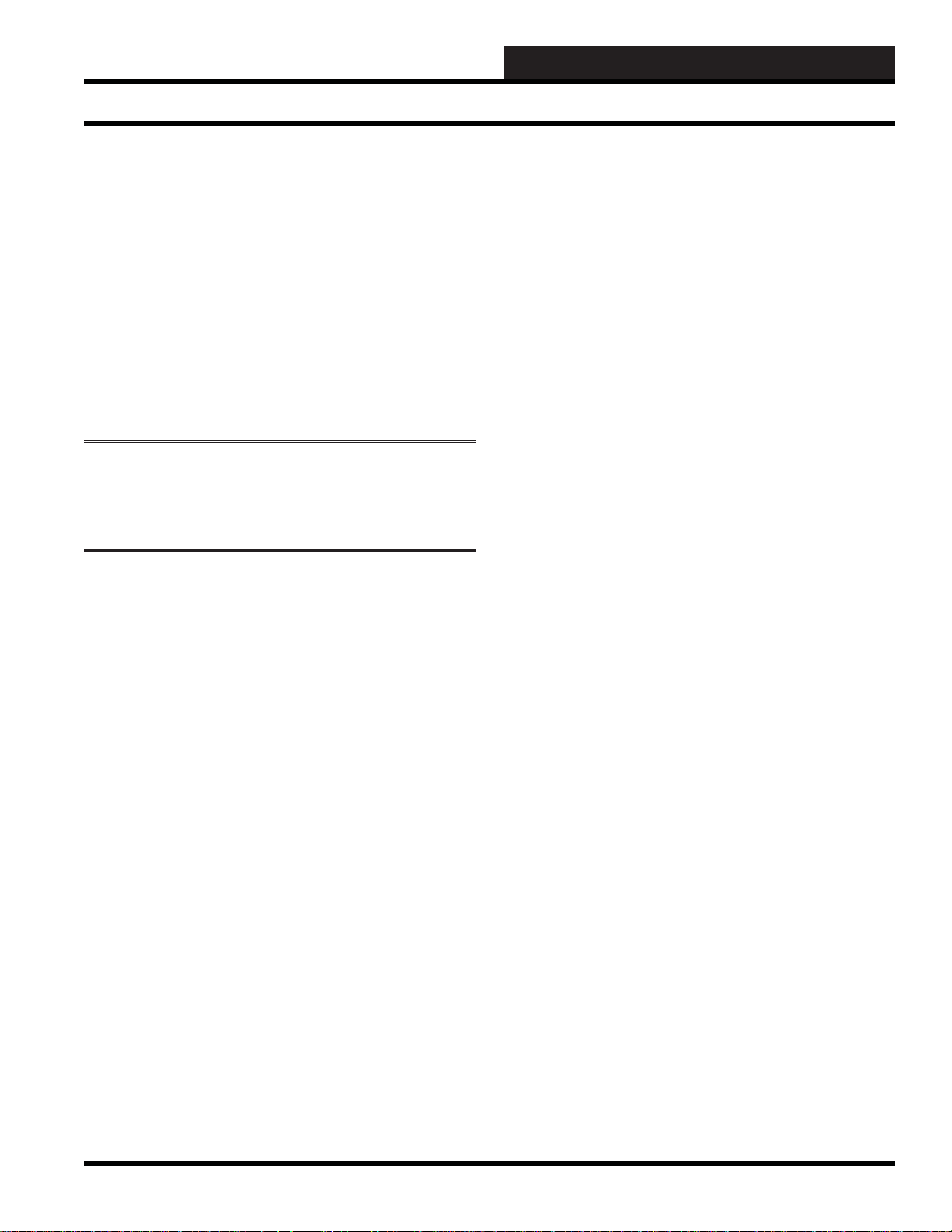

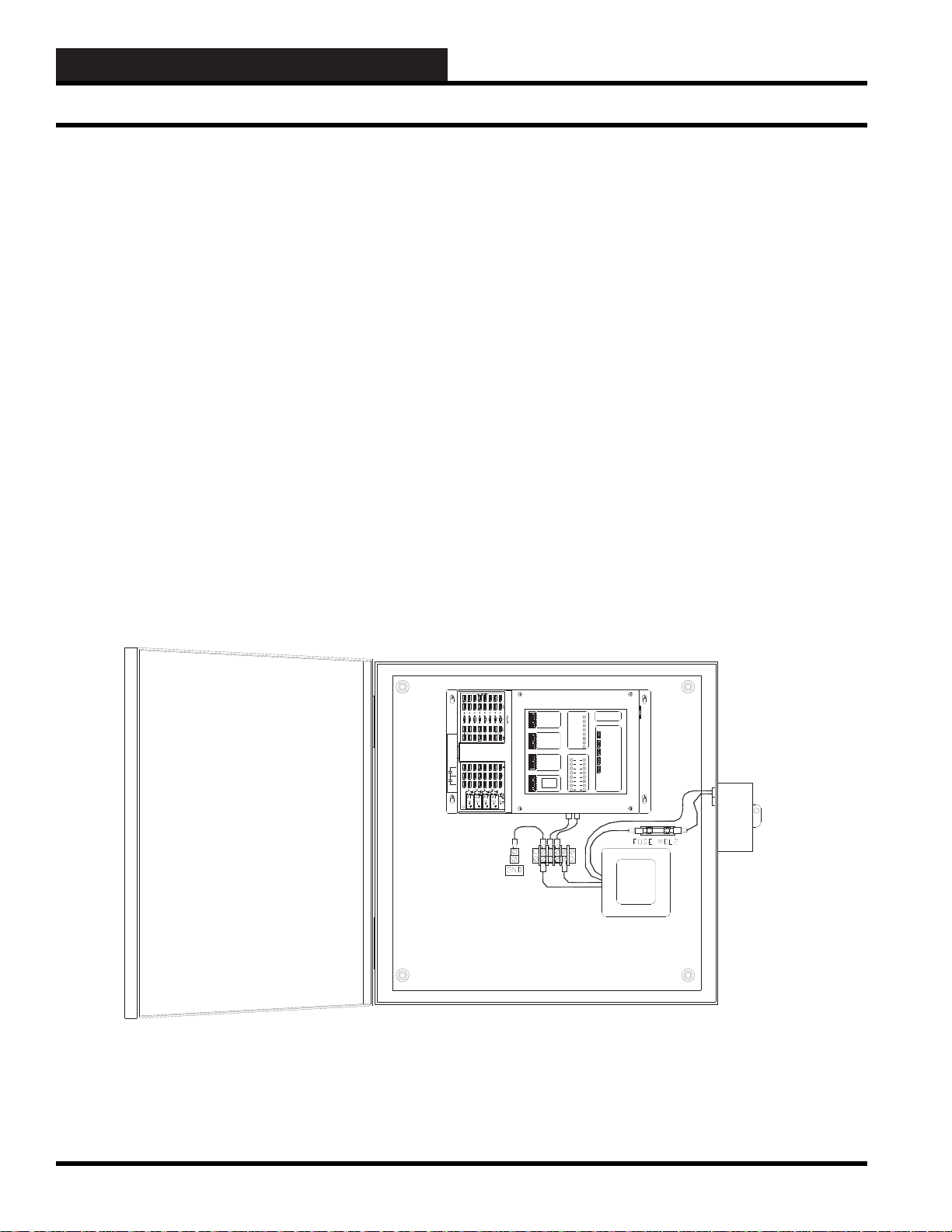

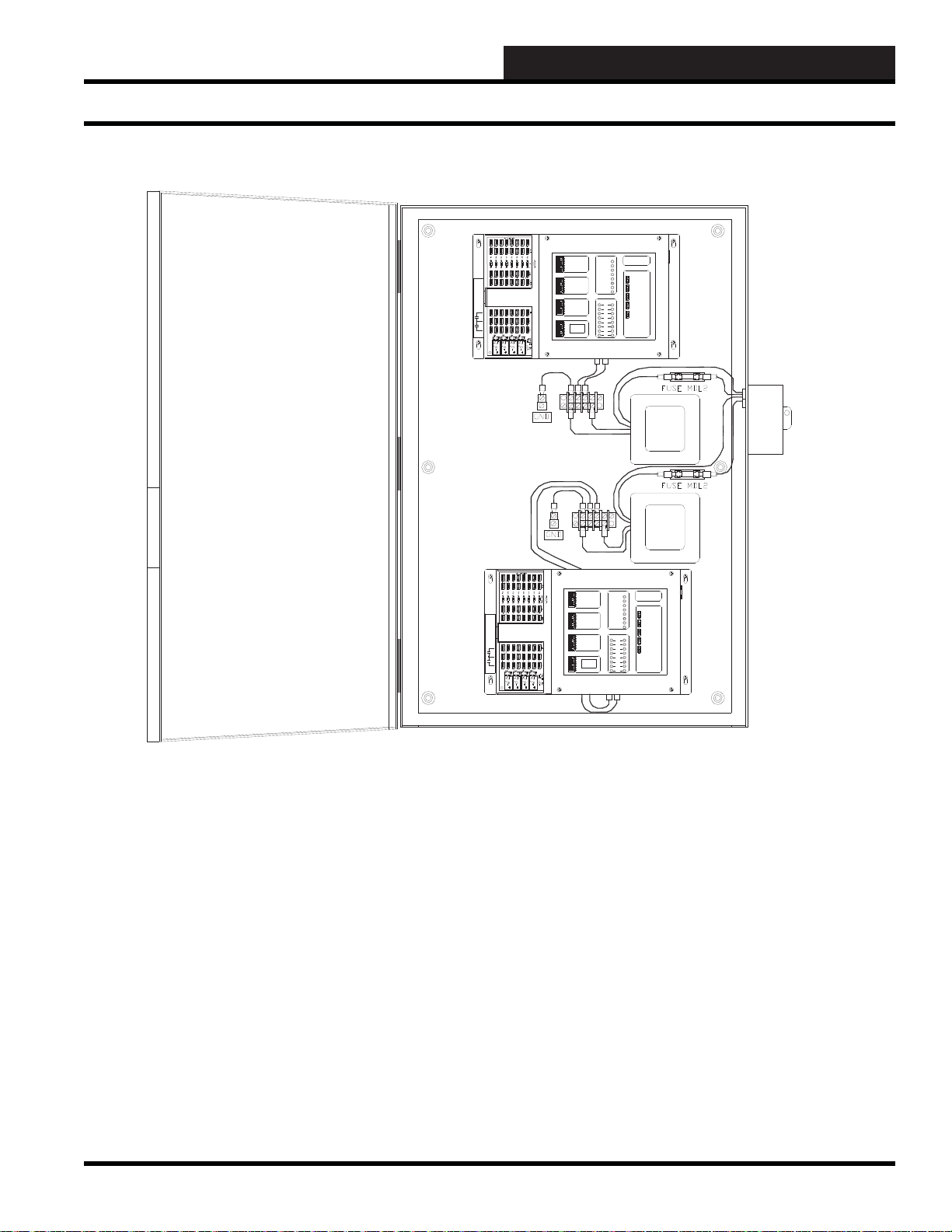

Satellite Controller Enclosure Mounting

Satellite Controller

Mounting in an Enclosure

The satellite controllers are designed to mount in any NEMA 1 or

NEMA 3 standard, six-inch deep, electrical enclosure. Typically,

this is a fi eld-mounted enclosure that contains transformers and

any accessory items required such as a binary input board, V-Out

Binary output board, control relays, etc. The best location for these

satellite panels is mounted on a wall in equipment or storage areas

or rooms at eye level near the controlled loads.

The satellite controllers may be ordered with or without the

NEMA type enclosures. If you order the satellite controller from

the factory without an enclosure, the SAT III and SAT 3C/D/F

dimensions as shown in Figure 12-13 and Figure 12-14 may be

helpful when selecting a suitable NEMA type enclosure.

The satellite controller must be mounted in an electrical enclosure.

If you do not order the satellite controller with an electrical

enclosure, you must provide your own electrical enclosure and

then provide and then install your own fused disconnect switch,

transformer, and terminal strip.

The size of the standard single SAT enclosure is designed to hold

only one satellite controller (or up to two SAT 3C/D/F controllers),

one fused disconnect switch, one transformer, one fi lter, and one

terminal strip which is normally about 15” x 15” x 6” deep with an

inter panel for mounting the SAT III controller, fuse block, 100VA

transformer, etc. The size of the standard dual SAT enclosure is

designed to hold two satellite controllers (or up to four SAT 3C/D/F

controllers), one fused disconnect switch, two transformers, two

fi lters, and two terminal strips is 30” x 18” x 6” deep with an inter

panel for mounting the two SAT III controllers, fuse block, 100VA

transformer, etc. If you install the satellite controller yourself,

make sure you leave room for wires that need to be connected to

the following terminals that are located on the sides of the SAT III

satellite controller (minimum recommended clearance is 2 inches):

You can also have both a SAT III controller and up to two SAT

3C/D/F controllers in the same dual enclosure.

24-VAC power source (100VA recommended)

RS-485 Communication loop

SAT III HSS Port connection

Figure 12-7: A typical SAT III controller in a single electrical panel (120-V AC po wered)

12-10

WCC III Technical Guide

Page 13

12. WCC III INSTALLATION

8

7

SATADDRESS

2

1

4

8

A3WIREROOMSENSORWILLNOT

REQUIREALOAD RESISTOR WHENSET

FORA1 VO LT INPUT.

WattMasterControlsInc.

BINARY

INPUTS

BINARY

INPUTS

L8

ON OFF

128

32

16

64

L4

L3

L2

L1

L6

L5

L7

L11

L12

ON OFF

L10

L9

ON OFF

L15

L16

L14

L13

CH

4

3

5

6

2

1

LOCALSET

STATUS2

STATUS3

STATUS1

HSSXMIT

LOCALSET

LOCALSETDISABLE

BATTON/OFF

PULSEINPUT

OPTION1

TEST

OPTION3

OPTION2

ON OFF

STATUS

HSSREC

SATXMIT

SATREC

ANALOGINPUT

JUMPERSELECTION

A2WIRE ROOMSENSORWILL REQUI RE

A300OHM LOAD RESISTOR WHENSET

FORA1 VO LT INPUT.

A4TO20 mA SENSORWILLREQUIREA

50OHMLOAD RESISTOR WHEN SET FOR

A1VOLTINPUT, OR A 250 OHM LOAD

RESISTORWHEN SET FO R A 5 VOLT INPUT.

CURRENT

INPUT

THERMISTOR

INPUT

0-1V

0-5V

0-10V

THERM

0-1V

0-5V

0-10V

THERM

0TO10V

INPUT

0TO5V

INPUT

0TO1V

INPUT

0-10V

0-1V

0-5V

0-10V

THERM

0-1V

0-5V

THERM

0-1V

0-5V

0-10V

THERM

PROGRAMMABLECONTROLLER

SAT III

H

C

COM

CHANNEL

2134

2134

567

8

5678

V

OUT

GND

L

O

A

D

+V

ATI

10A250VAC~

5A30VDC

SA

VDE

G5Q-1A4

OMRON

DC24V

CHINA

10A250VAC~

5A30VDC

SA

VDE

G5Q-1A4

OMRON

DC24V

CHINA

10A250VAC~

5A30VDC

SA

VDE

G5Q-1A4

OMRON

DC24V

CHINA

10A250VAC~

5A30VDC

SA

VDE

G5Q-1A4

OMRON

DC24V

CHINA

EACHCONTACT

ISRATEDFOR

24VACORVDC

@.5AMPMAX

0-15VDC

OUTPUT

MINLOAD

IS1KOHM

RESISTIVE

VDCONLY

100VA

TRANSFORMER

SWITCH

DISCONNECT

8

7

SATADDRESS

2

1

4

8

A3WIREROOM SENSOR WILLNOT

REQUIREALOADRESISTORWHENSET

FORA1VOLTINPUT.

WattMasterControlsInc.

BINARY

INPUTS

BINARY

INPUTS

L8

ON OFF

128

32

16

64

L4

L3

L2

L1

L6

L5

L7

L11

L12

ON OFF

L10

L9

ON OFF

L15

L16

L14

L13

CH

4

3

5

6

2

1

LOCALSET

STATUS2

STATUS3

STATUS1

HSSXMIT

LOCALSET

LOCALSET DI SABLE

BATTON/OFF

PULSEINPUT

OPTION1

TEST

OPTION3

OPTION2

ON OFF

STATUS

HSSREC

SATXMIT

SATREC

ANALOGINPUT

JUMPERSELECTION

A2WIREROOM SENSOR WILLREQUIRE

A300OHMLOADRESISTORWHENSET

FORA1VOLTINPUT.

A4TO 20 mA SENSOR WILL REQUIREA

50OHMLOAD RESISTOR WHEN SETFOR

A1VOLT INPU T, OR A250OHMLOAD

RESISTORWHEN SETFORA5 VOL T INPUT.

CURRENT

INPUT

THERMISTOR

INPUT

0-1V

0-5V

0-10V

THERM

0-1V

0-5V

0-10V

THERM

0TO10V

INPUT

0TO5V

INPUT

0TO1V

INPUT

0-10V

0-1V

0-5V

0-10V

THERM

0-1V

0-5V

THERM

0-1V

0-5V

0-10V

THERM

PROGRAMMABLECONTROLLER

SAT III

H

C

COM

CHANNEL

2134

2134

567

8

5678

V

OUT

GND

L

O

A

D

+V

ATI

10A250VAC~

5A30VDC

SA

VDE

G5Q-1A4

OMRON

DC24V

CHINA

10A250VAC~

5A30VDC

SA

VDE

G5Q-1A4

OMRON

DC24V

CHINA

10A250VAC~

5A30VDC

SA

VDE

G5Q-1A4

OMRON

DC24V

CHINA

10A250VAC~

5A30VDC

SA

VDE

G5Q-1A4

OMRON

DC24V

CHINA

EACHCONTAC T

ISRATEDFOR

24VACORVDC

@.5AMPMA X

0-15VDC

OUTPUT

MINLOAD

IS1KOHM

RESISTIVE

VDCONLY

INTER PANEL

100VA

TRANSFORMER

GUIDE

Satellite Controller Enclosure Mounting

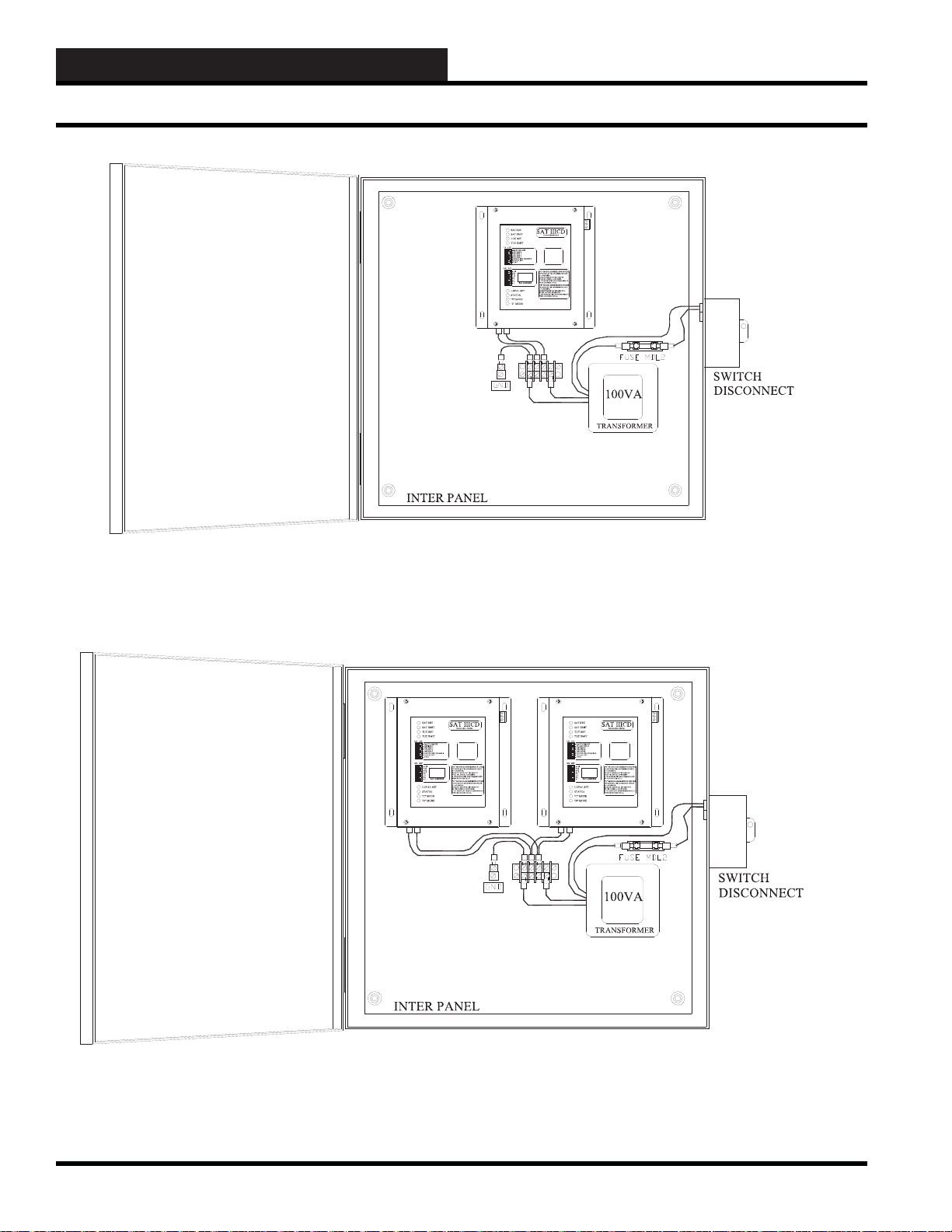

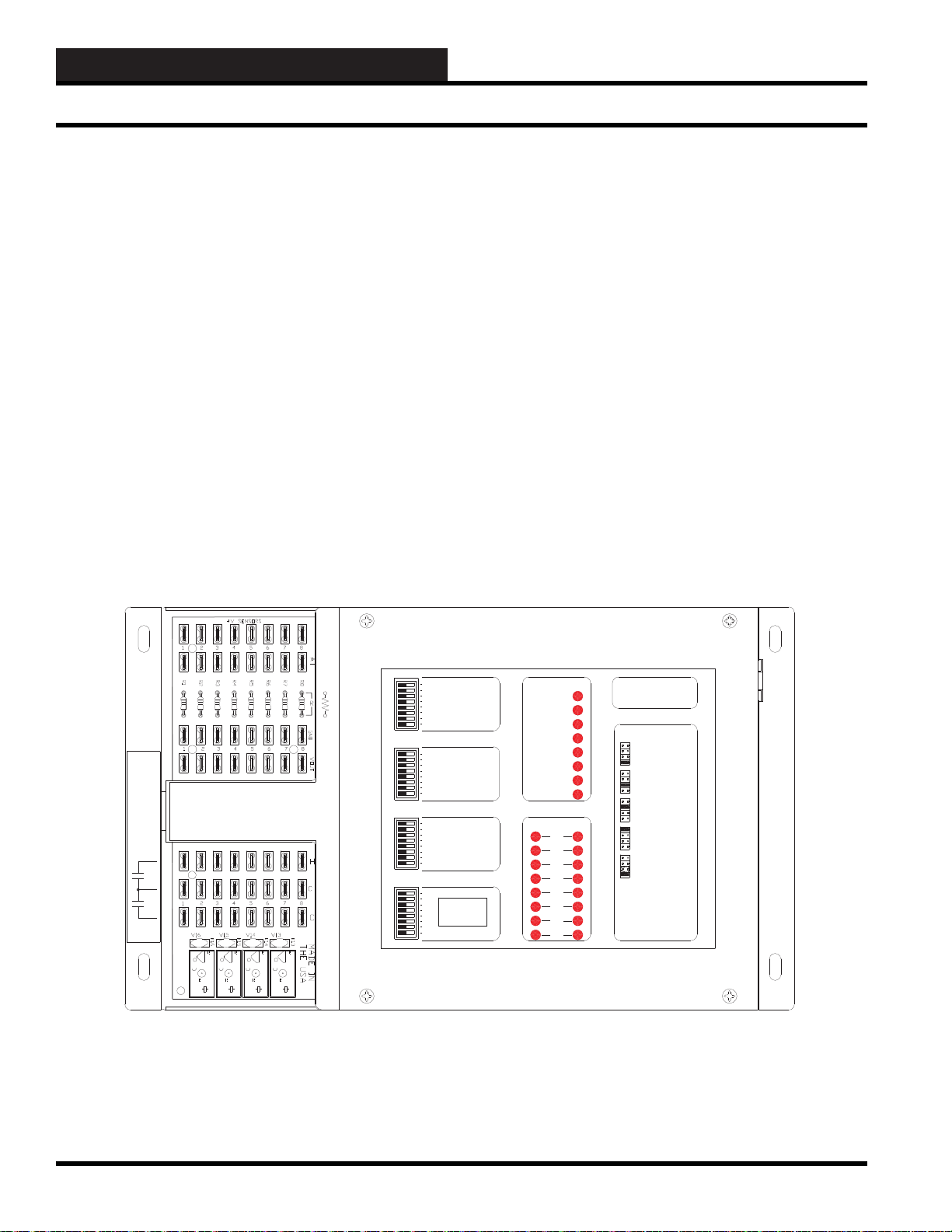

Figure 12-8: Two SA T III controllers in a typical dual electrical panel (120-VA C pow ered)

WCC III Technical Guide

12-11

Page 14

12. WCC III INSTALLATION

Satellite Controller Enclosure Mounting

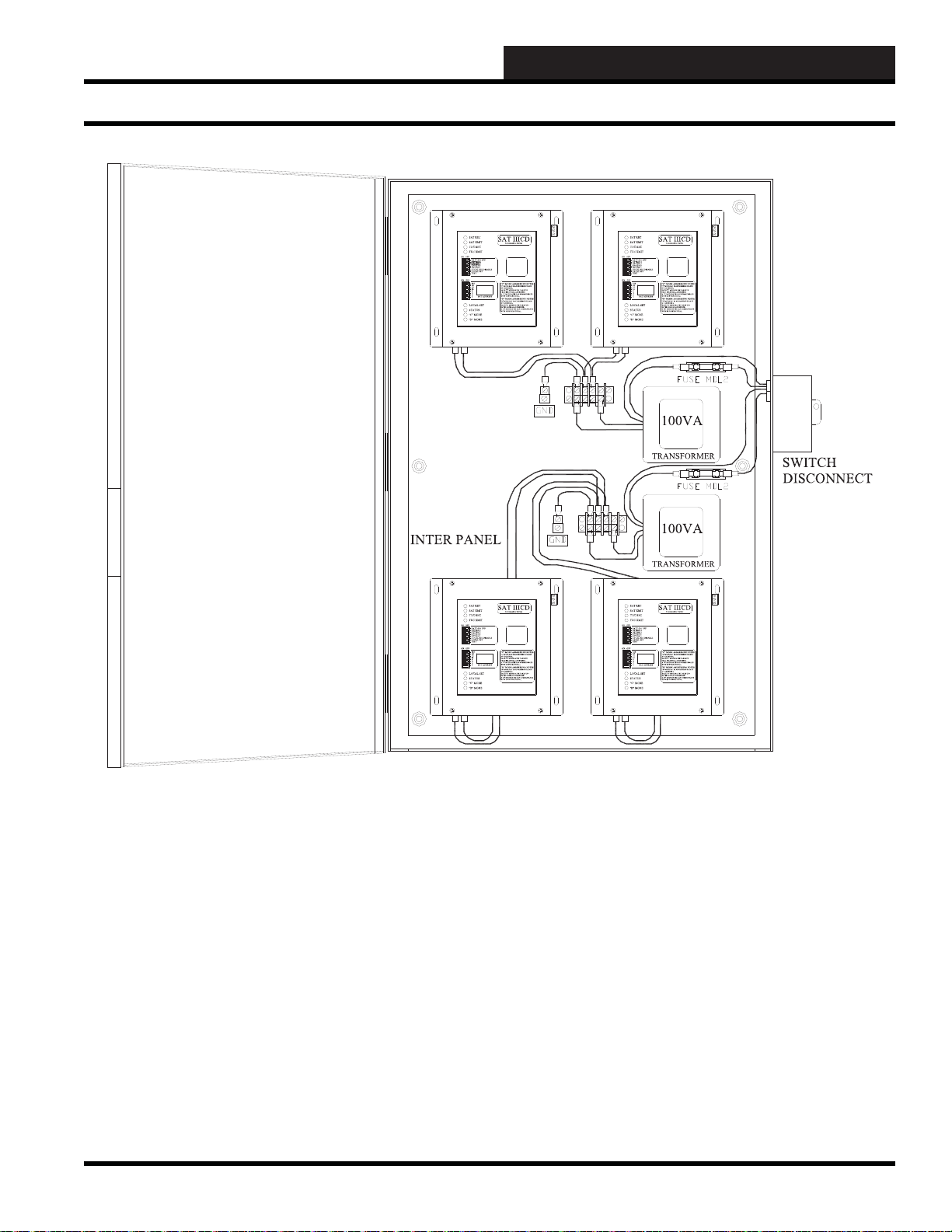

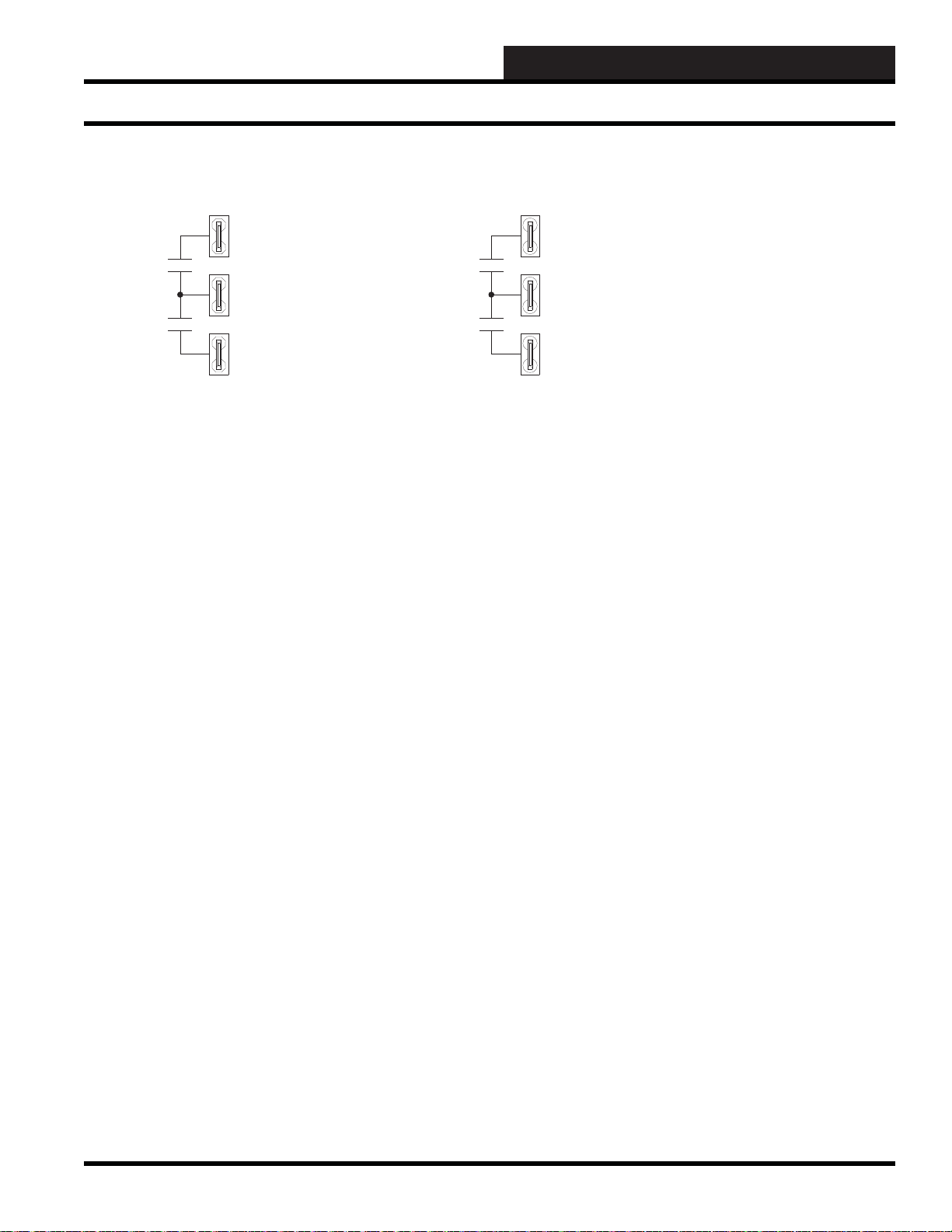

Figure 12-9: A typical SAT 3C/D/F controller in a single electrical panel (120-V AC po wered)

Figure 12-10: A typical SAT 3C/D/F controller in a (single) dual electrical panel (120-V AC po wered)

12-12

WCC III Technical Guide

Page 15

12. WCC III INSTALLATION

GUIDE

Satellite Controller Enclosure Mounting

Figure 12-11: A typical SAT 3C/D/F controller in a (dual) quad electrical panel (120-V A C pow ered)

WCC III Technical Guide

12-13

Page 16

12. WCC III INSTALLATION

GND 24VAC

100VA

2AMP

MDL

BLK

WHT

L

N

ORG

BRN

BLK

WHT

ORG

BRN

24VAC

GND

GND

24VAC

GND

SIG

+V

FLUSHMOUNT

TYPICAL 7 PLACES

SENSOR

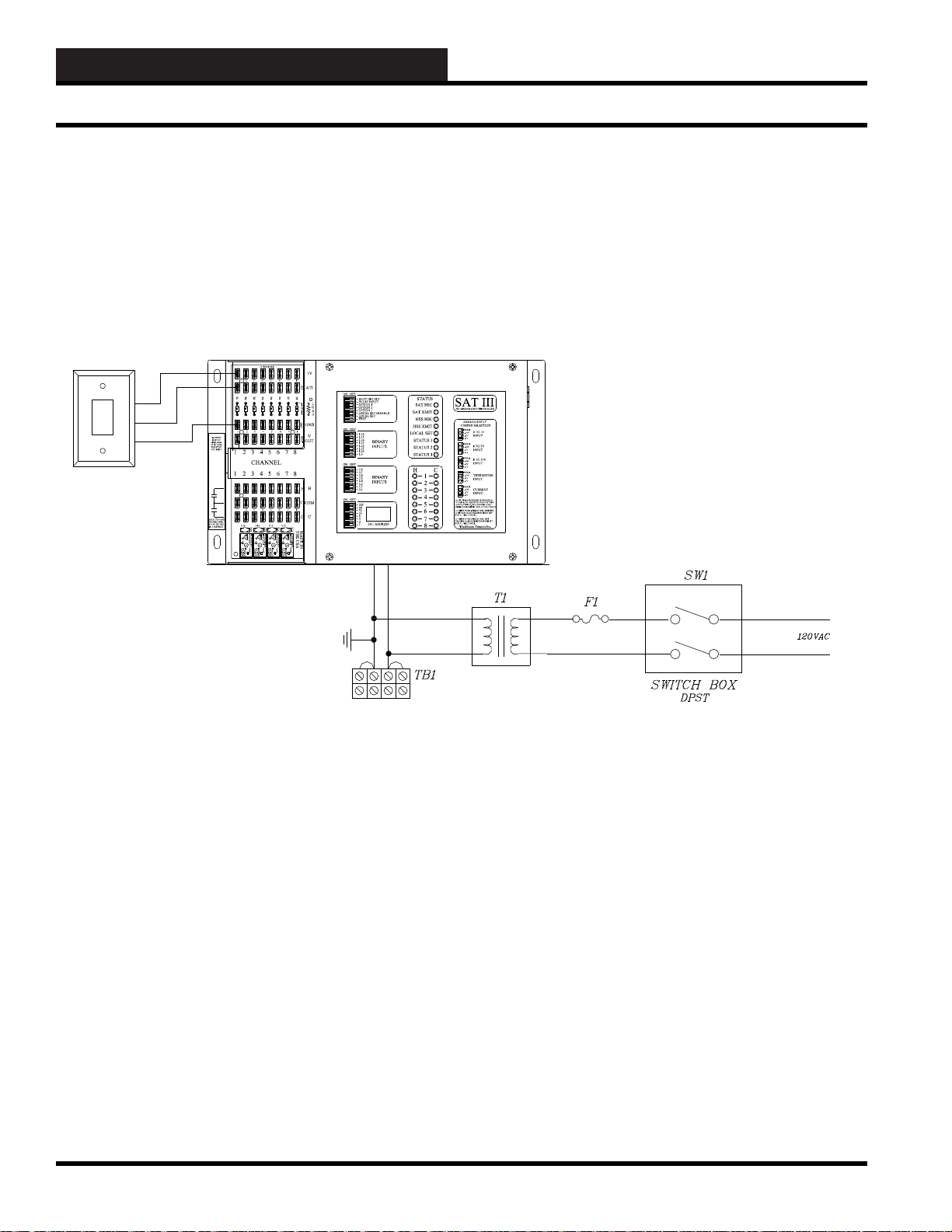

Satellite Controller Wiring

If you order the satellite controller in an enclosure, the factory will

provide and install the wires from the transformer to the satellite.

If you order the satellite controller separately, you must provide a

NEMA panel with an inter panel, disconnect switch, transformer(s),

fusing, terminal block(s), wire, crimp connectors, and then install

the wires from the transformer to the satellite controller. A typical

satellite controller wiring diagram is shown below:

Figure 12-12: SAT III controller typical single panel wiring diagram

12-14

WCC III Technical Guide

Page 17

Satellite Controllers - General Dimensions

8

7

SATADDRESS

2

1

4

8

A3 WIRE ROOM SENSOR WILLNOT

REQUIREA LOAD RESISTOR W HEN SET

FORA 1VOLT IN PUT.

WattMaster Controls Inc.

BINARY

INPUTS

BINARY

INPUTS

L8

ON OFF

128

32

16

64

L4

L3

L2

L1

L6

L5

L7

L11

L12

ON OFF

L10

L9

ON OFF

L15

L16

L14

L13

CH

4

3

5

6

2

1

LOCALSET

STATUS2

STATUS3

STATUS1

HSSXMIT

LOCALSET

LOCALSET DISABLE

BATTON/ OFF

PULSEI NPUT

OPTION1

TEST

OPTION3

OPTION2

ON OFF

STATUS

HSS REC

SATXMIT

SATREC

ANALOGINPUT

JUMPERSELECTION

A2 WIRE ROOM SENSOR WILLREQUIRE

A300OHM LOAD RESISTORWHENSET

FORA 1VOLT IN PUT.

A4 TO 20mA SE NSOR WILLRE QUIRE A

50OHM LOAD R ESISTOR WHENSET FOR

A1VOL T INPUT, OR A 250 OHM LOAD

RESISTORWHENSETFOR A5 VOLTINPUT.

CURRENT

INPUT

THERMISTOR

INPUT

0-1V

0-5V

0-10V

THERM

0-1V

0-5V

0-10V

THERM

0TO10V

INPUT

0TO5V

INPUT

0TO1V

INPUT

0-10V

0-1V

0-5V

0-10V

THERM

0-1V

0-5V

THERM

0-1V

0-5V

0-10V

THERM

PROGRAMMABLE CONTROLLER

SAT III

H

C

COM

CHANNEL

2134

2134

567

8

5678

V

OUT

GND

L

O

A

D

+V

ATI

10A250VAC~

5A30VDC

SA

VDE

G5Q-1A4

OMRON

DC24V

CHINA

10A250VAC~

5A30VDC

SA

VDE

G5Q-1A4

OMRON

DC24V

CHINA

10A250VAC~

5A30VDC

SA

VDE

G5Q-1A4

OMRON

DC24V

CHINA

10A250VAC~

5A30VDC

SA

VDE

G5Q-1A4

OMRON

DC24V

CHINA

123456

123456

+VSENSORS

R1

R212R3R4R5

R6

3456

C

78

C

H

VOUT

GND

7 8

R

R7

R8

78

AT

EACHCONTACT

ISRATEDFOR

24VACORVDC

@.5AMPMAX

0-15VDC

OUTPUT

MINLOAD

IS1K OHM

RESISTIVE

VDCONLY

MADE IN

THEUSA

K16

K15

K14

K13

V16 V15 V14 V13

11.90

11.25

5.85

7.18

GND

24 VAC

24 VAC

POWER

SAT

COMMUNICATION

RT

SHIELD

IN /OUT

HSS EXP

COMM

SATIIISIDE PROFILE VIEW (POWER INPUT)

SATIIISIDE PROFILE VIEW (SAT COMM & HSS PORT)

SATIII SIDE PROFILE VIEW (ANALOG IN/OUT - CONTROL OUTPUT)

3.00

7.18

12. WCC III INSTALLATION

GUIDE

Satellite Controller Dimensions

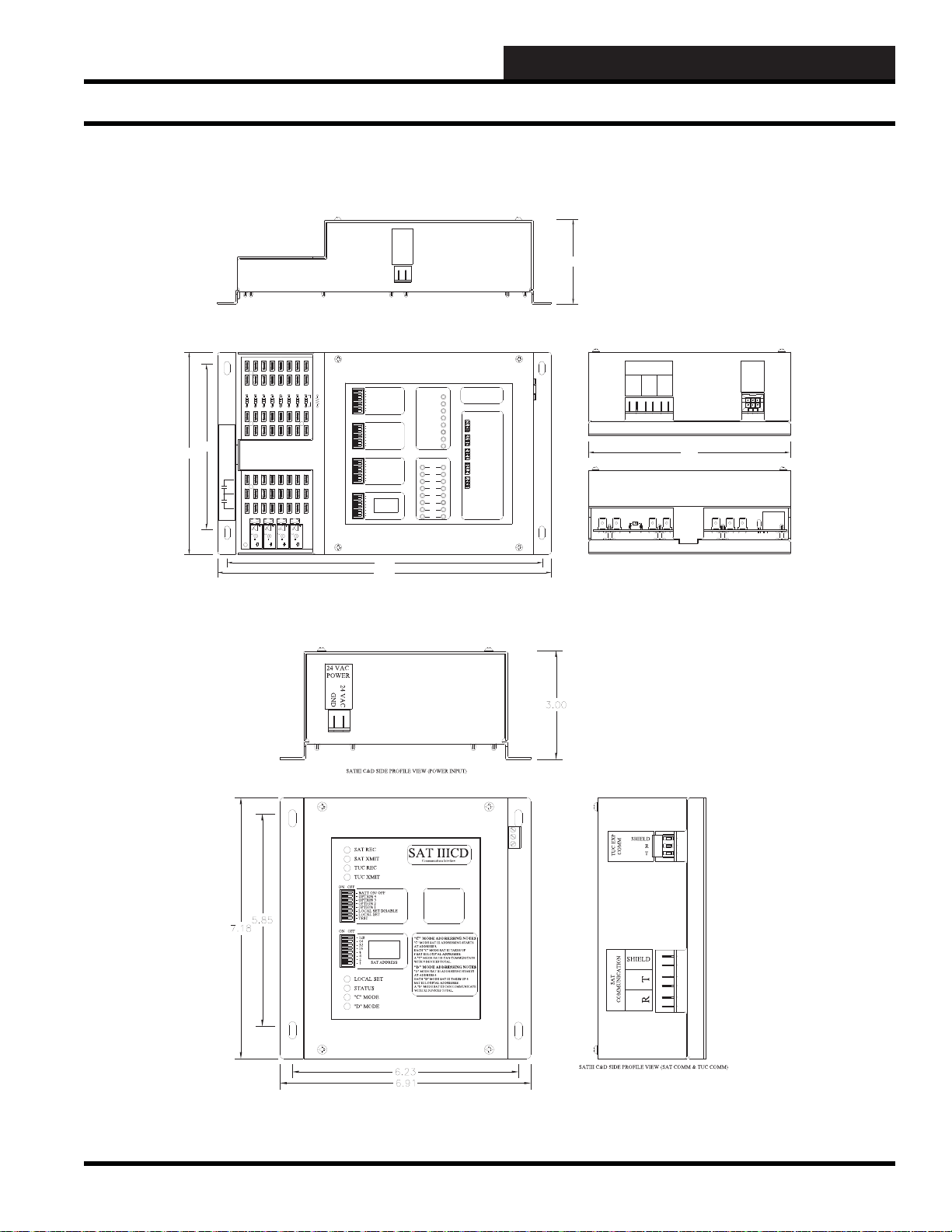

Figure 12-13: SAT III controller dimensions. All dimensions are in inches.

Figure 12-14: SAT 3C/D/F controller dimensions. All dimensions are in inches.

WCC III Technical Guide

12-15

Page 18

12. WCC III INSTALLATION

8

7

SAT ADDRESS

2

1

4

8

A3 WI RE ROOM SENSOR WILL NOT

REQUIRE A LOAD RESISTOR WHE N SET

FORA 1 V OLT INPUT.

WattMaster Controls Inc.

BINARY

INPUTS

BINARY

INPUTS

L8

ON OFF

128

32

16

64

L4

L3

L2

L1

L6

L5

L7

L11

L12

ON OFF

L10

L9

ON OFF

L15

L16

L14

L13

CH

4

3

5

6

2

1

LOCAL SET

STATUS 2

STATUS 3

STATUS 1

HSS XMIT

LOCAL SET

LOCAL SET DISABLE

BATT ON/ OFF

PULSE INPUT

OPTION 1

TEST

OPTION 3

OPTION 2

ON OFF

STATUS

HSS REC

SAT XMIT

SAT REC

ANALOG INPUT

JUMPER SELECTION

A2 WI RE ROOM SENSOR WILL REQUIRE

A30 0 OHM LOAD RESISTOR WHEN SET

FORA 1 V OLT INPUT.

A4 T O 20m A SENSOR WILL REQUIRE A

50OHM LOADRESISTORWHEN SETFOR

A1 V OLT INPUT, OR A 250 OHM LOAD

RESISTORWHENSET FOR A5 VOLT INPUT.

CURRENT

INPUT

THERMISTOR

INPUT

0-1V

0-5V

0-10V

THERM

0-1V

0-5V

0-10V

THERM

0 TO 10V

INPUT

0TO5V

INPUT

0TO1V

INPUT

0-10V

0-1V

0-5V

0-10V

THERM

0-1V

0-5V

THERM

0-1V

0-5V

0-10V

THERM

PROGRAMMABLECONTROLLER

SAT III

H

C

COM

CHANNEL

2134

2134

567

8

5678

V

OUT

GND

L

O

A

D

+V

ATI

10A250VAC ~

5A30VDC

SA

VDE

G5Q-1A4

OMRON

DC24V

CHINA

10A250VAC ~

5A30VDC

SA

VDE

G5Q-1A4

OMRON

DC24V

CHINA

10A250VAC ~

5A30VDC

SA

VDE

G5Q-1A4

OMRON

DC24V

CHINA

10A250VAC ~

5A30VDC

SA

VDE

G5Q-1A4

OMRON

DC24V

CHINA

EACH CONTACT

IS RATED FOR

24VACOR VDC

@ .5 AMP MAX

0-15VDC

OUTPUT

MINLOAD

IS 1K OHM

RESISTIVE

VDCONL Y

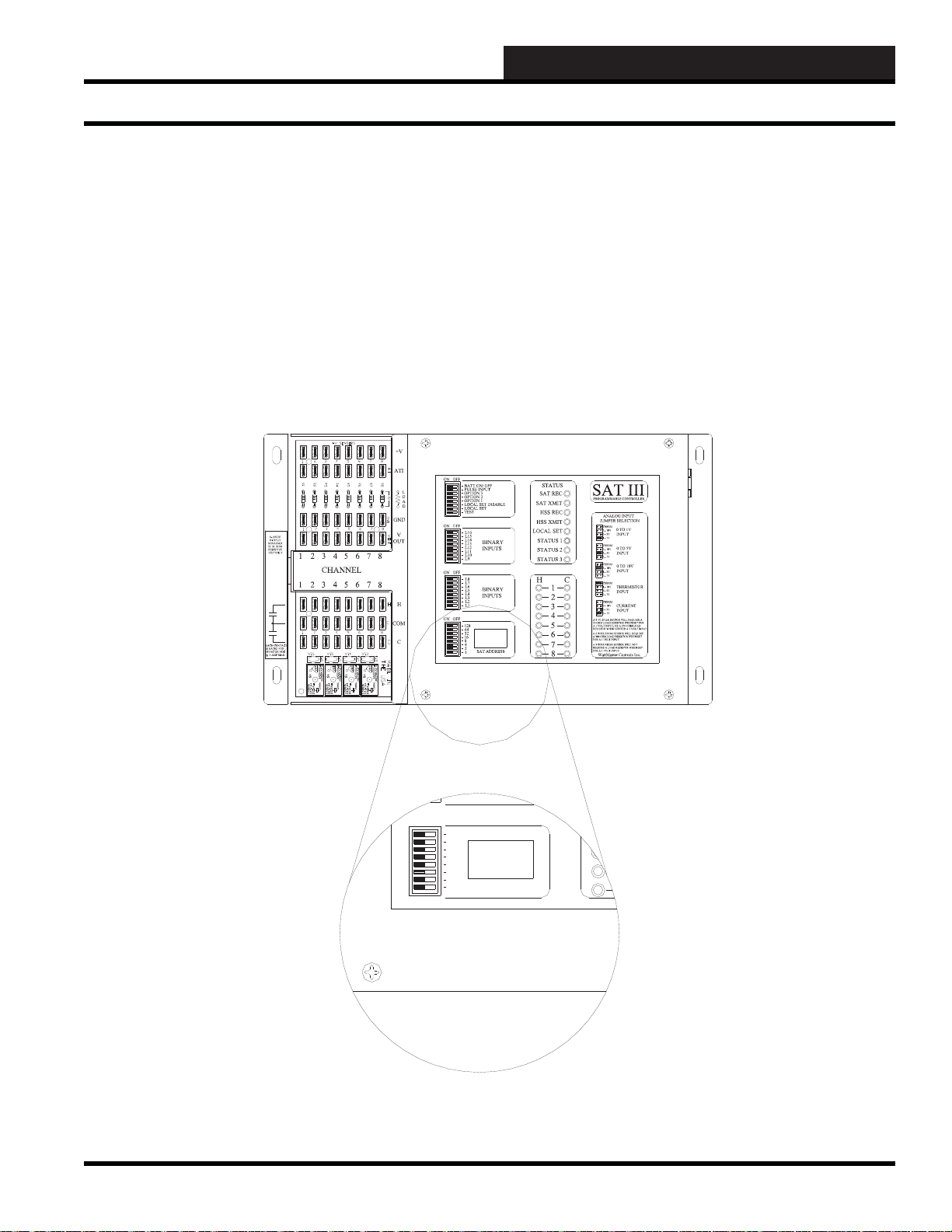

SA T III LED Descriptions

SA T III Controller—LED Information

(SS5003)

The SAT III Controller has 24 LEDs on the cover of the SAT III

controller. The top 8 Status LED functions are as follows:

SAT REC - This LED will be lit when communications are being

received by the SAT III Communications Loop.

SAT XMIT - This LED will be lit when communications are being

transmitted by the SAT III Communications Loop.

HSS REC - This LED will be lit when communications are being

received from the HSS port.

HSS XMIT - This LED will be lit when communications are

being transmitted to the HSS port.

LOCAL SET - This LED will be lit when communications

with the WCC III-MCD has not occurred for at least the last two

minutes. This means that the SAT III is not communicating on the

SAT III communications loop. Setpoint control in the SAT III is

dependent on the LOCAL SET parameters which are programmed

into each control point by the user.

STATUS 1 - LED blinks every 1 second if SAT III is alive.

STATUS 2 - LED blinks every 1 second during power on delay,

and then blinks every 8 seconds when watchdog is enabled.

STATUS 3 - LED blinks for every internal calculation loop

completion.

The lower 16 LEDs display the status of the 16 “H” and “C” Relay

Outputs. The 16 LEDs display the status of the eight “H” and eight

“C” contacts.

Figure 12-15: SAT III LED locations

12-16

WCC III Technical Guide

Page 19

12. WCC III INSTALLATION

GUIDE

SA T III Connection Points

SA T III Controller — Connection

Points

All of the external SAT III connection points are single tab ¼-inch

Sta-Con connectors. With the exception of the “old” connection

method of connecting the Binary Inputs which are 16-pin dip cable

connections and the HSS EXP COMM port which is a 6-pin premade MOLEX type mini-fi t cable connection.

+V Connections.

There are eight +12-VDC connections that power analog type

sensors of which the fi rst seven of these connections are fi xed to

+12VDC only. The eighth +V connector is jumper (JP1) selectable

for either +12VDC, or +24VDC. This (JP1) jumper can be set

to +12VDC, or +24VDC so that the voltage at the eighth +V

connection point is either +12VDC or +24VDC. The +24VDC

is useful when connecting 4-to-20 mA sensors that require a

connection voltage greater than +12VDC. You may connect up to

eight 4-to-20 mA sensors to this eight +V (+24VDC) connection

point. This JP1 jumper is located under the cover of the SAT III

controller, just to the right of the eighth +V connector.

A TI Connections

These eight connections are connection points for ATI #1 to ATI #8

analog inputs. ATI is the acronym for Analog Temperature Input.

These eight connection points are for Analog Inputs. This is where

analog type sensors are connected to the SAT III controller. The

types of sensors inputs that are supported on the SAT III controllers

are: 0-1V, 0-5V, 0-10V, 10K Type 3 Thermistor, 4-20mA (On both

the 0-1V, and 0-5V inputs). There are also eight Analog Input

selection jumpers that are located under the cover of the SAT III

controller near the Analog Inputs that actually set the type input

voltage ranges for each of the eight analog inputs. These Analog

Input selection jumpers are labeled JO1 to JO8. JO1 corresponds

to analog input #1, JO2 corresponds to analog input #2, JO3

corresponds to analog input #3, JO4 corresponds to analog input

#4, JO5 corresponds to analog input #5, JO6 corresponds to analog

input #6, JO7 corresponds to analog input #7, JO8 corresponds

to analog input #8. Each of these Analog Input selection jumpers

has four jumper options: 0-1V, 0-5V, 0-10V, and THERM. See

Figure 12-34 and 12-35 for further wiring details. See Section 3

for further programming instructions.

GND Connections

These GND connections are analog ground common connection

points for all of the analog input (ATI), and analog output (VOUT)

connections.

VOUT 1 to V OUT 8 Connections

These eight analog outputs are set up to provide 0 to +15 DC

Volts outputs at up to 15 milli-amps per output. These outputs are

typically used to drive a VFD, 0-10VDC or 2-10VDC actuator or

valve. VOUT is the acronym for Voltage Output. See Section 3 for

additional programming instructions.

H 1 to H 8 Connections

The eight “H” connection points of the SAT III controller were

originally classifi ed and labeled as “HEAT” contacts starting with

the SAT 0, SAT I, and SAT II controllers. They do not need to

be used only for “HEAT” contacts, as these contacts are general

purpose relay outputs. There is a load protection device called a

varistor across each of the eight “H” output connections that limit

the allowable voltage to no more than 32 volts AC\DC maximum

at 1 amp current draw for each contact. Attempting to switch

any voltage greater than 32 Volts, or current draws of more than

1 amp per contact could and will result in damage to the SAT

III controller. These “H” and “C” contact outputs are meant to

control tri-state actuators, contactors, relays, solenoids, and the PI

board AKA “ECC II ANALOG OUTPUT” board that WattMaster

Controls used to manufacture. See Figure 12-18 for further wiring

details. See Section 3 for additional programming instructions.

COM 1 to COM 8 Connections

The COM1 connection point is a common connection point for

H1 and C1 Relays. None of the COM connections are connected

to any of the other seven COM connection points. A jumper cable

is available to connect all of the COM connection points together.

Each corresponding “H” and “C” contact are connected to a single

corresponding “COM” connection point. So “H1” and “C1” are

connected to “COM1”, “H2” and “C2” are connected to “COM2”,

etc. See Figure 12-18 for further wiring details.

WCC III Technical Guide

12-17

Page 20

12. WCC III INSTALLATION

SA T III Connection Points

C 1 to C 8 Connections

The eight “C” connection points of the SAT III controller were

originally classifi ed and labeled as “COOL” contacts starting with

the SAT 0, SAT I, and SAT II controllers. They do not need to

be used only for “COOL” contacts, as these contacts are general

purpose relay outputs. There is a load protection device called

a varistor across each of the eight “COOL” output connections

that limits the allowable voltage to no more than 32 volts AC\DC

maximum at 1 amp current draw for each contact. Attempting to

switch any voltage greater than 32 Volts, or current draws of more

than 1 amp per contact could and will result in damage to the SAT

III controller. These “H” and “C” contact outputs are meant to

control tri-state actuators, contactors, relays, solenoids, and the PI

board AKA “ECC II ANALOG OUTPUT” board that WattMaster

Controls used to manufacture. See Figure 12-18 for further wiring

details. See Section 3 for additional programming instructions.

Binary Inputs

The SAT III controller has two sets of eight-position dipswitches

on its front panel labeled L1 - L8 and L9 - L16. Switches L1-L8 are

housed together in one dipswitch, and switches L9-L16 are housed

together in another dipswitch. For the old connection method one

dipswitch is removed for each Binary Input with Time Delay board,

and is then replaced with a ribbon cable which connects the Binary

Input with Time Delay board to the SAT III controller. The binary

devices to be monitored are then wired to the terminal strip of the

Binary Input with Time Delay board. The Binary Input with Time

Delay board requires a 24-VAC power source. Warning you must

observe polarity on the 24-VAC and GND connections of both the

Binary Input with Time Delay board and the SAT III controller,

as the grounds must be the same. Or, an alternative connection

method to the SAT III controller is now provided by the 6-pin HSS

expansion port on the side of the SAT III controller. See Figures

12-26, 12-27, & 12-28 for further wiring details.

24V AC & GND Connection

Located on the bottom side of the SAT III controller is a 24 VAC

and GND connection. This is the main power connection to the

SAT III controller. Each SAT III Controller draws - 15VA. External

relays and contactors are not included, but need to be considered

for total VA draw. The GND connection points must be the same

between all of the externally powered expansion boards and the

SAT III Controller. See Figure 12-27 for further wiring details.

SA T Communica tion Connection

These connection points are for wiring of the RS-485 communication

loop. There are two “T” (Transmit) connections, two “R” (Receive)

connections and two “SHIELD” connection points. There are two

connection points provided for each connection for easy “daisy

chaining” to the next Satellite Controller. When connecting the

RS-485 wiring from SAT III to SAT III or SAT 3C/D/F, or SAT 3P

controller the wiring connections are as follows: connect “R” TO

“R”, “T” TO “T”, AND “SHIELD” TO “SHIELD” OR “SH”. The

RS-485 wire specifi cations are plenum-rated, jacketed stranded

18-gauge, 2-wire twisted pair with shield. 18-gauge stranded wire

is mandatory to ensure a good connection with the ¼-inch Sta-Con

connectors which are used to terminate the wires at the WCC III MCD and at the satellite controllers.

HSS EXP COMM Connection

The HSS EXP (Expansion) Port enables newer versions of the

satellite expansion boards, most notably the Binary Input with

Time Delay Board and V-Out RELAY Board to work without

connecting the previous way (separate power and hard wiring was

required). The SAT III has a single connection via the built-in HSS

EXP port on the side of the SAT III. It is designed to connect and

power up 5 HSS Expansion Boards. Connecting more than 5 HSS

Boards is possible, but each additional board will require a 24VAC

power supply.

The HSS EXP port provides power and ground, along with

communications on a 6-pin pre-made MOLEX type mini-fi t cable

connection. This cable is made with 16-gauge wire.

Each HSS Expansion Board has an 8-position address dipswitch

that is used to set up the function of the board.

The HSS EXP port can be daisy chained to the next board. The

HSS cable connections allow the HSS expansion boards to be

located up to 150 feet away from the SAT III Controller.

HSS connection cables are available in the following sizes: 6-inch,

12-inch, 18-inch, 3 feet, 25 feet, 40 feet, 80 feet, and 120 feet.

12-18

WCC III Technical Guide

Page 21

12. WCC III INSTALLATION

8

SAT ADDRESS

2

1

4

ON OFF

128

32

16

64

SAT III ADDRESS SWITCH

GUIDE

SA T III Addressing

Addressing (Numbering) of SA T III

Controllers

The WCC III system can have up to 239 SAT III controllers. In

order for the central computer to communicate properly with each

individual SAT III controller, each controller must be assigned a

separate number, or address. The number is assigned by placing

the small dip switches on the front of the SAT III controller marked

“SAT ADDRESS” in the proper position.

The address dip switches are additive; that is to say placing

switches 1 and 2 in the ON position will cause the SAT III

controller to be identifi ed as satellite controller number 3. The SAT

III controller looks at the position of these switches only when it

is going through its initialization process after being powered up.

Simply changing the switch positions on a SAT III controller that is

currently “on-line” will not change its number. The switches need

to be placed in the proper position before powering up the SAT III

controller, or the SAT III must be powered down and then back up

for the SAT III to “read” the new position of the switches. When

placing the switches in the desired position, make sure the switch

has “clicked” into place and is properly seated.

Figure 12-16: SAT III address switch loca tion

WCC III Technical Guide

12-19

Page 22

12. WCC III INSTALLATION

SA T III Addressing

Care must be taken to ensure that two SAT III controllers do not

have the same address. When this condition is present, the central

computer does not know where to send the information, and the

information that should be sent to the SAT III controller is usually

lost.

You should be aware of the symptoms caused by two satellite

controllers having the same number. Let’s consider a new job in

which the satellite controllers have not yet been programmed and

2 SAT III controllers are named number #3. When you call up

satellite controller #3 to enter data, everything will appear to be

fi ne. You will be able to enter data on the screens as if nothing is

wrong. However, when you leave a screen and then return to the

same screen, all of the data you entered will be missing. Also, if

you fi nish programming the analog inputs for example, and then

go to the analog input summary screen to review your inputs, all

of the data you have entered will be missing.

Another situation that you might encounter is adding a SAT III

controller to an existing system and accidentally giving it the same

number as a SAT III presently “on-line.” Again, when you begin

to program the new SAT III controller, everything will appear fi ne

until you leave a screen or if you go to a summary screen. Only

now, all of the data is usually not missing. Generally, you get parts

of your data back and parts will be missing.

If you suspect you might have two SAT III controllers with the

same address (number 3 for example) the best thing to do is go

to the SAT III controller that you know is number 3, and remove

the 2-wire RS-485 communication loop from it. Then, go back to

the computer and call up satellite controller #3. If the computer

can still “talk” to satellite controller #3, there is another satellite

controller that is addressed #3 connected somewhere on the RS485 communication loop.

If a satellite controller was accidentally addressed #3, there will

be a satellite number missing. For example, if satellite controller

#7 was accidentally misaddressed to #3, satellite controller #7 will

not be present. One way of telling which satellite controllers are

“on-line” is to go to the Satellite Summary Screen (see Section

3) and see which satellite controllers the computer recognizes as

being “on-line.”

If satellite controller #7 was accidentally miss-addressed #3, there

would not be a satellite controller at address #7, and the computer

will give a “Non-Existing” message for satellite controller #7.

Option 1, 2, and 3 Switches

Option switches 2 and 3 do nothing. But, the SAT III controller

option “1” switch selects the A-to-D converter type that is on the

mother board. With the switch turned OFF, the A-to-D curve is

selected for the Maxim MAX147 part, and with the switch turned

“ON” for the TI-ADS7844 (BB marked) the software will use the

special A-to-D curve for the TI-ADS7844 part. See Section 3 for

proper A-to-D identifi cation.

BA TT ON/OFF s witc h

This switch is used to turn the Battery (Rechargeable Super cap) ON

and OFF to the SRAM located inside of the SAT III processor.

Since version 2.00 of the Satellite software the non-volatile

memory is now also stored in the EEPROM, instead of the SRAM,

and upon power up the memory is read from the EEPROM back

into the SRAM. This switch is not of any importance anymore.

Local Set Switch

When the LOCAL dipswitch is in the ON position, the SAT

III controller will operate according to their predefi ned user

programmed “local set” setpoints. That is, if the SAT III controller

was programmed by the user to correctly operate when and if the

WCC III - MCD is off-line or disconnected.

Local Set Disable Switch

When the LOCAL SET Disable dipswitch is in the ON position,

the SAT III controller will operate according to their predefi ned

user programmed “On” setpoints. That is, if the SAT III controller

were programmed by the user to correctly operate when and if the

WCC III - MCD is off-line or disconnected.

Test Switc h

The test mode is active only if the TEST dipswitch is in the ON

position. The word “TEST” can be input as the binary value within

the SAT III. Example of use would be if the user programmed the

word “TEST” into one of the control point values in the SAT III

controller to check the operation of the SAT III controller with an

alternate setpoint or schedule, the user could then place the TEST

switch in the ON position to make this function work with out

physically having to go back to the front-end computer to change a

setpoint via the computer.

12-20

WCC III Technical Guide

Page 23

12. WCC III INSTALLATION

8

7

SAT ADDRESS

2

1

4

8

A3 WI RE ROOM SE NSOR WILL NO T

REQUIREA LOADRESIST OR WHEN SET

FORA 1VOLT INPUT.

WattMaster Controls Inc.

BINARY

INPUTS

BINARY

INPUTS

L8

ON OFF

128

32

16

64

L4

L3

L2

L1

L6

L5

L7

L11

L12

ON OFF

L10

L9

ON OFF

L15

L16

L14

L13

CH

4

3

5

6

2

1

LOCAL SET

STATUS 2

STATUS 3

STATUS 1

HSS XMIT

LOCAL SET

LOCAL SET DISABLE

BATT ON/ OFF

PULSE INPUT

OPTION 1

TEST

OPTION 3

OPTION 2

ON OFF

STATUS

HSS REC

SAT XMIT

SAT REC

ANALOG INPUT

JUMPER SELECTI ON

A2 WI RE ROOM SE NSOR WILL REQUIRE

A300 OHMLOAD RESISTORWHEN SET

FORA 1VOLT INPUT.

A4TO20mASENSORWILLREQUIREA

50OHM LOADR ESISTOR WHEN SET FOR

A1 VO LT INPUT , OR A 250 OHML OAD

RESISTORWH EN SET FOR A 5 VOL T INPUT.

CURRENT

INPUT

THERMISTOR

INPUT

0-1V

0-5V

0-10V

THERM

0-1V

0-5V

0-10V

THERM

0TO10V

INPUT

0TO5V

INPUT

0TO1V

INPUT

0-10V

0-1V

0-5V

0-10V

THERM

0-1V

0-5V

THERM

0-1V

0-5V

0-10V

THERM

PROGRAMMABLECONTROLLER

SAT III

H

C

COM

CHANNEL

2134567

8

10A250VAC ~

5A30VDC

SA

VDE

G5Q-1A4

OMRON

DC24V

CHINA

10A250VAC~

5A30VDC

SA

VDE

G5Q-1A4

OMRON

DC24V

CHINA

10A250VAC ~

5A30VDC

SA

VDE

-1A4

ON

24V

CHINA

10A250VAC ~

5A30VDC

SA

VDE

G5Q-1A4

OMRON

DC24V

CHINA

NTACT

FOR

VDC

AX

GUIDE

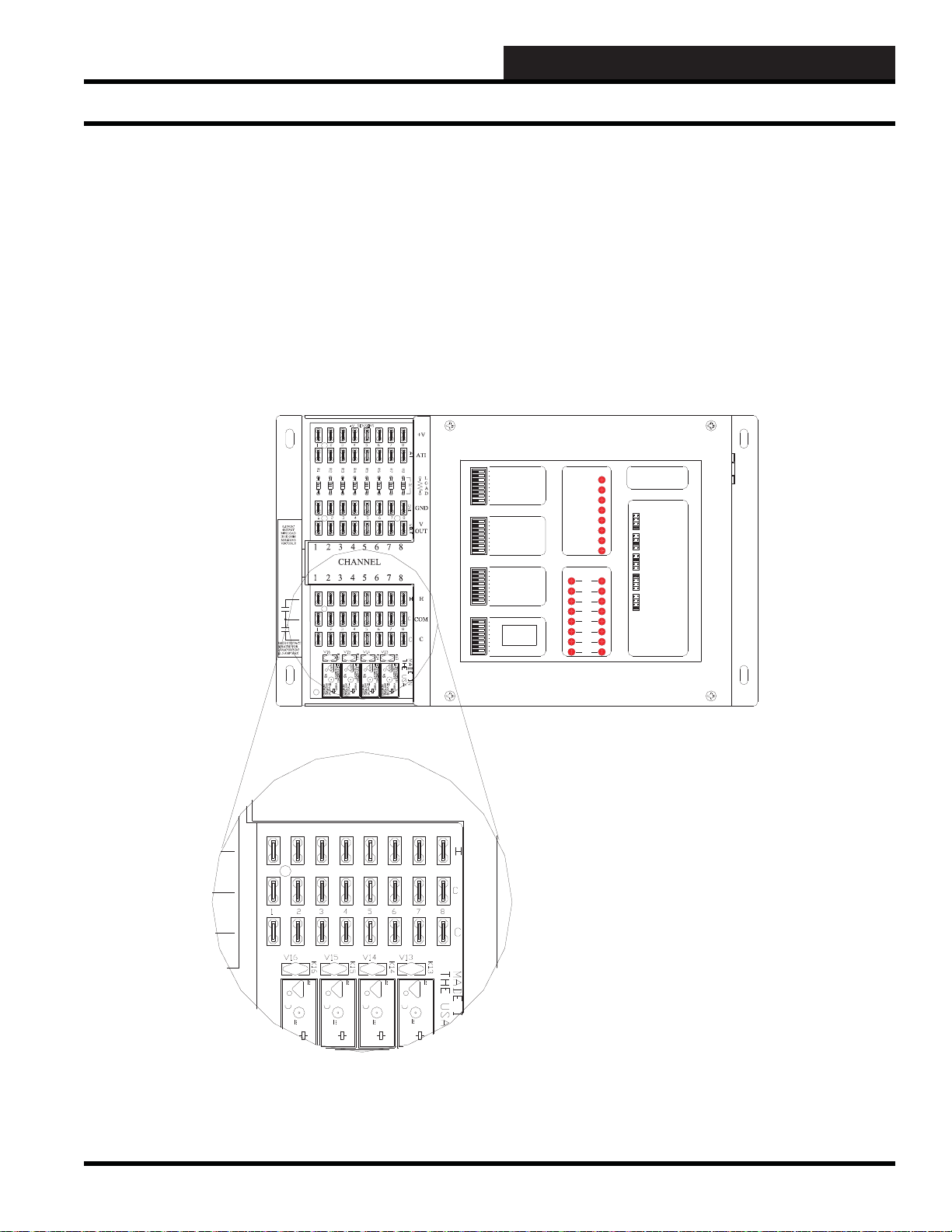

SA T III Relay Outputs

SA T III Relay Outputs

The standard SAT III controller is capable of providing 16 binary

(on/off) relay outputs. These 16 relay outputs are for driving pilot

duty relays. There is a load protection device called a varistor

across each of the 16 output connections that limits the allowable

voltage to no more than 32 volts AC\DC maximum at 1.0 or 1 amp

current draw for each contact.

Attempting to switch any voltage greater than 32 Volts, or current

draws of more than 1.0 or 1 amp per contact could and will result

in damage to the SAT III controller. These “H” and “C” contact

outputs are meant to control tri-state actuators, contactors, relays,

solenoids, and the PI board AKA “ECC II ANALOG OUTPUT”

board that WattMaster Controls used to manufacture. These relay

outputs can be programmed in three different types of modes of

basic operation: Time Clock, Dual Limit, and EA Mode. See

Section 3 for further details on Satellite programming instructions.

Figure 12-17: SAT III “H” and “C” control output wiring connections

WCC III Technical Guide

12-21

Page 24

12. WCC III INSTALLATION

H

COM

C

12345678

12345678

SA T III Relay Outputs

The terminals for the binary outputs are found at the lower lefthand corner of the SAT III controller and are labeled “H”, “COM”,

and “C”. The relay contact can make or break a 24-VAC or 24VDC circuit between the COM to H or COM to C terminals.

The COM to H contacts are referred to as XXXK1h-K8h in the

WCC III point addressing scheme, and the COM to C contacts

are referred to as XXXK1c-K8c in the WCC III point addressing

scheme. XXX is the Satellite address number 1 to 239, “K” stands

for contact, and the numbers 1-8 stand for the channel on the SAT

III controller.

Each “H” and “C” contact connection has a “COM” connection

associated with it. Please note that each one of the sets of the

corresponding “H” and “C” contacts are also isolated from each

other. The “COM” connection means common. When wiring

the control outputs, typically all of the “COM” connections are

wired together, using the supplied jumper wire (PL100867). This

“COM” common connection can either be connected to 24VAC /

24VDC or GROUND depending on the application.

Figure 12-18: SAT III “H” and “C” control output schematic

Figure 12-19: A control output common jumper wire is provided (PL100867) for connecting the eight “COM”

connections together

The pre-made control output common jumper wire is provided

in the initial spare parts kit that came with the SAT III controller.

This spare parts kit contains various input load resistor packs,

spare fuse, and the control output common jumper. The spare parts

kit is WattMaster part number PL102029.

12-22

WCC III Technical Guide

Page 25

1

1

1

1

COM - 24VAC COM - GROUND

H

C

H

C

Figure 12-20: COM connection as 24 VAC or as GR OUND

12. WCC III INSTALLATION

SA T III Relay Outputs

GUIDE

The “COM” or common connection point can either be connected

to 24 VAC / 24 VDC or GROUND. It is basically a point of view

of turning power “on” to a device, or removing “ground” going

to the device. It makes no difference, as both methods will work

equally well, and really depends on the application you are trying

to control.

WCC III Technical Guide

12-23

Page 26

12. WCC III INSTALLATION

Proportional-Integral (PI) Output Board

Proportional-Integral (PI) Output

Board

The Proportional-Integral (PI) Board is a separate integrated circuit

board which works in conjunction with the SAT III controller to

convert a pair of SAT III binary outputs to a varying DC voltage

signal. When one contact on the SAT III controller closes, the

voltage supplied by the PI board will ramp down at a pre-set rate.

When the other SAT III contact closes, the voltage ramps up at

the preset rate. When both contacts are open, the voltage supplied

by the PI board will remain at its present value. The maximum

DC voltage range is 0-14.5 volts, and the minimum allowable

resistance of the controlled device is 1000 ohms. See Section 3 for

further details on Satellite programming instructions.

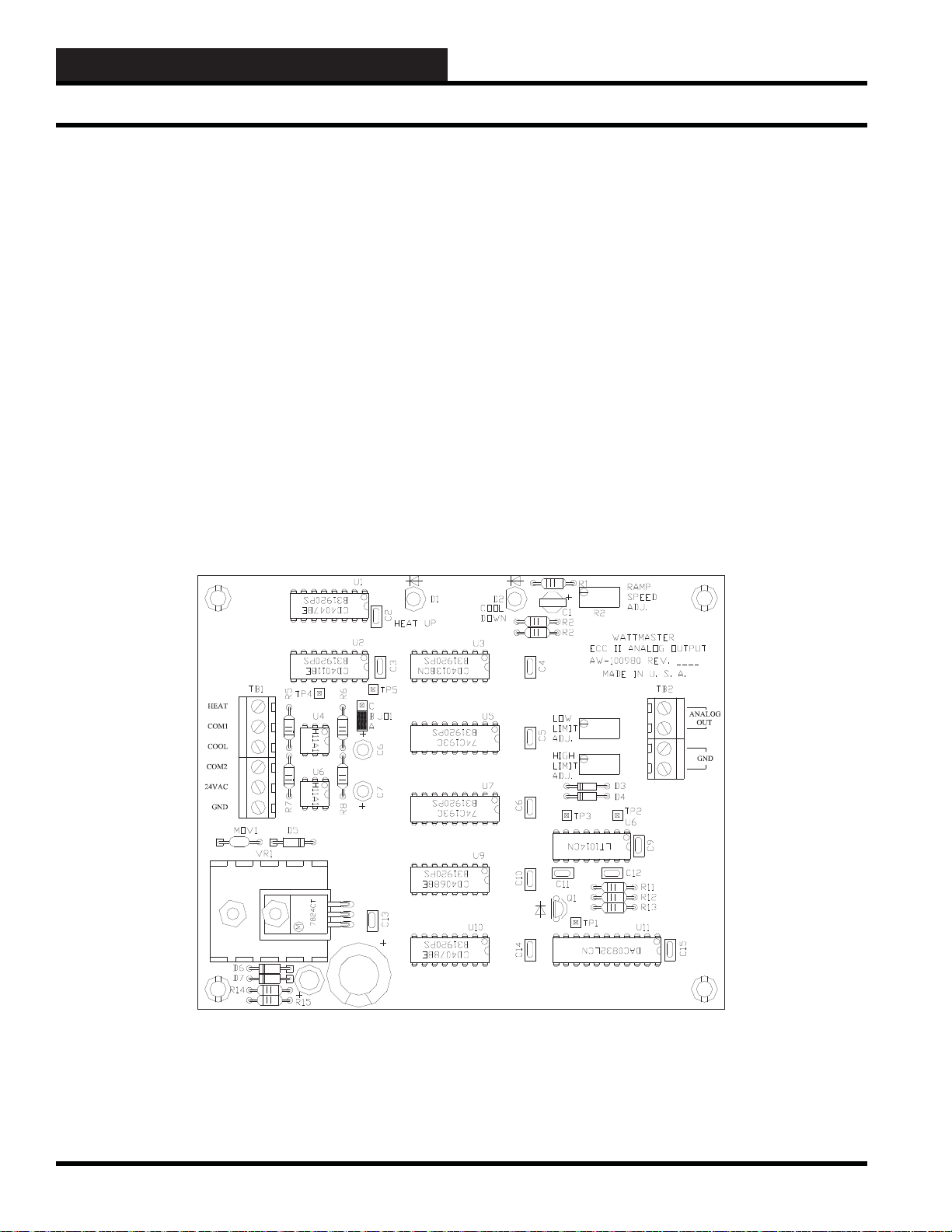

Figure 12-21: ECC II Analog Output Board

12-24

WCC III Technical Guide

Page 27

12. WCC III INSTALLATION

GUIDE

PI Board Connection Points

The DC voltage range along with the ramp speed is set at the PI

board. The ramp speed can be adjusted from 23 seconds to 38

minutes, and the maximum range is 0-14.5 volts DC.

To control a VFD drive from a SAT III controller using the

Proportional-Integral board, you must use two control outputs and

a circuit board (PI Board) that we no longer make. WattMaster

Controls does not make the PI Output Board anymore, but Kele

makes a similar circuit board that should work. It is a Tri-State-toAnalog Output circuit board (Kele Part # PWA-2T).

If only one contact closure is available to drive the PI Board, move

jumper J01 on the WattMaster PI board to the B-C position and use

the SAT III’s control output in the Dual Limit mode to control the

PI Board. Although when using this method with the WattMaster PI

Board, the DC voltages supplied by the WattMaster PI Board will

either be increasing or decreasing at the set ramp speed depending

on if the contact is open or closed.

The Global Analog Mode 9 Dual Ramp Screen was created to help

emulate the old WattMaster PI board in software. It basically uses

the control set points of two control outputs on a satellite controller

to control a single analog output on a satellite controller and should

be used when controlling an analog actuator or VFD that needs to

have an analog control setpoint. See Section 3 for further details on

Satellite programming instructions.

The Proportional-Integral (PI) Board connection points

All of external connections to Proportional-Integral (PI) Board

connection points are non de-pluggable screw-cage type of wire

clamped based terminal blocks.

24 V AC (TB1-5) & GND (TB1-6)

ANALOG OUT (TB2-1) & GND (TB2-3&4)

The “ANALOG OUT” and “GND” terminals supply the DC

voltage from the PI board.

Adjust Minimum Voltage

The PI board is factory set for a minimum voltage of 0 VDC +/-

0.2 VDC. If you want a minimum voltage other than 0 VDC, you

can reset it by adjusting the potentiometer (pot) labeled “R9.” The

voltage between test point #3 (labeled “TP #3” on the PI board)

and ground is set 300 mV lower than the desired minimum voltage.

That is to say, if you want 5 VDC as the minimum voltage to be

supplied between the “ANALOG OUT” and “GND” terminals,

adjust pot “R9” to get 4.7 VDC between “TP #3” and “GND.”

NOTE: The minimum voltage setpoint must be lower than the

maximum voltage setpoint.

Adjust Maximum Voltage

The PI board is factory set for a maximum voltage of 14.5 VDC

+/- 0.2 VDC. If you want a maximum voltage other than 14.5

VDC, you can reset it by adjusting the potentiometer (pot) labeled

“R10.” The voltage between test point #2 (labeled “TP #2” on the

PI board) and ground is set at 300 mV above the desired maximum

voltage. That is to say, if you want a maximum voltage of 10 VDC

to be supplied by the “ANALOG OUT” and “GND” terminals,

adjust pot “R10” to get 10.3 VDC between “TP #2” and “GND.”

NOTE: The maximum voltage setpoint must be higher than

the minimum voltage setpoint.

The PI board requires a 24 VAC power supply which is connected

to these terminals. The PI board is generally powered by the same

24 VAC transformer that powers the satellite controller. The GND

connection points must be the same between the PI board and the

SAT III Controller.

HEA T (TB1-1) & COM1 (TB1-2)

When 24 volts AC is supplied between the “HEAT” and “COM1”

terminals, the DC voltage supplied by the PI board will start

increasing at the set ramp speed.

COOL (TB1-1) & COM2 (TB1-4)

When 24 volts AC is supplied between the “COOL” and “COM2”

terminals, the voltage supplied by the PI board will start decreasing

at the set ramp speed.

WCC III Technical Guide

Adjust “Ramp” Speed

The ramp speed is the time it takes for the DC voltage between

the “ANALOG OUT” and “GND” terminals to change from the

minimum voltage to the maximum voltage and vice versa. The ramp

speed is factory set at about 19 minutes. If you want a ramp speed

other than 19 minutes, you can reset it by adjusting the potentiometer

(pot) located at R2. When R2 is fully counterclockwise, the ramp

speed is 38 minutes (+/- 10%). When R2 is fully clockwise, the

ramp speed is 23 seconds (+/- 10%). As the voltage is ramping up,

the small light labeled D1 will fl ash and as the voltage is ramping

down, the small light labeled D2 will fl ash.

12-25

Page 28

12. WCC III INSTALLATION

8

7

SAT ADDRESS

2

1

4

8

A3 WI RE ROOM SENSOR WILL NOT

REQUIREA LOAD RESISTOR WHEN SET

FORA 1 VOLT INPUT.

WattMaster Controls Inc.

BINARY

INPUTS

BINARY

INPUTS

L8

ON OFF

128

32

16

64

L4

L3

L2

L1

L6

L5

L7

L11

L12

ON OFF

L10

L9

ON OFF

L15

L16

L14

L13

CH

4

3

5

6

2

1

LOCAL SET

STATUS 2

STATUS 3

STATUS 1

HSS XMIT

LOCAL SET

LOCAL SET DISABLE

BATT ON/OFF

PULSEINPUT

OPTION 1

TEST

OPTION 3

OPTION 2

ON OFF

STATUS

HSS REC

SAT XMIT

SAT REC

ANALOG INPUT

JUMPER SELECTION

A2 WI RE ROOM SENSOR WILL REQUIRE

A30 0 OHM L OAD RESIST OR WHEN SET

FORA 1 VOLT INPUT.

A4 TO 20 mA SENSOR WILL REQUI RE A

50O HM LOAD RESISTOR WHEN SET FOR

A1 VOLT INPUT, OR A 250 OHM LOAD

RESISTOR WHEN SET FOR A 5 VOLT INPUT.

CURRENT

INPUT

THERMISTOR

INPUT

0-1V

0-5V

0-10V

THERM

0-1V

0-5V

0-10V

THERM

0TO10V

INPUT

0TO5V

INPUT

0TO1V

INPUT

0-10V

0-1V

0-5V

0-10V

THERM

0-1V

0-5V

THERM

0-1V

0-5V

0-10V

THERM

PROGRAMMABLE CONTROLLER

SAT III

24VAC 120VAC

120VAC WIRING

BY OTHERS

TO OTHER

SAT III OR TO

WCC III - MCD

24VAC

GND

TO OTHER

SAT III OR TO

WCC III - MCD

WIRE "T" TO "T"

"R" TO "R"

"SHD" TO "SHD"

WARNING: OBSERVE POLARITY

BETWEEN THE SAT III AND THE ECCII

ANALOG OUTPUT BOARD - GROUND

CONNECTIONS MUST BE THE SAME.

ECC II ANALOG OUTPUT BOARD

PI Board Typical Wiring Connections

If you want to test the ramp speed, disconnect all wires from the

“HEAT,” “COM1,” “COOL,” and “COM2” terminals and use a

volt meter to measure the DC voltage between “ANALOG OUT”

and “GND” as you jumper test point #4 (TP #4) to ground.

The voltage should increase from the minimum to the maximum

voltage during the set time interval. Then, remove the jumper from

“TP #4” and jumper “TP #5” to “GND.” The voltage between the

“ANALOG OUT” and “GND” terminals should decrease from the

maximum to the minimum voltage during the set time interval.

Figure 12-22: ECC II Analog Output typical wiring connections to a SAT III controller

12-26

WCC III Technical Guide

Page 29

12. WCC III INSTALLATION

GUIDE

Old SA T II Type Binary Input with Time Delay Board

Sequence of Operation

When the SAT III controller makes COM to H, 24 VAC is supplied