Page 1

10. RS-485 Communications

and Troubleshooting

WCC III

10. RS-485 Communications

and Troubleshooting

Page 2

T ABLE OF CONTENTS

SECTION 10:

RS-485 COMMUNICA TIONS AND

TROUBLESHOOTING

WCC III – MCD and SAT III Type

Controllers “RS-485 Network Loop”

Communications .......................................10-1

SAT 3C/D/F TUC Loop Communications ...10-2

RS-485 Wire Considerations .....................10-3

Power and Switchable RS-485

Communications Board ............................10-3

24VAC Power Wiring Considerations .......10-5

Typical WCC III System Communications

Wiring – Not the recommended and

preferred way ............................................10-6

Typical WCC III System Communications

Wiring – The recommended and

preferred way ............................................10-7

Lightning Suppression ..............................10-8

SAT III Communications

Troubleshooting with a

Digital Voltmeter .....................................10-10

SAT 3C/D/F Communications

Troubleshooting with a

Digital Voltmeter .....................................10-11

SAT 3P Communications

Troubleshooting with a

Digital Voltmeter .....................................10-13

TUC-2R Communications

Troubleshooting with a

Digital Voltmeter .....................................10-14

VAVZ II Communications

Troubleshooting with a

Digital Voltmeter .....................................10-16

TUC-5R Communications

Troubleshooting with a

Digital Voltmeter .....................................10-17

RTU-17 Communications

Troubleshooting with a

Digital Voltmeter .....................................10-19

MCD Communications Troubleshooting

with a Digital Voltmeter ...........................10-9

Global Bridge Communications

Troubleshooting with a

Digital Voltmeter .....................................10-21

Replacing RS-485 Driver Chips ...............10-22

Page 3

SECTION 10:

RS-485 COMMUNICA TIONS AND

TROUBLESHOOTING

__________________________________________

10. RS-485 COMMUNICATIONS

RS-485 Network Loop Communications

WCC III – MCD and SAT III Type

Controllers “RS-485 Network Loop”

Communications

The SAT III type controllers use a proprietary RS-485-based

protocol, and it is based on packetized data in predefi ned parameter

blocks. Troubleshooting of the SAT III type controllers’ RS-485

communications loop is possible with a Digital Voltmeter.

(The SAT II was based on Manchester encoded data, and was

very reliable, but was impossible to troubleshoot with a Digital

Voltmeter.)

For the WCC III - MCD system, WattMaster Controls has

developed a new, isolated RS-485 communication bus that

can support 239 SAT III type controllers on up to four separate

communications channels (loop connections). A single channel

(loop connection) can support up to 60 SAT III type controllers

on one communications loop. This is for redundant operation; if

an RS-485 communications channel goes down, it does not cause

other SAT III type controllers on the any of the other loops to lose

communications.

The maximum distance specifi ed for RS-485 communications

is 4000 feet. Using multiple channels (loop connections), it is

possible to go 4000 feet in one direction and 4000 feet in yet

another direction using the two communications channels (loop

connections) that are provided on the back of the standard WCC

III - MCD.

PLEASE NOTE: There are two physical RS-485 channels

(loop connections ) on the back of the standard WCC III - MCD

computer. T wo more ph ysical RS-485 loops are available as an

option for larger loop sizes (WattMaster part PL1 0 1 97 4 ).

This WCC III communications loop should also be thought of as a

major component of the WCC III system, not just a communications

loop that only connects SAT III type controllers to SAT III type

controllers. On this proprietary RS-485 communications loop, the

following commands are broadcast many times a second: Time,

Week Schedules, Global Binary, Global Analogs, Optimal Starts,

Overrides, PID programs, Duty Cycles programs, Proportional

programs, and Tenant Overrides. These commands are broadcast

from the WCC III - MCD to all of the SAT III Controllers and all

of the SAT 3C/D/F/P Controllers, as well as any TUC Controllers

that are connected to the SAT 3C/D/F Controllers. If your RS-485

communications wiring has a faulty or intermittent connection to

any of the SA T III type controllers, then a problem will result in the

proper operation of the WCC III system.

WCC III Technical Guide

10-1

Page 4

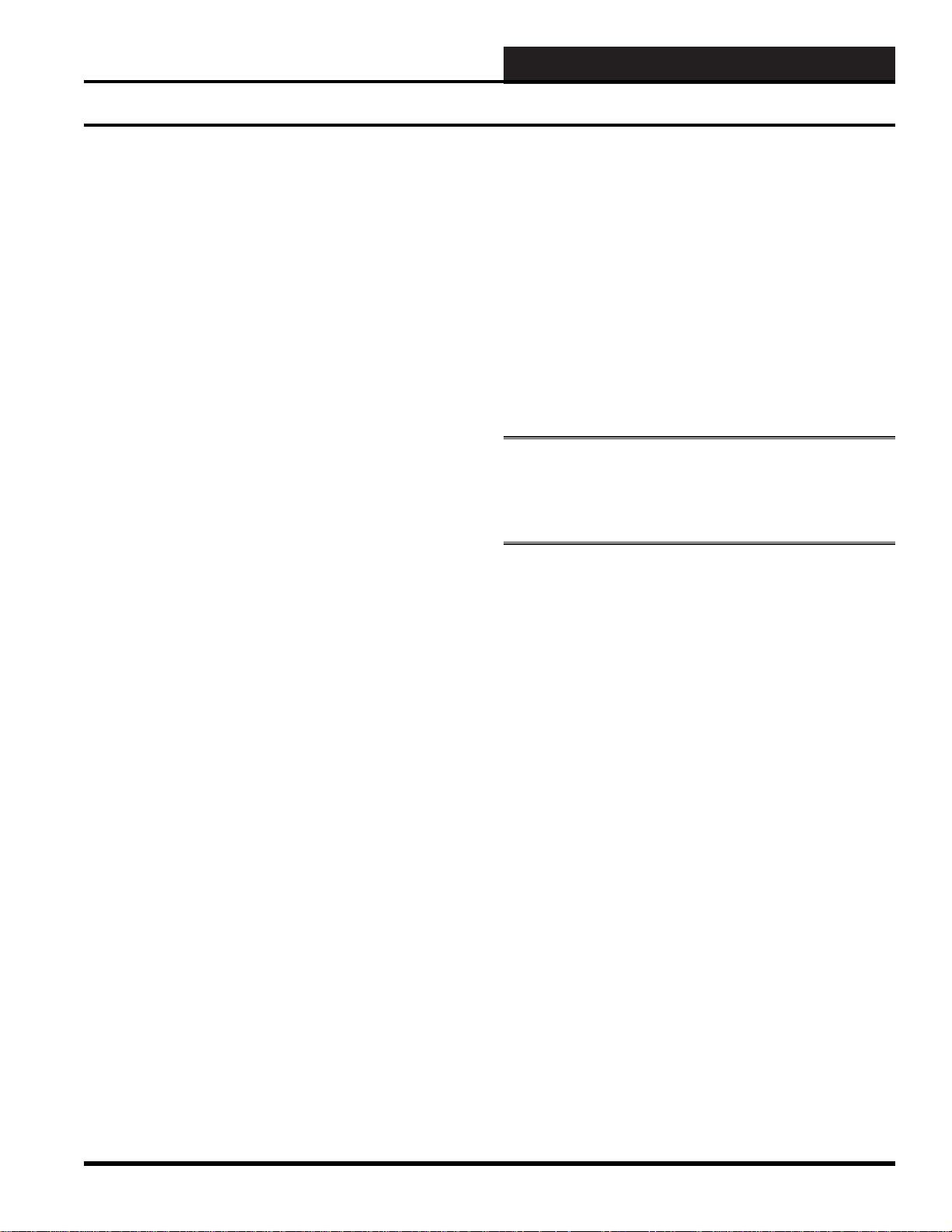

10. RS-485 COMMUNICATIONS

REAR PROFILE VIEW WCC I II - MCD (STANDARD WITH TWO SAT III COMMUNICATIONS CONNECTI ONS) REAR PROFILE VIEW WCC II I - MCD (WITH OPTIONAL TWO MORE SAT III COMMUNICATIONS CONNE CTIONS)

SA T 3C/D/F TUC Loop Communications

The SAT 3C/D/F TUC Loop

Communications

The software that is in the “old” existing TUC Controllers that

were connected to the “old” SAT 2c/d Controllers does not need

to be changed. WattMaster Controls decided to use the same

communications protocol to ease the replacement of the SA T 2C/D

controllers. Do not connect this loop to the SAT III “network”

communications loop as communication-related problems will

result.

PLEASE NOTE: Normally, all of the RS-485 wiring is

wired “R ” to “R,” “T” to “T, ” and “SHLD” to “SHLD” or

“SH.” This method of connection works for the wiring from

TUC Controller to TUC Controller. But, on the SA T 3C/D/F

Controller, the wire from the TUC “R” connection must

be wired to the SA T 3C/D/F “T” connection, and the SAT

3C/D/F Controller “R” connection must be wired to the TUC

“T” connecti on.

Figure 10-1: Rear Views of the WCC III – MCD showing SAT III RS-485 Communication Connections

Figure 10-2: Profi le of SAT III and SAT 3C/D/F showing the SAT III and TUC RS-485 Communication Connections

10-2

WCC III Technical Guide

Page 5

10. RS-485 COMMUNICATIONS

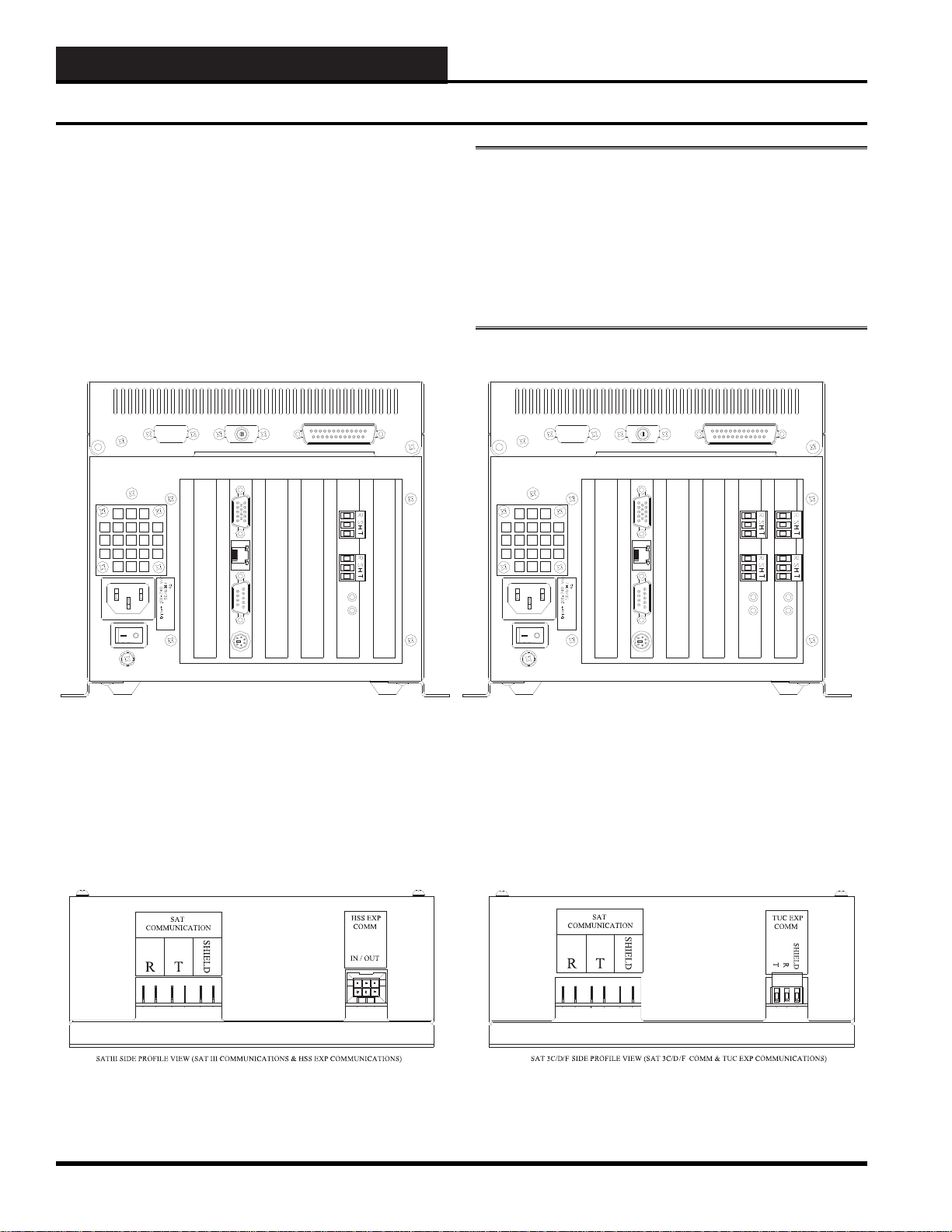

<<<LOCAL LOOP>>> AZWR-LL-WG-18>>> E76191 CL2P 18AWG (UL) 012112 FT

<<<NETWORK LOOP>>> AZWR-NL-WR-18>>> E76191 CL2P 18AWG (UL) 012112 FT

WATTMASTER LOCAL LOOP WIRE

WATTMASTER NETWORK LOOP WIRE

RS-485 Wire & P ower and Switchable RS-485 Communications Board

RS-485 Wire Considerations

The RS-485 wire specifi cations are generally a stranded 18-

gauge, 2-wire twisted pair with shield. 18-gauge stranded wire is

mandatory to ensure a good connection with the ¼-inch Sta-Con

connectors which are used to terminate the wires at the WCC III MCD and at the satellite controllers.

The old SAT II Manchester communications loop was supposed to

have used a 2-wire twisted pair with shield, but this was not used

in every installation. This old SAT II communications loop should

not be used for the new SAT III communications loop. A new RS485 communications loop should be run to each new replacement

SAT III Controller. The shield wire must be used on the new SAT

III Controller as it provides a “ground” reference for the RS-485

communication loop.

W attMaster Controls sells two versions of 18-gauge, 2-wire twisted

pair with shield communications wire:

• W attMaster part #WR-NL-WR-18 - marked “Network

Loop” with a red stripe for rapid identifi cation. This

wire should be run from the WCC III - MCD to the

SAT III, SAT 3C/D/F, SAT 3P, and then to the next

SAT 3-type controllers.

• W attMaster part #WR-LL-WG-18 - marked “Local

Loop” with a green stripe for rapid identifi cation for the

TUC loops that run from the SAT 3C/D/F controllers to

the TUC controllers.

Figure 10-3: WattMaster Controls various communications loop wire

Power and Switc hable RS-485

Communications Board

“Wire Nuts” on the RS-485 communications loop should be avoided

at all costs. As an alternative to the “Wire Nuts”, WattMaster

Controls has a Power and Switchable RS-485 Communications

Board - WattMaster part #PL102224. The Power and Switchable

RS-485 Communications Board can be thought of as a 24-VAC

power and communication distribution system for the SAT III

communications loop that will aid in initial startup and future

troubleshooting of the SAT III communications loop. The Power

and Switch Boards should be used on a fl oor-by-fl oor basis. The

board is sold alone or in a small metal electrical enclosure. See

Figure 10-4.

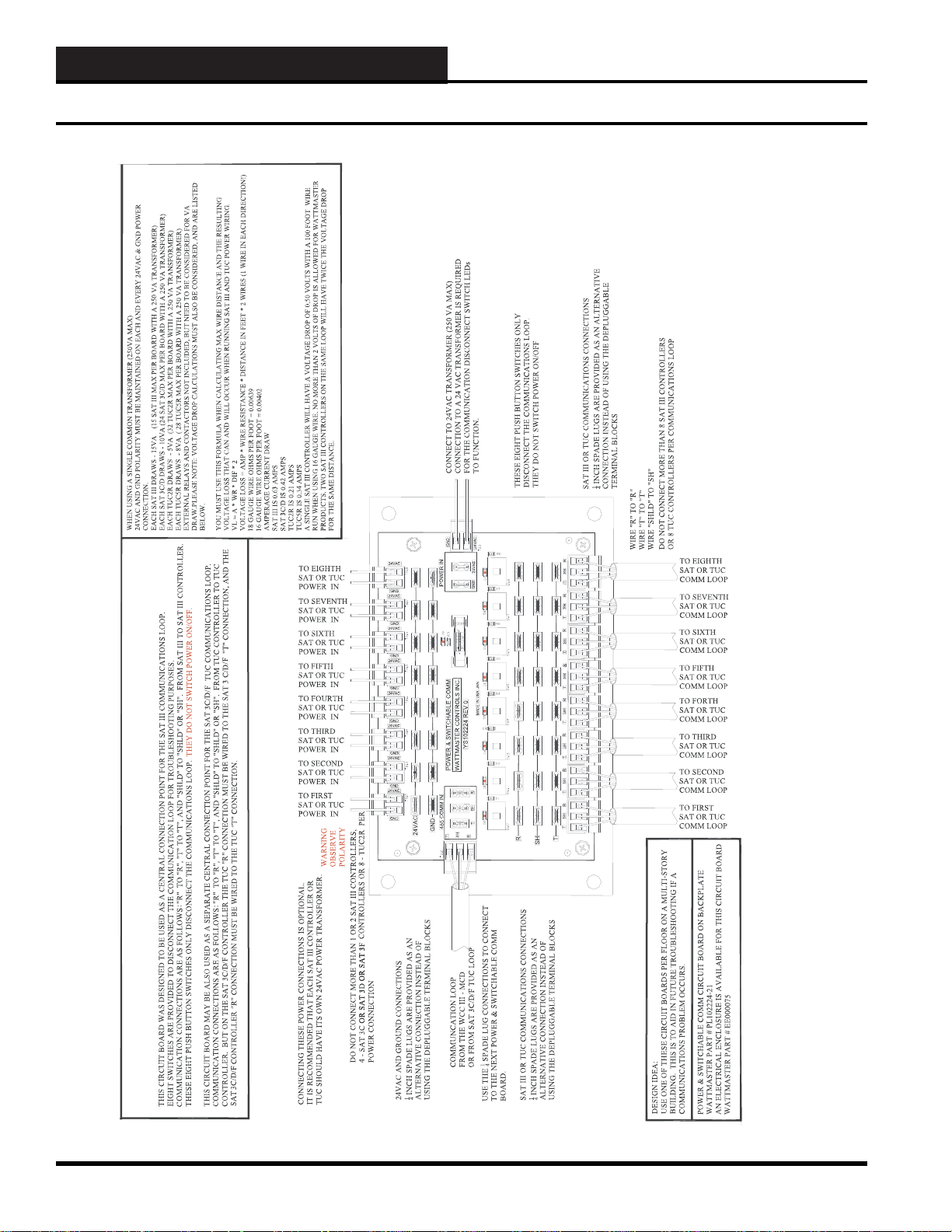

This circuit board was designed to be used as a central connection

point for the SAT III communications loop. The eight switches are

provided only to disconnect the RS-485 communications loop for

troubleshooting purposes.

Wiring for the communication connections are as follows: “R”

to “R,” “T” to “T,” and “SHLD” to “SHLD” or “SH.” Connect

the wiring from the SAT III to a SAT III, SAT 3C/D/F, or SAT 3P

Controller. These eight push-button switches only disconnect the

communications loop. THEY DO NOT SWITCH POWER ON/

OFF .

This circuit board may be also used as a separate central connection

point for the SAT 3C/D/F - TUC communications loop.

Wiring for the communications connections are as follows: “R” to

“R,” “T” to “T,” and “SHLD” to “SHLD” or “SH.” Connect the

wiring from TUC controller to TUC controller. But on the SAT

3C/D/F controller, the TUC “R” connection must be wired to the

SAT 3C/D/F “T” connection, and the SAT 3C/D/F controller “R”

connection must be wired to the TUC “T” connection.

WCC III Technical Guide

10-3

Page 6

10. RS-485 COMMUNICATIONS

Pow er and Switchable RS-485 Communications Board

10-4

Figure 10-4: Power and Switchable RS-485 Communications Board Application Drawing

WCC III Technical Guide

Page 7

10. RS-485 COMMUNICATIONS

24V AC Pow er Wiring

24V AC P o wer Wiring Considerations

You do not have to use the 24VAC connections on the Power

and Switchable RS-485 Communications Board, as each SAT

III panel should have its own 120VAC-to-24VAC transformer.

However, WattMaster Controls included the 24VAC connections

on the Power and Switchable RS-485 Communications Board as a

convenience option for 24VAC power distribution wiring.

When using the Power and Switchable RS-485 Communications

Board with a common 24VAC (250VA MAX) transformer,

the24VAC and GND polarity must be maintained on each and

every 24VAC & GND power connection.

• Each SAT III draws - 15VA (No more than 15

SAT III max per board with a 250 VA - 24 VAC

transformer)

• Each SAT 3C/D/F draws - 10VA (No more than

24 SAT 3C/D/F max per board with a 250 VA - 24

VAC transformer)

• Each TUC-2R draws - 5VA (No more than 32

TUC-2R max per board with a 250 VA - 24 VAC

transformer)

WIRE RESISTANCE STANDARDS

• 18-Gauge WIRE OHMS PER FOOT = 0.00639

• 16-Gauge WIRE OHMS PER FOOT = 0.00402

AMPERAGE CURRENT DRAW for WattMaster Controls

products

• SAT III controller is 0.63 AMPS

• SAT 3C/D/F controller is 0.42 AMPS

• TUC-2R controller is 0.21 AMPS with actuator

• TUC5-R controller is 0.34 AMPS

Example 1:

A single SAT III controller will have a voltage drop of 0.50 volts

with 100 feet of wire run when using 16-gauge wire. No more than

2 volts of drop is allowed for any WattMaster product. Two SAT

III controllers on the same loop will have twice the voltage drop

for the same distance.

0.506 Volts of loss = “0.63” x “0.00402” x “100 feet” x “2”

• Each TUC-5R draws - 8VA (No more than 28

TUC-R max per board with a 250 VA - 24 VAC

transformer)

• External relays and contactors are not included, but

need to be considered for total VA draw.

PLEASE NOTE: Vol tage loss in wire calculations must also

be considered and are listed below .

You must use the formula below when calculating max wire

distance and the resulting voltage loss that can and will occur

when running SAT III and TUC power wiring.

The formula is as follows: “VL” = “A” x “WR” x “DIF” x “2”

VL = Voltage Loss, A = AMP Draw , WR = Wire Resistance, DIF =

Distance In Feet, 2 = 2 Wires (1 Wire in each direction!)

Example 2:

A single TUC-2R controller will have a voltage drop of 0.671 volts

with 250 feet of wire run when using 18-gauge wire. No more than

2 volts of drop is allowed for any WattMaster product. Two TUC2R controllers on the same loop will have twice the voltage drop

for the same distance.

0.671 Volts of loss = “0.21” x “0.00639” x “250 feet” x “2”

Example 3:

A single SAT 3C/D/F controller will have a voltage drop of 1.69

volts with 500 feet of wire run when using 16-gauge wire. No

more than 2 volts of drop is allowed for any WattMaster product.

Two SAT III controllers on the same loop will have twice the

voltage drop for the same distance.

1.689 Volts of loss = “0.42” x “0.00402” x “500 feet” x “2”

WCC III Technical Guide

10-5

Page 8

10. RS-485 COMMUNICATIONS

8

7

SATADDRESS

2

1

4

8

A3WIREROOMSENSORWILLNOT

REQUIREALOADRESISTORWHENSET

FORA1VOLTINPUT.

WattMasterControlsInc.

BINARY

INPUTS

BINARY

INPUTS

L8

ONOFF

128

32

16

64

L4

L3

L2

L1

L6

L5

L7

L11

L12

ONOFF

L10

L9

ONOFF

L15

L16

L14

L13

CH

4

3

5

6

2

1

LOCALSET

STATUS2

STATUS3

STATUS1

HSSXMIT

LOCALSET

LOCALSETDISABLE

BATTON/OFF

PULSEINPUT

OPTION1

TEST

OPTION3

OPTION2

ONOFF

STATUS

HSSREC

SATXMIT

SATREC

ANALOGINPUT

JUMPERSELECTION

A2WIREROOMSENSORWILLREQUIRE

A300OHMLOADRESISTORWHENSET

FORA1VOLTINPUT.

A4TO20mASENSORWILLREQUIREA

50OHMLOADRESISTORWHENSETFOR

A1VOLTINPUT,ORA250OHMLOAD

RESISTORWHENSETFORA5VOLTINPUT.

CURRENT

INPUT

THERMISTOR

INPUT

0-1V

0-5V

0-10V

THERM

0-1V

0-5V

0-10V

THERM

0TO10V

INPUT

0TO5V

INPUT

0TO1V

INPUT

0-10V

0-1V

0-5V

0-10V

THERM

0-1V

0-5V

THERM

0-1V

0-5V

0-10V

THERM

PROGRAMMABLECONTROLLER

SATIII

100VA

TRANSFORMER

SWITCH

DISCONNECT

INTERPANEL

100VA

TRANSFORMER

SWITCH

DISCONNECT

INTERPANEL

D

8

7

SATADDRESS

2

1

4

8

A3WIREROOMSENSORWILLNOT

REQUIREALOADRESISTORWHENSET

FORA1VOLTINPUT.

WattMasterControlsInc.

BINARY

INPUTS

BINARY

INPUTS

L8

ONOFF

128

32

16

64

L4

L3

L2

L1

L6

L5

L7

L11

L12

ONOFF

L10

L9

ONOFF

L15

L16

L14

L13

CH

4

3

5

6

2

1

LOCALSET

STATUS2

STATUS3

STATUS1

HSSXMIT

LOCALSET

LOCALSETDISABLE

BATTON/OFF

PULSEINPUT

OPTION1

TEST

OPTION3

OPTION2

ONOFF

STATUS

HSSREC

SATXMIT

SATREC

ANALOGINPUT

JUMPERSELECTION

A2WIREROOMSENSORWILLREQUIRE

A300OHMLOADRESISTORWHENSET

FORA1VOLTINPUT.

A4TO20mASENSORWILLREQUIREA

50OHMLOADRESISTORWHENSETFOR

A1VOLTINPUT,ORA250OHMLOAD

RESISTORWHENSETFORA5VOLTINPUT.

CURRENT

INPUT

THERMISTOR

INPUT

0-1V

0-5V

0-10V

THERM

0-1V

0-5V

0-10V

THERM

0TO10V

INPUT

0TO5V

INPUT

0TO1V

INPUT

0-10V

0-1V

0-5V

0-10V

THERM

0-1V

0-5V

THERM

0-1V

0-5V

0-10V

THERM

PROGRAMMABLECONTROLLER

SATIII

100VA

TRANSFORMER

SWITCH

DISCONNECT

INTERPANEL

100VA

TRANSFORMER

SWITCH

DISCONNECT

INTERPANEL

D

8

7

SATADDRESS

2

1

4

8

A3WIREROOMSENSORWILLNOT

REQUIREALOADRESISTORWHENSET

FORA1VOLTINPUT.

WattMasterControlsInc.

BINARY

INPUTS

BINARY

INPUTS

L8

ONOFF

128

32

16

64

L4

L3

L2

L1

L6

L5

L7

L11

L12

ONOFF

L10

L9

ONOFF

L15

L16

L14

L13

CH

4

3

5

6

2

1

LOCALSET

STATUS2

STATUS3

STATUS1

HSSXMIT

LOCALSET

LOCALSETDISABLE

BATTON/OFF

PULSEINPUT

OPTION1

TEST

OPTION3

OPTION2

ONOFF

STATUS

HSSREC

SATXMIT

SATREC

ANALOGINPUT

JUMPERSELECTION

A2WIREROOMSENSORWILLREQUIRE

A300OHMLOADRESISTORWHENSET

FORA1VOLTINPUT.

A4TO20mASENSORWILLREQUIREA

50OHMLOADRESISTORWHENSETFOR

A1VOLTINPUT,ORA250OHMLOAD

RESISTORWHENSETFORA5VOLTINPUT.

CURRENT

INPUT

THERMISTOR

INPUT

0-1V

0-5V

0-10V

THERM

0-1V

0-5V

0-10V

THERM

0TO10V

INPUT

0TO5V

INPUT

0TO1V

INPUT

0-10V

0-1V

0-5V

0-10V

THERM

0-1V

0-5V

THERM

0-1V

0-5V

0-10V

THERM

PROGRAMMABLECONTROLLER

SATIII

100VA

TRANSFORMER

SWITCH

DISCONNECT

INTERPANEL

100VA

TRANSFORMER

SWITCH

DISCONNECT

INTERPANEL

D

100VA

TRANSFORMER

SWITCH

DISCONNECT

INTERPANEL

D

8

7

SATADDRESS

2

1

4

8

A3WIREROOMSENSORWILLNOT

REQUIREALOADRESISTORWHENSET

FORA1VOLTINPUT.

WattMasterControlsInc.

BINARY

INPUTS

BINARY

INPUTS

L8

ONOFF

128

32

16

64

L4

L3

L2

L1

L6

L5

L7

L11

L12

ONOFF

L10

L9

ONOFF

L15

L16

L14

L13

CH

4

3

5

6

2

1

LOCALSET

STATUS2

STATUS3

STATUS1

HSSXMIT

LOCALSET

LOCALSETDISABLE

BATTON/OFF

PULSEINPUT

OPTION1

TEST

OPTION3

OPTION2

ONOFF

STATUS

HSSREC

SATXMIT

SATREC

ANALOGINPUT

JUMPERSELECTION

A2WIREROOMSENSORWILLREQUIRE

A300OHMLOADRESISTORWHENSET

FORA1VOLTINPUT.

A4TO20mASENSORWILLREQUIREA

50OHMLOADRESISTORWHENSETFOR

A1VOLTINPUT,ORA250OHMLOAD

RESISTORWHENSETFORA5VOLTINPUT.

CURRENT

INPUT

THERMISTOR

INPUT

0-1V

0-5V

0-10V

THERM

0-1V

0-5V

0-10V

THERM

0TO10V

INPUT

0TO5V

INPUT

0TO1V

INPUT

0-10V

0-1V

0-5V

0-10V

THERM

0-1V

0-5V

THERM

0-1V

0-5V

0-10V

THERM

PROGRAMMABLECONTROLLER

SATIII

100VA

TRANSFORMER

SWITCH

DISCONNECT

INTERPANEL

BASEMENT

1st Floor

2nd Floor

8

7

SATADDRESS

2

1

4

8

A3WIREROOMSENSORWILLNOT

REQUIREALOADRESISTORWHENSET

FORA1VOLTINPUT.

WattMasterControlsInc.

BINARY

INPUTS

BINARY

INPUTS

L8

ONOFF

128

32

16

64

L4

L3

L2

L1

L6

L5

L7

L11

L12

ONOFF

L10

L9

ONOFF

L15

L16

L14

L13

CH

4

3

5

6

2

1

LOCALSET

STATUS2

STATUS3

STATUS1

HSSXMIT

LOCALSET

LOCALSETDISABLE

BATTON/OFF

PULSEINPUT

OPTION1

TEST

OPTION3

OPTION2

ONOFF

STATUS

HSSREC

SATXMIT

SATREC

ANALOGINPUT

JUMPERSELECTION

A2WIREROOMSENSORWILLREQUIRE

A300OHMLOADRESISTORWHENSET

FORA1VOLTINPUT.

A4TO20mASENSORWILLREQUIREA

50OHMLOADRESISTORWHENSETFOR

A1VOLTINPUT,ORA250OHMLOAD

RESISTORWHENSETFORA5VOLTINPUT.

CURRENT

INPUT

THERMISTOR

INPUT

0-1V

0-5V

0-10V

THERM

0-1V

0-5V

0-10V

THERM

0TO10V

INPUT

0TO5V

INPUT

0TO1V

INPUT

0-10V

0-1V

0-5V

0-10V

THERM

0-1V

0-5V

THERM

0-1V

0-5V

0-10V

THERM

PROGRAMMABLECONTROLLER

SATIII

100VA

TRANSFORMER

SWITCH

DISCONNECT

8

7

SATADDRESS

2

1

4

8

A3WIREROOMSENSORWILLNOT

REQUIREALOADRESISTORWHENSET

FORA1VOLTINPUT.

WattMasterControlsInc.

BINARY

INPUTS

BINARY

INPUTS

L8

ONOFF

128

32

16

64

L4

L3

L2

L1

L6

L5

L7

L11

L12

ONOFF

L10

L9

ONOFF

L15

L16

L14

L13

CH

4

3

5

6

2

1

LOCALSET

STATUS2

STATUS3

STATUS1

HSSXMIT

LOCALSET

LOCALSETDISABLE

BATTON/OFF

PULSEINPUT

OPTION1

TEST

OPTION3

OPTION2

ONOFF

STATUS

HSSREC

SATXMIT

SATREC

ANALOGINPUT

JUMPERSELECTION

A2WIREROOMSENSORWILLREQUIRE

A300OHMLOADRESISTORWHENSET

FORA1VOLTINPUT.

A4TO20mASENSORWILLREQUIREA

50OHMLOADRESISTORWHENSETFOR

A1VOLTINPUT,ORA250OHMLOAD

RESISTORWHENSETFORA5VOLTINPUT.

CURRENT

INPUT

THERMISTOR

INPUT

0-1V

0-5V

0-10V

THERM

0-1V

0-5V

0-10V

THERM

0TO10V

INPUT

0TO5V

INPUT

0TO1V

INPUT

0-10V

0-1V

0-5V

0-10V

THERM

0-1V

0-5V

THERM

0-1V

0-5V

0-10V

THERM

PROGRAMMABLECONTROLLER

SATIII

INTERPANEL

100VA

TRANSFORMER

8

7

SATADDRESS

2

1

4

8

A3WIREROOMSENSORWILLNOT

REQUIREALOADRESISTORWHENSET

FORA1VOLTINPUT.

WattMasterControlsInc.

BINARY

INPUTS

BINARY

INPUTS

L8

ONOFF

128

32

16

64

L4

L3

L2

L1

L6

L5

L7

L11

L12

ONOFF

L10

L9

ONOFF

L15

L16

L14

L13

CH

4

3

5

6

2

1

LOCALSET

STATUS2

STATUS3

STATUS1

HSSXMIT

LOCALSET

LOCALSETDISABLE

BATTON/OFF

PULSEINPUT

OPTION1

TEST

OPTION3

OPTION2

ONOFF

STATUS

HSSREC

SATXMIT

SATREC

ANALOGINPUT

JUMPERSELECTION

A2WIREROOMSENSORWILLREQUIRE

A300OHMLOADRESISTORWHENSET

FORA1VOLTINPUT.

A4TO20mASENSORWILLREQUIREA

50OHMLOADRESISTORWHENSETFOR

A1VOLTINPUT,ORA250OHMLOAD

RESISTORWHENSETFORA5VOLTINPUT.

CURRENT

INPUT

THERMISTOR

INPUT

0-1V

0-5V

0-10V

THERM

0-1V

0-5V

0-10V

THERM

0TO10V

INPUT

0TO5V

INPUT

0TO1V

INPUT

0-10V

0-1V

0-5V

0-10V

THERM

0-1V

0-5V

THERM

0-1V

0-5V

0-10V

THERM

PROGRAMMABLECONTROLLER

SATIII

100VA

TRANSFORMER

SWITCH

DISCONNECT

INTERPANEL

8

7

SATADDRESS

2

1

4

8

A3WIREROOMSENSORWILLNOT

REQUIREALOADRESISTORWHENSET

FORA1VOLTINPUT.

WattMasterControlsInc.

BINARY

INPUTS

BINARY

INPUTS

L8

ONOFF

128

32

16

64

L4

L3

L2

L1

L6

L5

L7

L11

L12

ONOFF

L10

L9

ONOFF

L15

L16

L14

L13

CH

4

3

5

6

2

1

LOCALSET

STATUS2

STATUS3

STATUS1

HSSXMIT

LOCALSET

LOCALSETDISABLE

BATTON/OFF

PULSEINPUT

OPTION1

TEST

OPTION3

OPTION2

ONOFF

STATUS

HSSREC

SATXMIT

SATREC

ANALOGINPUT

JUMPERSELECTION

A2WIREROOMSENSORWILLREQUIRE

A300OHMLOADRESISTORWHENSET

FORA1VOLTINPUT.

A4TO20mASENSORWILLREQUIREA

50OHMLOADRESISTORWHENSETFOR

A1VOLTINPUT,ORA250OHMLOAD

RESISTORWHENSETFORA5VOLTINPUT.

CURRENT

INPUT

THERMISTOR

INPUT

0-1V

0-5V

0-10V

THERM

0-1V

0-5V

0-10V

THERM

0TO10V

INPUT

0TO5V

INPUT

0TO1V

INPUT

0-10V

0-1V

0-5V

0-10V

THERM

0-1V

0-5V

THERM

0-1V

0-5V

0-10V

THERM

PROGRAMMABLECONTROLLER

SATIII

100VA

TRANSFORMER

SWITCH

DISCONNECT

INTERPANEL

3rd Floor

8

7

SATADDRESS

2

1

4

8

A3WIREROOMSENSORWILLNOT

REQUIREALOADRESISTORWHENSET

FORA1VOLTINPUT.

WattMasterControlsInc.

BINARY

INPUTS

BINARY

INPUTS

L8

ONOFF

128

32

16

64

L4

L3

L2

L1

L6

L5

L7

L11

L12

ONOFF

L10

L9

ONOFF

L15

L16

L14

L13

CH

4

3

5

6

2

1

LOCALSET

STATUS2

STATUS3

STATUS1

HSSXMIT

LOCALSET

LOCALSETDISABLE

BATTON/OFF

PULSEINPUT

OPTION1

TEST

OPTION3

OPTION2

ONOFF

STATUS

HSSREC

SATXMIT

SATREC

ANALOGINPUT

JUMPERSELECTION

A2WIREROOMSENSORWILLREQUIRE

A300OHMLOADRESISTORWHENSET

FORA1VOLTINPUT.

A4TO20mASENSORWILLREQUIREA

50OHMLOADRESISTORWHENSETFOR

A1VOLTINPUT,ORA250OHMLOAD

RESISTORWHENSETFORA5VOLTINPUT.

CURRENT

INPUT

THERMISTOR

INPUT

0-1V

0-5V

0-10V

THERM

0-1V

0-5V

0-10V

THERM

0TO10V

INPUT

0TO5V

INPUT

0TO1V

INPUT

0-10V

0-1V

0-5V

0-10V

THERM

0-1V

0-5V

THERM

0-1V

0-5V

0-10V

THERM

PROGRAMMABLECONTROLLER

SATIII

100VA

TRANSFORMER

SWITCH

DISCONNECT

INTERPANEL

100VA

TRANSFORMER

SWITCH

DISCONNECT

INTERPANEL

D

100VA

TRANSFORMER

SWITCH

DISCONNECT

INTERPANEL

D

4th Floor

4X4

HANDY BOX

WIRE

NUTS

WIRE

NUTS

TO

WCCIII - MCD

SAT III IN A ENCLOSURESAT3D INAENCLOSURE

2 - SAT III I N A DUAL ENCLOSURE

SAT III IN A ENCLOSURESAT3D INAENCLOSURE

SAT III IN A ENCLOSURESAT3D INAENCLOSURE

SAT III IN A ENCLOSURE

SAT III IN A ENCLOSURESAT3D INAENCLOSURESAT3D IN A ENCLOSURE

SAT III IN A ENCL OSURESAT III IN A ENCLOSURE

SAT 3D IN A ENCL OSURE

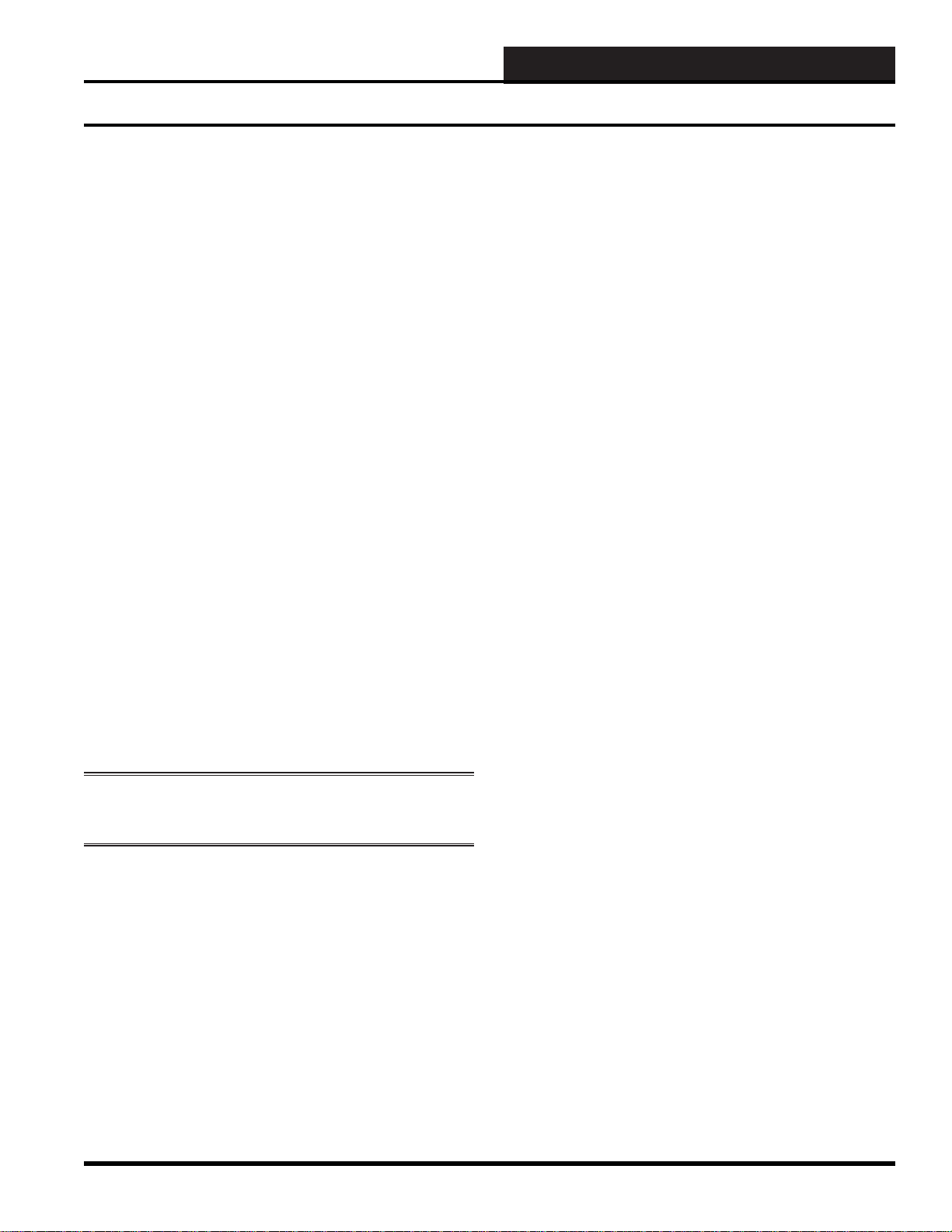

Wrong Communications Wiring

Figure 10-5: Typical WCC III System Communications Wiring – Not the recommended and preferred way

Wiring of the WCC III RS-485 communications loop as represented

in Figure 10-5 is not recommend for the following reasons:

1. The use of “Wire Nuts” to connect the communications wire at

a central hub (the 4x4 handy box) and inside of a SA T III enclosure

is not a good idea. The connections will oxidize over time and the

resistance of the “Wire-Nutted” connections will increase over

time. Generally speaking, the use of “Wire Nuts” can and will

cause a problem with the WCC III communication loop at some

point. Also, tugging or pulling on the WCC III communications

wiring during troubleshooting or during routine maintenance can

and generally will cause these “Wire Nuts” connections to break

apart.

10-6

2. The haphazard way the WCC III communications wiring was

run in Figure 10-5 is also not recommended. In this example,

wiring was run from the 2nd fl oor to the 4th fl oor and then back

to the 2nd fl oor and then back to the 4th fl oor again. The WCC III

communications wiring should make sense and never jump fl oors

or go back down a fl oor and then go back up a fl oor. See Figure

10-6 which shows a diagram of how the WCC III communications

wiring should be run and to use for troubleshooting purposes.

3. A Power and Switchable RS-485 communication board

(PL102224) was not used on a fl oor-by-fl oor basis. Use of this

board will aid in initial startup and in future troubleshooting.

WCC III Technical Guide

Page 9

10. RS-485 COMMUNICATIONS

8

7

SATADDRESS21

4

8

A3WIREROOMSENSORWILLNOT

REQUIREALOADRESISTORWHENSET

FORA1VOLTINPUT.

WattMasterControlsInc.

BINARY

INPUTS

BINARY

INPUTS

L8

ONOFF

128

32

16

64

L4

L3

L2

L1

L6

L5

L7

L11

L12

ONOFF

L10

L9

ONOFF

L15

L16

L14

L13

CH

4

3

5

6

2

1

LOCALSET

STATUS2

STATUS3

STATUS1

HSSXMIT

LOCALSET

LOCALSETDISABLE

BATTON/OFF

PULSEINPUT

OPTION1

TEST

OPTION3

OPTION2

ONOFF

STATUS

HSSREC

SATXMIT

SATREC

ANALOGINPUT

JUMPERSELECTION

A2WIREROOMSENSORWILLREQUIRE

A300OHMLOADRESISTORWHENSET

FORA1VOLTINPUT.

A4TO20mASENSORWILLREQUIREA

50OHMLOADRESISTORWHENSETFOR

A1VOLTINPUT,ORA250OHMLOAD

RESISTORWHENSETFORA5VOLTINPUT.

CURRENT

INPUT

THERMISTOR

INPUT

0-1V

0-5V

0-10V

THERM

0-1V

0-5V

0-10V

THERM

0TO10V

INPUT

0TO5V

INPUT

0TO1V

INPUT

0-10V

0-1V

0-5V

0-10V

THERM

0-1V

0-5V

THERM

0-1V

0-5V

0-10V

THERM

PROGRAMMABLECONTROLLER

SATIII

100VA

TRANSFORMER

SWITCH

DISCONNECT

INTERPANEL

100VA

TRANSFORMER

SWITCH

DISCONNECT

INTERPANEL

D

8

7

SATADDRESS21

4

8

A3WIREROOMSENSORWILLNOT

REQUIREALOADRESISTORWHENSET

FORA1VOLTINPUT.

WattMasterControlsInc.

BINARY

INPUTS

BINARY

INPUTS

L8

ONOFF

128

32

16

64

L4

L3

L2

L1

L6

L5

L7

L11

L12

ONOFF

L10

L9

ONOFF

L15

L16

L14

L13

CH

4

3

5

6

2

1

LOCALSET

STATUS2

STATUS3

STATUS1

HSSXMIT

LOCALSET

LOCALSETDISABLE

BATTON/OFF

PULSEINPUT

OPTION1

TEST

OPTION3

OPTION2

ONOFF

STATUS

HSSREC

SATXMIT

SATREC

ANALOGINPUT

JUMPERSELECTION

A2WIREROOMSENSORWILLREQUIRE

A300OHMLOADRESISTORWHENSET

FORA1VOLTINPUT.

A4TO20mASENSORWILLREQUIREA

50OHMLOADRESISTORWHENSETFOR

A1VOLTINPUT,ORA250OHMLOAD

RESISTORWHENSETFORA5VOLTINPUT.

CURRENT

INPUT

THERMISTOR

INPUT

0-1V

0-5V

0-10V

THERM

0-1V

0-5V

0-10V

THERM

0TO10V

INPUT

0TO5V

INPUT

0TO1V

INPUT

0-10V

0-1V

0-5V

0-10V

THERM

0-1V

0-5V

THERM

0-1V

0-5V

0-10V

THERM

PROGRAMMABLECONTROLLER

SATIII

100VA

TRANSFORMER

SWITCH

DISCONNECT

INTERPANEL

100VA

TRANSFORMER

SWITCH

DISCONNECT

INTERPANEL

D

8

7

SATADDRESS

2

1

4

8

A3WIREROOMSENSORWILLNOT

REQUIREALOADRESISTORWHENSET

FORA1VOLTINPUT.

WattMasterControlsInc.

BINARY

INPUTS

BINARY

INPUTS

L8

ONOFF

128

32

16

64

L4

L3

L2

L1

L6

L5

L7

L11

L12

ONOFF

L10

L9

ONOFF

L15

L16

L14

L13

CH

4

3

5

6

2

1

LOCALSET

STATUS2

STATUS3

STATUS1

HSSXMIT

LOCALSET

LOCALSETDISABLE

BATTON/OFF

PULSEINPUT

OPTION1

TEST

OPTION3

OPTION2

ONOFF

STATUS

HSSREC

SATXMIT

SATREC

ANALOGINPUT

JUMPERSELECTION

A2WIREROOMSENSORWILLREQUIRE

A300OHMLOADRESISTORWHENSET

FORA1VOLTINPUT.

A4TO20mASENSORWILLREQUIREA

50OHMLOADRESISTORWHENSETFOR

A1VOLTINPUT,ORA250OHMLOAD

RESISTORWHENSETFORA5VOLTINPUT.

CURRENT

INPUT

THERMISTOR

INPUT

0-1V

0-5V

0-10V

THERM

0-1V

0-5V

0-10V

THERM

0TO10V

INPUT

0TO5V

INPUT

0TO1V

INPUT

0-10V

0-1V

0-5V

0-10V

THERM

0-1V

0-5V

THERM

0-1V

0-5V

0-10V

THERM

PROGRAMMABLECONTROLLER

SATIII

100VA

TRANSFORMER

SWITCH

DISCONNECT

INTERPANEL

100VA

TRANSFORMER

SWITCH

DISCONNECT

INTERPANEL

D

100VA

TRANSFORMER

SWITCH

DISCONNECT

INTERPANEL

D

8

7

SATADDRESS

2

1

4

8

A3WIREROOMSENSORWILLNOT

REQUIREALOADRESISTORWHENSET

FORA1VOLTINPUT.

WattMasterControlsInc.

BINARY

INPUTS

BINARY

INPUTS

L8

ONOFF

128

32

16

64

L4

L3

L2

L1

L6

L5

L7

L11

L12

ONOFF

L10

L9

ONOFF

L15

L16

L14

L13

CH

4

3

5

6

2

1

LOCALSET

STATUS2

STATUS3

STATUS1

HSSXMIT

LOCALSET

LOCALSETDISABLE

BATTON/OFF

PULSEINPUT

OPTION1

TEST

OPTION3

OPTION2

ONOFF

STATUS

HSSREC

SATXMIT

SATREC

ANALOGINPUT

JUMPERSELECTION

A2WIREROOMSENSORWILLREQUIRE

A300OHMLOADRESISTORWHENSET

FORA1VOLTINPUT.

A4TO20mASENSORWILLREQUIREA

50OHMLOADRESISTORWHENSETFOR

A1VOLTINPUT,ORA250OHMLOAD

RESISTORWHENSETFORA5VOLTINPUT.

CURRENT

INPUT

THERMISTOR

INPUT

0-1V

0-5V

0-10V

THERM

0-1V

0-5V

0-10V

THERM

0TO10V

INPUT

0TO5V

INPUT

0TO1V

INPUT

0-10V

0-1V

0-5V

0-10V

THERM

0-1V

0-5V

THERM

0-1V

0-5V

0-10V

THERM

PROGRAMMABLE CONTROLLER

SATIII

100VA

TRANSFORMER

SWITCH

DISCONNECT

INTERPANEL

BASEMENT

1st Floor

2nd Floor

8

7

SATADDRESS21

4

8

A3WIREROOMSENSORWILLNOT

REQUIREALOADRESISTORWHENSET

FORA1VOLTINPUT.

WattMasterControlsInc.

BINARY

INPUTS

BINARY

INPUTS

L8

ONOFF

128

32

16

64

L4

L3

L2

L1

L6

L5

L7

L11

L12

ONOFF

L10

L9

ONOFF

L15

L16

L14

L13

CH

4

3

5

6

2

1

LOCALSET

STATUS2

STATUS3

STATUS1

HSSXMIT

LOCALSET

LOCALSETDISABLE

BATTON/OFF

PULSEINPUT

OPTION1

TEST

OPTION3

OPTION2

ONOFF

STATUS

HSSREC

SATXMIT

SATREC

ANALOGINPUT

JUMPERSELECTION

A2WIREROOMSENSORWILLREQUIRE

A300OHMLOADRESISTORWHENSET

FORA1VOLTINPUT.

A4TO20mASENSORWILLREQUIREA

50OHMLOADRESISTORWHENSET FOR

A1VOLTINPUT,ORA250OHMLOAD

RESISTORWHENSETFORA5VOLTINPUT.

CURRENT

INPUT

THERMISTOR

INPUT

0-1V

0-5V

0-10V

THERM

0-1V

0-5V

0-10V

THERM

0TO10V

INPUT

0TO5V

INPUT

0TO1V

INPUT

0-10V

0-1V

0-5V

0-10V

THERM

0-1V

0-5V

THERM

0-1V

0-5V

0-10V

THERM

PROGRAMMABLECONTROLLER

SATIII

100VA

TRANSFORMER

SWITCH

DISCONNECT

8

7

SATADDRESS

2

1

4

8

A3WIREROOMSENSORWILLNOT

REQUIREALOADRESISTORWHENSET

FORA1VOLTINPUT.

WattMasterControlsInc.

BINARY

INPUTS

BINARY

INPUTS

L8

ONOFF

128

32

16

64

L4

L3

L2

L1

L6

L5

L7

L11

L12

ONOFF

L10

L9

ONOFF

L15

L16

L14

L13

CH

4

3

5

6

2

1

LOCALSET

STATUS2

STATUS3

STATUS1

HSSXMIT

LOCALSET

LOCALSETDISABLE

BATTON/OFF

PULSEINPUT

OPTION1

TEST

OPTION3

OPTION2

ONOFF

STATUS

HSSREC

SATXMIT

SATREC

ANALOGINPUT

JUMPERSELECTION

A2WIREROOMSENSORWILLREQUIRE

A300OHMLOADRESISTORWHENSET

FORA1VOLTINPUT.

A4TO20mASENSORWILLREQUIREA

50OHMLOADRESISTORWHENSET FOR

A1VOLTINPUT,ORA250OHMLOAD

RESISTORWHENSETFORA5VOLTINPUT.

CURRENT

INPUT

THERMISTOR

INPUT

0-1V

0-5V

0-10V

THERM

0-1V

0-5V

0-10V

THERM

0TO10V

INPUT

0TO5V

INPUT

0TO1V

INPUT

0-10V

0-1V

0-5V

0-10V

THERM

0-1V

0-5V

THERM

0-1V

0-5V

0-10V

THERM

PROGRAMMABLECONTROLLER

SATIII

INTERPANEL

100VA

TRANSFORMER

8

7

SATADDRESS

2

1

4

8

A3WIREROOMSENSORWILLNOT

REQUIREALOADRESISTORWHENSET

FORA1VOLTINPUT.

WattMasterControlsInc.

BINARY

INPUTS

BINARY

INPUTS

L8

ONOFF

128

32

16

64

L4

L3

L2

L1

L6

L5

L7

L11

L12

ONOFF

L10

L9

ONOFF

L15

L16

L14

L13

CH

4

3

5

6

2

1

LOCALSET

STATUS2

STATUS3

STATUS1

HSSXMIT

LOCALSET

LOCALSETDISABLE

BATTON/OFF

PULSEINPUT

OPTION1

TEST

OPTION3

OPTION2

ONOFF

STATUS

HSSREC

SATXMIT

SATREC

ANALOGINPUT

JUMPERSELECTION

A2WIREROOMSENSORWILLREQUIRE

A300OHMLOADRESISTORWHENSET

FORA1VOLTINPUT.

A4TO20mASENSORWILLREQUIREA

50OHMLOADRESISTORW HE NSETFOR

A1VOLTINPUT,ORA250OHMLOAD

RESISTORWHENSETFORA5VOLTINPUT.

CURRENT

INPUT

THERMISTOR

INPUT

0-1V

0-5V

0-10V

THERM

0-1V

0-5V

0-10V

THERM

0TO10V

INPUT

0TO5V

INPUT

0TO1V

INPUT

0-10V

0-1V

0-5V

0-10V

THERM

0-1V

0-5V

THERM

0-1V

0-5V

0-10V

THERM

PROGRAMMABLECONTROLLER

SATIII

100VA

TRANSFORMER

SWITCH

DISCONNECT

INTERPANEL

8

7

SATADDRESS21

4

8

A3WIREROOMSENSORWILLNOT

REQUIREALOADRESISTORWHENSET

FORA1VOLTINPUT.

WattMasterControlsInc.

BINARY

INPUTS

BINARY

INPUTS

L8

ONOFF

128

32

16

64

L4

L3

L2

L1

L6

L5

L7

L11

L12

ONOFF

L10

L9

ONOFF

L15

L16

L14

L13

CH

4

3

5

6

2

1

LOCALSET

STATUS2

STATUS3

STATUS1

HSSXMIT

LOCALSET

LOCALSETDISABLE

BATTON/OFF

PULSEINPUT

OPTION1

TEST

OPTION3

OPTION2

ONOFF

STATUS

HSSREC

SATXMIT

SATREC

ANALOGINPUT

JUMPERSELECTION

A2WIREROOMSENSORWILLREQUIRE

A300OHMLOADRESISTORWHENSET

FORA1VOLTINPUT.

A4TO20mASENSORWILLREQUIREA

50OHMLOADRESISTORWHENSETFOR

A1VOLTINPUT,ORA250OHMLOAD

RESISTORWHENSETFORA5VOLTINPUT.

CURRENT

INPUT

THERMISTOR

INPUT

0-1V

0-5V

0-10V

THERM

0-1V

0-5V

0-10V

THERM

0TO10V

INPUT

0TO5V

INPUT

0TO1V

INPUT

0-10V

0-1V

0-5V

0-10V

THERM

0-1V

0-5V

THERM

0-1V

0-5V

0-10V

THERM

PROGRAMMABLECONTROLLER

SATIII

100VA

TRANSFORMER

SWITCH

DISCONNECT

INTERPANEL

3rd Floor

8

7

SATADDRESS

2

1

4

8

A3WIREROOMSENSORWILLNOT

REQUIREALOADRESISTORWHENSET

FORA1VOLTINPUT.

WattMasterControlsInc.

BINARY

INPUTS

BINARY

INPUTS

L8

ONOFF

128

32

16

64

L4

L3

L2

L1

L6

L5

L7

L11

L12

ONOFF

L10

L9

ONOFF

L15

L16

L14

L13

CH

4

3

5

6

2

1

LOCALSET

STATUS2

STATUS3

STATUS1

HSSXMIT

LOCALSET

LOCALSETDISABLE

BATTON/OFF

PULSEINPUT

OPTION1

TEST

OPTION3

OPTION2

ONOFF

STATUS

HSSREC

SATXMIT

SATREC

ANALOGINPUT

JUMPERSELECTION

A2WIREROOMSENSORWILLREQUIRE

A300OHMLOADRESISTORWHENSET

FORA1VOLTINPUT.

A4TO20mASENSORWILLREQUIREA

50OHMLOADRESISTORWHENSETFOR

A1VOLTINPUT,ORA250OHMLOAD

RESISTORWHENSETFORA5VOLTINPUT.

CURRENT

INPUT

THERMISTOR

INPUT

0-1V

0-5V

0-10V

THERM

0-1V

0-5V

0-10V

THERM

0TO10V

INPUT

0TO5V

INPUT

0TO1V

INPUT

0-10V

0-1V

0-5V

0-10V

THERM

0-1V

0-5V

THERM

0-1V

0-5V

0-10V

THERM

PROGRAMMABLECONTROLLER

SATIII

100VA

TRANSFORMER

SWITCH

DISCONNECT

INTERPANEL

100VA

TRANSFORMER

SWITCH

DISCONNECT

INTERPANEL

D

100VA

TRANSFORMER

SWITCH

DISCONNECT

INTERPANEL

D

4th Floor

GND

24VAC

GND

24VAC

24VAC

24VAC

24VAC

24VAC

24VAC

24VAC

24VAC

GND

GND

GND

GND

GND

GND

GND

24VAC

GND

24VAC

GND

485COMMIN

POWERIN

POWER&SWITCHABLECOMM

WATTMASTERCONTROLSINC.

YS102224REV0

MADEINUSAJRN

T

R

SH

TSHR

R

SH

T

TSHRTSHRTSHRTSHRTSHR TSHRTSHRTSHR

GND

24VAC

GND

24VAC

24VAC

24VAC

24VAC

24VAC

24VAC

24VAC

24VAC

GND

GND

GND

GND

GND

GND

GND

24VACGND

24VAC

GND

485COMMIN POWERIN

POWER&SWITCHABLECOMM

WATTMASTERCONTROLSINC.

YS102224REV0

MADEINUSAJRN

T

R

SH

TSHR

R

SH

T

TSHRTSHRTSHRTSHRTSHR TSHRTSHRTSHR

GND

24VAC

GND

24VAC

24VAC

24VAC

24VAC

24VAC

24VAC

24VAC

24VAC

GND

GND

GND

GND

GND

GND

GND

24VACGND

24VAC

GND

485COMMIN

POWERIN

POWER&SWITCHABLECOMM

WATTMASTERCONTROLSINC.

YS102224REV0

MADEINUSAJRN

T

R

SH

TSHR

R

SH

T

TSHRTSHRTSHRTSHRTSHR TSHRTSHRTSHR

GND

24VAC

GND

24VAC

24VAC

24VAC

24VAC

24VAC

24VAC

24VAC

24VAC

GND

GND

GND

GND

GND

GND

GND

24VACGND

24VAC

GND

485COMMIN

POWERIN

POWER&SWITCHABLECOMM

WATTMASTERCONTROLSINC.

YS102224REV0

MADEINUSAJRN

T

R

SH

TSHR

R

SH

T

TSHRTSHRTSHRTSHRTSHR TSHRTSHRTSHR

GND

24VAC

GND

24VAC

24VAC

24VAC

24VAC

24VAC

24VAC

24VAC

24VAC

GND

GND

GND

GND

GND

GND

GND

24VACGND

24VAC

GND

485COMMIN

POWERIN

POWER&SWITCHABLECOMM

WATTMASTERCONTROLSINC.

YS102224REV0

MADEINUSAJRN

T

R

SH

TSHR

R

SH

T

TSHRTSHRTSHRTSHRTSHR TSHRTSHRTSHR

TO

WCCIII - MCD

SATIIIINAENCLOSURESAT 3D IN A ENCL OSURE

2-SATIIIINADUALENCLOSURE

SATIIIINAENCLOSURESAT 3D IN A ENCL OSURE

SATIIIINAENCLOSURESAT 3D IN A ENCL OSURE

SATIIIINAENCLOSURE

SATIIIINAENCLOSURESAT 3D IN A ENCL OSURESAT 3D IN A ENC LOSURE

SAT III IN A ENCLOSURESAT III IN A ENCLOSURE

SAT 3D IN A ENCL OSURE

POWER & SWITCHABLE

COMMBOARD (PL102224)

POWER & SWITCHABLE

COMMBOARD (PL102224)

POWER & SWITCHABLE

COMMBOARD (PL102224)

POWER & SWITCHABLE

COMMBOARD (PL102224)

POWER & SWITCHABLE

COMMBOARD (PL102224)

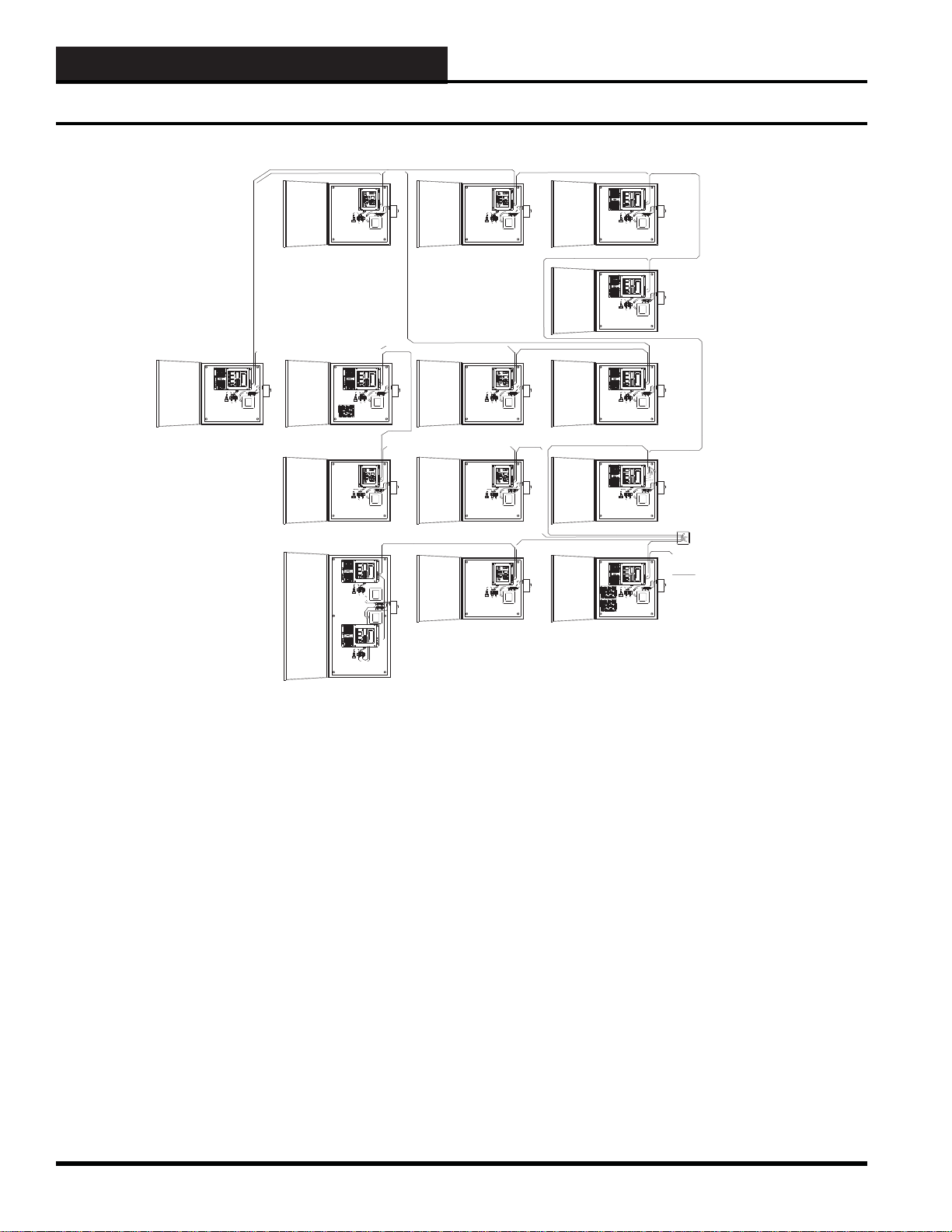

Recommended Communications Wiring

Figure 10-6: Typical WCC III System Communications Wiring – The recommended and preferred way

Wiring of the WCC III RS-485 communications loop as represented

in Figure 10-6 is recommended for the following reasons:

1. “Wire Nuts” were not used.

2. The way the WCC III communications wiring was run is also

recommended. Making a main WCC III communications trunk

line and wiring from the basement to the 1st fl oor, then to the 2nd

fl oor, then 3rd fl oor, and then to the 4th fl oor, makes logical sense.

The location of the WCC III - MCD is not shown, but it could be

3. A Power and Switchable RS-485 Communication Board

(PL102224) was used on a fl oor-by-fl oor basis. Use of this board

will aid in initial startup and in future troubleshooting. This Power

and Switchable RS-485 Communication Board (PL102224) has

push buttons on each of the 8 communications connections going

out from it. You can connect as many SAT III / SAT 3C/D/F

controllers as you wish to each switchable connection, but

remember that you can only isolate down to that loop of X number

of SAT III controllers.

anywhere in the building as long as it is connected to the main

trunk line. Also, lighting protection devices should be added on

every fl oor as a preventive measure.

WCC III Technical Guide

10-7

Page 10

10. RS-485 COMMUNICATIONS

Lightning Suppression

Lightning Suppression

Lightning is an act of nature and as such cannot be predicted or

controlled. There is NOTHING that will COMPLETELY protect

any electronic equipment from the massive effects of a direct or

near hit from lightning. WattMaster Controls has taken a number

of steps to protect the electronic components and the incoming

pathways of its equipment from voltage surges that may enter

them. These incoming pathways are defi ned as: 24VAC power,

RS-232 data communications, RS-485 data communications, input

wiring, and relay control circuits. All of these pathways have been

protected using a variety of devices, including varistors, diodes,

transorbs, and excessive ground planes on all of our circuit boards.

There are several “General Rules” that can be applied towards

lightning protection:

General Rule Number One: Any time the WCC III /Satellite

RS-485 communication’s loop enters or leaves a building, there

needs to be a properly installed and grounded lightning protection

device or lightning suppressor device.

General Rule Number Two: No lightning protection devices

or lightning suppressor devices will protect against a direct

lightning hit.

At some point you have to ask the question: “What

exactly are you trying to protect?”

Lightning could enter the building via an analog input on a TUC-2R,

and then it could cause problems with the RS-485 communications

loop on the SAT 3C/D/F TUC communications loop along with

more problems on the SAT RS-485 communications loop. You

could have your entire building’s control system go down due to a

close lightning strike. The most likely path that lightning would take

to do the most damage would be on the RS-485 communications

loop that connects the Satellite controllers to each other. You may

decide to put multiple lightning protection devices or lightning

suppressor devices on every RS-485 communications loop as a

preventive safety measure.

WattMaster Controls sells an RS-485 communications loop

lightning protection device. The WattMaster part number is

OE437-03.

General Rule Number Three: For a lightning protection

device or lightning suppressor device to work properly, there needs

to be an actual earth-ground connection point as near as possible

to the lightning protection device or lightning suppressor device.

Being feet away from the actual earth-ground connection does not

work, Being inches away is always the best possible connection

point for this actual ground connection.

10-8

WCC III Technical Guide

Page 11

10. RS-485 COMMUNICATIONS

MCD Troubleshooting with a Digital V oltmeter

MCD Communications T roubleshooting with a Digital Voltmeter

Troubleshooting of the WCC III system RS-485 satellite communications loop is possible with a digital voltmeter.

Figure 10-7: Typical WCC III - MCD RS-485 Satellite Communications DC V oltage Measurements with the Loop

Connected

The voltage measurements in Figure 10-7 are approximate voltages. These voltage measurements are taken when the power to the

WCC III - MCD is “ON” and the RS-485 communications loop is connected. These two voltages will fl uctuate slightly and also will

momentarily “fl ip” to the other meter reading’s value. The voltage measurement from “T” to “SHIELD” should be around 2.7 VDC. The

voltage measurement from “R” to “SHIELD” should be around 3.00 VDC. Typical bad voltage measurement values would be anything

above 3.8 VDC and anything below 1.5 VDC. This voltage measurement applies to both top and bottom RS-485 loop communications

connections.

Figure 10-8: Typical WCC III - MCD RS-485 Satellite Communications DC V oltage Measurements with the Loop

Disconnected

The voltage measurements in Figure 10-8 are approximate voltages. These voltage measurements are taken when the power to the

WCC III - MCD is “ON” and the RS-485 communications loop is disconnected. These two voltages will fl uctuate slightly and also will

momentarily “fl ip” to the other meter reading’s value. The voltage measurement from “T” to “SHIELD” should be around 2.7 VDC. The

voltage measurement from “R” to “SHIELD” should be around 3.00 VDC. Typical bad voltage measurement values would be anything

above 3.8 VDC and anything below 1.5 VDC. This voltage measurement applies to both top and bottom RS-485 loop communications

connections.

WCC III Technical Guide

10-9

Page 12

10. RS-485 COMMUNICATIONS

SA T III Troubleshooting with a Digital V oltmeter

SA T III Communications T roubleshooting with a Digital Voltmeter

Figure 10-9: Typical SAT III RS-485 Sa tellite Communications DC Voltage Measurements with the Loop

Connected

The voltage measurements in Figure 10-9 are approximate voltages. These voltage measurements are taken when the power to the SAT

III Controller is “ON” and the RS-485 SAT communications loop is connected. These two voltages will fl uctuate slightly and also will

momentarily “fl ip” to the other meter reading’s value. The voltage measurement from “T” to “SHIELD” should be around 2.7 VDC. The

voltage measurement from “R” to “SHIELD” should be around 3.00 VDC. Typical bad voltage measurement values would be anything

above 3.8 VDC and anything below 1.5 VDC. Helpful hint: Removal of the SAT III cover may aid in measuring the communication loop

voltages.

Figure 10-10: Typical SAT III RS-485 Sa tellite Communications DC Voltage Measurements with the Loop

Disconnected

The voltage measurements in Figure 10-10 are approximate voltages. These voltage measurements are taken when the power to the SAT

III Controller is “ON” and the RS-485 SAT communications loop is disconnected. These two voltages will not fl uctuate. The voltage

measurement from “T” to “SHIELD” should be around 3.25 VDC. The voltage measurement from “R” to “SHIELD” should be around

3.25 VDC. Typical bad voltage measurement values would be anything above 3.8 VDC and anything below 1.5 VDC. Helpful hint:

Removal of the SAT III cover may aid in measuring the communication loop voltages.

10-10

WCC III Technical Guide

Page 13

10. RS-485 COMMUNICATIONS

SA T 3C/D/F Troubleshooting with a Digital V oltmeter

SA T 3C/D/F Communications T roubleshooting with a Digital Voltmeter

Figure 10-11: Typical SAT 3C/D/F RS-485 Sa tellite Communications DC Voltage Measurements with the SAT

COMM Loop Connected

The voltage measurements in Figure 10-1 1 are approximate voltages. These voltage measurements are taken when the power to the SAT

3C/D/F Controller is “ON” and the RS-485 SA T communications loop is connected. These two voltages will fl uctuate slightly and also will

momentarily “fl ip” to the other meter reading’s value. The voltage measurement from “T” to “SHIELD” should be around 2.7 VDC. The

voltage measurement from “R” to “SHIELD” should be around 3.00 VDC. Typical bad voltage measurement values would be anything

above 3.8 VDC and anything below 1.5 VDC. Helpful hint: Removal of the SAT 3C/D/F cover may aid in measuring the communication

loop voltages.

Figure 10-12: Typical SAT 3C/D/F RS-485 Sa tellite Communications DC Voltage Measurements with the SAT

COMM Loop Disconnected

The voltage measurements in Figure 10-12 are approximate voltages. These voltage measurements are taken when the power to the SAT

3C/D/F controller is “ON” and the RS-485 SAT communications loop is disconnected. These two voltages will not fl uctuate. The voltage

measurement from “T” to “SHIELD” should be around 3.25 VDC. The voltage measurement from “R” to “SHIELD” should be around

3.25 VDC. Typical bad voltage measurement values would be anything above 3.8 VDC and anything below 1.5 VDC. Helpful hint:

Removal of the SAT 3C/D/F cover may aid in measuring the communication loop voltages.

WCC III Technical Guide

10-11

Page 14

10. RS-485 COMMUNICATIONS

SA T 3C/D/F Troubleshooting with a Digital V oltmeter

Figure 10-13: Typical SAT 3C/D/F TUC RS-485 Sa tellite Communications DC Voltage Measurements with the

TUC COMM Loop Connected

The voltage measurements in Figure 10-13 are approximate voltages. These voltage measurements are taken when the power to the SAT

3C/D/F Controller is “ON” and the RS-485 TUC EXP communications loop is connected. These two voltages will fl uctuate slightly and

also will momentarily “fl ip” to the other meter reading’s value. The voltage measurement from “T” to “SHIELD” should be around 2.7

VDC. The voltage measurement from “R” to “SHIELD” should be around 3.00 VDC. Typical bad voltage measurement values would

be anything above 3.8 VDC and anything below 1.5 VDC. Helpful hint: Removal of the SAT 3C/D/F cover may aid in measuring the

communication loop voltages.

Figure 10-14: Typical SAT 3C/D/F TUC RS-485 Sa tellite Communications DC Voltage Measurements with the

TUC COMM Loop Disconnected

The voltage measurements in Figure 10-14 are approximate voltages. These voltage measurements are taken when the power to the SAT

3C/D/F Controller is “ON” and the RS-485 TUC EXP communications loop is disconnected. These two voltages will not fl uctuate. The

voltage measurement from “T” to “SHIELD” should be around 3.25 VDC. The voltage measurement from “R” to “SHIELD” should be

around 3.25 VDC. T ypical bad voltage measurement values would be anything above 3.8 VDC and anything below 1.5 VDC. Helpful hint:

Removal of the SAT 3C/D/F cover may aid in measuring the communication loop voltages.

10-12

WCC III Technical Guide

Page 15

10. RS-485 COMMUNICATIONS

SA T 3P Troubleshooting with a Digital V oltmeter

Figure 10-15: Typical SAT 3P TUC RS-485 Sa tellite Communications DC Voltage Measurements with the SAT

COMM Loop Connected

The voltage measurements in Figure 10-15 are approximate voltages. All SAT 3P controllers should use the LT1785 driver chip. These

voltages are taken when the SAT 3P controller is “ON” and the RS-485 SAT communications loop is connected. These two voltages will

fl uctuate slightly and also will momentarily “fl ip” to the other meter reading’s value. The voltage measurements from “T” to “SHLD” should

be around 2.70 VDC. The voltage measurements from “R” to “SHLD” should be around 3.00 VDC. Typical bad voltages measurements

values would be anything above 3.8 VDC and anything below 1.5 VDC.

Figure 10-16: Typical SAT 3P TUC RS-485 Sa tellite Communications DC Voltage Measurements with the SAT

COMM Loop Disconnected

The voltage measurements in Figure 10-16 are approximate voltages. All SAT 3P controllers should use the LT1785 driver chip. These

voltages are taken when the SAT 3P controller is “ON” and the RS-485 SAT communications loop is disconnected. These two voltages

will not fl uctuate. The voltage measurements from “T” to “SHLD” should be around 3.25 VDC. The voltage measurements from “R” to

“SHLD” should be around 3.25 VDC. Typical bad voltages measurements values would be anything above 3.8 VDC and anything below

1.5 VDC.

WCC III Technical Guide

10-13

Page 16

10. RS-485 COMMUNICATIONS

TUC-2R Troubleshooting with a Digital V oltmeter

TUC-2R Communications T roubleshooting with a Digital Voltmeter

Figure 10-17: Typical TUC-2R RS-485 TUC Communications DC Voltage Measurements with the TUC COMM

Loop Disconnected – LT1785 Driv er

The voltage measurements in Figure 10-17 are approximate voltages. Newer TUC-2R Controllers use a different RS-485 driver chip.

These voltage measurements are taken when the power to the TUC-2R Controller is “ON” and the RS-485 TUC communications loop is

disconnected. These two voltages will not fl uctuate. The voltage measurement from “T” to “SHIELD” should be around 3.25 VDC. The

voltage measurement from “R” to “SHIELD” should be around 3.25 VDC. Typical bad voltage measurement values would be anything

above 3.8 VDC and anything below 1.5 VDC.

Figure 10-18: Typical TUC-2R RS-485 TUC Communications DC Voltage Measurements with the TUC COMM

Loop Disconnected – 75176 Driver

The voltage measurements in Figure 10-18 are approximate voltages. Older TUC-2R Controllers used a different RS-485 driver chip.

These voltage measurements are taken when the power to the TUC-2R Controller is “ON” and the RS-485 TUC communications loop is

disconnected. These two voltages will not fl uctuate. The voltage measurement from “T” to “SHIELD” should be around 2.50 VDC. The

voltage measurement from “R” to “SHIELD” should be around 2.50 VDC. Typical bad voltage measurement values would be anything

above 3.8 VDC and anything below 1.5 VDC.

10-14

WCC III Technical Guide

Page 17

10. RS-485 COMMUNICATIONS

TUC-2R Troubleshooting with a Digital V oltmeter

Figure 10-19: Typical TUC-2R RS-485 TUC Communications DC Voltage Measurements with the TUC COMM

Loop Connected – LT1785 Driv er

The voltage measurements in Figure 10-19 are approximate voltages. These voltages are taken when the TUC2R controller is “ON” and

the RS-485 TUC communications loop is connected. These two voltages will fl uctuate slightly and also will momentarily “fl ip” to the

other meter reading’s value. The voltage measurements from “T” to “SHLD” should be around 2.70 VDC. The voltage measurements

from “R” to “SHLD” should be around 3.00 VDC. Typical bad voltage measurement values would be anything above 3.8 VDC and

anything below 1.5 VDC.

Figure 10-20: Typical TUC-2R RS-485 TUC Communications DC Voltage Measurements with the TUC COMM

Loop Connected – 75176 Driver

The voltage measurements in Figure 10-20 are approximate voltages. These voltages are taken when the TUC2R controller is “ON” and

the RS-485 TUC communications loop is connected. These two voltages will fl uctuate slightly and also will momentarily “fl ip” to the

other meter reading’s value. The voltage measurements from “T” to “SHLD” should be around 2.70 VDC. The voltage measurements

from “R” to “SHLD” should be around 3.00 VDC. Typical bad voltage measurement values would be anything above 3.8 VDC and

anything below 1.5 VDC.

WCC III Technical Guide

10-15

Page 18

10. RS-485 COMMUNICATIONS

V AVZ II T roubleshooting with a Digital Voltmeter

Figure 10-21: Typical VAVZ II RS-485 TUC Communications DC Voltage Measurements with the TUC COMM

Loop Connected – LT1785 Driv er

The voltage measurements in Figure 10-21 are approximate voltages. All VAVZ II controllers should use the LT1785 driver chip. These

voltages are taken when the VAVZ II controller is “ON” and the RS-485 TUC communications loop is connected. These two voltages will

fl uctuate slightly and also will momentarily “fl ip” to the other meter reading’s value. The voltage measurements from “T” to “SHLD” should

be around 2.70 VDC. The voltage measurements from “R” to “SHLD” should be around 3.00 VDC. Typical bad voltages measurements

values would be anything above 3.8 VDC and anything below 1.5 VDC.

Figure 10-22: Typical VAVZ II RS-485 TUC Communications DC Voltage Measurements with the TUC COMM

Loop Disconnected – LT1785 Driv er

The voltage measurements in Figure 10-22 are approximate voltages. All VAVZ II controllers should use the LT1785 driver chip. These

voltages are taken when the VAVZ II controller is “ON” and the RS-485 TUC communications loop is disconnected. These two voltages

will not fl uctuate. The voltage measurements from “T” to “SHLD” should be around 3.25 VDC. The voltage measurements from “R” to

“SHLD” should be around 3.25 VDC. Typical bad voltages measurements values would be anything above 3.8 VDC and anything below

1.5 VDC.

10-16

WCC III Technical Guide

Page 19

10. RS-485 COMMUNICATIONS

TUC-5R Troubleshooting with a Digital V oltmeter

TUC-5R Communications T roubleshooting with a Digital Voltmeter

Figure 10-23: Typical TUC-5R RS-485 TUC Communications DC Voltage Measurements with the TUC COMM

Loop Disconnected – 75176 Driver

The voltage measurements in Figure 10-23 are approximate voltages. Older TUC-5R Controllers used a different RS-485 driver chip.

These voltage measurements are taken when the power to the TUC-5R Controller is “ON” and the RS-485 TUC communications loop is

disconnected. These two voltages will not fl uctuate. The voltage measurement from “T” to “SHIELD” should be around 2.50 VDC. The

voltage measurement from “R” to “SHIELD” should be around 2.50 VDC. Typical bad voltage measurement values would be anything

above 3.8 VDC and anything below 1.5 VDC.

Figure 10-24: Typical TUC-5R RS-485 TUC Communications DC Voltage Measurements with the TUC COMM

Loop Disconnected – LT1785 Driv er

The voltage measurements in Figure 10-24 are approximate voltages. Older TUC-5R Controllers used a different RS-485 driver chip.

These voltage measurements are taken when the power to the TUC-5R Controller is “ON” and the RS-485 TUC communications loop is

disconnected. These two voltages will not fl uctuate. The voltage measurement from “T” to “SHIELD” should be around 3.25 VDC. The

voltage measurement from “R” to “SHIELD” should be around 3.25 VDC. Typical bad voltage measurement values would be anything

above 3.8 VDC and anything below 1.5 VDC.

WCC III Technical Guide

10-17

Page 20

10. RS-485 COMMUNICATIONS

TUC-5R Troubleshooting with a Digital V oltmeter

Figure 10-25: Typical TUC-5R RS-485 TUC Communications DC Voltage Measurements with the TUC COMM

Loop Connected – 75176 Driver

The voltage measurements in Figure 10-25 are approximate voltages. Older TUC-5R Controllers used a different RS-485 driver chip.

These voltages are taken when the TUC5R controller is “ON” and the RS-485 TUC communications loop is connected. These two

voltages will fl uctuate slightly and also will momentarily “fl ip” to the other meter reading’ s value. The voltage measurements from “T” to

“SHLD” should be around 2.70 VDC. The voltage measurements from “R” to “SHLD” should be around 3.00 VDC. T ypical bad voltages

measurements values would be anything above 3.8 VDC and anything below 1.5 VDC.

Figure 10-26: Typical TUC-5R RS-485 TUC Communications DC Voltage Measurements with the TUC COMM

Loop Connected – LT1785 Driv er

The voltage measurements in Figure 10-26 are approximate voltages. Older TUC-5R Controllers used a different RS-485 driver chip.

These voltages are taken when the TUC5R controller is “ON” and the RS-485 TUC communications loop is connected. These two

voltages will fl uctuate slightly and also will momentarily “fl ip” to the other meter reading’ s value. The voltage measurements from “T” to

“SHLD” should be around 2.70 VDC. The voltage measurements from “R” to “SHLD” should be around 3.00 VDC. T ypical bad voltages

measurements values would be anything above 3.8 VDC and anything below 1.5 VDC.

10-18

WCC III Technical Guide

Page 21

10. RS-485 COMMUNICATIONS

RTU-17 T roubleshooting with a Digital Voltmeter

RTU-17 Communications T roubleshooting with a Digital Voltmeter

Figure 10-27: Typical RTU-17 RS-485 TUC Communications DC V oltage Measurements with the TUC COMM

Loop Disconnected – 75176 Driver

The voltage measurements in Figure 10-27 are approximate voltages. Older RTU-17 Controllers used a different RS-485 driver chip.

These voltage measurements are taken when the power to the TUC-5R Controller is “ON” and the RS-485 TUC communications loop is

disconnected. These two voltages will not fl uctuate. The voltage measurement from “T” to “SHIELD” should be around 2.50 VDC. The

voltage measurement from “R” to “SHIELD” should be around 2.50 VDC. Typical bad voltage measurement values would be anything

above 3.8 VDC and anything below 1.5 VDC.

Figure 10-28: Typical RTU-17 RS-485 TUC Communications DC V oltage Measurements with the TUC COMM

Loop Disconnected – LT1785 Driv er

The voltage measurements in Figure 10-28 are approximate voltages. Older RTU-17 Controllers used a different RS-485 driver chip.

These voltage measurements are taken when the power to the RTU-17 Controller is “ON” and the RS-485 TUC communications loop is

disconnected. These two voltages will not fl uctuate. The voltage measurement from “T” to “SHIELD” should be around 3.25 VDC. The

voltage measurement from “R” to “SHIELD” should be around 3.25 VDC. Typical bad voltage measurement values would be anything

above 3.8 VDC and anything below 1.5 VDC.

WCC III Technical Guide

10-19

Page 22

10. RS-485 COMMUNICATIONS

RTU-17 T roubleshooting with a Digital Voltmeter

Figure 10-29: Typical RTU-17 RS-485 TUC Communications DC V oltage Measurements with the TUC COMM

Loop Connected – 75176 Driver

The voltage measurements in Figure 10-29 are approximate voltages. Older RTU-17 Controllers used a different RS-485 driver chip.

These voltages are taken when the RTU-17 controller is “ON” and the RS-485 TUC communications loop is connected. These two

voltages will fl uctuate slightly and also will momentarily “fl ip” to the other meter reading’ s value. The voltage measurements from “T” to

“SHLD” should be around 2.70 VDC. The voltage measurements from “R” to “SHLD” should be around 3.00 VDC. T ypical bad voltages

measurements values would be anything above 3.8 VDC and anything below 1.5 VDC.

Figure 10-30: Typical RTU-17 RS-485 TUC Communications DC V oltage Measurements with the TUC COMM

Loop Connected – LT1785 Driv er

The voltage measurements in Figure 10-30 are approximate voltages. Older RTU-17 Controllers used a different RS-485 driver chip.

These voltages are taken when the RTU-17 controller is “ON” and the RS-485 TUC communications loop is connected. These two

voltages will fl uctuate slightly and also will momentarily “fl ip” to the other meter reading’ s value. The voltage measurements from “T” to

“SHLD” should be around 2.70 VDC. The voltage measurements from “R” to “SHLD” should be around 3.00 VDC. T ypical bad voltages

measurements values would be anything above 3.8 VDC and anything below 1.5 VDC.

10-20

WCC III Technical Guide

Page 23

10. RS-485 COMMUNICATIONS

Global Bridge Troubleshooting with a Digital V oltmeter

Global Bridge Communications T roubleshooting with a Digital Voltmeter

Figure 10-31: Typical Global Bridge RS-485 TUC Communications DC Voltage Measurements with the SAT

COMM Loop Connected

The voltage measurements in Figure 10-31 are approximate voltages. These voltage measurements are taken when the power to the

Global Bridge Controller is “ON” and the RS-485 SAT III communications loop is connected. These two voltages will fl uctuate slightly

and also will momentary “fl ip” to the other meter reading’s value. The voltage measurement from “T” to “SHIELD” should be around 2.7

VDC. The voltage measurement from “R” to “SHIELD” should be around 3.00 VDC. Typical bad voltage measurement values would be

anything above 3.8 VDC and anything below 1.5 VDC.

Figure 10-32: Typical Global Bridge RS-485 TUC Communications DC Voltage Measurements with the SAT

COMM Loop Disconnected

The voltage measurements in Figure 10-32 are approximate voltages. These voltage measurements are taken when the power to the

Global Bridge Controller is “ON” and the RS-485 SAT III communications loop is disconnected. These two voltages will not fl uctuate.

The voltage measurement from “T” to “SHIELD” should be around 3.25 VDC. The voltage measurement from “R” to “SHIELD” should

be around 3.25 VDC. Typical bad voltage measurement values would be anything above 3.8 VDC and anything below 1.5 VDC.

WCC III Technical Guide

10-21

Page 24

10. RS-485 COMMUNICATIONS

Replacing RS-485 Driv er Chip(s) on SAT III

Replacing RS-485 Driv er Chips

Y ou must fi rst disconnect the 24V AC power and then disconnect the three-wire RS-485 communications loop connections before you can

attempt to remove or replace a RS-485 communications driver chip. Failure to do so may result in a damaged driver chip and/or damaged

circuit board(s).

Figure 10-33: Replacing the RS-485 Driver Chip(s) on the SA T III Controller

10-22

WCC III Technical Guide

Page 25

10. RS-485 COMMUNICATIONS

Replacing RS-485 Driv er Chip(s) on SAT 3P and TUC-5R

Y ou must fi rst disconnect the 24V AC power and then disconnect the three-wire RS-485 communications loop connections before you can

attempt to remove or replace a RS-485 communications driver chip. Failure to do so may result in a damaged driver chip and/or damaged

circuit board(s).

Figure 10-34: Replacing the RS-485 Driver Chip(s) on the SA T 3P Controller

Figure 10-35: Replacing the RS-485 Driver Chip(s) on the TUC-5R / TUC-5R+ Controller

WCC III Technical Guide

10-23

Page 26

10. RS-485 COMMUNICATIONS

Replacing RS-485 Driv er Chips on RTU17, TUC-2R, and VA VZ II

Y ou must fi rst disconnect the 24V AC power and then disconnect the three-wire RS-485 communications loop connections before you can

attempt to remove or replace a RS-485 communications driver chip. Failure to do so may result in a damaged driver chip and/or damaged

circuit board(s).

Figure 10-36: Replacing the RS-485 Driver Chip(s) on the RTU-17 and TUC-2R Controller

Figure 10-37: Replacing the RS-485 Driver Chip(s) on the V AVZ II Controller

10-24

WCC III Technical Guide

Page 27

10. RS-485 COMMUNICATIONS

Replacing RS-485 Driv er Chips on Global Bridge

Figure 10-38: Replacing the RS-485 Driver Chip(s) on the Global Bridge Controller

WCC III Technical Guide

10-25

Page 28

10. RS-485 COMMUNICATIONS

Replacing RS-485 Driv er Chips on the SAT 3C/D/F

SAT C/D/F REV 3 TUC RS485 DRIVER

LOCATION "U16"

REPLACE THE 75176 CHIP WITH THE

LT1785 CHIP

74HC04

34063A

34063A

SAT 3C/D REV3 RS485 DRIVER LOCATION "U5"

THIS RS485 DRIVER IS FOR "SAT" COMM

REPLACE THE 75176 CHIP WITH THE

LT1785 CHIP

Figure 10-39: Replacing the RS-485 Driver Chip(s) on the SA T 3C/D/F

10-26

WCC III Technical Guide

Page 29

10. RS-485 COMMUNICATIONS

Replacing RS-485 Driv er Chips on the WCC3 Binary Input Board

WCC3 BINARYIN W/ TIME DELAY

WATTMASTER CONTROLS, INC

YS102072 REV 2

WCC3 BINARY INPUT

RS485 DRIVER LOCATION

REPLACE THE 75176 CHIP

WITH THE LT1785 CHIP

Figure 10-40: Replacing the RS-485 Driver Chip(s) on the WCC3 Binary Input Board

WCC III Technical Guide

10-27

Page 30

10. RS-485 COMMUNICATIONS

Replacing RS-485 Driv er Chips on the WCC3 V-Out R elay Board

OMRON

OMRON

OMRON

OMRON

OMRON

OMRON

OMRON

OMRON

G5Q-14

DC24V

SA

VDE

5A30VDC

CHINA

10A250VAC ~

G5Q-14

G5Q-14

DC24V

DC24V

5A30VDC

CHINA

10A250VAC ~

VDE

VDE

5A30VDC

CHINA

10A250VAC ~

G5Q-14

G5Q-14

DC24V

DC24V

5A30VDC

CHINA

10A250VAC ~

VDE

VDE

5A30VDC

CHINA

10A250VAC ~

G5Q-14

G5Q-14

DC24V

DC24V

VDE

5A30VDC

CHINA

CHINA

10A250VAC ~

SA

SA

SA

SA

SA

SA

5A30VDC

10A250VAC ~

SA

G5Q-14

DC24V

VDE

VDE

5A30VDC

CHINA

10A250VAC ~

V-OUT RELAY REV3 RS485

DRIVER LOCATION "U5"

REPLACE THE 75176 CHIP

WITH THE LT1785 CHIP

Figure 10-41: Replacing the RS-485 Driver Chip(s) on the WCC3 V -Out R elay Board

10-28

WCC III Technical Guide

Loading...

Loading...