Page 1

4. SCUSCR.EXE Screens

WCC III

4. SCUSCR.EXE Screens

Page 2

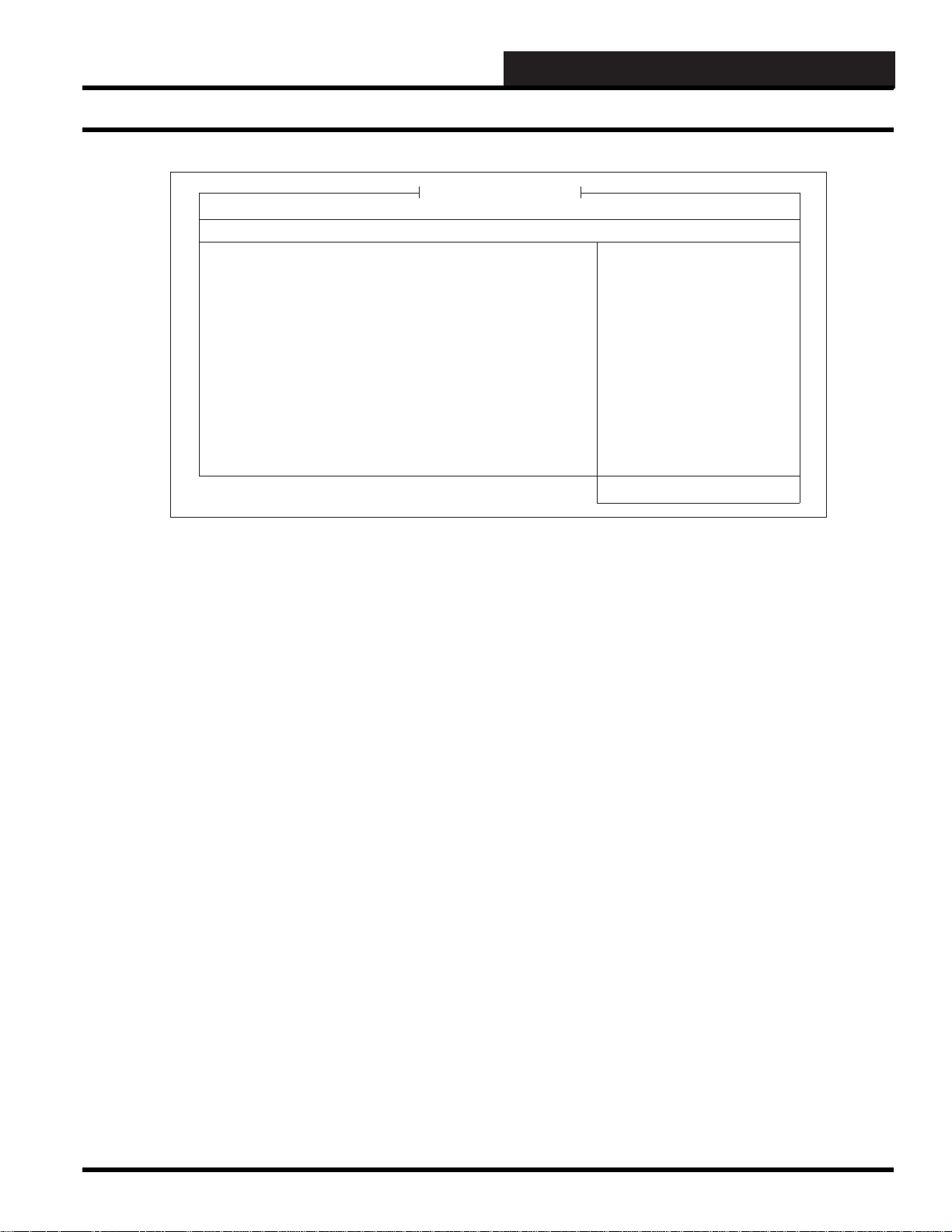

T ABLE OF CONTENTS

SECTION 4:

SCUSCR.EXE SCREENS

How to Start or Run the SCUSCR.exe

Program....................................................... 4-1

Controller Overview ....................................4-3

SCUSCR.EXE Screens Index.......................4-5

WCC VAV BOX III Sequence of Operation

(SS5010) ......................................................4-6

Modes of Operation ....................................4-8

Tenant Override Logs ...............................4-14

Series Fan Powered Pressure Dependent

Status & Setpoint Screens ....................... 4-58

Series Fan Powered Pressure Independent

Status & Setpoint Screens ....................... 4-60

Single Duct Changeover Pressure Dependent

Status & Setpoint Screens ....................... 4-62

Single Duct Changeover Pressure Independent

Status & Setpoint Screens ...................... 4-64

Single Duct Reheat Pressure Dependent

Status & Setpoint Screens ....................... 4-66

Single Duct Reheat Pressure Independent

Status & Setpoint Screens ....................... 4-68

Alarm Detection and Reporting ................4-15

WCC III VAV BOX III Trend Logging ..........4-15

Force Modes or Overrides ........................4-16

SCUSCR.EXE SCREENS ............................4-17

SAT 3D Addressing to TUC Control

Points ........................................................4-18

Single Duct Cooling-Only Screens............4-30

Single Duct Cooling-Only Screens –

Pressure Independent ..............................4-37

Parallel Fan Powered Pressure

Dependent Screens ..................................4-44

Parallel an Powered Pressure

Independent Screens ................................ 4-51

Page 3

4. SCUSCR.EXE SCREENS

Running the SCUSCR Program

SECTION 4:

SCUSCR.EXE SCREENS

__________________________________________

How to Start or Run the SCUSCR.exe

Program (SS5026)

The SCUSCR.exe shortcut icon should have

been installed on your WCC III front end

computer desktop with the WCC III Installation

Software CD. The WCC III Installation Software

CD is WattMaster Controls Part # DM1WC01101X.

To start the SCUSCR.exe program, double-click the left mouse

button on the Shortcut Icon found on the Windows desktop. After

a short period of time, dependent upon the CPU speed of your

Windows based computer and the speed of your IP connection to

the internet, the WCC III T ype Connection Dialog Box will appear.

on the WCC III Front end computer. This IP Address connection

is done on a higher address port number than normal (WCC

III connection is port number 39289) to help reduce the risk of

computer hacking.

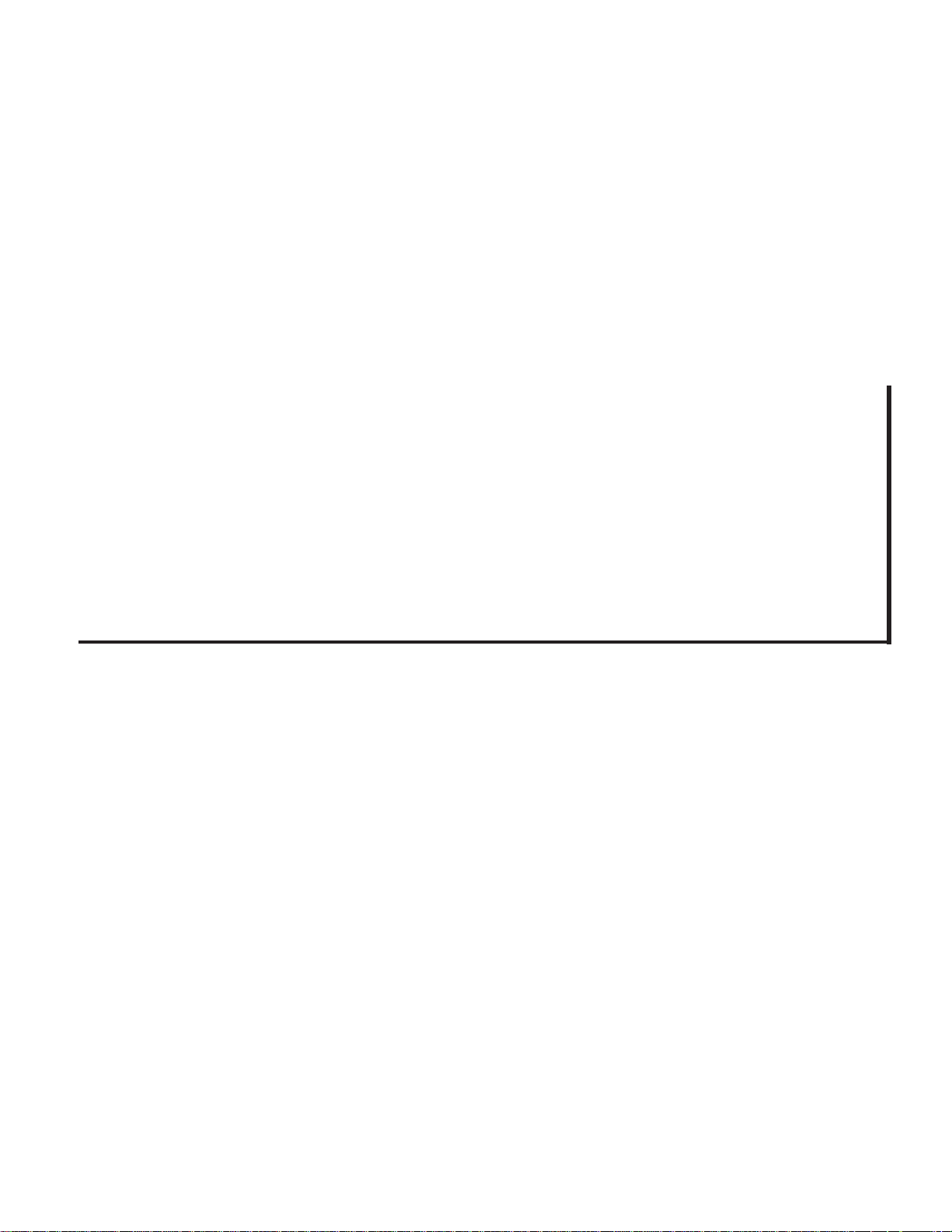

Using your mouse, left-click on the <Access Job Site> button.

The Remote Access Dialog Window will appear.

By selecting <OK>, the SCUSCR.exe program will now start to

connect to the selected WCC III – MCD via this selected IP address

connection. It should bring up the WCC III SCUSCR Set Password

Dialog screen within a new window. If the IP address connection

fails to connect to the WCC III – MCD, then another small dialog

box window will appear. This is the Cannot Communicate to

Backtask Dialog Box.

Once you click <OK>, you will exit the SCUSCR.exe program.

You will have to fi gure out why you cannot connect to the WCC

III – MCD via the IP address connection.

Server IP Address:

This is the static IP address of the WCC III – MCD. An IP Address

is like a phone number on the world wide web. The IP address for

the WCC III – MCD must be Static (does not change) as opposed

to Dynamic (constantly changing). This static IP address must be

provided by your internet service provider. (A static IP address

is the preferred IP connection method for the WCC III system to

function.) If you actually know the static IP address of the WCC

III – MCD that you wish to connect to, please enter it here in the

Server IP Address fi eld, or better yet, continue to the Remote Access

Dialog Window by selecting the <Access J ob Site> button.

You can use a Dynamic IP Address with the WCC III – MCD,

but you must then have what is called a static “Host Name”. This

static “Host name” must then be provided by your internet service

provider and is limited to 58 total characters.

Port Number:

The SCUSCR.exe program opens a two-way, secure

communications port that then allows for communication between

the WCC III – MCD and the SCUSCR.exe program that is running

WCC III Technical Guide

In the Set Password Dialog Screen enter an “Operator:”

identifi cation and a “Code:” or password equal to at least a pass

level 0 that has been previously set up on the WCCIII System

Parameter – Operator Code Screen. (See the Operator Code

Screen of the System Parameter Screen in Section 3 for information

on setting up Operator Codes.) Click <Check Password>. If the

“Current Pass Level:” stays at 0 or higher (1, 2, or 3), then click

<OK>. By selecting <OK>, the SCUSCR.exe program will now

start to connect to the selected WCC III – MCD via this selected

IP address connection. It should bring up the SCUSCR - Demo

Screen within a new window. If the “Current Pass Level:” changes

to –1 then you do not have access to the WCCIII – MCD. If you

do not have access to the WCCIII – MCD and you click <OK>

then this connection to the SCUSCR.exe program is not an actual

IP connection, but rather a “dummy” SCUSCR - demo screen

window with no values.

4-1

Page 4

4. SCUSCR.EXE SCREENS

Running the SCUSCR Program

The Remote Access Dialog Box will allow you to enter multiple

WCC III – MCD IP addresses based upon “Job Site” names. This

is done by typing in the name of the jobsite you wish to call your

system.

First you must select a “BLANK” line in the bottom box area

with your left mouse button. (This line will then be highlighted

in “Blue”.) You must then enter a Job Site name in the “Job Site”

fi eld, along with the static IP address and Port number (39289) for

the WCC III – MCD that you wish to connect to with the SCUSCR.

exe program.

If you are using a static “Host Name” instead of a static IP address,

please make sure that the Dynamic Address check box has been

selected, along with the static “Host Name” in the space provided.

As mentioned previously, you must get this static “Host Name”

from your internet service provider, and it is limited to 58 characters

total.

Please note that this “Job Site” name will also be the name of a

subdirectory that will automatically be created in the Local disk

C:\ProgramFiles\WCCIII\SCUSCR subdirectory on the WCC III

Front end computer. The Remote Access Dialog Box also creates

a JobSite.dat data fi le in the C:\ProgramFiles\WCCIII\SCUSCR

subdirectory. This data fi le is not a viewable type of fi le. The

JobSite.dat fi le can be copied and then can be used on other WCC

III front end computers. This reused JobSite.dat will then recreate

the needed “Job Site” subdirectories on the other WCC III front

end computers upon the reselection of the Job Site IP address.

In an already fi lled out Remote Access Dialog Box, you can simply

select from the list of previously entered Job Sites that are displayed

in the bottom box fi eld. Then left-click <OK>. This will take you

back to the Connection Dialog Box that was fi rst displayed. This

Connection Dialog Box now should have the desired IP address in

the Server IP Address location fi eld and the port number (39289)

in the Port Number location fi eld for the WCC III – MCD that you

wish to connect to with the SCUSCR.exe program.

IP Address:

This is the static IP address where the WCC III – MCD is located.

An IP Address is like a phone number on the world wide web.

The IP address for the WCC III – MCD must be static (does not

change) as opposed to Dynamic (constantly changing). This static

IP Address must be provided by your internet service provider.

(A static IP address is the preferred IP connection method for the

WCC III system to function.)

Port Number:

The SCUSCR.exe program opens a two-way, secure

communications port that then allows for communication between

the WCC III – MCD and the SCUSCR.exe program that is running

on the WCC III front end computer. This IP Address connection

is done on a higher address port number than normal (WCC

III connection is port number 39289) to help reduce the risk of

computer hacking.

Job Site:

This is the name of the jobsite you wish to call your system. Please

note that this name will also be the name of a subdirectory that

will automatically be created in the Local disk C:\ProgramFiles\

WCCIII\SCUSCR subdirectory.

Host Name:

You can use a Dynamic IP Address with the WCC III – MCD,

but you must then have what is called a static “Host Name”. This

static “Host name” must then be provided by your internet service

provider and is limited to 58 total characters.

When you have fi lled out all necessary fi elds, left-click <OK>.

This will take you back to the Connection Dialog Box that was

fi rst displayed. This Connection Dialog Box now should have the

desired IP address in the Server IP Address location fi eld and the

port number (39289) in the Port Number location fi eld for the

WCC III – MCD that you wish to connect to with the SCUSCR.

exe program.

Left-click

was fi rst displayed. The Connection Dialog Box will have the

same IP address as listed originally before in the Server IP Address

location fi eld and the port number (39289) in the Port Number

location fi eld.

Left-click <Print> to send all of this data in this Remote Access

Dialog Box to your Windows system default printer on the WCC

III front end computer. This print function is provided to give you

a hard paper backup copy of these IP address for the various WCC

III – MCD that you may have. This print function also creates a

Printscreen.dat data fi le in the C:\ProgramFiles\WCCIII\SCUSCR

subdirectory. This data fi le is not a viewable type of fi le.

<Cancel> to return to the Connection Dialog Box that

4-2

WCC III Technical Guide

Page 5

4. SCUSCR.EXE SCREENS

Overview of Controllers

Controller Overview

WattMaster Controls, Inc. produces a line of application-specifi c

controllers that perform a multitude of various specifi c dedicated

functions. These dedicated controllers have a WCC user’s

interface that is referred to as the SCUSCR.exe program. With

this SCUSCR.exe program, you can view temperatures, setpoints,

schedules, actuator position, global control commands, etc. and

conversely with this same SCUSCR.exe program, you would

be able to confi gure and modify the setpoints, schedules, global

control commands, etc. of any of these various specifi c dedicated

controllers. The three basic type controllers are listed below along

with the two types of WCC III types of interfaces:

TUC2R (OE320) - Used mainly for VVT or VAVBOX

type of applications

Two relays for direct control of the damper actuator with an actuator

output connector with damper position input, a room temperature

sensor input with override and adjust options, and an Expansion

board connector for optional AUX fan and AUX Heating, Hot

water/Chilled water valve connections.

You must consult the specifi c application for the wiring, setup, and

programming confi guration for the exact software application you

are using.

TUC5R (OE330) and TUC5R+ (OE331) - Used mainly

for CV and Heat Pump applications

One Relay output for Fan ON/OFF control and 4 relay outputs that

are usually confi gurable for 1 to 2 stages of heating and/or cooling.

Room temperature sensor input/ with override and adjust options,

various sensor connections for measuring, supply air, return air,

and outdoor air temperatures. Analog outputs for VFD control.

The TUC5R has an optional further enhancement called TUC5R+.

The TUC5R+ has an additional couple of analog inputs, and extra

analog output, and an I2C expansion connection.

RTU-17 (OE310) - Used for Main unit VVT control,

some complex CV, General Purpose Input Output

ON/OFF controller, and dedicated AHU control

applications

One Relay output for Fan ON/OFF control and 4 relay outputs

that are usually confi gurable for 1 to 2 stages of heating and/or

cooling. Two relays are for direct control of the damper actuator

with a damper position input, a Room Temperature sensor input

with override and adjust options, various sensor connections for

measuring, supply air, return air, and outdoor air temperatures.

Analog output for VFD control.

You must consult the specifi c application for the wiring, setup, and

programming confi guration for the exact software application you

are using.

SAT 3C (OE455) - Used to interf ace the RTU-17

controller and some of the more complex TUC5R(+)

controller software applications to the WCC III

system

The SAT 3C occupies 8 SAT III addresses on the Satellite

controller loop and is used as a data exchange device between the

RTU-17 and/or TUC5R(+) data control points and the main WCC

III data structures.

SAT 3D (OE455) - Used to interf ace the TUC2R

controller and some of the more complex TUC5R(+)

controller software applications to the WCC III

system

The SAT 3D occupies 4 SAT III addresses on the Satellite

controller loop and is used as a data exchange device between the

TUC2R and/or TUC5R(+) data control points and the main WCC

III data structures.

SAT 3F (OE456) - Used to interf ace the VAV/Zone

Actuator package with the more complex V AV/Zone

controller application software to the WCC III system

You must consult the specifi c application for the wiring, setup, and

programming confi guration for the exact software application you

are using.

WCC III Technical Guide

The SAT 3F occupies 4 SAT III addresses on the Satellite

controller loop and is used as a data exchange device between the

VAV/Zone controller actuator package data control points and the

main WCC III data structures.

4-3

Page 6

4. SCUSCR.EXE SCREENS

Variable Air V olume, Heat Pump, & Constant V olume Overview

V AV Ov erview

Variable Air volume (VAV) is a technique for controlling the

capacity of a heating, ventilating, and/or air-conditioning (HVAC)

system. The simplest VAV system incorporates one supply duct

that, when in cooling mode, distributes approximately 55°F (13°C)

supply air. Because the supply air temperature, in this simplest of

VAV systems, is constant, the airfl ow rate must vary to meet the

rising and falling heat gains or losses within the thermal zone

served.

There are two primary advantages to VAV systems. The fan

capacity control, especially with modern electronic variable

speed drives, reduces the energy consumed by fans which can

be a substantial part of the total cooling energy requirements of

a building. Dehumidifi cation demands are greater with a VAV

system than with a constant volume system which modulates the

discharge air temperature to attain part load cooling capacity.

The air blower’s airfl ow rate must be variable. For a single VAV air

handler that serves multiple thermal zones, the airfl ow rate to each

zone must be varied as well.

A VAV terminal unit controller, often called a VAV BOX, is

the zone-level airfl ow control device. It is basically a quality,

calibrated air damper with an electronically controlled actuator.

The VAV terminal unit is connected to a local SAT 3d controller

which then connects to a central control system (WCC III - MCD).

Historically, pneumatic control was commonplace, but electronic

direct digital contr ol systems are popular especially for mid-to-large

size applications. Hybrid control, for example, having pneumatic

actuators with digital data collection, is popular as well.

Control of the system’s main fan capacity is critical in VAV

systems. Without proper and rapid airfl ow rate control, the

system’s ductwork, or its sealing, can easily be damaged by over

pressurization. This system airfl ow control is usually done with a

SAT III controller with the feedback from the zones in a global

format.

While invented earlier, TempMaster (WattMaster) Corporation of

Kansas City, Missouri is generally credited with perfecting early

VAV technology. The VAV BOX hardware and software (Actuator,

TUC Controller, Temperature sensor, differential pressure sensor,

and proprietary software) is the heart of the technology.

Heat Pump Overview

The most common type of heat pump is an “air-source” system.

“Split” air-source systems have an outdoor unit which includes

a compressor, outdoor coil, fan, and reversing valve. The unit is

connected with refrigerant-fi lled tubing to an indoor component.

The indoor unit contains a fan, indoor coil, and a supplemental

resistance heating element. “Package” systems combine both

components in a single unit that’s typically placed on the roof.

Depending on whether the heat pump is in a cooling or heating

mode, the refrigerant moving through the system makes the indoor

coils either hot or cold. A blower draws room air in through a fi lter

and pulls it across the indoor coil. An optional electric-resistance

heating element can kick on when needed to supplement the heat.

As the air passes by the coils, it either gathers or gives off heat

depending on whether the coils are hot or cold. Warm or cool air

travels through ductwork and registers into the building’s rooms.

Heat pumps give off less heat at one time than do conventional

gas furnaces. This means that they offer a mellower type of heat,

do not turn off and on with the same frequency as a gas furnace,

and therefore circulate more air throughout the building. They are

controlled by the same type of basic controls used for forced-air

systems. On really cold days, a heat pump must work especially

hard to collect heat. That’s when the supplemental heater switches

on.

Constant V olume Overview

Constant Volume (CV) is a type of heating, ventilating, and airconditioning (HVAC) system. In a very basic simple CV system,

the supply air fl ow rate is constant, but the supply air temperature

is varied to meet the thermal loads of the space.

Most CV systems are small and serve a single thermal zone.

However, variations such as CV with reheat, CV multizone, and

CV primary-secondary systems can serve multiple zones and

larger buildings.

In mid to large size buildings, new central CV systems are not very

common. Due to fan energy savings potential, variable air volume

(VAV) systems are more common. However, in small buildings

and residences, CAV systems are often the system of choice due to

simplicity, low cost, and reliability. Such small CAV systems often

have on/off control rather than supply air temperature modulation

to vary their heating or cooling capacities.

There are two types of CV systems that are commonly in use to

modify the supply air temperature—the terminal reheat system and

the mixed air system.

The terminal reheat system cools the air in the air handling unit

down to the lowest possible needed temperature within its zone of

spaces. This supplies a comfortable quality to the space but wastes

energy.

The mixed air system has two air streams, typically one for the

coldest and one for the hottest needed air temperature in the zone.

The two air streams are strategically combined to offset the space’s

load. The mixed air system option is not as profi cient at controlling

the humidity, yet it does do well at controlling the temperature.

4-4

WCC III Technical Guide

Page 7

4. SCUSCR.EXE SCREENS

SCUSCR.EXE Screens Index

WCC V AV BOX III (WattMaster Software SS5010)

Sequence of Operation 4-6

Figure 4-1: VAV BOX Status Screen 4-17

Figure 4-2: VAV BOX Setpoint Screen 4-22

Figure 4-3: TempMaster Corporation V AV BOX CFM Sizing Chart 4-24

Figure 4-4: VAV BOX Globals Screen 4-25

Figure 4-5: VAV BOX Mode of Operation Screen 4-27

WCC V AV BOX II (WattMaster Software SS5001)

Sequence of Operation 4-28

Figure 4-6: Single Duct Cooling Only - Pressure Dependent Status Screen 4-30

Figure 4-7: Single Duct Cooling Only - Pressure Dependent Setpoint Screen 4-32

Figure 4-8: Single Duct Cooling Only - Pressure Dependent Globals Screen 4-34

Figure 4-9: Single Duct Cooling Only - Pressure Dependent Mode of Operation Screen 4-36

Figure 4-10: Single Duct Cooling Only - Pressure Independent Status Screen 4-37

Figure 4-11: Single Duct Cooling Only - Pressure Independent Setpoint Screen 4-39

Figure 4-12: Single Duct Cooling Only - Pressure Independent Globals Screen 4-41

Figure 4-13: Single Duct Cooling Only - Pressure Independent Setup Screen 4-43

Figure 4-14: Parallel Fan Powered - Pressure Dependent Status Screen 4-44

Figure 4-15: Parallel Fan Powered - Pressure Dependent Setpoint Screen 4-46

Figure 4-16: Parallel Fan Powered - Pressure Dependent Globals Screen 4-48

Figure 4-17: Parallel Fan Powered - Pressure Dependent Mode of Operation Screen 4-50

Figure 4-18: Parallel Fan Powered - Pressure Independent Status Screen 4-51

Figure 4-19: Parallel Fan Powered - Pressure Independent Setpoint Screen 4-53

Figure 4-20: Parallel Fan Powered - Pressure Independent Globals Screen 4-55

Figure 4-21: Parallel Fan Powered - Pressure Independent Mode of Operation Screen 4-57

Figure 4-22: Series Fan Powered - Pressure Dependent Status Screen 4-58

Figure 4-23: Series Fan Powered - Pressure Dependent Setpoint Screen 4-58

Figure 4-24: Series Fan Powered - Pressure Dependent Globals Screen 4-59

Figure 4-25: Series Fan Powered - Pressure Dependent Setup Screen 4-59

Figure 4-26: Series Fan Powered - Pressure Independent Status Screen 4-60

Figure 4-27: Series Fan Powered - Pressure Independent Setpoint Screen 4-60

Figure 4-28: Series Fan Powered - Pressure Independent Globals Screen 4-61

Figure 4-29: Series Fan Powered - Pressure Independent Setup Screen 4-61

Figure 4-30: Single Duct Changeover - Pressure Dependent Status Screen 4-62

Figure 4-31: Single Duct Changeover - Pressure Dependent Setpoint Screen 4-62

Figure 4-32: Single Duct Changeover - Pressure Dependent Globals Screen 4-63

Figure 4-33: Single Duct Changeover - Pressure Dependent Setup Screen 4-63

Figure 4-34: Single Duct Changeover - Pressure Independent Status Screen 4-64

Figure 4-35: Single Duct Changeover - Pressure Independent Setpoint Screen 4-64

Figure 4-36: Single Duct Changeover - Pressure Independent Globals Screen 4-65

Figure 4-37: Single Duct Changeover - Pressure Independent Setup Screen 4-65

Figure 4-38: Single Duct Reheat - Pressure Dependent Status Screen 4-66

Figure 4-39: Single Duct Reheat - Pressure Dependent Setpoint Screen 4-66

Figure 4-40: Single Duct Reheat - Pressure Dependent Globals Screen 4-67

Figure 4-41: Single Duct Reheat - Pressure Dependent Setup Screen 4-67

Figure 4-42: Single Duct Reheat - Pressure Independent Status Screen 4-68

Figure 4-43: Single Duct Reheat - Pressure Independent Setpoint Screen 4-68

Figure 4-44: Single Duct Reheat - Pressure Independent Globals Screen 4-69

Figure 4-45: Single Duct Reheat - Pressure Independent Setup Screen 4-69

WCC III Technical Guide

4-5

Page 8

4. SCUSCR.EXE SCREENS

WCC III V A V BOX III Sequence of Operations

WCC V A V BOX III Sequence of

Operation

(WattMaster Software Number SS5010)

Initialization

On initial power-up of the VAV BOX TUC-2R controller, the

SCAN LED is extinguished for a few seconds and then the VAV

BOX TUC-2R controller “fl ashes” its address switch setting. If

the address switch were set to 7, you would see 7 fl ashes. After

the address is fi nished, the LED will extinguish for another 5

seconds. At the conclusion of this 5 second delay, the LED will

begin a continuous fl ashing while the Damper Feedback limits

are calibrated. If the Damper is driving open, the LED will blink

slowly. If the Damper is driving closed, the LED will blink fast.

When the calibration is completed, the normal diagnostic fl ashes

will commence. These troubleshooting diagnostic LED fl ashes are

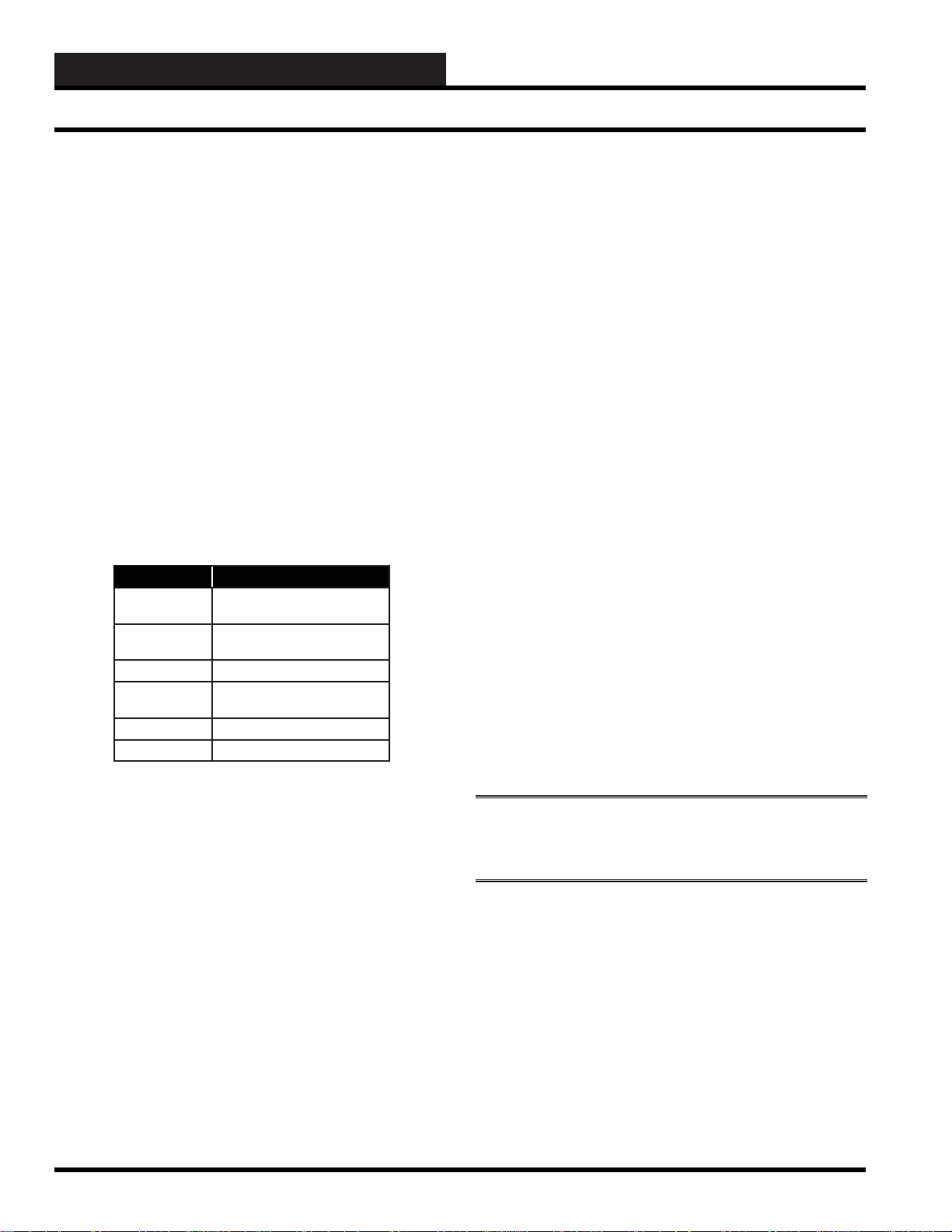

listed below in Table 4-1.

No. of Blinks Description

1 Normal Operation

No Alarm Conditions Exist

2 Push Button Override or

Group Override is Active

4 Bad Airfl ow Sensor

5 Bad or Missing Space

Sensor

6 Damper Failure

7 Damper Feedback Failure

Table 4-1: LED Blink Codes

V AVBOX Confi guration & Setup

General

There are several options that are available to confi gure the WCC

VAVBOX III controller for the appropriate equipment that it is

installed on. All of these options can be set from the “four main

screens” that are viewable from the SCUSCR.exe program. You

can toggle through these four screens selections by pressing <Ctrl>

+ <►> (right arrow), which means next page or <Ctrl> + <◄>

(left arrow), which means previous page.

VAV Box Control Method

Set this confi guration item for the type of box the VAVBOX

controller is used on. The options available are:

0 = Cooling Only Box (with Reheat if required)

1 = Heating/Cooling Changeover Box

2 = Series Fan Powered Box with Reheat

3 = Parallel Fan Powered Box with Reheat

Damper Operating Mode

Set the direction of rotation that the damper moves when driving

towards its full open position. The following options available

are:

0 = Direct Acting (Clockwise to Open Damper)

1 = Reverse Acting (Counterclockwise to Open Damper)

Pressure Independent Boxes - Airfl ow @ 1” W.C.

If this is a pressure independent box, this option allows you to

calibrate the box CFM correctly using the VAV box manufacturer’s

“K” factor. You must enter the correct “K” (CFM) factor for the

inlet diameter of the box you are confi guring.

NOTE: VAVBOX TUC-2R controllers will

automatically operate as pressure independent if the box

size constant is greater than 0 CFM.

There are quite a few confi guration selections available which

can be then used to tailor the WCC III VAV BOX III software

(WM Software # SS5010) operation to match the exact type of

mechanical VAV box equipment that this VAV BOX TUC-2R

controller is installed on. These setpoint and confi guration items

are programmed using a Windows-based personal computer that

has the WCC III computer front-end software installed.

The SCUSCR.exe is the program that is used to view, modify, or

program these selections. There are four main screens that are

used for the viewing, programming, and setup of the WCC III VAV

BOX III software that is installed on the TUC-2R controller.

4-6

Expansion Relays - Steps of Reheat

If the VAV box has reheat that is supplied by an electric coil, then

this option must be set for the number of electric heating stages on

the VAV box. If the VAV box has hot water heat with a 2 position

hot water valve, set the number of stages to “1”. For hot water heat

with a proportional hot water valve, set to “0”.

Options available are:

0 = No Staging

1 = 1 Stage of Reheat

2 = 2 Stages of Reheat

3 = 3 Stages of Reheat

WCC III Technical Guide

Page 9

4. SCUSCR.EXE SCREENS

WCC III V A V BOX III Scheduling

Proportional Heating Signal

If the VAV box has hot water reheat using a proportional hot water

valve, it is a 0-10 VDC Voltage Signal.

Allow V AV Box Heat with AHU Heat

If the VAV box that you are using has reheat, confi guring this

setting will allow the VAV box heat to operate at the same time as

the HVAC unit heat.

This is the actual statement on the screen “Allow box heat to

Remain On in the HVAC mode at the same time as the HVAC

unit”

Options available are:

0 = No

1 = Yes

Main Fan Status

If the VAVBOX TUC-2R controller is installed on a non-fan

powered box that has reheat, set this option to “1” in order to

enable box reheat only when the HVAC unit fan is running. A full

description of how this setting affects the various box types in the

occupied and unoccupied modes is contained under the “Mode

Sequence” heading that follows later in this manual. This is the

actual statement on the screen “This Box Needs the Main Fan

Status.”

Options available are:

0 = No - Heat can operate without fan

1 = Yes - Heat cannot operate without fan

Scheduling

Occupied/Unoccupied Mode

The VAVBOX TUC-2R controller monitors the SAT 3d - TUC

communications loop for its Occupied and Unoccupied mode of

operation command. The SAT 3d Controller receives this occupied

or unoccupied command from the WCC III - MCD, and then the

SAT 3d transmits the occupied command to the VAVBOX TUC-2R

controller. This requires that the VAVBOX TUC-2R controllers all

be connected to the SAT 3d controller via the TUC communication

loop through their RS-485 connector and the VAVBOX TUC2R controllers to be properly addressed for the command to be

received.

Push-button Override Operation

During unoccupied hours, you can force the VAVBOX TUC-2R

controller back to occupied operation by pressing the override

button on the Flushmount sensor for a period of time less than 3

seconds. This initiates the override or resets the override timer back

to zero during unoccupied hours of operation. During Override

operation, the user can cancel the override by pressing the override

button for a period of time between 3 seconds and 10 seconds. This

restores the normal unoccupied operation.

On larger installations with several terminal units, the VAVBOX

Controllers can be confi gured into groups with the Global Binaries

so that an override generated by one VAVBOX Controller can cause

several other controllers to follow along and return to occupied

mode for the programmed duration. Other VAVBOX Controllers

not in the same group will simply maintain an unoccupied damper

or airfl ow setting as set by the user.

Push-button overrides (Logic Switch) are broadcast continuously

by the initiating VAVBOX Controller until the controller itself

times out or the override is cancelled by the user. These associated

logic switches are meant to be used in Global Binary broadcasts

which then can be used to force the air handler to start its main fan

and provide cooling or heating, if so confi gured.

WCC III Technical Guide

NOTE: VAVBOX TUC-2R controllers will go into an

override condition for the user-programmed amount

of time when this button is pushed even if the unit is

already in an occupied condition.

4-7

Page 10

4. SCUSCR.EXE SCREENS

WCC III V A V BOX III Operation Modes

Modes of Operation

There are 7 possible modes of operation for the HVAC Unit and the

VAVBOX TUC-2R controller. These modes are determined by the

supply air and/or space demand conditions. They are as follows:

Supply Air Neutral Mode - (based on HVAC Unit Supply

Air Temperature)

Space Vent Mode - (based on VAVBOX TUC-2R

Controller Space Temperature)

Supply Air Cooling Mode - (based on HVAC Unit Supply

Air Temperature)

Space Cooling Mode - (based on VAVBOX Controller

Space Temperature)

Supply Air Heating Mode - (based on HVAC Unit Supply

Air Temperature)

Space Heating Mode - (based on VAVBOX Controller

Space Temperature)

Off Mode (Not displayed. See defi nition that follows.)

The process of determining each mode is discussed below, but

the actual operation of each mode is explained in the section that

follows.

deadband amount below the space temperature. To cancel the

supply air cooling mode, the supply air temperature must rise to

within 2°F of the space temperature.

Space Cooling Mode

This mode occurs when the Space Temperature rises above the

user-programmed Space Cooling Setpoint.

Supply Air Heating Mode

This mode occurs when the Supply Air Temperature rises the

deadband amount above the space temperature. To cancel the

supply air heating mode, the supply air temperature must fall to

within 2°F of the space temperature.

Space Heating Mode

This mode occurs when the Space Temperature falls below the

user-programmed Space Heating Setpoint.

Off Mode (Not Displayed)

During unoccupied mode, the mode is considered “OFF” if the

space temperature does not generate a heating mode or cooling

mode based on the unoccupied heating & cooling setpoints.

Defi nitions of Modes

VAVBOX Control Schemes

On all fan-powered and non-fan-powered terminal units, the supply

air modes are calculated from supply air temperature, and space

demands are calculated from setpoints. If the supply air temperature

rises the deadband amount above the space temperature, the

supply air mode is heating. To cancel the supply air heating mode,

the supply air temperature must fall to within 2ºF of the space

temperature. If the supply air falls the deadband amount below the

space temperature, the supply air mode is cooling. To cancel the

supply air cooling mode, the supply air temperature must rise to

within 2 ºF of the space temperature. If the supply air is between

the heating and cooling deadband amounts, it is considered to be

in neutral mode.

Supply Air Neutral Mode

This mode occurs when the Supply Air Temperature is between the

user-programmed heating and cooling deadband amounts.

Space Vent Mode

This mode occurs when the Space Temperature is between the

user-programmed heating and cooling setpoints.

Supply Air Cooling Mode

This mode occurs when the Supply Air Temperature falls the

Damper Positions

The actual values for the minimum damper positions that are

described in the following paragraphs can be user-confi gured by

changing the values in the setpoint screens of the VAVBOX TUC2R controller. These minimum values are expressed in damper

open percentages for pressure dependent terminal units or in CFM

for pressure independent terminal units.

Cooling Minimum

When the HVAC unit is in the Supply Air Cooling mode but the

space does not require cooling, the VAVBOX damper will go to the

Cooling Minimum position.

Heating Minimum

When the HVAC unit is in the Supply Air Heating mode but the

space does not require Heating, the VAVBOX damper will go to

the Heating Minimum position.

Vent Minimum

This is the position the VAVBOX damper will move to when the

HVAC unit is in the Supply Air Vent mode.

Nite/Reheat Minimum

This setpoint has two different functions depending on whether the

HVAC unit is in Occupied or Unoccupied mode.

4-8

WCC III Technical Guide

Page 11

4. SCUSCR.EXE SCREENS

WCC III V A V BOX III Operation Modes

Occupied Mode

If the VAVBOX TUC-2R controller is used on a non-fan-powered

terminal unit that has reheat, the VAVBOX damper will move

to the Nite/Reheat position whenever a Space Heating demand

occurs and the HVAC unit is in Supply Air Cooling or Neutral

mode. When the HVAC unit is in Supply Air Heating mode, the

VAVBOX damper will modulate as required to maintain the Space

Heating setpoint.

Unoccupied Mode

When using non-fan powered terminal units, the VAVBOX damper

will position itself in the Nite/Reheat minimum position. In order

for fan powered terminal units to position the damper to the Nite/

Reheat minimum position, the check for main fan status must be

selected and the HVAC unit fan must be operating.

Occupied Mode Sequences

Space Vent Mode

This mode only applies to the Occupied Mode of operation. If the

equipment is in the Unoccupied Mode, then a lack of heating or

cooling demand would generate the Off Mode.

If the HVAC unit is in Supply Air Neutral Mode, you can adjust

the damper position on pressure dependent terminal units and

the airfl ow on pressure independent terminal units to provide a

fi xed amount of ventilation air into the space when there are no

heating or cooling demands. During this time, the damper does

not modulate on pressure dependent terminal units. On pressure

independent terminal units, it only modulates to the extent required

to maintain the vent minimum airfl ow setting. If the VAVBOX

Controller detects that the HVAC unit is in Supply Air Heating

mode, indicating that the air handler has activated its heat, the

heating airfl ow minimum will be substituted for the vent minimum

position. If the VAVBOX Controller detects that the HVAC unit

is in Supply Air Cooling mode, indicating that the air handler

has activated its cooling, the cooling airfl ow minimum will be

substituted for the vent minimum position.

When the VAVBOX TUC-2R controller is in the Supply Air

Cooling mode, the damper is normally held at the minimum

cooling position until the space temperature begins to rise above

the cooling setpoint. As the space temperature rises to within 0.5 ºF

of the Occupied Cooling Setpoint, the damper/airfl ow calculation

causes the air valve to open proportionally until the maximum

setpoint is achieved at 1.5 ºF above the setpoint. This is a 2 ºF

proportional window starting 0.5 ºF below the cooling setpoint to

1.5 ºF above the cooling setpoint.

The damper/airfl ow is never allowed to modulate outside the

user adjusted minimum setpoint and the maximum setpoint. The

maximum damper/airfl ow setpoint applies to heating and cooling

modes of operation only. All of the modes have their own individual

minimum setting.

Series Flow Fan T erminals

If the VAVBOX TUC-2R controller has been confi gured as a Series

Fan Powered terminal unit, the series fan relay will activate and

run the series box fan continuously anytime the VAVBOX TUC2R controller is in occupied mode.

In all cases, before the series box fan can be activated, the air

damper is driven fully closed and held that way for 30 seconds to

make sure the series box fan hasn’t inadvertently started to spin

backwards. Once the series box fan starts, it waits an additional

10 seconds to allow the fan to spin up before it starts to open the

damper and introduce airfl ow from the HVAC unit fan.

Parallel Flow Fan T erminals

During normal cooling or vent mode and adequate air supply,

the parallel fan will be off. During the occupied cooling or

vent mode, the Parallel fan will only activate if the damper/

airfl ow is below a user defi ned low limit setting. This causes it

to be used as a make-up air source. When the damper/airfl ow

rises 15% above the low limit setpoint, the Parallel fan will be

deactivated.

The check for main fan status setting has no effect on the

Parallel Fan box when in the occupied mode.

Space Cooling Mode

Occupied Space Cooling mode is initiated by the temperature in

the space rising above the Occupied Cooling Setpoint.

If the VAVBOX TUC-2R controller is in the Supply Air Heating

mode and another VAVBOX TUC-2R controller has a cooling

demand, the damper/airfl ow for the VAVBOX TUC-2R controller

requiring cooling will position itself to provide the heating

minimum setpoint amount of air into the space. No modulation

open will occur because the space does not want the warm air

currently being supplied by the air handler.

WCC III Technical Guide

Space Heating Mode

Occupied Space Heating mode is initiated by the temperature in

the space falling below the Occupied Heating Setpoint.

If the VAVBOX TUC-2R controller is in the Supply Air Cooling

mode and another VAVBOX TUC-2R controller has a heating

demand, the damper/airfl ow for the VAVBOX TUC-2R controller

requiring heating will position itself to provide the Cooling

Minimum amount of air into the space. No modulation open will

occur because the space does not want the cold air currently being

supplied by the air handler.

4-9

Page 12

4. SCUSCR.EXE SCREENS

WCC III V A V BOX III Operation Modes

When the VAVBOX TUC-2R controller is in the Occupied

Supply Air Heating mode, the damper will be held at the Heating

Minimum position until the space temperature falls to within 0.5 ºF

of the Occupied Heating Setpoint.

As the space temperature falls below the heating setpoint,

the damper/airfl ow calculation causes the air valve to open

proportionally until the maximum setpoint is achieved at 1.5 ºF

below the setpoint. This is a 2 ºF proportional window starting 0.5

ºF above the heating setpoint to 1.5 ºF below the heating setpoint.

Two different confi gurations are available for the Occupied Space

Heating mode. If the box is confi gured to allow reheat during

HVAC Heat mode, the reheat relays can be activated even when

the VAVBOX TUC-2R controller is in the Supply Air Heating

mode. If the box is confi gured not to allow reheat when the HVAC

unit is in Heat mode, the box heat relays will be de-energized when

the VAVBOX TUC-2R controller is in Supply Air Heating mode.

In either confi guration, when the VAVBOX TUC-2R controller is

in the Supply Air Heating mode, the damper will modulate open

proportionally to the space demand. The proportional window for

the space temperature is 0.5 ºF above to 1.5 ºF below the heating

setpoint. This allows the space to take advantage of the warm

supply air in the duct.

The VAVBOX TUC-2R controller can activate auxiliary heating

relays if the Expansion module has been connected and the correct

number of heating stages (1, 2, or 3) has been confi gured. During

demands for heat, the fi rst stage will activate whenever the space

temperature drops below the heating setpoint. The second stage

will activate if the space temperature falls 1.0 ºF below the heating

setpoint. The third stage will activate if the space temperature falls

2.0 ºF below the heating setpoint. There is a two-minute delay

between staging. This prevents stages from activating at the same

time. Once a heating stage has been activated, it must remain on for

at least one minute. Once it has been deactivated, it must remain off

for at least two minutes. The third stage relay will deactivate when

the space temperature rises to within 1.0 ºF of the heating setpoint.

The second stage will deactivate when the space temperature rises

to the heating setpoint. The fi rst stage relay will deactivate when

the space temperature rises above the heating setpoint by 1.0 ºF.

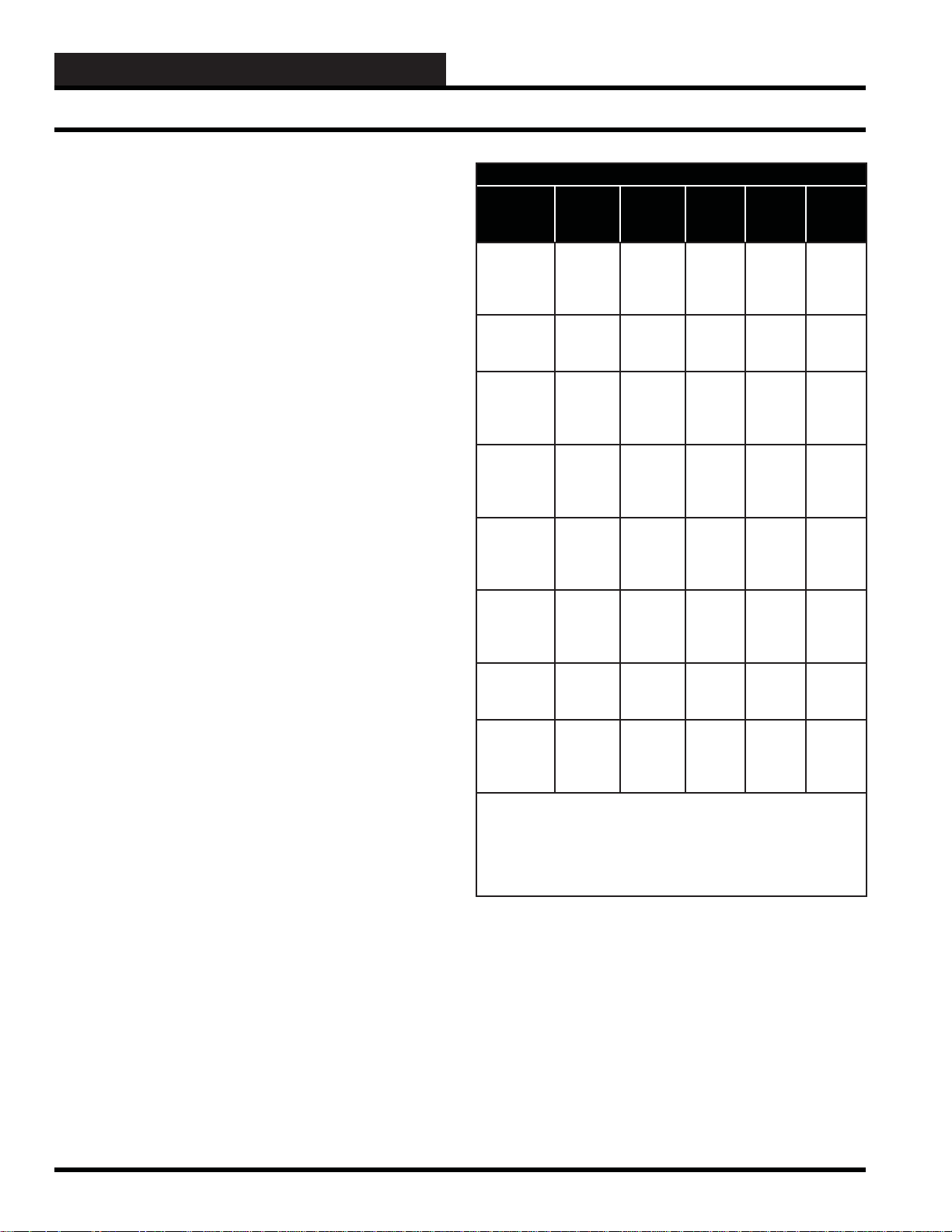

Box Fan Relay & Reheat Relay Staging Occupied Mode

Relays

Stage On

At

+0.5 F

Above

Box Heat

Setpoint

At Box

Heat

Setpoint

-1.0 F

Below

Box Heat

Setpoint

-2.0 F

Below

Box Heat

Setpoint

+1.0 F

Above

Box Heat

Setpoint

+1.0 F

Above

Box Heat

Setpoint

At Box

Heat

Setpoint

-1.0 F

Below

Box Heat

Setpoint

Note 1: The series fan will run continuously anytime the

VAVBOX TUC-2R controller is in occupied mode.

Note 2: The parallel fan will run whenever Space Heating Mode is

active. At all other times, the fan will only activate if the damper/airfl ow is below a user defi ned low limit setting.

Series

Fan

See

Note 1

See

Note 1

Parallel

Fan

See

Note 2

See

Note 2

Heat

Stage

1

X

X

Heat

Stage

2

X

X

Heat

Stage

3

X

X

Modulating (Proportional) Heat

The VAVBOX TUC-2R controller expansion board also provides

an analog output for control of a modulating hot water valve or

SCR electric heater. It provides a 0-10 VDC signal to control the

heating device. When the space temperature drops to 0.5 ºF above

the Heating Setpoint the output starts at 0 VDC and ramps up to 10

VDC at 1.5 ºF below the Heating Setpoint.

See Table 4-2: Relay Staging - Occupied Mode for a complete

layout of the various fan and heat relay staging points.

4-10

Table 4-2: Relay Staging Occupied Mode

WCC III Technical Guide

Page 13

4. SCUSCR.EXE SCREENS

WCC III V A V BOX III Operation Modes

Series Flow Fan T erminals

If the VAV/Zone Controller has been confi gured as a Series Fan

Powered terminal unit, the series fan relay will activate and run

the series box fan continuously anytime the VAVBOX TUC-2R

controller is in occupied mode.

In all cases, before the series box fan can be activated, the air

damper is driven fully closed and held that way for 30 seconds to

make sure the series box fan hasn’t inadvertently started to spin

backwards. Once the series box fan starts, it waits an additional

10 seconds to allow the fan to spin up before it starts to open the

damper and introduce airfl ow from the HVAC unit fan.

Parallel Flow Fan T erminals

On parallel fan powered terminal units, the fan will run whenever

Space Heating mode is active. At all other times, the fan will only

activate if the damper/airfl ow is below a user-defi ned low limit

setting. This causes it to be used as a make-up air source. When the

damper/airfl ow rises 15% above the low limit setpoint, the fan will

be deactivated if there are no heating stages active and no space

demand exists.

The check for main fan status setting has no effect on the Parallel

Fan box when in the occupied mode.

Unoccupied Mode Sequences

NOTE: For the Unoccupied Mode Sequences to work

correctly the VAV/Zone controller must be able to read the

Main Fan Status.

Space Vent Mode

This mode only applies to the Occupied Mode of operation.

If the equipment is in the Unoccupied Mode, then a lack of

heating or cooling demand would generate the Off Mode (not

displayed).

Off Mode (Not Displayed)

During unoccupied mode, the mode is considered ‘OFF’ if the

space temperature does not generate a heating mode or cooling

mode based on the unoccupied heating & cooling setpoints.

When using non-fan powered terminal units, the VAVBOX TUC2R controller damper will position itself in the Night/Reheat

minimum position. In order for fan powered terminal units to

position the damper to the Nite/Reheat minimum position, the

check for main fan status must be selected and the HVAC unit fan

must be operating. If check main fan status has not been selected

the damper will be in the fully closed position.

Space Cooling Mode

During Unoccupied Mode, the HVAC unit is normally off.

Unoccupied Space Cooling mode is initiated by the temperature in

the space rising to the Unoccupied Cooling Setpoint.

If the VAVBOX TUC-2R controller is in the Unoccupied Supply

Air Heating mode because one or more of the VAVBOX controllers

has a heating demand, and another VAVBOX controller has a

cooling demand, the damper/airfl ow for the VAVBOX controller

requiring cooling will position itself to provide the heating

minimum setpoint amount of air into the space. No modulation

open will occur because the space does not want the warm air

currently being supplied by the air handler.

When the VAVBOX TUC-2R controller is in the Unoccupied

Supply Air Cooling mode, the damper will be held at the Night/

Reheat minimum position until the space temperature begins to

rise above the cooling setpoint. As the space temperature rises to

within 0.5 ºF of the Unoccupied Cooling Setpoint, the damper/

airfl ow calculation causes the air valve to open proportionally until

the maximum setpoint is achieved at 1.5 ºF above the setpoint. This

is a 2 ºF proportional window starting 0.5 ºF below the cooling

setpoint to 1.5 ºF above the cooling setpoint.

The damper/airfl ow is never allowed to modulate outside the user

adjusted minimum setpoint and maximum setpoint. The maximum

damper/airfl ow setpoint applies to heating and cooling modes

of operation only. All of the modes have their own individual

minimum setting.

Series Flow Fan T erminals

If the VAVBOX TUC-2R controller has been confi gured as a

Series Fan Powered terminal unit and check for main status has

been selected, the series fan relay will activate and run the series

box fan continuously anytime the HVAC unit fan is running. The

series fan relay will activate and run the series box fan when the

space temperature rises to 0.5 ºF below the unoccupied cooling

setpoint anytime the HVAC unit fan is not running. The damper

will be held closed if the HVAC unit fan is not running and will be

held at the Nite/Reheat minimum until the space temperature rises

to 0.5 ºF below the unoccupied cooling setpoint if the HVAC unit

fan is running. If check for main fan status has not been selected,

the series fan relay will activate and run the series box fan when

the space temperature rises to 0.5 ºF below the unoccupied cooling

setpoint. The damper will be in the fully closed position until the

space temperature rises to 0.5 ºF below the unoccupied cooling

setpoint.

WCC III Technical Guide

4-11

Page 14

4. SCUSCR.EXE SCREENS

WCC III V A V BOX III Operation Modes

In all cases, before the series box fan can be activated, the air

damper is driven fully closed and held that way for 30 seconds to

make sure the series box fan hasn’t inadvertently started to spin

backwards. Once the series box fan starts, it waits an additional

10 seconds to allow the fan to spin up before it starts to open the

damper and introduce airfl ow from the HVAC unit fan.

NOTE: If check for main fan status is selected, the series fan

will activate any time the HVAC unit fan is operating.

Parallel Flow Fan T erminals

In the Unoccupied Cooling mode the parallel fan will be off

whether check for main fan status has been selected or not. If

check for mainfan status has been selected, the damper will be

held at the Nite/Reheat minimum until the space temperature

begins to rise to 0.5 ºF below the unoccupied cooling setpoint. If

check for main fan status has not been selected, the damper will

be held in the fully closed position until the space temperature

begins to rise to 0.5 ºF below the unoccupied the cooling

setpoint.

Space Heating Mode

During unoccupied mode, the HVAC unit is normally off.

Unoccupied Space Heating mode is initiated by the temperature in

the space falling below the Unoccupied Space Heating Setpoint.

If the VAVBOX TUC-2R controller is in the Unoccupied Supply

Air Cooling mode because one or more of the VAVBOX TUC-2R

controllers has a cooling demand and another VAVBOX controller

has a heating demand, the damper/airfl ow for the VAVBOX

controller requiring heating will position itself to provide the Night/

Reheat setpoint amount of air into the space. No modulation open

will occur because the space does not want the cold air currently

being supplied by the air handler.

When the VAVBOX TUC-2R controller is in the Unoccupied

Supply Air Heating mode, the damper will be held at the Night/

Reheat minimum position until the space temperature begins to fall

below the Unoccupied heating setpoint. As the space temperature

falls to 0.5 ºF above the unoccupied Heating Setpoint, the damper/

airfl ow calculation causes the air valve to open proportionally until

the maximum setpoint is achieved at 1.5 ºF below the setpoint.

This is a 2 ºF proportional window starting 0.5 ºF above the heating

setpoint to 1.5 ºF below the heating setpoint.

Heat mode, the box heat relays will be de-energized when the

VAVBOX TUC-2R controller is in Supply Air Heating mode. In

either confi guration, when the VAVBOX TUC-2R controller is

in the Supply Air Heating mode, the damper will modulate open

proportionally to the space demand. The proportional window for

the space temperature is 0.5 ºF above to 1.5 ºF below the heating

setpoint. This allows the space to take advantage of the warm

supply air in the duct.

If check for main fan status is not selected and the VAVBOX

terminal unit has auxiliary heat (baseboard heat etc.) that does not

require the HVAC unit fan to operate, reheat can be used without the

HVAC unit fan operating. If check for main fan status is selected,

the reheat will only operate when the HVAC unit fan is operating.

The VAVBOX TUC-2R controller can activate auxiliary heating

relays if the relay Expansion Board has been connected and the

correct number of heating stages (1,2, or 3) has been confi gured.

During demands for heat, the fi rst stage will activate whenever the

space temperature drops below the heating setpoint. The second

stage will activate if the space temperature falls 1.0 ºF below

the heating setpoint. The third stage will activate if the space

temperature falls 2.0 ºF below the heating setpoint. There is a twominute delay between staging. This prevents stages from activating

at the same time. Once a heating stage has been activated, it must

remain on for at least one minute. Once it has been deactivated, it

must remain off for at least two minutes. The third stage relay will

deactivate when the space temperature rises to within 1.0 ºF of the

heating setpoint. The second stage relay will deactivate when the

space temperature rises to the heating setpoint. The fi rst stage relay

will deactivate when the space temperature rises above the heating

setpoint by 1.0 ºF.

See Table 4-3: Relay Staging - Unoccupied Mode for a complete

layout of the various fan & heat relay staging points.

Modulating (Proportional) Heat

The VAVBOX TUC-2R controller expansion board also provides

an analog output for control of a modulating hot water valve or

SCR electric heater. It provides a 0-10 VDC signal to control the

heating device. When the space temperature drops to 0.5 ºF above

the Heating Setpoint the output starts at 0 VDC and ramps up to 10

VDC at 1.5 ºF below the Heating Setpoint.

As with the Occupied Mode of operation, two different

confi gurations are available for the Unoccupied Space Heating

mode. If the box is confi gured to allow reheat during HVAC Heat

mode, the reheat relays can be activated even when the VAVBOX

TUC-2R controller is in the Supply Air Heating mode. If the

box is confi gured not to allow reheat when the HVAC unit is in

4-12

WCC III Technical Guide

Page 15

4. SCUSCR.EXE SCREENS

WCC III V A V BOX III Operation Modes

Box Fan Relay & Reheat Relay Staging Unoccupied Mode

Relays

Stage On

At

+0.5 F

Above

Box Heat

Setpoint

At Box

Heat

Setpoint

-1.0 F

Below

Box Heat

Setpoint

-2.0 F

Below

Box Heat

Setpoint

+1.0 F

Above

Box Heat

Setpoint

+1.0 F

Above

Box Heat

Setpoint

At Box

Heat

Setpoint

-1.0 F

Below

Box Heat

Setpoint

Note 1: If check for main fan status is selected, the series fan will

activate any time the HVAC unit fan is operating.

Note 2: If the VAVBOX TUC-2R has been confi gured as a Parallel Fan

Powered terminal unit, the Parallel fan will run continuously when the

VAVBOX TUC-2R Controller is in the Space Heating mode no matter

whether check for main fan status has been selected or not.

Table 4-3: Relay Staging - Unoccupied Mode

Series Flow Fan T erminals

Series

Fan

See

Note 1

See

Note 1

Parallel

Fan

See

Note 2

See

Note 2

Heat

Stage 1

X

X

Heat

Stage 2

X

X

Heat

Stage 3

X

X

If the VAVBOX TUC-2R controller has been confi gured as a Series

Fan Powered terminal unit and check for main status has been

selected, the series fan relay will activate and run the series box

fan continuously anytime the HVAC unit fan is running. The series

fan relay will activate and run the series box fan when the space

temperature falls to within 0.5 ºF above the unoccupied heating

setpoint anytime the HVAC unit fan is not running. The damper

will be held closed if the HVAC unit fan is not running and will

be held at the Nite/Reheat minimum until the space temperature

falls to within 0.5 ºF above the unoccupied heating setpoint if the

HVAC unit fan is running. If check for main fan status has not

been selected, the series fan relay will activate and run the series

box fan when the space temperature falls to within 0.5 ºF above the

unoccupied heating setpoint and the damper will stay in the fully

closed position.

In all cases, before the series box fan can be activated, the air

damper is driven fully closed and held that way for 30 seconds to

make sure the series box fan hasn’t inadvertently started to spin

backwards. Once the series box fan starts, it waits an additional

10 seconds to allow the fan to spin up before it starts to open the

damper and introduce airfl ow from the HVAC unit fan.

NOTE: If check for main fan status is selected, the series fan

will activate any time the HVAC unit fan is operating.

Parallel Flow Fan T erminals

If the VAVBOX TUC-2R controller has been confi gured as a

Parallel Fan Powered terminal unit, the Parallel fan will run

continuously when the VAVBOX TUC-2R controller is in the

Space Heating mode no matter whether check for main fan

status has been selected or not. If check for main fan status is

selected, the damper will remain in the closed position until the

HVAC unit controller is broadcasting that the HVAC unit fan

is operating, regardless of whether it is calling for heat or not.

Once the broadcast is received, the damper will then move to

its Night/Reheat minimum position until the space temperature

begins to fall below 0.5 ºF above the unoccupied heating

setpoint. If check for main fan status has not been selected, the

damper will be held in the fully closed position until the space

temperature begins to fall below 0.5 ºF above the unoccupied

heating setpoint. When in Supply Air Heating mode, the damper

will modulate to maintain the Unoccupied Heating setpoint.

NOTE: For the VAVBOX TUC-2R controller to go

into Supply Air Heating mode the HVAC unit fan must

be operating and the Supply Air temperature must be the

deadband amount above the Space temperature.

WCC III Technical Guide

4-13

Page 16

4. SCUSCR.EXE SCREENS

WCC III V A V BOX III T enant Override Logs

Damper Control

The damper position is calculated by the mode and demand from

the space sensor. Included in this calculation is an Integral function.

This prevents the damper/airfl ow from stagnating at a position

somewhere above the setpoint because the supply air temperature

or duct pressure isn’t quite enough to satisfy the space at the

currently calculated proportional position. The Integral causes the

calculation to keep adding a small amount of the proportional error

back into the damper/airfl ow position each time a new position is

calculated. The amount the Integral adds back in is user adjustable.

This value is presented as a number between 0.0 and 100.0.

That means that if the integral is less than 10.0, you are adding a

percentage from 0 to 100% of the error back into the calculation.

If you increase the Integral above 10, you are adding more than

100% back in.

With just proportional control, a 1 ºF error would cause a 50%

increase in damper/airfl ow if the Integral is not included. (1 °F is

half of the 2 ºF Proportional Window.)

If you had set the Integral to 10, the calculation would add 2% to

the current damper/airfl ow calculation each time. The calculation

occurs once every 10 seconds, so it would take a little over 4

minutes to reach the programmed 100% maximum.

Example:

This sliding window allows the control to be much tighter on the

smaller terminal units than can be achieved on the larger terminal

units as far as CFM readings. On a large terminal unit, 25 CFM

may not be noticeable, but on a small terminal unit, 25 CFM may

be more than the minimum airfl ow setting for the space.

If the pressure sensor is disconnected or fails on a pressure

independent terminal unit, the damper position goes to 100% open

and the VAV/Zone controller generates a General TUC Alarm to

alert the user that a failure has occurred.

On either type of terminal unit, a space sensor failure will force the

damper to position itself to the 45% position and it will not change

until the sensor is repaired or replaced.

T enant Ov erride Logs

If you require tenant billing for push-button override usage, the

MCD has the ability to track the amount of override time generated

by each space sensor equipped with push-button override.

NOTE: The VAVBOX TUC-2R controller will go into an

override condition for the user programmed amount of time

when this button is pushed even if the unit is already in a

occupied condition.

1. 50% Remaining / 2% Integral = 25 Moves to get to a 100%

Maximum.

2. 25 Moves times 10 seconds = 250 seconds or a little over 4

minutes to reach the 100% maximum damper/airfl ow position.

Of course, different space temperature errors and different Integral

values cause this calculation to operate slower or faster. It is up to

the user to determine the optimum setting that provides the tightest

temperature control without causing the damper to continue to

hunt or modulate, causing premature wear of the actuator gears

and motor.

On pressure dependent terminal units, the damper position is

maintained to within ± 3% of the calculated position. No attempt

is made to position the damper exactly on the calculated position.

This reduces wear and tear on the actuator gears and motors, and

the amount of airfl ow involved is not affected by that small amount

of damper error.

On pressure independent terminal units, the airfl ow is maintained

to within roughly 3% of the terminal unit size constant but no

tighter than 16 CFM on the smallest terminal units. The actual

control window is based on the formula:

Window = Terminal unit size X Square Root (1 / 750), where

Terminal unit size refers to the total rated CFM of the terminal

unit.

Storing and retrieving these logs requires a dedicated front end

computer running the WCC III Trendlog front-end software

program. No other method exists for retrieving these logs. That

means that all of your VAV/Zone controllers will be connected

together on the communications loop and the loop will be terminated

at a Satellite device which is connected to another communications

loop that is terminated at an on-site MCD computer. The tenant

logs are kept on the dedicated job site computer’s hard drive. The

only limitation to the number of logs stored is the capacity of the

hard drive on the computer to which it is being logged.

NOTE: There is also a Tenant Override software that can

be programmed that tenants can use to turn on multiple

zones(among other things) at once without having to use the

push button override on the space sensor. See Section 6 of the

WCC III manual for detailed operation of this program.

WARNING: This WCC III - MCD computer must be on 24

hours a day, 7 days a week, running the Backtask.exe software

in order for tenant logging to be tracked. The tenant logs are

kept on the dedicated end user job site computer’s hard drive.

The only limitation to the number of logs stored is the capacity

of the hard drive on the computer they are being logged to.

4-14

WCC III Technical Guide

Page 17

4. SCUSCR.EXE SCREENS

WCC III V A V BOX III T rend Logging

Alarm Detection and Reporting

The VAVBOX TUC-2R controller continuously performs self

diagnostics during normal operations to determine if any operating

failures have occurred. These failures can be reported to the user in

several ways, depending on the type of system and options installed

by the user. If WCC III computer front-end software is installed,

the alarms will be reported on the Alarm summary screen of the

WCC3.exe program and will be logged to disk of the WCC III

- MCD. These system logs can be downloaded and viewed with

the WCC3Utilies.exe program. If the WCC III - MCD is set up to

Email out alarms, then the alarm can initiate an Email callout to

alert someone to the alarm condition. See the WCC III computer

front end WCC3.exe program operations manual for further

information on this topic.

Internal Trend Logging

The Satellite controller can maintain an Internal Trend Log which

records a fi xed set of values at an interval programmed by the user.

In order to utilize these logs, a computer with WCC III front-end

software installed must be able to communicate with the WCC III

system.

The available options for Satellite internal trend logging are:

Change of State, Run Time Total, Analog Trend, and Analog

Peaks. The Change of State trend log can log the on time and

date, and off time and date for up to 8 binary points per Satellite.

The Run Time Total trend log can log the total accumulated on

or off time in seconds, minutes, or hours of up to 8 binary points

within the satellite controller. The total amount of on time that can

be accumulated without being reset is 9999 seconds, minutes, or

hours. The Analog Trend log can log the current analog value for

up to 8 analog points within the satellite. The timed interval for the

Analog Trend logging can be from 1 to 99 minutes, or from 1 to

99 hours. The Analog Peaks trend log will record the time, date,

and value of the Last Low Peak and the time, date, and value of the

Last High Peak for up to 8 analog points.

On the Change of State and Analog Trend there are 48 log

positions available. Once the last (48th) position has been recorded,

depending on how the user programs the log, it can Roll(saving the

latest and deleting the oldest), or stop until the log is reset. This

means the user is required to retrieve the logs at an interval that is

shorter than the duration of the last 48 logs.

The items that can be logged in the log are listed below:

• Date (Automatic)

• Time (Automatic)

• Space Temperature (Analog Input “AX” with X =

1 to 8)

• Date and Time of latest High and Low Space

Temperature Peaks

• Cooling/Heating Demand (Data Register A

(“RXA” with X = 1 to 8)) Note: This point will

read out as a whole number with no decimal,

examples: a 3.4 cooling demand will read out 34, a

2.5 heating demand will read out -25

• Supply Air Temperature (User programmable

Global Analog “GAXXX” with X = 1 to 256)

• Push Button Override Status (Logic Switch/Input

“LX” with X = 1 to 8)

• Airfl ow on Pressure Independent Terminal Units

(Data Register B (“RXB” with X = 1 to 8))

• Damper Position (Analog Output “PX” with x = 1

to 8)

For more information on Internal Trend Logging, see chapter 3 of

the WCCIII manual.

CAUTION: These logs are subject to loss if a long power

outage occurs because there is no battery backed memory

on the VAVBOX controller. These values are stored on the

Satellite controller and its memory may only last up to 3 days.

External Trend Logging

Any addressable point on the WCC III system is capable of being

trend logged with the WCC3Trendlog.exe program. See section 8

for further details.

Shown below are some log intervals and the duration of 48 logs.

1 Minute Interval .......................... 48 Minute Duration

15 Minute Interval ........................ 12 Hour Duration

30 Minute Interval ........................ 24 Hour Duration

60 Minute Interval ........................ 48 Hour Duration

8 Hour Interval ...............................16 Day Duration

WCC III Technical Guide

4-15

Page 18

4. SCUSCR.EXE SCREENS

WCC III V A V BOX III F orce Modes

Force Modes or Overrides

The VAVBOX TUC-2R controller damper can be forced to

one of several positions. These force modes aid the user during

troubleshooting or air balancing, etc.

• Force Damper Full Open (Ignores Airfl ow

Reading)

• Force Damper Full Closed (Ignores Airfl ow

Reading )

• Force to Maximum Airfl ow/Damper Setpoint

• Force to Minimum Airfl ow/Damper Setpoint (for

the current Supply Air Mode)

• Force to Fixed Airfl ow/Damper Setpoint

• Force Damper to Re-Calibrate

The Force to Fixed Airfl ow/Damper mode also has a setpoint

associated with it. This allows the user to provide a non-changing

fi xed amount of air into the space that doesn’t affect the Minimum

or Maximum setpoints. That means the user doesn’t have to disturb

the real minimum and maximum setpoints to achieve a nonstandard

setting during their troubleshooting or air balancing modes.

The Force to Minimum mode uses the currently active minimum

setting based on the Supply Air Neutral, Cooling, or Heating

modes. Whatever mode the VAVBOX TUC-2R controller is in sets

the minimum used by the force mode.

The damper force modes will remain in effect until cancelled by the

user or until the power is removed. There are no force commands

available for the auxiliary relays.

Fan

Parallel

Fan

Heat

4-16

WCC III Technical Guide

Page 19

SCUSCR.EXE SCREENS

VAV BOX CONTROLLER

Satellite: _ 4 Unit: 1 Location: Version: 3.04

TYPE OF CONTROL METHOD: XXXXX XXXXX XXXXX

[ STATUS SCREEN ] [ EXPANSION OUTPUTS ]

{ Optional }

Operating Mode: OCCUPIED MODE

Space Temp Mode: VENT MODE Fan Status.......: OFF

Supply Air Mode: COOLING MODE

Heat Relay.......: OFF

Space Temperature...............: 76.2°F

Active Cooling Setpoint.........: 72.0°F Heat Relay.......: OFF

Active Heating Setpoint.........: 70.0°F

Current Heat/Cool Demand........: 4.2°F Proportional Heat: 0%

Sensor Slide Adjust...{Optional}: 0.0°F

EMS Effect on Setpoints.........: 0 %

Supply Air Temperature..........: 55.0°F

Discharge Temperature...........: 55.0°F

Airflow.........{Pr.Indep. ONLY}: 0 CFM Main Fan Status..: OFF

Calculated Damper/Airflow.......: 54%

Damper Position.................: 56%

< Ctrl-RIGHT ARROW > for Setpoints Screen File: SCR220.SDF

The SCUSCR.exe program is used to access stand-alone controllers

that have been preprogrammed with application-specifi c software

such as VAVBOX software, AHU control software, Heat Pump

control software, etc. These screens are displayed the same as the

older WCC II screens.

NOTE: Only the VAV BOX III software is explained in this

section.

V AV BO X III for WCC III Softw are

Screens

4. SCUSCR.EXE SCREENS

V AV BO X III Status Screen

Figure 4-1: VA V BOX Status Screen

This is the main summary screen for the WCC3 VAV BOX III

software for the WCC III system and there should be suffi cient

information on this screen that by simply viewing of this screen

an operator can detect if the VAV BOX III controller is operating

correctly or not.

Satellite: Unit:

The satellite fi eld is used to input a valid SAT 3d address number.

The unit number is used to select a valid TUC (Terminal Unit

Controller) that is connected to the SAT 3d controller.

WCC III Technical Guide

Valid SAT 3d addresses are in groups of 4, starting at address 4.

You cannot start a SAT 3d address with a 5, 6, 7, 9, 10, 11, 13,

14, 15 etc. It must be a derivative of address 4, example 4, 8, 12,

16, 20, 24, 28,etc. If there is a question with Satellite addressing,

please check the Satellite summary screen to see if a valid SAT 3d

exists before continuing.

4-17

Page 20

4. SCUSCR.EXE SCREENS

V AV BO X III Status Screen

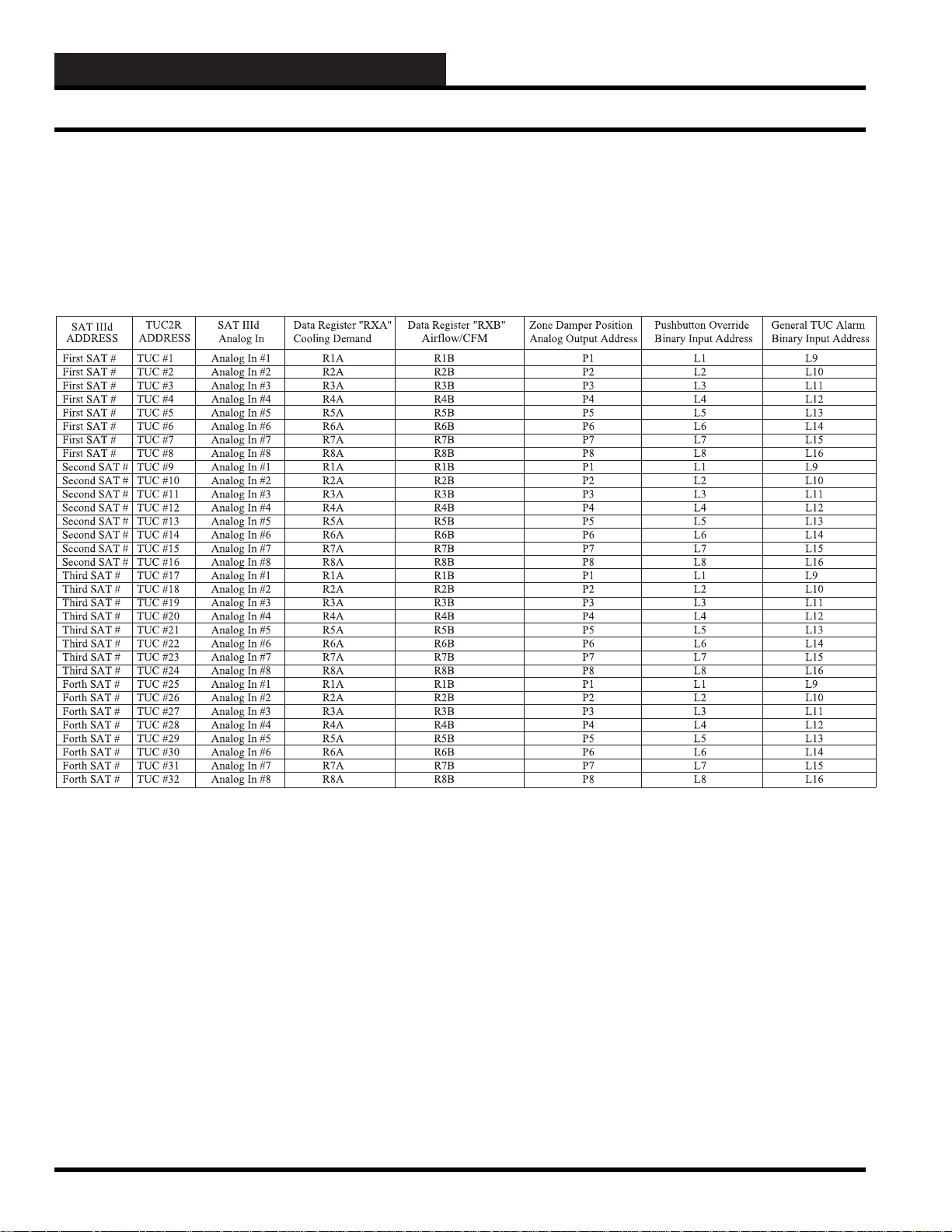

Each Sat3d uses up the address space of the equivalent of 4 regular

SAT III controllers. See Table 4-4: “SAT3d Addressing to TUC

control points” for a further explanation.

Certain TUC control points have been shoehorned into SAT 3d

control points so that they may be used in global calculations.

Table 4-4: SAT3d Addressing to TUC control points

4-18

WCC III Technical Guide

Page 21

4. SCUSCR.EXE SCREENS

VAV BOX CONTROLLER

Satellite: _ 4 Unit: 1 Location: Version: 3.04

TYPE OF CONTROL METHOD: XXXXX XXXXX XXXXX

[ STATUS SCREEN ] [ EXPANSION OUTPUTS ]

{ Optional }

Operating Mode: OCCUPIED MODE

Space Temp Mode: VENT MODE Fan Status.......: OFF

Supply Air Mode: COOLING MODE

Heat Relay.......: OFF

Space Temperature...............: 76.2°F

Active Cooling Setpoint.........: 72.0°F Heat Relay.......: OFF

Active Heating Setpoint.........: 70.0°F

Current Heat/Cool Demand........: 4.2°F Proportional Heat: 0%

Sensor Slide Adjust...{Optional}: 0.0°F

EMS Effect on Setpoints.........: 0 %

Supply Air Temperature..........: 55.0°F

Discharge Temperature...........: 55.0°F

Airflow.........{Pr.Indep. ONLY}: 0 CFM Main Fan Status..: OFF

Calculated Damper/Airflow.......: 54%

Damper Position.................: 56%

< Ctrl-RIGHT ARROW > for Setpoints Screen File: SCR220.SDF

V AV BO X III Status Screen

Figure 4-1, cont.: VA V BOX Status Screen

Location

The Location fi eld is a user programmable fi eld name that is used

to identify the location of the WCC3 VAV BOX zone or space that

the WCC3 VAV BOX III is controlling. (There is space in this fi eld

Space Temp Mode:

There are four types of Space temperature control modes: Space

Cooling Mode, Space Heating Mode, Space Vent Mode, and Space

Off Mode

for 20 alphanumeric characters.)

Space Cooling Mode

Type of Control Method:

The “Type of Control Method:” message fi eld at the top of this

This mode occurs when the Space Temperature rises above the

Space Cooling Setpoint.

screen comes from the VAV BOX mode of operation, which is

Screen #4 of the (Ctrl – Right Arrow – Three times) of the VAV

Space Heating Mode

BOX setup screens. See Figure 4-5 for further details. There