Page 1

1. General Instructions

WCC III

1. General Instructions

Page 2

T ABLE OF CONTENTS

SECTION 1: GENERAL

INSTRUCTIONS

WCC III FEATURES AND MAINTENANCE ....1-1

“Where To Find” Features .....................................................1-1

WCC III Routine Maintenance ..............................................1-1

WCC III SOFTWARE .....................................1-2

WCC III Installation Software CD Information ......................1-2

WCC III Software Version List ..............................................1-2

DATA ENTRY SEQUENCE ............................1-3

Recommended Data Entry Procedure..................................1-3

ANALOG INPUTS .........................................1-3

BINARY INPUTS ..........................................1-4

POINT ADDRESSES .....................................1-8

Point Addresses Table ..........................................................1-8

DATA REGISTERS ........................................ 1-9

Time Clock ............................................................................1-9

EA Driver ............................................................................1-10

Dual Limit............................................................................1-10

ALARMS.....................................................1-11

Alarm Call-Out ....................................................................1-11

Analog Alarm Limit..............................................................1-11

Run Time Alarm ..................................................................1-12

Satellite Fail Alarm ..............................................................1-12

ANALOG OUTPUTS .....................................1-6

BINARY OUTPUTS ......................................1-7

Page 3

1. GENERAL INSTRUCTIONS

WCC III F eatures and Maintenance

SECTION 1:

GENERAL INSTRUCTIONS

____________________________________________________

“Where T o Find” Features

The following is a list of commonly used WCC III features and the

screens you should access to use them.

FEATURES SCREEN

Alarms

“ E-mail-Out-On-Alarm”

Call “All” or “Either”

E-mail Address

Input E-mail Address

Clear ( Acknowledge) Alarms Alarm Summary

Set Alarm Limits

Analog Inputs

Run Time

Global Analog Values

Global Binary Values

View Alarms

All Alarms

Global Alarms

Demand Limiting Shed/Restore

Monitor Analog Inputs

(Temperature/Pressure etc.)

Find Highest or Lowest Building

Temp

Find A verage Building Temp

Present V alue

Trend Logs

Monitor Binary Inputs (air fl ow switch etc.)

Present V alue

Trend Log.

Password Entry

Assign Operator Access Codes

“ Sign-On”

“ Sign-Off”.

Schedules

Change Schedules Permanently.

Holiday Schedules

Setpoints

Change Setpoints - Satellite

Change Setpoints - TUC

Sequence Satellites After a Power Outage Satellite Summary

Time and Date Modifi cations System Parameters

System Parameters

Analog Input Screen

Trend Logs

Global Analog

Global Binary

Alarm Summary

Global Summary

Global Analog-Sort

Global Analog-A vg

Analog Input Summary

Analog Trend

Logic Switches

Change of State

Sys Par/Oper Codes

System Parameters

Secure Screen

Week Schedules

Holiday & Week Sch

Control Outputs

SCUSCR

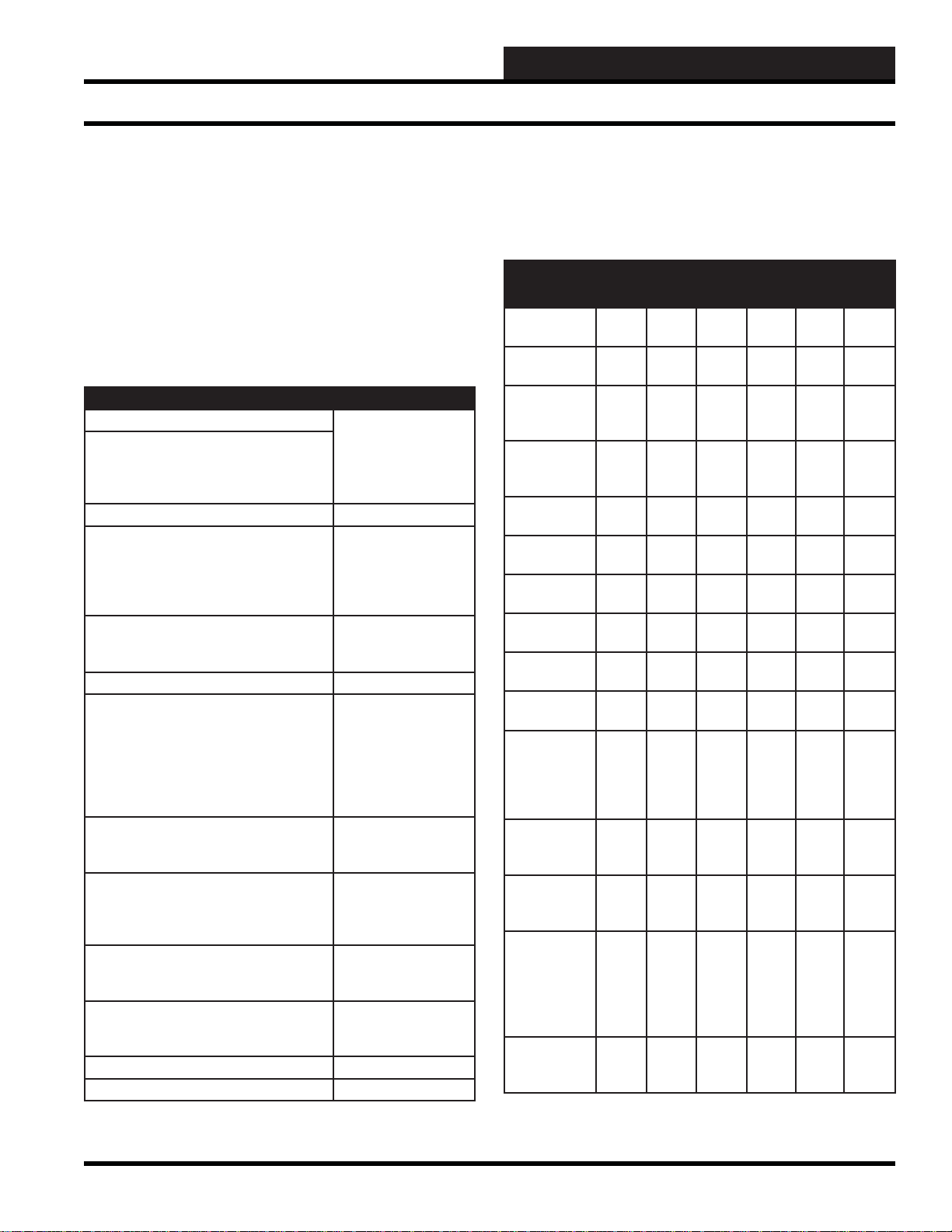

WCC III Routine Maintenance

The following maintenance items should be performed on a regular

basis:

Service Item As

Req’d

Blow out

keyboard

Blow out

MCD assy

Check all

external cable

connections

Test/Verify

U.P.S.

operation

Clean display

screen

Dim display

screen

Clean fl oppy

drive

Test fl oppy

drive

Test MCD

memory

Test display

monitor

Test modem

(system’s

ability to

e-mail-out-onalarm)

Delete “backup” (*.bak)

fi les

Make “backup” copies of

program

Check disks

for available

space to

prevent

overfi lling the

disk

Check loop

connection on

rear of MCD

Every WkEvery MoEvery

3 Mo

XX

XX

XX

XX

*X

XX

XX

XX

XX

XX

Every

6 Mo

X

X

X

X

X

Every

12 Mo

WCC III Technical Guide

1-1

Page 4

1. GENERAL INSTRUCTIONS

WCC III Software

Service Item As

Req’d

Save satellite

data to disk

Test satellites’

local-set

capability

Test satellites’

battery (or

capacitor)

Check/Reset

trend logs

View/Clear all

alarms

Cycle power

to MCD to

verify correct

system re-start

after a power

outage

Every WkEvery MoEvery

3 Mo

XX

XX

XX

Every

X

6 Mo

Every

12 Mo

X

X

* Set the screen’s intensity to the lowest setting when the system

is not being used.

WCC III Installation Software CD

Information

There are three available CD-ROMs available from WattMaster

Controls, Inc. - either from the factory or downloadable from the

wcc-controls.com website. They are as follows:

WattMaster Part # DM1WC011-01X*

This is the contractor installation CD for the main WCC III System.

This CD installs the following programs:

WCC3.EXE(SS5021), SCUSCR.EXE(SS5026),

WCCUTILITY.EXE(SS5023), TENANTOVERRIDE.

EXE(SS5024),TENANTREPORT.EXE(SS5025),

WCC3TRENDLOG.EXE(SS5028), WGCC3.

EXE(SS5029),WCC3DOWNLOAD.EXE(SS5030),

WCC3GUEST.EXE(SS5022).

WattMaster Part # DM1WC012-01X*

This is the end-user installation CD for “View Only” versions of

the WCC III system. This CD only installs the following programs:

WCC3GUEST .EXE(SS5022) and SCUSCRLtd.EXE(SS5027).

WattMaster Part # DM1WC013-01X*

This is the end-user installation CD for the Tenant Override

program. This CD only installs the following programs:

TENANTOVERRIDE.EXE(SS5024).

* = Where “X” is the software version A to Z.

WCC III Software Version List

The WCC III software is updated periodically to include more

features. The two fi les that change as the WCC III system is

upgraded are the WCC III fi le and the BACKTASK fi le. When

a WCC III fi le is installed in a system, the BACKTASK fi le may

need to be changed also. The Backtask software is located in the

MCD.

NOTE: Y ou can see the present WCC III and BA CKT ASK

version used by the system by looking at the lower left hand

corner of the Main Menu Screen.

1-2

WCC III Technical Guide

Page 5

1. GENERAL INSTRUCTIONS

8

7

SATADDRESS

2

1

4

8

A3 WIRE ROOM SENSOR WILL NOT

REQUIREA LOAD RESISTORWHEN SET

FORA 1 VOLTINPUT.

WattMasterControls Inc.

BINARY

INPUTS

BINARY

INPUTS

L8

ON OFF

128

32

16

64

L4

L3

L2

L1

L6

L5

L7

L11

L12

ON OFF

L10

L9

ON OFF

L15

L16

L14

L13

CH

4

3

5

6

2

1

LOCAL SET

STATUS 2

STATUS 3

STATUS 1

HSS XMIT

LOCALSET

LOCALSET DISABLE

BATTON/ OFF

PULSE INPUT

OPTION 1

TEST

OPTION 3

OPTION 2

ON OFF

STATUS

HSS REC

SATXMIT

SATREC

ANALOG INPUT

JUMPER SELECTION

A2 WIRE ROOM SENSOR WILL REQUIRE

A300 OHM LOAD RESISTOR WHEN SET

FORA 1 VOLTINPUT.

A4 TO 20 mASENSOR WILL REQUIRE A

50OHM LOAD RESISTOR WHEN SET FOR

A1 VOLTINPUT, OR A 250 OHM LOAD

RESISTORWHEN SET FOR A5 VOLT INPUT.

CURRENT

INPUT

THERMISTOR

INPUT

0-1V

0-5V

0- 10V

THERM

0-1V

0-5V

0- 10V

THERM

0 TO10V

INPUT

0TO5V

INPUT

0TO1V

INPUT

0- 10V

0-1V

0-5V

0- 10V

THERM

0-1V

0-5V

THERM

0-1V

0-5V

0- 10V

THERM

PROGRAMMABLECONTROLLER

SAT III

H

C

COM

CHANNEL

2134

2134

567

8

5678

V

OUT

GND

L

O

A

D

+V

ATI

Jumper

Data Entry Sequence and Analog Inputs

Recommended Data Entry Procedure

When setting up an WCC III system, the screens can be

programmed in any order. However, you may fi nd it easier to

follow this sequence:

1. Make Back-Up Copies of the Program/Data Files.

2. System Parameter Screen

3. Satellite Summary Screen

4. On/Off Units Messages Screen / Alarm Message

Screen —Enter the On/Off messages, units of

measure messages, and alarm messages, and then

print a copy of the messages. Keep a copy of

these messages handy while entering data on the

remaining screens.

5. W eek Schedule Screens

6. Holiday Screen

7. Analog Input Screens

8. Logic Switch Screens

9. Control Output Screens

10. TUC Screens

11. Analog Output Screens

Analog Inputs

An analog input is a numerical value (signal) sent from the SAT

III controller to allow monitoring of space temperatures, duct

pressures etc. The SAT III controller can accept 8 analog inputs

which are named, A1-A8. (NOTE: A1-A8 may be either analog

or binary inputs.) On certain screens (such as Global Analog

Screens), you must indicate the satellite controller number along

with the channel on the satellite controller. For example, 12A2

means satellite controller #12 analog input number 2.

The analog inputs are usually wired to the “+V” and “A TI” (Actual

Temperature In) terminals on the SAT III controller (three wire

sensors are wired to the “GND” terminal also.) The “+V” terminal

on channels 1-7 are a 12 VDC power source. The “+V” terminal

on channel 8 provides either 12 VDC or 24 VDC depending on

the position of the jumper under the cover near channel 8. To get

12 VDC from the “+V” terminal on channel 8, the jumper must

connect the 12 volt and center terminals. To get 24 VDC, the

jumper must connect the 24 volt and center terminals.

A thermistor and 20 mA sensor can be used on the SAT III

controller. You choose the type of sensor to be used by selecting

the appropriate jumper (located under the SAT III cover). The

choices are Thermistor, 0-10 V, 0-5 V, 0-1 V and Jumper A1 used

J01, A2 used J02 and so on up to A8 uses J08.

12. Analog Global Screens

13. Binary Global Screens

14. Optimal Start Screens

15. Shed/Restore Screens

16. Duty Cycle Screens

17. Proportional Reset Screens

18. Energy Consumption Screens

19. Trend Log Screens

20. Save Satellite Data to Disk

21. Make Back-Up Copies of the Program/Data Files.

WCC III Technical Guide

(Under Cover)

1-3

Page 6

1. GENERAL INSTRUCTIONS

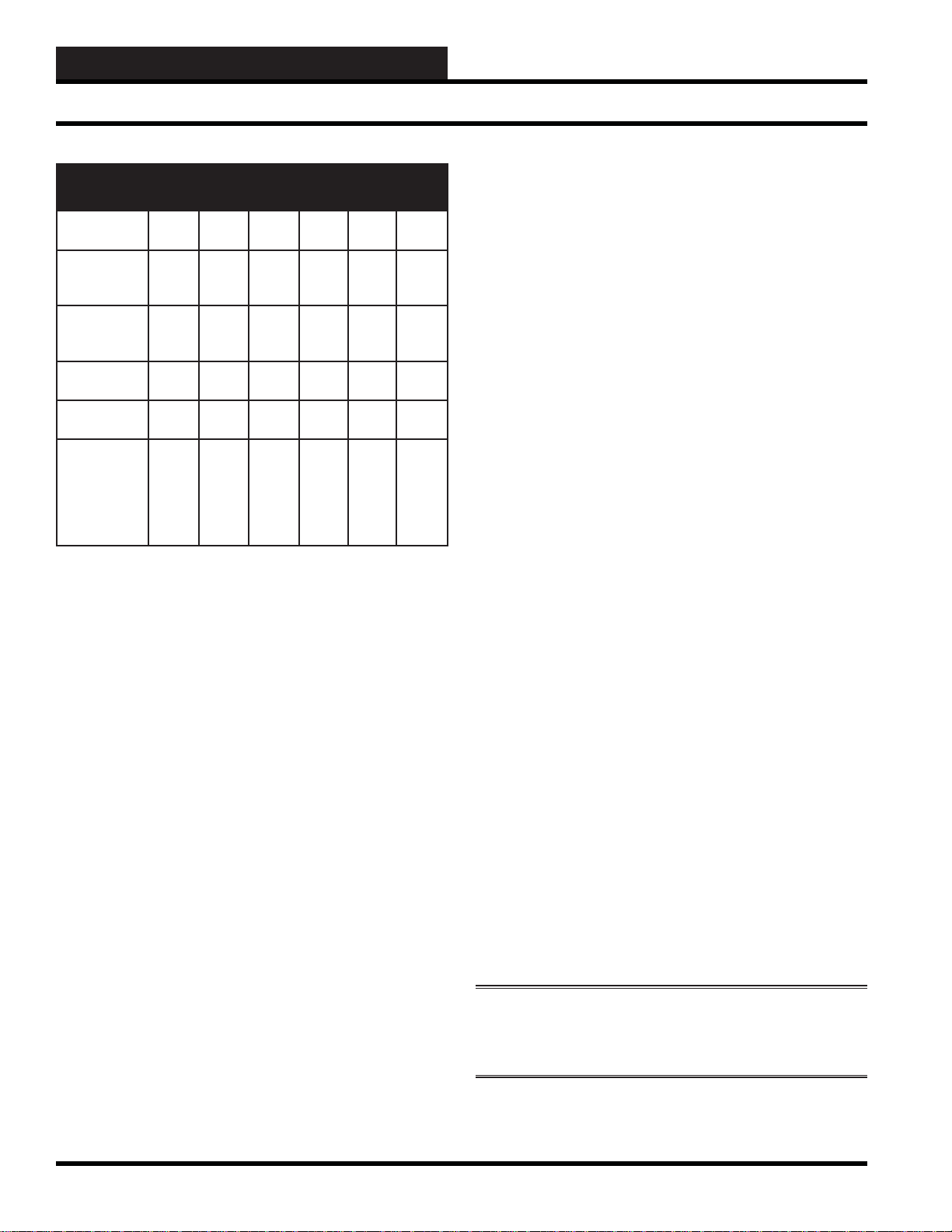

Binary Inputs

Binary Inputs

A binary input is an On/Off (dry contact closure) signal sent to

the SAT III controller to allow monitoring of air fl ow switches,

switch settings, etc. The SAT III controller comes standard with

16 small switches on its front panel labeled, L1-L16 which are in

effect manually controlled binary inputs. The WCC III monitors

the On/Off status of these switches and can control and/or alarm

based on the position of these switches. The binary input board(s)

allow the manual dip switches to be replaced with a terminal strip

which accepts wiring from remote mounted binary input devices.

The SAT III controller has two sets of 8 small switches on its front

cover labeled L1-L16. Switches L1-L8 are housed together in

one module, and switches L9-L16 are housed together in another

module. One module of switches is removed for each binary input

board and replaced with a ribbon cable which connects the binary

input board to the SAT III controller. The binary devices to be

monitored are then wired to the terminal strip of the binary input

board. The binary input board requires a 24 VAC power supply.

The SAT III can also accept two HSS Binary Input Boards.

1-4

WCC III Technical Guide

Page 7

1. GENERAL INSTRUCTIONS

8

7

SAT ADDRESS

2

1

4

8

A3 WIR E ROOMSENS OR WILL NOT

REQUIREA LOAD RESISTOR WHENSET

FORA 1 VOLT I NPUT.

WattMasterControlsInc.

BINARY

INPUTS

BINARY

INPUTS

L8

ON OFF

128

32

16

64

L4

L3

L2

L1

L6

L5

L7

L11

L12

ON OFF

L10

L9

ON OFF

L15

L16

L14

L13

CH

4

3

5

6

2

1

LOCALSET

STATUS 2

STATUS 3

STATUS 1

HSS XMI T

LOCALSET

LOCALSET DISABLE

BATTON/ OFF

PULSEINPUT

OPTION 1

TEST

OPTION 3

OPTION 2

ON OFF

STATUS

HSS RE C

SATXMIT

SATREC

ANALOGI NPUT

JUMPER SELECTION

A2 WIR E ROOMSENSO R WI LL REQUIRE

A300 OHM LOAD RESI STOR WHEN SET

FORA 1 VOLT I NPUT.

A4 TO 20 mASENSOR WILLREQUIRE A

50OHM LOADRES I STOR WHENSET FOR

A1 VOLT INPUT, OR A 250 OHMLOAD

RESISTORWHENSET FORA 5VOLT INPUT.

CURRENT

INPUT

THERMISTOR

INPUT

0-1V

0-5V

0-10V

THERM

0-1V

0-5V

0-10V

THERM

0TO 10V

INPUT

0TO5V

INPUT

0TO1V

INPUT

0-10V

0-1V

0-5V

0-10V

THERM

0-1V

0-5V

THERM

0-1V

0-5V

0-10V

THERM

PROGRAMMAB L E CONT R OL LE R

SAT II I

H

C

COM

CHANNEL

2134

2134

567

8

5678

V

OUT

GND

L

O

A

D

+V

ATI

10A250VAC~

5A30VDC

SA

VDE

G5Q-1A4

OMRON

DC24V

CHINA

10A250VAC~

5A30VDC

SA

VDE

G5Q-1A4

OMRON

DC24V

CHINA

10A250VAC~

5A30VDC

SA

VDE

G5Q-1A4

OMRON

DC24V

CHINA

10A250VAC~

5A30VDC

SA

VDE

G5Q-1A4

OMRON

DC24V

CHINA

EACHCONTACT

ISRATEDFOR

24VACOR VDC

@.5AMPMAX

0-15VDC

OUTPUT

MINL OAD

IS1KOHM

RESISTIVE

VDCONLY

WCC3BI NARY IN W/ T I ME DELAY

WATTMASTER CONTROLS, I NC

YS102072REV2

24 VAC 12 0VAC

120VACWIRING

BY OTHERS

TO OTHER

SAT III ORTO

WCCIII - MCD

CONNECTION FROM SAT I II TO BI NARY INPUT BOARD

USI NG THE "NEW" HSS CABLE CONNECT IO N MET HOD

HSS CABLE - ORDER STANDARD LENGTHS OF 1 F OOT, 1

1

2

FEET, 3 FEET, 25 FEET, 40 FEET, 80 FEET

DRY INPUT CONTACT S ONLY

24VAC

GND

TO OTHER

SAT III ORTO

WCCIII - MCD

WI R E " T" T O " T "

"R" TO"R"

"SHD" TO"SHD"

TWOBINARYINPUTBOARDSMAYBEWIREDTO

THE SAT II I CONTROLLER USING THI S METHOD.

CONNECT THE FI RST ONE TO THE SAT II I HSS

PORT, AND THE SECOND ONE TO THE FI RS T

BINARY INPUT BOARDS 2ND HSS PORT.

BINAR Y INPUT BOARD GETS POWER FROM THE HS S CABLE

SEE MANUAL FOR DI P

SWITCH SETTINGS

Binary Inputs

WCC III Technical Guide

1-5

Page 8

1. GENERAL INSTRUCTIONS

Analog Outputs

Analog Outputs

An analog output is a variable DC voltage signal sent from the

satellite controller used for proportional control of devices with

modulating actuators. The analog outputs are wired to the “ V-Out”

and “ Gnd” terminals on the SAT III controller and are named P1P8. The P stands for Proportional Output.

The SAT III controller has the capability of providing 8 analog

output signals which have a maximum range of 0-15 VDC.

V-OUT CONNECTIONS

0-15VDC

OUTPUT

MINLOAD

IS1K OHM

RESISTIVE

VDCONLY

EACHCONTACT

ISRATED FOR

24VACOR VDC

@.5 AMP MAX

5678

2134

CHANNEL

2134

567

VDE

VDE

SA

SA

5A30VDC

5A30VDC

10A250VAC~

10A250VAC~

CHINA

CHINA

DC24V

DC24V

G5Q-1A4

OMRON

G5Q-1A4

OMRON

OMRON

8

VDE

VDE

SA

SA

5A30VDC

5A30VDC

10A250VAC~

10A250VAC~

CHINA

CHINA

DC24V

DC24V

G5Q-1A4

OMRON

G5Q-1A4

Each analog output has a limit of 15 mA. The total current output

of all 8 analog outputs must be kept under 115 mA.

The SAT III controller comes standard with 8 analog outputs.

+V

ATI

GND

OUT

COM

L

O

A

D

V

H

C

ON OFF

ON OFF

ON OFF

ON OFF

BATTON/ OFF

PULSE INPUT

OPTION 3

OPTION 2

OPTION 1

LOCAL SETDISABLE

LOCAL SET

TEST

L16

L15

L14

BINARY

L13

L12

INPUTS

L11

L10

L9

L8

L7

L6

BINARY

L5

L4

INPUTS

L3

L2

L1

128

64

32

16

8

4

2

SATADDRESS

1

STATUS

SATREC

SATXMIT

HSS REC

HSS XMIT

LOCAL SET

STATUS 1

STATUS 2

STATUS 3

1

2

3

4

5

6

7

8

CH

SAT III

PROGRAMMABLE CONTROLLER

ANALOG INPUT

JUMPER SELECTION

THERM

0TO1V

0- 10V

0-5V

INPUT

0-1V

THERM

0TO5V

0- 10V

0-5V

INPUT

0-1V

THERM

0 TO 10V

0- 10V

INPUT

0-5V

0-1V

THERM

0- 10V

THERMISTOR

0-5V

INPUT

0-1V

THERM

0- 10V

CURRENT

0-5V

INPUT

0-1V

A4 TO 20 mA SENSOR WILLREQUIRE A

50OHM LOAD RESISTOR WHEN SET FOR

A1 VOLT INPUT,OR A 250 OHM LOAD

RESISTORWHEN SET FOR A 5 VOLTINPUT.

A2 WIRE ROOM SENSOR WILL REQUIRE

A300 OHM LOAD RESISTOR WHEN SET

FORA 1 VOLTINPUT.

A3 WIRE ROOM SENSOR WILL NOT

REQUIREA LOAD RESISTOR WHEN SET

FORA 1 VOLTINPUT.

WattMasterControls Inc.

1-6

WCC III Technical Guide

Page 9

1. GENERAL INSTRUCTIONS

Binary Outputs

Binary Outputs

A binary output on the SAT III controller is the electronic equivalent

of a relay contact which is used to complete a circuit to activate

on/off devices such as relays, 2-position valves, etc. The binary

output contacts can be used to complete a 24 volt DC circuit or

24 volt AC circuit at 1.0 amp maximum load. The binary output

terminals are labeled H, COM, and C.

The SAT III controller is capable of providing 16 binary (on/off)

outputs.

ON OFF

BATTON/ OFF

PULSE INPUT

OPTION 3

OPTION 2

OPTION 1

LOCAL SET DISABLE

LOCAL SET

TEST

ON OFF

L16

L15

L14

L13

L12

L11

L10

L9

ON OFF

L8

L7

L6

L5

L4

L3

L2

L1

ON OFF

128

64

32

16

8

4

2

1

The terminals for the binary outputs are found at the lower left hand

corner of the SAT III controller. The “COM” to “H” contacts are

referred to as K1h-K8h. The “COM” to “C” contacts are referred

to as K1c-K8c.

The SAT III can also accept up to three WCC III V-Out Relay

Boards.

STATUS

BINARY

INPUTS

BINARY

INPUTS

SATADDRESS

SAT REC

SAT XMIT

HSS REC

HSS XMIT

LOCAL SET

STATUS 1

STATUS 2

STATUS 3

CH

1

2

3

4

5

6

7

8

SAT III

PROGRAMMABLE CONTROLLER

ANALOG INPUT

JUMPER SELECTION

THERM

0TO1V

0 - 10V

0-5V

INPUT

0-1V

THERM

0TO5V

0 - 10V

0-5V

INPUT

0-1V

THERM

0 TO 10V

0 - 10V

INPUT

0-5V

0-1V

THERM

0 - 10V

THERMISTOR

0-5V

INPUT

0-1V

THERM

0 - 10V

CURRENT

0-5V

INPUT

0-1V

A4 TO 20 mA SENSOR WILL REQUIRE A

50 OHM LOAD RESISTORWHEN SET FOR

A1 VOLT INPUT, ORA 250 OHM LOAD

RESISTORWHEN SET FOR A 5 VOLTINPUT.

A2 WIRE ROOM SENSOR WILL REQUIRE

A300 OHM LOAD RESISTOR WHEN SET

FORA 1 VOLT INPUT.

A3 WIRE ROOM SENSOR WILL NOT

REQUIREA LOAD RESISTOR WHEN SET

FORA 1 VOLT INPUT.

WattMaster Controls Inc.

WCC III Technical Guide

1-7

Page 10

1. GENERAL INSTRUCTIONS

Point Addresses

Point Addresses

A Point Address uniquely identifi es a point within the WCC

III system. All point addresses have an associated “analog” or

“binary” value. The term “analog” simply means a value which

is represented by a number (such as room temperature, duct static

pressure, etc.). The term “binary” means the value is represented

by one of two conditions, ON or OFF. An input is a signal sent

to the WCC III system, and an output is sent from the WCC III

system. Therefore, room temperature is an analog input, fan status

is a binary input, and controlling a fan relay is a binary output.

In addition to the inputs and outputs that are wired to the SAT III

controllers, there are several software point addresses within the

system. For example, the WCC III system has 128 week schedules.

This means that separate day/night schedules can be assigned to

128 different areas of the building.

For example, assume that you have three different areas in a

building that have different schedules as shown in the following

table.

Area Occupied Time

W eek Schedule #1 1st Floor West 8:00 am - 5:00 pm, M-F

W eek Schedule #2 1st Floor East 7:00 am - 7:00 pm, M-F

W eek Schedule #3 2nd Floor 9:00 am - 4:00 pm, M-Th

Week Schedule #1 is named W1, and the value of W1 will be On

between 8:00 am and 5:00 pm, Monday through Friday, etc.

The Name column in the table that follows is the name that you

should use when specifying a point address to the system. The “n”

is where a “point number” for the point address is to be entered.

Table of Point Addresses

Name Description Value

RnB Data Registers (b) Analog

TnR Trend Logging Run T ime Analog

TnC Trend Logging Change of State None

TnA Trend Logging Analog Trend None

TnP Trend Logging Analog Peak None

Ln Logical Input On/Off

Wn W eek Schedules On/Off

Sn Optimal Starts On/Off

GBn Binary Globals On/Off

GAn Analog Globals Analog

On Binary Output On/Off

Constant Point Addresses

The following list shows several point addresses within the

system that are always available for use on many of the data input

screens.

Name Description Associated Data Type

0 Logical Zero Always Off

1 Logical One Always On

//// Logical Null Ignored

. . . . Logical Off Always Off/Not Used

NOTE: When a point option is not required, replace the

default value (/ / / /) with either a zero (0) or dot (. . . .)

to force the system to realize that the option is always

OFF. If the slashes are not replaced, the system will

ignore that input and the system can, in rare cases, see

the slashes as being ON.

Name Description Value

Cn Comparator (See analog input

screen binary setpoint)

An Analog Inputs Analog

Pn Analog Outputs Analog

KnH Control Outputs

(H Contacts)

KnC Control Outputs

(C Contacts)

RnA Data Registers (a) Analog

1-8

On/Off

On/Off

On/Off

Name Description

Analog 0 Initiates a 0 (zero) value

TIME Current Time (in HH:MM format)

TIMEB Current Time (in minutes-since-midnight format)

NEWSEC New Second

NEWMIN New Minute

NEWHR New Hour

NEWDA Y New Day

NEWMON New Month

WCC III Technical Guide

Page 11

1. GENERAL INSTRUCTIONS

Data Registers

Time & TimeB

These logical addresses are the actual time on HH:MM (TIME) and

minutes-since-midnight (TIMEB) formats. They are considered

analog values and have value ranges of 0000 to 2359 (TIME), and

0000 to 1439 (TIMEB).

Typical application of these logical addresses includes use in

the Dual Limit mode, allowing such modes of control as “OnBetween-Times” and “Off-Between-Times.”

NEWSEC, NEWMIN, NEWHR, NEWDAY, & NEWMON

These logical addresses are considered binary values and are based

on real-time. They have a pulse-type nature in that each of these

addresses has a value of one (or ON) for one second after the

occurrence of the specifi ed event. After the one second ON period

has elapsed, the value returns to zero (or OFF).

These addresses have several uses throughout the system. One

example would be the generation of a variable duty cycle output.

When used in conjunction with the separate “Minimum ON/OFF”

timers, these addresses can achieve cycles of from one second to

several days with a wide range of cycles.

Examples of “point addresses” within the system:

Name Description

GA12 Global Analog #12

135A5 Satellite #135, Analog Input #5

A5 Analog Input #5, Current Satellite

W12 W eek Schedule #12

S27 Optimal Start #27

C1 Setpoint Comparator on Analog Input #1

K1h

14P3

When K1h is ON, the relay within the satellite

controller which connects the electrical path

between the “H” and “COM” terminals on

channel 1 of the satellite controller is closed.

When K1h is OFF , the circuit is open.

Satellite #14, Analog Output #3.

Data Registers

The WCC III system has some capabilities built into the software

that are very helpful, and you should be aware of them. There is

a Data Register associated with each of the H/C Control Output

Screens. A H/C Control Output Screen allows the user to tell

the satellite controller when to open and close the binary output

contacts. A H/C Control Output Screen can be a Time Clock, EA

Driver, or Dual Limit Mode Scr een.

Time Clock

When the H/C Control contact on the satellite controller is

controlled by a Time Clock Screen, the contact opens and closes

based on time only. For example, a T ime Clock Scr een can be used

to run a water circulating pump from 8:00 am to 5:00 pm, Monday

through Friday. Each Time Clock Screen has a Data Register

associated with it.

The Data Register is an analog value which is the time in seconds

since the satellite controller binary output contact closed. Assume

the water circulating pump is controlled by satellite controller

contact K1h. That is to say, the “COM” to “H” contact on channel

1 of the satellite controller closes to complete a 24 VAC signal to

run the pump.

The Data Register for a Time Clock Screen is named RnA or RnB.

R stands for data register, n refers to channel 1-8 of the satellite

controller, A means the “COM” to “H” contact, and B means the

“COM” to “C” contact. Therefore, the Data Register for contact

K1h is R1A. As contact K1h closes, the Data Register for contact

Klh (R1A) starts recording time in seconds. That is to say , the value

of R1A is the time in seconds since contact K1h closed.

RnA = Time in seconds since COM to H contact closed

(9999 sec max)

RnB = Time in seconds since COM to C contact closed

(9999 sec max)

The Data Register for a Time Clock Screen might be used to

start one piece of equipment after another has been started. For

example, assume we want to start an air handler two minutes after

the water circulating pump starts. The pump would be controlled

by a Time Clock Scr een as mentioned above. The air handler would

be controlled using a Dual Limit Screen. The analog input value

for the Dual Limit Screen would be R1A, which is time in seconds

since the pump started. The Dual Limit Screen is set up to close the

contact for the air handler when the value of R1A is between 120

seconds and infi nity.

WCC III Technical Guide

The data register will also record time in negative seconds. When

the contact opens, the data register value will begin counting -1,

-2, etc.

1-9

Page 12

1. GENERAL INSTRUCTIONS

Data Registers

EA Driver

The EA Driver Mode is “3-point fl oating” control. For example,

assume that the H/C control outputs on channel 2 of the satellite

controller are used to control a VAV box using the EA Driver

Mode. When the space needs heat, the “COM” to “H” contacts on

the satellite controller will close to drive the damper in the VAV

box to the closed position. When the space needs cooling, the

“COM” to “C” contact on the satellite controller will close to open

the damper in the VA V box.

There are two Data Registers associated with an EA Driver Screen.

The value of the fi rst Data Register is equal to the setpoint entered

on the EA Driver Screen and is referred to as “RnA.” The value

of the second Data Register is equal to the difference between the

setpoint and the actual temperature and is referred to as “RnB.”

“R” stands for data register, and “n” refers to channel 1-8 of the

satellite controller.

RnA = Setpoint

RnB = Difference between Setpoint and Measured Value (error)

For example, assume that the setpoint for the room in question

is 72 °F, and the actual temperature is 70 °F. The value of Data

Register R2A (setpoint) is 72 °F, and the value of Data Register

R2B (error) is -2 °F, since the actual space temperature is 2 °F

below the setpoint.

The Data Register could be used to turn on a second stage of heat

whenever the space temperature falls 2 °F below setpoint. Assume

that the second stage of heat is a heating coil which is energized

when satellite controller contact K3h is closed. A Dual Limit Scr een

is used to control contact K3h. Data Register R2B is entered as

the analog input value for the Dual Limit Screen. When the value

of R2B is -2 or less (the space temperature is at least 2 °F below

setpoint), contact K3h closes to turn on the second stage of heat.

The Data Register for a Dual Limit Screen is named “RnA” or

RnB.” “R” stands for data register, “n” refers to channel 1-8 of the

satellite controller, “A” means the “COM” to “H” contact, and “B”

means the “COM” to “C” contact. Therefore, the Data Register for

contact Klh is R1A.

RnA = Difference between Setpoint and Measured Value

(COM to H)

RnB = Difference between Setpoint and Measured Value

(COM to C)

The Dual Limit Scr een has two setpoints, the high limit and the low

limit. Since the Data Register is the difference between the setpoint

and the actual temperature, you have to “tell” the system what you

are considering the setpoint to be. Therefore, the Data Register is

measured from either the “Midpoint” or “Nearest Limit” of the

setpoints, depending on how the Dual Limit Screen is set up.

For example, assume that a Dual Limit Screen is used to control a

heat pump compressor to have the compressor off if the space is

between 70 and 74 °F . If the space temperature is below 70 °F, the

compressor will be on for heating, and if the space temperature is

above 74 °F, the compressor will be on for cooling. Assume the

actual space temperature is 76 °F .

The Data Register can be measured from either the “Midpoint”

or the “Nearest Limit.” If the Data Register is measured from the

“Midpoint,” the value of the Data is 4 °F .

Low Limit High Limit Actual T emperature

70 72 74 76

4 Deg

Midpoint

Data Register

Dual Limit

When the H/C control output contact on the satellite controller

is controlled by a Dual Limit Screen, the contact opens and

closes based on how the analog input value compares to a pair

of setpoints. There is one Data Register for each contact on the

satellite controller which is controlled by a Dual Limit Screen. The

value of the Data Register is the difference between the setpoint

and the actual temperature.

1-10

Difference between actual temperature and the “Midpoint” of the

setpoints = 4 °F, and therefore, the value of the Data Register is 4

°F .

If the Data Register is measured from the nearest limit, the value of

the Data Register is 2 °F .

Low Limit High Limit Actual Temperature

70 74 76

2 Deg

Nearest

Limit

Data Register

WCC III Technical Guide

Page 13

1. GENERAL INSTRUCTIONS

Alarms

Alarm Call-Out

The WCC III will automatically e-mail a report of the alarms to

an e-mail address. There are eight different alarm types or alarm

priorities. The fi rst fi ve alarm types can “e-mail-out”; each of these

fi ve alarm types can e-mail 3 separate e-mail addresses.

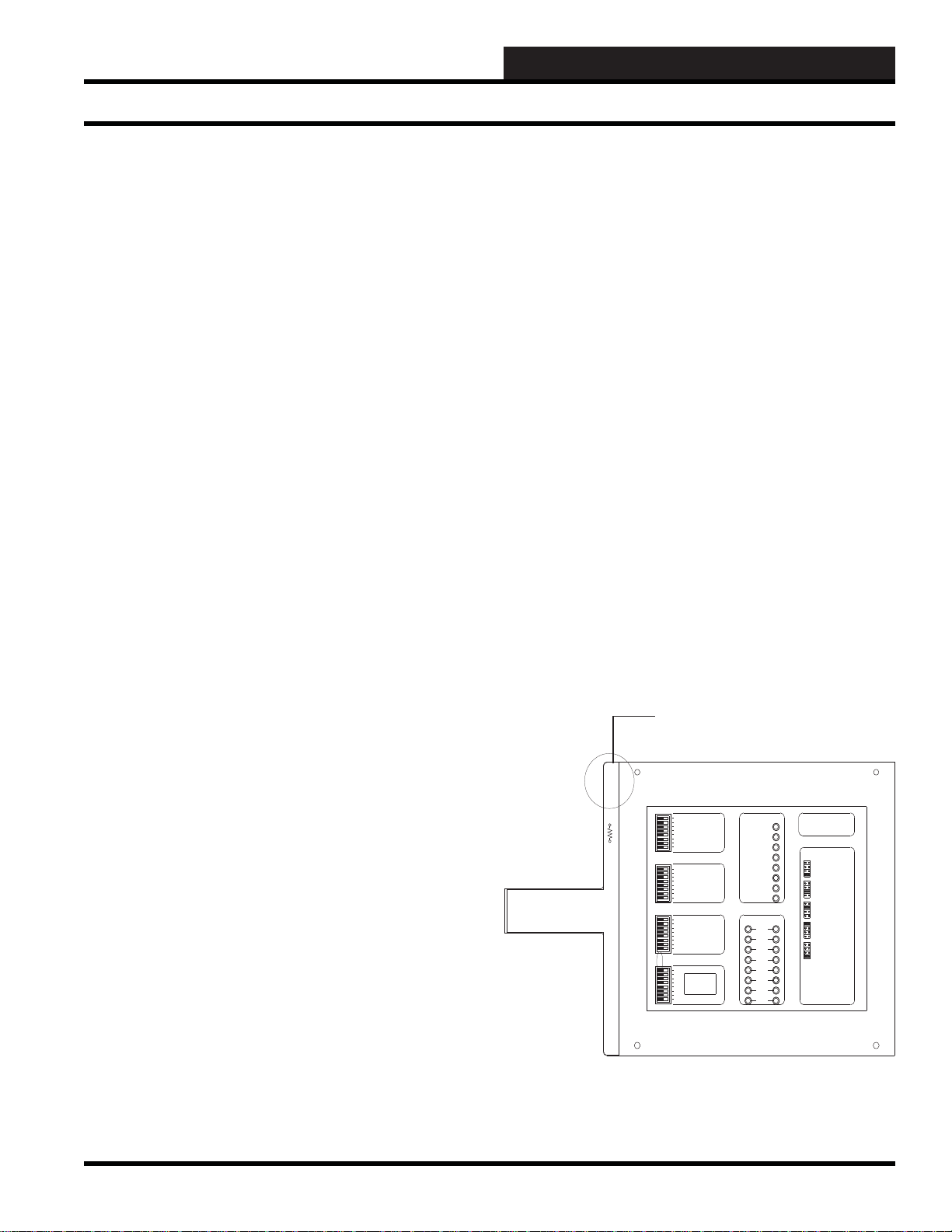

Analog Alarm Limit

Each analog input can have a low and high limit assigned to it

on the Analog Input Screen. If the value of the analog input falls

below the low limit or rises above the high limit, the system

automatically generates an alarm. For example, assume that the

analog input in question is a room temperature sensor located in

an offi ce space. If the space temperature falls below 68 °F or rises

above 80 °F during the occupied period, we want an alarm to call

out. T o set up the alarm limits, fi rst sign on by accessing the System

Parameter Screen and entering your password. An access level of

1 or greater is required to enter or change alarm limits. After you

are signed on, return to the Main Menu and place the cursor over

“ANALOG INPUT” and press <Enter>. An Analog Input Screen

similar to what is shown below should come into view:

The alarm limits along with the alarm type and alarm message

numbers are assigned on this screen (see the Analog Input Screen

in Section 3 for more information). If the space temperature drifts

out of the entered alarm limits, the system will automatically

generate an alarm. For example, assume that the space temperature

rises above the high limit value of 80 °F . Alarm message #1 (High

Temperature) along with the time and date of the alarm and the

high peak value of the room temperature will appear on Analog

Input Summary Screen and the Alarm Summary Screen. Within

one minute from the time the alarm appears on the screen, it

will automatically be e-mailed if enabled. (To acknowledge

alarms, select <Action> from the Top Menu Bar and then select

<Acknowledge Alarm> or <Acknowledge All Alarm> described

in the Help Screen, Analog Input Summary Screen, and Alarm

Summary Screen in Section 3 of this guide.

Satellite #1 ANALOG INPUT #1

Description: RM 101 Type: Analog

Pattern for values associated with this input: xxx.x

Units @ 0% scale: 0.0 Deg F Units of Measure Message #: 1

@ full scale: 100.0 Deg F Filter Time Constant: 8 seconds

-------------------ALARMS--------------------

Controlled by: W1 Limits Low High

Alarm Type: 1 On 68.0 80.0 Deg F

Alarm Message #’s: Low 2 High 1 Off 50.0 90.0 Deg F

Alternate Limits selected by:.... On (alt) 0.0 0.0 Deg F

Off (alt) 0.0 0.0 Deg F

Limit overlap time

after control change: 20 Minutes Local set 55.0 90.0 Deg F

----------------------BINARY SETPOINT---------------------- OFF Above 0.0 Deg F On Message #: 0

OFF Below 0.0 Deg F Off Message #: 0

HOME for menu

WCC III Technical Guide

1-11

Page 14

1. GENERAL INSTRUCTIONS

Alarms

Run Time Alarm

The WCC III system also has the capability of alarming if the total

ON time of a binary (on/off) value has exceeded the run time alarm

limit. T o assign a run time alarm limit, fi rst sign on by accessing the

System Parameter Screen and entering your password. An access

level of 2 or greater is required to enter or change alarm limits.

After you are signed on, return to the Main Menu and place the

cursor over “TREND LOGS” and press <Enter>. The Trend Log

Summary Screen should come into view. To access a Run Time

Trend Logging Screen, use the arrow keys to place the cursor (>)

by the desired run time point, and press <Enter>. The following

screen should come into view:

In this example screen, we are recording the total “ON” time of

contact Klc (COM to C contact closure) on satellite controller

#1. When contact Klc is closed, or “ON”, Fan #1 runs. Run time

recorder #1 records total accumulated run time of the fan. Alarm

message #7 (Grease Bearings) will automatically appear on the

Alarm Summary Screen when the total accumulated run time of

the fan exceeds 500 hours. Within one minute after the alarm

appears on the screen, it will automatically e-mail if enabled. (See

the Alarm Summary Screen in Section 3 for information about

how to acknowledge a run time alarm, and see the Run Time Trend

Logging Screen section in Section 3 of this manual for information

about how to reset the accumulated run time to zero.)

Satellite Fail Alarm

If the Master Communications Device loses communications

with a satellite controller, a Satellite SOS Alarm will show which

satellite is out of service and the time and date of the alarm.

Satellite # 1 TREND LOGGING # 1 of Type: RUN TIME

Records total ON time Starting at : *:* on */*

for K1c Fan # 1 Reset by: L16 being ON

Alarm Type: 6

Alarm Message #: 7

Current run time: 250 Hours Alarm Limit: 500 Hours

HOME for menu

1-12

WCC III Technical Guide

Loading...

Loading...