Page 1

WattMaster Control Center

WCC III

WCC III Provides Complete Control and Energy

Management for Any Size Facility

Economical For Small Systems

Because Of Modular Construction

The WCC III System is comprised of an MCD that operates primarily as a distribution point for control

schedules and data used/shared by direct digital control panels (satellite controllers and terminal unit controllers) which are distributed throughout the building.

Satellite controllers and terminal unit controllers

provide the actual control and are added and programmed to suit your specifi c system requirements.

Menu Driven Program Makes System

Set-up Easy And System Operation

Even Easier

All steps of the WCC III operation including initial satellite

controller set-up are menu driven. This means operators

do not have to be system programmers, and changes can

be made without referencing a complex computer program.

Reduced Costs

Equipment Cost is reduced because the system, including satellite controllers, is modular. You only buy the number of satellites required. Satellites have capacity for 8 selectable inputs (analog or binary), 16 binary and 8 analog

outputs, and there are expansion boards available to extend binary inputs and outputs along with analog outputs.

Direct Digital Control further reduces costs because

satellite controllers interface directly with valve and damper actuators, eliminating costly intermediate controls.

Terminal Unit Controllers Reduces Wiring Costs:

Use of terminal unit controllers further reduces installed

costs by greatly reducing fi eld wiring and often allow-

ing factory installation of controls on terminal units to

reduce fi eld labor and wiring errors. Special satellites

and terminal unit controllers are available to control fan

coil units, heat pumps, and pressure dependent and

pressure independent VAV and fan terminal boxes.

Operating Costs are reduced through menu driven programs, including adaptive optimal start, demand limiting,

deadband spreading, duty cycling, night setback, and other programs you can create for your specifi c requirements

thru the logic programs related to global commands.

Equipment Replacement Costs drop because equipment lasts longer. Close monitoring and logging of

performance and run time means service needs can

be recognized before a serious breakdown occurs.

Improved Cost Management: Equipment and lighting are precisely controlled during “normal occupancy

hours”. After hours override by tenants permits logging or extra usage so that costs can be properly allocated to tenants/departments using extra energy.

Installation Cost is reduced because “Global” information gathered at one satellite can be shared with other

satellites, eliminating wiring runs and control duplication.

Page 2

WCC III Provides

Comfort And Monitoring Features

Improved Comfort

Happy People: Comfortable tenants do not move out,

and comfortable employees work more effi ciently . The

WCC III is designed to monitor and control each terminal

unit in the building. Control is precise, and alarms are displayed when any temperature exceeds limits. Corrective

action can be taken before occupants become aware of

a problem.

Tenant Override and Report:

The override allows up to 500 different tenants to override

lights, heat, and air conditioning (or other functions) for a

selectable time period. Overrides are logged and totaled

by tenant and subcode for monthly billing purposes. Up to

12 month log is stored by month for each tenant.

Remote Monitoring/Alarm E-mail

Increases Effi ciency For Owners

Of Multiple Buildings

The WCC III system is supplied with remote access for

authorized operators. Setpoints, schedules, etc., may be

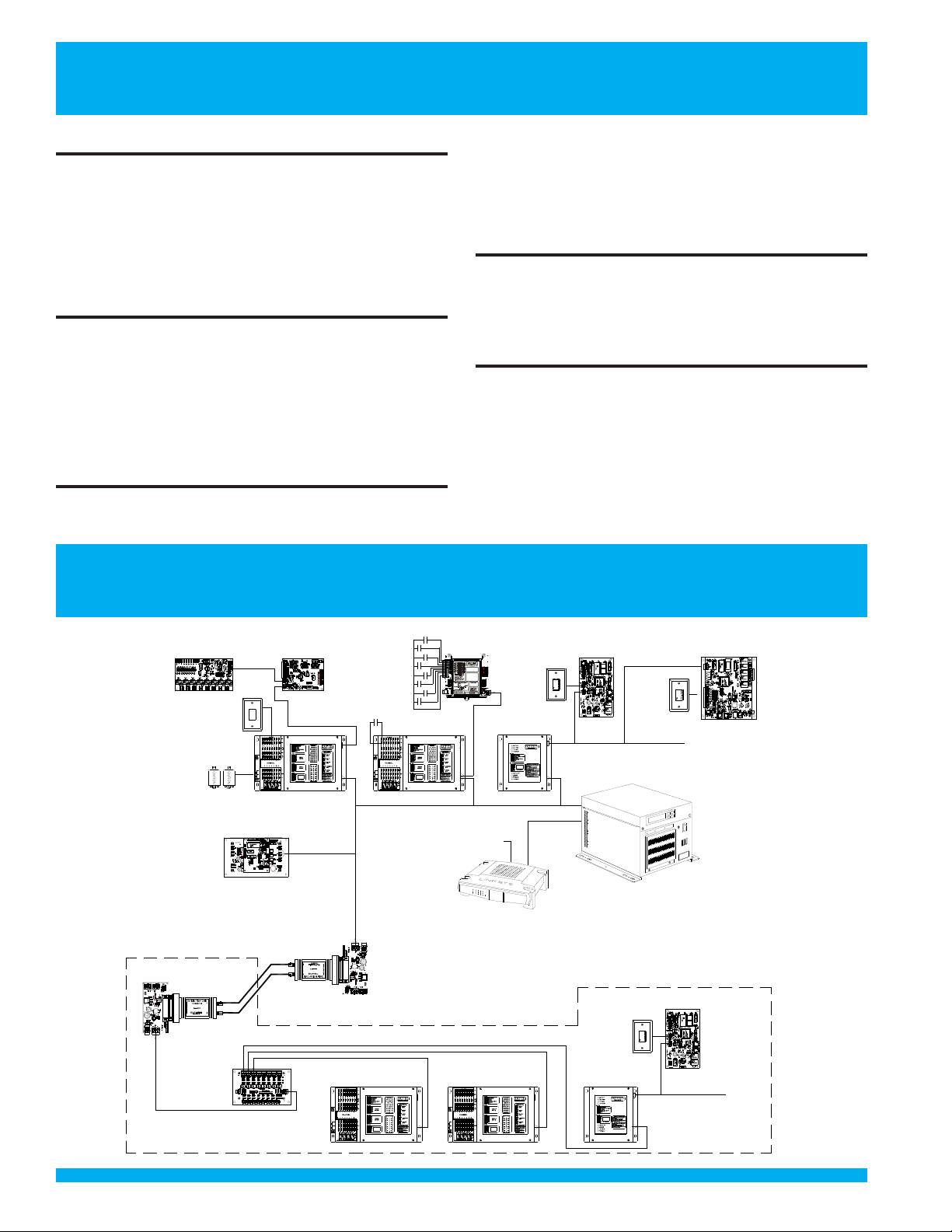

WCC III Typical

changed and system status monitored from this remote

location. Thus, the performance of multiple buildings can

be monitored from a single location and alarm reports automatically received at this or any other location through

the alarm e-mail function of the WCC III.

Enhanced Graphic Option

An enhanced graphics program (WGCC3) with standard

symbols and drawing package is available for the user desiring further refi nement of graphic capability. This is an

optional upgrade.

Internet Access:

Improves communication on large facilities: The ability

to have multiple operators that can have access to the

system simultaneously. This truly optimizes system performance by coordinating all service maintenance and

operators’ input in one operating program.

Optional B-OUT Board

( 8 RELAYOUTS)

(2 PER SATIII)

OE210

TYPICAL

SENSOR

(X8)

ON/OFF RELAY

PUMPS, LIGHTS,

ETC.

16 OUTPUTS

PER SATIII

WCC II TO WCC III

GLOBAL BRIDGE

CONNECTION

TO OLD WCC II

MANCHESTER

COMM LOOP

WATTMASTER CONTROLS INC

SATII

UP TO 60 TOTAL SAT III

OR SAT3C/D/F/P PER LOOP.

THERE ARE 4 POSSIBLE

SATIII RS485

COMMUNICATIONS LOOPS

(UP TO 239 SAT III MAXIMUM)

BUILDING # 2

PL102335

RS-485 TO FIBER

OPTIC ADAPTOR

USUALLYONE

OR TWO PER

FLOOR

SATCOMM LOOP

P 102224L

POWER AND

SWITCHABLE COMM

Optional B-INPUT Board

( 8 BINARY INPUTS)

(2 PER SATIII)

HSS PORT

GLOBALBRIDGE

PROGRAM SOCKET

YS102210 REV 1

MADE IN USA

ADDRESS

R/T

SHLD

PCF8583

C

COMMT

EEPROM

24C128

POWER

SATII STAT

485

COMM R

DRIVER

LT1785

SATIII

VBAT

COMM

24VAC

CHASSIS GND

GND

FIBER OPTIC LINES

MAXIUM OF 2.5 MILES

(USES "ST" CONNECTORS)

SATCOMM LOOP

System Schematic

OE455-P

SAT3P

CONTROLLER

PULSE INPUTS

P1

SATIII-P

PULSE METER BOARD

P2

ATTMASTER CONTROLS

YS102268 REV0

P3

MADE IN USA

P4

PULSE 1

P5

PULSE 2

TOTALWIRING FOR EACH INPUTNOT

PULSE 3

TO EXCEED 100 FEET.

P6

USE 18 GAUGETWISTED PAIR WITH

PULSE 4

SHIELD FOR EACH PULSE METER

PULSE 5

CONNECTION.

P7

PULSE 6

CONNECTTHE SHIELD WIRETO GND.

PULSE 7

P8

PULSE 8

STATREC

“P”MODEADDRESSING NOTES

GND

SATIIIADDRESSING STARTSAT

STATXMIT

ADDRESS NUMBER 8.

LOCALSET

EACH "P" MODE SATIIITAKES UP

GND

STATUS

(8) SATIII LOGICALADDRESSES.

THEREARE ONLY(8) USEDACTIVE

INPUTS PER SAT3P.

OPTIONS

ADDRESS

ANALOG INPUT#1 (PULSE INPUT#1)

SEL

ADD

ON EACH SATIIIADDRESS ISACTIVE.

1

ALLOTHER INPUTSAND OUTPUTS ON

TEST

THE SAT3PARE NOTFUNCTIONAL.

LOCAL

2

LDIS

4

OPT1

8

OPT2

16

OPT3

32

64

128

COMM

POWER

24 VAC

R

SH

GND

T

OE454/OE455/OE456

SAT3C/D/F

CONTROLLER

HIGH SPEED CABLE

MODEM / DSL ROUTER

SATCOMM LOOP

OE421- SATIII

CONTROLLER

OE213

TYPICAL

SENSOR

ETHERNET

CABLE

HSS PORT

MULTIPLE PULSE

INPUTS FROM

POWER METERS

SINGLE PULSE

INPUT FROM

POWER METER

OE421- SATIII

CONTROLLER

TO THE ISP

(INTERNET SERVICE PROVIDER)

CONNECTION TO THE INTERNET

(BY OTHERS)

PL102335

RS-485 TO FIBER

OPTIC ADAPTOR

USED IN MULTIPLES

OF TWO

OE421- SATIII

CONTROLLER

OE320

TUC-2R

VAV B O X

WCC III-MCD

OE213

TYPICAL

SPACE

SENSOR

OE455

SAT3D

CONTROLLER

OE213

TYPICAL

SENSOR

OE320

TUC-2R

VAV B O X

TUC COMM LOOP

UP TO 32 TOTAL

FAN COIL, HEAT PUMP

PD VAV TERMINAL UNITS

PI VAV TERMINAL UNITS

PARALLELFAN BOX, ETC.

OE331

TUC-5R+

HEATPUMP

UP TO 32 TOTAL

FAN COIL, HEAT PUMP

PD VAV TERMINAL UNITS

PI VAV TERMINAL UNITS

PARALLELFAN BOX, ETC.

Page 3

WCC III Provides

These Specifi c Features

Function Benefi t

Menu Driven Software Easiest system to operate on the market today

Sort By Descriptions

Automatic Daylight Savings Correction

Linux-Based Software Embedded system approach from the start

Capacitor Backup Memory for the Satellite Memory Protection from 72 plus hour power failure

Program Flow Trace Simplifi es program analysis on large systems

Multiple (8) Alarm Levels Reduces nuisance alarms

E-mailing of Alarms Improves service /maintenance support

Automatic Alarm Printout Provides hard copy record of alarms

Data Copy Functions Reduces set time and errors

Adaptive Optimal Starts (64 programs) Optimizes energy use and comfort

Demand Limiting, Deadband Spreading

Morning Warm-up Program Controlled warm-up maximizes comfort

Controlled Restart after Power Outages Prevents breaker lockout from electrical surges

Softstart for Morning Warm-up Reduces electrical surge and demand peak problems

Isolated RS-485 Communications to SATs Reduces damage from voltage surges

Fiber Optics Reduces damage from voltage surges

Multiple Levels of Operator Security Codes Prevents unauthorized access to program level

Temporary Overrides - Locally or Remotely Permits temporary schedule changes by the tenant or

maintenance

Analog Input Simulation Aids in service and system checkout and reduces

start-up time

Analog Input Trend Logs Log (and graph) of all analog inputs improves system analysis

Extreme Trend Logs Helps determine system performance

Change of State Logs Documents equipment operation time/characteristics

Runtime Accumulation Improves service, maintenance, and after hours billing

capabilities

Analog Comparison, Boolean Logic Optimizes system performance and minimizes energy use

Math Operators/Enthalpy Logic Energy consumption is reduced with customized

programs

User Confi gurable Lookup Tables Precise readout from nonlinear inputs

Event Initiated Logic Reduces wiring interlocks costs

Signal Selection/Averaging Optimizes reset schedules from selectable loads

Proportional Reset/Graph Reduces energy use, stabilizes control, and graph

simplifi es readout

Programmable Switch Hysteresis Extends equipment life by reducing cycling

Programmable Filter Time Constants Improves system stability and performance

Multiple Demand Limiting Ten energy consumption screens fi t multiple meter

facilities

Remote Monitoring/Uploading/Downloading Improves service capabilities

Internet Based Communications Accessible from anywhere

Terminal Unit Interface (Sat3 c/d/f) Reduces installed cost

Duty Cycling User Defi nable Versatile program for special applications

Page 4

WCC III

Technical Specifi cations

WCC III added system improvements over the WCC II

system:

SAT III controller added improvements over the SAT II

controller:

Recommended Computer for the WCC III program:

• Increased the Global Analogs from 128 to 256

• Increased the Global Binaries from 256 to 512

• Increased the Week Schedules from 32 to 128

• 16 dedicated PID programs

• Since the system is now internet based,

multiple workstations are now supported.

• Relay outputs instead of “Chipswitches”

• LED status indicators for the relay outputs

• HSS expansion port – supports new Binary

Input, Binary Output boards.

• Added HSS Binary Outputs to SAT III (Up to

16 more relay outputs)

• The SAT III has a 12 bit A to D converter,

while the SAT II has a 10 Bit A to D converter.

• Analog Inputs of 0 to 1 VDC, 0 to 5 VDC, 0 to

10 VDC, 4 to 20mA, and Thermistor sensors

are now supported.

• Pentium 4 computer or better that is running

at 2 GHz or faster

• 1 Gig RAM minimum

• Windows XP-Pro

• 80 Gig Hard Drive or larger

• High Speed internet access (cable modem

preferred)

• Printer (optional for data print outs)

Computer Power Requirements (WCC III-MCD):

SAT III Power Requirements:

Communications Loop:

Internet Access Requirements:

Operating Temperature:

• 96 to 143 VAC 50/60 Hz 200 Watts

• Use dedicated 120 VAC circuit (4-3 wire

ground plug required)

• (UPS is recommended)

• 24 VAC @ 1 Amp

• Each communications loop communicates

with up to 60 SATs. (4 loops are possible)

• Communications wire is 18 gage twisted with

shield.

• 4000 feet to furthest Satellite.

• Fiber Optics

• High Speed Access (cable modem is

preferred)

• 50 to 100 degrees Fahrenheit, 10% to

90% (non condensing)

Form: WM-WCCIII-SBR-01D Printed in the USA October 2011

All rights reserved. Copyright 2011

WattMaster Controls Inc. • 8500 NW River Park Drive • Parkville, Mo. · 64152

Phone (816) 505-1100 www.wcc-controls.com Fax (816) 505-1101

Loading...

Loading...