Page 1

Operator’s Guide

www.wattmaster.com

www.wattmaster.com

Operator’s Guide

WCC II

Page 2

WattMaster Controls, Inc.

8500 NW River Park Drive · Parkville, MO 64152

Toll Free PH: (866) 918-1100

PH: (816) 505-1100 · FAX: (816) 505-1101 · E-mail: mail@wattmaster.com

Visit our web site at www.wattmaster.com

Form: WM-WCCII-OGD-01A Copyright 2006 WattMaster Controls, Inc.

WattMaster Controls, Inc. assumes no responsibility for errors, or omissions.

This document is subject to change without notice.

Page 3

WCC II Operator’s Guide

Table of Contents

INTRODUCTION: SYSTEM OVERVIEW ......... I-1

Diagram of WCCII System ................................... I-1

Operator Control Console Components .............. I-2

Satellite Controller .............................................. I-2

SAT II .............................................................................I-3

SAT II-A ..........................................................................I-3

TUC Input/Output Features .........................................I-3

SAT II-B ..........................................................................I-3

System Features .................................................. I-4

Standard Software ........................................................I-4

Optional Enhanced Color Graphics ............................I-4

Optional Tenant Override ............................................I-4

System Size ..................................................................I-4

Modular Construction ..................................................I-4

SECTION 1: GENERAL INSTRUCTIONS ...... 1-1

“Where To Find” Features ................................... 1-1

ECC/WCC II Routine Maintenance ...................... 1-1

ECC/WCC II Software Version List ..................... 1-2

Recommended Data Entry Procedure ................ 1-3

Analog Inputs ...................................................... 1-3

Binary Inputs....................................................... 1-4

Analog Outputs ................................................... 1-5

Binary Outputs .................................................... 1-6

Point Addresses .................................................. 1-7

Data Registers .................................................... 1-8

Time Clock ...................................................................1-8

EA Driver ......................................................................1-9

Dual Limit .....................................................................1-9

Alarm Print-Out and Call-Out ............................ 1-10

Run Time Alarm .........................................................1-12

Satellite Fail Alarm ....................................................1-13

Operator Sign On/Off ........................................ 1-13

Manual Overrides .............................................. 1-13

System Re-Boot ................................................ 1-13

Hardware Requirements ................................... 1-13

SECTION 2: INITIATING THE SYSTEM......... 2-1

Dual Disk Drive Systems ..................................... 2-1

Hard Disk Drive Systems .................................... 2-2

Copying Disks ..................................................... 2-2

Formatting Disks................................................. 2-2

Copying Data - Dual Floppy Systems .................. 2-4

Copying Data - Hard Disk Drive Systems ........... 2-4

Returning to the ECC/WCC II Program ............... 2-6

Dual Disk Drive Systems ............................................2-6

Hard Disk Drive Systems ............................................2-6

Assign Operator Access Codes .......................... 2-6

Password Entry ................................................... 2-7

SECTION 3: SCREEN DESCRIPTIONS ......... 3-1

HELP SCREEN ..................................................... 3-1

MAIN MENU SCREEN .......................................... 3-5

ANALOG INPUT SUMMARY SCREEN .................. 3-7

ANALOG INPUT SCREEN .................................... 3-9

CONTROL OUTPUT SCREENS .......................... 3-12

CONTROL OUTPUT SUMMARY SCREEN ...............3-13

EA DRIVER SCREEN .................................................3-15

DUAL LIMIT SCREEN ................................................3-17

TIMECLOCK SCREEN ...............................................3-20

ANALOG OUTPUTS ........................................... 3-22

ANALOG OUTPUT SUMMARY SCREEN ..................3-22

ANALOG OUTPUT SCREEN .....................................3-24

TREND LOGGING .............................................. 3-25

TREND LOGGING SUMMARY SCREEN ...................3-26

ANALOG PEAK TREND LOG SCREEN ....................3-27

ANALOG TREND TREND LOG SCREEN .................3-28

CHANGE OF STATE TREND LOG SCREEN ............3-31

RUN TIME TREND LOG SCREEN .............................3-32

LOGIC SWITCH .................................................. 3-34

LOGIC SWITCH SUMMARY SCREEN ......................3-34

LOGIC SWITCH SCREEN ..........................................3-35

ALARM SUMMARY SCREEN .............................. 3-36

SATELLITE SUMMARY SCREEN ....................... 3-38

OVERRIDE SCREEN ........................................... 3-40

Operator Interfaces

TOC-1

Page 4

WCC II Operator’s Guide

Table of Contents

HOLIDAY SCHEDULE SCREEN .......................... 3-41

SYSTEM PARAMETERS SCREEN ...................... 3-43

OPERATOR CODES SCREEN ..................................3-45

ON/OFF UNITS OF MEASURE

MESSAGE SCREEN ............................................ 3-46

ALARM MESSAGE SCREEN ............................... 3-47

SATELLITE SAVE/RESTORE .............................. 3-48

SATELLITE COPY SCREEN ............................... 3-51

SECURE SCREEN .............................................. 3-52

ENERGY CONSUMPTION SCREEN .................... 3-53

WEEK SCHEDULES ........................................... 3-55

WEEK SCHEDULE SUMMARY SCREEN .................3-55

WEEK SCHEDULE SCREEN .....................................3-56

OPTIMAL START SCREEN ................................. 3-57

ANALOG GLOBALS ............................................ 3-60

ANALOG GLOBAL SUMMARY SCREEN .................3-61

ANALOG GLOBAL SCREEN .....................................3-62

ANALOG GLOBAL - AVERAGED LIST ...................3-64

ANALOG GLOBAL - SORTED LIST ........................3-65

ANALOG GLOBAL - INTEGRAL MODE .................3-66

SLIDING WINDOW .....................................................3-66

SLIDING WINDOW MODE SCREEN .........................3-67

AVERAGE MODE .......................................................3-69

AVERAGE MODE SCREEN .......................................3-70

ACCUMULATION MODE ...........................................3-71

ACCUMULATION MODE SCREEN ...........................3-73

MATH FUNCTION SCREEN .......................................3-75

LOOK UP TABLE MODE ...........................................3-77

LOOK UP TABLE SCREEN .......................................3-78

BINARY GLOBALS ............................................. 3-80

Binary Global Summary Screen...............................3-80

COMBINATORIAL MODE ..........................................3-82

COMPARE MODE ......................................................3-84

ALARM MODE ............................................................3-86

EXTERNAL MODE .....................................................3-87

ALARM-BY-CLASS MODE ........................................3-88

SHED/RESTORE SCREEN .................................. 3-89

DUTY CYCLE SCREEN....................................... 3-91

PROPORTIONAL RESET SCREEN ..................... 3-93

SPECIAL KEYS PROGRAM ................................ 3-96

UTILITY SCREEN .............................................. 3-98

SYSTEM PARAMETER II SCREEN ...........................3-99

REBUILD SATELLITE TABLE SCREEN .................3-101

SEARCH AND OVERRIDE SCREEN .......................3-102

POINT DESCRIPTION SEARCH SCREEN ..............3-104

LOGICAL ADDRESS SEARCH SCREEN ................3-106

ENHANCED GRAPHICS SCREEN ..........................3-108

CUSTOM SCREEN ................................................... 3-111

SET MONITOR COLOR SCREEN ...........................3-114

TENANT OVERRIDE SCREEN ................................3-115

TENANT OVERRIDE REPORT ................................3-115

Binary Global Screen - Combinatorial Mode ........3-118

Tenant Override Report ..........................................3-118

MESSAGE SCREEN ................................................3-120

WCC/SCC FILE MANAGEMENT SCREEN .............3-121

EXIT WCC II SYSTEM ..............................................3-124

TUC.................................................................. 3-125

GENERAL INFORMATION .......................................3-125

TUC - ANALOG INPUT SCREEN ............................3-127

TUC - CONTROL OUTPUT SUMMARY SCREEN .3-128

TUC - EA DRIVER SCREEN ..................................3-129

TUC SUMMARY SCREEN ........................................3-131

TUC SETUP SCREEN ..............................................3-134

PNEUMATIC OUTPUT SCREEN .............................3-140

STEPPER MOTOR ACTUATOR SCREEN ..............3-142

TUC-VR ........................................................... 3-144

GENERAL INFORMATION .......................................3-144

ANALOG INPUT SCREEN .......................................3-146

CONTROL OUTPUT SUMMARY SCREEN .............3-148

EA DRIVER SCREEN ...............................................3-149

TUC-VR EA DRIVER SCREEN ................................3-150

TUC-VR SETUP SCREEN ........................................3-152

TOC-2

Operator Interfaces

Page 5

WCC II Operator’s Guide

Table of Contents

SECTION 4: REMOTE

COMMUNICATIONS ..................................... 4-1

GENERAL INSTRUCTIONS .................................. 4-1

SYSTEM REQUIREMENTS ................................... 4-2

INITIALIZING THE DISK ..................................... 4-2

OPERATION INSTRUCTIONS .............................. 4-4

FCC/SCC II MAIN MENU ...................................... 4-5

SEARCH ROUTINES ............................................ 4-6

SATELLITE SAVE/RESTORE PROGRAM .............. 4-7

AUTOMATIC CALL OUT ON ALARM .................... 4-8

MODEM SWITCH SETTINGS ................................ 4-9

Hayes Smartmodem 1200 ...........................................4-9

ADC Modem Switch Settings ...................................4-10

Capetronics Modem Switch Settings ......................4-10

Okidata Modem Switch Settings ..............................4-12

SOFTWARE KEY ................................................ 4-13

SECTION 5: INSTALLATION GUIDE ............. 5-1

SAT II-A/TUC ...................................................... 5-26

The SAT II-A ...............................................................5-27

Addressing the SAT II-A ............................................5-28

Addressing (Numbering) TUC’s ...............................5-29

SAT II-A Wiring Diagram ...........................................5-30

SAT II-B ............................................................. 5-31

System Architecture .................................................5-31

SAT II-B - General Information .................................5-32

Addressing (Numbering) the SAT II-B .....................5-33

SAT II-B Wiring Diagram ...........................................5-34

CPU to SAT II-B Wiring .............................................5-35

TUC-VR .............................................................. 5-36

TUC-VR Communication Wires ................................5-40

SAT II-B to TUC-VR Wiring .......................................5-41

INDEX .......................................................... Index-1

OPERATOR CONTROL CONSOLE ........................ 5-1

Uninterruptable Power Supply ...................................5-1

MODEM SWITCH SETTINGS ................................ 5-2

Hayes Smartmodem 1200 ...........................................5-2

ADC Modem .................................................................5-3

Capetronics Modem ....................................................5-3

Okidata Okitel 1200 .....................................................5-5

SOFTWARE KEY .................................................. 5-6

SATELLITE CONTROLLER .................................. 5-7

Mounting in an Enclosure ..........................................5-7

System Wiring ...........................................................5-10

Addressing (Numbering) SAT II Controllers ...........5-13

SAT II Chip Switches .................................................5-15

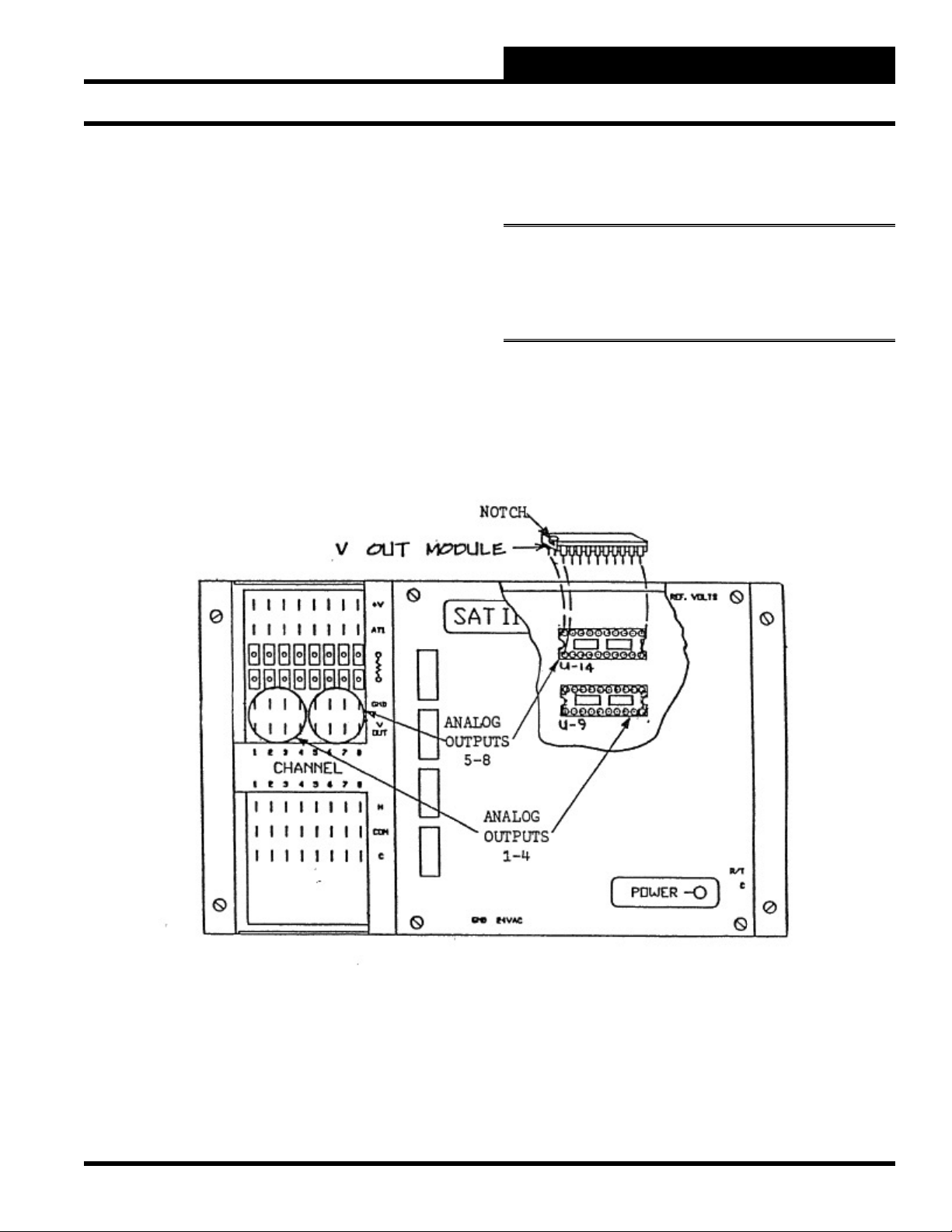

SAT II V-Out (DAC) Modules .....................................5-16

Binary Input Board ....................................................5-17

V-Out Binary Interface Board ...................................5-18

Proportional-Integral (PI) Output Board ..................5-21

Temperature Sensors ................................................5-24

Operator Interfaces

TOC-3

Page 6

WCC II Operator’s Guide

Table of Contents

TOC-4

Operator Interfaces

Page 7

WCC II Operator’s Guide

System Overview

INTRODUCTION: SYSTEM

OVERVIEW

____________________________________________________

The ECC/WCC II is a microprocessor based energy management

and temperature control system designed to minimize the energy

usage of a building and maximize the occupant comfort.The ECC/

WCC II system provides the building owner with a means of

monitoring and controlling building mechanical systems from one

central location. The ECC/WCC II system provides computerized

control of building mechanical systems, but requires no computer

experience to operate or program the system.

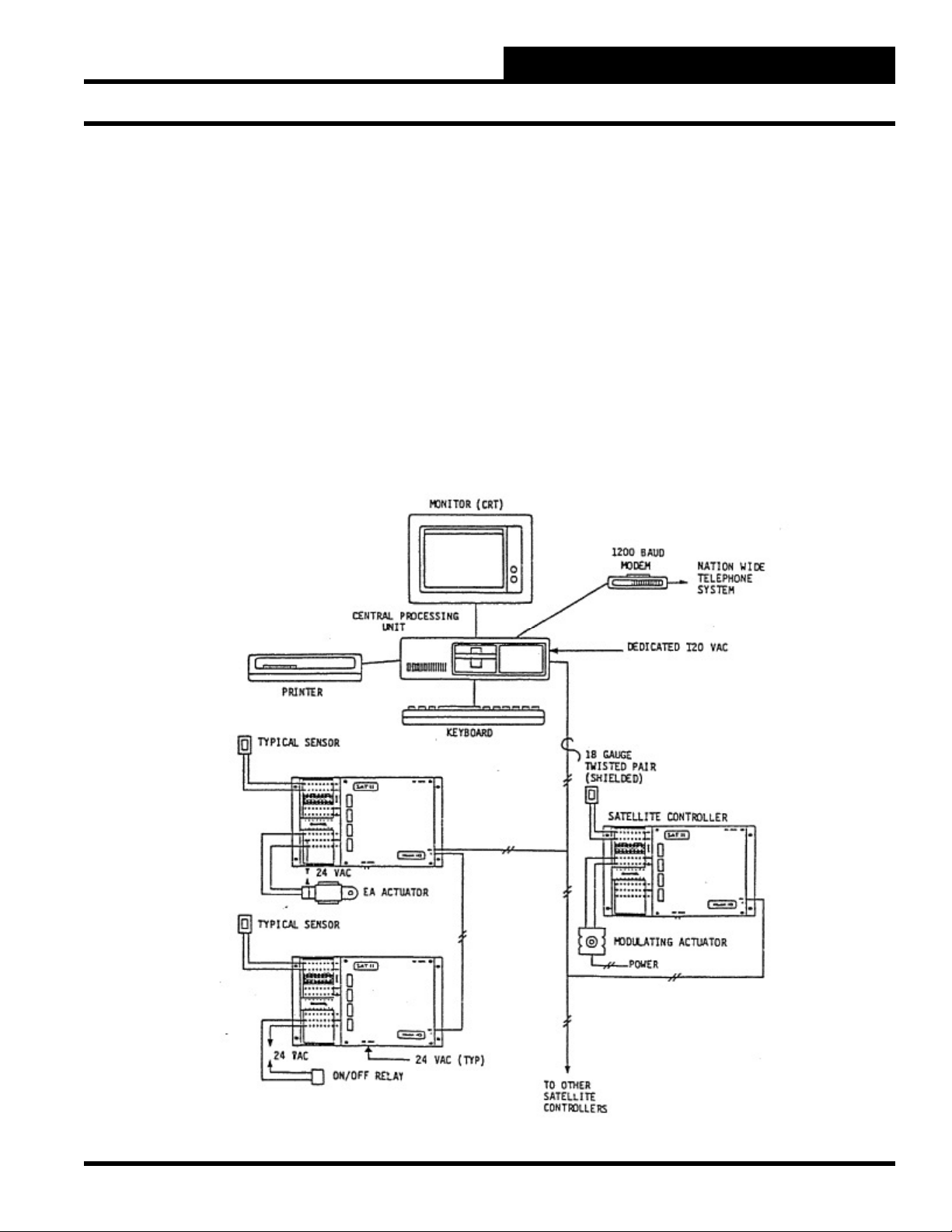

Diagram of WCCII System

The “front end” of the ECC/WCC II system consists of a personal

computer with custom communication boards. See Diagram that

follows. The computer is referred to as the Central Processing

Unit (CPU), and the computer, keyboard, monitor (screen), printer

(optional), and modem (optional) together are referred to as the

Operator Control Console. The CPU communicates with the

remote satellite controllers using a two-wire communication loop.

Operator Interfaces

I-1

Page 8

WCC II Operator’s Guide

System Overview

Operator Control Console

Components

The building operator monitors and controls the building

mechanical systems from one central location called the Operator

Control Console. The Operator Control Console consists of the

following components:

1. Central Processing Unit (CPU)

2. Keyboard

3. Monitor (CRT)

4. Printer (optional)

5. Modem (optional)

Central Processing Unit

A personal computer with custom communication boards acts as

the Central Processing Unit (CPU) which communicates with the

remote mounted satellite controllers via a two wire communication

loop.

The personal computer is dedicated to the ECC/WCC II system

and cannot be used for other functions. The use of hardware

accessories with the ECC/WCC II CPU that is not specifi cally

approved in writing by WattMaster Controls Group will void the

warranty on the ECC/WCC II system. The use of software other

than that furnished with the ECC/WCC II system may result in

system malfunction. WattMaster Controls Group is not responsible

for a system failure so generated.

Monitor

Note: We highly recommend that you only use the number

keys along the top of the keyboard while entering numeric

values and use the keypad ONLY for cursor control on the

ECC/WCC II system.

Printer

The on-site printer allows the operator to print status or schedule

summaries, a permanent record of entered programs, and trend

logging reports. The printer will automatically print alarms as they

occur, print operator ID as the user signs on and off the system,

and print any overrides that are entered.

Satellite Controller

The satellite controllers are fi eld mounted, microprocessor based

units which provide direct digital control of building mechanical

systems. The satellite controllers receive operating instructions

from the CPU, but once they are programmed, they have the

“brains” to monitor and control building mechanical systems

independently of the CPU. If communication from the CPU to

the satellite controllers is broken, the satellite controllers will

continue to control at programmable setpoints. In the event of a

primary power failure, the satellites will retain both their operating

instructions and accumulated data in battery backed memory.

The three versions of the satellite controller that will communicate

with the ECC/WCC II system are the SAT II, SAT II-A, and SAT

II-B.

The monitor resembles a television and displays computer data in

text on its cathode ray tube (CRT), or screen.

Keyboard

The keyboard is arranged like a typewriter to allow manual entry

of data and programs. We suggest that you fi rst become familiar

with the keyboard before attempting to operate the system. Refer

to the owner’s manual supplied with your computer for additional

keyboard information.

I-2

Operator Interfaces

Page 9

WCC II Operator’s Guide

System Overview

SAT II

Sensors and relays etc. are wired to the SAT II controller to allow

it to monitor and control loads directly. Each SAT II controller can

handle the following number of inputs and outputs:

8 analog or binary inputs

•

•

16 additional binary inputs

- 1 binary input board receives 8 binary inputs

- 2 binary input boards may be used with one

SAT II

8 analog outputs (0-15 VDC maximum range)

•

- 1 DAC module enables 4 analog outputs

- 2 DAC modules may be installed in SAT II

- Any or all of the 8 analog outputs may be

converted to binary outputs using 1 V-Out

to Binary board

- 1 chip switch is required for each binary

output

•

16 binary outputs

- 1 chip switch is required for each binary

output

SAT II-A

The SAT II-A is a version of the satellite controller that allows the

ECC/WCC II front end computer to communicate with remote

mounted Terminal Unit Controllers.

The Terminal Unit Controller (TUC) is a microprocessor based

device which can be used to control terminal units such as pressure

dependent variable air volume (VAV) boxes, pressure dependent

fan power boxes, fan coil units, heat pumps etc. The TUC can be

used as a stand-alone controller, or the TUC can be used with the

ECC/WCC II system.

The TUC accepts an input from a room temperature sensor to allow

it to monitor the space temperature and when used with the SA

(Stepper Actuator) actuator, provides pressure dependent control

of the primary air damper on terminal units such as variable air

volume boxes, constant fan power induction units, and intermittent

fan power induction units. The SA Actuator is not an integral

part of the TUC and must be ordered and purchased separately.

The TUC can also have three relay outputs to provide control of

the fan and fi rst and second stages of heat on fan terminal units,

or to control the fan, compressor, and reversing valve on a heat

pump. The TUC can also provide an output to control two 24 VDC

solenoid air valves to obtain “feed” and “bleed” type control of

pneumatic controlled devices. The TUC is generally mounted at

the terminal unit (i.e. VAV box, heat pump, etc.).

When the TUC’s are to be used with the ECC/WCC II system,

a type SAT II-A satellite controller is required as the interface

between the Central Processing Unit (CPU) and the Terminal Unit

Controller (TUC). The SAT II-A is a special version of the satellite

controller, and its only purpose is to interface with the TUC’s. Up

to 32 TUC’s can be connected to one SAT II-A using a 3-wire,

shielded cable. The TUC’s are wired to the SAT II-A in a “daisy

chain” arrangement. That is to say, the 3-wire cable does not have

to be run from each TUC back to the SAT II-A. The 3-wire cable

is run from the SAT II-1 to the nearest TUC and the 3-wire cable is

extended from that TUC to the next.

TUC Input/Output Features

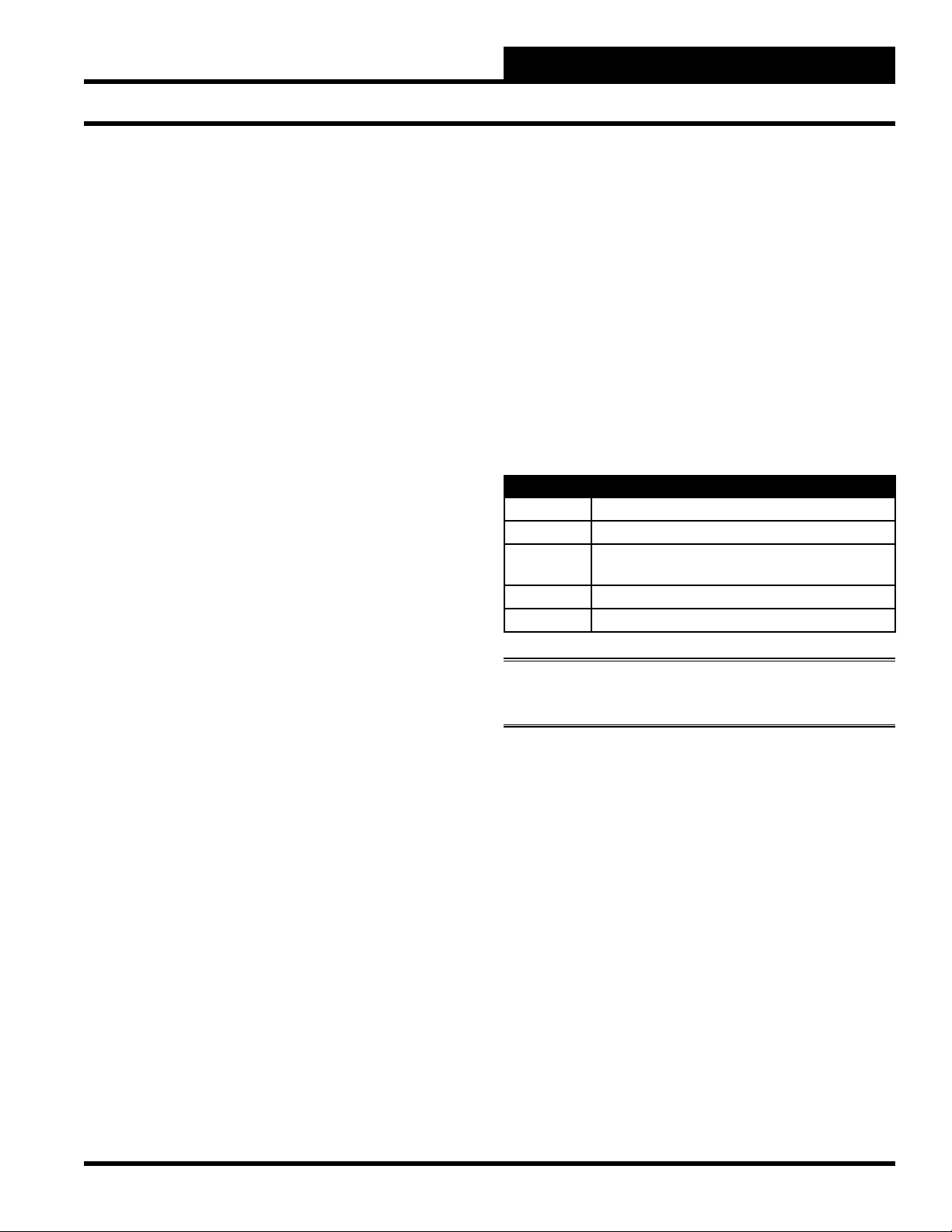

The fi ve versions of the pressure dependent TUC are shown in the

table that follows:

Model TUC Description

TUC-R 3 Relays with 2 amp, 24 Volt SPDT Contacts

TUC-A Stepper Motor Actuator Output

TUC-AR Stepper Motor Actuator Output & 3-24 Volt

SPDT Relays

TUC-P Pneumatic Output

TUC-PR Pneumatic Output & 3-24 Volt SPDT Relays

Note: The SA actuator and solenoid air valves must be

ordered and purchased separately.

SAT II-B

The SAT II-B is similar to the SAT II-A, only the SAT II-B

communicates with up to 32 TUC-VR’s.

The TUC-VR is a velocity resetting (pressure independent)

controller for use with variable air volume (VAV) terminal units.

The TUC-VR mounts on the VAV box and communicates with

the front end ECC/WCC II through a SAT II-B. The TUC-VR

provides precise direct digital control of the following types of

VAV terminal units:

1-Cooling Only

2-Cooling/Staged Electric Reheat

3-Cooling/Time Proportioning Electric Reheat

4-Cooling Proportional Reheat Valve

5-Parallel Fan Powered/No Reheat

6-Parallel Fan Powered/Staged Electric Reheat

Operator Interfaces

I-3

Page 10

WCC II Operator’s Guide

System Overview

7-Parallel Fan Powered/Time Proportioning Electric Reheat

8-Parallel Fan Powered/Proportional Reheat Valve

9-Series Fan Powered/No reheat

10-Series Fan Powered/Staged Electric Reheat

11-Series Fan Powered/Time Proportioning Electric Reheat

12-Series Fan Powered/Proportional Reheat Valve

System Features

Standard Software

The following features are part of the standard ECC/WCC II

software package:

User Designed Screens

•

Schedule Override by Room Number (or name)

•

Point Involvement Summary

•

Data Copy Routine

•

Message Screen

•

Math Operators/Enthalpy Logic

•

User Confi gurable Look Up Tables

•

Sliding Window Averaging of Values

•

Accumulation of Values

•

Trend Logging features which include:

•

Analog Trend (with graph)

Analog Peak

Change of State

Run Time

Proportional Reset (with graph)

•

Auto-Scan and Print Routines

•

Multiple Energy Consumption Tables

•

Remote monitoring

•

Local or remote override capability

•

Remote read and reset

•

Automatic print-out and call-out on alarm

•

16 operator codes with 4 levels of access

•

365 day timeclock with automatic daylight savings

•

time changeover

32 week schedules and 18 holiday schedules

•

8 alarm levels

•

Temperature control with automatic temperature

•

setback

Adaptive optimized start and optimized stop

•

Duty cycling

•

Timed overrides

•

Demand limiting

•

Dead band spreading

•

Lighting control

•

Optional Enhanced Color Graphics

The Enhanced Color Graphics option allows the ECC/WCC II

system to display up to 60 color graphic pictures in the same front

end computer that acts as the ECC/WCC II CPU. The color graphic

pictures can be drawn using nearly any color graphics package,

and once the picture is displayed on the screen, a “snap-shot” of

the picture is captured and used as the background picture on the

Enhanced Color Graphics Screen. Dynamic analog and binary

values are then placed on the screen to allow the user to see actual

temperatures, status, etc. in the proper place on the picture.

When ordering the Enhanced Color Graphics option, a WCC II with

a 20MB hard disk, an EGA card, and color monitor is required as

the front end computer along with the additional Enhanced Color

Graphics software and a graphics package such as PC Paintbrush.

Optional Tenant Override

The Tenant Override Feature allows the occupants in the building

to call the ECC/WCC II system on the telephone and cause the

lights and/or heating and/or cooling equipment to control according

to their occupied (daytime) control scheme. The system has the

capability of overriding the control for 500 zones.

The ECC/WCC II system will “talk” to the tenant using an artifi cial

voice, and the user instructs the ECC/WCC II system by pressing

the numbers on the telephone.

A summary report of which tenants used the telephone override

system is available for billing purposes. A separate telephone line

is required for the Tenant Override Feature.

System Size

The central processing unit is capable of communicating with up

to 240 SAT II controllers. The front end ECC/WCC II considers

each SAT II-A or SAT II-B as 4 SAT II controllers. The equivalent

number of satellite controllers must be under 240.

A system with 240 satellite controllers is capable of handling up to

11520 points, a point being a hard wired input or output.

Modular Construction

Equipment cost is reduced because the system, including the satellite

controllers, is modular. Only the number of satellite controllers

required for the job are purchased, and only the required number of

outputs are purchased for the satellites. Installation cost is reduced

because “global” information gathered at one satellite can be shared

with other satellites, eliminating costly intermediate controls.

I-4

Operator Interfaces

Page 11

WCC II Operator’s Guide

Section 1: General Instructions

SECTION 1: GENERAL

INSTRUCTIONS

____________________________________________________

“Where To Find” Features

The following is a list of commonly used ECC/WCC II features

and the screens you should access to use them.

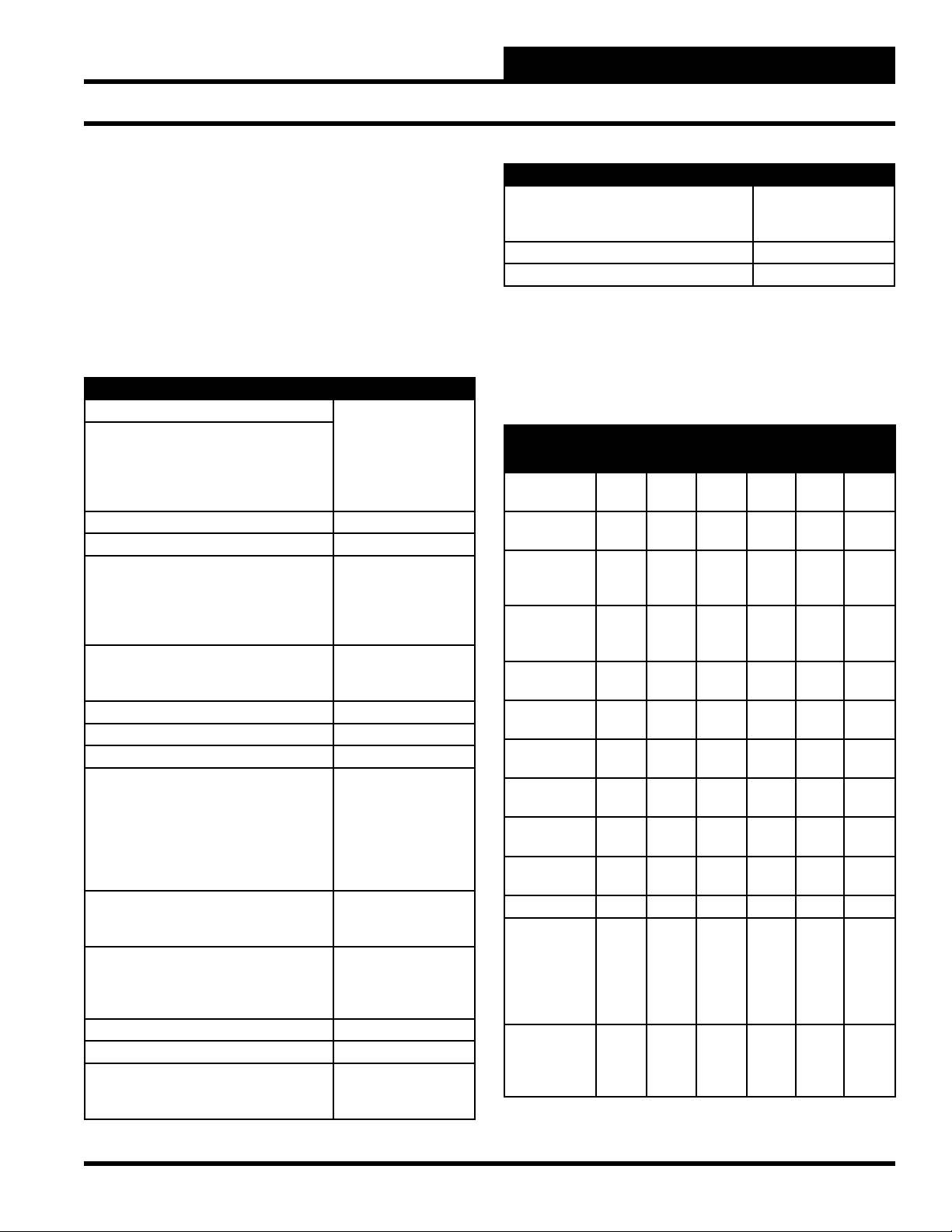

FEATURES SCREEN

Alarms

“Call-Out-On-Alarm”

Call “Both” or “Either” Phone

Number

Input Telephone Numbers

Select Remote Printer

Clear (Acknowledge) Alarms Alarm Summary

Disable Local Printer Utility-Sys Par II

Set Alarm Limits

Analog Inputs

Run Time

Global Analog Values

Global Binary Values

View Alarms

All Alarms (Except Globals)

Global Alarms

Daylight Savings Time Adjustment System Parameters

Demand Limiting Shed/Restore

Delete Back-Up Files Utility-File Mgmnt

Monitor Analog Inputs

(Temperature/Pressure etc.)

Find Highest or Lowest Building

Tem p

Find Average Building Temp

Present Value

Trend Logs

Monitor Binary Inputs (air fl ow switch etc.)

Present Value

Trend Log.

Password Entry

Assign Operator Access Codes

“Sign-On”

“Sign-Off”.

Print Screens Automatically Special Keys

Rebuild Satellite Tables Utility-Rbld Sat

Schedules

Change Schedules Permanently.

Holiday Schedules

Utility-Sys Par II

System Parameters

System Parameters

Analog Input Screen

Trend Logs

Global Analog

Global Binary

Alarm Summary

Global Summary

Global Analog-Sort

Global Analog-Avg

Analog Input Summary

Analog Trend

Logic Switches

Change of State

Sys Par/Oper Codes

System Parameters

Secure Screen

Week Schedules

Holiday & Week Sch

FEATURES SCREEN

Setpoints

Change Setpoints - Satellite

Change Setpoints - TUC

Sequence Satellites After a Power Outage Satellite Summary

Time and Date Modifi cations System Parameters

Control Outputs

EA Driver & TUC

ECC/WCC II Routine Maintenance

The following maintenance items should be performed on a regular

basis:

Service Item As

Req’d

Blow out

keyboard

Blow out CPU

assy

Check all

external cable

connections

Test/Verify

U.P.S.

operation

Clean display

screen

Dim display

screen

Clean fl oppy

drives

Tes t fl oppy

drives

Test CPU

memory

Test display

monitor

Test printer

Test modem

(system’s

ability to

answer

incoming

calls)

Test modem

(system’s

ability to callout-on-alarm)

Every WkEvery MoEvery

XX

XX

XX

XX

*X

XX

3 Mo

Every

6 Mo

X

X

X

X

X

Every

12 Mo

X

X

Operator Interfaces

1-1

Page 12

WCC II Operator’s Guide

Section 1: General Instructions

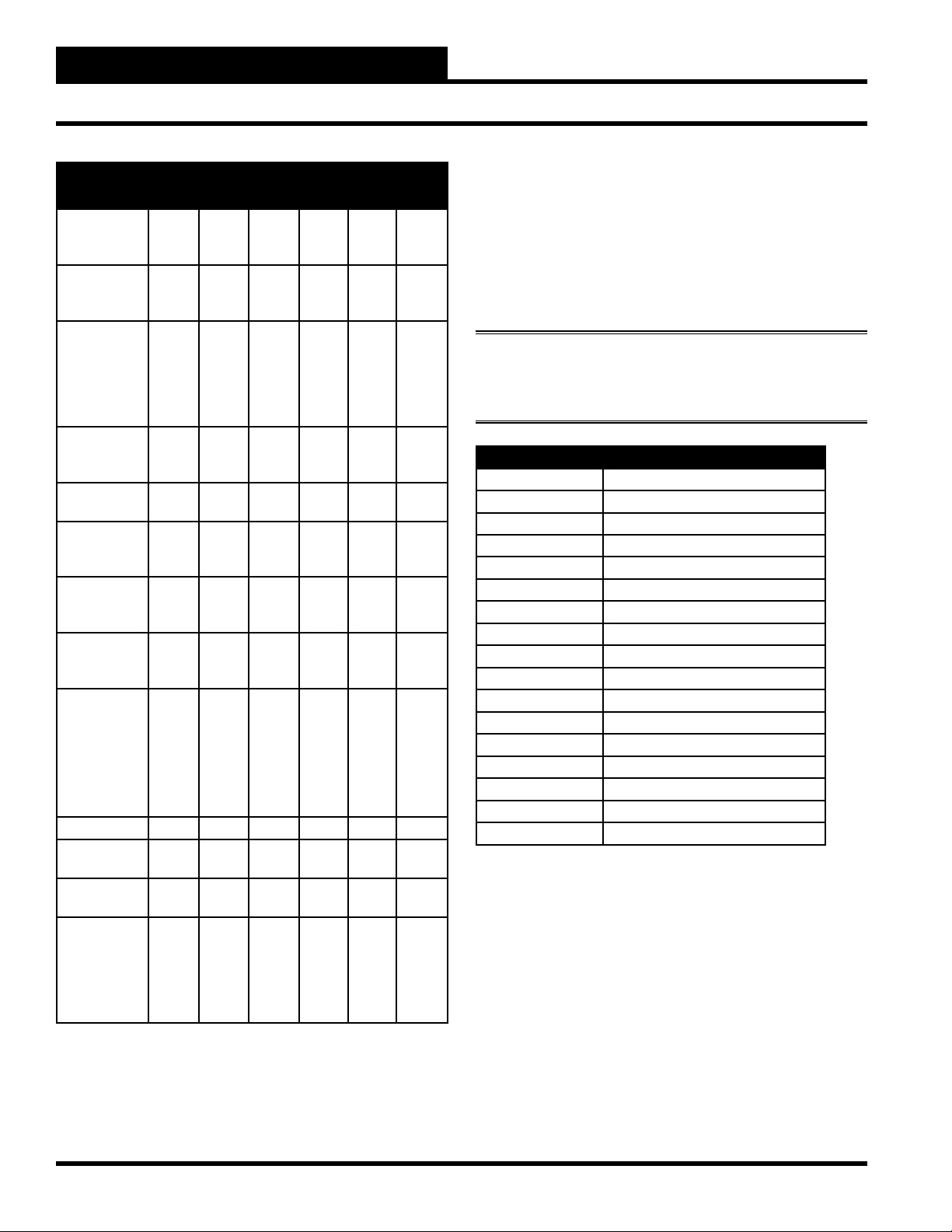

Service Item As

Req’d

Delete“backup” (*.bak)

fi les

Make “backup” copies of

disks

Check disks

for available

space to

prevent

overfi lling the

disk

Check loop

connection on

rear of CPU

Save satellite

data to disk

Rebuild all

satellite and

global tables

Test satellites’

local-set

capability

Test satellites’

battery (or

capacitor)

Check/Clear

satellite

communication errors

on

Satellite

Every WkEvery MoEvery

3 Mo

XX

XX

XX

XX

X

XX

Summary

Screen

Run loop test X

Check/Reset

trend logs

View/Clear all

alarms

Cycle power

to CPU to

verify correct

system re-start

after a power

outage

XX

XX

Every

6 Mo

Every

12 Mo

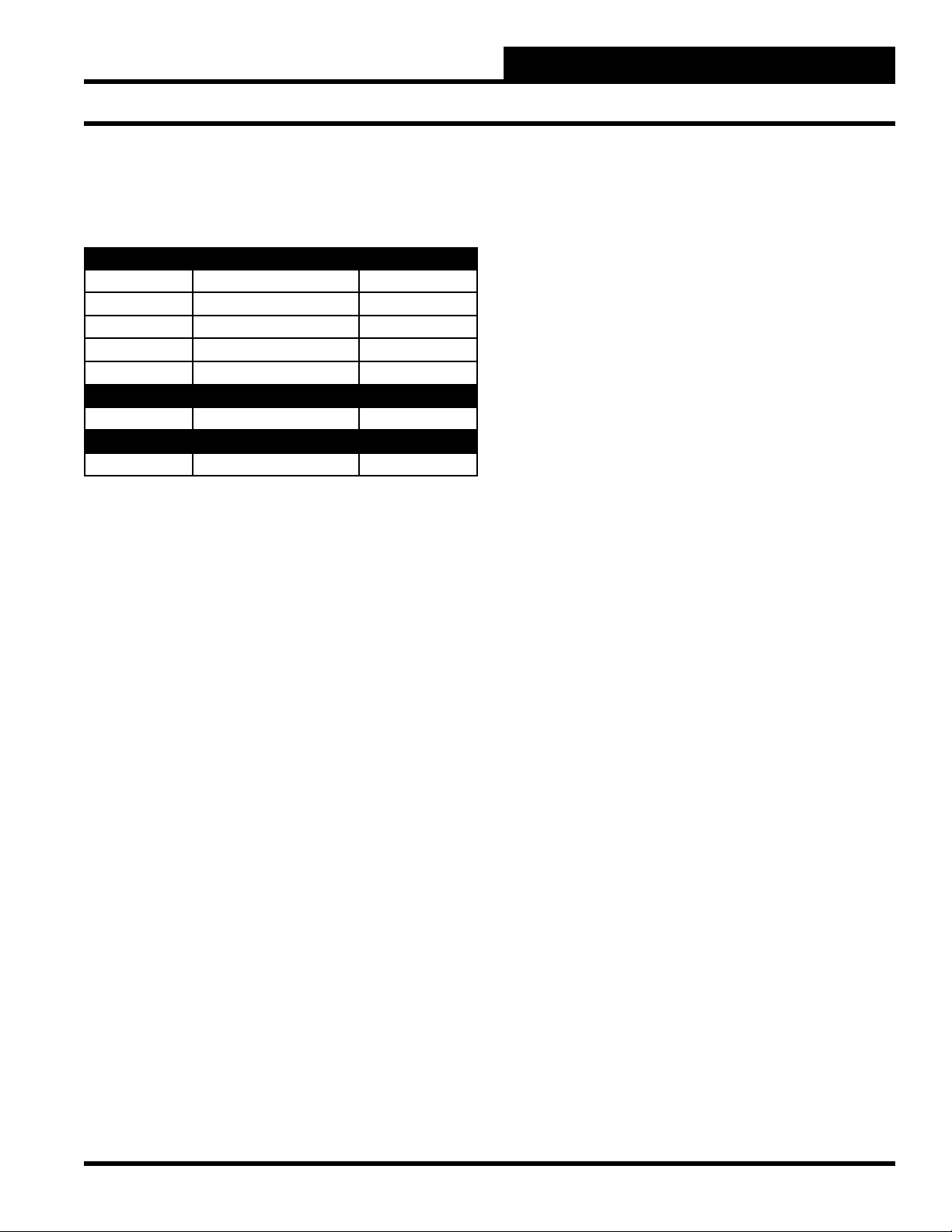

ECC/WCC II Software Version List

The ECC/WCC II software is updated periodically to include more

features. The two fi les that change as the ECC/WCC II system is

upgraded are the WCC2 fi le and the BACKTASK fi le. When a

WCC II fi le is installed in a system, the BACKTASK fi le may need

to be changed also. The following list shows the WCC2 version

numbers and the BACKTASK fi le that must be used with it.

Note: You can see the present WCC2 and BACKTASK

version used by the system by looking at the lower left hand

corner of the Main Menu Screen.

X

WCC2 Version Minimum BACKTASK Version

1.47* 1.1B

1.48* 1.1B

1.49* 1.1B

1.52 1.22

1.54 1.24

X

X

1.6A 1.24

1.6B 1.24

1.63 1.24

1.64 X.2B**

1.65 X.2BB**

1.67 1.2E

1.68 1.2E

1.69 1.4A

1.70 1.4A

1.71 1.4B

1.72 1.4B

1.74 1.4D

* These versions of software require the front end computer to

have 448K of RAM memory; later versions require 640K.

X

**X = 1 to 3

1 = IBM PC or XT

2 = IBM XT 286

3 = 3 satellite system

* Set the screen’s intensity to the lowest setting when the system

is not being used.

1-2

Operator Interfaces

Page 13

WCC II Operator’s Guide

Section 1: General Instructions

Recommended Data Entry Procedure

When setting up an ECC/WCC II system, the screens can be

programmed in any order. However, you may fi nd it easier to

follow this sequence:

Make back-up copies of the disks

1.

System Parameter Screen

2.

Utility Screen - Rebuild Satellite Tables

3.

Satellite Summary Screen

4.

On/Off Units Messages Screen / Alarm Message

5.

Screen —Enter the On/Off messages, units of

measure messages, and alarm messages, and then

print the messages using <Print Screen>. Keep a

copy of these messages handy while entering data

on the remaining screens

Week Schedule Screens

6.

Holiday Screen

7.

Analog Input Screens

8.

Logic Switch Screens

9.

Control Output Screens

10.

Analog Inputs

An analog input is a numerical value (signal) sent to the SAT II

controller to allow monitoring of space temperatures, duct pressures

etc. The SAT II controller can accept 8 analog inputs which

are named, A1-A8. (Note: A1-8 may be either analog or binary

inputs.) On certain screens (such as Global Analog Screens), you

must indicate the satellite controller number along with the channel

on the satellite controller. For example, 12A2 means analog input

number 2 on satellite controller #12.

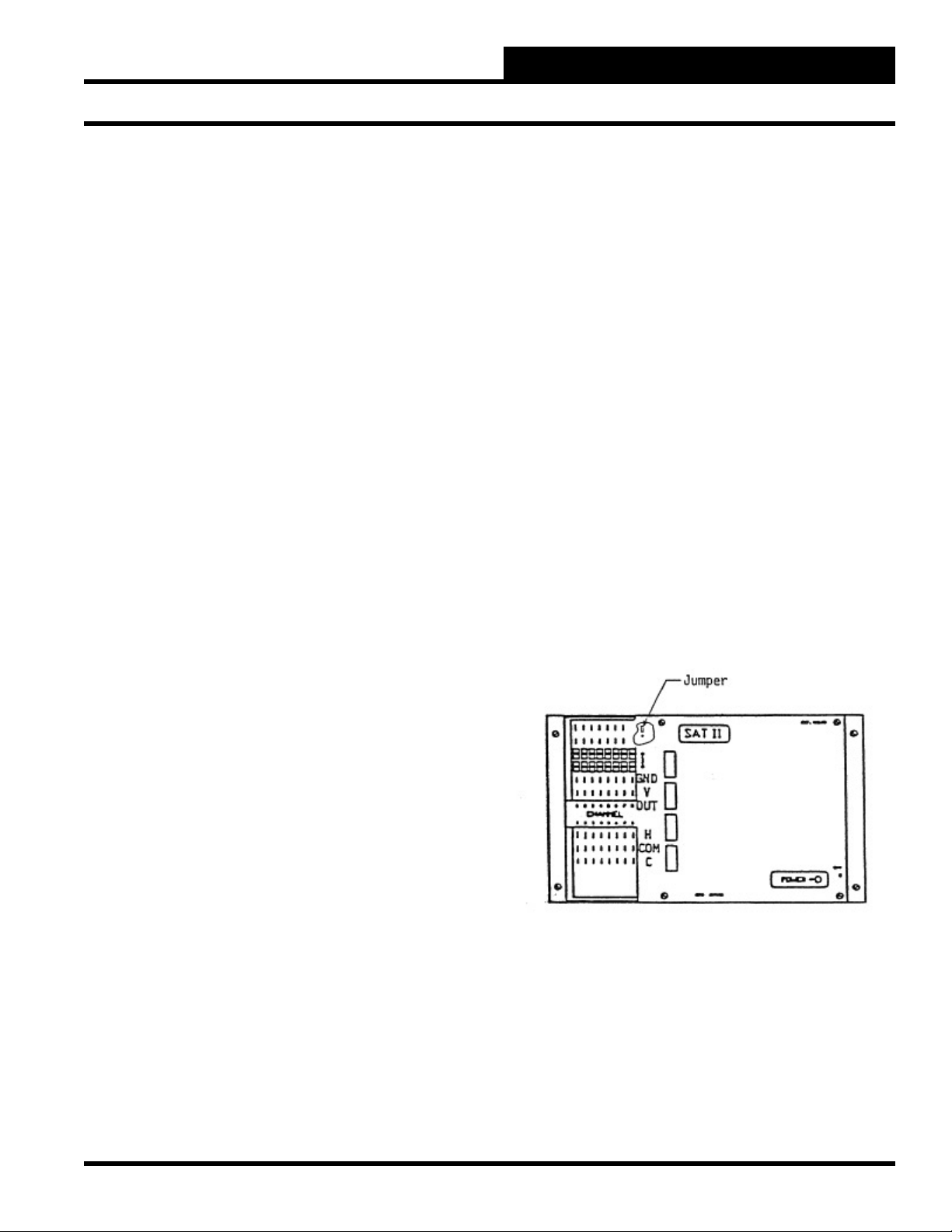

The analog inputs are usually wired to the “+V” and “ATI” (Actual

Temperature In) terminals on the SAT II controller (three wire

sensors are wired to the “GND” terminal also.) The “+V” terminal

on channels 1-7 are a 12 VDC power source. The “+V” terminal

on channel 8 provides either 12 VDC or 18 VDC depending on

the position of the jumper under the cover near channel 8. To get

12 VDC from the “+V” terminal on channel 8, the jumper must

connect the A and B terminals. To get 18 VDC, the jumper must

connect the B and C terminals.

A 20 mA sensor can be used on up to 5 channels on the SAT II

controller. The total current for all 8 analog inputs must be kept

under 115 mA.

TUC Screens

11.

Analog Output Screens

12.

Analog Global Screens

13.

Binary Global Screens

14.

Optimal Start Screens

15.

Shed/Restore Screens

16.

Duty Cycle Screens

17.

Proportional Reset Screens

18.

Energy Consumption Screens

19.

Trend Log Screens

20.

Custom Screens/Enhanced Graphic Screens

21.

Special Keys Programs

22.

Save Satellite Data to Disk

23.

Make Back-Up Copies of the Disks

24.

Operator Interfaces

1-3

Page 14

WCC II Operator’s Guide

Section 1: General Instructions

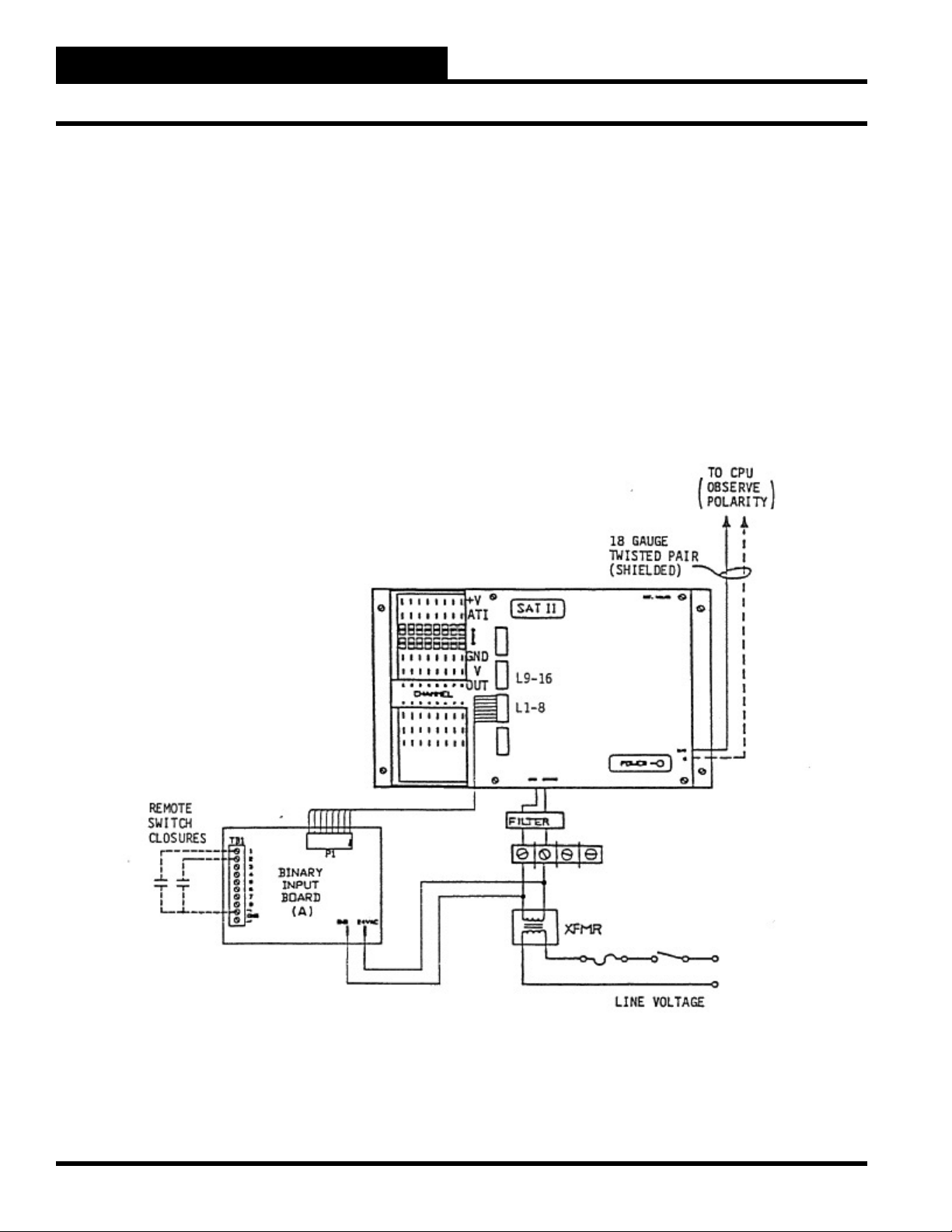

Binary Inputs

A binary input is an On/Off (dry contact closure) signal sent to

the SAT II controller to allow monitoring of air fl ow switches,

switch settings, etc. The SAT II controller comes standard with

16 small toggle switches on its front panel labeled, L1-L16 which

are in effect manually controlled binary inputs. The ECC/WCC II

monitors the On/Off status of these switches and can control and/or

alarm based on the position of these switches. The binary input

board(s) allow the manual toggle switches to be replaced with a

terminal strip which accepts wiring from remote mounted binary

input devices.

The SAT II controller has two sets of 8 small toggle switches on its

front cover labeled L1-L16. Switches L1-L8 are housed together in

one module, and switches L9-L16 are housed together in another

module. One module of switches is removed for each binary input

board and replaced with a ribbon cable which connects the binary

input board to the SAT II controller. The binary devices to be

monitored are then wired to the terminal strip of the binary input

board. The binary input board requires a 24 VAC power supply.

1-4

Operator Interfaces

Page 15

WCC II Operator’s Guide

Section 1: General Instructions

Analog Outputs

An analog output is a variable DC voltage signal sent from the

satellite controller used for proportional control of devices with

modulating actuators. The analog outputs are wired to the “V-Out”

and “Gnd” terminals on the SAT II controller and are named P1P8. The P stands for Proportional Output.

The SAT II controller has the capability of providing 8 analog

output signals which have a maximum range of 0-15 VDC. If the

analog outputs are to be used, V-Out modules must be purchased

and are fi eld installed. One V-Out module is required for 4 analog

outputs, and two V-Out modules can be installed in one satellite

controller to allow one satellite controller to provide up to eight

analog outputs.

Each analog output has a limit of 15 mA. The total current output

of all 8 analog outputs must be kept under 115 mA.

Note: Later versions of the satellite controllers require two

modules for each set of four analog outputs. On these models,

sockets U-9 and U-10 activate outputs 1-4, and sockets U-11

and U-14 activate outputs 5-8.

Operator Interfaces

1-5

Page 16

WCC II Operator’s Guide

Section 1: General Instructions

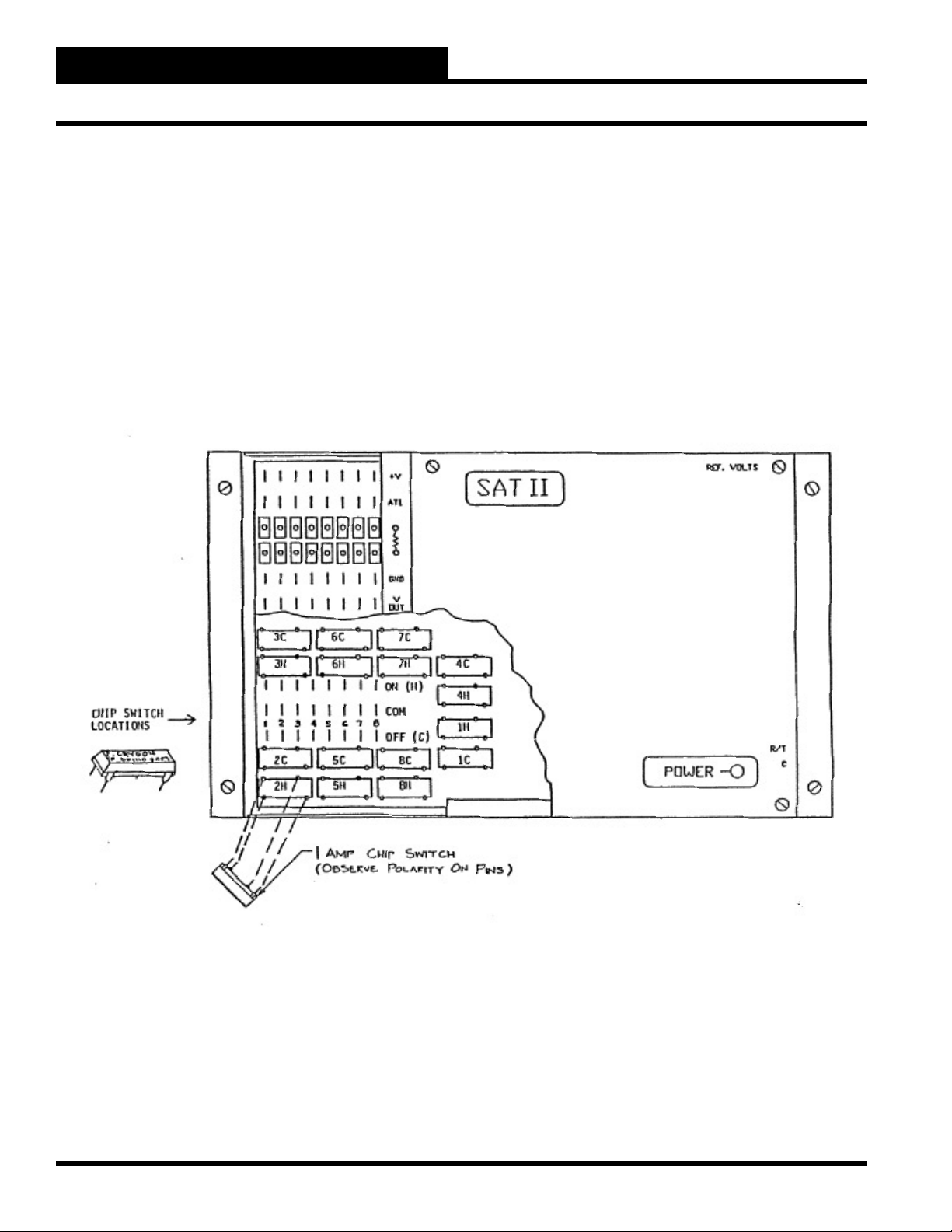

Binary Outputs

A binary output on the SAT II controller is the electronic equivalent

of a relay contact which is used to complete a 24 VAC circuit to

activate on/off devices such as relays, 2-position valves, etc. The

binary output contacts cannot be used to complete a DC voltage

circuit; they will work with AC circuits only. The binary output

terminals are labeled H, COM, and C.

The SAT II controller is capable of providing 16 binary (on/

off) outputs. Each binary output requires 1 chip switch which is

purchased separately and is fi eld installed.

The terminals for the binary outputs are found at the lower left hand

corner of the SAT II controller. The “COM” to “H” contacts are

referred to as K1h-K8h. The “COM” to “C” contacts are referred

to as K1c-K8c.

1-6

Operator Interfaces

Page 17

WCC II Operator’s Guide

Section 1: General Instructions

Point Addresses

A Point Address uniquely identifi es a point within the ECC/WCC

II system. All point addresses have an associated “analog” or

“binary” value. The term “analog” simply means a value which

is represented by a number (such as room temperature, duct static

pressure, etc.). The term “binary” means the value is represented by

one of two conditions, ON or OFF. An input is a signal sent to the

ECC/WCC II system, and an output is sent from the ECC/WCC II

system. Therefore, room temperature is an analog input, fan status

is a binary input, and controlling a fan relay is a binary output.

In addition to the inputs and outputs that are wired to the SAT

II controllers, there are several software point addresses within

the system. For example, the ECC/WCC II system has 32 week

schedules. This means that a separate day/night schedule can be

assigned to 32 different areas of the building.

For example, assume that you have three different areas in a

building that have different schedules as shown in the following

table.

Area Occupied Time

Week Schedule #1 1st Floor West 8:00 am - 5:00 pm, M-F

Week Schedule #2 1st Floor East 7:00 am - 7:00 pm, M-F

Week Schedule #3 2nd Floor 9:00 am - 4:00 pm, M-Th

Week Schedule #1 is named W1, and the value of W1 will be On

between 8:00 am and 5:00 pm, Monday through Friday, etc.

The Name column in the table that follows is the name that you

should use when specifying a point address to the system. The “n”

is where a “point number” for the point address is to be entered.

Name Description Value

TnC Trend Logging Change of State None

TnA Trend Logging Analog Trend None

TnP Trend Logging Analog Peak None

Ln Logical Input On/Off

Wn Week Schedules On/Off

Sn Optimal Starts On/Off

GBn Binary Globals On/Off

GAn Analog Globals Analog

Constant Point Addresses

The following list shows several point addresses within the

system that are always available for use on many of the data input

screens.

Name Description Associated Data Type

0 Logical Zero Always Off

1 Logical One Always On

//// Logical Null Ignored

. . . . Logical Off Always Off/Not Used

Note: When a point option is not required, replace the default

value (/ / / /) with either a zero (0) or dot (. . . .) to force the

system to realize that the option is always OFF. If the slashes

are not replaced, the system will ignore that input and the

system can, in rare cases, see the slashes as being ON.

Table of Point Addresses

Name Description Value

Cn Comparator (See analog input

screen binary setpoint)

An Analog Inputs Analog

Pn Analog Inputs Analog

KnH Control Outputs

(H Contacts)

KnC Control Outputs

(C Contacts)

RnA Data Registers (a) Analog

RnB Data Registers (b) Analog

TnR Trend Logging Run Time Analog

Operator Interfaces

On/Off

On/Off

On/Off

Name Description

Analog 0 Initiates a 0 (zero) value

TIME Current Time (in HH:MM format)

TIMEB Current Time (in minutes-since-midnight format)

NEWSEC New Second

NEWMIN New Minute

NEWHR New Hour

NEWDAY New Day

NEWMON New Month

1-7

Page 18

WCC II Operator’s Guide

Section 1: General Instructions

Time & TimeB

These logical addresses are the actual time on HH:MM (TIME) and

minutes-since-midnight (TIMEB) formats. They are considered

analog values and have value ranges of 0000 to 2359 (TIME), and

0000 to 1439 (TIMEB).

Typical application of these logical addresses includes use in

the Dual Limit mode, allowing such modes of control as “OnBetween-Times” and “Off-Between-Times.”

NEWSET, NEWMIN, NEWHR, NEWDAY, & NEWMON

These logical addresses are considered binary values and are based

on real-time. They have a pulse-type nature in that each of these

addresses has a value of one (or ON) for one second after the

occurrence of the specifi ed event. After the one second ON period

has elapsed, the value returns to zero (or OFF).

These addresses have several uses throughout the system. One

example would be the generation of a variable duty cycle output.

When used in conjunction with the separate “Minimum ON/OFF”

timers, these addresses can achieve cycles of from one second to

several days with a wide range of cycles.

Examples of “point addresses” within the system:

Data Registers

The ECC/WCC II system has some capabilities built into the

software that are very helpful, and you should be aware of them.

There is a Data Register associated with each of the Control

Output Screens. A Control Output Screen allows the user to tell

the satellite controller when to open and close the binary output

contacts. A Control Output Screen can be a Time Clock, EA Driver,

or Dual Limit Mode Screen.

Time Clock

When the binary output contact on the satellite controller is

controlled by a Time Clock Screen, the contact opens and closes

based on time only. For example, a Time Clock Screen can be used

to run a water circulating pump from 8:00 am to 5:00 pm, Monday

through Friday. Each Time Clock Screen has a Data Register

associated with it.

The Data Register is an analog value which is the time in seconds

since the satellite controller binary output contact closed. Assume

the water circulating pump is controlled by satellite controller

contact K1h. That is to say, the “COM” to “H” contact on channel

1 of the satellite controller closes to complete a 24 VAC signal to

run the pump.

Name Description

GA12 Global Analog #12

135A5 Satellite #135, Analog Input #5

A5 Analog Input #5, Current Satellite

W12 Week Schedule #12

S27 Optimal Start #27

C1 Setpoint Comparator on Analog Input #1

K1h

14P3

When K1h is ON, the chip switch within the

satellite controller which connects the electrical

path between the “H” and “COM” terminals on

channel 1 of the satellite controller is closed.

When K1h is OFF, the circuit is open.

Satellite #14, Analog Output #3.

The Data Register for a Time Clock Screen is named RnA or RnB.

R stands for data register, n refers to channel 1-8 of the satellite

controller, A means the “COM” to “H” contact, and B means the

“COM” to “C” contact. Therefore, the Data Register for contact

K1h is R1A. As contact K1h closes, the Data Register for contact

Klh (R1A) starts recording time in seconds. That is to say, the value

of R1A is the time in seconds since contact K1h closed.

RnA = Time in seconds since COM to H contact closed

RnB = Time in seconds since COM to C contact closed

The Data Register for a Time Clock Screen might be used to

start one piece of equipment after another has been started. For

example, assume we want to start an air handler two minutes after

the water circulating pump starts. The pump would be controlled

by a Time Clock Screen as mentioned above. The air handler would

be controlled using a Dual Limit Screen. The analog input value

for the Dual Limit Screen would be R1A, which is time in seconds

since the pump started. The Dual Limit Screen is set up to close the

contact for the air handler when the value of R1A is between 120

seconds and infi nity.

1-8

Operator Interfaces

Page 19

WCC II Operator’s Guide

Section 1: General Instructions

EA Driver

The EA Driver Mode is “3-point fl oating” control. For example,

assume that the control outputs on channel 2 of the satellite

controller are used to control a Tempmaster VAV box using the

EA Driver Mode. When the space needs heat, the “COM” to “H”

contacts on the satellite controller will close to drive the damper in

the VAV box to the closed position. When the space needs cooling,

the “COM” to “C” contact on the satellite controller will close to

open the damper in the VAV box.

There are two Data Registers associated with an EA Driver Screen.

The value of the fi rst Data Register is equal to the setpoint entered

on the EA Driver Screen and is referred to as “RnA.” The value

of the second Data Register is equal to the difference between the

setpoint and the actual temperature and is referred to as “RnB.”

“R” stands for data register, and “n” refers to channel 1-8 of the

satellite controller.

RnA = Setpoint

RnB = Difference between Setpoint and Measured Value (error)

For example, assume that the setpoint for the room in question

is 72 °F, and the actual temperature is 70 °F. The value of Data

Register R2A (setpoint) is 72 °F, and the value of Data Register

R2B (error) is -2 °F, since the actual space temperature is 2 °F

below the setpoint.

The Data Register could be used to turn on a second stage of heat

whenever the space temperature falls 2 °F below setpoint. Assume

that the second stage of heat is a heating coil which is energized

when satellite controller contact K3h is closed. A Dual Limit Screen

is used to control contact K3h. Data Register R2B is entered as

the analog input value for the Dual Limit Screen. When the value

of R2B is -2 or less (the space temperature is at least 2 °F below

setpoint), contact K3h closes to turn on the second stage of heat.

The Data Register for a Dual Limit Screen is named “RnA” or

RnB.” “R” stands for data register, “n” refers to channel 1-8 of the

satellite controller, “A” means the “COM” to “H” contact, and “C”

means the “COM” to “C” contact. Therefore, the Data Register for

contact Klh is R1A.

RnA = Difference between Setpoint and Measured Value (COM

to H)

RnB = Difference between Setpoint and Measured Value (COM

to C)

The Dual Limit Screen has two setpoints, the high limit and the low

limit. Since the Data Register is the difference between the setpoint

and the actual temperature, you have to “tell” the system what you

are considering the setpoint to be. Therefore, the Data Register is

measured from either the “Midpoint” or “Nearest Limit” of the

setpoints, depending on how the Dual Limit Screen is set up.

For example, assume that a Dual Limit Screen is used to control a

heat pump compressor to have the compressor off if the space is

between 70 and 74 °F. If the space temperature is below 70 °F, the

compressor will be on for heating, and if the space temperature is

above 74 °F, the compressor will be on for cooling. Assume the

actual space temperature is 76 °F.

The Data Register can be measured from either the “Midpoint”

or the “Nearest Limit.” If the Data Register is measured from the

“Midpoint,” the value of the Data is 4 °F.

Low Limit High Limit

70 72 74 76

4 Deg

Midpoint Actual Temperature

Data Register

Dual Limit

When the binary output contact on the satellite controller

is controlled by a Dual Limit Screen, the contact opens and

closes based on how the analog input value compares to a pair

of setpoints. There is one Data Register for each contact on the

satellite controller which is controlled by a Dual Limit Screen. The

value of the Data Register is the difference between the setpoint

and the actual temperature.

Operator Interfaces

Difference between actual temperature and the “Midpoint” of the

setpoints = 4 °F, and therefore, the value of the Data Register is 4

°F.

If the Data Register is measured from the nearest limit, the value of

the Data Register is 2 °F.

Low Limit High Limit

70 74 76

2 Deg

Nearest Actual

Limit Temperature

Data Register

1-9

Page 20

WCC II Operator’s Guide

Section 1: General Instructions

Alarm Print-Out and Call-Out

The ECC/WCC II will automatically print alarms as they occur

on a local printer or will call out over standard telephone lines

and report the alarms to a remote printer. There are eight different

alarm types or alarm priorities. The fi rst fi ve alarm types can “callout”; each of these fi ve alarm types can call a primary and alternate

number.

The following is a sample of the ECC/WCC II print-outs:

-----------------------------------------------------------------------------------------

ECC/WCC II SYSTEM ID: *** TEMPERATURE INDUSTRIES, INC. *** 14:36 10/08

ALARM: ANALOG LIMITS

SAT #: 1 [SCIENCE RM] Input: 1 went into alarm at 14:36 on 10/08. High: 80.6 Deg F

low: ****** Deg F Class: 4

OPERATOR LOG-ON

Operator 33333 logged-on locally at 14:37 on 10/08 [Pswd Level: 3]

ALARM: RUN-TIME

SAT #: 1 [GYM FAN] Point: 5 went into alarm at 14:39 on 10/08. [OIL BEARINGS] Value:

501 Hours Class: 3

OPERATOR LOG-OFF

Operator 33333 logged-off locally at 14:39 on 10/08 [Pswd Level reset to 0]. (Logon

time: 0 hours 2 minutes)

OPERATOR LOG-ON

Operator JOHN logged-on locally at 14:40 on 10/08 [Pswd Level: 3]

OVERRIDE

Override for W1 entered at 14:40 on 10/08. Start: 14:40 on 10/08 End: 18:40 on 10/08

Override value: OFF

OPERATOR TIME-OUT

Operator JOHN timed-out locally at 14:43 on 10/08 [Pswd Level reset to 01]. (Logon time:

0 hours 3 minutes)

-----------------------------------------------------------------------------------------

1-10

Operator Interfaces

Page 21

WCC II Operator’s Guide

Section 1: General Instructions

Analog Alarm Limit

Each analog input can have a low and high limit assigned to it

on the Analog Input Screen. If the value of the analog input falls

below the low limit or rises above the high limit, the system

automatically generates an alarm. For example, assume that the

analog input in question is a room temperature sensor located in

an offi ce space. If the space temperature falls below 68 °F or rises

above 80 °F during the occupied period, we want an alarm to print

on the printer. To set up the alarm limits, fi rst sign on by accessing

the System Parameter Screen and entering your password. An

access level of 1 or greater is required to enter or change alarm

limits. After you are signed on, return to the Main Menu and place

the cursor over “ANALOG INPUT” and press <RETURN>. An

Analog Input Screen similar to what is shown below should come

into view:

-----------------------------------------------------------------------------------------

Satellite #1 ANALOG INPUT #1

Description: RM 101 Type: Analog

Pattern for values associated with this input: xxx.x

Units @ 0% scale: 0.0 Deg F Units of Measure Message #: 1

@ full scale: 100.0 Deg F Filter Time Constant: 8 seconds

The alarm limits along with the alarm type and alarm message

numbers are assigned on this screen (see the Analog Input Screen

section of this guide on page 3-9 for more information). If the

space temperature drifts out of the entered alarm limits, the system

will automatically generate an alarm. For example, assume that the

space temperature rises above the high limit value of 80 °F. Alarm

message #1 (High Temperature) along with the time and date of the

alarm and the high peak value of the room temperature will appear

on Analog Input Summary Screen and the Alarm Summary Screen.

Within one minute from the time the alarm appears on the screen, it

will automatically be printed on the local printer. (To acknowledge

alarms, use the <Control-A> function described in the Help Screen

(page 3-1), Analog Input Summary Screen (page 3-7), and Alarm

Summary Screen (page 3-36) sections of this guide.)

-------------------ALARMS--------------------

Controlled by: W1 Limits Low High

Alarm Type: 1 On 68.0 80.0 Deg F

Alarm Message #’s: Low 2 High 1 Off 50.0 90.0 Deg F

Alternate Limits selected by:.... On (alt) 0.0 0.0 Deg F

Off (alt) 0.0 0.0 Deg F

Limit overlap time

after control change: 20 Minutes Local set 55.0 90.0 Deg F

--------------------BINARY SETPOINT---------------------- OFF Above 0.0 Deg F On Message #: 0

OFF Below 0.0 Deg F Off Message #: 0

Home for menu

-----------------------------------------------------------------------------------------

Operator Interfaces

1-11

Page 22

WCC II Operator’s Guide

Section 1: General Instructions

Run Time Alarm

The ECC/WCC II system also has the capability of alarming if

the total ON time of a binary (on/off) value has exceeded the

run time alarm limit. To assign a run time alarm limit, fi rst sign

on by accessing the System Parameter Screen and entering your

password. An access level of 2 or greater is required to enter or

change alarm limits. After you are signed on, return to the Main

Menu and place the cursor over “TREND LOGS” and press

<RETURN>. The Trend Log Summary Screen should come into

view. To access a Run Time Trend Logging Screen, use the arrow

keys to place the cursor (>) by the desired run time point, and press

<RETURN>. The following screen should come into view:

-----------------------------------------------------------------------------------------

Satellite # 1 TREND LOGGING # 1 of Type: RUN TIME

Records total ON time Starting at : *:* on */*

for K1c Fan # 1 Reset by: L16 being ON

Alarm Type: 6

Alarm Message #: 7

In this example screen, we are recording the total “ON” time of

contact Klc (COM to C contact closure) on satellite controller

#1. When contact Klc is closed, or “ON”, Fan #1 runs. Run time

recorder #1 records total accumulated run time of the fan. Alarm

message #7 (Grease Bearings) will automatically appear on the

Alarm Summary Screen when the total accumulated run time of

the fan exceeds 500 hours. Within one minute after the alarm

appears on the screen, it will automatically print out on the local

printer. (See the Alarm Summary Screen section, page 3-36, for

information about how to acknowledge a run time alarm, and see

the Run Time Trend Logging Screen section, page 3-32, of this

manual for information about how to reset the accumulated run

time to zero.)

-

Current run time: 250 Hours Alarm Limit: 500 Hours

Home for Menu

-----------------------------------------------------------------------------------------

1-12

Operator Interfaces

Page 23

WCC II Operator’s Guide

Section 1: General Instructions

Satellite Fail Alarm

If the Central Processing Unit loses communications with a satellite

controller, a Satellite Alarm will print on the printer showing which

satellite is out of service and the time and date of the alarm.

Operator Sign On/Off

The ECC/WCC II system will automatically print the operator ID,

time, and date when an operator signs on or off the system. The

message will also indicate the password level of the operator and

if he or she signed on/off locally or remotely. When the operator

signs off, the total amount of time the operator has been signed on

the system will also be printed.

Manual Overrides

When the operator uses the Override Screen to force a point to

another value, a message will be printed indicating what was

overridden along with the time and date of the override.

To utilize the “call-out” on alarm feature, a 1200 baud Hayes

compatible modem is required at the on-site ECC/WCC II

computer, and a 1200 baud Hayes compatible modem and an IBM

graphics compatible printer, custom confi gured with a high speed

serial adapter is required at the remote site.

System Re-Boot

When the system is re-booted or restarted by either shutting the

computer off and then turning it back on or using <Ctrl> <Alt>

and <Del>, a message is shown on the printer showing the time

and date of the re-boot.

Hardware Requirements

The ECC/WCC II print routine is a standard software feature, and

the standard CPU has all of the hardware items required to support

a local printer. If local print-out is desired, an Okidata 182A, IBM

compatible, parallel printer with a standard IBM compatible cable

is recommended. We cannot offer trouble-shooting support if other

printers are used.

The local printer must be a parallel printer as opposed to a serial

printer. The ECC/WCC II CPU has a parallel and a serial port for

data output. The difference between a parallel and serial port is the

way in which data is transmitted. The only purpose a parallel port

serves is to send data to a printer on-site, and therefore the local

printer must be a parallel printer.

Operator Interfaces

1-13

Page 24

WCC II Operator’s Guide

Section 1: General Instructions

1-14

Operator Interfaces

Page 25

WCC II Operator’s Guide

Section 2: Initiating the System

SECTION 2: INITIATING THE SYSTEM

__________________________________________

The programs and data which are necessary to cause the personal

computer to act as the ECC/WCC II Central Processing Unit

are saved on a diskette(s) similar to the way music is stored on a

cassette tape.

Note: The personal computer also has special integrated

circuit boards, manufactured at WattMaster, which allow it to

act as the CPU.

After the satellite controllers have been installed and powered up,

the Central Processing Unit (personal computer) set up, and the 2wire communication line between the satellite controllers and the

CPU hooked up (see the Installation and Trouble Shooting Guide

for satellite controller start-up and check-out information), the

software needs to be loaded into the system. Loading the software

is a term which means that data on the diskettes is transferred into

the memory of the personal computer and/or into the memory of

the satellite controllers.

The personal computer used with the ECC/WCC II system may

have either two fl oppy disk drives or one fl oppy disk drive and one

hard disk drive. If the front end computer is an IBM system 2, the

fl oppy disks are 3.5 inch; otherwise, they are 5.25 inch disks. The

3.5 inch disks are sometimes referred to as micro fl oppy disks or

micros. The disk drive on the left hand side of the computer (Drive

A) always accepts a fl oppy disk. The right hand disk drive uses

either a fl oppy disk or a hard disk. If it is a fl oppy disk, then it is

referred to as drive B; if it is a hard disk then it is referred to as drive

C. Hard disks hold much more data than a fl oppy. A hard disk is

recommended on systems which have over 20 satellite controllers

and is required on systems which utilize Enhanced Color Graphics

or the Telephone Override Feature.

You should receive the following disks with an ECC/WCC II

system:

Dual Floppy Systems

“DOS Disk - Version 3.3”

“Drive A Operating Disk”

“Drive B Operating Disk”

“Drive A Back Up Disk”

“Drive B Back Up Disk”

Hard Disk Drive Systems

“DOS Disk - Version 3.3”

“Back Up Disk #1”

“Back Up Disk #2”

The DOS (Disk Operating System) Manual is shipped in the box

with the ECC/WCC II CPU (personal computer). You should

fi nd two disks in the back of the DOS manual; you need the disk

labeled “DOS”. The ECC/WCC II system will operate with DOS

2.1 or greater.

CAUTION: DOS 2.1 must be used on dual fl oppy systems

which have 5.25 inch disk drives. The DOS 3.3 fi le is too large

and will not allow enough room for the other ECC/WCC II

fi les.

If you have a dual disk system, “Disk A” will stay in Drive A of the

ECC/WCC II CPU (personal computer) and “Disk B” will remain

in drive B. If you have a “Hard Disk” system, the “Disk A” and

“Disk B” will be copies onto the hard disk (Drive C).

It is very important to make back-up copies of the disks after the

system has been “programmed” to control your building.

You can tell if your system has a hard disk by looking at the disk

drives on the personal computer. A disk drive that uses a fl oppy

disk has a door with a slot which allows you to insert and remove

the disk. The hard disk is permanently in the drive, and therefore

there is no door on the front of the drive. If your system has two

fl oppy disk drives, then it is referred to as a “ Dual Floppy” or a

“ Dual Disk Drive” system. If the disk on the right does not have a

disk drive door, then the disk in the right hand drive is a hard disk,

and the system is referred to as a “Hard Disk” or “Fixed Disk”

system.

Operator Interfaces

Dual Disk Drive Systems

If the ECC/WCC II CPU (personal computer) has two “fl oppy”

disk drives, then the following procedure should be followed to

load the software into the computer. Before you can load the ECC/

WCC II software, you need to have the following items:

1) “Drive A Operating Disk”

2) “Drive B Operating Disk”

2-1

Page 26

WCC II Operator’s Guide

Section 2: Initiating the System

Insert the ECC/WCC II “Drive A Operating Disk” into drive A

(left hand drive), the “Drive B Operating Disk” into drive B (right

hand drive) and “boot-up” the system.

If your computer is off: Turn the power on. Then close the

disk drive doors.

If your computer is on: Press and hold <Ctrl> and <Alt>.

Then press and hold <Del>.

After a few seconds the computer should read the data from the

disks, and it will automatically bring up the ECC/WCC II Main

Menu.

Note: As you program a system to control a building,

information is written on the disks. It is very important to

make back-up copies of the “Working” disks after the system

has been programmed to control the building.

Hard Disk Drive Systems

If the ECC/WCC II CPU (personal computer) is a “Hard-Disk”

system, the ECC/WCC II program is stored on the hard disk so

“booting-up” the system will cause the ECC/WCC II Main Menu

to appear on the screen.

If your computer is off: Open the drive A door and then turn

the power on.

If your computer is on: Press and hold <Ctrl> and <Alt>.

Then press and hold <Del>.

After a few seconds the computer should read the date from the

hard disk (drive C) and the ECC/WCC II Main Menu system

should eventually appear on the screen.

The hard disk can hold a vast amount of data which can accidentally

be erased or lost due to system malfunction, operator error, etc.

Therefore it is extremely important to make a back-up copy of

the data on the hard disk. As you program a system to control a

building, information is written on the disks. Therefore, back-up

copies of the hard disk should be made after the system has been

programmed to control the building.

Copying Disks

“ Backing-up” a disk means to make a copy of the disk’s data on

another disk. Back-up copies of all of the disks should be made in

case the primary disk is destroyed, lost or stolen. The information

on a hard disk can be transferred to several fl oppy disks, a cassette

tape or another hard disk.

To make a back-up copy of a disk, you must have the following

items:

1 - The “Source Disk” (the disk you want to back up)

2 - The “Target Disk” (the disk that will receive the data)

3 - DOS (version 2.1 or higher)

Formatting Disks

The fi rst step in copying disks is to format the disk which will serve

as the “Target Disk.” After the disk has been formatted, the system

can direct the fi les to be stored in certain places.

The following procedure should be followed to format disks:

WARNING: Make sure that the disk that you format does not

contain any programs that you want to save. The formatting

process will erase everything presently on the disk.

Before you start the disk formatting procedure, the “A>“ should

appear on the screen. If you are using the ECC/WCC II system

to format the disks, you should “exit” from the ECC/WCC II

system.

To exit from the ECC/WCC II program, you must have level 3

access. Access the Utility Screen and then move the cursor down

to “WCC/SCC File Management” and then press the right arrow

key. The cursor should move to “Exit WCC II System.” Then press

<Enter>. The system should exit to DOS and either an A>, B> or

C> will appear on the screen. If the B> or C> appears, the A> will

appear if you enter the following command:

B>A: <Enter>

2-2

Formatting the Target Disk Using a Dual Floppy

System

Insert the DOS version 2.1 or higher diskette into the

1.

left disk drive (drive A) and close the door.

Operator Interfaces

Page 27

Insert the “Target Disk” (new, blank disk) into the right

2.

disk drive (drive B) and close the door.

WARNING: Make sure that the disk that you format does not

contain any programs that you want to save. The formatting

process will erase everything presently on the disk.

If the disk you are formatting is to be a back-up for

3.

drive A, at the DOS prompt (A>), type in the following

command to format the blank diskette in drive B with

the system fi les:

A>FORMAT B:/S <Enter>

If the disk you are formatting is to be a back-up for drive B,

at the DOS prompt (A>), type in the following command

to format the blank diskette in drive B without the system

fi les:

A>FORMAT B: <Enter>

WCC II Operator’s Guide

Section 2: Initiating the System

The diskette in drive B has now been formatted.

5.

Remove this diskette and lay it to one side in its

protective envelope. If you need to format another

diskette, insert another new, blank diskette into drive B

and close the door. The computer will now ask you if

you wish to format another diskette. Press <Y> to format

the additional diskette.

Format another (Y/N)? Y <Enter>

If you do not wish to format any additional diskettes, simply

press <N> in response to this question. You will then return to

the DOS operating system.

Format another (Y/N)? <N>

A>

Formatting the Target Disk Using a Hard Disk Drive

System

Insert the DOS version 2.1 or higher diskette into the

1.

left disk drive (drive A) and close the door.

The computer will instruct you to insert the new diskette

4.

in drive B and press <Enter> when ready. Since you

have already put the blank diskette in drive B, press

<Enter>. Messages similar to that shown below will be

displayed on the screen:

Formatting... Formatting...format

complete

System Transferred

362496 bytes total disk space

40960 bytes used by system

321536 bytes available on disk

If the system states that “Bad Sectors” appear

(displayed on the screen):

1. Remove the diskette from the drive.

2. Put the diskette back into the drive.

3. Format the diskette again.

If the “Bad Sectors” message reappears, discard the

diskette and acquire another diskette for formatting.

If the “Bad Sectors” message does not reappear, format the

diskette once again to verify results. (This is a “best-twoout-of-three formats” technique. Oftentimes the diskette is

not “seated” properly in the disk drive when fi rst inserted,

and as such, the format process may fail.)

Type in the following command:

2.

A>FORMAT A: <Enter>

The computer will instruct you to insert the new diskette in

drive A and press <Enter> when ready.

WARNING: Make sure that the disk that you format does not

contain any programs that you want to save. The formatting

process will erase everything presently on the disk.

Remove the DOS disk from drive A and insert the

3.

“Target Disk” (new, blank disk) into drive A, close the

disk drive door, and press <Enter>.

Messages similar to those shown below will appear on the

screen:

Formatting...

Formatting...Format complete

362496 bytes total disk space

362496 bytes available on disk

If the system states that “Bad Sectors” appear

(displayed on the screen):

Operator Interfaces

2-3

Page 28

WCC II Operator’s Guide

Section 2: Initiating the System

1. Remote the diskette from the drive.

2. Put the diskette back into the drive.

3. Format the diskette again.

If the “Bad Sectors” message reappears, discard the

diskette and acquire another diskette for formatting.

If the “Bad Sectors” message does not reappear,

format the diskette once again to verify results. (This is a

“best-two-out-of-three formats” technique. Oftentimes the

diskette is not “seated” properly in the disk drive when fi rst

inserted, and as such, the format process may fail.)

The diskette in drive A has now been formatted.

4.

Remove this diskette and lay it to one side in its

protective envelope. If you need to format another

diskette, insert another new, blank diskette into drive B

and close the door. The computer will now ask you if

you wish to format another diskette. Press <Y> to format

the additional diskette.

Format another (Y/N)? Y <Enter>

If you do not wish to format any additional diskettes,

simply press <N> in response to this question. You will

then return to the DOS operating system.

Format another (Y/N)? <N>

A>

AUTOEXEC.BAT

-

-

-

-

n File(s) copied

The diskette in drive B now contains the same data as the disk in

drive A. Remove this diskette and label it using a SOFT FELT TIP

PEN.

We recommend using the newly made disk in the system and

keeping the original in a safe place to be used as back-up in case

of an emergency.

Copying Data - Hard Disk Drive

Systems

The data that is stored on the hard disk can be accidentally erased

or the hard disk can malfunction resulting in all the data being

destroyed. Since a hard disk can hold such a huge amount of data,

it is extremely important to have a back-up copy of the information

on the hard disk.

There are several ways to obtain a back-up copy of the hard disk,

which include:

Floppy Disk Back-Up

Cassette Tape Back-Up

Selected Program Back-Up

Copying Data - Dual Floppy Systems

The information from the “Source Disk” is copied onto the “Target

Disk” using the following procedure:

1) Insert the “Source Disk” into drive A (left drive) and

1.

close the door. Insert a newly formatted diskette into

drive B and close the door. With the A> prompt showing

on the screen, type the following command:

A>COPY *.* B:/V <Enter>

The screen will now display the copy process:

A>COPY *.* B:<Enter>

COMMAND.COM

2-4

The information from the hard disk can be copied onto fl oppy disks

using the disk copy procedure outlined in the DOS manual. The

problem with this method is that it is very time consuming and it

requires many fl oppy disks. Therefore, we recommend using either

a cassette tape or a selected program to back up the data on the hard

disk. If you need help in selecting a tape or selected program for

your system, feel free to contact WattMaster for assistance.

If your system has a 5.25 inch fl oppy drive, it will take several

disks to back up the hard disk, and therefore, a back-up program

should be used. If your system has a 3.5 inch fl oppy drive, you can

generally copy all of the system fi les and help fi les onto one disk,

all of the data fi les onto another disk, and the custom screen fi les

onto a third disk. If the color graphics option is used, a back-up

program is recommended.

Operator Interfaces

Page 29

WCC II Operator’s Guide

Section 2: Initiating the System

Generally, the ECC/WCC II systems with less than 20 satellite

controllers which do not use the optional telephone override feature

or the color graphics feature require three 3.5 inch fl oppy drives to

back up the hard disk.

Floppy Disk #1 System Files Help Files

AUTOEXEC.BAT HELP*.*

MCOMM33.COM

BACK###.EXE

GO2.COM

WCC2###.EXE

Floppy Disk #2 Data Files

*.DAT

Floppy Disk #3 Custom Screen Files

*.TXT

Files can be copied from the hard disk to the fl oppy disk without

exiting from the ECC/WCC II program by using the WCC/SCC

File Management Screen. Complete the following steps to make a

back-up copy of the hard disk:

Label three 3.5 inch formatted, blank disks as follows

1.

------------------------------------------- File name: *.COM

New fi lename: A:*.COM

Direction: WCC

Action: Copy

---------------------------------------------

Leave Disk #1 in drive A and fi ll out the WCC/SCC File

5.

Management Screen as shown below to copy WCC###.

EXE and BACK###.EXE from drive C to drive A:

---------------------------------------------

File name:

New fi lename: A:*.EXE

Direction: WCC

Action: Copy

---------------------------------------------

Leave Disk #1 in drive A and fi ll out the WCC/SCC File

6.

*.EXE

Management Screen as shown below to copy the help

fi les from drive C to drive A:

---------------------------------------------

Disk #1 - ECC/WCC II Back-up Disk #1 - System and

Help fi les