Page 1

www.wattmaster.com

VAV Systems

Technical Guide

Page 2

Table Of Contents

Selecting The Right WattMaster VAV System ................................................................................................ 3

Using the Selection Chart........................................................................................................................................................... 3

Networked Single Loop System ...................................................................................................................... 4

Operators Interface Options ....................................................................................................................................................... 4

Communication Device Options ................................................................................................................................................. 4

Add-on Device Requirements..................................................................................................................................................... 5

Networked Multiple Loop System ................................................................................................................... 6

Operators Interface Options ....................................................................................................................................................... 6

Communication Device Options ................................................................................................................................................. 6

Add-on Device Requirements..................................................................................................................................................... 7

Figure 1: Typical Networked Single Loop System - Connections & Wiring ............................................................................... 8

Figure 2: Typical Networked Single Loop System - Connections & Wiring Using Computer & Remote Link ........................ 9

Figure 3: Typical Networked Single Loop System - Connections & Wiring Using Computer & IP-Link................................ 10

Figure 4: Typical Networked Multiple Loop System - Connections & Wiring ...........................................................................11

Figure 5: Typical Networked Multiple Loop System - Connections & Wiring Using Computer & Remote Link ................... 12

Figure 6: Typical Networked Multiple Loop System - Connections & Wiring Using Computer & IP-Link............................. 13

Notes:............................................................................................................................................................. 14

WattMaster Controls Inc.

8500 NW River Park Drive · Parkville , MO 64152

Toll Free Phone: 866-918-1100

PH: (816) 505-1100 · FAX: (816) 505-1101 · E-mail: mail@wattmaster.com

Visit our web site at www.wattmaster.com

Form: WM-VAV-SYS-TGD-01A Copyright 2004 WattMaster Controls, Inc.

WattMaster Controls, Inc. assumes no responsibility for errors, or omissions.

Page 3

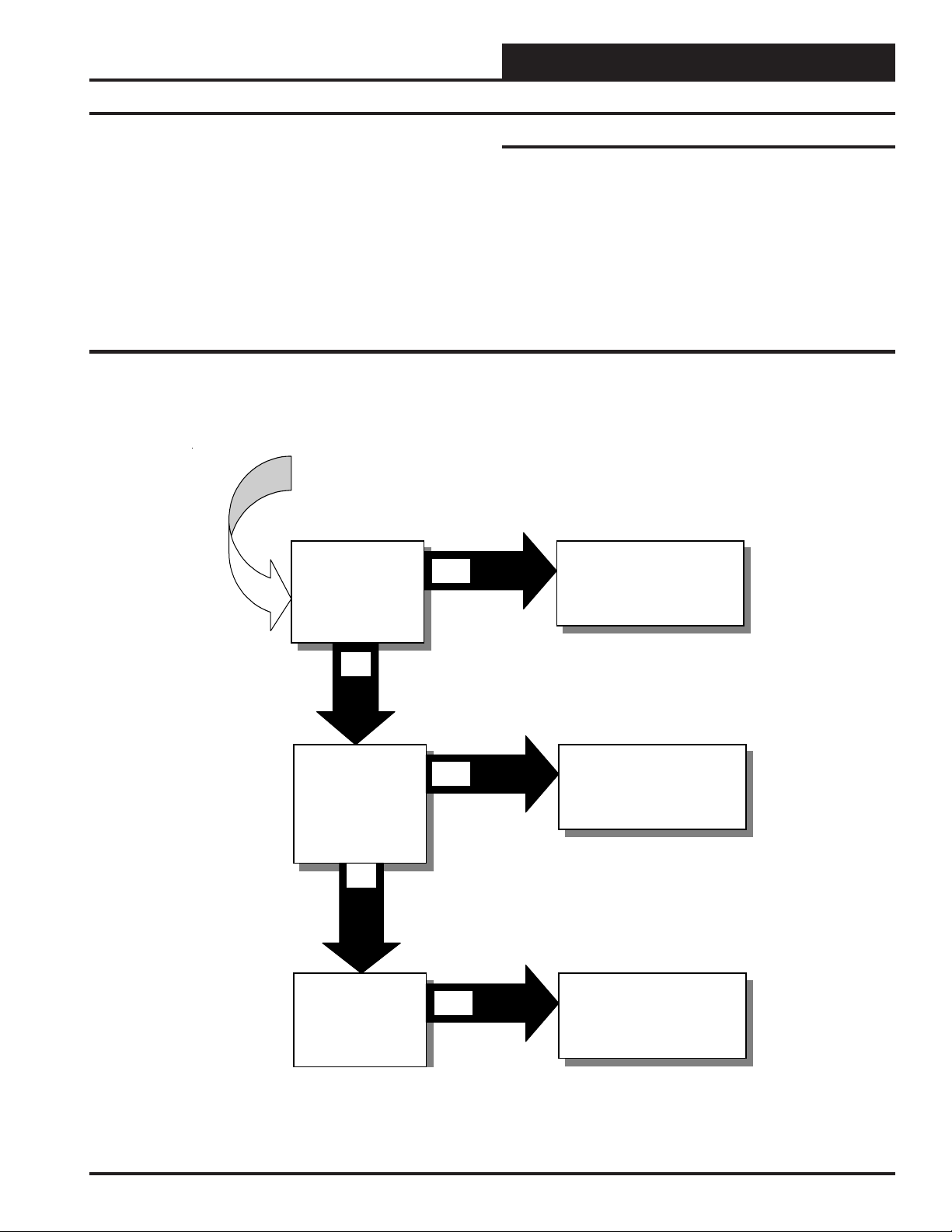

Selecting The Right WattMaster VAV System

Technical Guide

The WattMaster VAV series of controllers and components are connected together with communication wiring to form complete systems

solutions. W attMaster VA V controllers can be configured into two main

system types, which are the Networked Single Loop or the Networked

Multiple Loop system. The right system for you depends on the number

and types of controllers being used. Each of these main system types

have a series of options available that relate to what kind of operators

interface(s) you wish to use to program and monitor your WattMaster

VAV system. Several other options are available depending on the system type and operators interface you have selected. By selecting the

right system and options you can build a complete HVAC controls system that will meet your job requirements.

Which WattMaster VAV System

Should I Select?

Do You Have A Single

HVAC Unit With

VAVBOX Controllers

Total Number of All

Controllers Combined

Cannot Exceed 59

YES

Using the Selection Chart

WattMaster has designed this publication in order to make it easy to

select the right WattMaster VAV system type for your specific application. Start by selecting a main system type from the selection chart below. Proceed to the pages listed on the selection chart for information

and available options for that system type. After deciding what operators interface and other options you want, proceed to the connections &

wiring section pages listed for that system type for detailed installation

information.

Use The Networked

Single Loop System

See Pages 4, 5 & 6

NO

Do You Have Between

1 to 59 HVAC Unit or

Add-On Co n trolle r s

With One Un it That h as

VAVBOX Contr ollers .

Total Number of All

Controllers Combined

Cannot Exceed 59

NO

Do You Have More Than

59 HVAC Unit Or Add-On

Controllers And/Or

Multiple HVAC Units

Using VAVBOX

Controllers

YES

YES

Use The Networked

Single Loop System

See Pages 4, 5 & 6

Use The Networked

Multiple Loop System

See Pages 7, 8 & 9

Systems

3

Page 4

Technical Guide

Networked Single Loop System

The Networked Single Loop system is used when you have between 1

to 59 WMVAV controllers, VAVBOX controllers and Add-on Device

controllers total. Only one of the WMVAV controllers on the loop may

also have VAVBOX controllers attached. If your system exceeds any of

these limitations you will need a Networked Multiple Loop System.

When your proposed system has WMVAV and/ or Add-on Device controllers with only 1 WMVAVcontroller that has VAVBOX controllers

and the total number of these controllers and Add-on Devices is 59 or

less, you should use the Networked Single Loop System. If you have

more than 1 WMVAV with VAVBOX controllers or more than 59 total

controllers and Add-on Devices, please see the Networked Multiple Loop

section that follows. To create this system simply connect the controllers together in a daisy chain fashion using WattMaster communications wire or 18 gauge 2 conductor twisted pair with shield wire (Belden

#82760 or equivalent). These are then connected to the system communication devices. All WattMaster VAV systems require that a

CommLink II and a MiniLink Polling Device system communication

device are purchased and wired into the communications loop. The

required CommLink and MiniLink Polling Device are available as a

kit by ordering the OE715-VAV WMVAV System Package. Programming and status monitoring are accomplished by selecting and installing an operators interface. For most controllers, any one of the operators interfaces can be used for system programming and monitoring or

two or all three can be used together if desired. The exception to this is

when any Add-on Devices are used. The Add-on Devices must be programmed with a PC using the WattMaster VAV Prism software, they

cannot be programmed with the System Manager or the Modular Service T ool. See the section titled “Operators Interface Options” that follows for a list and block connection diagrams of the operators interface

options available along with their capabilities and limitations. For detailed wiring and connection diagrams of the Networked Single Loop

systems see pages 10, 11 and 12.

Operators Interface Options

Modular Service Tool

The Modular Service T ool provides complete programming and monitoring capabilities for WMVAV and VAVBOX controllers. Add-on Device controllers cannot be programmed with the Modular Service T ool.

The Modular Service Tool connects to the controller by means of a

modular cable with DIN connectors. It is normally used to program and

service the unit and then is removed by the service person upon completion of these tasks. The Service Tool is not designed for permanent installation. Generally the service person would only connect it when servicing or reprogramming the controller. For this reason if continuous

monitoring of the controllers is required, it is better to select a System

Manager or an on site PC for programming and monitoring. The Service T ool can be used in conjunction with the other operators interfaces

if desired.

System Manager

The System Manager provides programming and monitoring of controllers in a package that is designed for permanent wall mounting in

the space or an equipment room. It is housed in an off white plastic

housing that is suitable for most decors. The System Manager is also

provided with alarm and override LED indicators on its faceplate. Addon Device controllers cannot be programmed with a System Manager.

.

Personal Computer With Prism Software

A computer interface can also be used in conjunction with the other

operators interfaces listed above, or by itself. The PC used can be a

laptop or desktop computer. WattMaster VAV Prism software must be

installed on the PC. WattMaster VAV Prism Software is available free

of charge at our website, www.wattmaster.com. If remote connection

via a phone line is required you must also purchase and install a Remote

Link. For remote computer connection via an intranet or Internet you

would purchase and install the IP-Link instead of the Remote Link.

Both an on-site and remote PC can be used together if desired.

The personal computer to be used with the Orion Prism software must

meet or exceed the following specifications:

• IBM™ Compatible Computer

• Pentium 200 MHz or Faster Microprocessor

• 64 Meg RAM

• Windows 95 / 98 / ME / XP / 2000/ NT

• Super VGA Monitor w/ 1024 x 768 Resolution Minimum

• Available Serial Port for On Site Installations

• Internal or External Modem for Remote Installations

• Network Card for TCP/IP Communications

A PC with Prism installed provides features not available with the other

operators interfaces:

• Trend logs can be exported for easy use into any standard

spreadsheet/database program

• Automatic installation

• Alarm logs are maintained on disk

• E-mailing of alarms

• History logs of user interactions with the system

• On site or remote modem or TCP/IP communications

• User programmable descriptions for every piece of

equipment

• User definable passcode levels for setpoints

• Current status printouts

• User defined custom screens for floor plans, etc.

• Tenant log creation for tenant override Billing

• Automatic retrieval of trend logs

Communication Device Options

All Networked Single Loop system require that you have both a

CommLink and MiniLink PD installed on the system for correct operation. Other optional communication devices are listed in the following

paragraphs along with a description of how they function with the Networked Single Loop control system.

4

Systems

Page 5

Technical Guide

Remote Link

The Remote Link is used with the CommLink to provide for a remote

PC to interface to the system via a phone line. It can also be used with

the CommLink to provide alarm callouts to a pager without requiring

an on site or remote PC.

IP-Link

The IP-Link is used with the CommLink to provide for a remote PC to

interface to the system via a local intranet or the Internet. The IP-Link

will allow up to 5 computer TCP/IP connections to be operating at the

same time.

PERSONAL COMPUTER

CLII

omm ink

MINILINK PD

RV1

F

E

CX3

R

V

U3

CX4

2

U4

X

C

4

R

LED1

LED2

EPROM

RAM

2

X

POWER

C

C8

26

25

C7

R

R

1

V

27

AIN2

AIN1

R

THERM

THERM

4-20mA

4-20mA

U12

0-10V

0-10V

31

R

OFF=0-5V

C

D

1

2

4

N

D

+5V

AIN

AIN

24VA

G

C11

1

D5

TB2

TB

LOCAL LOOP

COMMLINK

RLINK

COMP

LOOP

STATUS

NETWORK LOOP

P1

C4

YS101818P552

X1

PROCESSORPBOARD

C1

C2

CX5

U5

PHILIPS

1

D

U1

1

1

R

U6

CX1

C3

U2

CX6

R2

WDOG

24

R

LD4

PROC.

LOOP

NETWORK

DRIVER

DRIVER

DRIVER

15

14

13

X

X

X

C

C

C

14

13

15

U

U

U

LD6

LD5

NETWORK

LOCALLOOP

LOOP

LD

LD

D

N

P4

G

R

SH

T

R

T

SH

3

4

TB

TB

CONTROLS

UP

Mode

Selection

NEXT

PREV

U1

CX7

U7

1

CX

X6

C

U6

U10

YS101900PMINILINK

POLLING

DEVICE

REV.1

RN2

U11

C9

RN3

X2

3

R28

P

R29

R30

4

1

2

8

32

16

P5

D

D

A

OFF

SW1

STATUS

SETPOINTS

DOWN

CLEAR

1

C

R3

X1

3

C

C10

ESC

SCHEDULES

ENTER

OVERRIDES

13

2

ALARMS

CONFIGURATION

BALANCE-TEST

708

DEC

ON

MODULAR

SERVICE

TOOL

654

9

MINUS

-

SYSTEM MANAGER

UP

13

2

PREV

654

ESC

DOWN

708

9

DEC

MINUS

ENTER

-

WMVAV CONTROLLER

(Variable Volume)

Add-on Device Requirements

If you wish to use any of the Add-on Device controllers on your system

you must use a PC with the Prism software installed for programming

and monitoring of the controllers. These devices cannot be programmed

or monitored from the System Manager or Service Tool.

The Add-on Controllers that require a PC for programming and monitoring are:

• GPC and GPC-17

• Lighting Controller

• Optimal Start Scheduler

STATUS

SETPOINTS

NEXT

SCHEDULES

CLEAR

OVERRIDES

ALARMS

WMVAV CONTROLLER

(Constant Volume)

(1MEG)

(1MEG)

WMVAV CONTROLLER

(Constant Volume)

WMVAV CONTROLLER

(Constant Volume)

(1MEG)

WMVAV CONTROLLER

(Constant Volume)

VAVBOX

CONTROLLER - TYP

AIRFLOW

CX4

CX3

CX1

CX8

RN1

U3

U4

U8

PJ3

P.U.

D5

R27

D6

P.U.

R32

T'STAT

R28

R33

D7

COMM

485

DR

R26

YS101562REV.3

D4

R35

V3

24VAC

GND

C16

AIRFLOW

PJ3

P.U.

D5

R27

D6

P.U.

R32

T'STAT

R28

R33

D7

COMM

485

DR

R26

YS101562REV.3

D4

R35

V3

24VAC

GND

C16

U1

R34

R18

CX9

U9

C13

C9

C14

R22

VREF

ADJ

P.U.

C10

R23

R24

U11

R19

R20

C11

C15

EWDOG

R25

ADDRESS

ADD

CX10

OFF

U10

SW1

V

POWER

SCAN

R21

L1

VR1

OI

7824

R16

R17

CX8

RN1

U8

R34

R18

CX9

U9

C13

C9

C14

R22

VREF

ADJ

P.U.

C10

R23

R24

U11

R19

R20

C11

C15

EWDOG

R25

ADDRESS

ADD

CX10

OFF

U10

SW1

V

POWER

SCAN

R21

L1

VR1

OI

7824

R16

R17

0

PAL

R1

R2

Q1

R3

EPROM

C8

U5

CX2

X1

C1

U2

C2

R4

CX5

R5

R6

R8

R7

PJ1

U6

1

EXPANSION

2

4

CX6

C3

8

16

32

C4

TOKEN

C5

PJ2

R100

NET

ACTUATOR

R14

R13

REC

V1

R9

K1

R12

R11

C6

Q2

D1

D3

K2

C7

R15

Q3

U7

D2

V2

CX4

CX3

CX1

U3

U4

U1

0

PAL

R1

R2

Q1

R3

EPROM

C8

U5

CX2

X1

C1

U2

C2

R4

CX5

R5

R6

R8

R7

PJ1

U6

1

EXPANSION

2

4

CX6

C3

8

16

32

C4

TOKEN

C5

PJ2

R100

NET

ACTUATOR

R14

R13

REC

V1

R9

K1

R12

R11

C6

Q2

D1

D3

K2

C7

R15

Q3

U7

D2

V2

AIRFLOW

CX4

CX3

CX1

CX8

RN1

U3

U4

U8

1

1

PJ3

P.U.

D5

R27

D6

P.U.

R32

T'STAT

R28

R33

D7

COMM

485

DR

R26

YS101562REV.3

D4

R35

V3

24VAC

GND

C16

AIRFLOW

PJ3

P.U.

D5

R27

D6

P.U.

R32

T'STAT

R28

R33

D7

COMM

485

DR

R26

YS101562REV.3

D4

R35

V3

24VAC

GND

C16

U1

R34

R18

CX9

U9

C13

C9

C14

R22

VREF

ADJ

P.U.

C10

R23

R24

U11

R19

R20

C11

C15

EWDOG

R25

ADDRESS

ADD

CX10

OFF

U10

SW1

V

POWER

SCAN

R21

L1

VR1

OI

7824

R16

R17

CX8

RN1

U8

R34

R18

CX9

U9

C13

C9

C14

R22

VREF

ADJ

P.U.

C10

R23

R24

U11

R19

R20

C11

C15

EWDOG

R25

ADDRESS

ADD

CX10

OFF

U10

SW1

V

POWER

SCAN

R21

L1

VR1

OI

7824

R16

R17

0

PAL

R1

R2

Q1

R3

EPROM

C8

U5

CX2

X1

C1

U2

C2

R4

CX5

R5

R6

R8

R7

PJ1

U6

1

EXPANSION

2

4

CX6

C3

8

16

32

C4

TOKEN

C5

PJ2

R100

NET

ACTUATOR

R14

R13

REC

V1

R9

K1

R12

R11

C6

Q2

D1

D3

K2

C7

R15

Q3

U7

D2

V2

CX4

CX3

CX1

U3

U4

U1

0

PAL

R1

R2

Q1

R3

EPROM

C8

U5

CX2

X1

C1

U2

C2

R4

CX5

R5

R6

R8

R7

PJ1

U6

1

EXPANSION

2

4

CX6

C3

8

16

32

C4

TOKEN

C5

PJ2

R100

NET

ACTUATOR

R14

R13

REC

V1

R9

K1

R12

R11

C6

Q2

D1

D3

K2

C7

R15

Q3

U7

D2

V2

AIRFLOW

CX4

CX3

CX1

CX8

RN1

U3

U4

U8

1

1

PJ3

P.U.

D5

R27

D6

P.U.

R32

T'STAT

R28

R33

D7

COMM

485

DR

V

R26

YS101562REV.3

D4

R35

V3

OI

24VAC

GND

C16

AIRFLOW

RN1

PJ3

P.U.

D5

R27

C13

C14

D6

P.U.

ADJ

R32

T'STAT

R28

R33

R25

D7

COMM

485

DR

V

R26

YS101562REV.3

D4

R35

V3

OI

24VAC

GND

C16

U1

R34

R18

CX9

U9

R1

C13

C9

R2

R3

EPROM

C8

U5

C14

CX2

R22

VREF

ADJ

P.U.

C10

X1

R23

C1

R24

C2

U11

R19

R20

C11

C15

R4

CX5

EWDOG

R5

R25

ADDRESS

R6

R8

ADD

R7

CX10

PJ1

OFF

U6

1

2

4

CX6

U10

C3

SW1

8

16

32

POWER

C4

TOKEN

C5

PJ2

R100

NET

R14

R13

SCAN

REC

V1

R21

R9

R12

R11

C6

Q2

L1

D1

D3

VR1

C7

R15

7824

Q3

U7

R16

R17

D2

V2

CX4

CX3

CX1

CX8

U3

U4

U8

R34

R18

CX9

U9

R1

C9

R2

R3

EPROM

C8

U5

CX2

R22

VREF

P.U.

C10

X1

R23

C1

R24

C2

U11

R19

R20

C11

C15

R4

CX5

EWDOG

R5

ADDRESS

R6

R8

ADD

R7

CX10

PJ1

OFF

U6

1

2

4

CX6

U10

C3

SW1

8

16

32

POWER

C4

TOKEN

C5

PJ2

R100

NET

R14

R13

SCAN

REC

V1

R21

R9

R12

R11

C6

Q2

L1

D1

D3

VR1

C7

R15

7824

Q3

U7

R16

R17

D2

V2

1

0

PAL

Q1

U2

EXPANSION

ACTUATOR

K1

K2

U1

1

0

PAL

Q1

U2

EXPANSION

ACTUATOR

K1

K2

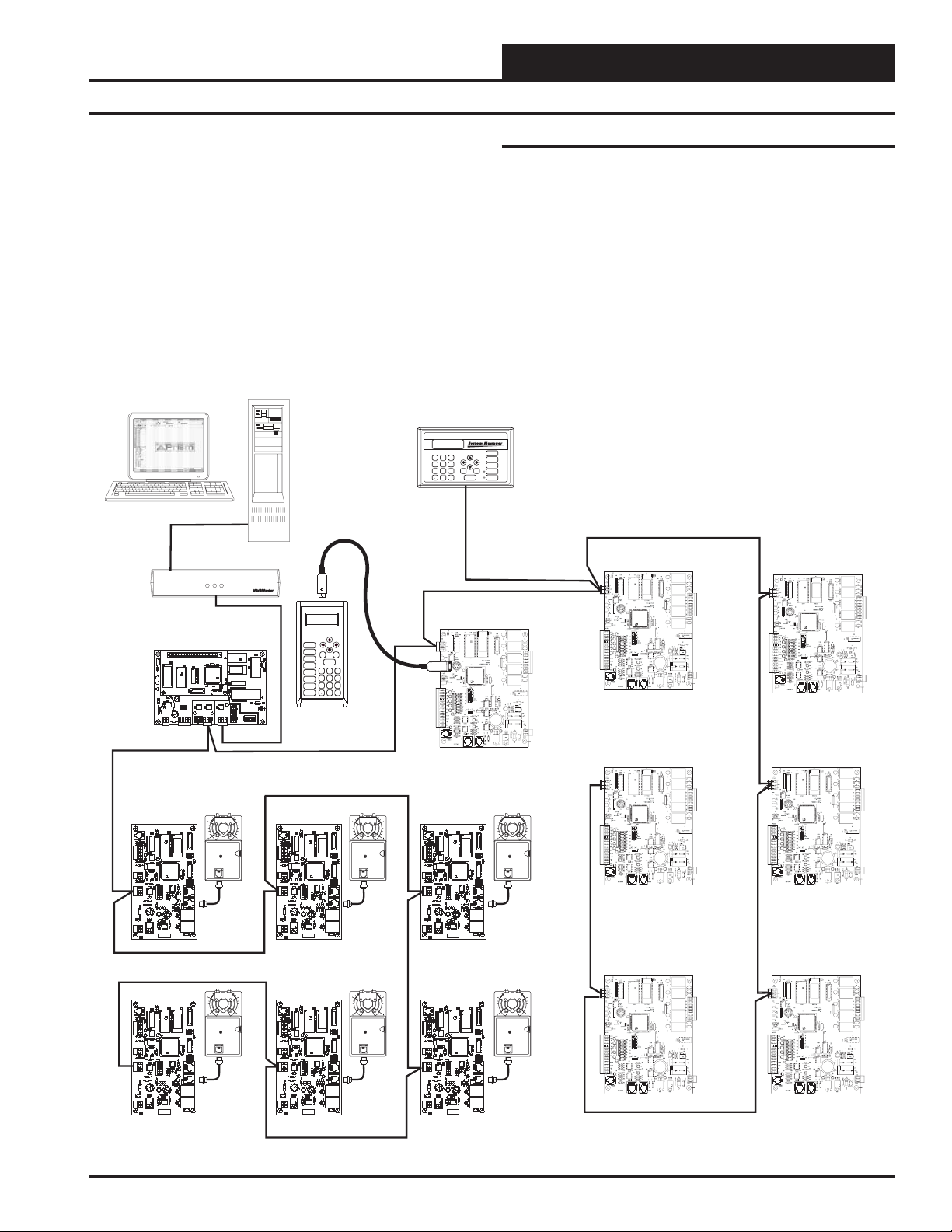

Typical Networked Single Loop System With All Operators Interface Options

Systems

(1MEG)

ADD-ON DEVICE

(1MEG)

(1MEG)

ADD-ON DEVICE

(1MEG)

5

Page 6

Technical Guide

Networked Multiple Loop System

The Networked Multiple Loop system is used when you have more

than 59 WMVAV controllers and/or Add-on Device controllers or are

using multiple WMVAV controllers that are connected to VAVBOX

controllers. These groups of controllers are broken up into multiple

“Local Loops” which connect to each other via the “Network Loop”.

Each individual MiniLink PD handles its specific local loop’s communications requirements. The CommLink communications interface

handles all the communications between the individual MiniLink PDs

to form the network loop. Up to 60 local loops can connected together

with this configuration. This provides the capability for over 3500 controllers to be networked together.

If you have more than 59 WMVAV and or Add-on Device controllers or

multiple WMVAV controllers that have VAVBOX controllers you must

split them into separate local loops with no more than 59 controllers

total on each local loop and only 1 WMVAV with VAVBOX controllers

on each loop. Each loop must have its own MiniLink PD. T o create this

system simply connect the controllers together on each local loop in a

daisy chain fashion using W attMaster communications wire or 18 gauge

2 conductor twisted pair with shield wire (Belden #82760 or equivalent). These loops are then connected to the system communication

devices. The Networked Multiple Loop systems require that 1

CommLink and 1 MiniLink Polling Device per local loop are purchased and wired into the communications loop. The required

CommLink and 1 MiniLink Polling Device are available as a kit by

ordering the OE715-VAV WMVAV System Package. The other

MiniLink PDs for each local loop are ordered individually. The

MiniLink PDs on the system are connected together in daisy chain fashion between their network loop terminals by using W attMaster communications wire or 18 gauge 2 conductor twisted pair with shield wire

(Belden #82760 or equivalent). The first MiniLink PD on the network

loop also connects to the CommLink using 18 gauge 2 conductor twisted

pair with shield wire. Programming and status monitoring are accomplished by selecting and installing an operators interface. For most

controllers, any one of the operators interfaces can be used for system

programming and monitoring or two or all three can be used together if

desired. The exception to this is when any Add-on Devices are used.

The Add-on Devices must be programmed with a PC using the WattMaster VAV Prism software, they cannot be programmed with the System Manager or the Modular Service Tool. See the section titled “Operators Interface Options” below for a list and block connection diagrams of the operators interface options available along with their capabilities and limitations. For actual detailed wiring and connection diagrams of the Networked Multiple Loop systems see pages 13, 14 and

15.

Operators Interface Options

Service Tool

The Service Tool provides complete programming and monitoring capabilities for the controllers. It can be connected to any controller on

the loop. The Service Tool connects to the controller by means of a

modular cable with DIN connectors. It is normally used to program and

service the unit and then is removed by the service person upon completion of these tasks. The Service Tool is not designed for permanent installation. Generally the service person would only connect it when servicing or reprogramming the controller. For this reason if continuous

monitoring of the controllers is required, it is better to select a System

Manager or an on site PC for programming and monitoring. The Service T ool can be used in conjunction with the other operators interfaces

if desired.

System Manager

The System Manager provides programming and monitoring of the controllers in a package that is designed for permanent wall mounting in

the space or an equipment room. It is housed in an off white plastic

housing that is suitable for most decors. The System Manager is also

provided with alarm and override LED indicators on its faceplate.

.

Personal Computer With Prism Software

A computer interface can also be used in conjunction with the other

operators interfaces listed above, or by itself. The PC used can be a

laptop or desktop computer. WattMaster VAV Prism software must be

installed on the PC. WattMaster VAV Prism Software is available free

of charge at our website, www.wattmaster.com. If remote connection

via a phone line is required you must also purchase and install a Remote

Link. For remote computer connection via an intranet or Internet you

would purchase and install the IP-Link instead of the Remote Link.

Both an on-site and remote PC can be used together if desired.

The personal computer to be used with the Orion Prism software must

meet or exceed the following specifications:

• IBM™ Compatible Computer

• Pentium 200 MHz or Faster Microprocessor

• 64 Meg RAM

• Windows 95 / 98 / ME / XP / 2000/ NT

• Super VGA Monitor w/ 1024 x 768 Resolution Minimum

• Available Serial Port for On Site Installations

• Internal or External Modem for Remote Installations

• Network Card for TCP/IP Communications

A PC with Prism installed provides features not available with the other

operators interfaces:

• Trend logs can be exported for easy use into any standard

spreadsheet/database program

• Automatic installation

• Alarm logs are maintained on disk

• E-mailing of alarms

• History logs of user interactions with the system

• On site or remote modem or TCP/IP communications

• User programmable descriptions for every piece of

equipment

• User definable passcode levels for setpoints

• Current status printouts

• User defined custom screens for floor plans, etc.

• Tenant log creation for tenant override Billing

• Automatic retrieval of trend logs

Communication Device Options

All Networked Multiple Loop systems require that you have

1CommLink per system and 1MiniLink PD for each local loop installed

on the system for correct operation. Other optional communication de-

6

Systems

Page 7

Technical Guide

vices are listed in the following paragraphs along with a description of

how they function with the Networked Multiple Loop control system.

Remote Link

The Remote Link is used with the CommLink to provide for a remote

PC to interface to the system via a phone line. It can also be used with

the CommLink to provide alarm callouts to a pager without requiring

an on site or remote PC.

IP-Link

The IP-Link is used with the CommLink to provide for a remote PC to

interface to the system via a local intranet or the Internet. The IP-Link

will allow up to 5 computer TCP/IP connections to be operating at the

same time.

PERSONAL COMPUTER

COMMLINK

CLII

omm ink

MP

OP

RLINK

CO

LO

STATUS

CONTROLS

LED2

POWER

LOCAL LOOP

RV1

EF

VR

X2

C

4

R

LED1

1

V

31

R

4

D

TB1

CX3

U3

EPROM

C7

R26

R25

U12

C

D

N

G

24VA

C11

D5

MINILINK PD

CX4

CX5

U4

U5

R1

U2

RAM

X2

C

C8

PROC.

DRIVER

27

15

AIN1

AIN2

R

CX

THERM

THERM

4-20mA

4-20mA

0-10V

0-10V

LD6

OFF=0-5V

LOCALLOOP

1

2

ND

IN

IN

P4

+5V

G

A

A

TB2

NETWORK LOOP

U1

P1

C4

YS101818P552

X1

PROCESSORPBOARD

C1

C2

U6

PHILIPS

U10

D1

U1

1

U6

CX1

C3

CX6

R2

WDOG

24

R

LD4

LOOP

NETWORK

DRIVER

DRIVER

14

X13

CX

C

3

P

14

15

13

U

U

U

LD5

NETWORK

LOOP

LD

LD

H

H

R

R

S

T

T

S

P5

3

DD

4

A

TB

TB

CX7

U7

1

X

C

1

C

3

R

1

X

X6

C

YS101900PMINILINK

POLLING

DEVICE

REV.1

RN2

U11

C10

C9

RN3

X2

R28

R29

R30

4

1

2

8

32

16

OFF

SW1

UP

Mode

Selection

NEXT

PREV

STATUS

SETPOINTS

DOWN

CLEAR

ESC

SCHEDULES

ENTER

OVERRIDES

13

2

3

ALARMS

C

CONFIGURATION

BALANCE-TEST

708

DEC

ON

MODULAR

SERVICE

TOOL

654

9

MINUS

-

Add-on Device Requirements

If you wish to use any of the Add-on Device controllers on your system

you must use a PC with the Prism software installed for programming

and monitoring of the controllers. These devices cannot be programmed

or monitored from the System Manager or Service Tool.

The Add-on Controllers that require a PC for programming and monitoring are:

• GPC and GPC-17

• Lighting Controller

• Optimal Start Scheduler

SYSTEM MANAGER

STATUS

UP

13

2

SETPOINTS

NEXT

PREV

654

SCHEDULES

CLEAR

ESC

DOWN

OVERRIDES

708

9

DEC

MINUS

ENTER

ALARMS

-

WMVAVCONTROLLER

(Variable Volume)

(1MEG)

WMVAVCONTROLLER

(Constant Volume)

(1MEG)

WMVAVCONTROLLER

(Constant Volume)

WMVAVCONTROLLER

(Constant Volume)

(1MEG)

WMVAVCONTROLLER

(Constant Volume)

Local Loop #1

Local Loop #2

VAVBOX

CONTROLLER - TYP

AIRFLOW

CX4

CX3

CX8

RN1

U3

U4

U8

PJ3

R34

R18

P.U.

D5

R27

CX9

U9

R1

C13

C9

R2

R3

EPROM

C8

U5

C14

R22

D6

P.U.

VREF

ADJ

P.U.

C10

X1

R32

R23

C1

T'STAT

R28

R24

C2

U11

R19

R20

C11

C15

R4

CX5

R33

EWDOG

R5

R25

D7

ADDRESS

R6

R8

ADD

R7

COMM

CX10

PJ1

OFF

U6

1

2

485

DR

4

CX6

U10

C3

SW1

V

8

16

32

POWER

C4

TOKEN

C5

PJ2

R100

NET

R26

R14

R13

SCAN

REC

V1

YS101562REV.3

D4

R21

R9

R35

R12

R11

C6

Q2

L1

V3

D1

D3

VR1

OI

C7

R15

24VAC

7824

Q3

U7

R16

R17

D2

GND

V2

C16

AIRFLOW

CX4

CX3

CX8

RN1

U3

U4

U8

PJ3

R34

R18

P.U.

D5

R27

CX9

U9

R1

C13

C9

R2

R3

EPROM

C8

U5

C14

R22

D6

P.U.

VREF

ADJ

P.U.

C10

X1

R32

R23

C1

T'STAT

R28

R24

C2

U11

R19

R20

C11

C15

R4

CX5

R33

EWDOG

R5

R25

D7

ADDRESS

R6

R8

ADD

R7

COMM

CX10

PJ1

OFF

U6

1

2

485

DR

4

CX6

U10

C3

SW1

V

8

16

32

POWER

C4

TOKEN

C5

PJ2

R100

NET

R26

R14

R13

SCAN

REC

V1

YS101562REV.3

D4

R21

R9

R35

R12

R11

C6

Q2

L1

V3

D1

D3

VR1

OI

C7

R15

24VAC

7824

Q3

U7

R16

R17

D2

GND

V2

C16

RV1

EF

CX3

VR

U3

U4

X2

C

4

R

LED1

LED2

EPROM

POWER

C7

R26

R25

V1

27

R

THERM

4-20mA

U12

0-10V

31

R

C

D

N

D4

G

24VA

C11

D5

TB2

TB1

LOCAL LOOP

VAVBOX

CONTROLLER - TYP

AIRFLOW

CX4

CX8

RN1

U3

U4

U8

PJ3

R34

R18

P.U.

D5

R27

CX9

U9

C13

C9

EPROM

C8

U5

C14

R22

D6

P.U.

VREF

ADJ

P.U.

C10

R32

R23

T'STAT

R28

R24

U11

R19

R20

C11

C15

R33

EWDOG

R25

D7

ADDRESS

ADD

COMM

CX10

OFF

U6

1

2

485

DR

4

CX6

U10

SW1

V

8

16

32

POWER

TOKEN

C5

R100

NET

R26

R14

R13

SCAN

REC

YS101562REV.3

D4

R21

R35

R12

R11

C6

Q2

L1

V3

D3

VR1

OI

C7

R15

24VAC

7824

Q3

U7

R16

R17

GND

C16

CX1

U1

0

PAL

Q1

CX2

U2

EXPANSION

ACTUATOR

K1

K2

CX1

U1

0

PAL

Q1

CX2

U2

EXPANSION

ACTUATOR

K1

K2

MINILINK PD

YS101818P552

CX4

PROCESSORPBOARD

C1

CX5

U5

1

1

R

C3

U2

RAM

X2

C

C8

PROC.

DRIVER

15

AIN1

AIN2

X13

CX

C

THERM

15

4-20mA

U

0-10V

LD6

OFF=0-5V

LOCALLOOP

1

2

D

N

P4

+5V

G

T

AIN

AIN

CX3

CX1

U1

PAL

R1

R2

Q1

R3

CX2

X1

C1

U2

C2

R4

CX5

R5

R6

R8

R7

PJ1

EXPANSION

C3

C4

PJ2

ACTUATOR

V1

R9

K1

D1

K2

D2

V2

1

1

NETWORK LOOP

U1

CX7

U7

1

P1

CX

C4

X1

C2

6

X

C

U6

PHILIPS

U10

YS101900PMINILINK

1

D

POLLING

U1

DEVICE

REV.1

U6

CX1

CX6

RN2

U11

R2

WDOG

4

R2

C9

RN3

LD4

LOOP

NETWORK

DRIVER

DRIVER

14

X2

CX

3

4

R28

P

13

U1

U

R29

R30

LD5

NETWORK

D

LOOP

L

LD

4

1

2

8

32

16

H

R

R

SH

T

S

P5

3

DD

4

A

B

OFF

TB

T

SW1

1

0

(1MEG)

AIRFLOW

CX4

CX3

CX1

CX8

RN1

U3

U4

U8

U1

PJ3

R34

R18

0

PAL

P.U.

D5

R27

CX9

U9

R1

C13

C9

R2

Q1

R3

EPROM

C8

U5

C14

CX2

R22

D6

P.U.

VREF

ADJ

P.U.

C10

X1

R32

R23

C1

U2

T'STAT

R28

R24

C2

U11

R19

R20

C11

C15

R4

CX5

R33

EWDOG

R5

R25

D7

ADDRESS

R6

R8

ADD

R7

COMM

CX10

PJ1

OFF

U6

1

EXPANSION

2

485

DR

4

CX6

U10

C3

SW1

V

8

16

32

POWER

C4

TOKEN

C5

PJ2

R100

NET

R26

ACTUATOR

R14

R13

SCAN

REC

V1

YS101562REV.3

D4

R21

R9

R35

K1

R12

R11

C6

Q2

L1

V3

D1

D3

VR1

OI

K2

C7

R15

24VAC

7824

Q3

U7

R16

R17

D2

GND

V2

C16

AIRFLOW

CX4

CX3

CX1

CX8

RN1

U3

U4

U8

U1

PJ3

R34

1

R18

P.U.

D5

R27

CX9

U9

C13

C9

EPROM

C8

U5

C14

R22

D6

P.U.

VREF

ADJ

P.U.

C10

R32

R23

T'STAT

R28

R24

U11

R19

R20

C11

C15

R33

EWDOG

R25

D7

ADDRESS

ADD

COMM

CX10

OFF

U6

1

2

485

DR

4

CX6

U10

SW1

V

8

16

32

POWER

TOKEN

C5

R100

NET

R26

R14

R13

SCAN

REC

YS101562REV.3

D4

R21

R35

R12

R11

C6

L1

V3

D3

VR1

OI

C7

R15

24VAC

7824

U7

R16

R17

GND

C16

1

0

PAL

R1

R2

Q1

R3

CX2

X1

C1

U2

C2

R4

CX5

R5

R6

R8

R7

PJ1

EXPANSION

C3

C4

PJ2

ACTUATOR

V1

R9

K1

Q2

D1

K2

Q3

D2

V2

ADD-ON DEVICE

AIRFLOW

CX4

CX3

CX1

CX8

RN1

U3

U4

U8

U1

PJ3

R34

R18

0

PAL

P.U.

D5

R27

CX9

U9

R1

C13

C9

R2

Q1

R3

EPROM

C8

U5

C14

CX2

R22

D6

P.U.

VREF

ADJ

P.U.

C10

X1

R32

R23

C1

U2

T'STAT

R28

R24

C2

U11

R19

R20

C11

C15

R4

CX5

R33

EWDOG

R5

R25

D7

ADDRESS

R6

R8

ADD

R7

COMM

CX10

PJ1

OFF

U6

1

EXPANSION

2

485

DR

4

CX6

U10

C3

SW1

V

8

16

32

POWER

C4

TOKEN

C5

PJ2

R100

NET

R26

ACTUATOR

R14

R13

SCAN

REC

V1

YS101562REV.3

D4

R21

R9

R35

K1

R12

R11

C6

Q2

L1

V3

D1

D3

VR1

OI

K2

C7

R15

24VAC

7824

Q3

U7

R16

R17

D2

GND

V2

C16

1

C

3

R

X1

3

C

C10

AIRFLOW

CX4

CX3

CX1

CX8

RN1

U3

U4

U8

U1

PJ3

R34

R18

0 0

PAL

P.U.

D5

R27

CX9

U9

R1

C13

C9

R2

Q1

R3

EPROM

C8

U5

C14

CX2

R22

D6

P.U.

VREF

ADJ

P.U.

C10

X1

R32

R23

C1

U2

T'STAT

R28

R24

C2

U11

R19

R20

C11

C15

R4

CX5

R33

EWDOG

R5

R25

D7

ADDRESS

R6

R8

ADD

R7

COMM

CX10

PJ1

OFF

U6

1

EXPANSION

2

485

DR

4

CX6

U10

C3

SW1

V

8

16

32

POWER

C4

TOKEN

C5

PJ2

R100

NET

R26

ACTUATOR

R14

R13

SCAN

REC

V1

YS101562REV.3

D4

R21

R9

R35

K1

R12

R11

C6

Q2

L1

V3

D1

D3

VR1

OI

K2

C7

R15

24VAC

7824

Q3

U7

R16

R17

D2

GND

V2

C16

AIRFLOW

CX4

CX3

CX1

CX8

RN1

U3

U4

U8

U1

PJ3

R34

1

R18

P.U.

D5

R27

CX9

U9

C13

C9

C8

U5

C14

R22

D6

P.U.

VREF

ADJ

P.U.

C10

R32

R23

T'STAT

R28

R24

U11

R19

R20

C11

C15

R33

EWDOG

R25

D7

ADDRESS

ADD

COMM

CX10

OFF

U6

1

2

485

DR

4

U10

SW1

V

8

16

32

POWER

TOKEN

C5

NET

R26

R14

R13

SCAN

REC

YS101562REV.3

D4

R21

R35

R12

C6

L1

V3

D3

VR1

OI

C7

R15

24VAC

7824

U7

R16

R17

GND

C16

WMVAVCONTROLLER

(Variable Volume)

1

0

PAL

R1

R2

Q1

R3

EPROM

CX2

X1

C1

U2

C2

R4

CX5

R5

R6

R8

R7

PJ1

EXPANSION

CX6

C3

C4

PJ2

R100

ACTUATOR

V1

R9

K1

R11

Q2

D1

K2

Q3

D2

V2

WMVAVCONTROLLER

(Constant Volume)

(1MEG)

AIRFLOW

CX4

CX3

CX1

CX8

RN1

U3

U4

U8

U1

PJ3

R34

1 1

R18

0 0

PAL

P.U.

D5

R27

CX9

U9

R1

C13

C9

R2

Q1

R3

EPROM

C8

U5

C14

CX2

R22

D6

P.U.

VREF

ADJ

P.U.

C10

X1

R32

R23

C1

U2

T'STAT

R28

R24

C2

U11

R19

R20

C11

C15

R4

CX5

R33

EWDOG

R5

R25

D7

ADDRESS

R6

R8

ADD

R7

COMM

CX10

PJ1

OFF

U6

1

EXPANSION

2

485

DR

4

CX6

U10

C3

SW1

V

8

16

32

POWER

C4

TOKEN

C5

PJ2

R100

NET

R26

ACTUATOR

R14

R13

SCAN

REC

V1

YS101562REV.3

D4

R21

R9

R35

K1

R12

R11

C6

Q2

L1

V3

D1

D3

VR1

OI

K2

C7

R15

24VAC

7824

Q3

U7

R16

R17

D2

GND

V2

C16

AIRFLOW

CX4

CX3

CX1

CX8

RN1

U3

U4

U8

U1

PJ3

R34

1 1

R18

PAL

P.U.

D5

R27

CX9

U9

R1

C13

C9

R2

Q1

R3

EPROM

C8

U5

C14

CX2

R22

D6

P.U.

VREF

ADJ

P.U.

C10

X1

R32

R23

C1

U2

T'STAT

R28

R24

C2

U11

R19

R20

C11

C15

R4

CX5

R33

EWDOG

R5

R25

D7

ADDRESS

R6

R8

ADD

R7

COMM

CX10

PJ1

OFF

U6

1

EXPANSION

2

485

DR

4

CX6

U10

C3

SW1

V

8

16

32

POWER

C4

TOKEN

C5

PJ2

R100

NET

R26

ACTUATOR

R14

R13

SCAN

REC

V1

YS101562REV.3

D4

R21

R9

R35

K1

R12

R11

C6

Q2

L1

V3

D1

D3

VR1

OI

K2

C7

R15

24VAC

7824

Q3

U7

R16

R17

D2

GND

V2

C16

(1MEG)

(1MEG)

AIRFLOW

CX4

CX8

RN1

U4

U8

PJ3

R34

R18

P.U.

D5

R27

CX9

U9

C13

C9

C8

C14

R22

D6

P.U.

VREF

ADJ

P.U.

C10

R32

R23

T'STAT

R28

R24

U11

R19

R20

C11

C15

R33

EWDOG

R25

D7

ADDRESS

ADD

COMM

CX10

OFF

U6

1

2

485

DR

4

U10

SW1

V

8

16

32

POWER

TOKEN

NET

R26

R14

SCAN

REC

YS101562REV.3

D4

R21

R35

L1

V3

D3

VR1

OI

C7

24VAC

7824

U7

R16

R17

GND

C16

ADD-ON DEVICE

WMVAVCONTROLLER

(Constant Volume)

CX3

CX1

U3

U1

PAL

R1

R2

Q1

R3

EPROM

U5

CX2

X1

C1

U2

C2

R4

CX5

R5

R6

R8

R7

PJ1

EXPANSION

CX6

C3

C4

C5

PJ2

R100

ACTUATOR

R13

V1

R9

K1

R12

R11

C6

Q2

D1

K2

R15

Q3

D2

V2

(1MEG)

(1MEG)

(1MEG)

Typical Multiple Loop System With All Operators Interface Options

Systems

7

Page 8

Technical Guide

SHLD

T

LOOP

R

G

T

WMVAV Controller

R

485

Typical Terminal Blocks. All

Wiring To Be T To T, SHLD (G)

To SHLD (G)&RToR

Typical Single Loop Networked System

WHITE (T)

Note: A Modular System

Manager, A Modular Service

NEXT

UP

PREV

STATUS

Mode

Selection

(1MEG)

DRAIN WIRE (SHLD)

BLACK (R)

Tool Or A PC With Prism

Software Installed Can Be

Used To Program And

Configure TheWattMaster

P

CommLink

Front View of CommLink

CLEAR

DOWN

ENTER

ESC

SETPOINTS

SCHEDULES

Line Voltage

RED (24 VAC)

VAV System.

110 VA C To

RLINK

COM

LOOP

6

2

5

13

4

ALARMS

OVERRIDES

CONFIGURATION

24 VAC

(6 VA)

GREEN (GND)

BROWN (GND)

Connect To Modular

I/O Connectors

24 VAC

Power Pack

CONTROLS

STATUS

Back View of CommLink

9

-

MINUS

0

8

7

DEC

ON

BALANCE-TEST

Located On Back

Of The System Manager

GND

24V

R

G

T

(DCE)

COMPUTER

(DTE)

REMOTE LINK

TB1

ER

LOOP

Modular Service

24 VAC

(8 VA)

POW

485

Tool

Line Voltage

STATUS

SETPOINTS

UP

2

13

NEXT

PREV

SCHEDULES

6

5

4

Connect To Next

VAVBOX Controller

1 1

0 0

1

0

ALARMS

OVERRIDES

CLEAR

DOWN

ENTER

ESC

9

-

MINUS

0

8

7

DEC

Local Loop

Modular System Manager

MiniLink PD Loop 1

ACTUATOR

EXPANSION

U2

Q1

PAL

VAVBOX

Controller

U1

ACTUATOR

EXPANSION

U2

Q1

PAL

VAVBOX

Controller

U1

ACTUATOR

EXPANSION

U2

Q1

VAVBOX

Controller

PAL

U1

C

1

X

1

R

3

CX7

U7

C

X6

C

X1

U1

C4

P1

C2

X1

YS101818P552

PROCESSORPBOARD

C1

CX5

U5

CX4

U4

CX3

U3

C

X

2

RV1

R

4

V

R

E

F

24 VAC

V2

K2

R17

R16

D2

U7

Q3Q2

R15

7824

C7

D3

D1

K1

VR1

L1

R10

R12C6R11

SCAN

REC

R9

R21

LD2

LD1

V1

R14

R13

NET

PJ2

R100

C4

TOKEN

C5

POWER

LD3

32

16

8

C3

U10

CX6

SW1

4

75176

R8

2

U6

1

PJ1

R7

R6

R5

CX5

R4

C2C1

X1

CX2

R3

R2

R1

16L8

CX1

CX3

V2

V1

PJ2

PJ1

R7

R6

R5

CX5

R4

C2C1

X1

CX2

R3

R2

R1

16L8

CX1

CX3

V2

PJ2

PJ1

R7

R6

R5

R4

C2C1

X1

CX2

R3

R2

R1

16L8

CX1

CX3

C3

YS101900PMINILINK

POLLING

DEVICE

U6

U10

D

1

U1

PHILIPS

1

LED1

LED2

CX10

ADD

ADDRESS

U5

R25

EWDOG

C15

R20

C11

R19

U11

R24

R23

C10

P.U.

VREF

ADJ

2

R22

80C55

C14

C8

EPROM

RAM

C13

C9

U9

CX9

1

RN1

U8

U3

U4

CX8

CX4

R34

R18

K2

R17

D2

R16

U7

Q3Q2

R15

7824

C7

D3

D1

K1

VR1

L1

R12C6R11

R10

SCAN

REC

R9

R21

LD2

LD1

R14

R13

NET

R100

C4

TOKEN

C5

POWER

LD3

32

16

8

U10

C3

CX6

SW1

4

75176

R8

2

U6

1

CX10

ADD

ADDRESS

U5

R25

EWDOG

C15

R20

C11

R19

U11

R24

R23

C10

P.U.

VREF

ADJ

2

R22

80C55

C14

C8

EPROM

RAM

C13

C9

U9

CX9

1

RN1

U8

U3

U4

CX8

CX4

R34

R18

K2

R17

D2

R16

U7

Q3Q2

R15

7824

C7

D3

D1

K1

VR1

L1

R12C6R11

R10

SCAN

REC

R9

R21

LD2

LD1

V1

R14

R13

NET

R100

C4

TOKEN

C5

POWER

LD3

32

16

8

C3

U10

CX6

SW1

4

75176

R8

2

U6

1

CX10

ADD

ADDRESS

U5

R25

EWDOG

CX5

REV.1

U6

CX1

R

1

C15

R20

C11

R19

U11

R24

R23

C10

P.U.

VREF

ADJ

2

R22

80C55

C14

C8

EPROM

RAM

C13

C9

U9

CX9

U8

U3

U4

CX8

CX4

R34

R18

C10

R30X2R29

R28

32

U11

C9

16

8

4

2

RN2

1

RN3

P3

P5

R24

LD4

R

U

14

CX6

LD

SH

WDOG

T

NETWORK

DRIVER

C

X

14

NETWORK

LOOP

R2

U

13

LD5

R

LD

H

S

LOOP

DRIVER

C3

T

C

X

13

U

15

PROC.

DRIVER

U2

LOCALLOOP

C

X

15

LD6

P4

D

N

G

0-10V

THERM

4-20mA

C

X

2

2

IN

A

AIN2

1

AIN

RAM

OFF=0-5V

C8

+5V

AIN1

0-10V

THERM

4-20mA

R

27

C7

EPROM

D

N

G

U12

C

24VA

R

25

R

26

D

4

R

31

V1

POWER

24 VAC

(6 VA)

(6VA Min.)

GND

24VAC

V3

562REV 3

R35

YS101

D4

R26

R

SHLD

COMM

T

D7

GND

TMP

R28

T'STAT

R32

D5

GND

AUX2

AUX1

+VS

R27

AUX

D5

FLOW

GND

24VAC

V3

562REV 3

R35

YS101

D4

R26

R

SHLD

COMM

T

D7

GND

TMP

R28

T'STAT

R32

D5

GND

AUX2

AUX1

+VS

R27

AUX

D5

FLOW

GND

24VAC

V3

562REV 3

R35

YS101

D4

R26

R

SHLD

COMM

T

D7

GND

TMP

R28

T'STAT

R32

D5

GND

AUX2

AUX1

+VS

R27

AUX

D5

1

RN1

FLOW

OFF

SW1

AD

D

4

TB

3

TB

TB

2

C11

D5

TB

1

Line Voltage

24 VAC

(6VA Min.)

Line Voltage

24 VAC

(6VA Min.)

Line Voltage

Local

Network

JOB NAME

Local

B. Crews

DRAWN BY:

DESCRIPTION:

05/12/04

FILENAME

DATE:

VAV-Network-SingleLoop1B.CDR

PAGE

Network System - Single Loop

1of3

Wiring & Connection Diagram

omm ink

CLII

SERIAL#

Note: See Page 2 Of

This Drawing For

Optional Computer

And Remote Link

Connection Diagram.

Figure 1: T ypical Networked Single Loop System - Connections & Wiring

8

Systems

Page 9

Technical Guide

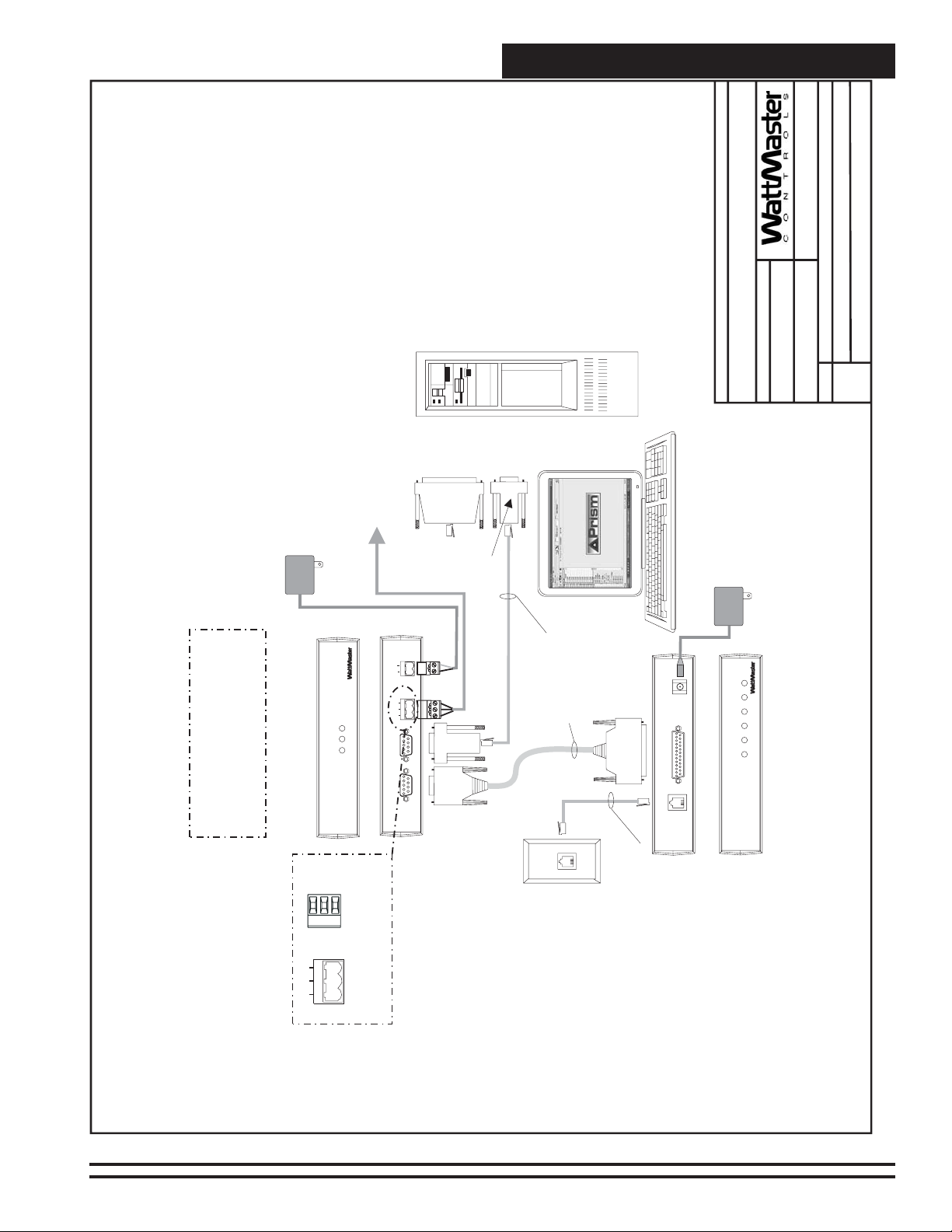

JOB NAME

FILENAME

B. Crews

DRAWN BY:

DESCRIPTION:

Wiring & Connection Diagram

Network System - Single Loop

03/24/04

DATE:

VAV-Network-SingleLoop1B.CDR

PAGE

2of3

Optional Computer Connection Diagram

Using Remote Link For Remote Connection

Note: If Direct Computer Connection

Is Required, Connect To PC As Shown.

Remote Link Is Only Required If

Alarm Callout Or Remote Computer

Connection Is Required.

110 VA C To

RLINK

COM

P

LOOP

CommLink

Front View of CommLink

omm ink

CLII

SHLD

T

R

LOOP

485

R

G

T

24 VAC

CONTROLS

STATUS

Typical Terminal Blocks. All

Power Pack

Connect To MiniLink PD Network Terminals

See Page 1 Of This Drawing

ER

W

GND

24V

OP

R

G

T

(DCE)

COMPUTER

(DTE)

Back View of CommLink

REMOTE LINK

SERIAL#

Wiring To Be T To T, SHLD (G)

To SHLD (G)&RToR

25 Pin

Female

9 Pin

(If Reqd)

Connector

Female

Connector

(By Others)

Personal Computer

Serial Port

PO

485 LO

Connect To Computer

9 Pin

Female

Connector

Assembly

8 Conductor

Modular Cable

Molded

25 Pin

Male End

POWER

500mA

9VDC @

Cable Assembly

SERIALDATA

LINE

TELCO

Back View of Remote Link

9 Pin

End

Female

Outlet

(By Others)

TELCO

SERIAL#

LINE

Cable

Assembly

Telephone

emote ink

RL

9 VDC

110 VA C To

Power Pack

PWR

CONTROLS

REC

SND

RDY

DET

SIG

(Optional)

Remote Link

Front View of Remote Link

Dedicated Telephone

Figure 2: Typical Networked Single Loop System - Connections & Wiring Using Computer & Remote Link

Systems

9

Page 10

Technical Guide

JOB NAME

B. Crews

DRAWN BY:

DESCRIPTION:

03/24/04

FILENAME

DATE:

VAV-Network-SingleLoop1B.CDR

PAGE

Network System - Single Loop

3of3

Wiring & Connection Diagram

Note: If Direct Computer Connection

Using IP-Link For Remote Connection

Optional Computer Connection Diagram

Is Required, Connect To PC As Shown. IP-Link Is

Only Required If E-mail Alarm Notification Or

Remote Computer Connection Is Required.

Connect To MiniLink PD Network Terminals

See Page 1 Of This Drawing

Note:

1.Set CommLink Internal Switch To”Multi”

2. Replace CommLink EPROM With IP-Link

EPROM Supplied With IP-Link Kit

110 VA C To

RLINK

COM

P

LOOP

CommLink

Front View of CommLink

omm ink

CLII

SHLD

T

R

LOOP

485

R

G

T

24 VAC

CONTROLS

STATUS

Typical Terminal Blocks. All

Power Pack

PO

ER

W

GND

24V

LOOP

485

R

G

T

(DCE)

COMPUTER

(DTE)

Back View of CommLink

REMOTE LINK

SERIAL#

Wiring To Be T To T, SHLD (G)

To SHLD (G)&RToR

25 Pin

Female

9 Pin

(If Reqd)

Connector

Serial Port

Connect To Computer

9 Pin

Female

End

Female

Cable Assembly

Connect Ethernet RJ45

9 Pin

Female

Connector

8 Conductor

Connector

(By Others)

On Ethernet Router

To 10 BaseT Connection

Assembly

Modular Cable

Or Modem

(By Others)

Molded

Supplied With

Cable Assembly

IP-Link Kit

9 Pin Male End

RJ45 Cable

Connect Ethernet

Port On IP-Link

Connect To Serial

9VDC

Serial

10BaseT

Assembly

On IP-Link

To 10BaseT Port

Mode

(By Others)

Personal Computer

ne

onnect

C

Back View of IP-Link

9 VDC

110 VA C To

Power Pack

PWR

R

E

S

V

C

R

LNK

T

C

A

IP-Link

(Optional)

Front View of IP- Link

Figure 3: T ypical Networked Single Loop System - Connections & Wiring Using Computer & IP-Link

10

Systems

Page 11

Technical Guide

SHLD

T

LOOP

R

G

T

R

485

Typical Terminal Blocks. All

Wiring To Be T To T, SHLD (G)

To SHLD (G)&RToR

Typical Multiple Loop Networked System

WMVAV Controller

WHITE (T)

Note: A Modular System Manager,

A Modular Service Tool Or A PC

With Prism Software Installed Can

NEXT

CLEAR

UP

DOWN

ENTER

ESC

PREV

STATUS

Mode

SETPOINTS

OVERRIDES

SCHEDULES

Selection

(1MEG)

Line Voltage

DRAIN WIRE (SHLD)

RED (24 VAC)

BLACK (R)

Be Used To Program And

Configure The WattMaster VAV

System.

110 VA C To

RLINK

COM

P

LOOP

CommLink

Front View of CommLink

6

2

5

13

4

ALARMS

CONFIGURATION

24 VAC

(6 VA)

GREEN (GND)

BROWN (GND)

Connect To Modular

I/O Connectors

24 VAC

Power Pack

CONTROLS

STATUS

Back View of CommLink

9

-

MINUS

0

8

7

DEC

ON

BALANCE-TEST

Located On Back

Of The System Manager

GND

24V

R

G

T

(DCE)

COMPUTER

(DTE)

REMOTE LINK

TB1

ER

LOOP

Modular Service

24 VAC

(8 VA)

POW

485

Tool

Line Voltage

STATUS

SETPOINTS

UP

2

13

NEXT

PREV

Connect To

SCHEDULES

6

5

4

Next VAVBOX

1

0

1

0

1

0

ALARMS

OVERRIDES

CLEAR

DOWN

ENTER

ESC

9

MINUS

0

8

7

DEC

Controller On

-

Loop 1

Modular System Manager

U1

MiniLink PD Loop 1

VAVBOX

VAVBOX

VAVBOX

CX7

U7

CX

1

P1

RV1

V2

K2

D2

Q3Q2

D1

K1

R10

R9

V1

ACTUATOR

PJ2

C4

C3

CX6

R8

EXPANSION

PJ1

R7

R6

R5

CX5

R4

C2C1

U2

X1

Q1

CX2

R3

EPROM

R2

R1

16L8

PAL

U1

U3

CX1

CX3

Controller

V2

K2

D2

D1

K1

R10

R9

V1

ACTUATOR

PJ2

C4

C3

R8

EXPANSION

PJ1

R7

R6

R5

CX5

R4

C2C1

U2

X1

Q1

CX2

R3

R2

R1

16L8

PAL

Controller

U1

U3

CX1

CX3

V2

K2

D2

D1

K1

R10

R9

V1

ACTUATOR

PJ2

C4

C3

R8

EXPANSION

PJ1

R7

R6

R5

CX5

R4

C2C1

U2

X1

Q1

CX2

R3

R2

R1

16L8

Controller

PAL

U1

U3

CX1

CX3

C

3

C1

X1

R3

YS101900PMINILINK

POLLING

DEVICE

REV.1

CX

6

RN2

U6

U10

D1

C4

U6

CX6

U1

C2

PHILIPS

X1

CX1

C3

YS101818P552

PROCESSORPBOARD

C1

1

R

1

U2

CX5

U5

CX4

U4

CX3

U3

C

X

2

R

4

V

R

E

F

LED1

LED2

24 VAC

24 VAC

(6VA Min.)

GND

R17

R16

U7

R15

R12C6R11

R13

R100

C5

24VAC

7824

C7

D3

VR1

V3

L1

562REV 3

SCAN

REC

R35

YS101

R21

LD2

LD1

D4

R14

R26

NET

TOKEN

POWER

LD3

32

R

16

SHLD

8

U10

SW1

4

75176

COMM

2

U6

U5

2

80C55

CX4

T

1

CX10

ADD

ADDRESS

D7

R25

EWDOG

C15

GND

R20

C11

R19

TMP

U11

R24

R28

T'STAT

R23

R32

C10

P.U.

VREF

ADJ

D5

R22

C14

C8

RAM

GND

C13

C9

U9

AUX2

CX9

AUX1

+VS

R27

AUX

D5

1

RN1

U8

U4

CX8

FLOW

R34

R18

Line Voltage

JOB NAME

B. Crews

DRAWN BY:

DESCRIPTION:

Network System - Multiple Loop

Wiring & Connection Diagram

05/12/04

24 VAC

Q3Q2

R15

D3

R12C6R11

R13

R100

C5

CX6

U6

2

80C55

EPROM

CX4

Q3Q2

R15

R12C6R11

R13

R100

C5

CX6

EPROM

CX4

24VAC

7824

C7

VR1

V3

L1

562REV 3

SCAN

REC

R35

YS101

R21

LD2

LD1

D4

R14

R26

NET

TOKEN

POWER

LD3

32

R

16

SHLD

8

U10

SW1

4

75176

COMM

2

T

1

CX10

ADD

ADDRESS

D7

U5

R25

EWDOG

C15

GND

R20

C11

R19

TMP

U11

R24

R28

T'STAT

R23

R32

C10

P.U.

VREF

ADJ

D5

R22

C14

C8

RAM

GND

C13

C9

U9

AUX2

CX9

AUX1

+VS

R27

AUX

D5

1

RN1

U8

U4

CX8

FLOW

R34

R18

GND

R17

R16

U7

24VAC

7824

C7

D3

VR1

V3

L1

562REV 3

SCAN

REC

R35

YS101

R21

LD2

LD1

D4

R14

R26

NET

TOKEN

POWER

LD3

32

R

16

SHLD

8

U10

SW1

4

75176

COMM

2

U6

2

80C55

T

1

CX10

ADD

ADDRESS

D7

U5

R25

EWDOG

C15

GND

R20

C11

R19

TMP

U11

R24

R28

T'STAT

R23

R32

C10

P.U.

VREF

ADJ

D5

R22

C14

C8

RAM

GND

C13

C9

U9

AUX2

CX9

AUX1

+VS

R27

AUX

D5

1

RN1

U8

U4

CX8

FLOW

R34

R18

24 VAC

Line Voltage

(6VA Min.)

Line Voltage

(6VA Min.)

GND

R17

R16

U7

FILENAME

DATE:

VAV-Network-MultLoop1B.CDR

Loop 3

MiniLink Polling Device

Connect To Loop 2

Connect To

1of3

PAGE

VAVBOX Controller

Or WMVAV Controller

Local

Local

C10

R30X2R29

R28

OFF

SW1

32

U11

C9

16

8

4

2

1

RN3

AD

D

P3

P5

R24

LD4

R

U14

LD

H

S

WDOG

T

NETWORK

DRIVER

C

X

14

4

TB

NETWORK

LOOP

R2

3

TB

U

13

LD5

R

LD

SH

LOOP

DRIVER

T

C

X13

U

15

PROC.

DRIVER

LOCALLOOP

C

X

15

LD6

P4

D

N

G

0-10V

THERM

4-20mA

C

X

2

2

IN

A

AIN2

1

AIN

RAM

OFF=0-5V

C8

+5V

AIN1

TB2

0-10V

THERM

4-20mA

R

27

C7

EPROM

D

U12

C

R

25

R

26

R

31

V

1

POWER

Network

C11

D5

N

G

24VA

TB1

D

4

Local

(6 VA)

C

3

C

1

X1

R

3

CX7

U7

C

X6

C

X

1

U1

U6

U10

C4

P1

C2

PHILIPS

X1

YS101818P552

PROCESSORPBOARD

C1

CX5

U5

CX4

U4

CX3

MiniLink PD Loop 2

U3

C

X

2

RV1

R

4

V

R

EF

LED1

YS101900PMINILINK

1

LED2

Network

C10

R30X2R29

R28

U11

C9

POLLING

DEVICE

REV.1

RN2

RN3

3

P

R

24

D

LD4

U6

U

14

CX6

U1

WDOG

NETWORK

DRIVER

C

X

14

NETWORK

R2

CX1

U

13

LD5

LOOP

DRIVER

C3

C

X13

U

15

1

PROC.

R

1

DRIVER

U2

LOCALLOOP

C

X15

LD6

0-10V

THERM

4-20mA

C

X

2

AIN2

RAM

OFF=0-5V

C8

AIN1

0-10V

THERM

4-20mA

R

27

C7

EPROM

U12

C

R

25

R

26

R

31

V1

POWER

Network

OFF

SW1

32

16

8

4

2

1

A

D

D

P5

R

LD

H

S

T

4

TB

LOOP

3

TB

R

LD

SH

T

P4

D

N

G

2

AIN

1

AIN

+5V

TB2

C11

D5

D

N

G

24VA

TB

1

D

4

omm ink

CLII

SERIAL#

Note: See Page 2 and

IP-LinkConnections

3 Of This Drawing For

Optional Computer To

Remote Link or

Figure 4: Typical Networked Multiple Loop System - Connections & Wiring

Systems

24 VAC

(6 VA)

11

Page 12

Technical Guide

JOB NAME

B. Crews

DRAWN BY:

DESCRIPTION:

03/24/04

FILENAME

DATE:

VAV-Network-MultLoop1B.CDR

PAGE

Network System - Multiple Loop

2of3

Wiring & Connection Diagram

Optional Computer Connection Diagram

Using Remote Link For Remote Connection

Note: If Direct Computer Connection

Is Required, Connect To PC As Shown.

Remote Link Is Only Required If

Alarm Callout Or Remote Computer

Connection Is Required.

110 VAC To

RLINK

COM

P

LOOP

CommLink

Front View of CommLink

omm ink

CLII

SHLD

T

R

LOOP

485

R

G

T

24 VAC

CONTROLS

STATUS

Typical Terminal Blocks. All

Power Pack

Connect To MiniLink PD Network Terminals

See Page 1 Of This Drawing

ER

GND

24V

LOO

P

R

G

T

(DCE)

COMPUTER

(DTE)

Back View of CommLink

REMOTE LINK

SERIAL#

Wiring To Be T To T, SHLD (G)

To SHLD (G)&RToR

25 Pin

Female

9 Pin

(If Reqd)

Connector

Female

Connector

(By Others)

Personal Computer

Serial Port

POW

485

Connect To Computer

9 Pin

Female

Connector

Assembly

8 Conductor

Modular Cable

Molded

25 Pin

Male End

POWER

500mA

9VDC @

Cable Assembly

SERIALDATA

LINE

TELCO

Back View of Remote Link

9 Pin

Female

End

Outlet

(By Others)

TELCO

SERIAL#

LINE

Cable

Assembly

Telephone

emote ink

RL

9 VDC

110 VAC To

Power Pack

PWR

CONTROLS

REC

SND

RDY

DET

SIG

(Optional)

Remote Link

Front View of Remote Link

Dedicated Telephone

Figure 5: Typical Networked Multiple Loop System - Connections & Wiring Using Computer & Remote Link

12

Systems

Page 13

Technical Guide

JOB NAME

FILENAME

B. Crews

DRAWN BY:

DESCRIPTION:

Wiring & Connection Diagram

Network System - Multiple Loop

03/24/04

DATE:

VAV-Network-MultLoop1B.CDR

PAGE

3of3

Note: If Direct Computer Connection

Using IP-Link For Remote Connection

Optional Computer Connection Diagram

Is Required, Connect To PC As Shown. IP-Link Is

Only Required If E-mail Alarm Notification Or

Remote Computer Connection Is Required.

Connect To MiniLink PD Network Terminals

See Page 1 Of This Drawing

Note:

1.Set CommLink Internal Switch To”Multi”

2. Replace CommLink EPROM With IP-Link

EPROM Supplied With IP-Link Kit

110 VAC To

RLINK

COM

P

LOOP

CommLink

Front View of CommLink

omm ink

CLII

SHLD

T

R

LOOP

485

R

G

T

24 VAC

CONTROLS

STATUS

Typical Terminal Blocks. All

Power Pack

ER

W

GND

24V

R

G

T

(DCE)

COMPUTER

(DTE)

Back View of CommLink

REMOTE LINK

SERIAL#

Wiring To Be T To T, SHLD (G)

To SHLD (G)&RToR