Page 1

www.wattmaster.com

VAVBOX Contr oller

Technical Guide

Page 2

Table Of Contents

Controller Overview ........................................................................................................................................ 3

Features...................................................................................................................................................................................... 3

Controller Inputs and Outputs ........................................................................................................................ 5

General ....................................................................................................................................................................................... 5

VAVBOX Controller Analog Inputs:............................................................................................................................................. 5

Other Controller Connections ..................................................................................................................................................... 5

Optional - Expansion Board Outputs .......................................................................................................................................... 5

Controller Installation & Wiring ...................................................................................................................... 6

Important Wiring Considerations ................................................................................................................................................ 6

General ....................................................................................................................................................................................... 7

Controller Mounting .................................................................................................................................................................... 7

Transformer Sizing & Wiring ....................................................................................................................................................... 7

Expansion Board Installation & Wiring .......................................................................................................... 8

Wiring Considerations ................................................................................................................................................................ 8

Start-up & Commissioning ............................................................................................................................10

General ..................................................................................................................................................................................... 10

Controller Addressing ............................................................................................................................................................... 10

Power Wiring .............................................................................................................................................................................11

Initialization ................................................................................................................................................................................11

Programming The Controller .................................................................................................................................................... 12

Sequence Of Operations ............................................................................................................................... 13

Initialization ............................................................................................................................................................................... 13

VAVBOX Configuration & Setup............................................................................................................................................... 13

Scheduling ................................................................................................................................................................................ 14

Modes Of Operation ................................................................................................................................................................. 14

Damper Positions ..................................................................................................................................................................... 15

Occupied Mode Sequences ..................................................................................................................................................... 15

Unoccupied Mode Sequences .................................................................................................................................................. 16

Damper Control ........................................................................................................................................................................ 18

Tenant Override Logs ............................................................................................................................................................... 19

Alarm Detection And Reporting ................................................................................................................................................ 19

Internal Trend Logging.............................................................................................................................................................. 19

Force Modes or Overrides ........................................................................................................................................................ 20

Troubleshooting ............................................................................................................................................ 21

Using LED’s To Verify Operation .............................................................................................................................................. 21

Other Checks............................................................................................................................................................................ 22

WattMaster Controls Inc.

8500 NW River Park Drive · Parkville , MO 64152

Toll Free Phone: 866-918-1100

PH: (816) 505-1100 · FAX: (816) 505-1101 · E-mail: mail@wattmaster.com

Visit our web site at www.wattmaster.com

Form: WM-VAVBOX-TGD-01C Copyright 2006 WattMaster Controls, Inc.

WattMaster Controls, Inc. assumes no responsibility for errors, or omissions.

This document is subject to change without notice.

Page 3

Controller Over view

Technical Guide

Features

VAVBOX Controller

This manual applies to the VAVBOX controller that is included in the

following W attMaster products:

MG742-VAV Pressure Dependent VAVBOX Kit For

Terminal Units w/oFan Electric or Hot

Water Heat

MG744-VAV Pressure Independent VAVBOX Kit For

Terminal Units w/oFan Electric or Hot

Water Heat

MG742-03-VAV Pressure Dependent VAVBOX Kit For

Terminal Units or Fan Terminal Units

With Electric or Hot Water Heat

MG744-03-VAV Pressure Independent VAVBOX Kit For

Terminal Units or Fan Terminal Units

With Electric or Hot Water Heat

The VAVBOX Controller is used for controlling airflow and operation

of VAV terminal units. It is a programmable digital controller, which

allows for program setpoints to be stored in non-volatile memory. The

controller is connected to a room sensor which monitors space temperature allowing the VAVBOX controller to modulate a damper in response to space temperature, duct temperature and airflow requirements

in the controlled space.

The VAVBOX controller is provided with two relays for tri-state control of the damper actuator. All outputs and the relay common are electrically isolated from all other circuitry on the board. All relay outputs

are supplied with transient suppression devices across each set of contacts to reduce EMI and arcing. The relay output contacts are rated for

pilot duty control of a maximum of 2 Amps @ 24 VAC or 24 VDC.

The actuator connects via a modular cable to the board and provides the

VAVBOX controller with feedback monitoring for precise positioning

of the actuator.

OE322 Output Expansion Board

The OE322, 3 Relay with Analog Output Expansion board is used in

conjunction with the VAVBOX Controller board to allow for control

of VAV terminal units, including series and parallel fan terminal units

with up to 2 stages of electric heat or modulating hot water heat. The

OE322, 3 Relay with Analog Output Expansion board provides 3

relay outputs for pilot duty switching control, and 1 Analog output for

control of a 0-10 V modulating hot water valve.

The OE322 Output Expansion board connects to the VAVBOX

controller board by means of a modular cable provided with the

expansion board. Power is supplied to the board by means of this

modular cable. Screw terminals are provided for connection of field

wiring to the relay and analog outputs.

The relay outputs are N.O. contacts with one common terminal. All

outputs and the relay common are electrically isolated from all other

circuitry on the board. All relay outputs are supplied with transient

suppression devices across each set of contacts to reduce EMI and

arcing. The relay output contacts are rated for pilot duty control of a

maximum of 2 Amps @ 24 VAC or 24 VDC. The analog output provides

a 0 – 10 VDC modulating signal output into a 1K ohm minimum load.

The VAVBOX controller has three integral modular jacks for connection to the actuator, airflow sensor (for pressure independent applications), and relay or analog expansion boards, via modular cables. The

controller has an on-board dip switch provided for board addressing.

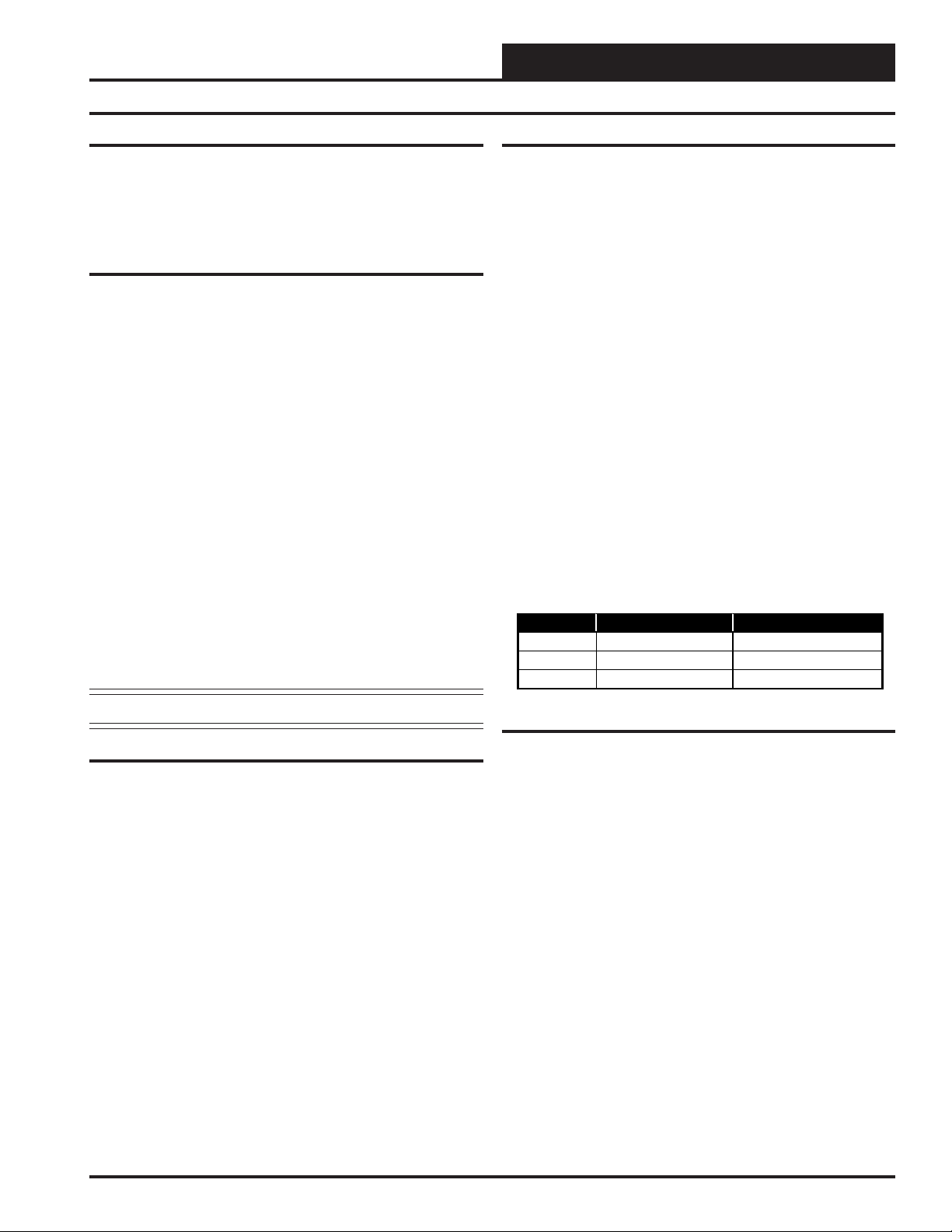

562 REV 3

YS101

R35

R26

D4

LD3

POWER

R21

L1

SCAN

LD2

REC

C6

R12

R11

R10

TOKEN

32

NET

16

LD1

R14

R13

C5

R100

R9

C4

V1

PJ2

ACTUATOR

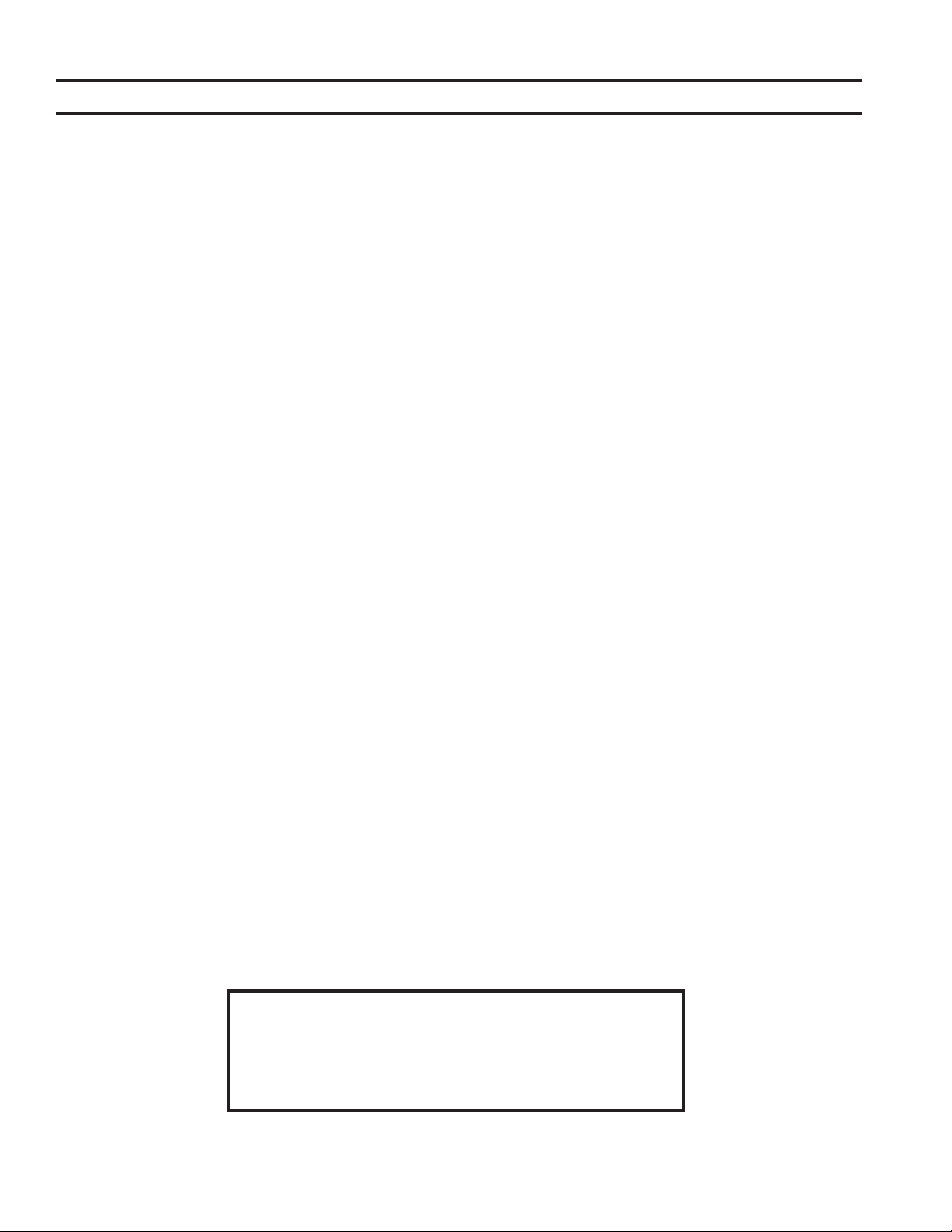

4.00”

GND

V2

24VAC

R17

R16

U7

Q3Q2

D2

K2

7824

R15

V3

VR1

C7

D3

D1

K1

7.00"

AUX2

AUX1

AUX

+VS

GND

TMP

T'S TAT

D7

COMM

CX10

75176

U10

SW1

ADDRESS

ADD

2

4

8

1

U6

CX6

R8

C3

PJ1

R6

R7

EXPANSION

R28

R25

C15

U11

R24

C11

R20

EWDOG

R19

U5

CX5

R5

C2C1

R4

U2

GND

R32

D5

ADJ

C14

VREF

R23

P.U.

R22

C10

RAM

C8

EPROM

X1

R2

R3

CX2

Q1

D5

FLOW

R27

C13

CX9

U9

C9

R1

16L8

1

RN1

U8

CX8

R34

R18

U4

CX4

U3

CX3

CX1

U1

PAL

Figure 1: V AVBOX Controller Dimensions

V A VBO X Controller 3

Page 4

Technical Guide

Controller Over view

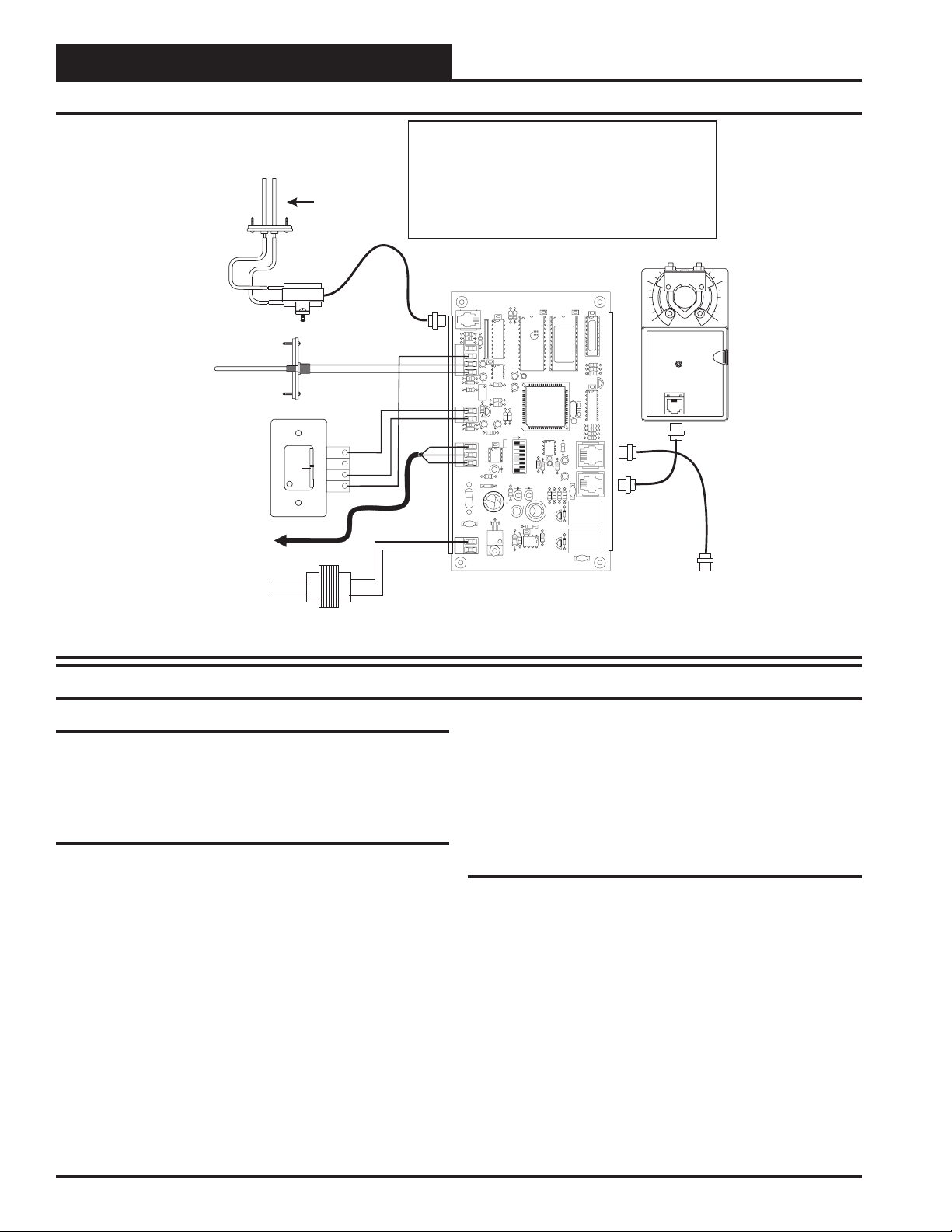

Figure 2: OE322 Output Expansion Boards

Air Flow Sensor

Modular Connector

Auxiliary

Wiring

Terminals

Room

Sensor Wiring

Terminals

Address Switch

(SetBetween1&58)

Communication

Wiring

Terminals

Communications

Driver Chip

Power LED

24 VAC Power

Terminals

Typical

Pin 1

Indicator

FLOW

D5

AUX

+VS

AUX1

AUX2

GND

D5

R32

T'S TAT

TMP

GND

T

SHLD

R

YS101

R35

562 REV 3

V3

24VAC

GND

RAM

Chip

R34

CX8

U8

RN1

1

R27

CX9

U9

C13

C14

R22

ADJ

VREF

P.U.

R23

R28

R24

U11

R19

C11

R20

C15

EWDOG

R25

D7

COMM

R26

D4

CX10

75176

ADDRESS

SW1

U10

LD3

POWER

R21

L1

VR1

7824

EPROM

Chip

R18

CX4

U4

C9

RAM

C8

C10

U5

ADD

1

U6

2

4

8

16

32

TOKEN

NET

R14

LD2

LD1

REC

SCAN

C7

U7

R16

R17

80C55

2

D3

U3

EPROM

R8

CX6

C5

C4

R100

R13

R9

R10

R12C6R11

Q2

K1

D1

R15

Q3

D2

PAL

Chip

CX3

CX1

U1

PAL

16L8

R1

R2

R3

CX2

X1

CX5

PJ1

C3

PJ2

V1

K2

V2

U2

C2C1

R4

R5

R6

R7

Q1

EXPANSION

ACTUATOR

Damper Actuator

Positioning Relay

“Open”

Damper Actuator

Positioning Relay

“Close”

Snap Track

For Controller

Mounting

Expansion Board

Modular Connector

Damper Actuator

Modular Connector

Figure 3: V AVBOX Controller Component Locations

4

“REC” LED

“SCAN” LED

V A VBO X Controller

Page 5

Controller Inputs and Outputs

Technical Guide

General

The following inputs and outputs are available on the VAVBOX controller and the OE322 Output Expansion Board that can be added by

connecting it to the main controller board expansion port. For component locations of the inputs on the VAVBOX Controller see Figure 3.

For wiring of inputs and outputs see Figure 4 thru 9.

V AVBOX Controller Analog Inputs:

Input #1: Space Temperature Sensor

The Room Sensor that reads space temperature is attached the TMP and

GND terminals. If the Room Sensor with slide adjust option is used a

third wire connects to terminal AUX1.

Input #2: Airflow Sensor

If the VA VBOX Controller is to be configured for pressure independent

operation, you need to install the OE274 Airflow Sensor and connect

the modular plug from the pressure sensor to this input. The pressure

signal from the Airflow Sensor is used for CFM (airflow) calculations.

If an OE274 Airflow Sensor is attached to this input, the VAVBOX

controller will automatically detect this and switch to pressure independent operation. If the sensor is not attached or becomes defective, the

controller automatically reverts to pressure dependent operation.

Input #3: Supply Air Temperature Sensor

The optional Supply Air Temperature Sensor is connected to terminals

AUX2 and GND when it is used. If it is to be used as a Supply Air

Sensor , it should be mounted in the supply duct close to the terminal

unit where the VA VBOX controller is installed. This sensor can be used

for monitoring purposes or in place of the Supply Air T emperature Broadcast from the WMVAV Controller.

Note: All temperature sensors must be Thermistor Type III.

Optional - OE322 Expansion Board

As previously stated when control of a fan or if heating is required the

OE322 Output Expansion board must be used.

Relay Output #1 - Fan Enable

The first expansion relay on the Output Expansion boards is used for

enabling the fan for Series or Parallel Fan Terminal Units.

Relay Output #2 - Stage 1 Heating

If you have at least one stage of auxiliary heating, this is the relay used

to energize the 1st stage of terminal unit heating. This heating stage can

either be used with electric heat or On/Off hot water valve control.

Relay Output #3 - Stage 2 Heating

If you have two stages of auxiliary heating, this relay controls the 2nd

stage of electric heat. For 3 stage heating, this relay output would be

energized for both the 2nd and 3rd stage of heat. See the following

section for more information regarding 3 stage heating applications.

3 Stage Heating Applications

If three stages of electric heat are configured, relays #2 and #3 will

stage in a staggered sequence. This allows you to achieve 3 stages of

heating using only relays #2 and #3. Each of the 3 heating elements

should be sized for 1/3 of the total KW output required. Both the 2nd

and 3rd stage heating contactors (C2 & C3) must be connected to Relay

Output #3. See Table 1 for relay sequencing information.

Stag e No. Relay Output #2 Relay Output #3

#1 ON (C1) OFF (C2 & C3)

#2 OFF (C1) ON (C2 & C3)

#3 ON (C1) ON (C2 & C3)

Table 1: Relay Sequencing For 3 Stage Heating

Other Controller Connections

Expansion Board Modular Connector

This modular connector is used to connect the optional OE322 Output

Expansion Board to the VAVBOX controller. These boards are only

required when electric or hot water heating and/or fan terminal control

is required. The expansion boards are not required for cooling only

terminal units.

Actuator Modular Connector

This modular connector is used to connect a modular cable from the

VAVBOX controller to a tri-state actuator.

V A VBO X Controller

24 VDC Power Terminals (+V & GND)

These terminals can supply 24 Volts DC for a 24 VDC hot water valve

actuator if desired. This output is rated at 12 Watts maximum load.

Analog Output

If you are using hot water or steam heating via a modulating steam or

hot water valve, this output can supply a 0-10 Volts DC signal for proportional control of the valve.

5

Page 6

Technical Guide

Hi

Lo

Controller Inputs and Outputs

Airflow Probe & Sensor

(For Pressure Independent Applications Only)

Airflow

Duct Supply

Or Discharge

Temperature

Sensor

(See Note 2)

Connection To AUX

Terminal Is Only Required

When Sensor Is Specified

With Slide Adjust Option

Connect To Next VAVBOX

Controller Or WMVAV

Controller On Local

Communications Loop

Line Voltage

Locate In Supply Or

Discharge Duct

Near Zone Damper

Room Sensor

W

A

R

M

E

R

C

O

O

OVR

L

E

R

TMP

GND

AUX

Notes:

1.) All wiring to be in accordance with local and national electrical codes

and specifications.

2.) A Duct SupplyAir Temperature Sensor is not required when the VAVBOX

Controller is connected to an WMVAV Unit Controller board. A global Supply

Air temperature is broadcast by the WMVAV Unit Controller. The Supply Air

Temperature Sensor is required if the VAVBOX Controller is required to

operate as a “Stand Alone” controller. The Duct Sensor can also be placed on

the discharge side of the VAVBOX duct and used as a Discharge

Temperature Sensor to monitor VAVBOX discharge air temperature if desired.

This is normally used only if the VAV Terminal unit has heating capabilties.

Zone Actuator

R34

R18

CX4

CX3

CX8

U4

U8

RN1

1

R27

CX9

U9

C13

C9

RAM

C8

C14

ADJ

VREF

R28

U11

C15

R25

D7

CX10

COMM

R26

D4

80C55

R22

2

P.U.

C10

R23

R24

R19

C11

R20

EWDOG

U5

ADDRESS

ADD

1

U6

2

75176

4

SW1

U10

8

16

32

LD3

POWER

TOKEN

NET

R14

LD2

LD1

R21

REC

SCAN

L1

VR1

D3

C7

7824

U7

R16

R17

CX1

U3

U1

PAL

16L8

R1

R2

EPROM

R3

CX2

Q1

X1

C1

U2

C2

R4

CX5

R5

R6

R7

PJ1

EXPANSION

R8

CX6

C3

C5

C4

R100

PJ2

R13

R12C6R11

R10

Q2

R15

Q3

ACTUATOR

V1

R9

K1

D1

D2

K2

V2

To Optional Relay

Expansion Board

SHLD

24VAC

GND

AUX1

AUX2

GND

TMP

GND

FLOW

D5

AUX

+VS

AUX1

AUX2

GND

D5

R32

T'STAT

TMP

GND

T

R

YS101

R35

562REV 3

V3

24VAC

GND

10

24 VAC Transformer

Size For 6 VA

Maximum Load

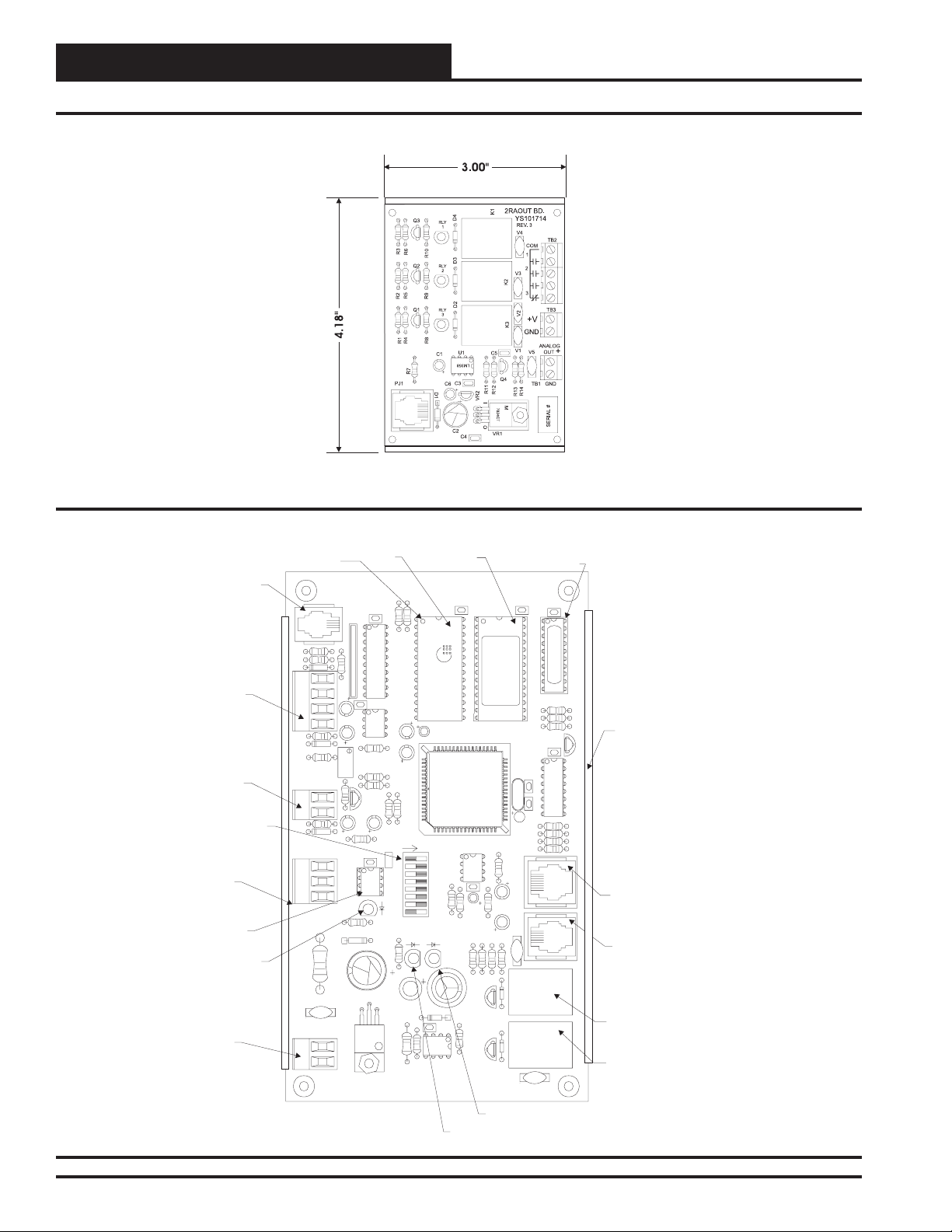

Figure 4: V AVBOX Controller Wiring

Controller Installation & Wiring

General

Correct wiring of the VAVBOX controller is the most important factor

in the overall success of the controller installation process. The VA VBOX

controller wiring has been simplified by the use of modular connectors

and prefabricated modular cables.

Controller Mounting

If the Round Zone Dampers were purchased from W attMaster , the controller and actuator are factory mounted and wired in the damper control enclosure. If your VAVBOX controllers are pressure independent,

an airflow probe and pressure sensor will also be factory mounted and

wired.

Most terminal unit manufacturers will offer the option of factory mounting the WattMaster controls in their terminal units for an additional

charge. An installation worksheet and instructions are available for the

WattMaster VAVBOX controller package which can be shipped with

the VAVBOX control(s) to the terminal unit manufacturer to simplify

third party factory mounting and wiring of the controller.

When the VAVBOX controller is to be field mounted, it is important to

mount the controller in a location that is free from extreme high or low

temperatures, moisture, dust and dirt. The VAVBOX controller board

must be mounted within 10” of the damper actuator in order for the

actuator cable to extend between the controller and the actuator.

Be careful not to damage the electronic components when mounting

the controller. Remove the controller from its snap track mount. Mark

the control enclosure base using the snap track as a template. Drill pilot

holes in the enclosure base and secure the snap track to it using sheet

metal screws. Do not allow metal shavings to fall onto the circuit board.

Reattach the controller to the snap track. Mount the damper actuator to

the damper shaft following the instructions supplied with the damper

actuator.

Important Wiring Considerations

Please carefully read and apply the following information when wiring

the WMVAV controller. See Figure 4 for VAVBOX controller wiring

diagram.

1. Size and wire the transformer per the instructions. Failure

to size the transformer and/or wire the transformer

correctly may cause the VAVBOX controllers to not

operate erratically or not at all. See Figure 5 for wiring

and transformer sizing information.

2. If a Duct Sensor is to be connected, the minimum

wire size used should be 24 gauge.

3. Do not pry on the connectors when connecting or

disconnecting the modular cables. Be sure to push in on the

connector release clip and then pull straight up.

6

V A VBO X Controller

Page 7

Technical Guide

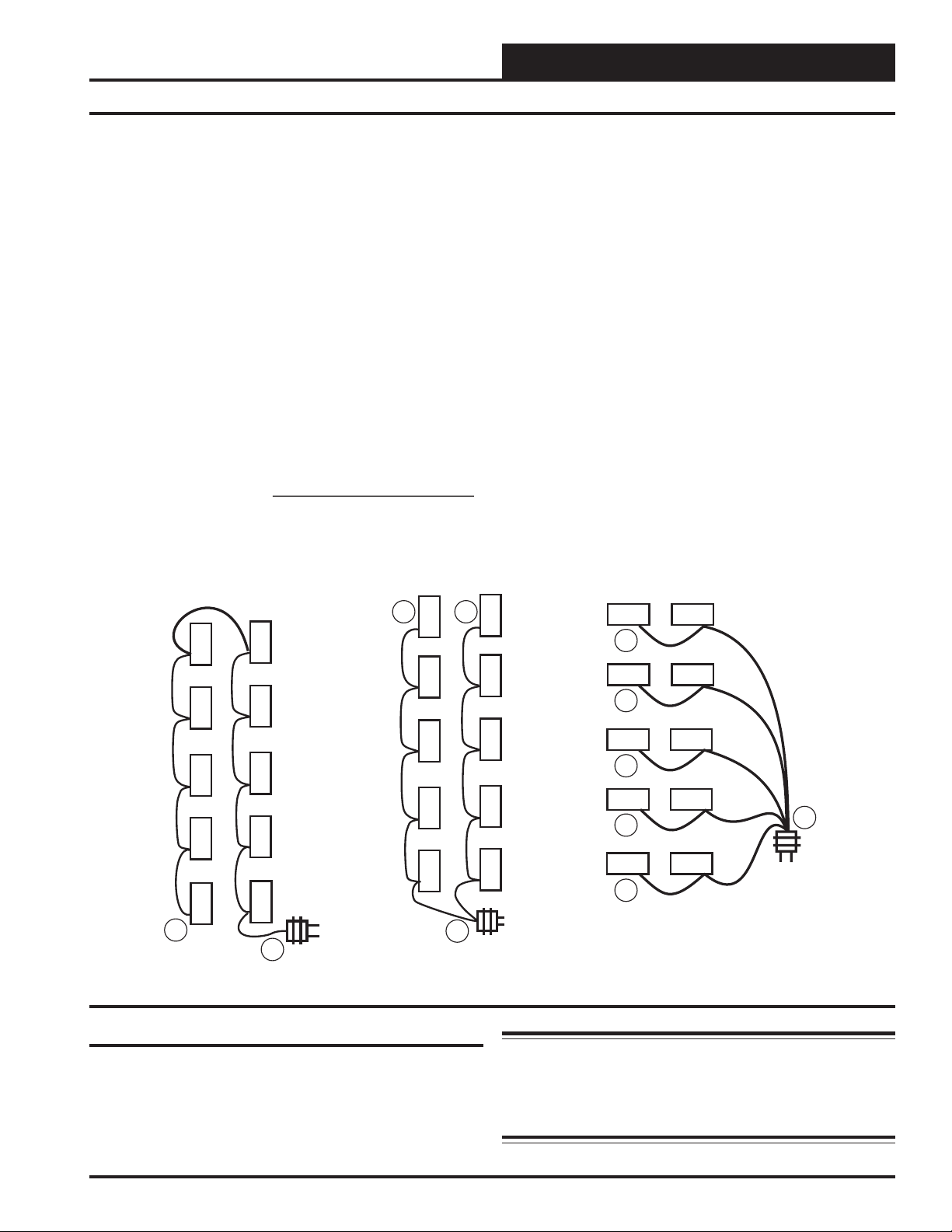

Some installers like to use one large 24VAC transformer to power several devices. This is allowable as long as polarity is maintained to each device on

the transformer circuit.

using a separate transformer for each device in order to eliminate the potential for damaging controllers due to incorrect polarity.

separate transformers also allows redundancy in case of a transformer failure. Instead of having 8 controllers inoperative because of a malfunctioning

transformer you have only 1 controller off line. If the installer does decide to use a large transformer to supply power to several devices, the following

transformer and wire sizing information is presented to help the installer correctly supply 24VAC power to the devices.

Following is a typical example to help the installer to correctly evaluate transformer and wiring designs.

Each VAVBOX Controller requires 6 VA @ 24VAC power. In the examples below we have a total of 10 VAV Controllers.

10 VAVBOX Controllers @ 6VA each................ 10 x 6VA =60VA.

The above calculation determines that our transformer will need to be sized for a minimum of 60VA if we are to use one transformer to power all the

controllers. We will use a 75 VA transformer, as this is a readily available size that meets our VA load requirements.

Next we must determine the maximum length of run allowable for the wire gauge we wish to use in the installation. Each wire gauge below has a

voltage drop per foot value we use to calculate total voltage drop.

18ga wire.................................0.00054 = voltage drop per 1’ length of wire

16ga wire.................................0.00034 = voltage drop per 1’ length of wire

14ga wire.................................0.00021 = voltage drop per 1’ length of wire

For our example we will use 18 gauge wire. WattMaster recommends 18 gauge as a minimum wire size for all power wiring.

Next use the voltage drop per foot value for 18 gauge wire from the list above and multiply by the total VA load of the 10 controllers to be installed.

0.00054 (Voltage drop per foot for 18 gauge wire) x 60VA controller load = Volts/Ft.

WattMaster VAVBOX controllers will operate efficiently with a voltage drop no greater than 2 Volts. Divide the total allowable voltage drop of 2 Volts by

the number you arrived at above and you have the maximum number of feet you can run the 18 gauge wire with an 75 VA transformer with no more

thana2Voltdropatthefarthest controller from the transformer..

Parallel circuiting of the wiring instead of wiring all 10 controllers in series allows for longer wire runs to be used with the same size wire (as shown in

our examples below).

transformer size, multiple transformers, circuiting, etc., when laying out an installation. No matter what layout scheme is decided upon, it is mandatory

that the farthest controller on the circuit is supplied with a minimum of 22 Volts and that the polarity is maintained to all controllers connected to the

transformer.

Warning:

It is often necessary for the installer to calculate and weigh the cost and installation advantages and disadvantages of wire size,

If polarity is not maintained, severe damage to the devices may result. WattMaster Controls recommends

0.0324

2 (Volts total allowable voltage drop)

0.0324 (Voltage drop per 1 ft. @ 60VA load)

= 61.73

feet

Using

24VAC Power - Transformer & Wire Sizing Considerations For VAVBOX Controllers

BC

B

A

120 / 24VAC

Distance A to B cannot exceed 61.73 Ft.

Distance from A to B cannot exceed 123.46 Ft.

Distance from A to C cannot exceed 123.46 Ft.

A

Figure 5: WMVAV Controller Transformer Sizing

Transformer Sizing & Wiring

Each VAVBOX controller requires 6 VA minimum at 24 VAC in order

to function properly. Wiring and transformer information shown above

is provided to help correctly size and layout wiring schemes for the

VAVBOX controllers. As stated above, all wiring should be 18 Ga.

minimum. Long runs may require heavier gauge wire to keep the voltage drop within the 2 volt maximum range. Please follow these guidelines.

V A VBO X Controller

F

E

D

C

120 / 24VAC

B

120 / 24VAC

Distance from A to B cannot exceed 230.40 Ft.

Distance from A to C cannot exceed 308.64 Ft.

Distance from A to D cannot exceed 308.64 Ft.

Distance from A to E cannot exceed 308.64 Ft.

Distance from A to F cannot exceed 308.64 Ft.

Warning: If polarity between controllers is not maintained,

severe damage to the controllers may result.

W attMaster recommends using a separate transformer

for each controller in order to eliminate the potential

for damaging controllers due to incorrect polarity.

A

7

Page 8

Technical Guide

Expansion Board Installation & Wiring

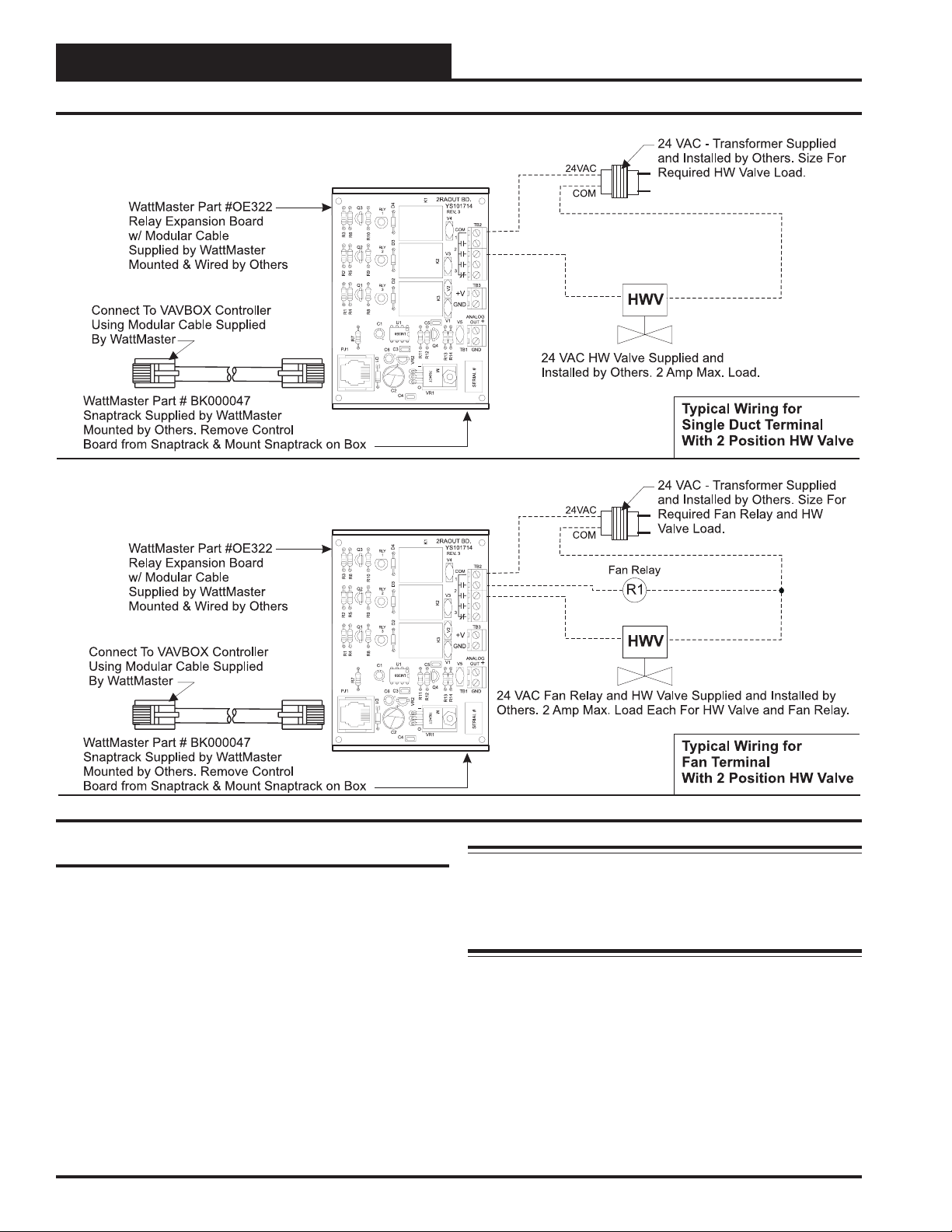

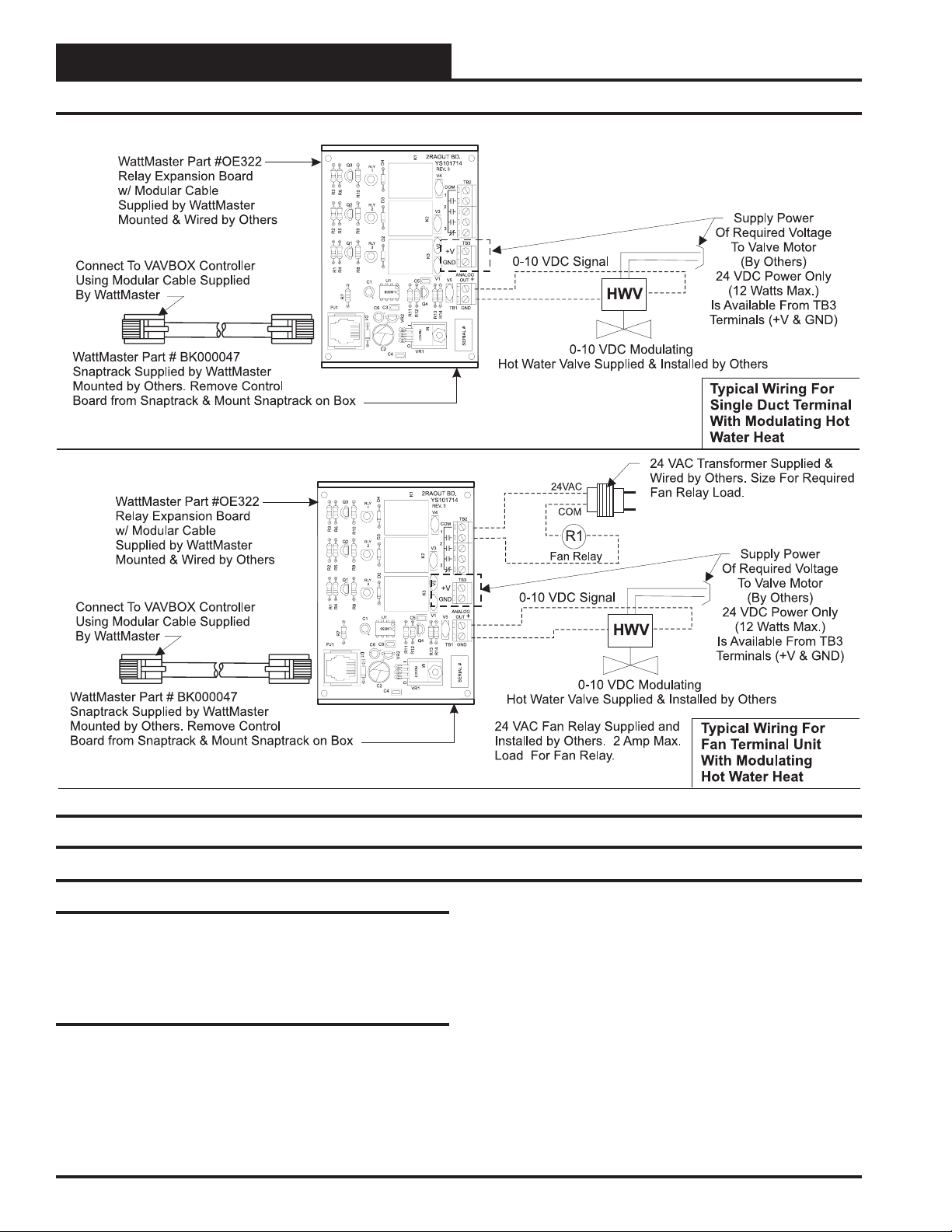

Figure 6: Expansion Board Wiring For Two Position Hot Water Heat Applications

Wiring Considerations

Warning: The 3 relay outputs available on the OE322

Expansion boards are used to supply extra relays and/or analog outputs

to control fan and heating functions for the VAVBOX controller.

When Round VAVBOX Dampers or Rectangular VAVBOX Controller

Kits are ordered from W attMaster, the OE322 Expansion board is shipped

loose for field mounting by others.

Mounting of the OE322 Expansion Board is identical to the previously

described mounting for the VAVBOX controller. Mount the Expansion

board near the VAVBOX controller using the sheet metal screws provided. Be sure the mounting location is close enough so that the supplied modular cable will reach from the VAVBOX controller to the

Expansion board.

The wiring consideration information previously outlined for the

VAVBOX controller should be followed when wiring the OE322 Expansion Boards.

Output Expansion board are each rated for 2 Amps

@ 24 VAC. If your device load exceeds these limits,

a pilot duty relay (by others) must be used in the

circuit.

8

V A VBO X Controller

Page 9

Expansion Board Installation & Wiring

Technical Guide

WattMaster Part #OE322

Relay Expansion Board

R3

w/ Modular Cable

R6

Supplied by WattMaster

Mounted by Others

Connect To VAVBOX Controller

Using Modular Cable Supplied

By WattMaster

PJ1

WattMaster Part # BK000047

Snaptrack Supplied by WattMaster

Mounted by Others. Remove Control

Board from Snaptrack & Mount Snaptrack on Box

WattMaster Part #OE322

Relay Expansion Board

R3

w/ Modular Cable

R6

Supplied by WattMaster

Mounted by Others

Connect To VAVBOX Controller

Using Modular Cable Supplied

By WattMaster

PJ1

WattMaster Part # BK000047

Snaptrack Supplied by WattMaster

Mounted by Others. Remove Control

Board from Snaptrack & Mount Snaptrack on Box

24VAC

2RAOUT BD.

K1

D4

Q3

RLY

1

R10

D3

RLY

Q2

2

R9R5R2

D2

Q1

RLY

3

R8R4R1

U1

C1

R7

C3

C6

D1

C2

C4

YS101714

REV.3

V4

TB2

COM

1

2

V3

K2

3

TB3

V2

+V

K3

GND

ANALOG

V1

OUTV5

C5

LM358

Q4

R11

R12

VR2

I

7824CT

O

VR1

+

Note: 3 Stage Heating is Attained by Sizing All 3

TB1 GND

R14

R13

M

Heating Elements For Equal KW Output. Each

Element Should be Sized for 1/3 of the Total KW

Output Required. To Achieve 3 Stage Heating the

System would be Configured to Energize

SERIAL #

Contactor C1 for First Stage Heat. For 2nd Stage

Heat the System Would be Configured to Deenergize Contactor C1 and Energize Contactor C2

& C3. For 3rd Stage Heat the System Would be

Configured to Leave Contactor C2 & C3 Energized

and also Energize Contactor C1.

COM

C1

C2

C3

& Wired by Others. Size For

Required Contactor(s) Load.

1st Stage Heat Contactor

2nd Stage Heat Contactor

3rd Stage Heat Contactor

24 VAC Contactor(s)

Supplied & Installed

By Others. 2 Amp

Max. Load Each.

Typical Wiring for

Single Duct Terminal

with Electric Heat

24 VAC Transformer Supplied

24VAC

2RAOUT BD.

K1

D4

Q3

RLY

1

R10

D3

RLY

Q2

2

R9R5R2

D2

Q1

RLY

3

R8R4R1

U1

C1

R7

C3

C6

D1

C2

C4

YS101714

REV.3

V4

TB2

COM

1

2

V3

K2

3

TB3

V2

+V

K3

GND

ANALOG

V1

OUTV5

C5

LM358

Q4

R11

R12

VR2

I

7824CT

O

VR1

+

TB1 GND

R14

R13

M

SERIAL #

COM

Fan Relay

24 VAC Fan Relay

Supplied & Installed

By Others. 2 Amp

Max. Load.

24 VAC Transformer Supplied

& Wired by Others. Size For

Required Fan Relay Load.

R1

Typical Wiring for

Fan Terminal Unit

with Cooling Only

2RAOUT BD.

K1

WattMaster Part #OE322

Relay Expansion Board

w/ Modular Cable

Supplied by WattMaster

Mounted & Wired by Others

Connect To VAVBOX Controller

Using Modular Cable Supplied

By WattMaster

WattMaster Part # BK000047

Snaptrack Supplied by WattMaster

D4

Q3

RLY

1

R3

R6

R10

D3

RLY

Q2

2

R9R5R2

D2

Q1

RLY

3

R8R4R1

U1

C1

R7

PJ1

C3

C6

D1

C2

C4

YS101714

REV.3

V4

TB2

COM

1

2

V3

K2

3

TB3

V2

+V

K3

GND

ANALOG

V1

OUTV5

C5

LM358

Q4

R11

R12

VR2

I

7824CT

O

VR1

+

Note: 3 Stage Heating is Attained by Sizing All 3 Heating

Elements For Equal KW Output. Each Element Should be

TB1 GND

Sized for 1/3 of the Total KW Output Required. To Achieve 3

R14

R13

M

Stage Heating the System would be Configured to Energize

Contactor C1 for First Stage Heat. For 2nd Stage Heat the

System Would be Configured to De-energize Contactor C1

SERIAL #

and Energize Contactor C2 & C3. For 3rd Stage Heat the

System Would be Configured to Leave Contactor C2 & C3

Energized and also Energize Contactor C1.

Mounted by Others. Remove Control

Board from Snaptrack & Mount Snaptrack on Box

Figure 7: Expansion Board Wiring For Electric Heat Applications

V A VBO X Controller

24VAC

COM

C3

Fan Relay

R1

C1

C2

24 VAC Transformer Supplied &

Wired by Others. Size For Required

Fan Relay & Contactor(s) Load.

24 VAC Fan

Relay &

1st Stage Heat Contactor

2nd Stage Heat Contactor

3rd Stage Heat Contactor

Contactor(s)

Supplied &

Installed By

Others. 2

Amp Max.

Load Each.

Typical Wiring for

Fan Terminal Unit

with Electric Heat

9

Page 10

Technical Guide

Figure 8: Expansion Board Wiring For Modulating Hot Water Heat Applications

Star t-up & Commissioning

General

In order to have a trouble free start-up it is important to follow a few

simple procedures. Before applying power for the first time it is very

important to correctly address the controller and run through a few simple

checks.

Controller Addressing

All VAVBOX controllers are equipped with address switches. If the

VAVBOX controller is to operate as a Stand Alone controller (not connected to any other HVAC unit or VAVBOX controllers) the controller

address switch should be set for address 1. When the VAVBOX con-

10

troller is to be connected to other controllers on a communication loop,

each VAVBOX controllers address switch must be set with a unique

address between 1 and 58.

When programming the VA VBOX controller and asked to enter the Unit

ID you would first enter the MiniLink loop address for the loop the

controller is connected to and then enter the VAVBOX controllers address. See Figure 10 for a diagram depicting address switch settings.

V A VBO X Controller

Page 11

Star t-up & Commissioning

Technical Guide

32

TOKEN

NET

Address Switch Shown Is

Set For Address 9

ADD

SW1

ADD

1

2

4

8

16

Controller

Address Switch

The Address For Each Controller

Must Be Between 1 And 58 And Be

Unique To The Other Controllers

On The Local Loop

1

2

4

8

16

32

TOKEN

NET

NET

Address Switch Shown Is

Set For Address 13

TOKEN

VAVBOX Controller Board

R34

FLOW

RN1

1

D5

AUX

R27

+VS

AUX1

AUX2

ADD

1

2

4

8

16

32

GND

TMP

GND

SHLD

YS101

562 REV 3

C13

D5

ADJ

R32

T'STAT

R28

C15

R25

D7

T

COMM

R

R26

D4

R35

V3

24VAC

GND

R18

C9

C10

R19

ADDRESS

SCAN

R16

R17

CX4

U4

RAM

C8

80C55

2

U5

ADD

1

U6

2

4

8

16

32

TOKEN

NET

R14

LD2

LD1

REC

D3

C7

U7

CX8

U8

CX9

U9

C14

R22

VREF

P.U .

R23

R24

U11

C11

R20

EWDOG

CX10

75176

SW1

U10

LD3

POWER

R21

L1

VR1

7824

CX3

CX1

U3

EPROM

CX5

R8

CX6

C3

C5

C4

R100

R13

V1

R9

R10

R12C6R11

Q2

K1

D1

R15

Q3

D2

K2

U1

PAL

16L8

R1

R2

R3

CX2

X1

Q1

U2

C2C1

R4

R5

R6

R7

PJ1

PJ2

V2

EXPANSION

ACTUATOR

Figure 9: Address Switch Setting

For detailed information regarding communication wiring and connection for Interconnected and Networked systems, please see the WattMaster WMVAV System Installation & Troubleshooting Guide.

Power Wiring

One of the most important checks to make before powering up the system for the first time, is to confirm proper voltage and transformer

sizing for the VAVBOX boards that are connected to it. Each V AVBOX

controller requires 6 VA of power delivered to it at 24 VAC. See page

7 of this manual for complete wiring and transformer sizing information for the VAVBOX controller.

Check all connections to be sure they are tight with no loose wire starnds

hanging loose. Confirm that all sensors required for your system are

mounted in the appropriate location and wired correctly to the VA VBOX

controller. Check the actuator cable and be sure it is plugged in and

secured to the modular connector on the actuator and the VAVBOX

controller board modular connector. Be sure any expansion boards connected to the VAVBOX controller are also correctly wired per the expansion board wiring instructions on pages 8 through 102 of this manual.

After all the above wiring checks are complete, apply power to the first

VAVBOX on the loop, that is connected to the WMVAV controller.

Initialization

Upon applying power to the VAVBOX controller the following should

occur:

On system power-up, the SCAN LED is extinguished for a few seconds

and then the controller “flashes” its address switch setting. If the address switch were set to 7, you would see 7 flashes. After the address is

finished, the LED will extinguish for another 5 seconds. At the conclusion of this 5-second delay, the LED will begin a continuous flashing

while the Damper Feedback limits are calibrated. If the Damper is driving open, the LED will blink slowly. If the Damper is driving closed,

the LED will blink fast. When the calibration is completed, the normal

diagnostic flashes will commence. These diagnostic flashes are described

later in this document. In addition, during the first few seconds of powerup, all default setpoints are initialized and all outputs are turned off.

a 30 second start-up delay to protect the fan and other components

from short cycling during intermittent power conditions. If all inputs

are operating correctly it will blink once every ten seconds.

V A VBO X Controller

11

Page 12

Technical Guide

Programming The Controller

The next step is programming the controller for your specific requirements. In order to configure and program the VAVBOX controller you

must have a central operators interface or a personal computer with the

Prism computer front end software installed. Two different operators

interfaces are available for programming of the VAVBOX controller.

You may use either the Modular Service Tool or the Modular System

Manager to access the status and setpoints of any VA VBOX controller

or WMVAV controller on the systems communications loop. See the

Operators Interface T echnical Guide for VAVBOX controller programming information. If you are going to use a personal computer and the

Prism computer front end software, please see the WattMaster Prism

Computer Front End Operations Manual. No matter which operators

interface you use, it is recommended that you proceed with the programming and setup of the controller in the order that follows:

1. Configure The Controller For Your Application

2. Program The Controller Setpoints.

3. Review Controller Status Screens To Verify System

Operation And Correct Controller Configuration

Mode

Selection

STATUS

SETPOINTS

SCHEDULES

OVERRIDES

ALARMS

CONFIGURATION

BALANCE - TEST

ON

PREV

UP

DOWN

ESC

ENTER

13

2

5

4

708

DEC

Figure 10: Operators Interfaces

CLEAR

6

9

MINUS

-

NEXT

13

2

MINUS

-

PREV

6

9

4

708

DEC

5

System Manager

UP

NEXT

DOWN

ENTER

CLEAR

ESC

STATUS

SETPOINTS

SCHEDULES

OVERRIDES

ALARMS

12

V A VBO X Controller

Page 13

Sequence Of Operations

Technical Guide

Initialization

On system power-up, the SCAN LED is extinguished for a few seconds

and then the controller “flashes” its address switch setting. If the address switch were set to 7, you would see 7 flashes. After the address is

finished, the LED will extinguish for another 5 seconds. At the conclusion of this 5 second delay, the LED will begin a continuous flashing

while the Damper Feedback limits are calibrated. If the Damper is driving open, the LED will blink slowly. If the Damper is driving closed,

the LED will blink fast. When the calibration is completed, the normal

diagnostic flashes will commence. These diagnostic flashes are described

later in this document.

V AVBOX Configuration & Setup

There are a few configuration selections available to the user, which

can be used to tailor the software operation to match the mechanical

equipment this controller is installed on. These are programmed using

either the Modular System Manager, Modular Service Tool or a personal computer with Prism computer front end software installed. See

the Operator Interfaces Technical Guide or the Prism Computer Front

End Software manual for specific programming information.

General

Several options are available to configure the VAVBOX controller for

the appropriate equipment it is installed on. All of these options can be

set from the “Configuration” menu with the exception of “AHU Heat

Call” which is set from the “Setpoints” menu. Again, please refer to the

Operators Interface Technical Guide or the Prism Computer Front End

Software manual for detailed programming information.

Box Control Method

Set this configuration item for the type of box the VAVBOX controller

is used on. The options available are:

0 = Cooling Only Box (With Reheat if Required)

1 = Heating/Cooling Changeover Box

2 = Series Fan Powered Box With Reheat

3 = Parallel Fan Powered Box With Reheat

Damper Operating Mode

This allows the user to set the direction of rotation the damper moves

when driving towards its full open position. The options available are:

0 = Direct Acting (Clockwise To Open Damper)

1 = Reverse Acting (Counterclockwise To Open Damper)

Pressure Independent Boxes - Airflow @ 1” W .C.

If this is a pressure independent box, this option allows you to calibrate

the box CFM correctly using the box manufacturers “K” factor. Enter

the correct “K” (CFM) factor for the inlet diameter of the box you are

configuring.

Options available are:

0 = No Staging

1 = 1 Stage of Reheat

2 = 2 Stages of Reheat

3 = 3 Stages of Reheat

Proportional Heating Signal

If the box has hot water reheat using a proportional hot water valve, set

this option to match the voltage signal required by the hot water valve

you are using. Options available are:

0 = 0-10 VDC Voltage Signal

1 = 2-10 VDC Voltage Signal

Allow Box Hea t With AHU Heat

If the box you are using has reheat, configuring this setting to 1=Yes

will allow the box heat to operate at the same time as the HVAC unit

heat. Options available are:

0 = No

1 = Yes

Main Fan Status

If the VAVBOX controller is installed on a non-fan powered box that

has reheat set this option to “Yes” in order to enable box reheat only

when the HVAC unit fan is running. A full description of how this

setting affects the various box types in the occupied and unoccupied

modes is contained under the “Mode Sequence” heading that follows

later in this manual. Options available are:

0 = No Heat can operate without fan

1 = Yes Heat cannot operate without fan

Push Button Override Group ID#

During Unoccupied Mode, all VA VBOX controllers with a corresponding Group ID# will resume Occupied operation whenever any of the

VAVBOX controllers with the same Group ID # has it’s push-button

depressed to initiate an override condition. This allows you to group

zones in various areas of the building. For example, individual tenants

with several offices could restore occupied mode for just their zones

and not affect other zones in the building. If you don’t want a specific

zone to be a part of any group, enter a ‘0’ for its Group ID #.

Dump Zone

If this VAVBOX controller is to be used as a “Dump Zone” set this

configuration to 1=Yes. The dump zone is a controller without an actuator that is used to control a duct heater or auxiliary heat. Options

available are:

0 = No

1 = Yes

Expansion Relays - Steps of Reheat

If the box has reheat supplied by an electric coil, this option must be set

for the number of electric heating stages on the box. If the box has hot

water heat with a 2 position hot water valve, set the number of stages to

“1”. For hot water heat with a proportional hot water valve this must be

set for “0”.

V A VBO X Controller

AHU Heat Call

This setting is located under the “Setpoints” menu on screen #3. This is

used only for the unoccupied mode. This temperature setpoint is used

to allow auxiliary heat such as baseboard heaters to be energized in an

attempt to satisfy the heating demand prior to initiating the HVAC unit

Supply Air Heating mode.

13

Page 14

Technical Guide

Sequence Of Operations

During unoccupied mode when the temperature in the space drops below the AHU Heat Call setpoint the VA VBOX controller sends a signal

to the WMVA V controller to initiate the HVAC unit Supply Air Heating

Mode. This setpoint temperature can be set higher or lower than the

Space Heating setpoint.

Scheduling

Occupied/Unoccupied Mode

The VAVBOX Controller monitors the communications loop for its

Occupied and Unoccupied mode of operation command. Either the

WMVAV Controller or a special Optimal Start Scheduling device can

transmit the Occupied command to the VAVBOX Controller. This requires the VAVBOX Controllers to all be connected to the system communication loop through their RS-485 connector and to be properly

addressed for the command to be received.

Push-button Override Operation

During unoccupied hours, the user can force the VAVBOX Controller

and WMVAV Controller back to occupied operation by pressing the

override button for a period of time less than 3 seconds. This initiates

the override or resets the override timer back to zero during unoccupied

hours of operation.

During Override operations, the user can cancel the override by pressing the override button for a period of time between 3 seconds and 10

seconds. This restores the normal unoccupied operation.

On larger installations with several terminal units, the VAVBOX Controllers can be configured into groups so that an override generated by

one VAVBOX Controller can cause several other controllers to follow

along and return to occupied mode for the programmed duration. Other

VAVBOX Controllers not in the same group will simply maintain an

unoccupied damper or airflow setting as set by the user.

Push-button overrides are broadcast continuously by the initiating

VA VBOX Controller until the controller itself times out or the override

is cancelled by the user. This broadcast forces the air handler to start its

main fan and provide cooling or heating, if so configured. It will remain

on until the override broadcast has not been detected for at least 2 consecutive minutes.

Modes Of Operation

General

There are 7 possible modes of operation for the HVAC Unit and the

VAVBOX controller. These modes are determined by the supply air

and/or space demand conditions. They are:

• Supply Air V ent Mode

(Based on HVAC Unit SAT)

• Space Vent Mode

(Based on VAVBOX Controller Space Temp.)

• Supply Air Cooling Mode

(Based on HVAC Unit SAT)

• Space Cooling Mode

(Based on VAVBOX Controller Space Temp.)

• Supply Air Heating Mode

(Based on HVAC Unit SAT)

• Space Heating Mode

(Based on VAVBOX Controller Space Temp.)

• Off Mode (Not displayed. See definition below)

The process of determining each mode is discussed below, but the actual operation of each mode is explained in the section that follows.

Definitions Of Modes

VAVBOX Control Schemes

On all fan-powered and non-fan-powered terminal units, supply air

modes and space demands are calculated the same. If the supply air

rises 1 ºF above the cooling setpoint, the supply air mode is heating. T o

cancel the supply air heating mode, the supply air temperature must fall

below the cooling setpoint. If the supply air falls 1 ºF below the heating

setpoint, the supply air mode is cooling. To cancel the supply air cooling mode, the supply air temperature must rise above the heating setpoint.

If the supply air is between the heating and cooling setpoints, it is considered vent mode.

Supply Air V ent Mode

This mode occurs when the Supply Air Temperature is between the

heating and cooling setpoints.

Space Vent Mode

This mode occurs when the Space T emperature is between 0.5 °F below the Cooling Setpoint and 0.5 °F above the Heating Setpoint.

Supply Air Cooling Mode

This mode occurs when the Supply Air Temperature falls to 1.0 °F

below the Space Heating Setpoint.

Space Cooling Mode

This mode occurs when the Space Temperature rises to 0.5 °F below

the Space Cooling Setpoint.

Supply Air Heating Mode

This mode occurs when the Supply Air Temperature rises to 1.0 °F

above the Space Cooling Setpoint.

Space Heating Mode

This mode occurs when the Space Temperature falls to 0.5 °F above

the Space Heating Setpoint.

Off Mode

During unoccupied mode, the mode is considered “OFF” if the space

temperature does not generate a heating mode or cooling mode based

on the unoccupied heating & cooling setpoints.

14

V A VBO X Controller

Page 15

Technical Guide

Damper Positions

The actual values for the minimum damper positions that are described

in the following paragraphs can be user configured by changing the

values in setpoint screens 5, 6 and 7 for the VA VBOX controller . These

minimums are expressed in damper open percentages for pressure dependent terminal units or in CFM for pressure independent terminal

units.

Cooling Minimum

When the HVAC unit is in the Supply Air Cooling mode but the space

does not require cooling, the VAVBOX damper will go to the Cooling

Minimum position.

Heating Minimum

When the HVAC unit is in the Supply Air Heating mode but the space

does not require Heating, the VAVBOX damper will go to the Heating

Minimum position.

Vent Minimum

This is the position the VA VBOX damper will move to when the HVAC

unit is in the Supply Air Vent mode.

Nite/Reheat Minimum

This setpoint has two different functions depending on whether the

HVAC unit is in Occupied or Unoccupied mode.

Occupied Mode

If the VAVBOX controller is used on a non-fan-powered terminal unit

that has reheat, the VAVBOX damper will move to the Nite/Reheat

position whenever a Space Heating demand occurs and the HVAC unit

is in Supply Air Cooling or Vent modes. When the HVAC unit is in

Supply Air Heating mode the VAVBOX damper will modulate as required to maintain the Space Heating setpoint.

Unoccupied Mode

When using non-fan powered terminal units, the VA VBOX damper will

position itself in the Nite/Reheat minimum position. In order for fan

powered terminal units to position the damper to the Nite/Reheat minimum position, the check for main fan status must be selected and the

HVAC unit fan must be operating.

Occupied Mode Sequences

Space Vent Mode

This mode only applies to the Occupied Mode of operation. If the equipment is in the Unoccupied Mode, then a lack of heating or cooling

demand would generate the Off Mode.

If the HVAC unit is in Supply Air Vent Mode, the user can adjust the

damper position on pressure dependent terminal units and the airflow

on pressure independent terminal units to provide a fixed amount of

ventilation air into the space when there are no heating or cooling demands. During this time, the damper does not modulate on pressure

dependent terminal units. On pressure independent terminal units, it

only modulates to the extent required to maintain the vent minimum

airflow setting.

If the VAVBOX Controller detects that the HV AC unit is in Supply Air

Heating mode, indicating that the air handler has activated its heat, the

heating airflow minimum will be substituted for the vent minimum position.

If the VAVBOX Controller detects that the HV AC unit is in Supply Air

Cooling mode, indicating that the air handler has activated its cooling,

the cooling airflow minimum will be substituted for the vent minimum

position.

.

Space Cooling Mode

Occupied Space Cooling mode is initiated by the temperature in the

space rising to within 0.5 ºF of the Occupied Cooling Setpoint.

If the HVAC unit is in the Supply Air Heating and another VAVBOX

controller has a cooling demand, the damper/airflow for the VAVBOX

controller requiring cooling will position itself to provide the heating

minimum setpoint amount of air into the space. No modulation open

will occur because the space does not want the warm air currently being

supplied by the air handler.

When the HVAC unit is in the Supply Air Cooling mode, the damper is

normally held at the minimum cooling position until the space temperature begins to rise above the cooling setpoint. As the space temperature

rises to within 0.5 ºF of the Occupied Cooling Setpoint, the damper/

airflow calculation causes the air valve to open proportionally until the

maximum setpoint is achieved at 3.5 ºF above the setpoint. This is a 4

ºF proportional window starting 0.5 ºF below the cooling setpoint to

3.5 ºF above the cooling setpoint.

The damper/airflow is never allowed to modulate outside the user adjusted minimum setpoint and the maximum setpoint. The maximum

damper/airflow setpoint applies to heating and cooling modes of operation only. All of the modes have their own individual minimum setting.

Series Flow Fan Terminals

If the VAVBOX Controller has been configured as a Series Fan Powered terminal unit, the series fan relay will activate and run the series

box fan continuously anytime the HVAC unit fan is running.

In all cases, before the series box fan can be activated, the air damper is

driven fully closed and held that way for 30 seconds to make sure the

series box fan hasn’t inadvertently started to spin backwards. Once the

series box fan starts, it waits an additional 10 seconds to allow the fan

to spin up before it starts to open the damper and introduce airflow from

the HVAC unit fan.

Parallel Flow Fan Terminals

During normal cooling or vent mode and adequate air supply, the parallel fan will be off. During the occupied cooling mode the fan will only

activate if the damper/airflow is below a user defined low limit setting.

This causes it to be used as a make-up air source. When the damper/

airflow rises 15% above the low limit setpoint, the fan will be deactivated

V A VBO X Controller

15

Page 16

Technical Guide

Sequence Of Operations

Space Heating Mode

Occupied Space Heating mode is initiated by the temperature in the

space falling to within 0.5 ºF of the Occupied Heating Setpoint.

If the HVAC unit is in the Supply Air Cooling mode and another

VAVBOX controller has a heating demand, the damper/airflow for the

VA VBOX controller requiring heating will position itself to provide the

Cooling Minimum amount of air into the space. No modulation open

will occur because the space does not want the cold air currently being

supplied by the air handler.

When the HVAC unit is in the Occupied Supply Air Heating mode, the

damper will be held at the Heating Minimum position until the space

temperature falls to within 0.5 ºF of the Occupied Heating Setpoint.

As the space temperature falls below the heating setpoint, the damper/

airflow calculation causes the air valve to open proportionally until the

maximum setpoint is achieved at 3.5 ºF below the setpoint. This is a 4

ºF proportional window starting 0.5 ºF above the heating setpoint to 3.5

ºF below the heating setpoint.

Two different configurations are available for the Occupied Space Heating mode. If the box is configured to allow reheat during Supply Air

Heating mode, the reheat relays can be activated even when the HVAC

unit is in the Supply Air Heating mode. If the box is configured not to

allow reheat when the HVAC unit is in Supply Air Heating mode, the

box heat relays will be de-energized when the HVAC unit is in Supply

Air Heating mode. In either configuration, when the HVAC unit is in

the Supply Air Heating mode, the damper will modulate open proportionally to the space demand. The proportional window for the space

temperature is 0.5 ºF above to 3.5 ºF below the heating setpoint. This

allows the space to take advantage of the warm supply air in the duct.

See Table 2: Relay Staging - Occupied Mode for a complete layout of

the various fan and heat relay staging points.

Series Flow Fan Terminals

If the VAVBOX Controller has been configured as a Series Fan Powered terminal unit, the series fan relay will activate and run the series

box fan continuously anytime the HVAC unit fan is running.

Box Fan R elay & Reh eat Relay Staging

Relays Stage

On At

+0 .5 º F

Above Box

Heat

Setpoint

At Box Heat

Setpoint

-1.0 º F

Below Box

Heat

Setpoint

-2.0 º F

Below Box

Heat

Setpoint

Relays Stage

Off At

+1 .0 º F

Above Box

Heat

Setpoint

+1 .0 º F

Above Box

Heat

Setpoint

At Box Heat

Setpoint

-1.0 º F

Below Box

Heat

Setpoint

Occupied Mode

Series

Fan

With

HVAC

Fan

Series

Fan

OFF

With

HVAC

Fan

Pa r a lle l

Fan

ON

Pa r a lle l

Fan

X

X

X

Heat

Stage

X

Heat

Stage

X

Heat

Stage

1

X

1

2

X

Heat

Stage

2

Table 2: Relay Staging - Occupied Mode

Heat

Stage

3

X

Heat

Stage

3

In all cases, before the series box fan can be activated, the air damper is

driven fully closed and held that way for 30 seconds to make sure the

series box fan hasn’t inadvertently started to spin backwards. Once the

series box fan starts, it waits an additional 10 seconds to allow the fan

to spin up before it starts to open the damper and introduce airflow from

the HVAC unit fan.

Parallel Flow Fan Terminals

On parallel fan powered terminal units, the fan will run whenever Space

Heating mode is active. At all other times, the fan will only activate if

the damper/airflow is below a user defined low limit setting. This causes

it to be used as a make-up air source. When the damper/airflow rises

15% above the low limit setpoint, the fan will be deactivated if there are

no heating stages active, and no space demand exists.

The check for main fan status setting has no effect on the Parallel Fan

box when in the occupied mode. The Parallel Fan will only be energized when in the Space Heating mode.

16

Unoccupied Mode Sequences

Space Vent Mode

This mode only applies to the Occupied Mode of operation. If the equipment is in the Unoccupied Mode, then a lack of heating or cooling

demand would generate the Off Mode.

Off Mode

This mode only applies to the Unoccupied Mode of operation. If the

equipment is in the Unoccupied Mode, then a lack of heating or cooling

demand would generate this mode. The VAVBOX controller will put

the damper into the Night/Reheat minimum position if check main fan

status has been selected. If check main fan status has not been selected

the damper will be in the fully closed position.

Space Cooling Mode

During unoccupied mode the HVAC unit is normally off. Unoccupied

Space Cooling mode is initiated by the temperature in the space rising

to within 0.5 ºF of the Unoccupied Cooling Setpoint.

V A VBO X Controller

Page 17

Technical Guide

If the HVAC unit is in the Unoccupied Supply Air Heating mode because one or more of the VAVBOX controllers has a heating demand,

and another VAVBOX controller has a cooling demand, the damper/

airflow for the VAVBOX controller requiring cooling will position itself to provide the heating minimum setpoint amount of air into the

space. No modulation open will occur because the space does not want

the warm air currently being supplied by the air handler.

When the HVAC unit is in the Unoccupied Supply Air Cooling mode,

the damper will be held at the Night/Reheat minimum position until the

space temperature begins to rise above the cooling setpoint. As the

space temperature rises to within 0.5 ºF of the Unoccupied Cooling

Setpoint, the damper/airflow calculation causes the air valve to open

proportionally until the maximum setpoint is achieved at 3.5 ºF above

the setpoint. This is a 4 ºF proportional window starting 0.5 ºF below

the cooling setpoint to 3.5 ºF above the cooling setpoint.

The damper/airflow is never allowed to modulate outside the user adjusted minimum setpoint and the maximum setpoint. The maximum

damper/airflow setpoint applies to heating and cooling modes of operation only. All of the modes have their own individual minimum setting.

Series Flow Fan Terminals

If the VAVBOX Controller has been configured as a Series Fan Powered terminal unit and check for main status has been selected, the series fan relay will activate and run the series box fan continuously anytime the HVAC unit fan is running. The damper will be held at the Nite/

Reheat minimum until the space temperature begins to rise above the

cooling setpoint. If check for main fan status has not been selected, the

series fan relay will activate and run the series box fan when in the

Space Cooling mode. The damper will be in the fully closed position

until the space temperature begins to rise above the cooling setpoint.

In all cases, before the series box fan can be activated, the air damper is

driven fully closed and held that way for 30 seconds to make sure the

series box fan hasn’t inadvertently started to spin backwards. Once the

series box fan starts, it waits an additional 10 seconds to allow the fan

to spin up before it starts to open the damper and introduce airflow from

the HVAC unit fan.

Parallel Flow Fan Terminals

In the Unoccupied Cooling mode the parallel fan will be off whether

check for main fan status has been selected or not. If check for main fan

status has been selected the damper will be held at the Nite/Reheat

minimum until the space temperature begins to rise above the cooling

setpoint. If check for main fan status has not been selected the damper

will be held in the fully closed position until the space temperature

begins to rise above the cooling setpoint.

Space Heating Mode

During unoccupied mode the HVAC unit is normally off. Unoccupied

Space Heating mode is initiated by the temperature in the space falling

to within 0.5 ºF of the Unoccupied Space Heating Setpoint.

When the HVAC unit is in the Unoccupied Supply Air Heating mode,

the damper will be held at the Night/Reheat minimum position until the

space temperature begins to fall below the Unoccupied Heating Setpoint.

As the space temperature falls to 0.5 ºF below the Unoccupied Heating

Setpoint, the damper/airflow calculation causes the air valve to open

proportionally until the maximum setpoint is achieved at 3.5 ºF below

the setpoint. This is a 4 ºF proportional window starting 0.5 ºF above

the heating setpoint to 3.5 ºF below the heating setpoint.

As with the Occupied Mode of operation, two different configurations

are available for the Unoccupied Space Heating mode. If the box is

configured to allow reheat during Supply Air Heating mode, the reheat

relays can be activated even when the HVAC unit is in the Supply Air

Heating mode. If the box is configured not to allow reheat when the

HVAC unit is in Supply Air Heating mode, the box heat relays will be

de-energized when the HVAC unit is in Supply Air Heating mode. In

either configuration, when the HVAC unit is in the Supply Air Heating

mode, the damper will modulate open proportionally to the space demand. The proportional window for the space temperature is 0.5 ºF

above to 3.5 ºF below the heating setpoint. This allows the space to take

advantage of the warm supply air in the duct.

If check for main fan status is not selected and the VAVBOX terminal

unit has auxiliary heat (baseboard heat etc.) that does not require the

HVAC unit fan to operate, reheat can be used without the HVAC unit

fan operating. If check for main fan status is selected, the reheat will

only operate when the HVAC unit fan is operating.

The VAVBOX Controller can activate auxiliary heating relays if the

relay expansion board has been connected and the correct number of

heating stages (1,2 or 3) has been configured. During demands for heat,

the first stage will activate whenever the space temperature drops below the heating setpoint. The second stage will activate if the space

temperature falls 1.0 ºF below the heating setpoint. The third stage will

activate if the space temperature falls 2.0 ºF below the heating setpoint.

There is a two-minute delay between staging. This prevents stages from

activating at the same time. Once a heating stage has been activated, it

must remain on for at least one minute. Once it has been deactivated, it

must remain off for at least two minutes. The third stage relay will

deactivate when the space temperature rises to within 1.0 ºF of the heating setpoint. The second stage relay will deactivate when the space

temperature rises to the heating setpoint. The first stage relay will deactivate when the space temperature rises above the heating setpoint by

1.0 ºF. See Table 3: Relay Staging - Unoccupied Mode for a com-

plete layout of the various fan & heat relay staging points.

Series Flow Fan Terminals

If the VAVBOX Controller has been configured as a Series Fan Powered terminal unit, the series fan will run continuously when the

VAVBOX controller is in the Space Heating mode no matter whether

check for main fan status has been selected or not. If the HVAC unit is

in Supply Air Heating mode the damper will modulate to maintain the

Space Heating Setpoint.

If the HVAC unit is in the Unoccupied Supply Air Cooling mode because one or more of the VAVBOX controllers has a cooling demand,

and another VAVBOX controller has a heating demand, the damper/

airflow for the VAVBOX controller requiring heating will position itself to provide the Night/Reheat setpoint amount of air into the space.

No modulation open will occur because the space does not want the

cold air currently being supplied by the air handler.

V A VBO X Controller

Any series fan terminal unit that has check for main fan status selected

will also operate its series box fan anytime the HVAC unit controller is

broadcasting that the HV AC unit fan is operating, regardless of whether

it is calling for heat or not. The damper will be held at the closed position until the main fan status broadcast is received. Once the broadcast

17

Page 18

Technical Guide

Sequence Of Operations

is received the damper will then move to its Nite/Reheat minimum position. If check for main fan status has not been selected, the series box

fan will only activate and run when it is in Space Heating mode. When

in Space Heating mode the damper will move to its Nite/Reheat minimum position. When in Supply Air Heating mode the damper will modulate to maintain the Unoccupied Heating setpoint.

In all cases, before the series box fan can be activated, the air damper is

driven fully closed and held that way for 30 seconds to make sure the

series box fan hasn’t inadvertently started to spin backwards. Once the

series box fan starts, it waits an additional 10 seconds to allow the fan

to spin up before it starts to open the damper and introduce airflow from

the HVAC unit fan.

Box Fan Relay & Reheat Relay Staging

Rela y s S ta g e

On At

+0.5 º F

Above Box

Heat

Setpoint

At Box Heat

Setpoint

-1.0 ºF

Below Box

Heat

Setpoint

-2.0 ºF

Below Box

Heat

Setpoint

Rela y s S ta g e

Off At

+1.0 º F

Above Box

Heat

Setpoint

+1.0 º F

Above Box

Heat

Setpoint

At Box Heat

Setpoint

-1.0 ºF

Below Box

Heat

Setpoint

Notes:

1.) If che c k fo r main fan s ta tu s is s e lec te d th e s e rie s fa n w ill a c tiv a te

anytime the HVAC unit fan is operating.

Unoccupied Mode

Series

Fan

See

Note

Series

Fan

See

Note

Para lle l

Fan

X

1

X

1

X

Para lle l

Fan

X

Heat

Stage

Heat

Stage

Heat

Stage

1

X

1

X

2

X

Heat

Stage

2

X

Heat

Stage

3

X

Heat

Stage

3

X

Parallel Flow Fan Terminals

If the VAVBOX Controller has been configured as a Parallel Fan Powered terminal unit, the Parallel fan will run continuously when the

VAVBOX controller is in the Space Heating mode no matter whether

check for main fan status has been selected or not. At all other times,

the fan will only activate if the damper/airflow is below a user defined

low limit setting. This causes it to be used as a make-up air source.

When the damper/airflow rises 15% above the low limit setpoint, the

fan will be deactivated if there are no heating stages active, and no

space demand exists.

If check for main fan status is selected the damper will remain in the

closed position until the HVAC unit controller is broadcasting that the

HVAC unit fan is operating, regardless of whether it is calling for heat

or not. The damper will be held at the closed position until the main fan

status broadcast is received. Once the broadcast is received the damper

will then move to its Nite/Reheat minimum position. If check for main

fan status has not been selected, the damper will stay in the closed position until Space Heating mode is initiated. When in Space Heating

mode the damper will move to its Nite/Reheat minimum position. When

in Supply Air Heating mode the damper will modulate to maintain the

Unoccupied Heating setpoint.

Damper Control

The damper position is calculated by the mode and demand from the

space sensor. Included in this calculation is an Integral function. This

prevents the damper/airflow from stagnating at a position somewhere

above the setpoint because the supply air temperature or duct pressure

isn’t quite enough to satisfy the space at the currently calculated proportional position. The Integral causes the calculation to keep adding a

small amount of the proportional error back into the damper/airflow

position each time a new position is calculated. The amount the Integral

adds back in is user adjustable. This value is presented as a number

between 0.0 and 10.0. That means that if the integral is less than 1.0,

you are adding a percentage, from 0 to 100% of the error back into the

calculation. If you increase the Integral above 1.0, you are adding more

than 100% back in.

With just proportional control, a 2 ºF error would cause a 50% increase

in damper/airflow if the Integral is not included. (2 °F is half of the 4 ºF

Proportional Window)

If you had set the Integral to 1.0, the calculation would add 2% to the

current damper/airflow calculation each time. The calculation occurs

once every 10 seconds, so it would take a little over 4 minutes to reach

the programmed 100% maximum.

Table 3: Relay Staging - Unoccupied Mode

18

V A VBO X Controller

Page 19

Technical Guide

Example:

1. 50% Remaining / 2% Integral = 25 Moves to get to a 100%

Maximum

2. 25 Moves times 10 seconds = 250 seconds or a little over 4

minutes to reach the 100% maximum damper/airflow

position.