Page 1

www.wattmaster.com

WattMaster VAV

Component & System

Wiring - Technical Guide

Page 2

Table Of Contents

WattMaster Controls Inc.

8500 NW River Park Drive · Parkville , MO 64152

Toll Free Phone: 866-918-1100

PH: (816) 505-1100 · FAX: (816) 505-1101 · E-mail: mail@wattmaster.com

Visit our web site at www.wattmaster.com

Form: WM-VAVWIRE-TGD-01C Copyright 2008 WattMaster Controls, Inc.

WattMaster Controls, Inc. assumes no responsibility for errors, or omissions.

This document is subject to change without notice.

System Configurations Installation & Commissioning .................................................................................. 5

Networked Single Loop System ........................................................................................................................................................................... 6

Networked Single Loop - Computer Connection With Remote Link .................................................................................................................... 7

Networked Single Loop - Computer Connection With IP-Link ............................................................................................................................. 8

Networked Multiple Loop System ......................................................................................................................................................................... 9

Networked Multiple Loop - Computer Connection With Remote Link ................................................................................................................ 10

Networked Multiple Loop - Computer Connection With IP-Link ......................................................................................................................... 11

Systems Overview .............................................................................................................................................................................................. 12

General Information ............................................................................................................................................................................................ 12

Installation Procedures ....................................................................................................................................................................................... 12

System Commisioning ........................................................................................................................................................................................ 15

Transformer & Wire Sizing ................................................................................................................................................................................. 16

WMVAV Controller Wiring .............................................................................................................................. 17

WMVAV Controller Wiring .................................................................................................................................................................................. 18

WMVAV Controller Addressing ........................................................................................................................................................................... 19

Space Sensor Wiring .......................................................................................................................................................................................... 20

Supply & Return Sensor Wiring .......................................................................................................................................................................... 21

Outside Air Sensor Wiring .................................................................................................................................................................................. 22

Remote Occupied Contact To WMVAV Wiring ................................................................................................................................................... 23

Humidity Sensor Wiring ...................................................................................................................................................................................... 24

Supply Fan VFD Wiring ...................................................................................................................................................................................... 25

Bypass Damper Actuator Wiring ........................................................................................................................................................................ 26

2 Slot Expansion Base Board Wiring ................................................................................................................................................................. 27

4 Slot Expansion Base Board Wiring ................................................................................................................................................................. 28

4 Analog Input 1 Analog Output Expansion Board Wiring .................................................................................................................................. 29

4 Analog Input 1 Analog Output Expansion Board Wiring (Cont’d) .................................................................................................................... 30

4 Analog Input 1 Analog Output Expansion Board Wiring (Cont’d) .................................................................................................................... 31

4 Binary Input Expansion Board Wiring .............................................................................................................................................................. 32

4 Relay Output Expansion Board Wiring ............................................................................................................................................................ 33

VAVBOX Controller Diagrams .......................................................................................................................35

VAVBOX Controller Wiring ................................................................................................................................................................................. 36

3 Relay Output Expansion Board Wiring ............................................................................................................................................................ 37

3 Relay Output Expansion Board Wiring (Cont’d) .............................................................................................................................................. 38

3 Relay Output Expansion Board Wiring (Cont’d) .............................................................................................................................................. 39

Communication Devices Diagrams ............................................................................................................... 41

System Manager Modular Cable Pigtail - Wiring Schematic ............................................................................................................................. 42

System Manager Modular Cable Pigtail - Wiring Detail ..................................................................................................................................... 43

Modular Service Tool Connections ..................................................................................................................................................................... 44

CommLink II Wiring & Cabling Connections ...................................................................................................................................................... 45

MiniLink Polling Device Wiring Using Wire Terminals ........................................................................................................................................ 46

RS-232 Serial Port To USB Port Converter ........................................................................................................................................................ 47

Page 3

Table Of Contents

Add-On Devices Diagrams ............................................................................................................................. 49

Lighting Panel Wiring For Standard Lighting Contactors ................................................................................................................................... 50

Lighting Panel Wiring For GE® Latching Relay Lighting Contactors ................................................................................................................. 51

Optimal Start Scheduler Wiring .......................................................................................................................................................................... 52

GPC Wiring ......................................................................................................................................................................................................... 53

GPC-17 Wiring ................................................................................................................................................................................................... 54

Miscellaneous Diagrams & Technical Information ...................................................................................... 55

Over Voltage Board Wiring ................................................................................................................................................................................. 56

Chip Locations .................................................................................................................................................................................................... 57

Chip Locations (Cont’d) ...................................................................................................................................................................................... 58

Chip Installation Procedures ............................................................................................................................................................................... 59

Temperature & Humidity Sensor Voltage-Resistance Tables ............................................................................................................................. 60

Pressure Sensors Voltage-Resistance Tables ................................................................................................................................................... 61

Notes .................................................................................................................................................................................................................. 62

Notes .................................................................................................................................................................................................................. 63

Component & System Wiring 3

Page 4

Component & System Wiring4

Page 5

System Configurations

Installation &

Commissioning

Component & System Wiring 5

Page 6

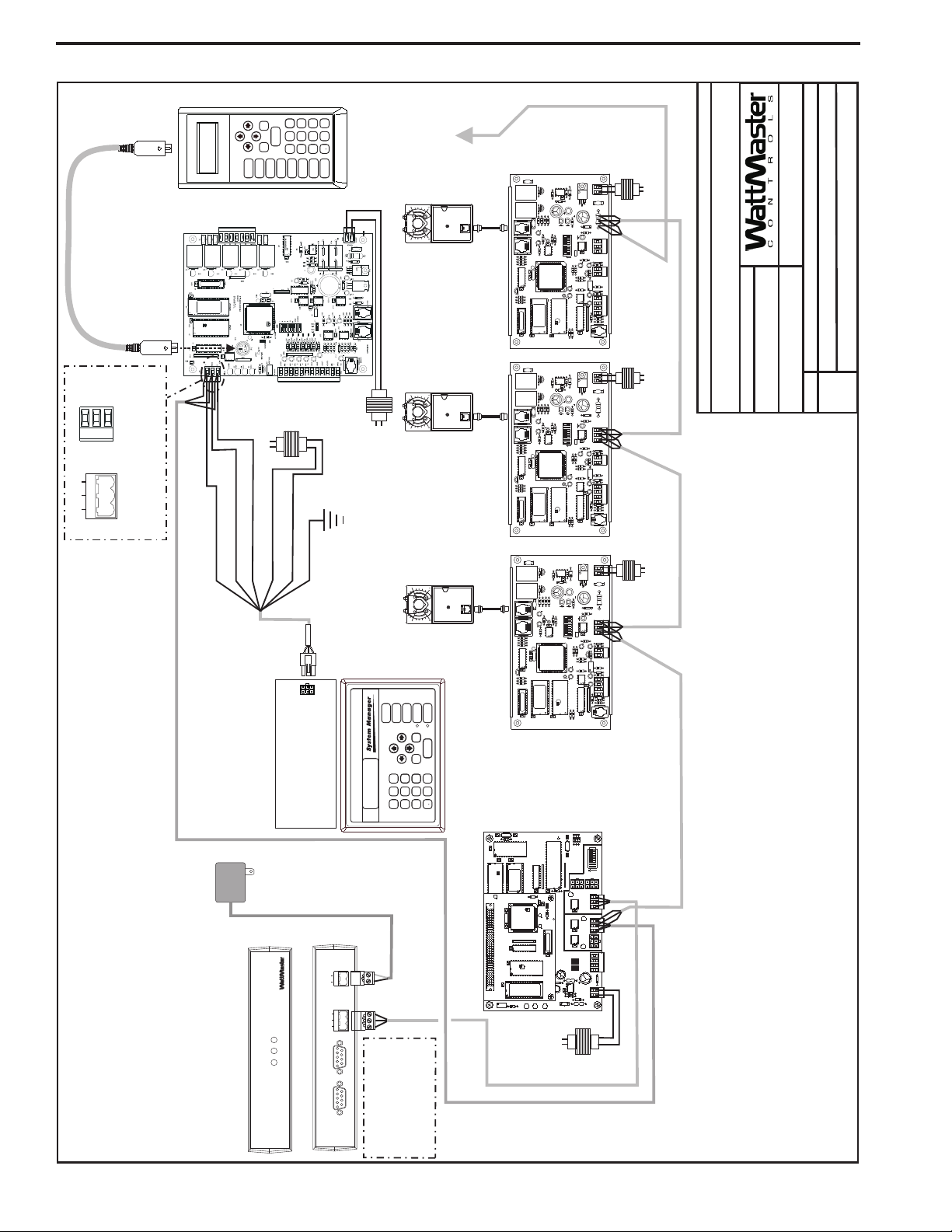

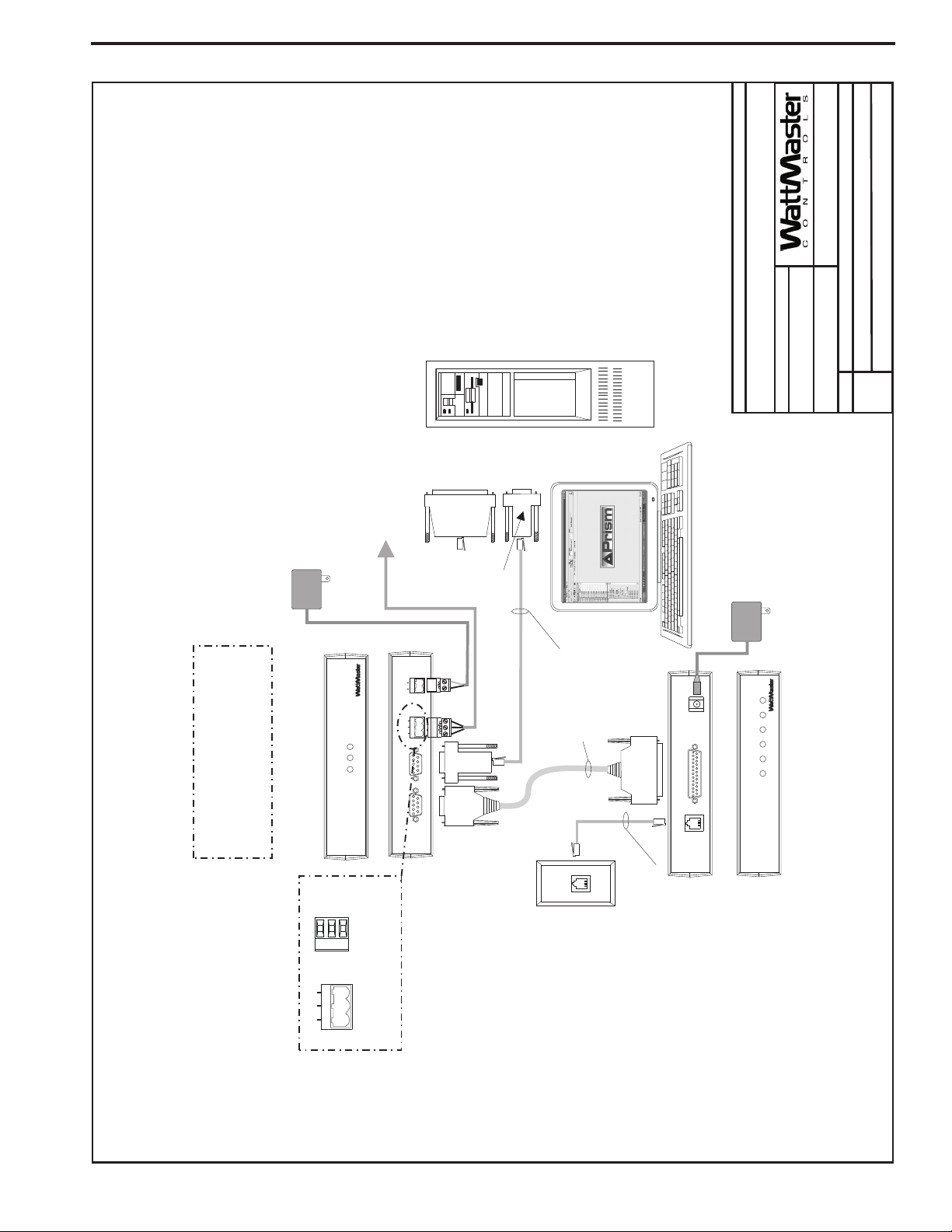

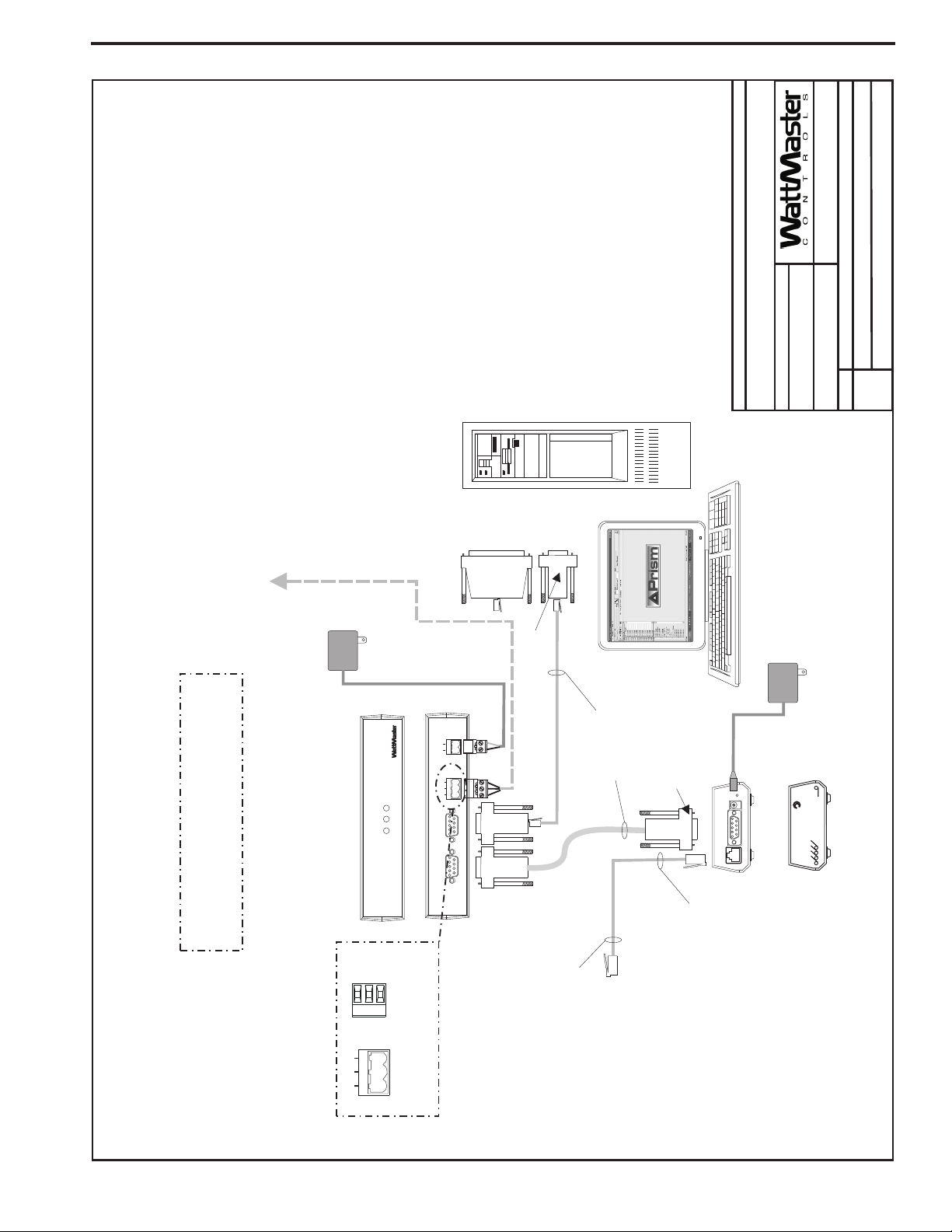

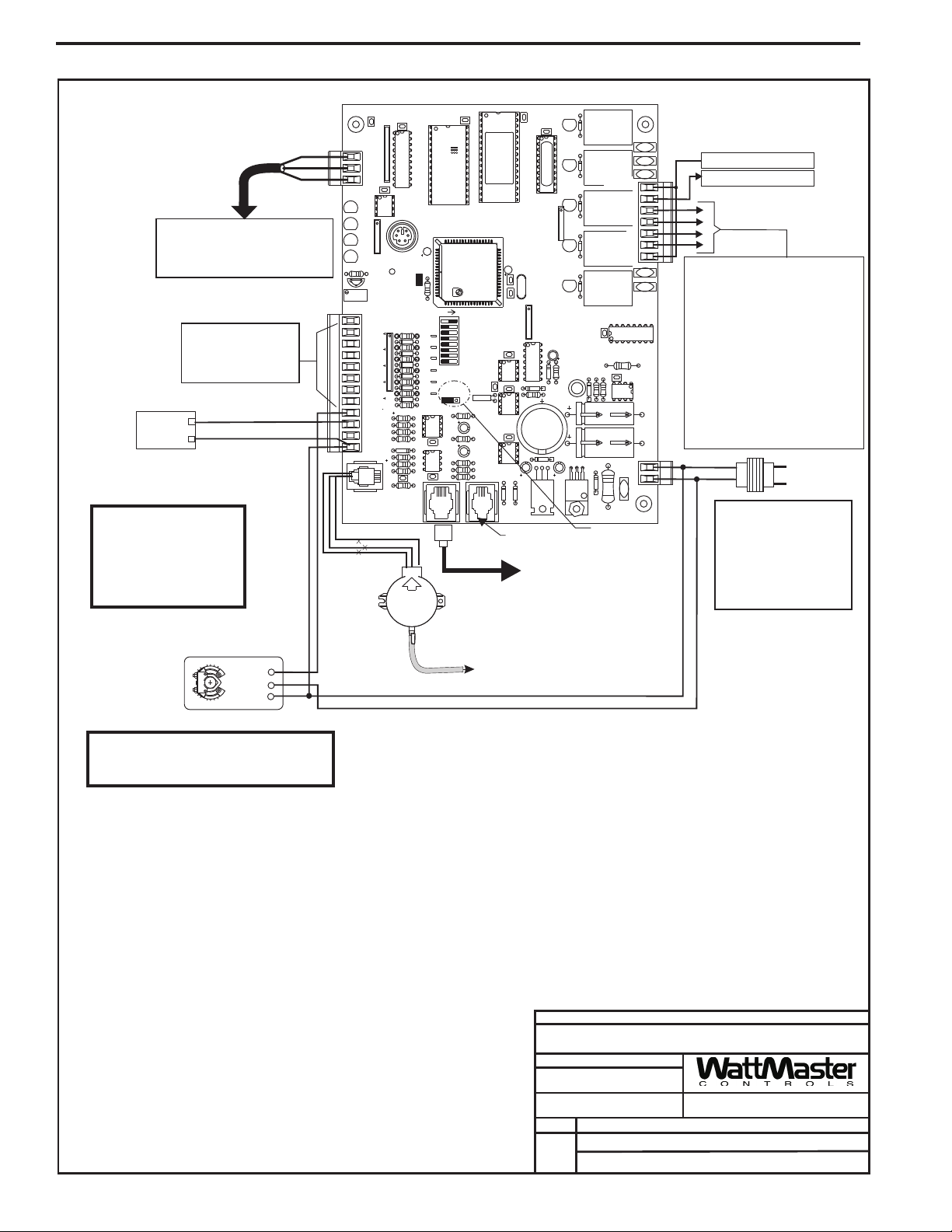

Networked Single Loop System

EPROM

U3

U5

RAM

C

X

2

1

U2

R

1

C3

U4

CX3

CX4

YS101818P552

PROCESSORPBOARD

CX5

C1

U1

R2

CX1

CX6

WDOG

U6

PHILIPS

D

1

P1

X1

C2

C4

0-10V

4-20mA

THERM

R

27

R

31

D

4

G

N

D

24VA

C

TB1

D5

C11

U12

LED2

POWER

V

1

R

25

R

26

C7

C

X15

C

X

13

PROC.

DRIVER

LOOP

DRIVER

LOCALLOOP

G

N

D

A

IN

2

A

IN

1

+5V

T

B2

P4

OFF=0-5V

AIN2

AIN1

0-10V

4-20mA

THERM

TB

3

U

15

LD5

LD6

U

13

C8

LED1

RV1

R

4

V

R

EF

C

X

2

U11

YS101900PMINILINK

POLLING

DEVICE

REV.1

OFF

1

2

4

8

16

32

C

X

14

NETWORK

DRIVER

RN3

SH

LD

S

H

LD

T

T

TB

4

R

R

U14

NETWORK

LOOP

P5

A

D

D

P

3

R

24

LD4

C9

U10

RN2

SW1

R30X2R29

R28

C10

U6

C

X6

C

X1

U7

U1

X

1

C3

C

1

R

3

CX7

Line Voltage

Line Voltage

Network

Local

Local

24 VAC

(8 VA)

24 VAC

(6 VA)

24 VAC

(6 VA)

Back View of CommLink

Front View of CommLink

CLIIomm ink

LOOP

24V

T

G

R

GND

REMOTE LINK

(DTE)

COMPUTER

(DCE)

485

LOOP

STATUS

POW

ER

COM

P

RLINK

SERIAL #

CONTROLS

110 VAC To

24 VAC

Power Pack

CommLink

MiniLink PD Loop 1

VAVBOX

Controller

VAVBOX

Controller

VAVBOX

Controller

WMVAV Controller

(1MEG)

TB1

Connect To Modular

I/O Connectors

Located On Back

Of The System Manager

ENTER

CLEAR

ESC

PREV

NEXT

DOWN

UP

6

5

4

DEC

7

0

8

13

2

9

MINUS

-

STATUS

SETPOINTS

SCHEDULES

ALARMS

OVERRIDES

Modular System Manager

Note: A Modular System

Manager, A Modular Service

Tool Or A PC With Prism

Software Installed Can Be

Used To Program And

Configure TheWattMaster

VAV System.

Note: See Page 2 Of

This Drawing For

Optional Computer

And Remote Link

Connection Diagram.

1 1

1

0 0

0

Modular Service

Tool

Mode

Selection

ENTER

CLEAR

ESC

PREV

NEXT

DOWN

UP

6

5

4

DEC

7

0

8

13

2

9

MINUS

-

STATUS

SETPOINTS

SCHEDULES

CONFIGURATION

ALARMS

ON

OVERRIDES

BALANCE-TEST

Connect To Next

VAVBOX Controller

Local Loop

SHLD

T

R

Typical Terminal Blocks. All

Wiring To Be T To T, SHLD (G)

To SHLD (G)&RToR

T

G

R

485 LOOP

Typical Single Loop Networked System

05/12/04

VAV-Network-SingleLoop1B.CDR

Network System - Single Loop

FILENAME

DATE:

B. Crews

DESCRIPTION:

PAGE

DRAWN BY:

Wiring & Connection Diagram

JOB NAME

1of3

WHITE (T)

DRAIN WIRE (SHLD)

BLACK (R)

RED (24 VAC)

Line Voltage

24 VAC

(6VA Min.)

BROWN (GND)

GREEN (GND)

CX6

SW1

U10

75176

EXPANSION

Q3Q2

D3

VR1

7824

GND

R

SHLD

GND

GND

AUX2

AUX1

AUX

+VS

TMP

T

24VAC

R17

R16

U7

C7

R15

POWER

R21

R35

YS101

562REV 3

D4

R26

LD3

L1

SCAN

REC

R12C6R11

TOKEN

NET

LD2

32

R14

R13

R100

LD1

C5

D1

K1

V2

V3

K2

D2

ACTUATOR

R10

R9

PJ2

V1

C4

EPROM

VREF

ADJ

R23

C10

EWDOG

COMM

D7

CX10

R25

R28

T'STAT

U11

C15

R20

C11

R24

8

16

2

4

ADDRESS

ADD

1

U6

U5

R19

U9

CX9

R32

D5

C14

P.U.

R22

C13

R27

D5

RAM

C9

C8

80C55

2

CX5

PJ1

C3

R8

R7

R5

R6

R4

C2C1

X1

U2

R1

R2

R3

CX2

Q1

16L8

R34

FLOW

U8

1

RN1

CX8

U4

R18

CX4

U3

CX3

U1

PAL

CX1

CX6

SW1

U10

75176

EXPANSION

Q3Q2

D3

VR1

7824

GND

R

SHLD

GND

GND

AUX2

AUX1

AUX

+VS

TMP

T

24VAC

R17

R16

U7

C7

R15

POWER

R21

R35

YS101

562REV 3

D4

R26

LD3

L1

SCAN

REC

R12C6R11

TOKEN

NET

LD2

32

R14

R13

R100

LD1

C5

D1

K1

V2

V3

K2

D2

ACTUATOR

R10

R9

PJ2

V1

C4

EPROM

VREF

ADJ

R23

C10

EWDOG

COMM

D7

CX10

R25

R28

T'STAT

U11

C15

R20

C11

R24

8

16

2

4

ADDRESS

ADD

1

U6

U5

R19

U9

CX9

R32

D5

C14

P.U.

R22

C13

R27

D5

RAM

C9

C8

80C55

2

CX5

PJ1

C3

R8

R7

R5

R6

R4

C2C1

X1

U2

R1

R2

R3

CX2

Q1

16L8

R34

FLOW

U8

1

RN1

CX8

U4

R18

CX4

U3

CX3

U1

PAL

CX1

CX6

SW1

U10

75176

EXPANSION

Q3Q2

D3

VR1

7824

GND

R

SHLD

GND

GND

AUX2

AUX1

AUX

+VS

TMP

T

24VAC

R17

R16

U7

C7

R15

POWER

R21

R35

YS101

562REV 3

D4

R26

LD3

L1

SCAN

REC

R12C6R11

TOKEN

NET

LD2

32

R14

R13

R100

LD1

C5

D1

K1

V2

V3

K2

D2

ACTUATOR

R10

R9

PJ2

V1

C4

EPROM

VREF

ADJ

R23

C10

EWDOG

COMM

D7

CX10

R25

R28

T'STAT

U11

C15

R20

C11

R24

8

16

2

4

ADDRESS

ADD

1

U6

U5

R19

U9

CX9

R32

D5

C14

P.U.

R22

C13

R27

D5

RAM

C9

C8

80C55

2

CX5

PJ1

C3

R8

R7

R5

R6

R4

C2C1

X1

U2

R1

R2

R3

CX2

Q1

16L8

R34

FLOW

U8

1

RN1

CX8

U4

R18

CX4

U3

CX3

U1

PAL

CX1

Line Voltage

Line Voltage

24 VAC

(6VA Min.)

24 VAC

(6VA Min.)

Component & System Wiring6

Page 7

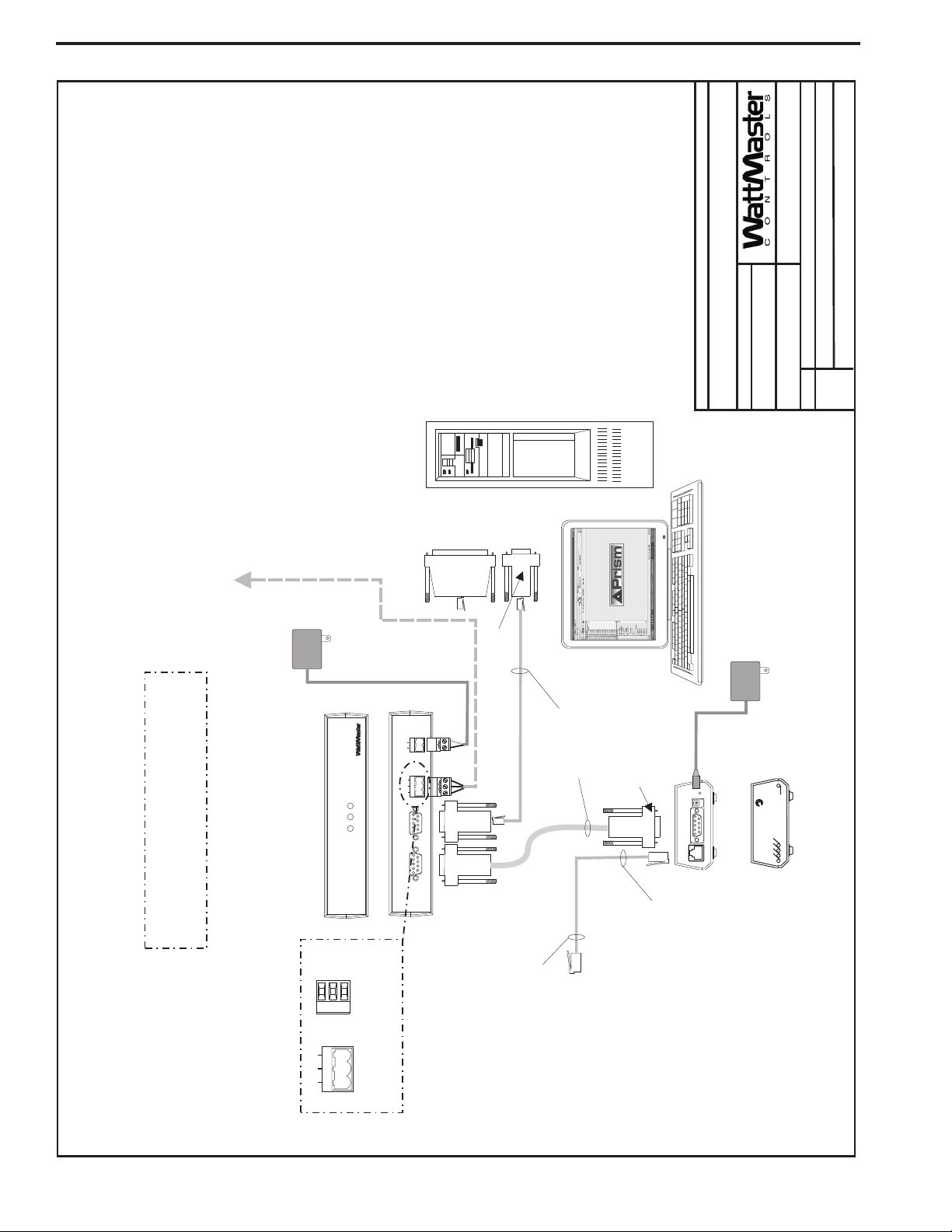

Networked Single Loop - Computer Connection With Remote Link

VAV-Network-SingleLoop1B.CDR

9Pin

Female

End

Telephone

Cable

Assembly

9Pin

Female

Connector

9Pin

Female

Connector

Molded

Cable Assembly

25 Pin

Male End

25 Pin

Female

Connector

(If Reqd)

Connect To Computer

Serial Port

Personal Computer

(By Others)

Dedicated Telephone

Outlet

(By Others)

Back View of CommLink

Back View of Remote Link

Front View of CommLink

Note: If Direct Computer Connection

Is Required, Connect To PC As Shown.

Remote Link Is Only Required If

Alarm Callout Or Remote Computer

Connection Is Required.

Front View of Remote Link

CLIIomm ink

LOOP

24V

T

G

R

GND

REMOTE LINK

(DTE)

COMPUTER

(DCE)

485

LOOP

STATUS

POW

ER

COMP

RLINK

SERIAL #

CONTROLS

RL

emote ink

SIG

TELCO

LINE

TELCO

LINE

SERIAL DATA

DET

RDY

SND

REC

PWR

SERIAL #

CONTROLS

8 Conductor

Modular Cable

Assembly

110 VAC To

9 VDC

Power Pack

110 VAC To

24 VAC

Power Pack

CommLink

Remote Link

(Optional)

Connect To MiniLink PD Network Terminals

See Page 1 Of This Drawing

POWER

9VDC @

500mA

SHLD

T

R

Typical Terminal Blocks. All

Wiring To Be T To T, SHLD (G)

To SHLD (G)&RToR

T

G

R

485

LOOP

FILENAME

DATE:

B. Crews

DESCRIPTION:

PAGE

DRAWN BY:

Wiring & Connection Diagram

JOB NAME

2of3

Network System - Single Loop

03/24/04

Optional Computer Connection Diagram

Using Remote Link For Remote Connection

Component & System Wiring 7

Page 8

Networked Single Loop - Computer Connection With IP-Link

JOB NAME

FILENAME

B. Crews

DRAWN BY:

DESCRIPTION:

Wiring & Connection Diagram

Network System - Single Loop

03/24/04

DATE:

VAV-Network-SingleLoop1B.CDR

PAGE

3of3

Note: If Direct Computer Connection

Using IP-Link For Remote Connection

Optional Computer Connection Diagram

Is Required, Connect To PC As Shown. IP-Link Is

Only Required If E-mail Alarm Notification Or

Remote Computer Connection Is Required.

Connect To MiniLink PD Network Terminals

See Page 1 Of This Drawing

Note:

1.Set CommLink Internal Switch To”Multi”

2. Replace CommLink EPROM With IP-Link

EPROM Supplied With IP-Link Kit

110 VAC To

RLINK

COM

P

LOOP

CommLink

Front View of CommLink

omm ink

CLII

SHLD

T

R

LOOP

485

R

G

T

24 VAC

Power Pack

CONTROLS

STATUS

Typical Terminal Blocks. All

ER

GND

24V

LOOP

R

G

T

(DCE)

COMPUTER

(DTE)

Back View of CommLink

REMOTE LINK

SERIAL #

Wiring To Be T To T, SHLD (G)

To SHLD (G)&RToR

25 Pin

Female

9 Pin

(If Reqd)

Connector

Female

Connector

(By Others)

Personal Computer

ne

onnect

C

9 VDC

110 VAC To

Power Pack

PWR

R

E

S

V

C

R

K

N

L

T

C

A

IP-Link

(Optional)

Front View of IP- Link

Serial Port

POW

485

Connect To Computer

9 Pin

Female

Connector

Assembly

8 Conductor

Modular Cable

Molded

Supplied With

Cable Assembly

IP-Link Kit

9 Pin Male End

Port On IP-Link

Connect To Serial

Mode

9VDC

Serial

10BaseT

Back View of IP-Link

End

9 Pin

Female

Assembly

On IP-Link

RJ45 Cable

To 10BaseT Port

Connect Ethernet

Or Modem

(By Others)

Cable Assembly

Connect Ethernet RJ45

(By Others)

On Ethernet Router

To 10 BaseT Connection

Component & System Wiring8

Page 9

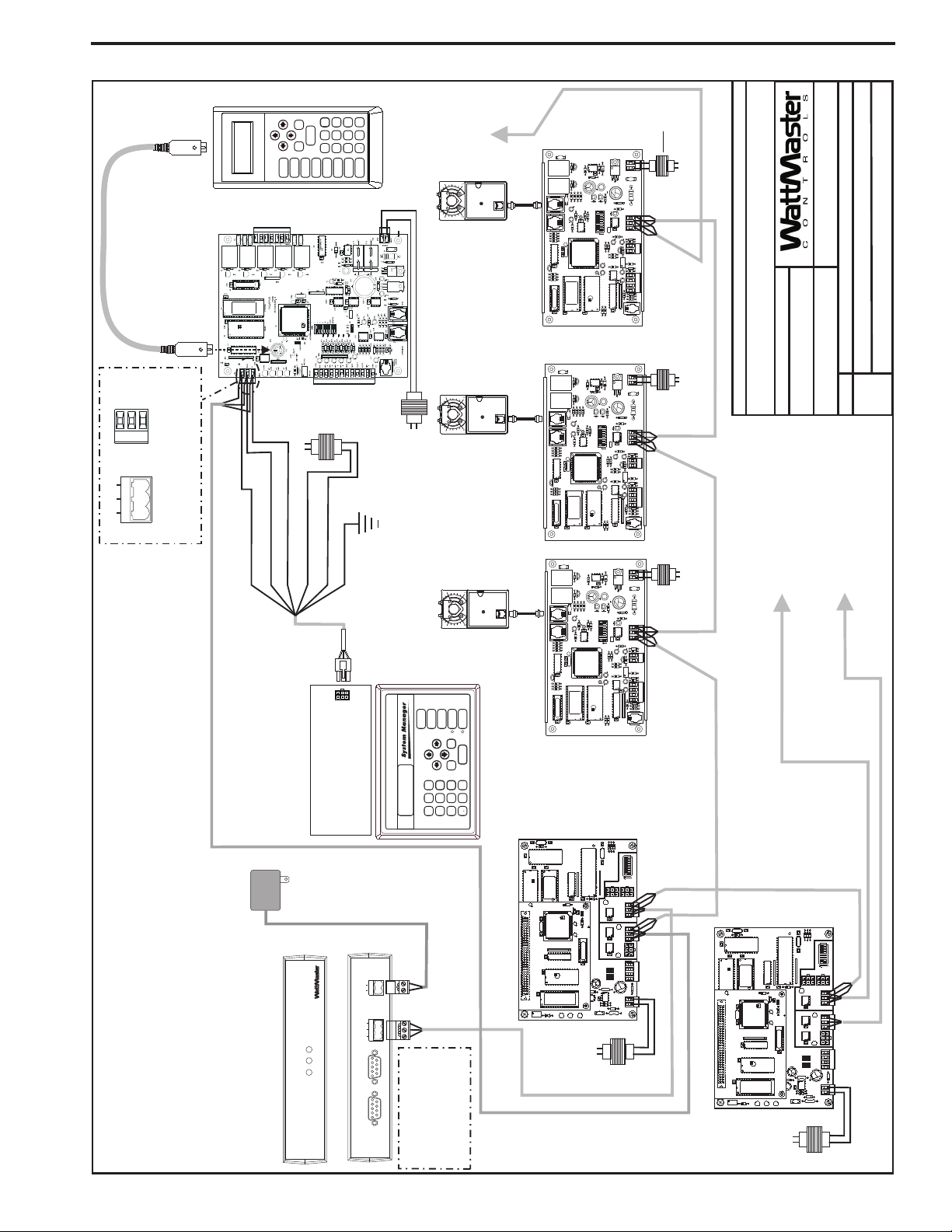

Networked Multiple Loop System

SHLD

T

R

G

T

R

485 LOOP

Typical Terminal Blocks. All

Wiring To Be T To T, SHLD (G)

ToSHLD(G)&RToR

Typical Multiple Loop Networked System

WMVAV Controller

WHITE (T)

Note: A Modular System Manager,

A Modular Service Tool Or A PC

With Prism Software Installed Can

NEXT

CLEAR

UP

DOWN

ENTER

ESC

PREV

STATUS

Mode

SETPOINTS

OVERRIDES

SCHEDULES

Selection

(1MEG)

Line Voltage

DRAIN WIRE (SHLD)

RED (24 VAC)

BLACK (R)

Be Used To Program And

Configure The WattMaster VAV

System.

24 VAC

110 VAC To

RLINK

COM

P

STATUS

LOOP

CommLink

Front View of CommLink

6

9

8

2

5

13

7

4

ALARMS

BALANCE-TEST

CONFIGURATION

24 VAC

(6 VA)

GREEN (GND)

BROWN (GND)

Connect To Modular

I/O Connectors

Located On Back

Power Pack

CONTROLS

Back View of CommLink

-

MINUS

0

DEC

ON

24 VAC

TB1

Of The System Manager

POW

ER

GND

24V

LOOP

485

R

G

T

(DCE)

COMPUTER

(DTE)

REMOTE LINK

Tool

Modular Service

(8 VA)

Line Voltage

Connect To

STATUS

SETPOINTS

OVERRIDES

SCHEDULES

NEXT

CLEAR

UP

DOWN

ESC

PREV

6

2

5

13

4

Next VAVBOX

Controller On

1

0

1

0

1

0

ALARMS

ENTER

9

-

MINUS

0

8

7

DEC

Loop 1

Modular System Manager

U1

MiniLink PD Loop 1

VAVBOX

VAVBOX

VAVBOX

1

CX7

U7

C

X

1

P1

RV1

V2

K2

D2

Q3Q2

D1

K1

R10

R9

V1

ACTUATOR

PJ2

C4

C3

R8

EXPANSION

PJ1

R7

R6

R5

CX5

R4

C2C1

U2

X1

Q1

CX2

R3

EPROM

R2

R1

16L8

PAL

U1

U3

CX1

CX3

Controller

V2

K2

D2

D1

K1

R10

R9

V1

ACTUATOR

PJ2

C4

C3

R8

EXPANSION

PJ1

R7

R6

R5

CX5

R4

C2C1

U2

X1

Q1

CX2

R3

R2

R1

16L8

PAL

Controller

U1

U3

CX1

CX3

V2

K2

D2

D1

K1

R9

V1

ACTUATOR

PJ2

C4

C3

R8

EXPANSION

PJ1

R7

R6

R5

CX5

R4

C2C1

U2

X1

Q1

CX2

R3

R2

R1

16L8

Controller

PAL

U1

U3

CX1

CX3

C

3

C

X

1

R3

YS101900PMINILINK

POLLING

DEVICE

REV.1

C

X

6

U6

U10

D

1

C4

U6

CX6

U1

C2

PHILIPS

X1

CX1

C3

YS101818P552

PROCESSORPBOARD

C1

1

R

1

U2

CX5

U5

CX4

U4

CX3

U3

C

X2

R

4

V

R

E

F

LED1

LED2

24 VAC

24 VAC

(6VA Min.)

GND

R17

R16

U7

R15

R12C6R11

R13

R100

C5

CX6

CX4

24VAC

7824

C7

D3

VR1

V3

L1

562REV 3

SCAN

REC

R35

YS101

R21

LD2

LD1

D4

R14

R26

NET

TOKEN

POWER

LD3

32

R

16

SHLD

8

U10

SW1

4

75176

COMM

2

U6

U5

2

80C55

T

1

CX10

ADD

ADDRESS

D7

R25

EWDOG

C15

GND

R20

C11

R19

TMP

U11

R24

R28

T'STAT

R23

R32

C10

P.U.

VREF

ADJ

D5

R22

C14

C8

RAM

GND

C13

C9

U9

AUX2

CX9

AUX1

+VS

R27

AUX

D5

1

RN1

U8

U4

CX8

FLOW

R34

R18

Line Voltage

JOB NAME

B. Crews

DRAWN BY:

DESCRIPTION:

Network System - Multiple Loop

Wiring & Connection Diagram

05/12/04

24 VAC

Q3Q2

R15

R12C6R11

R13

R100

C5

CX6

EPROM

CX4

Q3Q2

R15

R12C6R11

R10

R13

R100

C5

CX6

EPROM

CX4

24VAC

7824

C7

D3

VR1

V3

L1

562REV 3

SCAN

REC

R35

YS101

R21

LD2

LD1

D4

R14

R26

NET

TOKEN

POWER

LD3

32

R

16

SHLD

8

U10

SW1

4

75176

COMM

2

U6

U5

2

80C55

U7

D3

R14

U6

U5

2

80C55

T

1

CX10

ADD

ADDRESS

D7

R25

EWDOG

C15

GND

R20

C11

R19

TMP

U11

R24

R28

T'STAT

R23

R32

C10

P.U.

VREF

ADJ

D5

R22

C14

C8

RAM

GND

C13

C9

U9

AUX2

CX9

AUX1

+VS

R27

AUX

D5

1

RN1

U8

U4

CX8

FLOW

R34

R18

GND

R17

R16

24VAC

7824

C7

VR1

V3

L1

562REV 3

SCAN

REC

R35

YS101

R21

LD2

LD1

D4

R26

NET

TOKEN

POWER

LD3

32

R

16

SHLD

8

U10

SW1

4

75176

COMM

2

T

1

CX10

ADD

ADDRESS

D7

R25

EWDOG

C15

GND

R20

C11

R19

TMP

U11

R24

R28

T'STAT

R23

R32

C10

P.U.

VREF

ADJ

D5

R22

C14

C8

RAM

GND

C13

C9

U9

AUX2

CX9

AUX1

+VS

R27

AUX

D5

1

RN1

U8

U4

CX8

FLOW

R34

R18

Line Voltage

24 VAC

(6VA Min.)

Line Voltage

(6VA Min.)

GND

R17

R16

U7

FILENAME

DATE:

VAV-Network-MultLoop1B.CDR

Loop 3

Connect To

MiniLink Polling Device

Connect To Loop 2

1of3

PAGE

VAVBOX Controller

Or WMVAV Controller

Local

Local

C10

R30X2R29

R28

OFF

SW1

32

U11

C9

16

8

4

2

RN2

1

RN3

D

D

A

3

P

P5

R

24

LD4

R

U

14

LD

H

S

WDOG

T

NETWORK

DRIVER

C

X14

4

TB

NETWORK

LOOP

R2

3

TB

U

13

LD5

R

LD

SH

LOOP

DRIVER

T

C

X

13

U

15

PROC.

DRIVER

LOCALLOOP

C

X

15

LD6

P4

D

N

G

0-10V

THERM

4-20mA

C

X2

2

IN

A

AIN2

1

AIN

RAM

OFF=0-5V

C8

+5V

AIN1

TB

2

0-10V

THERM

4-20mA

R

27

C7

EPROM

U12

C

R

25

R

26

R

31

V1

POWER

Network

C11

D5

D

N

G

24VA

T

B1

D

4

Local

(6 VA)

C

3

C

1

X1

R

3

CX7

U7

C

X

6

C

X

1

U1

U6

U10

C4

P1

C2

PHILIPS

X1

YS101818P552

PROCESSORPBOARD

C1

CX5

U5

CX4

U4

CX3

MiniLink PD Loop 2

U3

C

X2

RV1

R

4

VR

EF

LED1

YS101900PMINILINK

POLLING

D

1

LED2

Network

C10

R30X2R29

R28

U11

C9

DEVICE

REV.1

RN2

RN3

3

P

R

24

LD4

U6

U

14

CX6

U1

1

LD

WDOG

NETWORK

DRIVER

C

X

14

NETWORK

LOOP

R2

CX1

U

13

LD5

LD

LOOP

DRIVER

C3

C

X

13

U

15

PROC.

R

1

DRIVER

U2

LOCALLOOP

C

X15

LD6

0-10V

THERM

4-20mA

C

X2

2

AIN2

1

RAM

OFF=0-5V

C8

AIN1

0-10V

THERM

4-20mA

R

27

C7

EPROM

D

U12

C

R

25

R

26

R

31

V1

POWER

Network

OFF

SW1

32

16

8

4

2

1

D

AD

P5

R

H

S

T

4

TB

3

TB

R

SH

T

P4

D

N

G

AIN

IN

A

+5V

TB

2

C11

D5

N

G

24VA

TB1

D

4

omm ink

CLII

SERIAL #

Note: See Page 2 and

IP-LinkConnections

3 Of This Drawing For

Optional Computer To

Remote Link or

24 VAC

(6 VA)

Component & System Wiring 9

Page 10

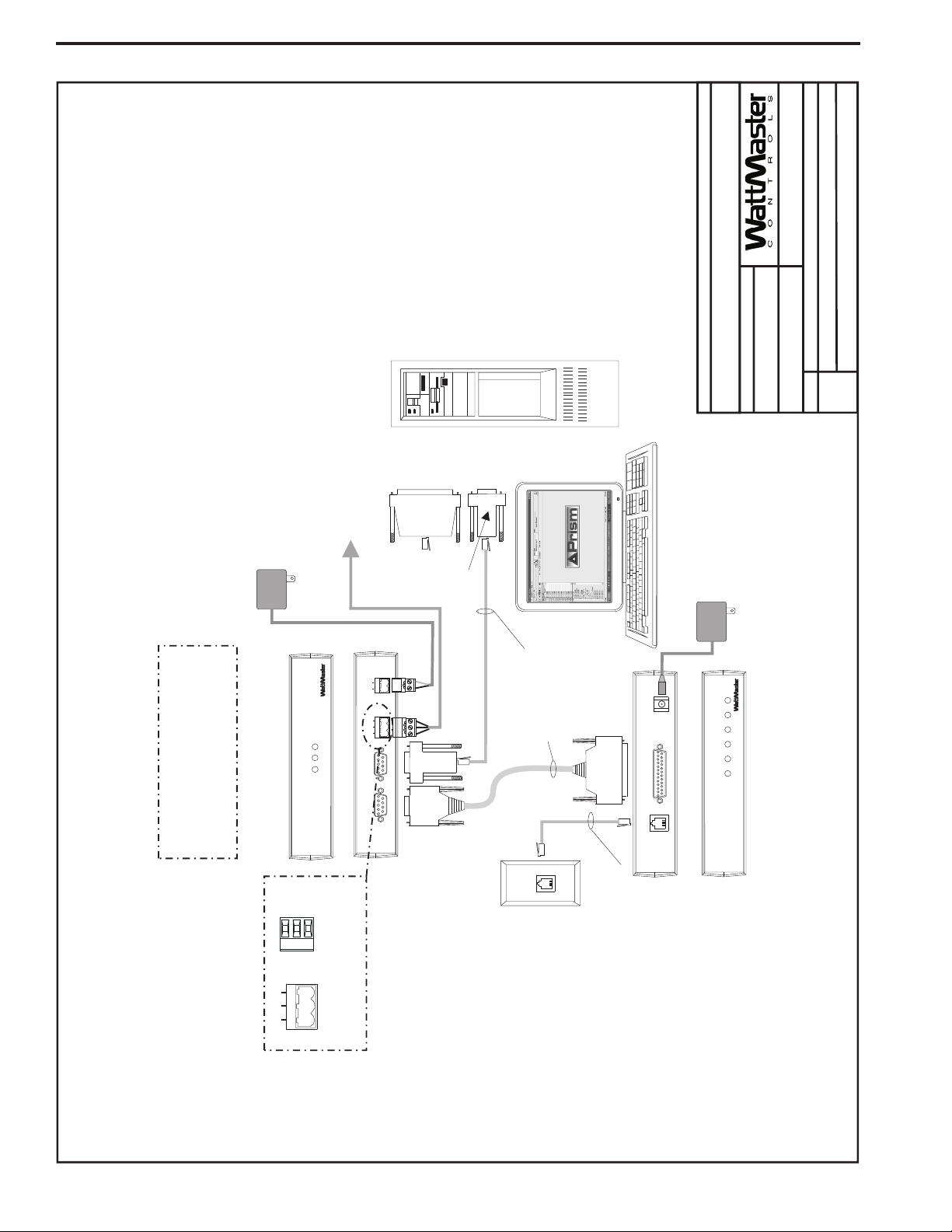

Networked Multiple Loop - Computer Connection With Remote Link

03/24/04

VAV-Network-MultLoop1B.CDR

FILENAME

DATE:

B. Crews

DESCRIPTION:

PAGE

DRAWN BY:

Wiring & Connection Diagram

JOB NAME

2of3

Network System - Multiple Loop

9Pin

Female

End

Telephone

Cable

Assembly

9Pin

Female

Connector

9Pin

Female

Connector

Molded

Cable Assembly

25 Pin

Male End

25 Pin

Female

Connector

(If Reqd)

Connect To Computer

Serial Port

Personal Computer

(By Others)

Dedicated Telephone

Outlet

(By Others)

Back View of CommLink

Back View of Remote Link

Front View of CommLink

Note: If Direct Computer Connection

Is Required, Connect To PC As Shown.

Remote Link Is Only Required If

Alarm Callout Or Remote Computer

Connection Is Required.

Front View of Remote Link

CLII

omm ink

LOOP

24V

T

G

R

GND

REMOTE LINK

(DTE)

COMPUTER

(DCE)

485 LOOP

STATUS

POWER

COMP

RLINK

SERIAL #

CONTROLS

RL

emote ink

SIG

TELCO

LINE

TELCO

LINE

SERIAL DATA

DET

RDY

SND

REC

PWR

SERIAL #

CONTROLS

8 Conductor

Modular Cable

Assembly

110 VAC To

9 VDC

Power Pack

110 VAC To

24 VAC

Power Pack

CommLink

Remote Link

(Optional)

Connect To MiniLink PD Network Terminals

See Page 1 Of This Drawing

POWER

9VDC @

500mA

SHLD

T

R

Typical Terminal Blocks. All

Wiring To Be T To T, SHLD (G)

To SHLD (G)&RToR

T

G

R

485 LOOP

Optional Computer Connection Diagram

Using Remote Link For Remote Connection

Component & System Wiring10

Page 11

Networked Multiple Loop - Computer Connection With IP-Link

JOB NAME

FILENAME

VAV-Network-MultLoop1B.CDR

B. Crews

DRAWN BY:

DESCRIPTION:

Network System - Multiple Loop

03/24/04

DATE:

3of3

PAGE

Wiring & Connection Diagram

Note: If Direct Computer Connection

Using IP-Link For Remote Connection

Optional Computer Connection Diagram

Is Required, Connect To PC As Shown. IP-Link Is

Only Required If E-mail Alarm Notification Or

Connect To MiniLink PD Network Terminals

See Page 1 Of This Drawing

Remote Computer Connection Is Required.

Note:

1.Set CommLink Internal Switch To”Multi”

2. Replace CommLink EPROM With IP-Link

EPROM Supplied With IP-Link Kit

110 VAC To

RLINK

COMP

LOOP

CommLink

Front View of CommLink

CLIIomm ink

SHLD

T

R

LOOP

485

R

G

T

24 VAC

Power Pack

CONTROLS

STATUS

Typical Terminal Blocks. All

ER

GND

24V

R

G

T

(DCE)

COMPUTER

(DTE)

Back View of CommLink

REMOTE LINK

SERIAL #

Wiring To Be T To T, SHLD (G)

To SHLD (G)&RToR

25 Pin

Female

9Pin

(If Reqd)

Connector

Female

Connector

(By Others)

Personal Computer

ne

onnect

C

9 VDC

110 VAC To

Power Pack

PWR

R

E

S

V

C

R

K

N

L

T

C

A

IP-Link

(Optional)

Front View of IP- Link

Serial Port

POW

485 LOOP

Connect To Computer

9Pin

Female

Connector

Assembly

8 Conductor

Modular Cable

Molded

Supplied With

Cable Assembly

IP-Link Kit

9 Pin Male End

Port On IP-Link

Connect To Serial

Mode

9VDC

Serial

10BaseT

Back View of IP-Link

End

9Pin

Female

Assembly

On IP-Link

RJ45 Cable

To 10BaseT Port

Connect Ethernet

Or Modem

(By Others)

Cable Assembly

Connect Ethernet RJ45

(By Others)

On Ethernet Router

To 10 BaseT Connection

Component & System Wiring 11

Page 12

Systems Overview

General Information

The WattMaster VAV system components can be configured into different types of systems depending on the type and number of controllers required. It is a good idea to become familiar with the types of

systems and their architecture by reading the information in this section

and looking at the configuration diagrams in the System Configurations Installation & Commissioning section of this manual. The information below is designed to help you understand how the system components integrate with each other and the available configuration options.

System Types

Two different system configurations are available depending on the type

and number of controllers that you have on your system.

1. Networked Single Loop

(See Pages 6 Through 8 For Connection Diagrams)

2. Networked Multiple Loop

(See Pages 9 Through 11 For Connection Diagrams)

System Type Definitions

Networked Single Loop

The Networked Single Loop system, as its name implies, consists of a

single communications loop. The system can consist of the following

controllers and devices.

1. A single WMVAV controller used as a VAV controller and

it’s associated VAVBOXcontrollers. Other WMVAV

controllers used for constant volume units and/or and Addon Devices may also be connected as long as the total of all

controllers on the loop does not exceed 59. Only one VAV

controller with it’s VAVBOX controllers can be installed

per loop. If more than one VAV controller with VAVBOX

controllers is required, you must have a separate loop for

each.

This system requires one CommLink communications interface and

one MiniLink Polling Device. Programming and status monitoring are

accomplished by the following methods.

1. By using an operators interface. This can be either a

Modular System Manager, a Modular Service Tool or both

devices. The System Manager or Modular Service Tool

can connect to any controller on the local loop.

2. A computer interface can also be used in conjunction with

the other operators interfaces listed above, or by itself. This

requires a personal computer with the Prism computer front

end software installed. The PC connects to the CommLink

via a supplied cable.

2. A single WMVAV controller used as a VAV controller and

its associated VAVBOX controllers. Other WMVAV

controllers used for constant volume units and/or and Addon Devices may also be connected as long as the total of all

controllers on the loop does not exceed 59. Only one VAV

controller with its VAVBOX controllers can be installed

per local loop.

To form the Networked Multiple Loop System the following network

devices are required.

1. A MiniLink Polling Device is required per loop (Local

Loop). This allows the controllers to share information that

is broadcast from one controller to all controllers on that

local loop and also provides alarming and trend logging

capabilities.

2. One CommLink is required for the entire system. It resides

on the Network Loop and allows for communications

between all the local loops and provides for global

broadcasts to all controllers on the entire system.

Programming and status monitoring are accomplished by one or more

of the following methods.

1. By using an operator interface. This can be either a

Modular System Manager, a Modular Service Tool or both

devices. The System Manager or Modular Service Tool can

connect to any controller on any “Local Loop” on the

entire system.

2. A computer interface can also be used in conjunction with

the other operators interfaces listed above, or by itself. This

requires a personal computer with the Prism computer front

end software installed. The PC connects to the CommLink

via a supplied cable.

Network Communications Devices

MiniLink Polling Device

1. This device is required for all Networked Single loop

systems.

2. One of these device is required on each local loop of all

Networked Multiple Loop systems

CommLink

1. One CommLink is required on all Networked Single Loop

or Multiple Loop Systems

2. Up to 60 local loops can be connected to the CommLink

Installation Procedures

Networked Multiple Loop

This Networked Multiple Loop System consists of two or more loops,

each being called ‘Local Loops’, with one ‘Network Loop’ that ties the

“Local Loops” together. Each of these local loops can consist of the

following controllers and devices.

1. A series of WMVAV controllers for constant volume units

and/or Add-on devices without any VAVBOX controllers.

Up to 59 controllers may be connected on the loop in this

manner.

The installation procedures that follow are based on recommended methods of wiring connection and controller installation. Installation procedures vary depending on the which Networked system you are installing. The system you are installing could be “Networked Single Loop”

or a “Networked Multiple Loop” system. The Networked Systems

also have installation variations based on the type of components you

are installing for that system. The following information explains the

procedures for all of these systems. Please find the system and components that closely match your system and follow the outlined procedures.

Component & System Wiring12

Page 13

Networked Single Loop Systems

See the “Networked System - Single Loop Wiring” on pages 6 through

8 of this manual for detailed wiring information. Also see page 16 for

wire and transformer sizing information. You should review these diagrams before attempting connections or powering up the controller or

interface devices.

1. Connect all WMVAV or Add-on Device controllers in a

daisy chain or star ring format by connecting from each

controller’s communication terminal block to the next using

18 gauge, 2 conductor shielded cable. Install a separate 24

VAC, transformer for each controller and wire from each

controller’s power terminal block to its transformer using

18 gauge minimum, 2 wire cable for power. See Wire and

Transformer Sizing section on page 16 for detailed

transformer and wire sizing information. Observe polarity

on all board power wiring. Install a separate 24 VAC, 6 VA

minimum, transformer for each VAVBOX controller on the

loop and wire from each controller’s power terminal block

to its transformer using 18 gauge minimum, 2 wire cable.

Observe polarity on all boards! As an alternative, a single

transformer that connects to all VAVBOX controllers may

also be used. It must be sized to handle the minimum load

of 6 VA per VAVBOX controller connected to it. When

using this method, the polarity of all wiring between the

transformer and the VAVBOX controllers is extremely

critical and must be maintained to prevent damage to

all boards connected! See the wire and transformer sizing

information on page 16 of this manual for complete

wire and transformer sizing information.

Warning: If polarity between controllers is not maintained,

severe damage to the controllers may result.

WattMaster recommends using a separate transformer

for each controller in order to eliminate the potential

for damaging controllers due to incorrect polarity.

2. Using 18 gauge 2 conductor shielded cable, connect from

the WMVAV controller’s 3 wire communications

connector to the MiniLink PD’s 3 wire communications

connector marked “Local Loop”.

3. Connect 2 conductor shielded cable from the

MiniLink PD’s 3 wire communications terminal blocks

labeled “Network Loop” to the CommLink’s 3 wire

communications terminal block located on the back of the

CommLink. Find the 110 VAC/24 VAC power supply

furnished with the CommLink and connect the 2 stripped

wire leads to the 24 VAC terminals on the back of the

CommLink. The CommLink’s internal jumper must be set

to “Multiple” for all WattMaster VAV systems. See page 45

of this manual for complete CommLink wiring and jumper

setting information. After determining all wiring and

jumper settings are correct, connect the power supply plugin transformer to a 110 V receptacle.

4. Install a 24 VAC, 6 VA minimum, transformer for the

MiniLink PD and wire it to the 24 VAC power terminal

block on the MiniLink PD using 18 gauge minimum, 2

wire cable. See page 46 of this manual for complete

MiniLink PD wiring diagrams and instructions.

5. When the Modular Service Tool is to be used for

programming and monitoring of the controllers it can be

connected to the WMVAV controllers using the supplied

cable with DIN connectors on both ends. The DIN

connector on the WMVAV controller is located near the

communications terminals. To connect the Modular Service

Tool to a VAVBOX controller first unplug the 3 wire

communication terminal block from the VAVBOX

controller. Connect the DIN to terminal adapter terminal

end to the communication terminals block socket on the

VAVBOX controller then connect the DIN connector side

of the adapter to the Modular Service Tool cable DIN

connector. See page 44 of this manual for complete

Modular Service Tool connection diagrams and

instructions.

6. The Modular System Manager comes supplied with a 12

foot modular cable pigtail with a modular connector on one

end and stripped wires on the other. Plug the modular

connector end into the System Manager modular connector.

Run 18 gauge, 2 conductor shielded cable for

communications from the MiniLink PD or any controller

on the local loop by connecting one end of the controller’s

or MiniLink PD’s 3 wire “Local Loop” communications

terminal block to a junction box located within 12 feet of

the System Manager. Run 18 gauge, 2 wire, power wires

supplied by a separate 24 VAC, 6 VA minimum transformer

into the junction box. Splice the stripped modular cable

ends from the System Manager to the communications and

power wire inside of the junction box using solid

connections made with wire nuts or butt-splice connectors.

See Modular System Manager wiring on pages 42 and 43

of this manual for wiring color coding and complete wiring

instructions. The Modular System Manager MUST always

be connected on the “Local Loop”, never the “Network

Loop”.

Networked Multiple Loop Systems

See the “Networked System - Multiple Loop Wiring” on pages 9 through

11 of this manual for detailed wiring diagrams. Also see page 16 for

wire and transformer sizing information. You should review these diagrams before attempting connections or powering up the controller or

interface devices.

Loop(s) with WMVAV Controllers without VAVBOX Controllers

1. For each local loop on the system, connect all controllers in

a daisy chain or star ring format by connecting from each

controllers communication terminal block to the next using

18 gauge, 2 conductor shielded cable. Install a separate 24

VAC, 8 VA minimum, transformer for each controller and

wire from each controller’s power terminal block to its

transformer using 18 gauge minimum, 2 wire cable for

power. Observe polarity on all boards.

2. Select one of the local loops and connect 2 conductor

shielded cable from one of its WMVAV controller’s 3 wire

communications terminal blocks to it’s associatedMiniLink

PD’s 3 wire communications terminal block marked “Local

Loop”. Repeat this procedure for all loops on the entire

system.

Component & System Wiring 13

Page 14

System Installation

3. Connect 2 conductor shielded cable from one of the

systems MiniLink PD’s 3 wire communications terminal

blocks labeled “Network Loop” to the CommLink’s 3 wire

communications terminal block located on the back of the

CommLink. Find the 110 VAC/24 VAC power supply

furnished with the CommLink and connect the 2

stripped wire leads to the 24 VAC terminals on the back of

the CommLink. The CommLink’s internal jumper must be

set to “Multiple” for all WattMaster VAV systems. See page

45 of this manual for complete CommLink wiring and

jumper setting information. After determining all wiring

and jumper settings are correct, connect the power supply

plug-in transformer to a 110 V receptacle.

4. Connect 2 conductor shielded cable for network

communications between each MiniLink PD on the system

including the one that was just connected to the

CommLink. This is accomplished by connecting between

each MiniLink PD’s 3 wire communications terminal block

labeled “Network Loop” and the next MiniLink PD’s

communications terminal block labeled “Network Loop”.

Install a 24 VAC, 6 VA minimum, transformer for each of

the MiniLink PDs on the system and wire each transformer

to the 24 VAC power terminal block for its respective

MiniLink PD using 18 gauge minimum, 2 wire cable. See

page 46 of this manual for complete MiniLink PD wiring

diagrams and instructions.

5. When the Modular Service Tool is to be used for

programming and monitoring of the controllers it can be

connected to the WMVAV controllers using the supplied

cable with DIN connectors on both ends. The DIN

connector on the WMVAV controller is located near the

communications terminals. See page 44 of this manual for

complete Modular Service Tool connection diagrams and

instructions.

6. The Modular System Manager comes supplied with a 12

foot modular cable pigtail with a modular connector on one

end and stripped wires on the other. Plug the modular

connector end into the System Manager modular connector.

Run 18 gauge, 2 conductor shielded cable for

communications from the MiniLink PD or any controller

on the local loop by connecting one end the controller’s or

MiniLink PD’s 3 wire “Local Loop” communications

terminal block to a junction box located within 12 feet of

the System Manager. Run 18 gauge, 2 wire, power wires

supplied by a separate 24 VAC, 6 VA minimum transformer

into the junction box. Splice the stripped modular cable

ends from the System Manager to the communications and

power wire inside of the junction box using solid

connections made with wire nuts or butt-splice connectors.

See Modular System Manager wiring on pages 42 and 43

of this manual for wiring color coding and complete wiring

instructions. The Modular System Manager MUST always

be connected on the “Local Loop”, never the “Network

Loop”.

Loop(s) with WMVAV and VAVBOX Controllers

1. Select one of the local loops on your system. Connect all

WMVAV or Add-on Device controllers in a daisy chain or

star ring format by connecting from each controller’s

communication terminal block to the next using 18 gauge,

2 conductor shielded cable. Install a separate 24 VAC,

transformer for each controller and wire from each

controller’s power terminal block to its transformer using

18 gauge minimum, 2 wire cable for power. See Wire and

Transformer Sizing section on page 16 for detailed

transformer and wire sizing information. Observe polarity

on all board power wiring. Install a separate 24 VAC, 8 VA

minimum, transformer for each VAVBOX controller on the

loop and wire from each controller’s power terminal block

to it’s transformer using 18 gauge minimum, 2 wire cable.

Observe polarity on all boards! As an alternative, a single

transformer that connects to all VAVBOX controllers may

also be used. It must be sized to handle the minimum load

of 6 VA per VAVBOX controller connected to it. When

using this method, the polarity of all wiring between the

transformer and the VAVBOX controllers is extremely

critical and must be maintained to prevent damage to

all boards connected! See the wire and transformer sizing

information on page 16 of this manual for complete wire

and transformer sizing information. Repeat this procedure

for each loop with VAVBOX controllers on your system.

Warning: If polarity between controllers is not maintained,

severe damage to the controllers may result.

WattMaster recommends using a separate transformer

for each controller in order to eliminate the potential

for damaging controllers due to incorrect polarity.

2. For each local loop on the system do the following. Using

18 gauge 2 conductor shielded cable, connect from

one of the WMVAV controller’s on the loop, 3 wire

communications connector to that loop’s MiniLink PD 3

wire communications terminal block marked “Local Loop”.

3. To install the CommLink, connect 2 conductor shielded

cable from one of the system’s MiniLink PD’s 3 wire

communications terminal blocks labeled “Network Loop”

to the CommLink’s 3 wire communications terminal block

located on the back of the CommLink. Find the 110 VAC/

24 VAC power supply furnished with the CommLink and

connect the 2 stripped wire leads to the 24 VAC terminals

on the back of the CommLink. The CommLink’s internal

jumper must be set to “Multiple” for all WattMaster VAV

systems. See page 45 of this manual for complete

CommLink wiring and jumper setting information. After

determining all wiring and jumper settings are correct,

connect the power supply plug-in transformer to a 110 V

receptacle.

4. The following procedure must be performed for each

MiniLink PD on your system. Install a 24 VAC, 6 VA

minimum, transformer for theMiniLink PD and wire it to

the 24 VAC power terminal block on the MiniLink PD

using 18 gauge minimum, 2 wire cable. See page 46 of this

manual for complete MiniLink PD wiring diagrams and

instructions. Be sure that all MiniLink PDs on the entire

system are wired as required.

Component & System Wiring14

Page 15

5. When the Modular Service Tool is to be used for

programming and monitoring of the controllers it can be

connected to the WMVAV controllers using the supplied

cable with DIN connectors on both ends. The DIN

connector on the WMVAV controller is located near the

communications terminals. To connect the Modular Service

Tool to a VAVBOX controller, first unplug the 3 wire

communication terminal block from the VAVBOX

controller. Connect the DIN to terminal adapter terminal

end to the communication terminals block socket on the

VAVBOX controller then connect the DIN connector side

of the adapter to the Modular Service Tool cable DIN

connector. See page 44 of this manual for complete

Modular Service Tool connection diagrams and

instructions.

System Commissioning

6. The Modular System Manager comes supplied with a 12foot modular cable pigtail with a modular connector on one

end and stripped wires on the other. Plug the modular

connector end into the System Manager modular connector.

Run 18 gauge, 2 conductor shielded cable for

communications from the MiniLink PD or any controller

on the local loop by connecting one end the controller’s or

MiniLink PD’s 3 wire “Local Loop” communications

terminal block to a junction box located within 12 feet of

the System Manager. Run 18 gauge, 2 wire, power wires

supplied by a separate 24 VAC, 6 VA minimum transformer

into the junction box. Splice the stripped modular cable

ends from the System Manager to the communications and

power wire inside of the junction box using solid

connections made with wire nuts or butt-splice connectors.

See Modular System Managerl wiring on pages 42 and 43

of this manual for wiring color coding and complete wiring

instructions. The Modular System Manager MUST always

be connected on the “Local Loop”, never the “Network

Loop”.

The following information is a brief overview of the procedures required to commission a typical WattMaster VAV System.

1. Address each MiniLink PD on the system with a unique

address from 1 to 60.

2. On a loop of WMVAV controllers and/or Add-on Devices,

without VAVBOX Controllers, address the controllers and

devices from 1 to 59.

3. On a loop which has VAVBOX controllers, address

the VAVBOX controllers from 1 to 58. Address the

WMVAV controller serving the VAVBOX controllers as

address 59. Address all other controllers with addresses not

already used by other controllers on the loop.

4. Always apply power to the system in the following order.

WMVAV controllers or Add-on Devices, MiniLink PD(s),

CommLink, VAVBOX controllers (if used).

5. After powering up verify diagnostics LED indicator for

proper operation of all controllers. See the technical guide

for each specific controller for detailed information on the

location of its diagnostic LED, and each controller’s

start-up sequence.

6. If a computer is used, install the Prism computer front end

software on it and connect it to the CommLink to access

all of the controllers on the entire system for programming.

7. If a computer is not used, and if a Modular System Manger

is not already connected on the local loop, connect a

Modular Service Tool to one of the controllers to perform

programming of all controllers on the entire system.

Component & System Wiring 15

Page 16

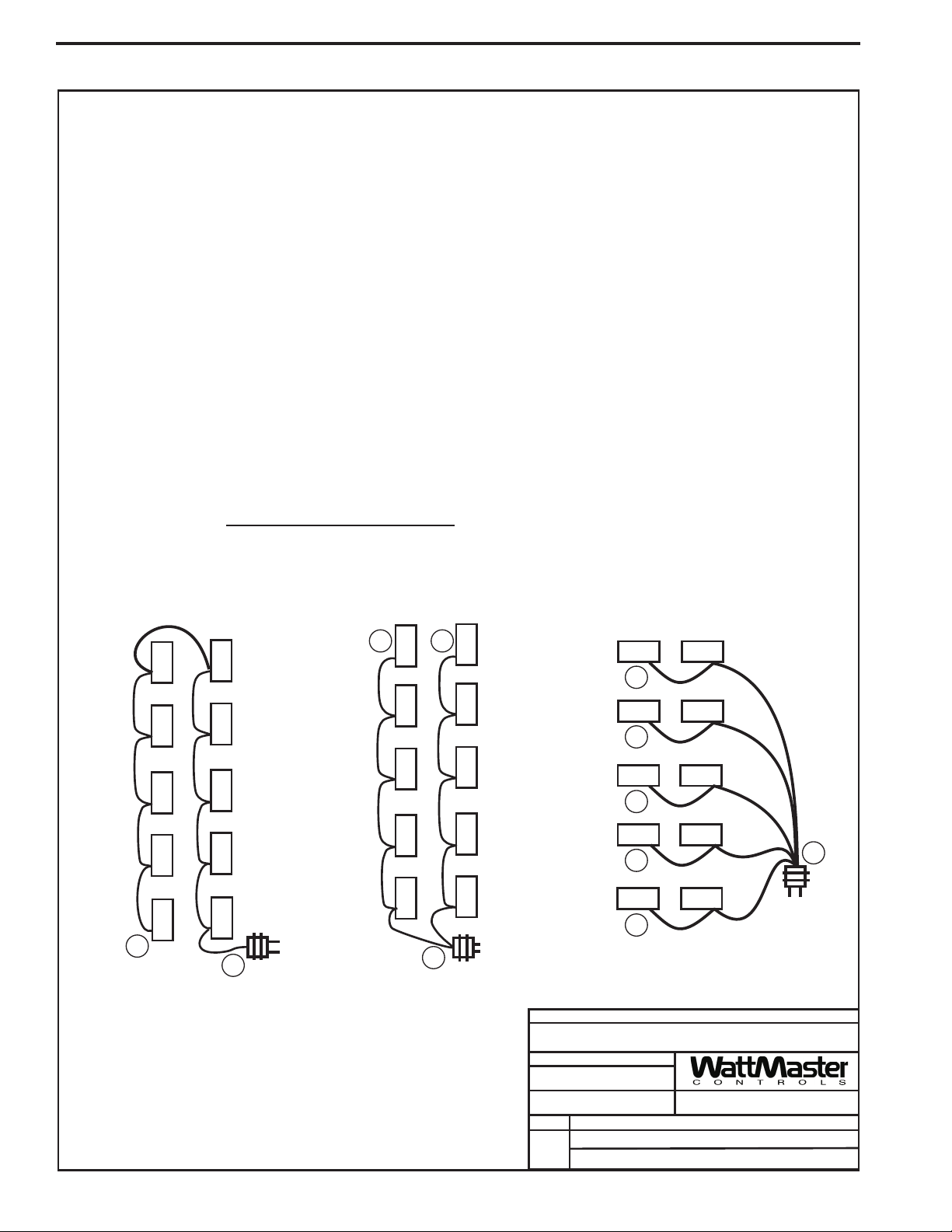

Transformer & Wire Sizing

24VAC Power - Transformer & Wire Sizing Considerations For VAVBOX Controllers

Some installers like to use one large 24VAC transformer to power several devices. This is allowable as long as polarity is maintained to each device on

the transformer circuit.

using a separate transformer for each device in order to eliminate the potential for damaging controllers due to incorrect polarity.

separate transformers also allows redundancy in case of a transformer failure. Instead of having 8 controllers inoperative because of a malfunctioning

transformer you have only 1 controller off line. If the installer does decide to use a large transformer to supply power to several devices, the following

transformer and wire sizing information is presented to help the installer correctly supply 24VAC power to the devices.

Following is a typical example to help the installer to correctly evaluate transformer and wiring designs.

Each VAVBOX Controller requires 6 VA @ 24VAC power. In the examples below we have a total of 10 VAV Controllers.

10 VAVBOX Controllers @ 6VA each................ 10 x 6VA =60VA.

The above calculation determines that our transformer will need to be sized for a minimum of 60VA if we are to use one transformer to power all the

controllers. We will use a 75 VA transformer, as this is a readily available size that meets our VA load requirements.

Next we must determine the maximum length of run allowable for the wire gauge we wish to use in the installation. Each wire gauge below has a

voltage drop per foot value we use to calculate total voltage drop.

18ga wire.................................0.00054 = voltage drop per 1’ length of wire

16ga wire.................................0.00034 = voltage drop per 1’ length of wire

14ga wire.................................0.00021 = voltage drop per 1’ length of wire

For our example we will use 18 gauge wire. WattMaster recommends 18 gauge as a minimum wire size for all power wiring.

Next use the voltage drop per foot value for 18 gauge wire from the list above and multiply by the total VA load of the 10 controllers to be installed.

0.00054 (Voltage drop per foot for 18 gauge wire) x 60VA controller load = Volts/Ft.

WattMaster VAVBOX controllers will operate efficiently with a voltage drop no greater than 2 Volts. Divide the total allowable voltage drop of 2 Volts by

the number you arrived at above and you have the maximum number of feet you can run the 18 gauge wire with an 75 VA transformer with no more

thana2Voltdrop at the farthest controller from the transformer..

Parallel circuiting of the wiring instead of wiring all 10 controllers in series allows for longer wire runs to be used with the same size wire (as shown in

our examples below).

transformer size, multiple transformers, circuiting, etc., when laying out an installation. No matter what layout scheme is decided upon, it is mandatory

that the farthest controller on the circuit is supplied with a minimum of 22 Volts and that the polarity is maintained to all controllers connected to the

transformer.

Warning:

It is often necessary for the installer to calculate and weigh the cost and installation advantages and disadvantages of wire size,

If polarity is not maintained, severe damage to the devices may result. WattMaster Controls recommends

0.0324

2 (Volts total allowable voltage drop)

0.0324 (Voltage drop per 1 ft. @ 60VA load)

= 61.73

feet

Using

B

A

120 / 24VAC

Distance A to B cannot exceed 61.73 Ft.

Component Power Requirements

VAV/CAV Controller ..................8VA

VAVBOX Controller..... ..............6VA

Optimal Start Scheduler............10VA

GPC Controller.................. .......8VA

BC

A

120 / 24VAC

Distance from A to B cannot exceed 123.46 Ft.

Distance from A to C cannot exceed 123.46 Ft.

GPC-17 Controller....................10VA

Lighting Panel Controller ..........10VA

MiniLink Polling Device............. 6VA

Distance from A to B cannot exceed 230.40 Ft.

Distance from A to C cannot exceed 308.64 Ft.

Distance from A to D cannot exceed 308.64 Ft.

Distance from A to E cannot exceed 308.64 Ft.

Distance from A to F cannot exceed 308.64 Ft.

FILENAME

VAV-WIRSIZ1.CDR

DATE:

05/12/04

PAGE

1of1

Wire & Transformer Sizing

F

E

D

C

B

JOB NAME

DRAWN BY:

DESCRIPTION:

WattMaster VAV

A

120 / 24VAC

B. CREWS

Component & System Wiring16

Page 17

WMVAV Controller Wiring

Component & System Wiring 17

Page 18

WMVAV Controller Wiring

3

2

1

+

_

All Comm Loop Wiring Is

Straight Thru

TtoT

RtoR

SHLD to SHLD

Connect To Next Controller,

MiniLink PD Or System Manager

See Individual Sensor

Wiring Diagrams For

Detailed Sensor Wiring

VFD 0-10VDC Input

GND

Supply Fan

Variable Frequency Drive

(By Others)

The VFD Unit Must Be

Configured For 0-10VDC

Input. The Input Resistance

At The VFD Must Not Be

Less Than 1000 Ohms When

Measured At The VFD

Terminals With All Input

Wires Removed.

Local Loop RS-485

9600 Baud

On Local Loop

Analog Inputs

C21

RN1

1

TB1

COMM

T

SHLD

R

CX5

LD6

COMM

LD7

1

PWR

LD8

LED1

RN3

LD9

LED2

R1

+VREF

TESTPOINT

U7

RV1

VREFADJ

INPUTS

+VDC

RN5

AIN1

AIN2

AIN3

AIN4

AIN5

C10

GND

GND

AOUT1

AOUT2

AIN7

GND

PJ1

TB3

PRESSURE

SENSOR

EXPANSION

Splice If Req’d

S.P.

Transducer

CX1

U2

U1

U5

RS-485

COMM

5.11V

C12

C17

P1

EWDOG

R26

RAM

HH

C1

R28

ADDRESS

PU1

D6

PU2

D7

PU3

D8

PU4

SW1

D9

PU5

D11

PU7

0-5

VDC

D14

U13

CX13

D15

U15

C20

CX15

PJ2

CX2

U6

PHILIPS

0-1

ADD

2

4

8

16

32

TOKEN

NETWORK

VDC

JP1

U3

CX3

EPROM

TUC-5R PLUS

(1 MEG)

YS101816 REV.2

CX6

C2

X1

C3

1

CX10

U10

CX12

C11

X2

R15

U12

CX14

C14

R19

U14

C15

R22

R24

R25

D18

D17

PJ3

C18

T'STAT

Not Used

Connect To

Expansion Board

Base (When Used)

D1

CX4

U4

RLY1

D2

RLY2

D3

PAL

1

RLY3

D4

RN2

RLY4

D5

RLY5

1

RN4

U9

C7

R7

D10

L1

R10

D13

D12

R13

SC1

D19

C19

VR1

VR2

Jumper Must

Be In 0-5V Position

As Shown

CX8

D16

COM1-3

COM4-5

NE5090NPB3192

0PS

R6

C9

R11

R27

V6

R1

R2

R3

R4

R5

U8

9936

V1

V2

V3

V5

U11

MC34064A

C13

C16

GND

POWER

24VAC

R - 24VAC

G - Fan ON/OFF Only

TB2

Relay Output Dry Contacts

R2 Thru R5 May Be User Configured

V4

For The Following:

1 - Heating (Aux. Heating)Stages

2 - Cooling (Compressor) Stages

3 - Warm-up Mode Command For Boxes

4 - Reversing Valve (Air To Air Heat Pumps)

5 - Gas Reheat Control For Dehumidification

6 - Exhaust Fan Interlock

7 - Preheat Coil

8 - Alarm Relay

9 - Override

10 - Occupied

11 - Economizer

Note: Up To 16 More Relays Are Available By

Adding Relay Expansion Boards. All

Expansion Board Relay Outputs Are User

Configurable As Listed Above.

TB4

GND

24VAC

Size Transformer For

Correct Total Load. WMVAV

Controller = 8 VA Power

Consumption. If Economizer

Option Is Used

The Economizer Actuator

VA load Must Also Be

Considered When Sizing

The Transformer.

Line Voltage

Economizer

Actuator

(Belimo Shown)

Consult Factory For

Other Manufacturers

Wiring Connections

Warning:

24 VAC Must Be Connected So That All Ground

Wires Remain Common. Failure To Do So Will

Result In Damage To The Controllers.

Notes:

1.)24 VAC Must Be Connected So That

All Ground Wires Remain Common.

2.)All Wiring To Be In Accordance With

Local And National Electrical Codes

and Specifications.

3.)All Communication Wiring To Be 18

Ga. Minimum, 2 Conductor Twisted

Pair With Shield. Belden #82760 Or

Equivalent.

4.)When Humidity Sensor Is To Be

Installed A 250 Ohm Resistor Must Be

Installed On The Ground Side Of The

Sensor And Pull Up Resistor PU5

Must Be Removed From The

Controller. See Humidity Sensor

Wiring Diagram In The WMVAV

section of this manual.

Connect Tubing To High Pressure

Port (Bottom Tube) and Route To Static

Pressure Pickup Probe Located In Unit

Discharge. Leave Port Marked “Lo” Open

GND

To Atmosphere

24VAC

5.)If The Slide Adjust Option Is Used On

The Room Sensor , The AUX

Connection Must Be Wired To AIN7.

The Fan Proof Of Flow Switch,

Which Normally Connects To AIN7, Is

Not Available For Use When The

Slide Adjust Option Is Used.

FILENAME

VAV-WMVAVWIR1A.CDR

DATE:

05/12/04

PAGE

1of2

JOB NAME

DRAWN BY:

B. Crews

DESCRIPTION:

WMVAV Controller

Component Wiring Diagram

Component & System Wiring18

Page 19

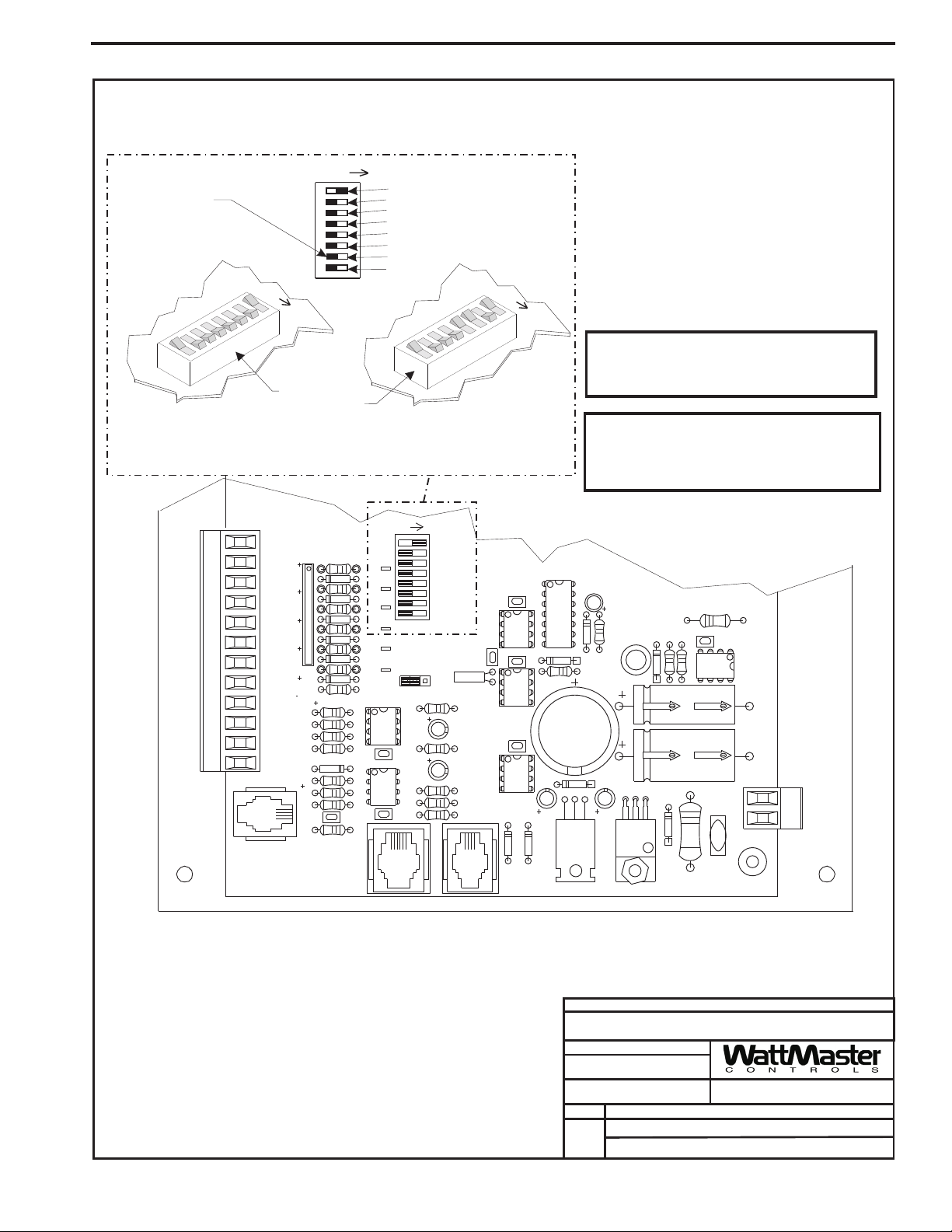

WMVAV Controller Addressing

This Switch Should Be

In The OFF Position

As Shown

ADDRESS ADD

Address Switch Shown Is

Set For Address 1

The Address For Each Controller

Must Be Unique To The Other Controllers

On The Local Loop And Be Between 1 and 59

INPUTS

+VDC

AIN1

AIN2

AIN3

AIN4

AIN5

GND

GND

AOUT1

AOUT2

AIN7

GND

PJ1

TB3

PRESSURE

SENSOR

ADDRESS ADD

Controller

Address Switch

RN5

C10

C17

C12

R26

C20

D15

PU1

D6

PU2

D7

PU3

D8

PU4

D9

PU5

D11

PU7

D14

PJ2

EXPANSION

1

2

4

8

16

32

TOKEN

NETWORK

ADDRESS ADD

Address Switch Shown Is

Set For Address 13

0-5

CX13

CX15

U15

SW1

VDC

0-1

ADD

1

2

4

8

16

32

TOKEN

NETWORK

VDC

JP1

PJ3

C14

C15

U10

C11

X2

R15

R19

R22

R24

R25

ADDRESS

U13

U14

D17

CX10

U12

CX14

D18

CX12

Note:

The Power To The Controller Must Be Removed And

Reconnected After Changing The Address Switch

Settings In Order For Any Changes To Take Effect.

Caution

Disconnect All Communication Loop Wiring From The

Controller Before Removing Power From The Controller.

Reconnect Power And Then Reconnect Communication

Loop Wiring.

C7

D16

R6

C9

R11

U11

C13

C16

TB4

GND

R27

V6

POWER

C18

D10

D12

R13

SC1

D19

C19

R7

L1

R10

D13

24VAC

VR1

VR2

JOB NAME

FILENAME

VAV-WMVAVWIR1A.CDR

PAGE

2of2

DATE:

05/12/04

DRAWN BY:

DESCRIPTION:

WMVAV Controller

Component Wiring Diagram

B. Crews

Component & System Wiring 19

Page 20

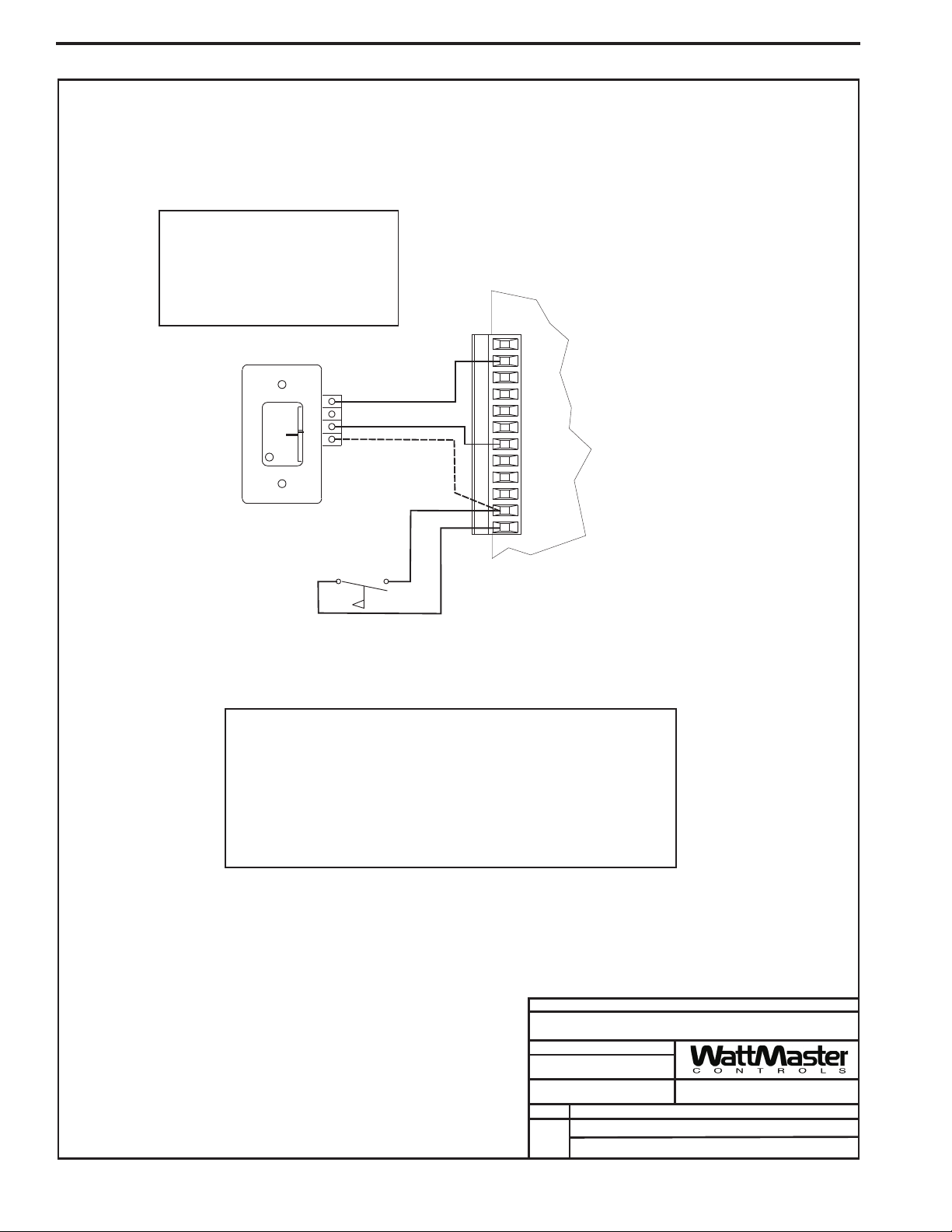

Space Sensor Wiring

Note:

If The Slide Adjust Option Is Used On

The Room Sensor The AUX Terminal

Must Be Wired To AIN7. The Fan Proof

Of Flow Switch, Which Normally

Connects To AIN7, Is Not Available For

Use When The Slide Adjust Option Is

Used.

Space Temperature Sensor

NORMAL

OVR

W

A

R

M

E

R

C

O

O

L

E

R

TMP

GND

AUX (See Note)

Fan Proof Of

Flow Switch

(See Note)

INPUTS

+VDC

AIN1

AIN2

AIN3

AIN4

AIN5

GND

GND

AOUT1

AOUT2

AIN7

GND

WMVAV Controller Board

Space Temperature Sensor Information

The Space Temperature Sensor is typically used for constant volume HVAC

unit applications controlling one zone. The Space Temperature Sensor is a

10K Type III thermistor sensor. The Space Temperature Sensor should be

mounted approximately 5 ft. above the floor in the space that is to be

controlled. The Space Temperature Sensor is available in a sensor only,

sensor with override button, sensor with slide adjust and sensor with slide

adjust and override configurations. If the Space Temperature Sensor with

Slide Adjust option is to be used, the Fan Proof of Flow Switch cannot be

used.

Notes:

1.)All Wiring To Be In Accordance With

Local And National Electrical Codes

and Specifications.

FILENAME

VAV-SpaceTempWire1.CDR

DATE:

05/12/04

PAGE

1

Space Temperature Sensor To

WMVAV Controller Wiring

JOB NAME

DRAWN BY:

DESCRIPTION:

B. Crews

Component & System Wiring20

Page 21

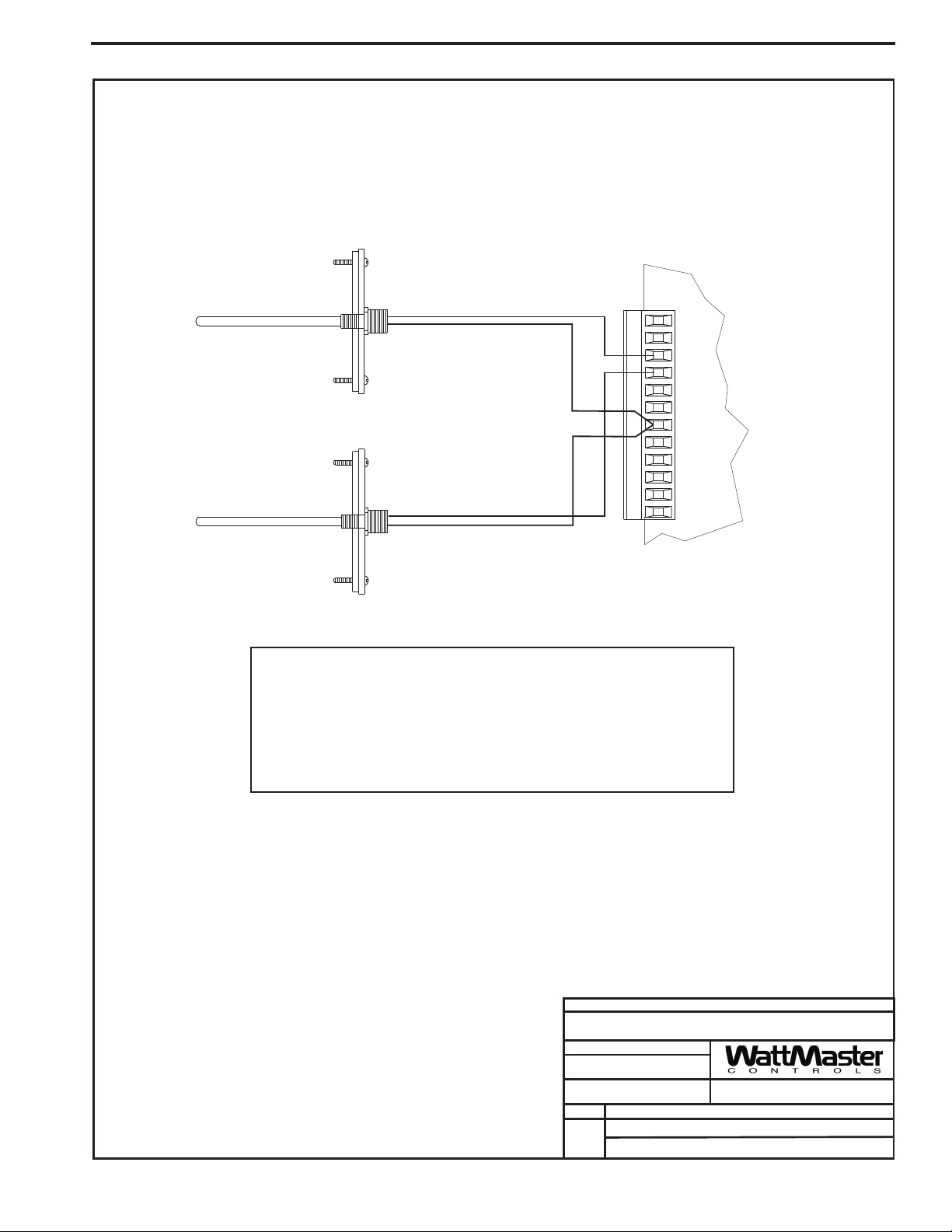

Supply & Return Sensor Wiring

Supply

Air Temperature

Sensor

Mount In HVAC

Unit Supply

Air Duct

Return

Air Temperature

Sensor

INPUTS

+VDC

AIN1

AIN2

AIN3

AIN4

AIN5

GND

GND

AOUT1

AOUT2

AIN7

GND

Mount In HVAC

Unit Return

Air Duct

WMVAV Controller Board

Supply & Return Sensor Information

The Supply and Return Air Temperature Sensors must be wired as shown in the

illustration below for proper operation. The Supply and Return Air Temperature

Sensors are 10K Type III thermistor sensors. The Supply Air Temperature Sensor

should be mounted in the unit discharge plenum or in the supply air duct. The Return

Air Temperature Sensor should be mounted in the return air duct. If the system has a

bypass damper installed, be sure the return air sensor is located upstream of the

bypass duct connection.

Notes:

1.)All Wiring To Be In Accordance With

Local And National Electrical Codes

and Specifications.

FILENAME

VAV-SupRetTempWire1.CDR

DATE:

03/24/04

PAGE

Supply & Return Air Temperature Sensor To

1

JOB NAME

DRAWN BY:

DESCRIPTION:

WMVAV Controller Wiring

B. Crews

Component & System Wiring 21

Page 22

Outside Air Sensor Wiring

Caution:

Be sure to mount the Outside Air Sensor in an area that is not exposed to direct sunlight. A