Page 1

www.wattmaster.com

MUA II Controller

Technical Guide

Page 2

Table of Contents

Controller Overview ......................................................................................................................................... 3

Features .......................................................................................................................................................................................3

Controller Inputs and Outputs ......................................................................................................................... 6

General.........................................................................................................................................................................................6

MUA II Controller Analog Inputs ...................................................................................................................................................6

Relay Outputs...............................................................................................................................................................................6

Analog Output ..............................................................................................................................................................................6

Controller Installation & Wiring ...................................................................................................................... 7

General.........................................................................................................................................................................................7

Controller Mounting ......................................................................................................................................................................7

Important Wiring Considerations ..................................................................................................................................................7

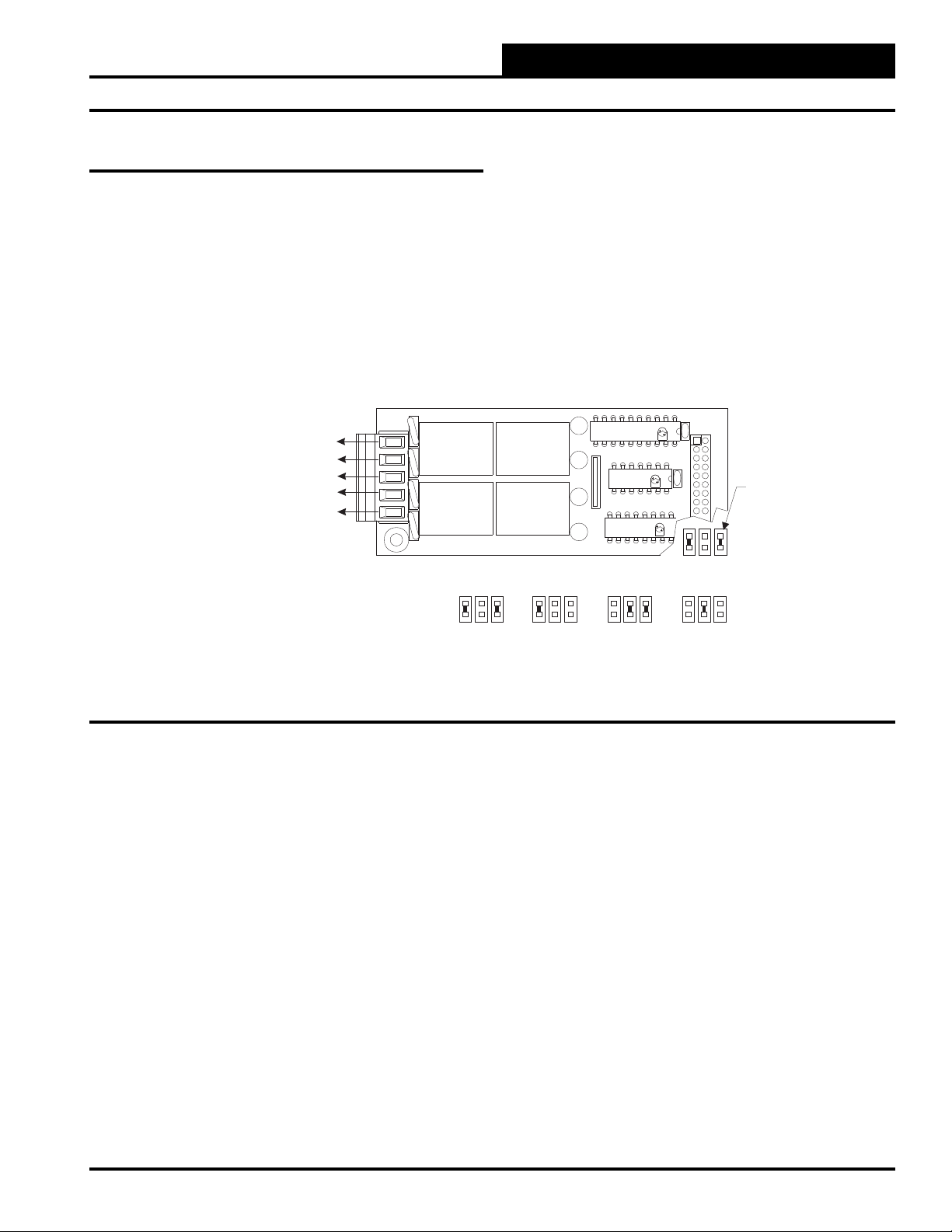

Expansion Board Installation & Wiring ........................................................................................................... 9

Jumper Settings ...........................................................................................................................................................................9

Wiring Considerations ................................................................................................................................................................10

Wiring Details ................................................................................................................................................. 11

Space Temperature Sensor ........................................................................................................................................................ 11

Supply Air Temperature Sensor ..................................................................................................................................................12

Outside Air

Remote Occupied Contact ........................................................................................................................................................13

Outside Air Humidity Sensor .....................................................................................................................................................14

Space Humidity Sensor ..............................................................................................................................................................15

Fan Proof of Flow Switch ...........................................................................................................................................................15

Temperature Sensor .................................................................................................................................................13

Start-up & Commissioning............................................................................................................................. 16

Controller Addressing .................................................................................................................................................................16

Power Wiring .............................................................................................................................................................................16

Initialization.................................................................................................................................................................................17

Programming The Controller ......................................................................................................................................................17

Sequence of Operations ................................................................................................................................ 18

MUA Operation Overview ...........................................................................................................................................................18

MUA Modes ................................................................................................................................................................................18

Initialization.................................................................................................................................................................................21

MUA II Confi guration & Setup ....................................................................................................................................................21

Scheduling..................................................................................................................................................................................22

Force Modes or Overrides..........................................................................................................................................................23

Internal Trend Logging ...............................................................................................................................................................23

Troubleshooting ............................................................................................................................................. 24

Using LED’s To Verify Operation ................................................................................................................................................24

Appendix ........................................................................................................................................................ 26

WattMaster Controls Inc.

8500 NW River Park Drive · Parkville , MO 64152

Toll Free Phone: 866-918-1100

PH: (816) 505-1100 · FAX: (816) 505-1101 · E-mail: mail@wattmaster.com

Visit our web site at www.wattmaster.com

Form: WM-MUAII-TGD-01A Copyright 2009 WattMaster Controls, Inc.

WattMaster Controls, Inc. assumes no responsibility for errors, or omissions.

This document is subject to change without notice.

Page 3

Controller Overview

MUA II Controller

Features

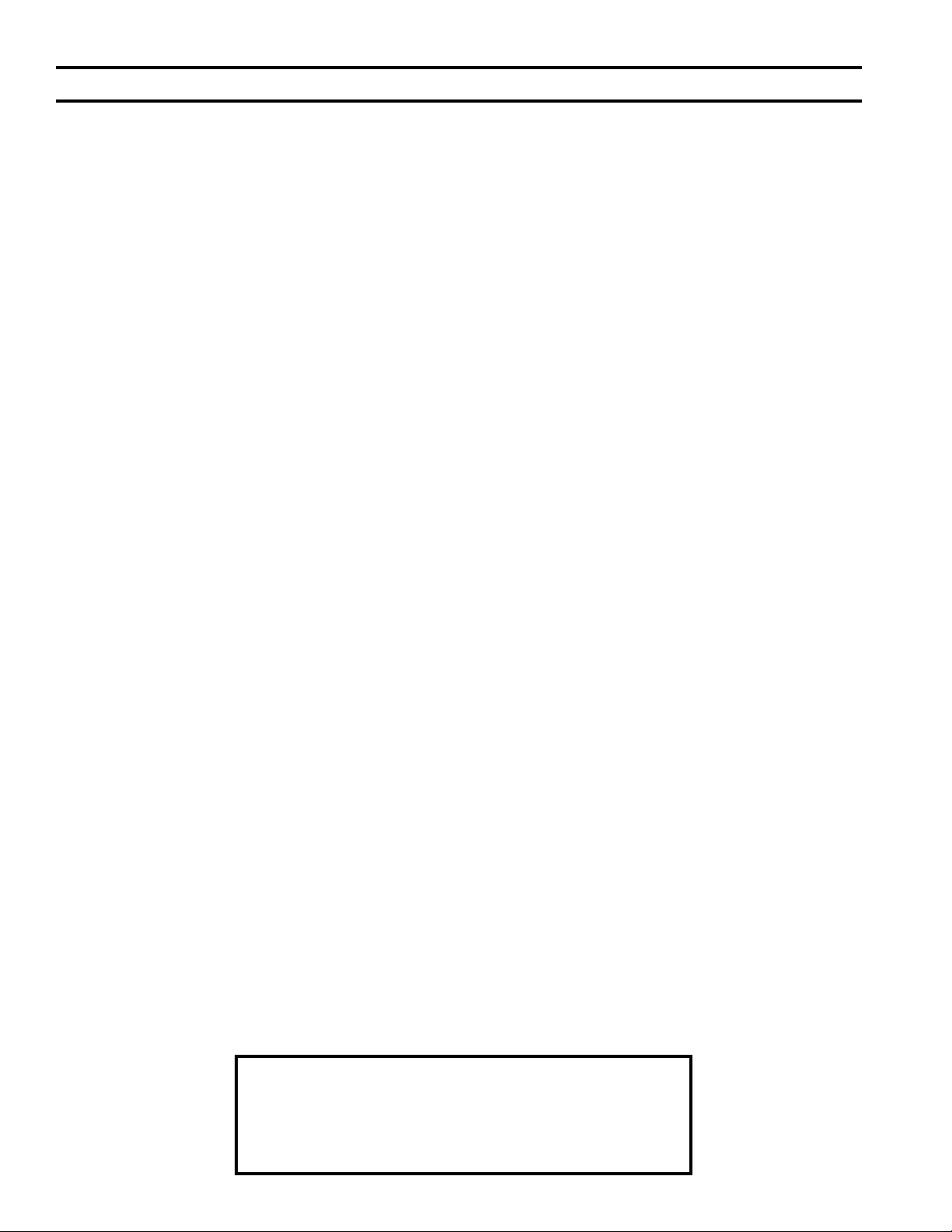

The MUA II Controller Board is designed with 5 usable analog inputs

and 5 relay outputs. The controller’s input and output capabilities can

be expanded by use of either 2-slot or 4-slot expansion boards that plug

into the MUA II Controller by means of a modular cable. The MUA II

Controller is designed for use with Makeup Air HVAC units. Features

include the following:

• Up to 8 Stages of Cooling (4 on board, 4 more with

expansion board)

• Up to 8 Stages of Heating (4 on board, 4 more with

expansion board)

• External Modulating Heat

• Fan Proving Interlock

• Supply Air Setpoint Reset From Temperature Input

• Dewpoint Setpoint Reset From Humidity Input

• Accepts Remote Occupied Signal

• De-Humidifi cation Capable

• 7-Day, 2-Event-Per-Day Scheduler Built In

• 14-Day Holiday Scheduler Built In

• Internal Trend Logging

Most makeup air control confi gurations can be confi gured with the

standard MUA II Controller. If the application requires more outputs,

optional relay expansion boards are available from the factory to

provide for additional relay outputs as required. These expansion

boards are installed on the MUA II Controller board via a modular

cable connection.

The available expansion board configurations allow for up to 16

additional binary (relay) outputs. The various expansion boards connect

to the expansion board base. Jumpers must be set according to the board

type installed. Up to 4 Relay Output Expansion Boards can be installed

on the expansion base board connected to the controller.

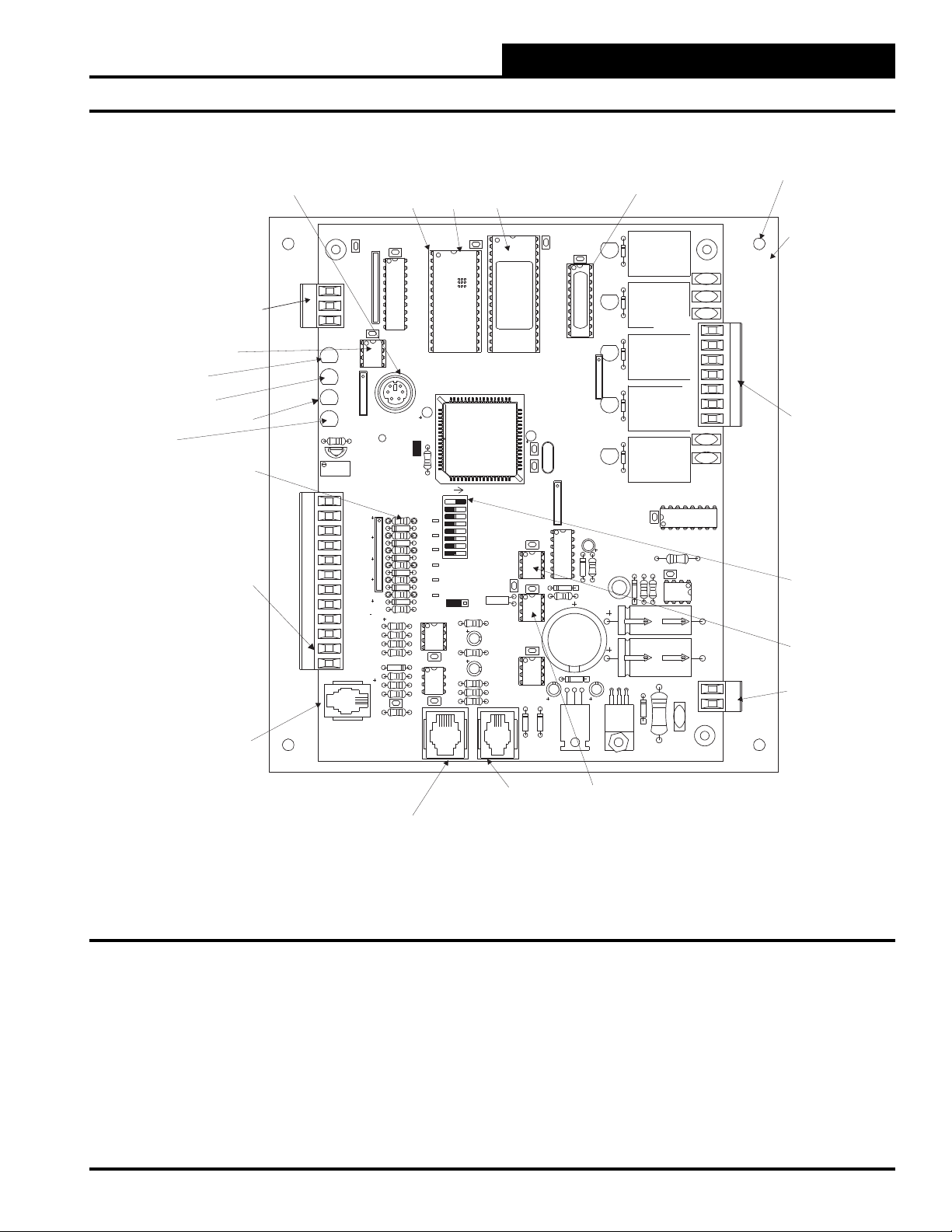

.20 Dia.

Typ. of 4

7.3”

C21

TB1

COMM

T

SHLD

R

CX5

LD6

COMM

LD7

PWR

LD8

LED1

LD9

LED2

R1

U7

RV1

VREFADJ

INPUTS

+VDC

AIN1

AIN2

AIN3

AIN4

AIN5

GND

GND

AOUT1

AOUT2

AIN7

GND

PJ1

TB3

PRESSURE

SENSOR

CX1

RN1

1

U5

RS-485

COMM

1

RN3

P1

+VREF

5.11V

TESTPOINT

EWDOG

RN5

C10

C12

C17

R26

EXPANSION

6.2“

U3

CX2

U2

U1

RAM

HH

U6

C1

R28

ADD

ADDRESS

1

2

4

PU1

8

D6

16

PU2

32

D7

TOKEN

PU3

NETWORK

D8

PU4

SW1

D9

PU5

D11

PU7

D14

D15

C20

PJ2

X2

0-1

0-5

VDC

VDC

JP1

U13

R15

C14

R19

CX13

U15

C15

R22

R24

R25

CX15

PJ3

EPROM

TUC-5RPLUS

YS101816REV. 2

U10

C11

U14

D17

CX3

(1MEG)

CX6

C2

C3

CX10

CX12

U12

CX14

D18

C18

T'STAT

D1

CX4

U4

RLY1

D2

RLY2

D3

PAL

1

RLY3

D4

RN2

RLY4

D5

X1

RLY5

1

RN4

U9

C7

D10

R7

L1

D13

D12

R13

SC1

D19

C19

VR1

VR2

CX8

R10

D16

COM1-3

COM4-5

R6

R11

R27

V6

C9

R1

R2

R3

R4

R5

U8

V1

V2

V3

V4

V5

U11

C13

C16

TB4

GND

POWER

24VAC

TB2

6.6”

6.7”

Figure 1: MUA II Controller Dimensions

Technical Guide 3

Page 4

MUA II Controller

Controller Overview

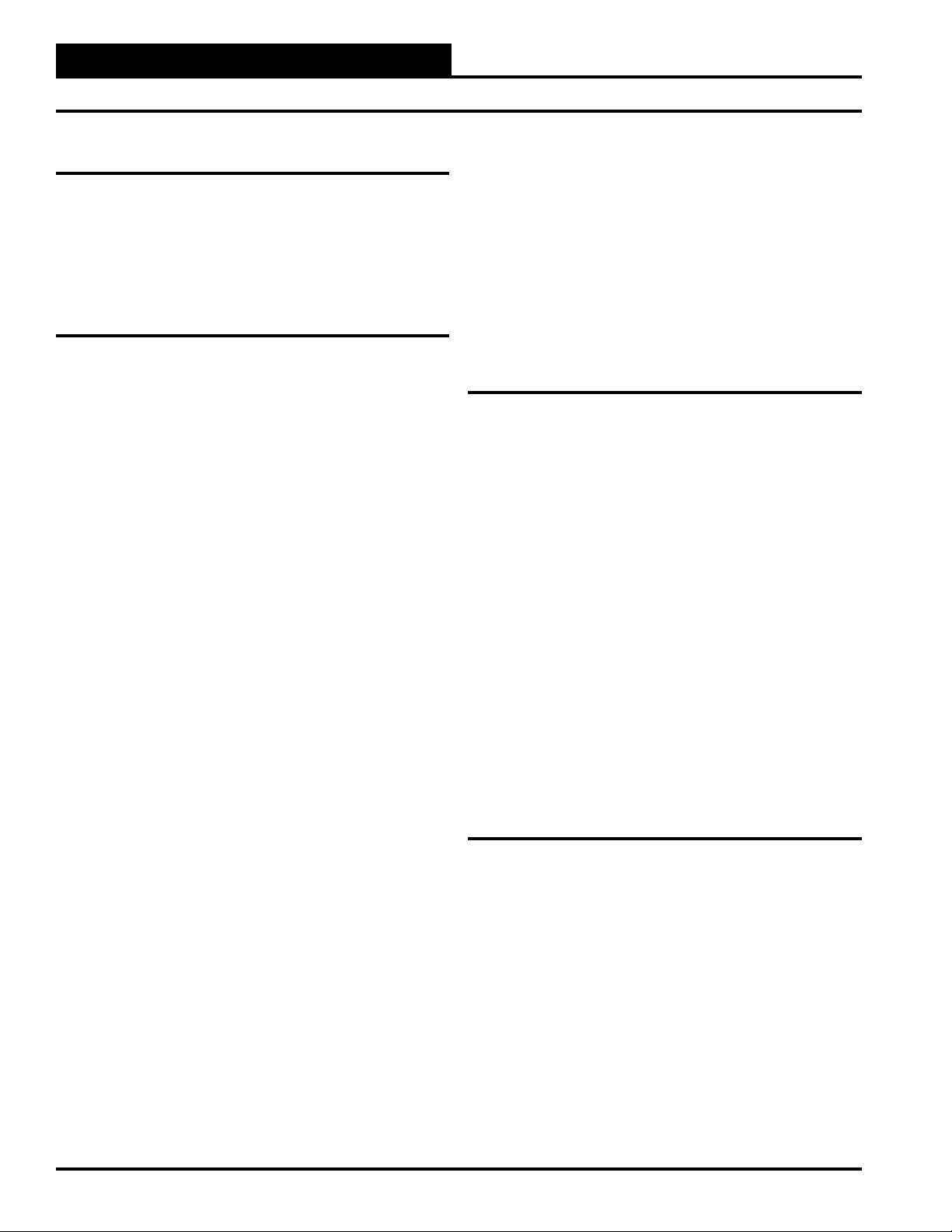

2.12

TB2

TB1

C6

GND

24VAC-IN

PWR

LD1

R14

D3

VR2

VR3

4.73

VR4

VR5

VR6

R13

MC

7824CT

CX3

MC

7805ACT

MC

7812CT

MC

7824CT

MC

7824CT

2-Slot Expansion

Base Board

C1

C2 C3

C4 C5

4.24

GND

+24VDC-OUT

YS101780

4.00

4.00

0.28

TB2

TB1

GND

+24VDC-OUT

24VAC-IN

GND

PJ2

PJ1

R11

R9

D2D1 R8

R7

P1

U1

P82B715P

CX1

JP1

R1

R2

R3

U2

P2 JP2

LM358N

CX2

VR1

R10

R4

2 SLOT MODULAR I/O

R5

R6

R12

5.96

5.40

C8

VR2

VR3

VR4

VR5

VR6

9.52

VR7

VR8

LD1

PWR

R20

D3

7824CT

7805ACT

7812CT

7824CT

7824CT

7824CT

7824CT

4 SLOTMODULAR I/O BD.

YS101782

PJ2

PJ1

R17

R19

CX3

R15

D1

D2

C1

R13

R14

P1

U1

P82B715P

C2

C3

C4

C5

C6

C7

CX1

JP1

R1

R2

R3

U2

P2

LM358N

CX2

JP2

R5R4 R6

P3

JP3

R9R8R7

P4

VR1

R16

JP4

R10

R11

R12

R18

8.29

8.96

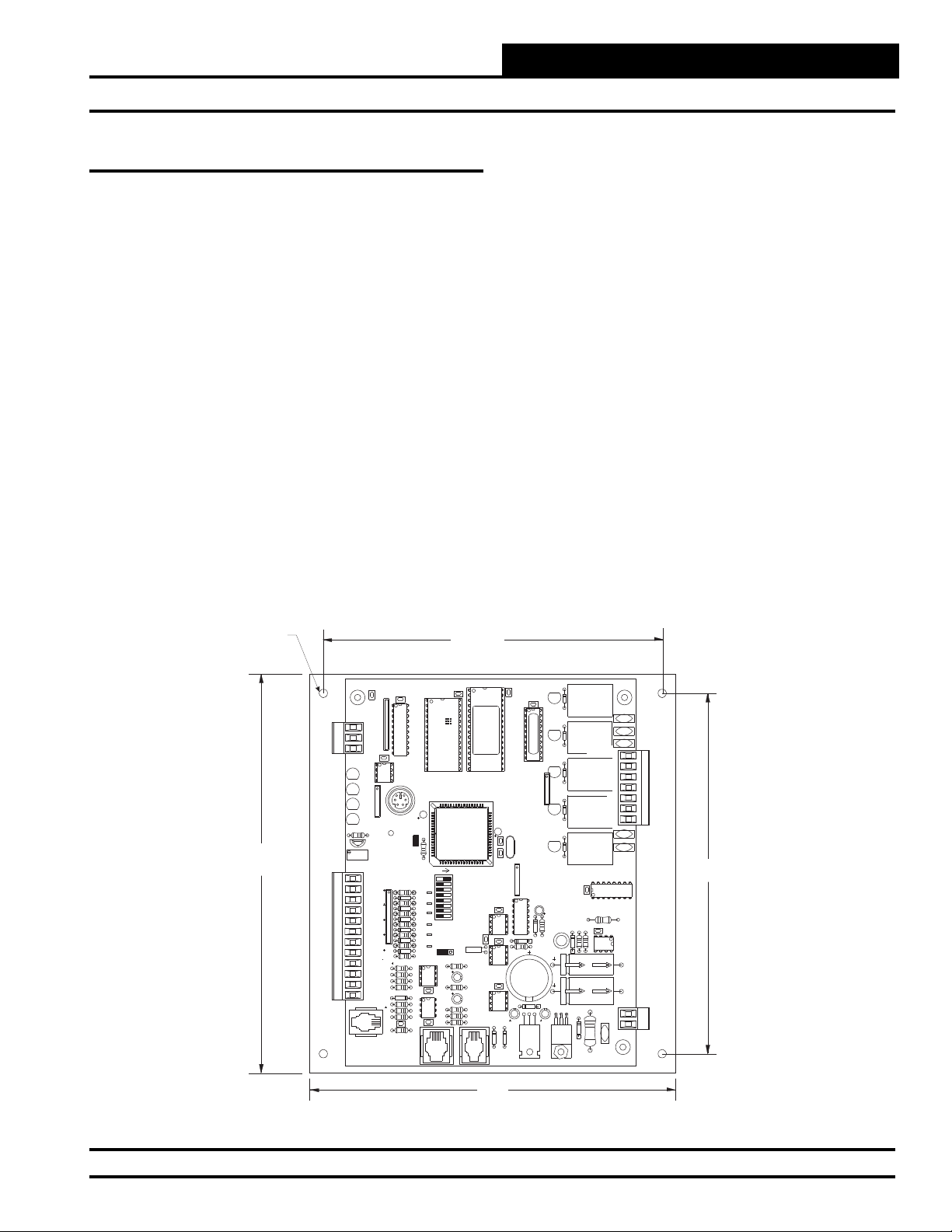

Figure 2: Expansion Base Board Dimensions

V4

4RLY IO BD.

K4

YS101790

4.00

K3

K4

OMRON

24VDC

G5L-114P-PS

OMRON

24VDC

G5L-114P-PS

K3

RN1

1.67

UL 5A250VAC

CONTACT:

UL 5A250VAC

CONTACT:

K2

OMRON

24VDC

G5L-114P-PS

OMRON

24VDC

G5L-114P-PS

K1

2.12

4-Slot Expansion

Base Board

TB1

V1

UL 5A250VAC

CONTACT:

K1

4.24

UL 5A250VAC

CONTACT:

K2

0.28

4.24

Figure 3: Relay Expansion Board Dimensions

4

U3

CX3

PCF8574P

74HC04N

ULN2803A/

CX2

PHILIPS

TL

HA

AN

ID

U1

CX1

P1

U2

Technical Guide

Page 5

MUA II Controller

Controller Overview

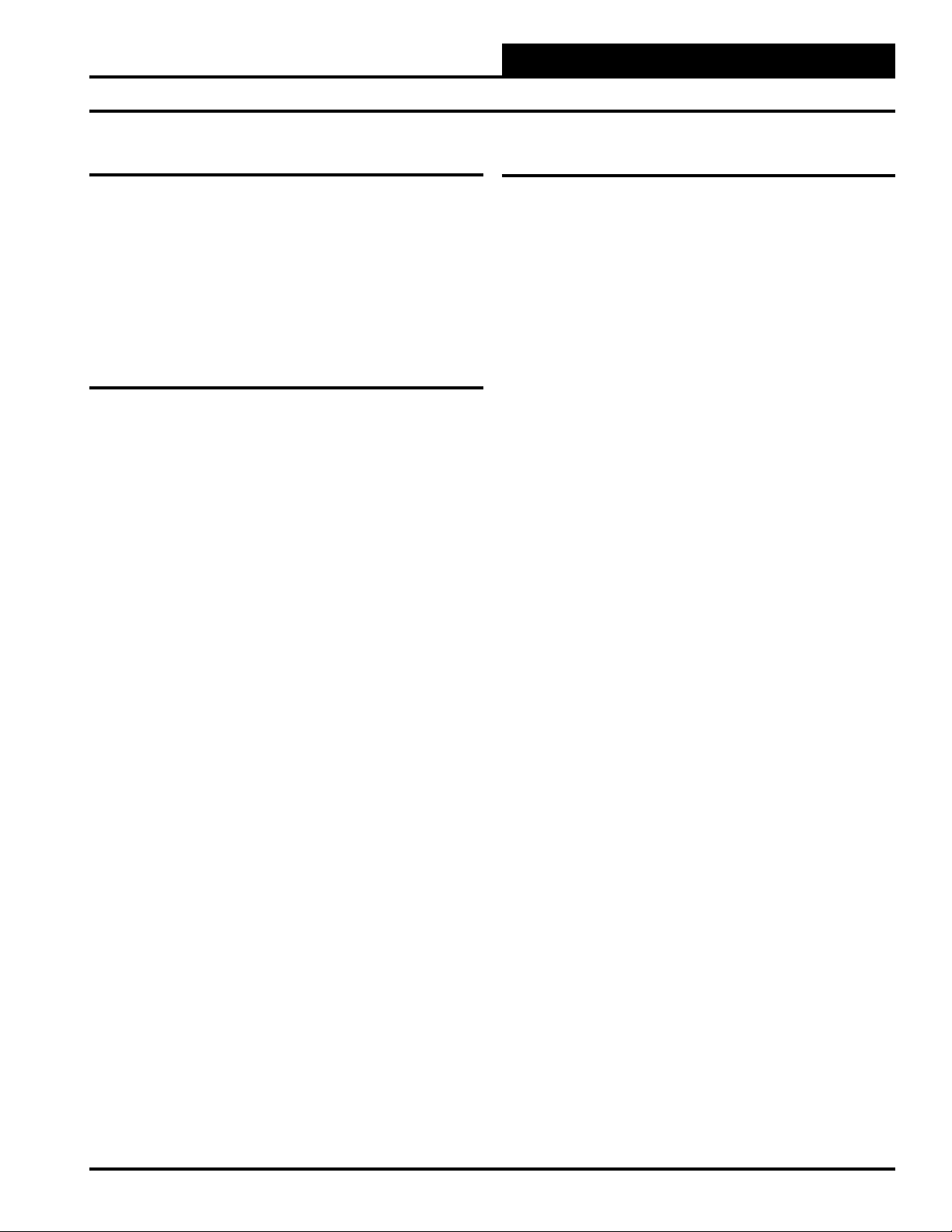

RS-485

Communications

Loop Connection

RS-485

Communications

Driver Chip

Comm

LED

Power

LED

Diagnostic

Blink Code

LED

Pull-up Resistors

For Analog Inputs

Analog Input

And Output

Terminal Block

Pressure Sensor

(AIN6 Modular Connection)

Not

Used

Modular Service

Tool - Mini Din

Connector

C21

TB1

COMM

T

SHLD

R

CX5

LD6

COMM

LD7

PWR

LD8

LED1

LD9

LED2

R1

U7

RV1

VREF ADJ

INPUTS

+VDC

AIN1

AIN2

AIN3

AIN4

AIN5

GND

GND

AOUT1

AOUT2

AIN7

GND

PJ1

TB3

PRESSURE

SENSOR

Typical

Pin 1

Indicator

CX1

RN1

1

U1

U5

RS-485

COMM

1

RN3

P1

+VREF

5.11V

TEST POINT

EWDOG

RN5

C10

C12

D15

C17

C20

R26

EXPANSION

Mounting Hole

EPROM

RAM

Chip

Chip

ADD

1

2

4

8

16

32

TOKEN

NETWORK

VDC

JP1

PJ3

X2

R15

C14

R19

C15

R22

R24

R25

U3

EPROM

TUC-5R PLUS

YS101816 REV.2

C2

CX10

U10

C11

U12

CX14

U14

D17

T'STAT

(1 MEG)

C3

CX3

CX4

U4

PAL

1

RN2

CX6

X1

1

RN4

U9

C7

D10

CX12

D12

R13

SC1

D19

D18

C19

C18

VR1

CX2

U2

RAM

HH

U6

C1

R28

ADDRESS

PU1

D6

PU2

D7

PU3

D8

PU4

SW1

D9

PU5

D11

PU7

0-1

0-5

VDC

D14

U13

CX13

U15

CX15

PJ2

PAL

Chip

D1

RLY1

D2

RLY2

D3

V1

V2

V3

COM1-3

R1

R2

RLY3

D4

R3

R4

R5

RLY4

RLY5

R7

COM4-5

D5

CX8

L1

R10

D13

D16

TB2

V4

V5

U8

R6

C9

R11

U11

C13

C16

TB4

GND

R27

V6

POWER

24VAC

VR2

Typof4

Mounting

Backplate

Relay Output

Terminal Block

Address Switch

EEPROM

24 VAC

Power Input

Expansion Board

(Modular Connection)

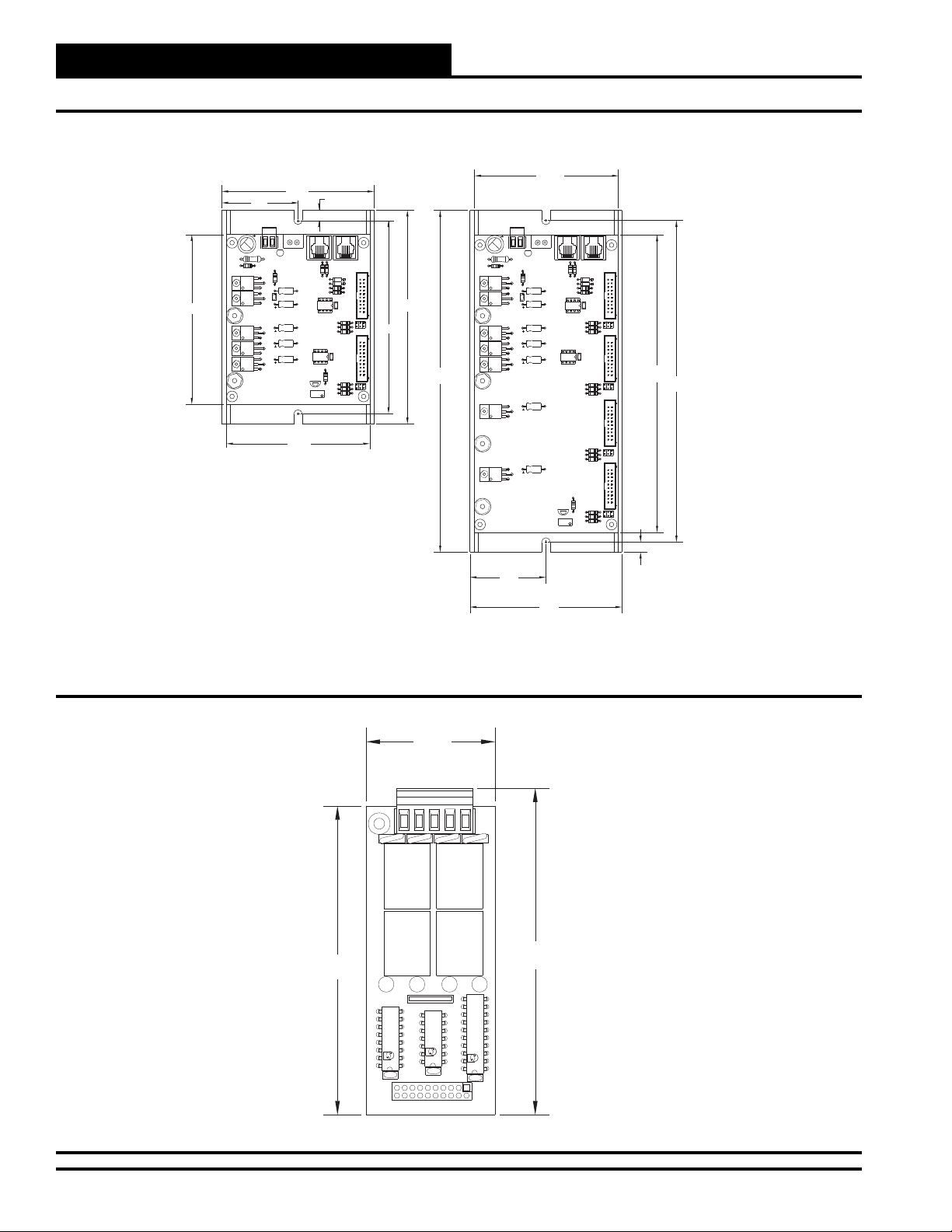

Figure 4: MUA II Controller Component Locations

Technical Guide

Not Used

Real Time

Clock Chip

5

Page 6

MUA II Controller

Controller Inputs and Outputs

General

The following inputs and outputs are available on the MUA II Controller

and/or the relay expansion boards that can be added to the main controller board expansion port. For component locations of the inputs on the

MUA II Controller, see Figure 4. For wiring of inputs and outputs, see

Figure 5 and 6.

MUA II Controller Analog Inputs

Input #1 - Reset Temperature Sensor

A space temperature sensor can be connected here and used for modulation of the Supply Air Setpoint. At a specifi ed Space Temperature

Setpoint, the Supply Air Setpoint will be reset towards the Maximum

Supply Air Temperature Setpoint.

Input #2 - Supply Air Temperature

The Supply Air Temperature Sensor is connected to this input. This

sensor is used to control heating and cooling staging.

Input #3 - Remote Occupied Contact

This input can be confi gured to monitor a contact closure from another

building automation system which indicates that the equipment should be

operating in the occupied mode. If the remote occupied signal is being

monitored, you must program all the internal schedules to be zero for

both the start and stop times on every day of the week.

Input #4 - Outdoor Air Temperature

The Outdoor Air Temperature Sensor is connected to this input. The

Outdoor Air Temperature Sensor is used to initiate the heating, cooling,

and vent modes of operation. It is also used in combination with the

outdoor air humidity to calculate the Dewpoint Temperature.

Input #5 - Outdoor Air Humidity

This input is used for an Outdoor Air Humidity Sensor that, combined

with the outdoor air temperature, is used to calculate a Dewpoint Temperature for the purpose of dehumidifi cation.

Input #7 - Fan Proof of Flow Switch

or Reset Humidity Sensor

A Proof of Flow Switch that provides a contact closure whenever the fan

is moving air can be monitored on this input. If this contact opens while

the fan is on, all heating and cooling is suspended. This is an optional

item. If a switch is installed, you must confi gure the MUA II to utilize

the signal. If this option is not confi gured, the unit will default to reset

humidity input. An indoor Humidity Sensor can be installed on this

input instead of the Proof of Flow Switch. This extra Humidity Sensor

is used to provide for reset of the Dewpoint setpoint.

Relay Outputs

Relay #1 - Fan (Enable)

This is a non-confi gurable output.

Relay #2 - #5 Confi gurable Relays

These relays are located on the MUA Controller. Confi guration order

and options are the same as for relays #6 through #21 as outlined in the

information for these relays that follows.

Relay #6 - #21 Confi gurable Relays

These relays are available by using Relay Expansion boards connected

to the MUA II Controller. Relays can be confi gured in any order, but we

recommend that they be confi gured in the following order:

1. Heating (aux. heating) stages

2. Cooling (compressor) stages

3. Gas Reheat Control for De-Humidifi cation

4. External Heat Enable

You can have up to 8 stages of Heating (aux. heating) and 8 stages of

Cooling (compressors) as well as individual relays assigned to options

3 and 4 above.

Analog Output

Input #6 - Not Used

6

AOUT1

The MUA II Controller has 1 Analog Output available. The usable output

is located at terminal AOUT1 and is used for controlling an external

heating device. Voltage ranges for this output are user-confi gurable for

either a 0-10 VDC or 2-10 VDC signal.

Technical Guide

Page 7

MUA II Controller

Controller Installation & Wiring

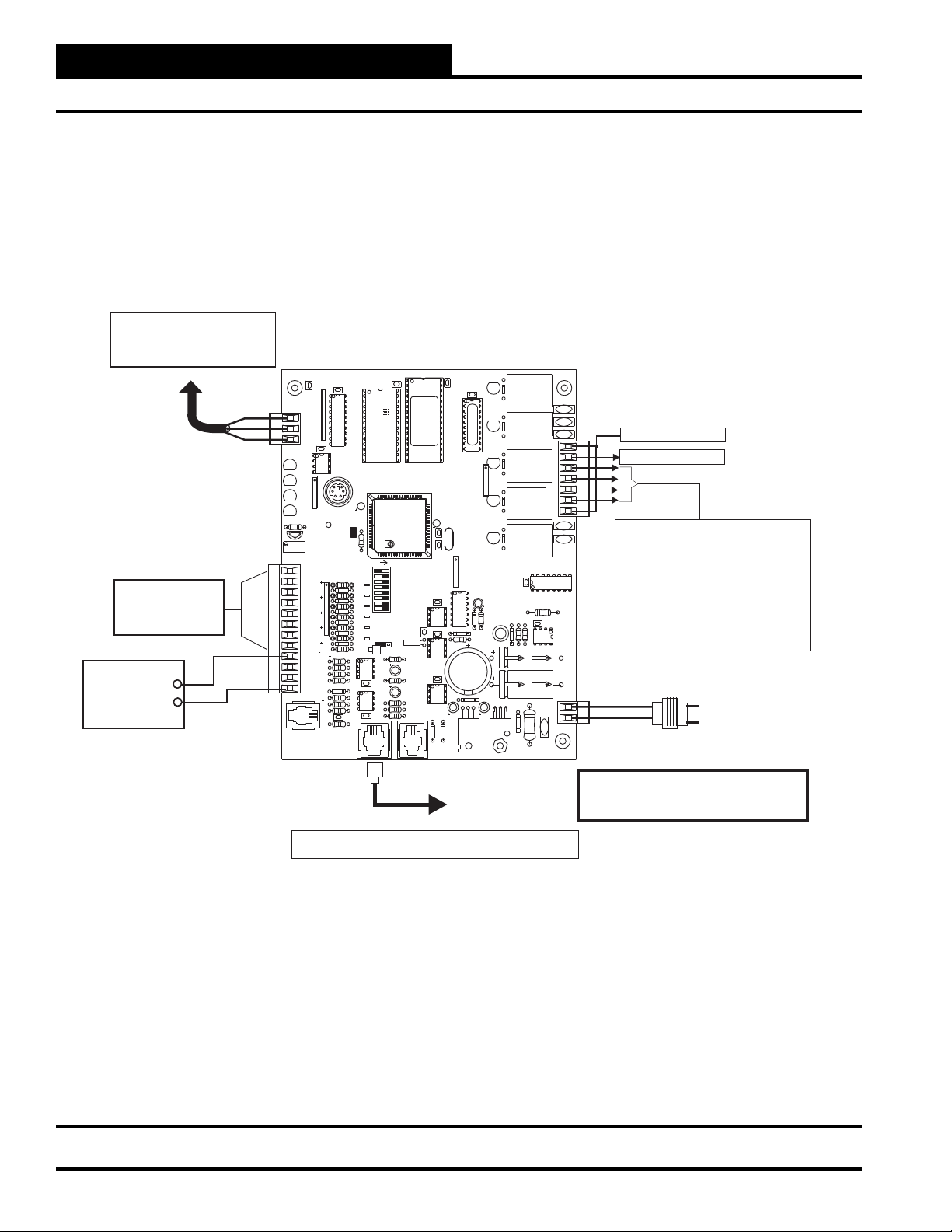

General

Correct wiring of the MUA II Controller is the most important factor in

the overall success of the controller installation process. In general, most

MUA II Controllers are factory installed and wired. It is also possible to

purchase these controllers directly from WattMaster Controls for installation in the fi eld. Some of the following information pertains to fi eld

wiring and may not apply to your installation since it was pre-wired at

the factory. However, in the unlikely event that troubleshooting of the

controller is required, it is a good idea to be familiar with the system

wiring, no matter if it was factory or fi eld wired.

Controller Mounting

When the controller is to be fi eld mounted, it is important to mount the

controller in a location that is free from extreme high or low temperatures,

moisture, dust, and dirt. It is recommended that it be installed in the

HVAC unit control panel. If this is not practical, it should be mounted

in a separate control enclosure that is weathertight. Be careful not to

damage the electronic components when mounting the controller. Remove the controller from its backplate. Mark the control enclosure base

using the backplate as a template. Drill pilot holes in the enclosure base

and secure the backplate to it using sheet metal screws. Do not allow

metal shavings to fall onto the circuit board. Reattach the controller to

the backplate.

Important Wiring Considerations

Please carefully read and apply the following information when wiring

the MUA II Controller. See Figure 5 for MUA II Controller wiring

diagram.

1. All 24 VAC wiring must be connected so that all ground

wires remain common. Failure to follow this procedure

can result in damage to the controller and connected

devices.

2. All wiring is to be in accordance with local and national

electrical codes and specifi cations.

3. Minimum wire size for 24 VAC wiring should be 18 gauge.

4. Minimum wire size for all sensors should be 24 gauge.

Some sensors require 2-conductor wire and some require

3-conductor.

5. Be sure that all wiring connections are properly inserted

and tightened into the terminal blocks. Do not allow wire

strands to stick out and touch adjoining terminals which

could potentially cause a short circuit.

6. When communication wiring is to be used to interconnect

controllers together or to connect to other communication

devices, all wiring must be minimum 18-gauge,

2-conductor, twisted pair with shield.

7. Before applying power to the MUA II Controller, be sure

to recheck all wiring connections and terminations

thoroughly.

Technical Guide

7

Page 8

MUA II Controller

Controller Installation & Wiring

Connect To Next Controller And/Or

MiniLink PD On Local Loop

For Stand Alone Applications

Connect To System Manager

All Comm Loop Wiring Is

Straight Thru

TtoT

RtoR

SHLD to SHLD

Analog Inputs

See Individual Sensor

Wiring Diagrams For

Detailed Sensor Wiring

0-10 VDC

0r 2-10 VDC

Connect To

External Heat

Device If Used

Local Loop RS-485

9600 Baud

+

_

C21

CX1

RN1

1

TB1

COMM

T

SHLD

R

CX5

U5

LD6

INPUTS

TB3

RS-485

COMM

COMM

LD7

1

PWR

LD8

LED1

RN3

LD9

LED2

R1

+VREF

5.11V

TESTPOINT

U7

RV1

VREFADJ

+VDC

RN5

AIN1

AIN2

AIN3

AIN4

AIN5

C10

GND

GND

C12

AOUT1

AOUT2

AIN7

C17

GND

PJ1

PRESSURE

SENSOR

EXPANSION

Note: All Temperature Sensors Must Be Thermistor Type III Which

Provide 10K Ohms Resistance @77 Deg. F

U2

U1

RAM

HH

C1

P1

EWDOG

R28

ADDRESS

PU1

D6

PU2

D7

PU3

D8

SW1

PU4

D9

PU5

D11

PU7

0-5

VDC

D14

U13

CX13

D15

U15

C20

CX15

R26

PJ2

MUA II Controller

CX2

U6

PHILIPS

ADD

1

2

4

8

16

32

TOKEN

NETWORK

X2

0-1

VDC

JP1

R15

C14

R19

C15

R22

R24

R25

PJ3

U3

EPROM

TUC-5RPLUS

YS101816REV. 2

U10

C11

U14

D17

T'STAT

C2

CX10

U12

CX14

(1MEG)

CX6

C3

CX12

D18

CX3

X1

C18

Connect To

Expansion Board

Base (When Used)

D1

CX4

U4

RLY1

D2

RLY2

D3

PAL

1

RLY3

D4

RN2

RLY4

D5

RLY5

1

RN4

U9

C7

D10

R7

L1

R10

D13

D12

R13

SC1

D19

C19

7824CT

M

VR1

VR2

CX8

D16

COM1-3

COM4-5

R11

R27

V1

V2

R1

R2

R3

R4

R5

U8

NE5090NPB3192

0PS

R6

C9

9936

U11

MC34064A

C13

C16

GND

V6

POWER

24VAC

V3

TB2

V4

V5

TB4

R - 24VAC

G - Fan ON/OFF Only

Relay Output Dry Contacts

R2 Thru R5 May Be User Configured For

The Following:

1 - Heating (Aux. Heating)Stages

2 - Cooling (Compressor) Stages

3 - Gas Reheat Control For Dehumidification

4 - External Heat Enable

Note: Up To 16 More Relays Are Available

By Adding Relay Expansion Boards. All

Expansion Board Relay Outputs Are User

Configurable As Listed Above.

GND

24VAC

Required VA For

Transformer = 8VA

Warning:

24 VAC Must Be Connected So That All Ground

Wires Remain Common. Failure To Do So Will

Result In Damage To The Controllers.

Line Voltage

Figure 5: MUA II Controller Wiring

8

Technical Guide

Page 9

Expansion Board Installation & Wiring

Jumper Settings

The expansion boards are connected to the MUA II Controller with

a modular cable. Up to 2 Expansion Base Boards can be populated

with expansion boards to provide additional inputs and outputs. The

expansion boards can be placed on the expansion base board in any

order; however, the jumpers on the Expansion Base Board must be set

correctly for proper operation. See Figure 6 for correct jumper settings

and jumper locations.

4 Relay Output Expansion Board

Relay Outputs - 6 Through 21

N.O. Contact #6 - Configurable

N.O. Contact #7 - Configurable

N.O. Contact #8 - Configurable

N.O. Contact #9 - Configurable

TB1

Common

V1

V4

4RLY IO BD.

Relays 6-9 Relays 10-13

MUA II Controller

K1

UL 5A250VAC

CONTACT:

24VDC

G5L-114P-PS

OMRON

UL 5A250VAC

CONTACT:

24VDC

G5L-114P-PS

OMRON

K4

YS101790

K2

UL 5A250VAC

CONTACT:

K1

24VDC

G5L-114P-PS

OMRON

K2

UL 5A250VAC

CONTACT:

24VDC

G5L-114P-PS

K3

RN1

OMRON

K3

K4

Relays 14-17 Relays 18-21

CX1

ULN2803A/

74HC04N

PCF8574P

P1

PHILIPS

TL

HA

AN

ID

U1

CX2

U2

Address Jumpers

Jumpers

Under

Expansion

Board To Be

Set As Shown

Figure 6: Expansion Board Jumper Settings

Technical Guide

9

Page 10

MUA II Controller

Expansion Board Installation & Wiring

Wiring Considerations

The expansion base boards must be connected to 24 VAC as shown in

the wiring diagram below. As noted below, the power requirement for

a two-slot base board is 10 VA. A four-slot base board requires 20 VA.

Be sure that the transformer used for powering the base boards meets

these minimums. See Figure 7 for complete wiring details.

Observe Polarity! All boards must be wired with GND-to-GND and 24VAC-to-24VAC.

Failure to observe polarity will result in damage to one or more of the boards. Expansion

Boards must be wired in such a way that power to both the expansion boards and the

controller are always powered together. Loss of power to the expansion board will cause the

controller to become inoperative until power is restored to the expansion board.

Relay Output #6 - Configurable (N.O. Dry Contact)

Relay Output #7 - Configurable (N.O. Dry Contact)

Relay Output #8 - Configurable (N.O. Dry Contact)

Relay Output #9 - Configurable (N.O. Dry Contact)

Relay Output #10 - Configurable (N.O. Dry Contact)

Relay Output #11 - Configurable (N.O. Dry Contact)

Relay Output #12 - Configurable (N.O. Dry Contact)

Relay Output #13 - Configurable (N.O. Dry Contact)

Common

Common

WARNING!!

24VAC

POWER

INPUT

GND

4RLY IO BD.

4RLY IO BD.

24VAC

YS101790

YS101790

Connect to

MUA

Controller Board

Relay Output #14 - Configurable (N.O. Dry Contact)

Relay Output #15 - Configurable (N.O. Dry Contact)

Relay Output #16 - Configurable (N.O. Dry Contact)

Relay Output #17 - Configurable (N.O. Dry Contact)

Relay Output #18 - Configurable (N.O. Dry Contact)

Relay Output #19 - Configurable (N.O. Dry Contact)

Relay Output #20 - Configurable (N.O. Dry Contact)

Relay Output #21 - Configurable (N.O. Dry Contact)

Figure 7: Expansion Board Wiring

10

Common

Common

4RLY IO BD.

4RLY IO BD.

YS101790

YS101790

Technical Guide

Page 11

Space Temperature Sensor

A Space Temperature Sensor is used with the MUA II Controller to

provide for Supply Air Temperature Reset. At a specifi ed Space Temperature Setpoint, the Supply Air Setpoint will be reset towards the

Maximum Supply Air Temperature Setpoint. For more information on

the operation of this sequence, see the Sequence of Operation section of

this manual. This sensor is a 10K Type III thermistor sensor. See Figure

8 for complete sensor wiring details.

Space Temperature Sensor

TMP

GND

MUA II Controller

Wiring Details

INPUTS

+VDC

AIN1

AIN2

AIN3

AIN4

AIN5

GND

GND

AOUT1

AOUT2

AIN7

GND

Figure 8: Space Temperature Sensor Wiring

MUA II Unit Controller Board

Technical Guide

11

Page 12

MUA II Controller

Wiring Details

Supply Air Temperature Sensor

The Supply Air Temperature Sensor should be mounted in the unit

discharge plenum or in the supply air duct.

The Supply Air Temperature Sensors are 10K Type III thermistor sensors.

Supply

Air Temperature

Sensor

Mount In MUA

Unit Supply

Air Duct

INPUTS

+VDC

AIN1

AIN2

AIN3

AIN4

AIN5

GND

GND

AOUT1

AOUT2

AIN7

GND

Figure 9: Supply Air Temperature Sensor Wiring

12

MUA II Controller Board

Technical Guide

Page 13

MUA II Controller

GND

INPUTS

GND

AOUT1

AOUT2

GND

+VDC

AIN1

AIN2

AIN3

AIN4

AIN5

AIN7

MUA II Controller Board

Remote Occupied

Contact

(Relay By Others)

Wiring Details

Outside Air Temperature Sensor

The Outside Air Sensor must be wired as shown in the illustration

below for proper operation. The Outside Air Temperature Sensor is a

10K Type III thermistor sensor. The sensor should be mounted in the

upright position as shown in an area that is protected from the elements

and direct sunlight. Be sure to make the wiring splices inside of the

Outside Air Temperature Sensor weathertight enclosure. See Figure

10 for detailed wiring.

Outdoor

Air Temperature

Sensor

Make Splice Connections

Inside Sensor Enclosure

As Shown. Seal All

Conduit Fittings With

Silicone Sealant.

Mount Sensor Outdoors

In Shaded Protected

Area & In Upright

Position As Shown

Caution: Be sure to mount the Outside Air Sensor in

an area that is not exposed to direct sunlight. A

shaded area under the eve of the building or

under the HVAC unit rainhood is normally a

good location. If the sensor is not located as

specifi ed, erroneous outside air temperature

readings will result. Unused conduit opening(s)

must have closure plugs installed and must be

coated with sealing compound to provide rain

tight seal. Water can damage sensor!

INPUTS

+VDC

AIN1

AIN2

AIN3

AIN4

AIN5

GND

GND

AOUT1

AOUT2

AIN7

GND

Figure 10: Outside Air Temperature Sensor Wiring

Remote Occupied Contact

A Remote Occupied contact closure supplied from another Building

Automation System device can be used to enable Occupied and Unoccupied modes on the MUA II Controller. This relay contact must be

a dry contact and be wired as shown below. See Figure 11 below for

detailed wiring.

Figure 11: Remote Occupied Contact Wiring

Technical Guide

13

Page 14

MUA II Controller

Wiring Details

Outside Air Humidity Sensor

If you want to install a humidity sensor onto the MUA II Controller, it

is important that you follow these instructions. There are 2 terminals

labeled “H+” and “H-”. Terminal “H+” will connect to the connection

labeled “+VDC” on the analog input block. See Figure 12. Terminal

“H-” connects to the connection labeled “AIN 5” on the analog input

block. Also, the resistor labeled “PU5” needs to be removed. Lastly, a

supplied 250 Ohm, ¼ Watt, 1% resistor needs to be installed between

“AIN 5” and “GND”. See Figure 12 for detailed wiring.

Outdoor

Air Humidity

Sensor - 4-20mA

H+(T1)

H-(T4)

Seal All Conduit Fittings

With Silicone Sealant.

250 Ohm

Resistor

(Shipped With Sensor)

To be Installed Between

AIN5 and GND

MUA II Controller Board

Warning: It is very important to be certain that all wiring is

correct as shown in the wiring diagram below.

Failure to observe the correct polarity will result in

damage to the Humidity Sensor or controller.

The Pull-up Resistor (PU5)

INPUTS

+VDC

AIN1

AIN2

AIN3

AIN4

AIN5

GND

GND

AOUT1

AOUT2

AIN7

GND

Must Be Removed

When Using A 4-20ma Device

If YouAre Using The Standard Factory Supplied Humidity Sensor, It

Has Terminals Labeled “H+ (T1)” And “H- (T4)”. Terminal “H+ (T1)” Is

The Voltage Input And Should Be Connected To The Terminal Labeled

+VDC On The VAV/CAV Controller. Terminal “H- (T4)” Is The 4-20 Ma

Output Signal And Should Be Connected To The Terminal Labeled AIN

5 On The VAV/CAV Controller.

Should Be Connected Between AIN 5 AndA Ground Terminal On The

VAV/CAV Controller.

Factory Is Used, Refer To The Wiring Instructions Shipped With The

Sensor.

Figure 12: Humidity Sensor Wiring

A Factory Supplied 250 Ohm Resistor

If A Sensor Other Than The One Supplied By The

14

Technical Guide

Page 15

MUA II Controller

Wiring Details

Space Humidity Sensor

A Space Humidity Sensor or a Fan Proof of Flow Switch can be connected to AIN7 on the MUA II Controller. Shown below is the Space

Humidity Sensor wiring.

If YouAre Using The Standard Factory Supplied Humidity Sensor, It Has

Terminals Labeled “+ (T1)”And - (T2)”. Terminal + (T1)” Is The Voltage

Input And Should Be Connected To The Terminal Labeled +VDC On The

MUA II Controller. Terminal “- (T2)” Is The 4-20 Ma Output Signal And

Should Be Connected ToThe Terminal Labeled AIN7 On The MUA II

Controller.

A Factory Supplied 250 Ohm Resistor Should Be Connected

Between AIN 7 AndA Ground Terminal On The MUAII Controller.

Sensor Other Than The One Supplied By The Factory Is Used, Refer To

The Wiring Instructions Shipped With The Sensor.

+ (T1)

- (T2)

250 Ohm

Resistor

(Shipped With Sensor)

To be Installed Between

AIN7 and GND

If A

Figure 13: Space Humidity Sensor Wiring

The Pull-up Resistor (PU7)

Must Be Removed

When Using A 4-20ma Device

INPUTS

+VDC

AIN1

AIN2

AIN3

AIN4

AIN5

GND

GND

AOUT1

AOUT2

AIN7

GND

MUA II Controller Board

Fan Proof of Flow Switch

If a Fan Proof of Flow Switch is required, then obviously the Space

Humidity Sensor option is not available. By the same token, if a Space

Humidity Sensor is required, then the Fan Proof of Flow Switch option

is not available. See Fan Proof of Flow Switch wiring below.

INPUTS

+VDC

AIN1

AIN2

AIN3

AIN4

AIN5

GND

GND

Fan Proof Of Flow

Switch

MUA II Controller Board

Figure 14: Fan Proof of Flow Switch Wiring

AOUT1

AOUT2

AIN7

GND

Technical Guide

15

Page 16

MUA II Controller

Start-up & Commissioning

In order to have a trouble free start-up, it is important to follow a few

simple procedures. Before applying power for the fi rst time, it is very

important to correctly address the controller and run through a few

simple checks.

Controller Addressing

All MUA II Controllers are equipped with address switches. If the MUA

II Controller is to operate as a stand-alone system (not connected to any

other controllers), the controller address switch should be set for address

1. When using the Modular Service Tool or System Manager to program

and confi gure the MUA II Controller, you would enter this address to

communicate with the controller. When the system is to be connected to

other HVAC unit controllers on a communication loop, each controllers

address switch must be set with a unique address between 1 and 59. See

Figure 15 for address switch setting information.

This Switch Should Be

In The OFF Position

As Shown

ADDRESS

Address Switch Shown Is

Set For Address 1

ADDRESS ADD

1

2

4

8

16

32

TOKEN

NETWORK

ADD

Controller

Address Switch

The Address For Each Controller

Must Be Unique To The Other Controllers

On The Local Loop And Be Between 1 and 59

Address Switch Shown Is

Set For Address 13

Power Wiring

One of the most important checks to make before powering up the system

for the fi rst time, is to confi rm proper voltage and transformer sizing for

the controller. Each MUA II Controller requires 10 VA of power delivered

to it at 24 VAC. Each 2-slot expansion board requires 5 VA at 24 VAC

and each 4-slot expansion board requires 10 VA at 24 VAC. You may

use separate transformers for each device (preferred) or power several

devices from a common transformer. If several devices are to be powered

from a single transformer, correct polarity must be followed.

Warning: Observe Polarity! All boards must be wired with

GND-to-GND and 24 VAC-to-24 VAC. Failure to

observe polarity will result in damage to

one or more of the boards. Expansion Boards must be

wired in such a way that power to both the expansion

boards and the controller are always powered together.

Loss of power to the expansion board will cause the

controller to become inoperative until power is

restored to the expansion board.

ADDRESS

ADD

Note:

The Power To The Controller Must Be Removed And

Reconnected After Changing The Address Switch Settings

Caution

Disconnect All Communication Loop Wiring From The

Controller Before Removing Power From The Controller.

Reconnect Power And Then Reconnect Communication Loop

Wiring.

INPUTS

+VDC

AIN1

AIN2

AIN3

AIN4

AIN5

GND

GND

AOUT1

C10

ADDRESS

RN5

PU1

D6

PU2

D7

PU3

D8

PU4

D9

PU5

D11

PU7

0-5

D14

U13

C12

AOUT2

AIN7

GND

PJ1

TB3

PRESSURE

SENSOR

C17

R26

EXPANSION

CX13

D15

C20

CX15

PJ2

Figure 15: MUA II Controller Address Switch Setting

16

ADD

1

2

4

8

16

32

TOKEN

NETWORK

SW1

0-1

VDC

VDC

JP1

U15

PJ3

CX10

U10

C11

X2

R15

U12

CX14

C14

R19

U14

C15

R22

R24

R25

D17

C7

D10

R7

CX12

D18

C18

L1

D12

R13

SC1

D19

C19

VR1

VR2

R6

C9

R10

D13

R11

U11

C13

C16

TB4

GND

R27

D16

V6

POWER

24VAC

Technical Guide

Page 17

MUA II Controller

Mode

Selection

ENTER

CLEAR

ESC

PREV

NEXT

DOWN

UP

6

5

4

DEC

708

13

2

9

MINUS

-

STATUS

SETPOINTS

SCHEDULES

CONFIGURATION

ALARMS

ON

OVERRIDES

BALANCE - TEST

ENTER

CLEAR

ESC

PREV

NEXT

DOWN

UP

6

5

4

DEC

708

13

2

9

MINUS

-

STATUS

SETPOINTS

SCHEDULES

ALARMS

OVERRIDES

System Manager

Start-up & Commissioning

Check all wiring leads at the terminal block for tightness. Be sure that

wire strands do not stick out and touch adjacent terminals. Confi rm that

all sensors required for your system are mounted in the appropriate location and wired into the correct terminals on the MUA II Controller. Be

sure any expansion boards connected to the MUA II Controller are also

correctly wired just as you did for the MUA II Controller.

After all the above wiring checks are complete, apply power to the MUA

II Controller and all expansion boards connected to it.

Initialization

Upon applying power to the MUA II Controller, the following should

occur:

On system power-up, a 30 second start-up delay is performed where

all default setpoints are initialized, LEDs are initialized, and all outputs

are turned off.

When power is fi rst applied, LED2 is turned off for 5 seconds. At this

time, the LED will “blink” to indicate the setting of the address switch

and then extinguish for another 5 seconds. The LED will now “blink”

for a 30-second start-up delay to protect the fan and other components

from short cycling during intermittent power conditions. If all inputs are

operating correctly, the LED will blink once every ten seconds.

The PWR LED should glow continuously. If this is a stand-alone or

interconnected system, the COMM LED should also glow continuously

after its initial start-up routine. If this is a networked system, the COMM

LED should fl icker approximately once every second to indicate communications are occurring. If the LEDs are behaving as indicated, proceed

to the next step. If the LEDs fail to light or do not behave as indicated,

please proceed to the troubleshooting section of this manual to diagnose

and correct the problem before proceeding with the start-up process.

Programming The Controller

The next step is programming the controller for your specifi c requirements. In order to confi gure and program the MUA II Controller, you

must have a central Operator’s Interface or a personal computer with

the Prism computer front-end software installed. Two different central

operator’s interfaces are available for programming of the MUA II Controller. You may use either the Modular Service Tool or the Modular

System Manager to access the status and setpoints of any controller on

your communications loop. See the Modular Service Tool and System

Manager Programming Guide for MUA II Controller programming.

If you are going to use a personal computer and the Prism computer

front-end software, please see the Prism Graphical Communications

Interface Technical Guide. No matter which operator’s interface you

use, it is recommended that you proceed with the programming and

setup of the controller in the order that follows:

1. Confi gure the controller for your application.

2. Program the controller’s setpoints.

3. Program the controller’s operation schedules.

4. Set the controller’s current time and date.

5. Review controller status screens to verify system

operation and correct controller confi guration.

Technical Guide

Figure 16: Operator’s Interfaces

17

Page 18

MUA II Controller

Sequence of Operations

MUA Operation Overview

The MUA Controller is designed to control an HVAC unit to provide

fresh air of neutral temperature (and humidity if required) into a building

that has a net air loss caused by air being exhausted from the building.

The MUA-controlled HVAC unit can have heating, cooling, and/or dehumidifi cation capabilities. Heating and cooling sequences are controlled

based on outside air temperature. Whenever the outside air temperature

is outside of the heating or cooling setpoints, the appropriate heating

or cooling staging will be initiated to bring the supply air temperature

within the required range and maintain it at that condition.

The outside air humidity and temperature in the form of a dewpoint

temperature setpoint control the MUA Controller dehumidifi cation

sequence. Since dewpoint temperature by defi nition is the temperature

at which water vapor condenses from the air mixture, it is good indicator

of when dehumidifi cation is required. The controller uses the outside air

humidity sensor in conjunction with an outside air temperature sensor to

calculate the dewpoint temperature of the outside air. If the outside air

dewpoint exceeds the dewpoint setpoint with respect to the outside air

temperature, the dehumidifi cation sequence will be initiated to bring the

supply air dewpoint temperature within the required range and maintain

it at that condition.

MUA Modes

This controller has a total of 6 modes of operation that behave differently. These are divided into 1 unoccupied mode and 5 occupied

modes. The operation of each of these modes is explained on the pages

that follow.

The diagrams that follow depict the operational modes of the MUA II

Controller.

Figure 17 illustrates how the OAT (Outdoor Air Temperature) and the

Dewpoint Temperature initiate the various normal operational modes.

Figure 18 illustrates the Temperature Protect Modes which are determined by the Supply Air Temperature.

Cool

Cool Setpoint

=

Dehumidification

Heat Setpoint

=

(OAT)

Outdoor Air Temperature

Vent

Heat

Cool Setpoint

Heat Setpoint

Dewpoint Temperature

Supply Setpoint + Cool Deadband

Dewpoint Setpoint

Supply Setpoint - Heat Deadband

Figure 17: Operational Modes

Unoccupied

In this mode, the controller will shut off the cooling, the heating, and

the blower.

Occupied

In the occupied cycle, the unit has the following modes:

• Cooling

• Vent

• Dehumidifi cation

• Heating

• Temperature Protect Mode

Low SAT

Cutoff Limit

0F°

(SAT) Supply Air Temperature

Figure 18: Temperature Protect Mode

High SAT

Cutoff Limit

150 F°

18

Technical Guide

Page 19

MUA II Controller

Sequence of Operations

Cool

This mode occurs when the controller reads an OAT one Cooling

Deadband above the Supply Air Setpoint and a Dewpoint Temperature below the Dewpoint Setpoint. The migration table for this mode

is shown below.

Condition Mode

Outside Dewpoint rises above the

Dewpoint Setpoint Dehumidifi cation

OAT drops below the Cool Setpoint Vent

During this mode, the controller will maintain the SAT between a ±

Cooling Deadband from the Supply Air Setpoint. This is achieved

by activating and deactivating the stages of cooling.

Figure 19: Cool Mode Staging

Vent Mode

This mode occurs when the controller reads an OAT between the

Cooling and Heating Deadband from the Supply Air Setpoint and a

Dewpoint reading below the Dewpoint Setpoint. The migration table

for this mode is shown below.

Dehumidifi cation Mode

This mode occurs when the controller reads a Dewpoint Temperature

above the Dewpoint Setpoint. The migration table for this mode is

shown below.

Condition Mode

OAT falls below the Heat Setpoint

and Dewpoint Temperature falls

below the Dewpoint Setpoint

OAT rises above the Cool Setpoint

and Dewpoint Temperature falls

below the Dewpoint Setpoint

Dewpoint Temperature falls below

the Dewpoint Setpoint Vent

In this mode, the controller will use the Outside Enthalpy to calculate the

number of compressors needed to extract the moisture from the air. At the

same time, the Reheat Control will be active to avoid over-cooling.

Reheat Control

The controller can utilize a combination of different heating methods to

reheat the supply air during dehumidifi cation mode. The following is the

method the controller will use to try to reheat the supply air:

Dehumidifi cation Heat

You can elect to use the unit heating source to reheat the air during dehumidifi cation or to supplement Hot Gas Reheat dehumidifi cation control. If the HVAC unit is not equipped with Hot Gas

Reheat or the Hot Gas Reheat is not able to bring the Supply Air

Temperature to the desired setpoint, the MUA II Controller will

activate the heat source to maintain the Supply Air Temperature

Setpoint. The heat source can be either internal or external to the

HVAC unit.

Heat

Cool

Condition Mode

OAT falls below the Heat Setpoint Heat

OAT rises above the Cool Setpoint Cool

Dewpoint Temperature rises above

the Dewpoint Setpoint Dehumidifi cation

During this mode, the controller will shut off heating and cooling, but

will allow the blower to continue its normal operation.

Technical Guide

19

Page 20

MUA II Controller

Sequence of Operations

Heat

This mode occurs when the controller reads an OAT one Heating Dead-

Band below the Supply Air Setpoint and a Dewpoint Temperature

below the Dewpoint Setpoint. The migration table for this mode is

shown below.

Condition Mode

OAT rises above the Heat Setpoint Vent Mode

Dewpoint Temperature rises above

the Dewpoint Setpoint Dehumidifi cation

Temperature Protect

This mode occurs when the SAT rises above the High Cutoff Tempera-

ture Setpoint or drops below the Low Cutoff Temperature Setpoint

for a defi ned period of time. To return to the normal mode, the SAT

must drop 10°F below the High Cutoff Temperature Setpoint or rise

10°F above the Low Cutoff Temperature Setpoint, depending on the

situation. See the table that follows:

Condition Mode

SAT rises above the High Cutoff

Temperature

SAT drops below the Low Cutoff

Temperature

After Temperature Protect is

initiated and SAT rises 10ºF above

the Low Cutoff Temperature Return to Normal

After Temperature Protect is

initiated and SAT drops 10ºF below

the High Cutoff Temperature

Heating & Cooling

Disabled

Blower Operation

for 3 Minutes

Then Off

Operation

Figure 19: Heat Mode Staging

External Heating

This feature is designed to control an external Hot Water Valve or an

SCR Controller. Confi guring a relay for External Heating Control enables this feature. This relay is activated any time the unit needs heat.

The output follows a proportional control scheme and can be confi gured for a range of 0-10 VDC or 2-10 VDC. The External Heat relay is

deactivated when the call for heat or reheat is canceled or the Supply

Air Temperature rises one Heating Deadband above the Supply Air

Temperature Setpoint.

20

Technical Guide

Page 21

MUA II Controller

Sequence of Operations

Initialization

On system power-up, a 30-second start-up delay is performed where

all default setpoints are initialized, LEDs are initialized, and all outputs

are turned off.

When power is fi rst applied, LED2 is turned off for 5 seconds. At this

time, the LED will “blink” to indicate the setting of the address switch

and then extinguish for another 5 seconds. The LED will now “blink”

for a 30-second start-up delay to protect the fan and other components

from short cycling during intermittent power conditions.

MUA II Confi guration & Setup

There are a few confi guration selections available to you which can be

used to tailor the software operation to match the mechanical equipment

this controller is installed on.

Resets

Supply Temperature Reset from Space Temperature

This feature requires a Space Temperature Sensor connected to the controller. The reset is always upwards from the Supply Temp Setpoint to

the Maximum Supply temp (Maximum Supply temp = Supply Temp

Setpoint + Reset band). When the Space Temperature is at the Min

Temp Reset, the desired Supply temp is the Supply Temp Setpoint.

When the Space Temperature is at the Max Temp Reset, the desired

Supply temp is the Maximum Supply temp.

Outside Dewpoint Reset from Space Humidity

This feature requires a Space Humidity Sensor connected to the controller

on analog input AIN7. When this option is used, the Fan Proof of Flow

Switch option is not available as it also connects to analog input AIN7.

The reset is always downwards from the Outside Dewpoint Setpoint

to the Minimum Outside Dewpoint (Minimum Outside Dewpoint =

Outside Dewpoint Setpoint - Reset Band). When the Space Humidity

is at the Space Hum Min Reset, the desired Outside Dewpoint is the

Minimum Outside Dewpoint. When the Space Humidity is at the

Space Hum Max Reset, the desired Outside Dewpoint is the Outside

Dewpoint Setpoint.

Other Control Options

Fan Proof of Flow Switch

The MUA II Controller can monitor a Fan Proof of Flow Switch contact closure on analog input #7. When this option is used, the Outside

Dewpoint Reset from Space Humidity option is not available as it also

connects to analog input #7. Anytime the fan is running, this contact must

be closed. If the contact does not close or remain closed, no heating or

cooling outputs can activate or remain active. If this option is selected,

the loss of this signal can generate an alarm so that you know there is a

problem that needs to be corrected. There is a built-in fi ve-second fi lter

provided to prevent intermittent contact “bounce” from affecting the

operation. This option is not available.

Remote Occupied Contact

If you have a separate source that will provide a dry contact closure

to indicate the occupied mode, you can monitor this contact closure in

place of a humidity sensor on analog input #3.

Outside Air Temperature Broadcast

If you have several Air Handlers on a jobsite and they are connected

together via the RS-485 communications loop, you can select this option and confi gure the controller to broadcast Outside Air Temperature

to all controllers on the network, instead of installing a Outside Air

Temperature sensor on every unit. This saves you from having to install

duplicate sensors on every air handler.

Outside Air Humidity Broadcast

If you have several Air Handlers on a jobsite and they are connected

together via the RS-485 communications loop, you can select this option

and confi gure the controller to broadcast Outside Air Humidity to all

controllers on the network, instead of installing a Outside Air Humidity

sensor on every unit. This saves you from having to install duplicate

sensors on every air handler.

Relay Confi guration

Output Relay Confi guration

Relays #2 through #21 can be confi gured for the type of function that

matches the MUA II Controller options. The relays can be confi gured for

any of the following: Heating (aux. Heating) Stages, Cooling (compressor) Stages, Gas Reheat Control for De-Humidifi cation, and External

Heat Enable for control of external heating devices.

Technical Guide

21

Page 22

MUA II Controller

Sequence of Operations

Scheduling

The MUA II Controller has an internal battery backed-up Real Time

Clock (RTC) that allows the controller to keep the time and allows for

scheduling.

The MUA II Controller has an internal 7-day schedule with 2 start-stop

events per day. You can also have 1 holiday schedule with 2 start-stop

events. This holiday schedule can be used for 14 different holiday

periods.

One thing to be noted is that you cannot view the current time when you

are viewing the MUA II Controller with the Modular Service Tool or

the System Manager. You can, however, change the time on the MUA

II Controller through the Modular Service Tool or the System Manager.

If there is any doubt on the current time, re-enter the time and date and

it will change the controller to match what you have entered. If you

want the feature of viewing the current time the MUA II Controller is

using, you must install a Personal Computer and the Prism computer

front-end software.

Alarm Detection and Reporting

The MUA II Controller continuously performs self diagnostics during

normal operations to determine if any operating failures have occurred.

These failures can be reported to you in several ways, depending on the

type of system and options you have installed.

If a Modular Service Tool or System Manager is connected, the alarms

will be reported on the Status Screens. If the Prism computer front-end

software is installed, the alarms will be reported on the main screen of

the program and logged to disk. If neither remote communication option

is installed, you can check for alarms by viewing LED2 on the MUA

II Controller board. If everything is operating normally, the LED will

blink once every 10 seconds. If there is a problem detected, the LED will

fl ash a specifi c number of times every 10 seconds to indicate what the

problem is. These fl ashes or “blink codes” are described below in order

of priority. The highest priority condition must be corrected before any

lower conditions can be observed and corrected. One blink is the lowest

priority and indicates no alarms. Five blinks is the highest priority.

If the Remote Link (modem) is installed, any alarm condition can initiate a callout to a pager to alert someone to the alarm condition. See the

Prism Graphical Communications Interface Technical Guide for further

information on this topic.

No. of Blinks Blink Code Description

1 Normal Operations. No

Alarm Conditions

2 Sensor Failure

(OAT, OAH, SAT)

3 Mechanical Failure

4 Fan Proving Alarm

5 Unit In Force Mode

Table 2: Diagnostic Blink Codes

22

Technical Guide

Page 23

MUA II Controller

Sequence of Operations

Force Modes or Overrides

The MUA II Controller relay outputs can be user-overridden if the Modular Service Tool or the Prism graphical front-end program is available.

The modes of operation for the relays are:

0 = Auto (Normal Operation)

1 = Forced ON

2 = Forced OFF

The analog outputs are forced if you specify a value between 0.0 and

10.0 VDC. To cancel the force mode, enter a value less than zero (-1.0

VDC).

When the analog outputs are forced, the display on the Modular Service

Tool or front-end can be interpreted as the actual voltage. During normal

operation, the display indicates the percentage signal applied based on

the user-defi ned voltage limits. For example, if you defi ne a 2.0 VDC to

10.0 VDC range, then 50% would be 6.0 VDC instead of the 5.0 VDC

applied when the range is 0.0 VDC to 10.0 VDC.

As mentioned, force modes can only be activated with an attached remote

communications device described previously. Furthermore, the override

condition can only remain in effect as long as the remote device is connected and communicating with the unit. That means that you cannot set

an override condition and then “walk away” from the equipment with

the override still active. The loss of communications or the removal of

the remote interface will automatically terminate the override within

10 minutes. This is to protect the equipment and to prevent an override

condition from remaining active indefi nitely, resulting in ineffi cient

operation of the equipment.

Caution: No equipment protection is available during the

force mode of operation. That means you could

start a compressor without running the fan or

create other conditions that WILL damage the

HVAC equipment. WattMaster Controls, Inc.

assumes no responsibility or liability for the

misuse of these user overrides that cause

damage to the HVAC equipment!

Internal Trend Logging

The MUA II Controller continuously maintains an Internal Trend Log

which records a fi xed set of values at an interval programmed by you.

These values can be retrieved only with the Prism graphical front-end

program. If you don’t have the Remote Communications option with a

front-end program, you do not have access to these logs.

There are 120 log positions available. Once the last (120th) position

has been recorded, the log jumps back to the fi rst position and begins

overwriting the old data. This means you are required to retrieve the logs

at an interval that is shorter than the duration of the last 120 logs.

Shown below are some log intervals and the duration of 120 logs.

1-Minute Interval = 2-Hour Duration

15-Minute Interval = 30-Hour Duration

30-Minute Interval = 60-Hour Duration

60-Minute Interval = 120-Hour Duration

The fi xed items in the log are listed below:

Date

Time

Supply Air Temperature

Outside Air Temperature

Supply Air Setpoint

Outdoor Air Humidity

Dewpoint Setpoint

Onboard Relay Status (BIT Pattern)

Expansion Board Relay Status (BIT Pattern)

External Heat (% of Max Heat)

These items and values are explained in greater detail in the Prism

Graphical Communications Interface Technical Guide.

Technical Guide

23

Page 24

MUA II Controller

Troubleshooting

Using LED’s To Verify Operation

The MUA II Controller is equipped with LEDs that can be used as very

powerful troubleshooting tools. There are four LEDs on the MUA II

Controller board. Three of these LEDs are used in troubleshooting.

See Figure 18 for the LED locations. The LEDs and their uses are as

follows:

“COMM”

This LED will light up to indicate system communications.

“PWR”

This LED will light up to indicate that 24 VAC power has been applied

to the controller.

“LED1”

This LED is not used for this controller application.

“LED2”

This is the diagnostic blink code LED. It will light up and blink out

diagnostic codes.

PWR LED Operations

When the MUA II Controller is powered up, the “PWR” LED should

light up and stay on continuously. If it does not light up, check to be

sure that you have 24 VAC connected to the board, that the wiring

connections are tight, and that they are wired for the correct polarity.

The 24 VAC power must be connected so that all ground wires remain

common. If after making all these checks, the PWR LED does not light

up, please contact WattMaster Technical Support’s toll free number at

866-918-1100 for further assistance

COMM LED Operations

When power is applied to the controller, the “COMM” LED will also

light up. If this is a Stand-Alone System (one controller only on the loop)

or an Interconnected System (several MUA II Controllers tied together

without a CommLink) the COMM LED will glow continuously. The

COMM LED will fl icker when you are connected to the MUA II Controller, and you are entering setpoints with the Modular Service Tool or

the System Manager. It will also fl icker if this is a Networked System.

If this is a Networked System (the system has a CommLink installed),

the COMM LED should fl icker rapidly, indicating that the system is

communicating. A “fl icker” is defi ned as a brief moment when the LED

turns off then back on. It may be easier to see this “fl icker” if you cup

your hand around the LED.

If the COMM LED does not operate as indicated above, fi rst check the

address switch setting. Verify the address switch as outlined in LED

(Diagnostic LED) Operations. If the address switch setting is correct and

the COMM LED still does not behave as indicated above, check to be

sure the operator’s interface is connected correctly. The System Manager

must be connected to a local communications loop either at the MUA II

Controller as shown in Figure 20 or to another controller on the same

local communications loop. If you are using the Modular Service Tool,

verify that it is plugged in securely to the DIN connection on the MUA

II Controller. See Figure 20 for DIN connector location.

24

Technical Guide

Page 25

MUA II Controller

Troubleshooting

MUA II Controller Board

Communications Terminals

System Manager Can Be

Connected Here

(COMM) Communications

(PWR) Power

(LED1) Not Used

(LED2) Diagnostic

COMM

T

SHLD

R

COMM

PWR

LED1

LED2

DIN Connector

For Modular

Service Tool

Figure 20: LED & Interface Connection Locations

If the COMM LED still does not behave correctly, check the voltages

at the communications terminal block. Be sure the board is powered up

for this test. Unplug the communications terminal block from the board

and check the DC voltage between T and SHLD and between R and

SHLD. Check the voltage with a digital multimeter set to DC volts. The

voltage should be between 2.4 to 2.5 VDC between SHLD and either T

or R. If your voltage is not in this range, you probably have a damaged

driver chip that must be replaced.

LED2 (Diagnostic LED) Operations

When power is fi rst applied, LED2 is turned off for 5 seconds. At this

time, LED2 will “blink” to indicate the setting of the address switch and

then extinguish for another 5 seconds. Verify that the address switch

setting is correct by counting the number of blinks. If the address switch

setting is not correct, remove the communication loop terminal plug from

the controller and then the power terminal plug. Correctly set the address

switch setting (see Figure 15) with the dip switches on the controller,

reconnect the power connection, and then the communication loop.

Reapply power to the controller and observe the blink code to verify

the address is set correctly.

Note: Power to the controller being addressed must always be

cycled after changing address switch settings in order

for the changes to take effect. Always unplug the communications terminal block before removing the power

terminal block from the board. When fi nished, reinstall

the power terminal block fi rst and then the communications terminal block.

If LED2 blinks the correct address, your board is addressed correctly.

If it does not light up at all, the board is not operating correctly and

could be defective.

If all of these tests are made and the controller still doesn’t operate,

contact the WattMaster Technical Support’s toll free number at 866918-1100 for further assistance.

Technical Guide

25

Page 26

MUA II Controller

Appendix

Sensor Checks

The following sensor voltage and resistance tables are provided to aid in

checking sensors that appear to be operating incorrectly. Many system

operating problems can be traced to incorrect sensor wiring. Be sure all

sensors are wired per the wiring diagrams in this manual.

If the sensors still do not appear to be operating or reading correctly,

check voltage and/or resistance to confi rm that the sensor is operating

correctly per the tables. Please follow the notes and instructions below

each chart when checking sensors.

Temperature – Resistance – Voltage for

Type III 10 K Ohm Thermistor Sensors

Temp

(ºF)

Resistance

(Ohms)

Voltage @

Input (VDC)

-10 93333 4.620

-5 80531 4.550

0 69822 4.474

5 60552 4.390

10 52500 4.297

15 45902 4.200

20 40147 4.095

25 35165 3.982

30 30805 3.862

35 27140 3.737

40 23874 3.605

45 21094 3.470

50 18655 3.330

52 17799 3.275

54 16956 3.217

56 16164 3.160

58 15385 3.100

60 14681 3.042

62 14014 2.985

64 13382 2.927

66 12758 2.867

68 12191 2.810

69 11906 2.780

70 11652 2.752

71 11379 2.722

72 11136 2.695

73 10878 2.665

Temperature – Resistance – Voltage for

Type III 10 K Ohm Thermistor Sensors

Temp

(ºF)

Resistance

(Ohms)

Voltage @

Input (VDC)

74 10625 2.635

75 10398 2.607

76 10158 2.577

78 9711 2.520

80 9302 2.465

82 8893 2.407

84 8514 2.352

86 8153 2.297

88 7805 2.242

90 7472 2.187

95 6716 2.055

100 6047 1.927

105 5453 1.805

110 4923 1.687

115 4449 1.575

120 4030 1.469

125 3656 1.369

130 3317 1.274

135 3015 1.185

140 2743 1.101

145 2502 1.024

150 2288 0.952

Table 3 cont: Temperature/Resistance for Type III

10K Ohm Thermistor Sensors

Thermistor Sensor Testing Instructions

Use the resistance column to check the thermistor sensor while disconnected from the controllers (not powered).

Use the voltage column to check sensors while connected to powered

controllers. Read voltage with meter set on DC volts. Place the “-”(minus) lead on GND terminal and the “+”(plus) lead on the sensor input

terminal being investigated.

If the voltage is above 5.08 VDC, then the sensor or wiring is “open.” If

the voltage is less than 0.05 VDC, the sensor or wiring is shorted.

Table 3: Temperature/Resistance for Type III 10K

Ohm Thermistor Sensors

26

Technical Guide

Page 27

MUA II Controller

Appendix

OE265-11, -13 & -14 Relative Humidity Transmitters –

Humidity vs. Voltage for 0-5 VDC Sensors

Humidity

Percentage

(RH)

0% 0.00 44% 2.20

2% 0.10 46% 2.30

4% 0.20 48% 2.40

6% 0.30 50% 2.50

8% 0.40 52% 2.60

10% 0.50 54% 2.70

12% 0.60 56% 2.80

14% 0.70 58% 2.90

16% 0.80 60% 3.00

18% 0.90 62% 3.10

20% 1.00 64% 3.20

22% 1.10 66% 3.30

24% 1.20 68% 3.40

26% 1.30 70% 3.50

28% 1.40 72% 3.60

30% 1.50 74% 3.70

32% 1.60 76% 3.80

34% 1.70 78% 3.90

36% 1.80 80% 4.00

38% 1.90 82% 4.10

40% 2.00 84% 4.20

42% 2.10 86% 4.30

Voltage

@

Input

(VDC)

Humidity

Percentage

(RH)

Voltage

@

Input

(VDC)

OE265-11, -13 & -14 Relative Humidity Transmitters –

Humidity vs. Voltage for 0-5 VDC Sensors

Humidity

Percentage

(RH)

88% 4.40 96% 4.80

90% 4.50 98% 4.90

92% 4.60 100% 5.00

94% 4.70

Table 4: Humidity/Voltage for OE265-11, -13 & -14

Humidity Sensors

OE265 Relative Humidity Sensors

Testing Instructions:

Use the voltage column to check the Humidity Sensor while connected

to a powered controller.

Read the voltage with meter set on DC volts. Place the “-” (minus) lead

on GND terminal and the “+”(plus) lead on the sensor input terminal

being investigated.

If the voltage is above 5.08 VDC, then the sensor or wiring is “open.” If

the voltage is less than 0.05 VDC, the sensor or wiring is shorted.

Voltage

@

Input

(VDC)

Humidity

Percentage

(RH)

Voltage

@

Input

(VDC)

Table 4: Humidity/Voltage for OE265-11, -13 & -14

Humidity Sensors

Technical Guide

27

Page 28

Form: WM-MUAII-TGD-01A Printed in the USA April 2009

All rights reserved. Copyright 2009

WattMaster Controls Inc. • 8500 NW River Park Drive • Parkville, MO • 64152

Phone (816) 505-1100 www.wattmaster.com Fax (816) 505-1101

Loading...

Loading...