Page 1

MG331-21-VAVCAV

r

VAV System

Description

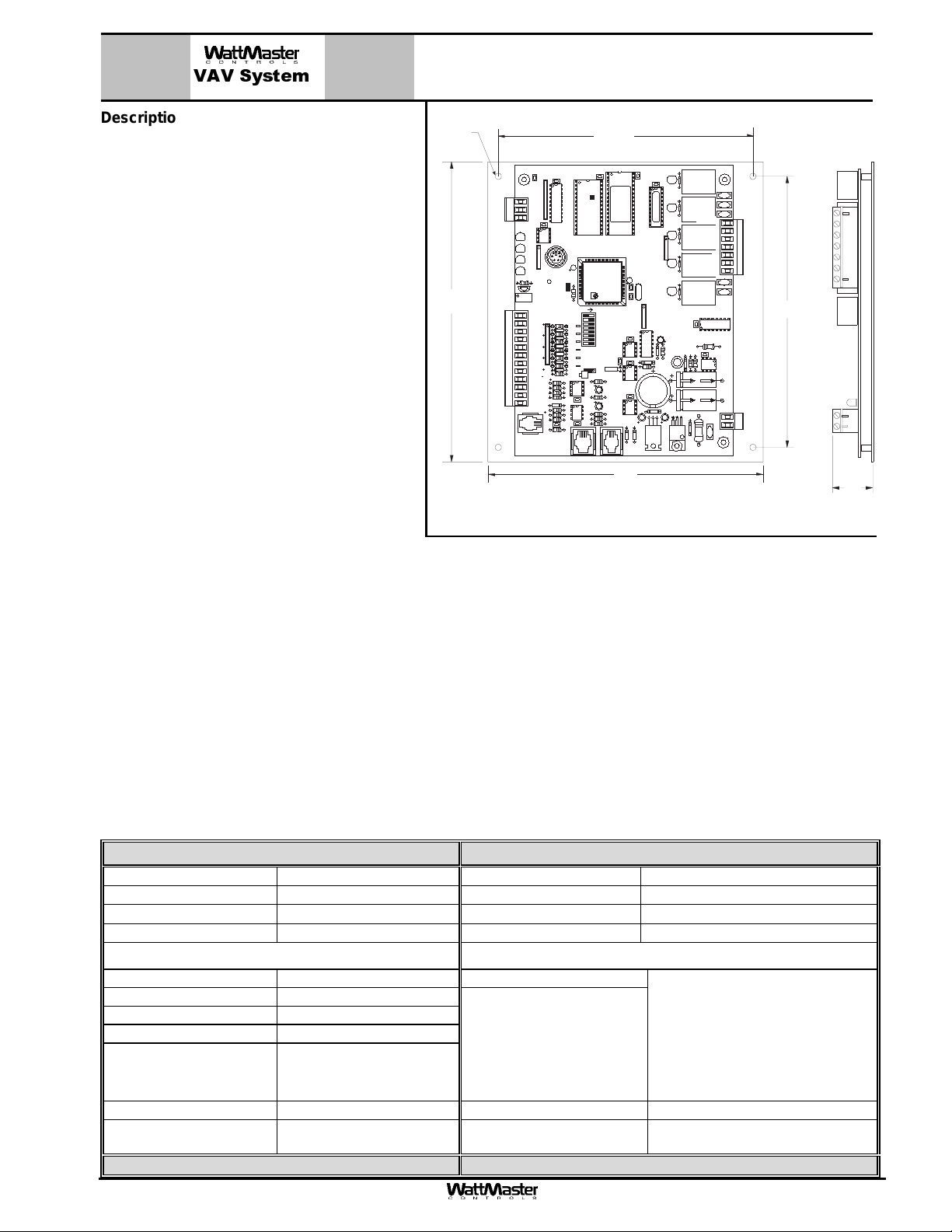

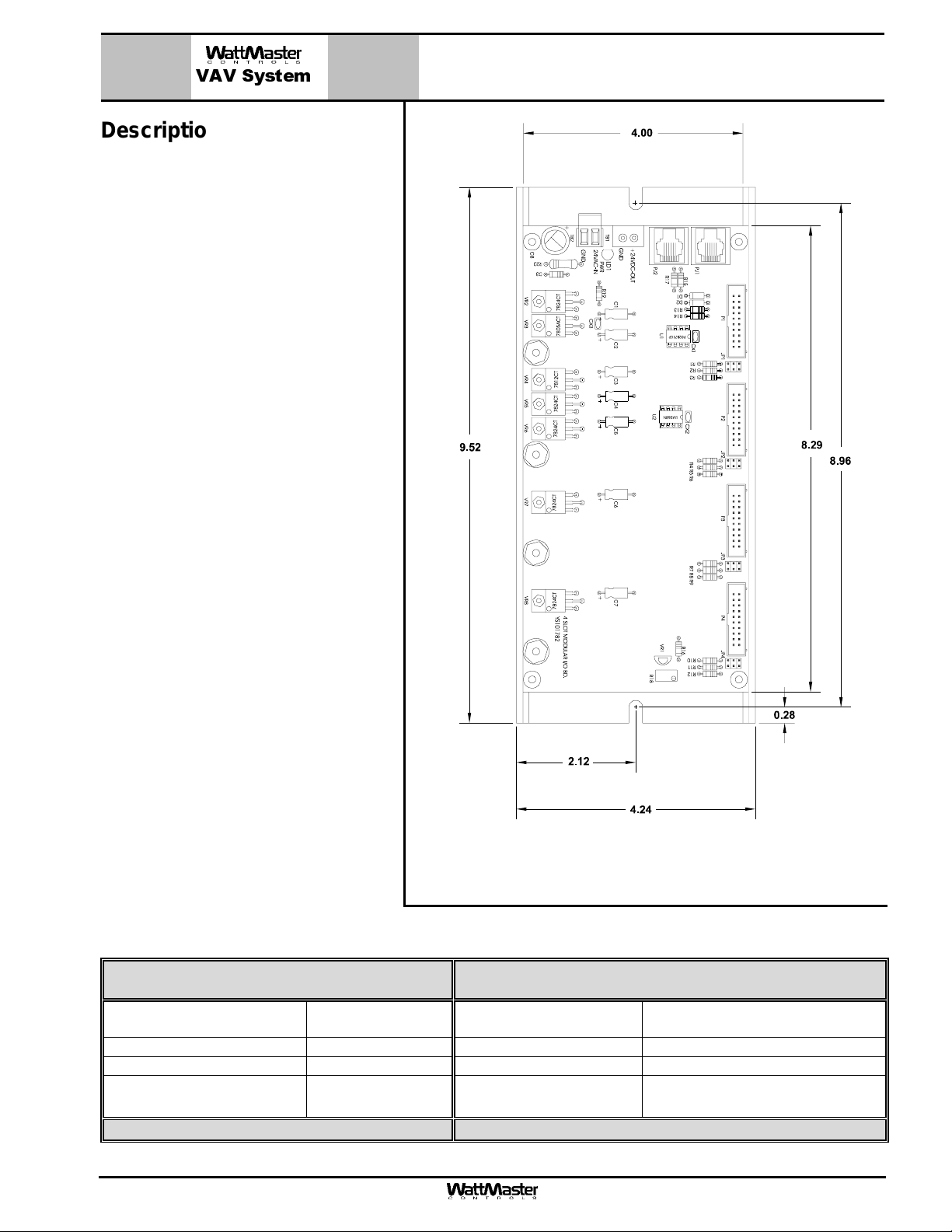

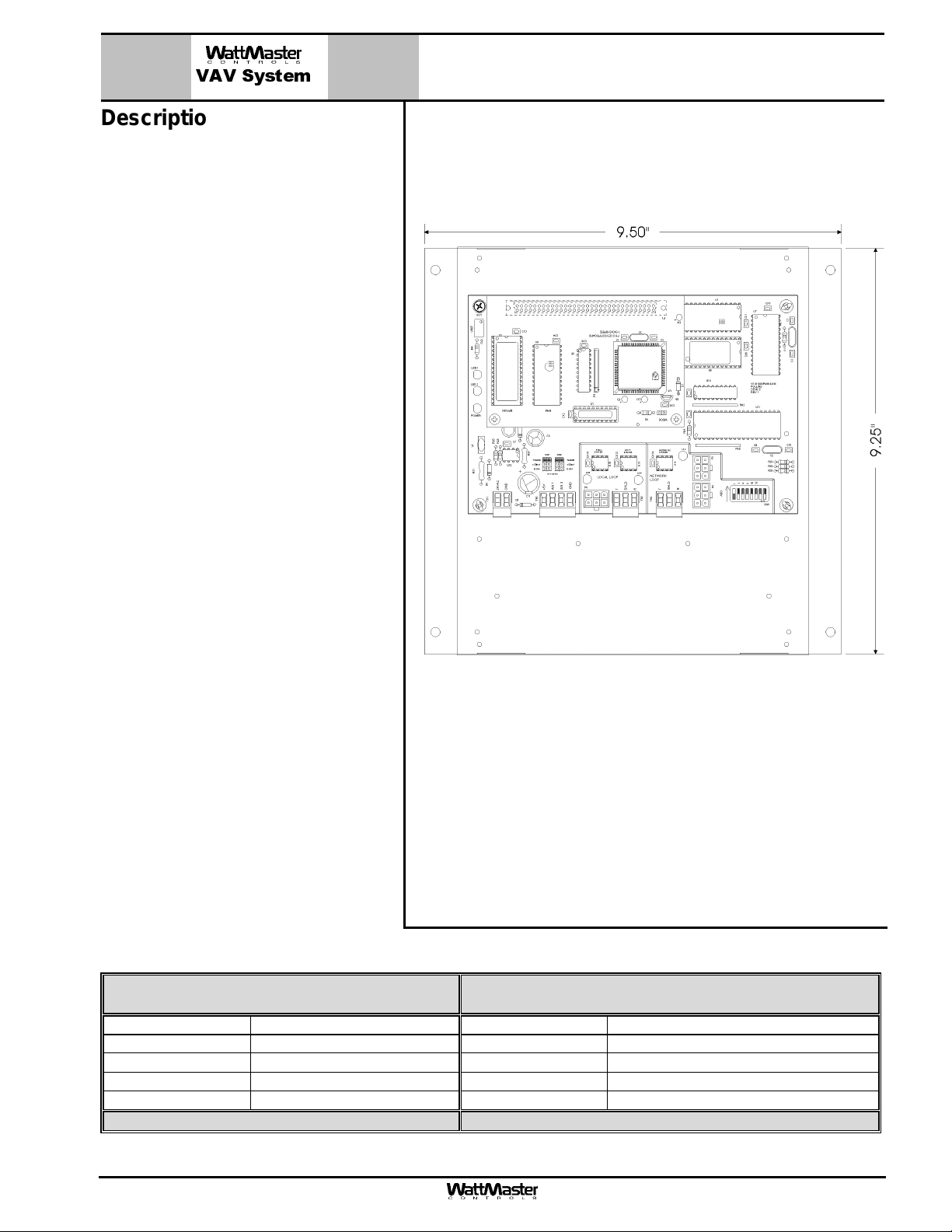

The VAV/CAV Controller Board is designed with

7 usable analog inputs, 2 analog outputs and 5

relay outputs. The controllers input and output

capabilities can be expanded by use of either 2

slot or 4 slot expansion boards that plug into the

WMVAV Controller by means of a modular cable.

The WMVAV Controller can be configured for

control of VAV Units (with or without VAVBOX

Controllers), Constant Volume Units and Air to Air

Heat Pump Units. Features include the following:

• Up to 8 Stages Each of Cooling and Heating

(4 on board, 12 more with expansion boards)

• Selectable Control Sensor

• Fan Proving Interlock

• Wetbulb Control of Economizer Operation

• Accepts Remote Occupied Signal

• Relief Pressure Control

• De-Humidification Capable

• Full Economizer Control

.20 Dia.

Typ. of 4

7.3”

TB1

COMM

T

SHLD

R

LD6

COMM

LD7

PWR

LD8

LED1

LD9

LED2

R1

U7

INPUTS

+VDC

AIN1

AIN2

AIN3

AIN4

AIN5

GND

GND

AOUT1

AOUT2

AIN7

GND

PJ1

TB3

PRESSURE

SENSOR

C21

RN1

1

CX5

1

RN3

+VREF

TESTPOINT

RV1

VREFADJ

C10

EXPANSION

WMVAV Controlle

6.2“

CX1

U1

U5

RS-485

COMM

HH

C1

P1

5.11V

EWDOG

R28

ADDRESS

RN5

PU1

D6

PU2

D7

PU3

D8

PU4

D9

PU5

D11

PU7

D14

C12

D15

C17

C20

R26

PJ2

U3

CX2

U2

EPROM

RAM

TUC-5RPLUS

(1MEG)

YS101816REV. 2

U6

C2

PHILIPS

C3

ADD

1

2

4

8

16

CX10

32

TOKEN

NETWORK

U10

SW1

C11

X2

0-5

0-1

VDC

VDC

JP1

U13

R15

U12

CX14

C14

R19

U14

CX13

U15

C15

R22

R24

R25

CX15

D17

PJ3

T'STAT

6.7”

D1

CX3

CX4

U4

RLY1

RLY2

PAL

1

RLY3

RN2

RLY4

CX6

X1

RLY5

1

RN4

U9

C7

R7

D10

L1

CX12

D12

R13

SC1

D19

D18

C19

C18

VR1

VR2

V1

D2D3D4D5

V2

V3

COM1-3

R1

R2

R3

R4

R5

COM4-5

TB2

V4

V5

U8

NE5090NPB3192

0PS

CX8

R6

C9

R10

D13

9936

R11

U11

MC34064A

C13

C16

TB4

GND

R27

D16

V6

POWER

7824CT

24VAC

M

6.6”

1.1”

• I.A.Q. Control with C0

Sensor Monitoring • Internal Trend Logging

2

• 7 Day, 2 Event per Day Scheduler Built In • 14 Day Holiday Scheduler Built In

• Optimal Start Scheduling Built In • Override from Occupied to Unoccupied Mode

• Supply Air Reset Capability

• Accepts Remote HVAC Mode Selection

Most HVAC unit applications can be configured with the standard WMVAV Controller. If the application requires more inputs

and/or outputs, optional relay expansion boards are available from the factory to provide for additional analog, binary or digital inputs and outputs as required. These expansion boards are installed on either a 2 slot or 4 slot expansion base board

that connects to the WMVAV Controller board via a modular cable connection.

Mounting – Factory Installed

If purchased separately the WMVAV Controller is provided with an integral backplate and can be mounted in the HVAC unit

control panel or remotely located and wired to the HVAC unit.

Technical Data MG331-21-VAV Controller

Power 24 Volt AC Weight 1.5 lb.

Power Consumption 8 VA Maximum Network Connection RS-485

Operating Temp

10°F to 149°F

Operating Humidity 90% RH Non-Condensing Communications RS-485 - 9600 Baud

Inputs: Outputs:

Room Temperature Type III-10kohm sensor (1) Fan-ON/OFF

Supply Air Temperature Type III-10kohm sensor

Outside Air Temperature Type III-10kohm sensor

Static Pressure Sensor 0-5VDC

Humidity Sensor 4-20Ma

Remote Occupied Signal Binary Contact Economizer Analog Output 0-10 VDC

Fan Proof Of Flow Binary Contact VFD, Bypass or Inlet Vane

Three Year Warranty WattMaster reserves the right to change specifications without notice

Form: WMS-MG331-21-VAV-WMVAVController-01D.doc Page 1 of 1

Protocol HSI Open Protocol Token Passing

(5) Relays - (2 Amp @ 24 VAC)

(4) User Configurable For :

Heating Or Cooling

Stages, Reversing Valve,

Warm-up Mode Box Command, Hot Gas Reheat

Control, Relief Fan Interlock, Preheat Coil

Analog Output 0-10 VDC

Control

Page 2

MG320-00-VAV

V

r

VAV System

Description

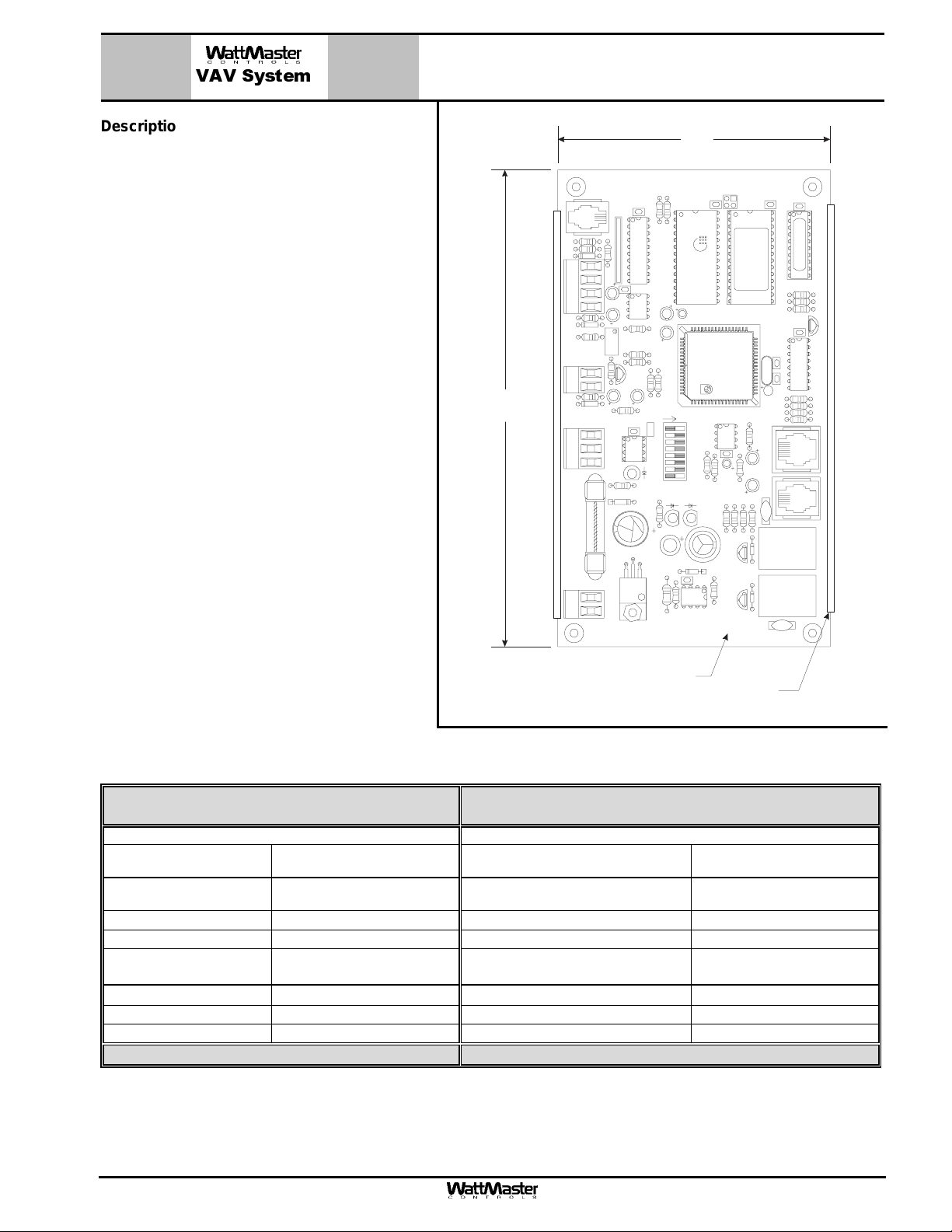

The MG320-00-VAV VAVBOX controller is used for

controlling airflow and operation of VAV terminal

units. It is a programmable digital controller, which

allows for program setpoints to be stored in nonvolatile memory. The controller is connected to a

room sensor via a modular cable assembly, which

monitors space temperature allowing the VAVBOX

controller to modulate a damper in response to

space temperature, duct temperature and airflow

requirements in the controlled space.

The MG320-00-VAV VAVBOX Controller has three

integral modular jacks for connection to the actuator, airflow sensor (for pressure independent applications) and relay or analog expansion boards, via

modular cables. A 2 wire terminal block is provided

for connection of a 24VDC power transformer, a 2

wire terminal block is provided for the Room Temperature Sensor and a 3 wire terminal block is provided for connection of the communications loop.

The controller has an on-board dip switch provided

for board addressing.

The VAVBOX controller is provided with two relays

for tri-state control of the damper actuator. The

actuator connects via a modular cable to the board

and provides the VAVBOX controller with feedback

monitoring for precise positioning of the actuator.

Mounting

Each VAVBOX controller is provided with a plastic

snap track modular mounting base. The snap track

is designed to be mounted with sheet metal screws

to a flat surface using the pre-punched mounting

slots provided. The VAVBOX controller is then

snapped into place on the snap track providing for

easy field mounting and servicing.

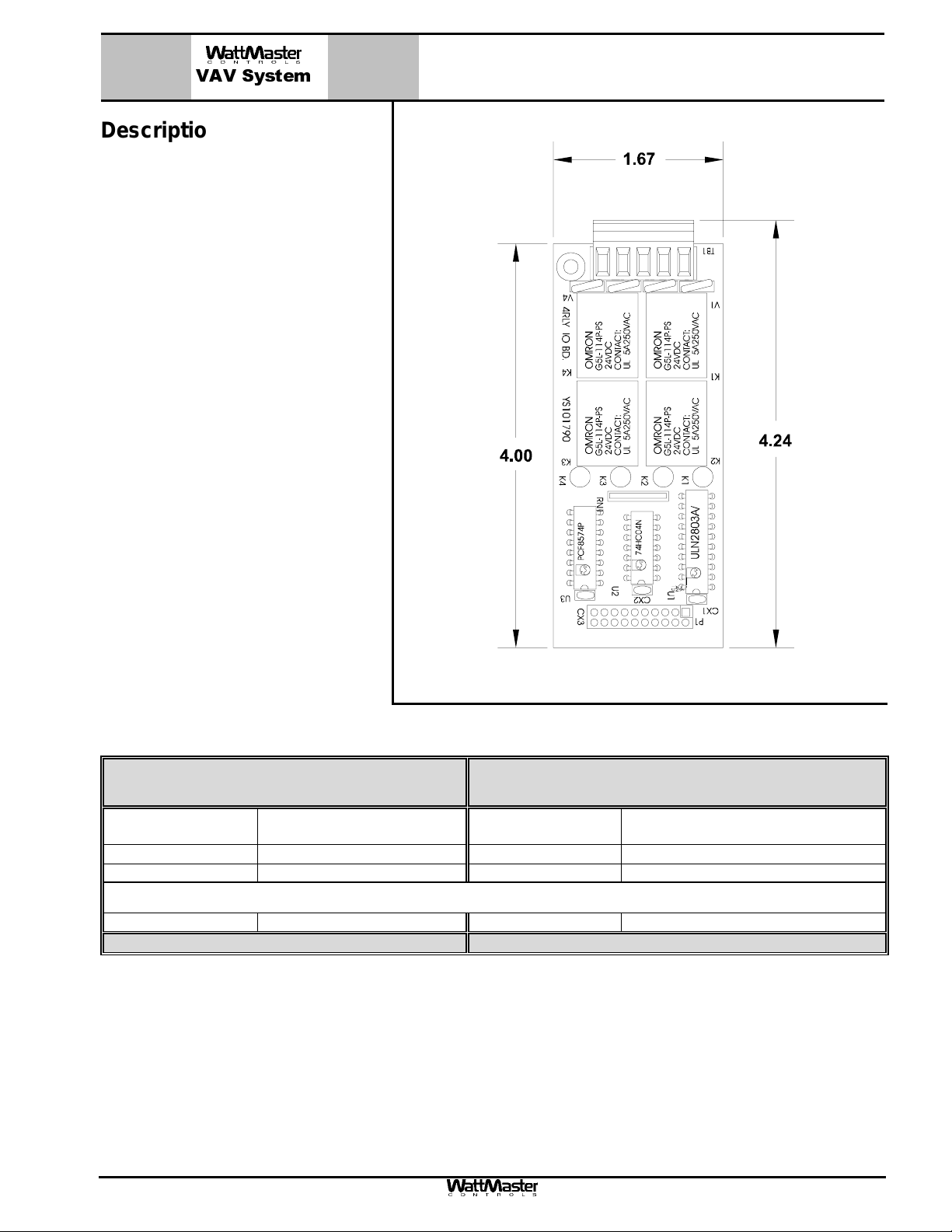

7.00"

AVBOX Controlle

FLOW

CX8

U8

RN1

1

B31920PS

74HC573N

D5

R27

CX9

C13

LMC662

C14

D5

R32

T'STA

T

F1

562

YS101

REV. 2

24VAC

GND

Zone Controller Board

R22

ADJ

VREF

P.U .

R23

R28

R24

U11

C11

R20

C15

EWDOG

R25

D7

CX10

COMM

75176

U10

LD3

POWER

R26

250

D4

MDL

VR1

T

7824

7824C

M

4.00"

U4

MS6264L-70PC

9936

RAM

C8

ADD

1

2

4

8

16

32

TOKEN

NET

LD2

LD1

REC

C7

9936

CX4

80C55

2

PHILIPS

PHILIPS

U5

U6

R14

D3

64A

MC340

U7

RAM

8K

32K

EPROM

PCB80C552-5-16WP

500650=1/3

DFD9940SM

93C46

CX6

C5

R100

R13

R12C6R11

Q2

R15

Q3

U3

V4.00F C094

AZZONE

R8

C3

C4

V1

R9

R10

fTimes New

fTimes New

Roman|b0|i0|

Roman|b0|i0|c0|p18;

c0|p18;OMRON

G5L-114P-PS

24VDC

CONTACT:

UL / CSA 5A250VAC

K1

D1

fTimes New

fTimes New

Roman|b0|i0|

Roman|b0|i0|c0|p18;

c0|p18;OMRON

G5L-114P-PS

24VDC

CONTACT:

D2

UL / CSA 5A250VAC

K2

CX3

CX1

U1

TCU32K2V

16L8

R1

R2

R3

CX2

X1

CX5

PJ1

PJ2

V2

Q1

B31920PS

74HC259

U2

C2C1

R4

R5

R6

R7

SION

EXPAN

TOR

ACTUA

R34

R18

U9

C9

C10

R19

ADDRE

SS

SW1

R21

SCAN

L1

R16

R17

Snap Track

Technical Data MG320-00-VAV

VAVBOX Controller

Specifications: Inputs:

Supply Power 24 Volt AC/DC Room Temperature Sensor Type III-10kohm Sensor

Power Consumption 4 VA Maximum Air Flow Sensor

(PI Applications Only)

Operating Temperature

35°F to 125°F

Power Wire Terminals

0-5” H2O Velocity Pressure

Modular Cable Connection

Operating Humidity 90% RH Non-Condensing Communications Wire Terminal s

Memory EEPROM Duct Temperature Sensor Type III-10kohm Sensor

Communications RS-485 - 9600 Baud

Outputs:

Mounting Method Snap Track Actuator Modular Cable Connection

Addressing Rocker Type Dip Switch Expansion Boards- Digital or Analog Modular Cable Connection

Three Year Warranty WattMaster reserves the right to change specifications without notice

Form: WMS-MG320-VAVBOXController-1C.doc Page 1 of 1

Wire Termi nal s

Wire Termi nal s

Page 3

VAV System

Description

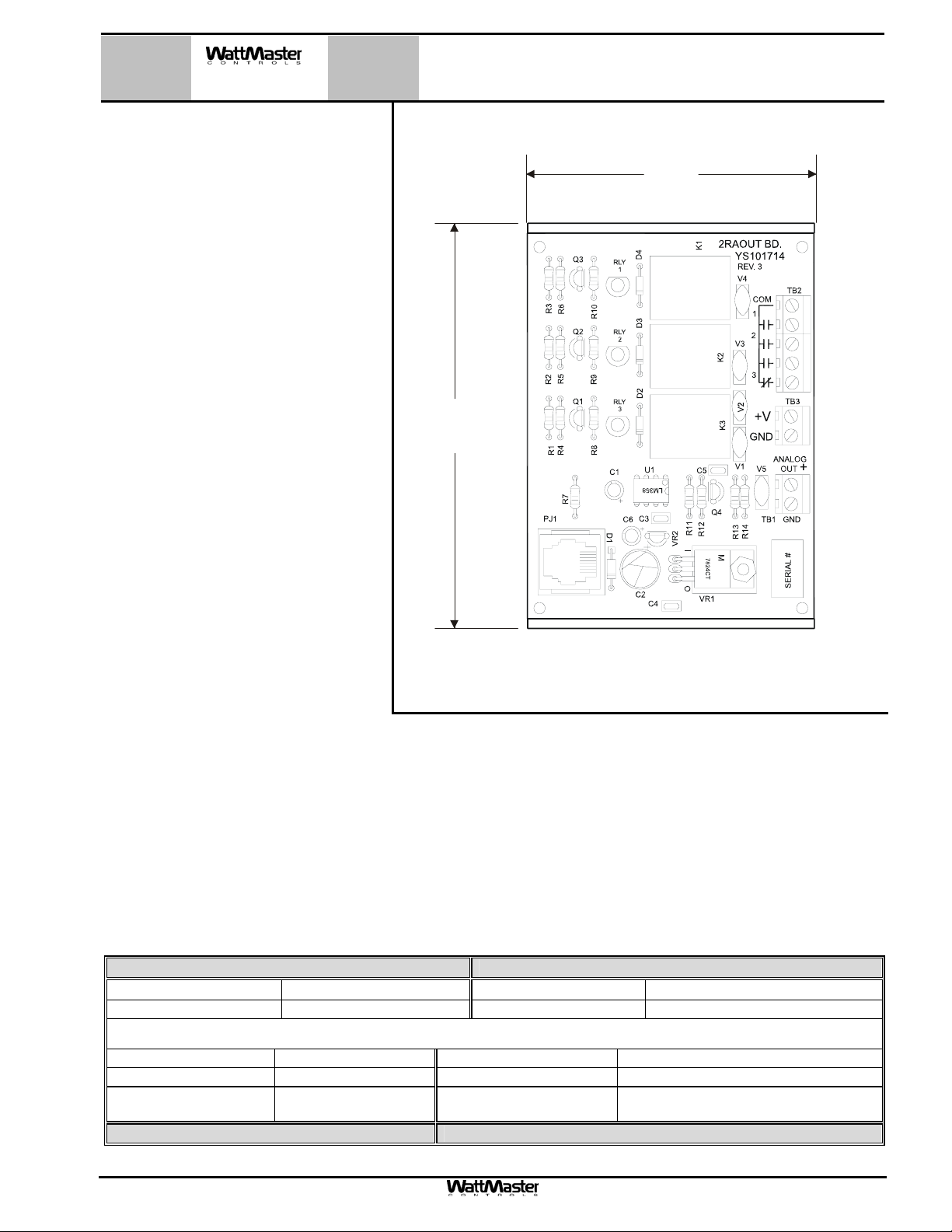

The OE322 - 3 Relay with Analog Output Expansion board is used in conjunction with the MG320–00-VAVZ controller board to allow for control of VAV

terminal units, including series and parallel fan terminal units with up to 3

stages of electric heat, SCR electric

heat or with modulating hot water heat.

The OE322 Analog Output Expansion

board provides 3 relay outputs for pilot

duty switching control, and 1 Analog

output for control of a 0-10V modulating

hot water valve or SCR controlled electric heating coil. The expansion board is

also equipped with 24 VDC (+V and

GND) output terminals for powering a

24 VDC hot water valve actuator if desired. A 24 VAC hot water valve actuator can also be used but will require the

use of a separate field supplied 24 VAC

transformer to power the valve actuator.

The OE322 - 3 Relay W/ Analog Output

Expansion board connects to the

MG320–00-VAVZ controller board by

means of a modular cable provided with

the OE322 board. Power is supplied to

the board by means of this modular cable. Screw terminals are provided for

connection of field wiring to the relay

and analog outputs.

The relay outputs are N.O. contacts with one common terminal. All outputs and the relay common are electrically

isolated from all other circuitry on the board. All relay outputs are supplied with transient suppression devices

across each set of contacts to reduce EMI and arcing. The relay output contacts are rated for pilot duty control of

a maximum of 2 Amps @ 24 VAC or 24 VDC. The analog output provides a 0 – 10 VDC modulating signal output

into a 1k Ohm minimum load. The 24 VDC (+V and GND) output terminals are rated for control of a 24 VDC

valve actuator with a maximum load rating of 12 Watts or less.

OE322 - 3 Relay W/ Analog Output

Expansion Board

3.00"

4.18"

Mounting

The OE322 - 3 Relay W/ Analog Output Expansion Board is supplied mounted on a plastic Snap Track channel.

The Snap Track channel has two mounting holes which are used to field mount the board with the provided

screws. The board should be mounted in close proximity to the MG320–00-VAV controller board to allow for connection of the modular cable.

Technical Data OE322- 3 Relay W/ Analog Output Expansion board

Operating Temp

Weight 4 oz Connection to Controller: Modular Cable

Analog Output Qty. 1 Analog Output Rating 0-10 VDC @ 1k Ohm minimum load

Relay Output Qty. 3 – Electrically Isolated Relay Contact Rating 2 Amp @ 24 VAC

Valve Actuator Power

Terminals Voltage

Three Year Warranty

Form: WMS-OE322-3Relay-1AnOutExpBrd-1C.doc Page 1 of 1

10°F to 149°F

24 VDC 24 VDC Valve Actuator

Operating Humidity 90% RH Non-Condensing

Outputs:

12 Watts

Maximum Load

WattMaster reserves the right to change specifications without notice

Page 4

VAV System

Description

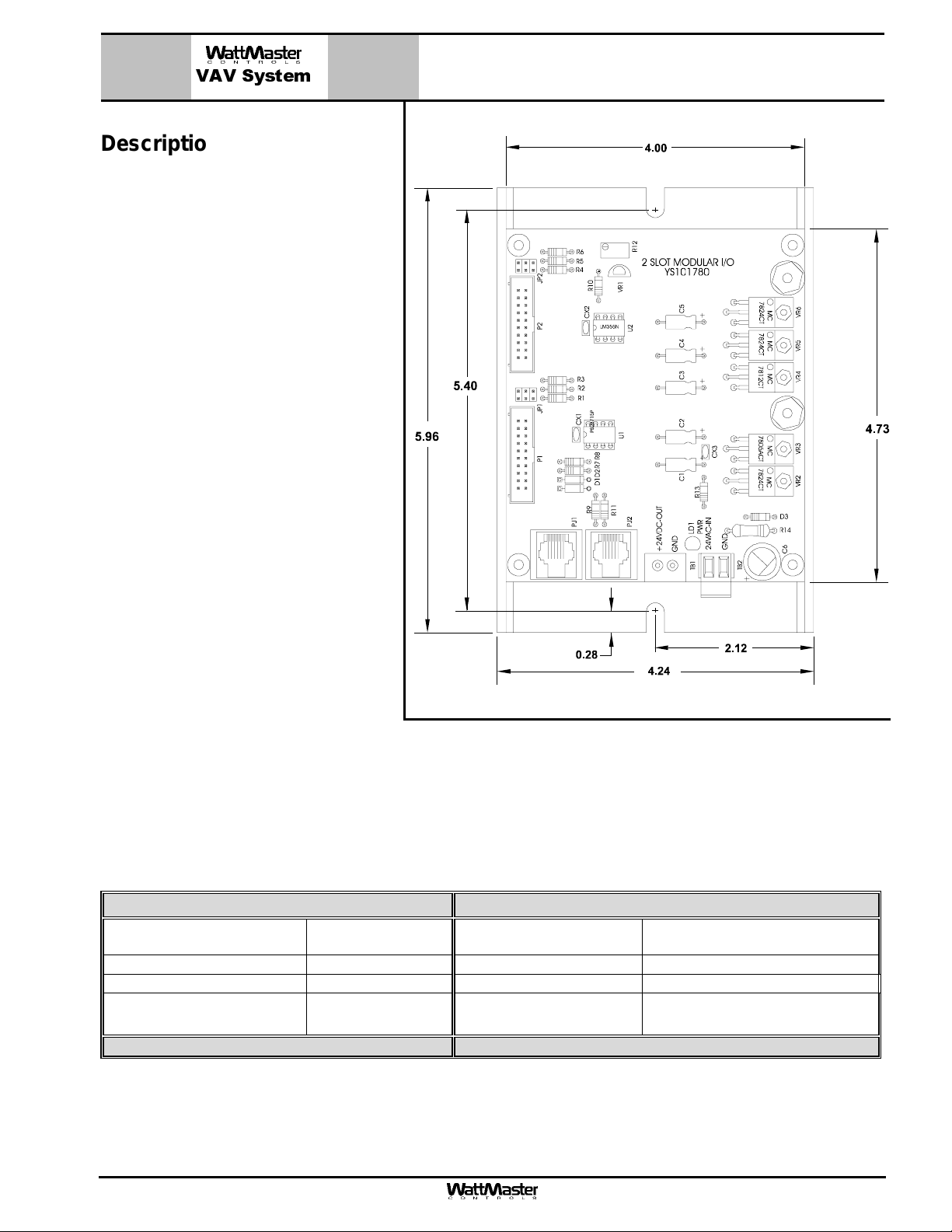

The OE352 – 2 Slot Modular I/O Base

Board is used in conjunction with the following Modular Expansion Boards:

• O354 – 4 Analog Input &

1 Analog Output

• OE355 – 4 Analog Output

• OE356 – 4 Digital Inputs

• OE357 – 4 Relay Outputs

For easy wiring the OE352 – 2 Slot

Modular I/O Base Board provides for up

to (2) of the above expansion boards to

be connected to it by means of an integral

male/female push-in connector arrangement. Power is supplied to the Expans ion

Boards through this connector, simplifying

installation and connection. Jumpers are

also provided on the OE352 Modular I/O

Base Board for addressing and configuration of the Modular Expansion Board(s).

OE352 – 2 Slot

Modular I/O Base Board

Any combination of Modular Expansion

Boards may be connected to the OE352

Modular I/O Base Board to provide the

input/output capabilities required.

The main controller software used with

the OE352 Modular I/O Base determ ines

which Modular Expansion Boards m ay be

used.

Mounting

The OE352 – 2 Slot Modular I/O Base Board is supplied m ounted on a plastic Snap Track channel. T he Snap

Track channel has two mounting holes, which are used to field mount the board with the provided screws. The

board should be mounted in close proximity to the MG331-21-VAV HVAC Unit Controller board to allow for connection of the modular cable.

Technical Data

Operating

Power

Operating Temp

Communications Integral I2 C Chip Weight 8 oz.

Qty of Slots Provided For

Modular Expansion Boards

Three Year Warranty WattMaster reserves the right to change specifications without notice

24 VAC Power Consumption 5 VA Maximum

10°F to 149°F

Operating Humidity 90% RH Non-Condensing

Mounting Provisions Supplied with

2

OE352 – 2 Slot Modular I/O Base Board

Snap Track Base

Form: WMS-OE3522SlotBaseBoard-1B.doc Page 1 of 1

Page 5

VAV System

Description

The OE353 – 4 Slot Modular I/O Base

Board is used in conjunction with the following Modular Expansion Boards:

• O354 – 4 Analog Input &

1 Analog Output

• OE355 – 4 Analog Output

• OE356 – 4 Digital Inputs

• OE357 – 4 Relay Outputs

For easy wiring the OE353 – 4 Slot

Modular I/O Base Board provides for up

to (4) of the above expansion boards to

be connected to it by means of an integral

male/female push-in connector arrangement. Power is supplied to the Expans ion

Boards through this connector, simplifying

installation and connection. Jumpers are

also provided on the OE353 Modular I/O

Base Board for addressing and configuration of the Modular Expansion Board(s).

OE353 – 4 Slot

Modular I/O Base Board

Any combination of Modular Expansion

Boards may be connected to the OE353

Modular I/O Base Board to provide the

input/output capabilities required.

The main controller software used with

the OE353 Modular I/O Base determ ines

which Modular Expansion Boards m ay be

used.

Mounting

The OE353 – 4 Slot Modular I/O Base

Board is supplied mounted on a plastic

Snap Track channel. The Snap Track

channel has two mounting holes, which

are used to field mount the board with the

provided screws. The board should be

mounted in close proximity to the MG33121-VAV HVAC Unit Controller board to

allow for connection of the modular cable.

Technical Data OE353 – 4 Slot

Modular I/O Base Board

Operating

Power

Operating Temp

Communications Integral I2 C Chip Weight 8 oz.

Qty of Slots Provided For

Modular Expansion Boards

Three Year Warranty

24 VAC Power Consumption 5 VA Maximum

10°F to 149°F

Operating Humidity 90% RH Non-Condensing

Mounting Provisions Supplied with

4

WattMaster reserves the right to change specifications without notice

Snap Track Base

Form: WMS-OE353-4SlotBaseBoard-1B.doc Page 1 of 1

Page 6

OE354 – 4 Analog Input/1 Analog

VAV System

Description

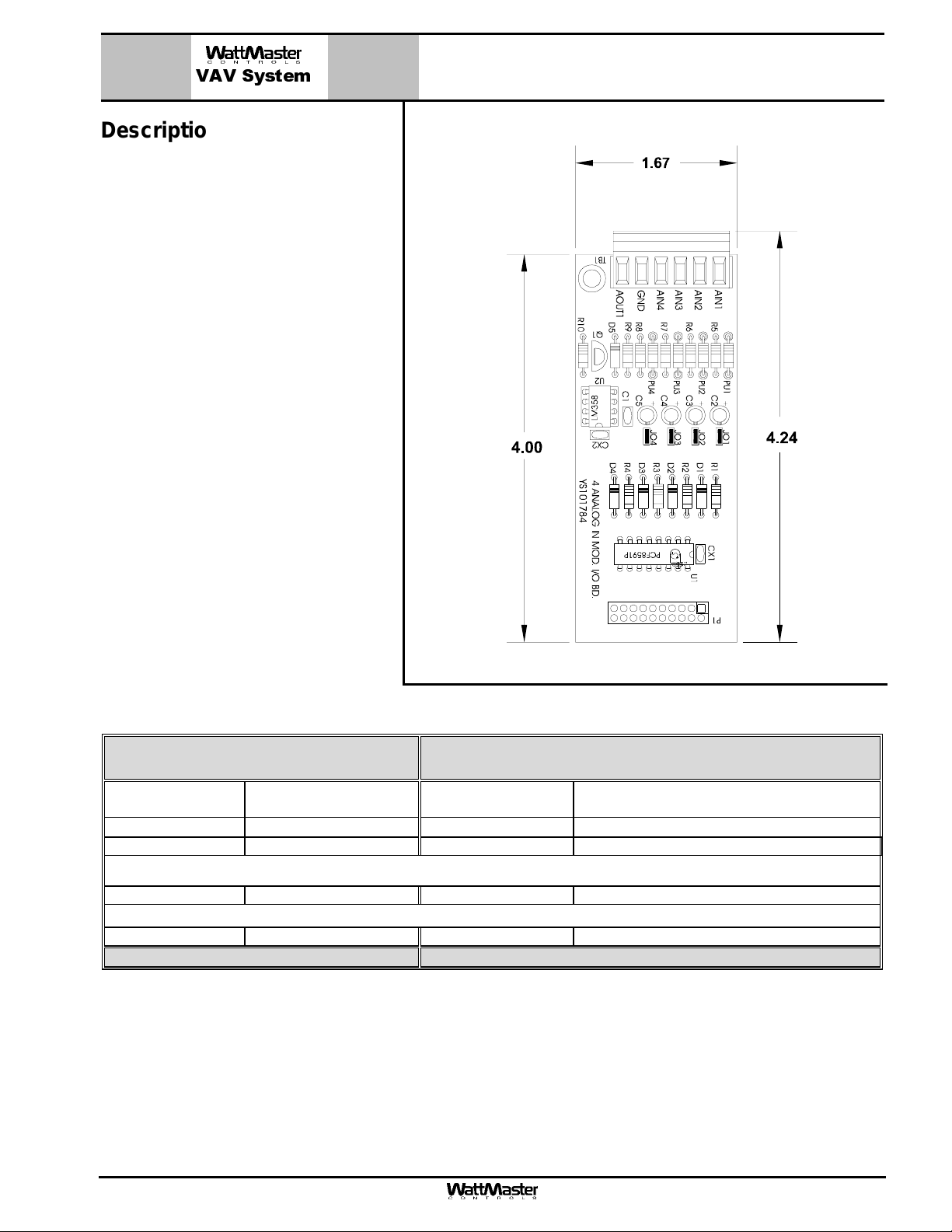

The OE354 - 4 Analog Input/1 Analog

Output Modular Expansion Board is us ed

in conjunction with the OE352 - 2 Slot

Modular I/O Base Board or the OE353 - 4

Slot Modular I/O Base Board. The OE354

Expansion Board provides 4 analog inputs and 1 analog output.

For easy wiring the OE354 – 4 Analog

Input/1 Analog Output Modular Expansion

Board connects to the OE352 or OE353

Modular I/O Base Boards by means of an

integral connector arrangem ent. Power is

supplied to the OE354 - Expansion Board

through this connector, sim plifying installation and connection. Jumpers are provided on the OE352 and OE353 Modular

I/O Base Boards for addressing of the

OE354 - Expansion Board(s).

The analog inputs have removable pullup resistors associated with each input,

which can be used for connection of

thermistor type sensors or dry contact

closure configuration. The pull-up resistors are removed when a voltage signal is

to be used. Jumpers are pr ovided to configure the inputs for either 0-5 Volt or 0-10

Volt operation. Input and output resolution

is 0.4% or (0.04 Volts).

Output Modular Expansion Board

Technical Data OE354 – 4 Analog Input/1 Analog Output

Modular Expansion Board

Operating

Power

Operating Temp

Communications Integral I2 C Chip Weight 4 oz.

From OE352/OE353

Modular I/O Board

10°F to 149°F

Power Consumption 2 VA Maximum

Operating Humidity 90% RH Non-Condensing

Inputs:

Analog Input Qty. 4 Analog Input Types 10K Thermistor, Dry Contact, 0-10 or 0-5 Volt

Output:

Analog Output Qty. 1 Analog Output Rating 0-10 VDC @ 1K Ohm

Three Year Warranty WattMaster reserves the right to change specifications without notice

Form: WMS-OE354-4AI-1AO-ModExpBoard-1B.doc Page 1 of 1

Page 7

OE355 – 4 Analog Output

VAV System

Description

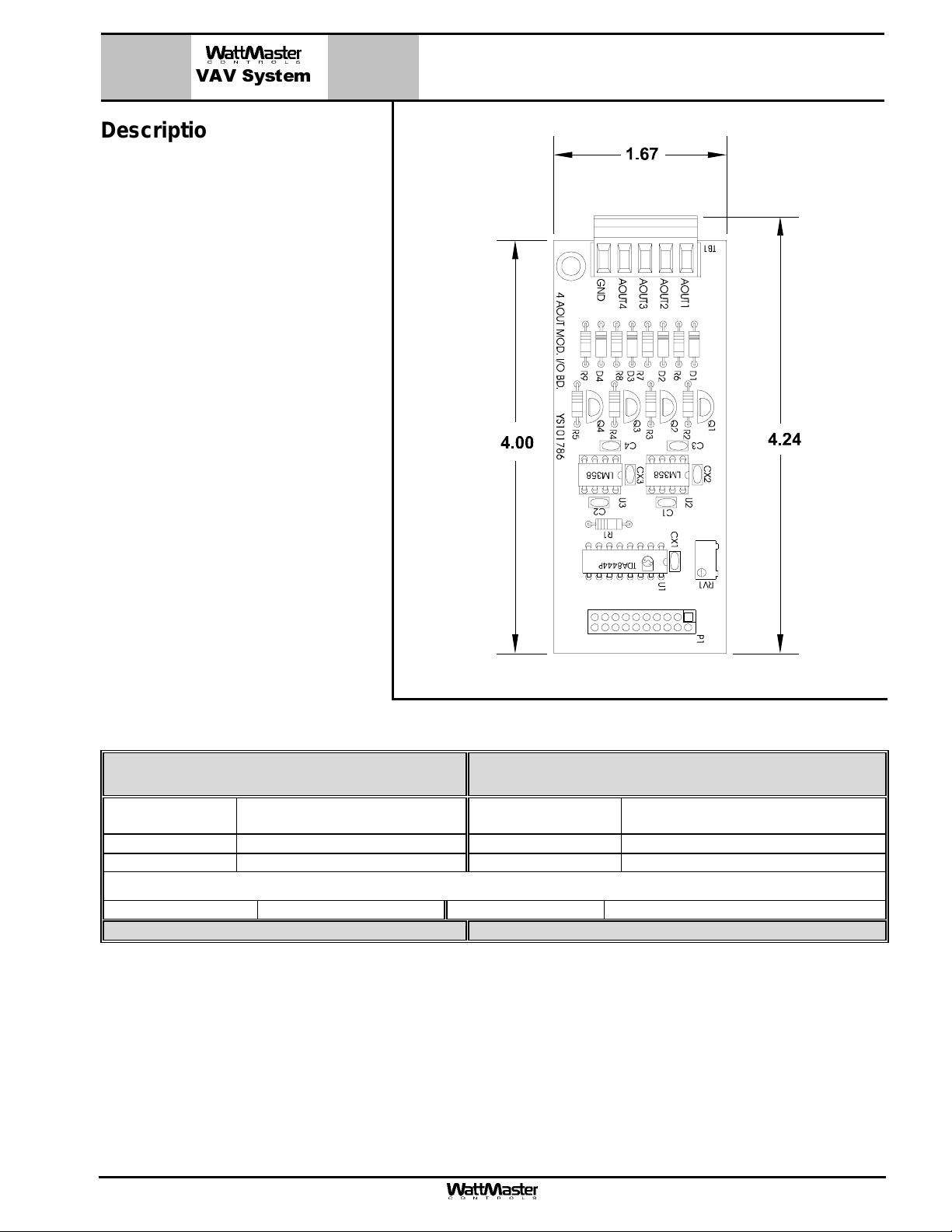

The OE355 - 4 Analog Output Modular

Expansion Board is used in conjunc tion

with the OE352 - 2 Slot Modular I/O

Base Board or the OE353 - 4 Slot

Modular I/O Base Board. The OE355

Expansion Board provides (4) 0-10 VDC

analog outputs for driving actuators,

valves etc.

For easy wiring the OE355 – 4 Analog

Output Modular Expansion Board connects to the OE352 or OE353 Modular

I/O Base Boards by means of an integral connector arrangement. Power is

supplied to the OE355 - Expansion

Board through this connector, simplifying installation and connection. Jumpers

are also provided on the OE352 and

OE353 Modular I/O Base Boards for

addressing of the OE355 - Expansion

Board(s).

Modular Expansion Board

The analog outputs are designed to

drive a 1K Ohm minim um load. All outputs have a resolution of 1.6% or (.16

Volts).

Technical Data

Operating

Power

Operating Temp

Communications Integral I2 C Chip Weight 4 oz

Analog Output Qty. 4 Analog Output Rating 0-10 VDC @ 1K Ohm

Three Year Warranty WattMaster reserves the right to change specifications without notice

From OE352/OE353

Modular I/O Board

10°F to 149°F

Power Consumption 2 VA Maximum

Operating Humidity 90% RH Non-Condensing

Outputs:

OE355 – 4 Analog Output

Modular Expansion Board

Form: WMS-OE355-4AO-ModExpBoard-1B.doc Page 1 of 1

Page 8

VAV System

Description

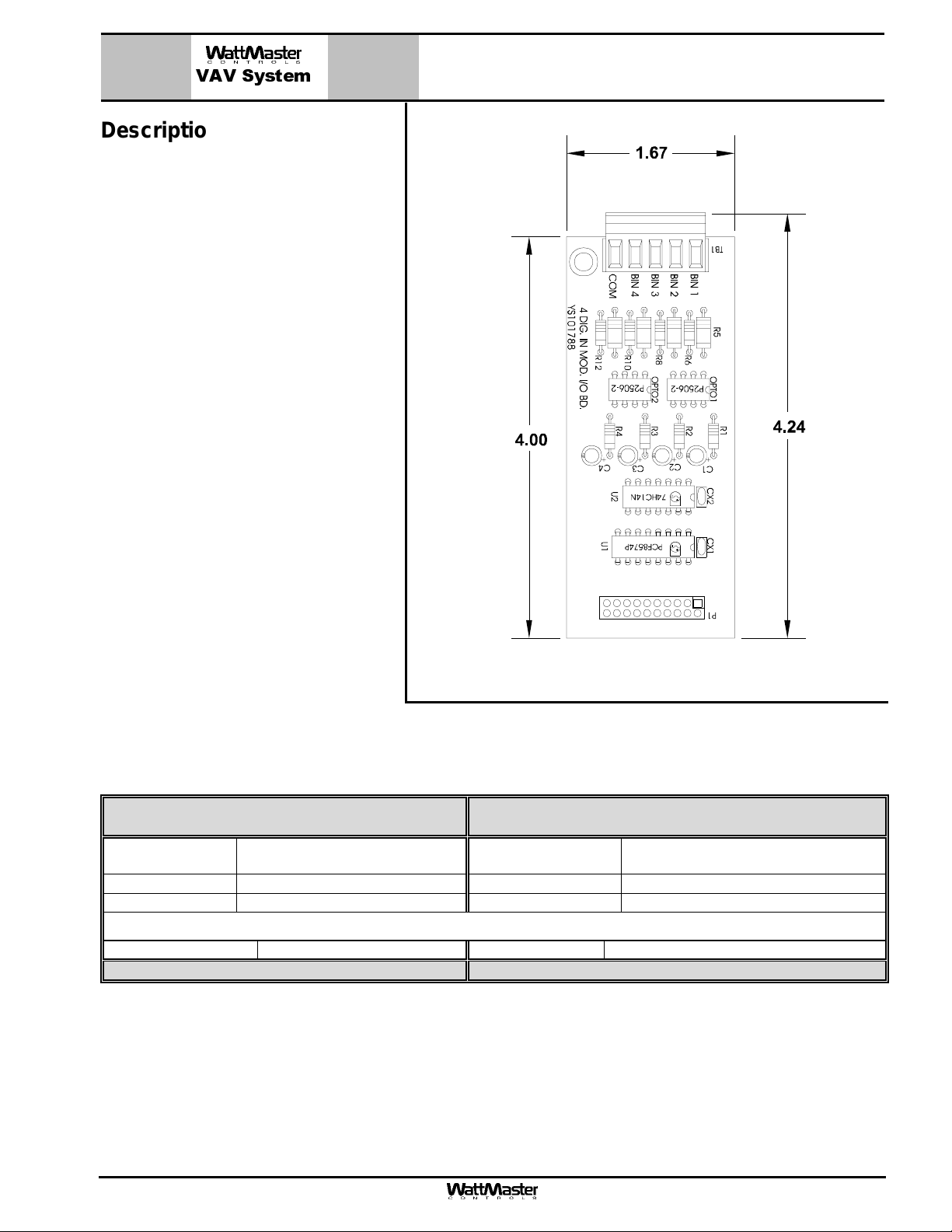

The OE356 - 4 Digital Input Modular Ex pansion Board is used in conjunction with

the OE352 - 2 Slot Modular I/O Base

Board or the OE353 - 4 Slot Modular I/O

Base Board. The OE356 Expansion

Board provides 4 digital inputs f or s ensing

status of connected dry contact closures

or connected voltage depending on how

the external equipment is wired to the

digital inputs on the OE356 board.

For easy wiring the OE356 – 4 Digital Input Modular Expansion Board connects to

the OE352 or OE353 Modular I/O Base

Boards by means of an integral connector

arrangement. Power is supplied to the

OE356 - Expansion Board through this

connector, simplifying installation and

connection. Jumpers ar e also provided on

the OE352 and OE353 Modular I/O Base

Boards for addressing of the OE356 - Expansion Board(s).

OE356 - 4 Digital Input

Modular Expansion Board

The digital inputs on the OE356 share one

common terminal between the 4 inputs.

The comm on terminal may be connected

to either 24 VAC or the 24 VAC com mon

depending on how the board is to be

wired to the equipment. Inputs are optically isolated from other circuitry.

Technical Data OE356 – 4 Digital Input

Modular Expansion Board

Operating

Power

Operating Temp

Communications Integral I2 C Chip Weight 4 oz.

Digital Input Qty. 4 Digital Input Rating 24 VAC or Dry Contact Closure

Three Year Warranty WattMaster reserves the right to change specifications without notice

From OE352/OE353

Modular I/O Board

10°F to 149°F

Power Consumption 2 VA Maximum

Operating Humidity 90% RH Non-Condensing

Inputs:

Form: WMS-OE356-DigitalInput-ModExpBoard-1B.doc Page 1 of 1

Page 9

VAV System

Description

The OE357 - 4 Relay Output Modular

Expansion Board is used in conjunc tion

with the OE352 - 2 Slot Modular I/O

Base Board or the OE353 - 4 Slot

Modular I/O Base Board. The OE357

Expansion Board provides 4 relay outputs for pilot duty switching control.

For easy wiring the OE357 – 4 Relay

Output Modular Expansion Board connects to the OE352 or OE353 Modular

I/O Base Boards by means of an integral connector arrangement. Power is

supplied to the OE357 - Expansion

Board through this connector, simplifying installation and connection. Jumpers

are also provided on the OE352 and

OE353 Modular I/O Base Boards for

addressing of the OE357 - Expansion

Board(s).

OE357 - 4 Relay Output

Modular Expansion Board

The relay outputs are N.O. contacts with

one common terminal. All outputs and

the relay common are electrically isolated from all other circuitry on the

board. All relay outputs are supplied

with transient suppression devices

across each set of contacts to reduce

EMI and arcing. The relay output contacts are rated for pilot duty control at a

maximum of 2 Amps @ 24 VAC or 24

VDC.

Technical Data OE357 – 4 Relay Output

Modular Expansion Board

Operating

Power

Operating Temp

Communications Integral I2 C Chip Weight 4 oz

From OE352/OE353

Modular I/O Board

10°F to 149°F

Power Consumption 2 VA Maximum

Operating Humidity 90% RH Non-Condensing

Outputs:

Relay Qty. 4 Relay Contact Rating 2 Amps @ 24 VAC

Three Year Warranty WattMaster reserves the right to change specifications without notice

Form: WMS-OE357-4RelayOutput-ModExpBoard-1B.doc Page 1 of 1

Page 10

VAV System

Description

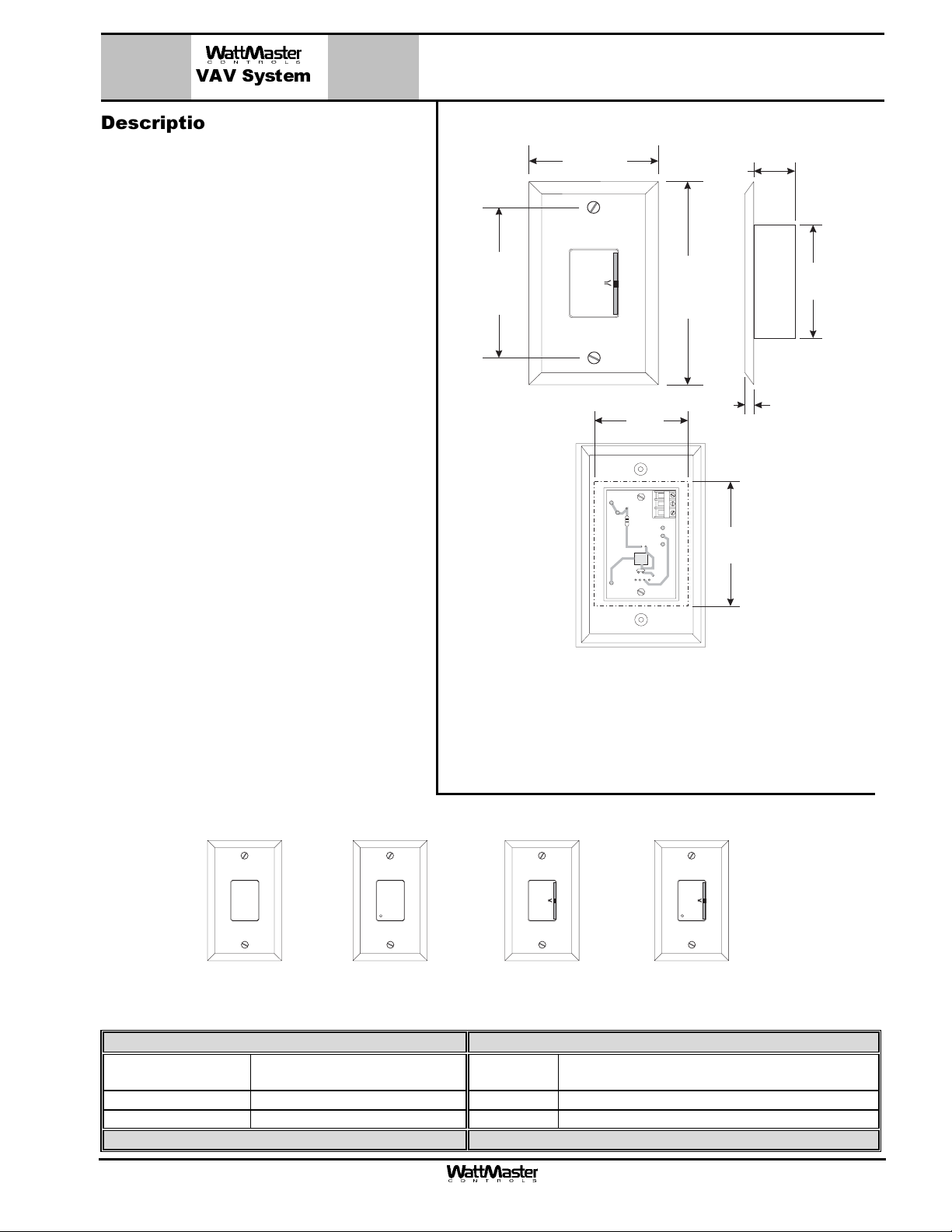

The patented design, OE21x series Standard

Room Sensor provides accurate sensing of

the room temperature. Its design allows for

flush wall mounting yet rejects the influence of

surface and internal wall temperatures. The

Standard Room Sensor is used in conjunction

with the WMVAV and the VAVBOX controllers.

Wire terminals are provided on the sensor for

connection to the controllers.

The Room Sensor’s attractive styling and off

white casing color make it suitable for most

building decors. If interior decoration requires,

the Room Sensor casing can also be painted

or wall papered without affecting the sensor's

performance. Room Sensors are available in 4

different configurations:

• OE210 Sensor Plain

• OE211 Sensor with Override

• OE212 Sensor with Setpoint

Adjustment

• OE213 Sensor with Setpoint

Adjustment and Override

3.25“

OE210, 211, 212 & 213

Standard Room Sensors

2.75“

W

A

R

M

E

R

C

O

O

L

E

R

2.00“

TMP

GND

AUX

OUT

4.50“

0.88“

0.25“

2.50"

Wall Cut-Out Dimensions

When Sensor Is To Be

Mounted Without

2.75“

Handy Box (By Others)

Modular cable from the W MVAV or VAVBOX

controllers to the Modular Room Sensor

should not be run in conduit with other AC line

voltage wiring, or with any conductors carrying

highly inductive loads.

Mounting

The Room Sensors are designed to be

mounted on a vertical, 2” x 4” electrical box

recessed in the wall. If the wall cannot be

penetrated, a plastic surface mount box such

as those made by Wiremold™, may be used to

mount the sensor to the wall surface.

W W

A A

R R

M M

E E

R R

C C

O O

OVR OVR

OE210 OE211

Room Sensor - Plain

Room Sensor

With Override

Technical Data OE210, OE211, OE212, OE213 Standard Room Sensor

Sensor Element Type III Thermistor

10k ohm @ 77º F

Accuracy

±0.4º F between 40º F to 95º F

Range -30º F to 150º F Weight 4 oz.

3 Year Warranty WattMaster reserves the right to change specifications without notice

Mounting Designed to be Flush Mounted to Wall

Line Loss 0.25º F max. error, using 22 AWG wire at 1000 ft

O O

L L

E E

R R

OE212

Room Sensor

With Setpoint Adjust

using Vertical 2” x 4” Handy Box (by others)

OE213

Room Sensor

With Setpoint Adjust

& Overide

Form: WMS-StandardRoomSensor-1B.doc Page 1 of 1

Page 11

MG392-05

r

VAV System

Description

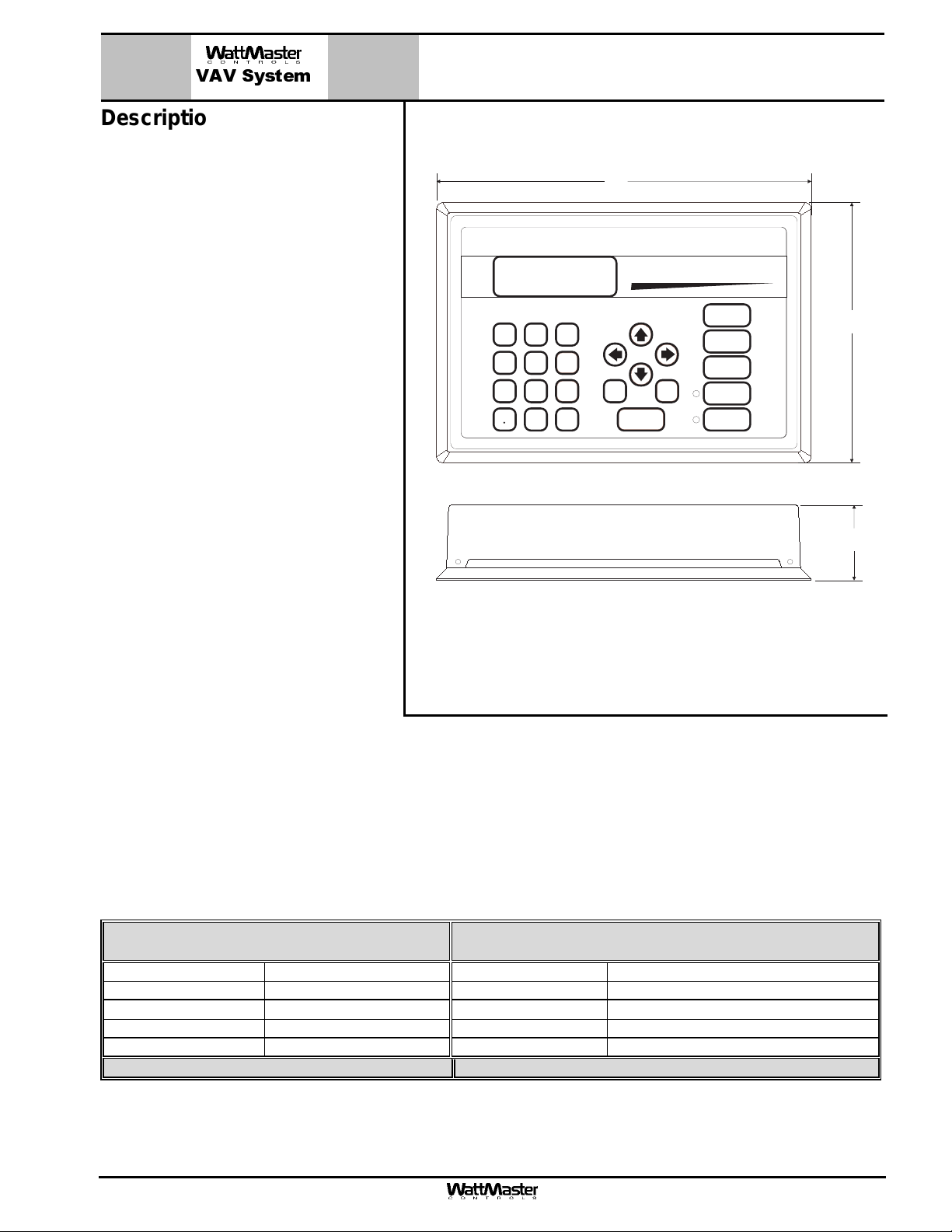

The MG392-05 Modular System Manager

provides a direct link to enable the system

operator to view the status and to adjust

the setpoints of any controller on the control system communications loop. The

Modular System Manager is designed to

be used with the WattMaster VAV Control

System. The System Manager is housed

in an attractive beige colored plastic enclosure. The System Manager is

equipped with a four line by 20 character

backlighted display panel and a 24 key

membrane k eypad for data selection and

entry. All keypad operations are simple

and straight forward, utilizing non-cryptic

plain English language messages. Menu

driven programm ing allows for eas y setup

and operation without the need for specialized training. The System Manager

also has 2 integral LED’s for user notification of system alarm conditions and

override initiations. Protection from unauthorized users is provided by the System Manager’s integral multi-level passcode authorization programming.

Modular System Manage

9.00"

System Manager

STATUS

SETPOINTS

NEXT

SCHEDULES

OVERRIDES

ALARMS

13

2

MINUS

-

PREV

6

ESC

9

4

708

DEC

5

DOWN

ENTER

UP

CLEAR

6.25"

1.81"

The Modular System Manager is connected to the communic ations and power

loop of the system via modular cables

that simply plug into the System Manager

board and are pigtailed into 6 individual

wires on the other end for hard wiring into

a 24 VAC transformer (by others) the local communications wiring loop.

Mounting

The Modular System Manager is designed f or wall mounting. Mounting holes are provided to attach the Modular

System Manager to a standard handy box. It is recomm ended that the System Manager be m ounted at approximately eye level to allow for ease of programming and r eading of the display. The System Manager is typically

mounted in the building manager or s uperintendent’s office or in an equipm ent room. The attractive enclosure is

quite suitable for mounting in any location or with most decors.

Technical Data MGOE392-05

Modular System Manager

Power 24 Volt AC/DC Display 4 Line by 20 Character Backlighted LCD

Power Consumption 5 VA Maximum Network Connection RS-485

Operating Temp

10°F to 149°F

Operating Humidity 90% RH Non-Condensing Housing Material Beige Plastic

Keypad 24 Key Membrane Type Communications RS-485 - 9600 Baud

3 Year Warranty WattMaster reserves the right to change specifications without notice

Protocol HSI Open Protocol Token Passing

Form: WMS-MG392-05-ModularSystemManager-1C.doc Page 1 of 1

Page 12

VAV System

Description

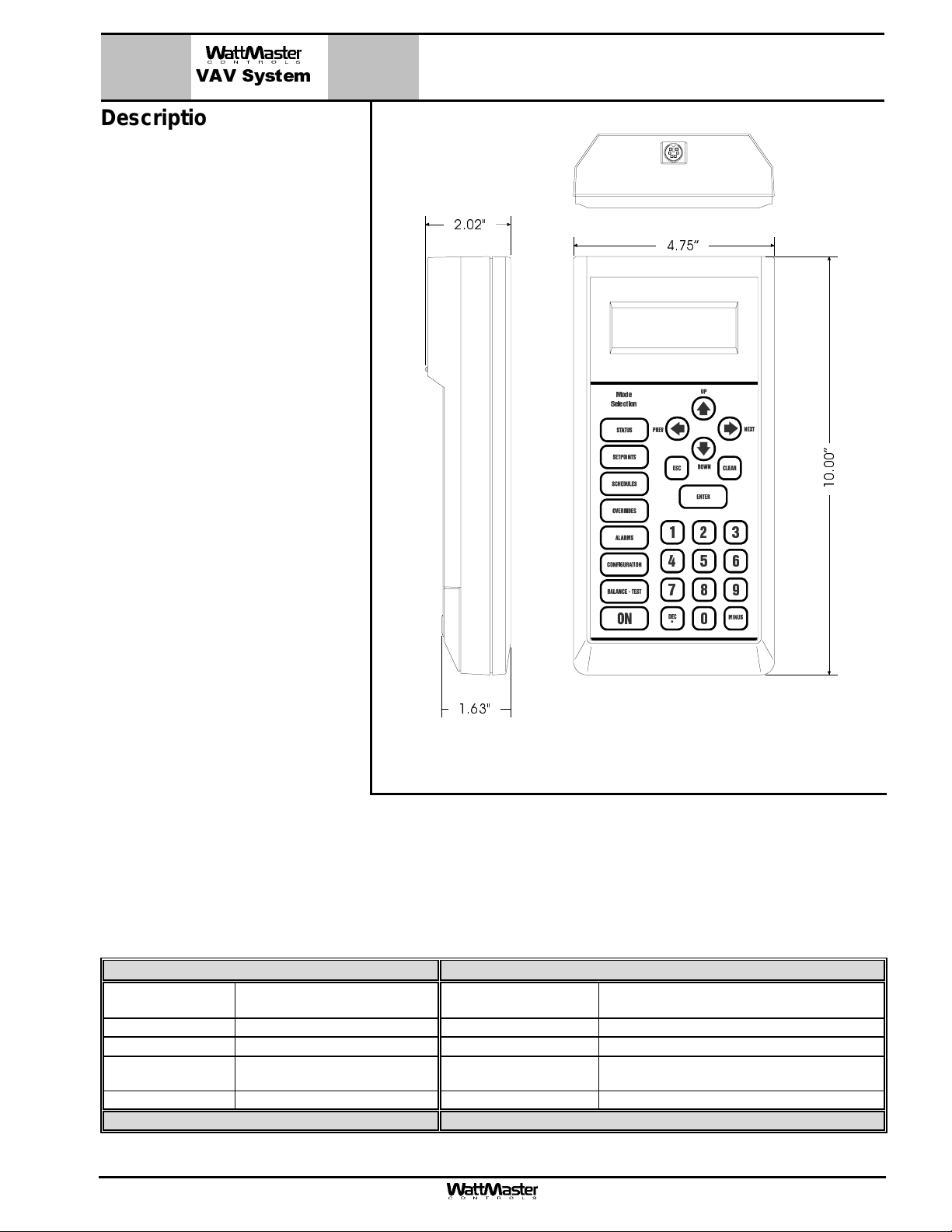

The MG391-05 Modular Service Tool

is a system interface that provides a

direct link to enable the system operator to view the status, configure

and to adjust the setpoints of any

controller on the control system

communications loop. The Modular

Service Tool is housed in an attractive beige colored plastic enclosure.

The display area is covered with a

clear plastic bezel for protection of

the display screen. The Modular

Service Tool has a four line by 20

character display panel with adjustable contrast control and a 27 key

membrane keypad for data selection

and entry. All keypad operations are

simple and straight forward, utilizing

non-cryptic plain English language

messages. Menu driven programming allows for easy setup and operation without the need for specialized training. The MG391-05 Modular Service Tool is supplied with (4)

AA (1.5V) Volt alkaline battery, a 120

VAC/5 VDC power supply and a

communication cable terminated

with an 8 pin DIN connector for connection to the Service Tool. The cable allows the user to setup and program any controller equipped with a

8 pin DIN connector to be programmed by simply plugging the

quick connect terminal into the

socket on the controller. A PL101904

Modular Service Tool Adapter is also

provided for use on controllers that

do not have 8 pin DIN connectors on

their circuit board.

2.02"

1.63"

MG391-05

Modular Service Tool

4.75”

Mode

Selection

”

0

0

.

0

1

13

2

654

708

9

-

The Modular Service Tool is designed to be carried by the system installer or service technician. Its rugged plastic

housing, provides superior protection for the electronic components housed inside. The OE391-054 Modular

Service Tool is a top quality service tool that will stand up to the demands of the typical job site environment for

many years.

Technical Data MGE391-05 Modular Service Tool

Power (4) AA (1.5V) Batteries

Supplied

Power Switch Membrane Switch Network Connection RS-485

Operating Temp

Operating Humid-

ity

Keypad 27 Key Membrane Style Communications RS-485 9600 Baud

3 Year Warranty WattMaster reserves the right to change specifications without notice

Form: WMS-MG391-05-ModularServiceTool-1C.doc Page 1 of 1

90% RH Non-Condensing Color Beige

10°F to 149°F

Display 4 Line by 20 Character

Protocol HSI Open Protocol Token Passing

Page 13

MG364-22– MiniLink

VAV System

Description

The MG364-22 MiniLink Polling Device is

a network controller that is used to integrate multiple local communication loops

into a network communications system.

“Network” loop terminals on the MiniLink

Polling Device are designed to be connected to the CommLink II and to other

MiniLink Polling Devices on the ”Network”

communications loop. “Local” loop terminals are designed to be connected to

controllers installed on the “Local” communications loop.

The MiniLink Polling Device is provided

with a 2 wire terminal block for connection

to the required 24 VAC source(by others).

It also has (2) 3 wire terminal blocks for

communications wiring. One of the terminal blocks is field connected to the “Local”

communications loop and the other is

field connected to the “Network” communications loop.

Polling Device

The MiniLink Polling Device utilizes token

passing communication architecture. The

MiniLink Polling Device is designed to

serve as the local communications loop

master. This means that it is responsible

for sending the token to all the controllers

on the local communications loop. Network communications are of the RS-485

type operating at 19,200 baud. Local

communications are also of the RS-485

type and operate at on systems requiring

override or alarm indication. It also provides tenant-logging capabilities for the

WattMaster VAV system.

MiniLink Polling Device Is Supplied Factory Mounted To

Control Enclosure. Cover Shown Removed For Clarity

Mounting

The MiniLink Polling Device is factory

mounted in a galvanized sheet metal enclosure. Mounting holes are provided in

the enclosure for surface mounting.

Technical Data MGE364-22 – MiniLink

Polling Device

Power 24 Volt AC System Connection Molex® Connectors & Terminals

Power Consumption 6VA Maximum Network Connection RS-485

Operating Temp

Operating Humidity 90% RH Non-Condensing Housing Material 22 Ga. Galvanized Steel

Communications RS-485 - 9600 Baud, Local Communications RS-485 - 19200 Baud, Network

3 Year Warranty WattMaster reserves the right to change specifications without notice

10°F to 149°F

Protocol HSI Open Protocol Token Passing

Form: WMS-MG364-22MiniLinkPollingDevice-1B.doc Page 1 of 1

Page 14

VAV System

Description

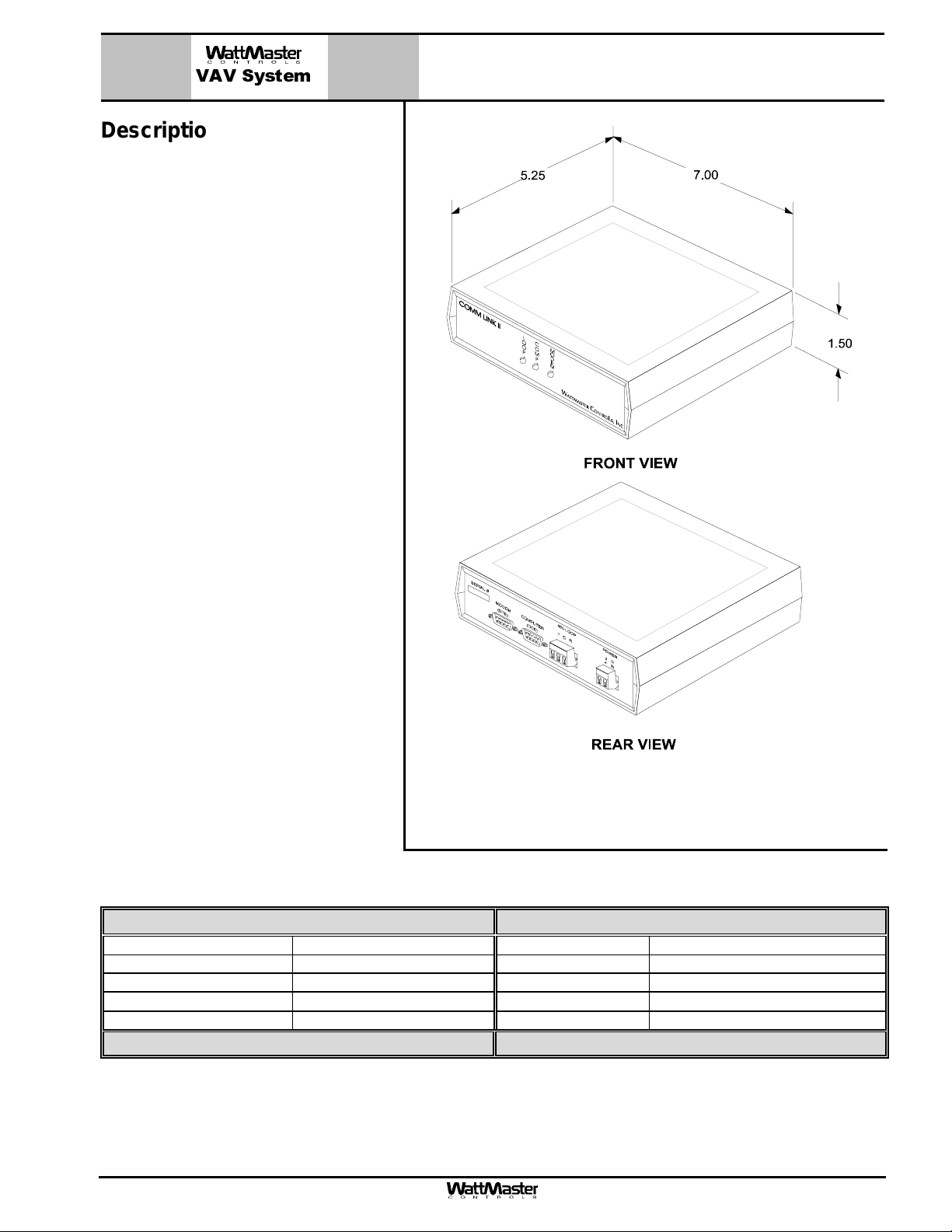

The OE361 - CommLink II Communications Interface allows user ac cess to any

controller connected to the controls system. The CommLink II comes packaged

in an attractive beige colored plastic enclosure. The Comm Link II is powered by

a small wall mounted plug-in transfor mer

that is included. Locally, an optional onsite computer may be connected to the

CommLink II for direct access to system

control parameters. Remote access is

obtained via an optional modem which is

connected with the CommLink II Communication Interface. With a modem installed, the CommLink II may be configured to call a number, if an alar m condition occurs. With the modem option the

system could be dialed and monitored

from a remote location by a PC. Computer and modem cables (6ft long) are

provided with the CommLink II.

OE361 – CommLink II

Communications Interface

Mounting

If an on-site computer is to be used for

direct connection and monitoring of the

system, the CommLink II should be located near the computer terminal to

monitor the system. If no on-site computer is to be used, locate the Comm Link

II near the phone line jack for ease of

connection to a modem. If for any reason

you use cables of greater length than

those provided with the CommLink II (6 ft.

long) be sure the cables that connect the

CommLink II to the modem and the

CommLink II to the on-site computer do

not exceed twenty-five feet in length.

Technical Data OE 361 - CommLink II Communication Interface

Power 24 Volt AC Computer Connection RS-232

Plug-in Transformer 110V to 24V (Included) Network Connection RS-485

Power Consumption 14 VA Maximum Protocol HSI Open Protocol Token Passing

Operating Temperature

Operating Humidity 90% RH Non-Condensing Communications RS-485 - 9600 Baud

Three Year Warranty WattMaster reserves the right to change specifications without notice

10°F to 140°F

Physical Connections (2) 9 Pin/DB9 Male

Form: WMS-OE361-CommLink-1B.doc Page 1 of 1

Page 15

1.50

7.00

REAR VIEW

FRONT VIEW

VAV System

Description

The OE361-08 CommLink III Communications Interface allows com puter access

into the WattMas ter VAV controls system

and also provides communications across

multiple local communications loops on

the control system.

The CommLink III comes pac kaged in an

attractive beige colored plastic enclos ure.

The Comm Link III is powered by a small

wall mounted plug-in transformer that is

included. Locally, an optional on-site Personal Computer with Prism software installed may be connected to the

CommLink III to provide direct access to

system control parameters by using the

supplied USB cable (6 ft. long).

Remote telephone access to the control

system can be obtained via the optional

OE419-05 Modem Kit which can be field

installed inside the CommLink III Communication Interface. With the optional

modem kit installed, the control system

can be accessed remotely by using a

Remote Link modem (purchased separately) connected to a Personal Computer

with Prism software installed at the remote location and dialing the phone number of the phone line the CommLink III

with modem kit is c onnected to. Also with

the modem k it installed the CommLink III

can be configured to call a pager or cell

phone number, if an alarm condition occurs. A USB cable (6ft long) is provided

with the CommLink III for connection to

your computer.

OE361-08 CommLink III

Communications Interface

5.25

Mounting

If an on-site c omputer is to be used for direct c onnection and monitoring of the system, the Comm Link III s hould

be located near the c omputer term inal to m onitor the system . If no on-site com puter is to be used and/or you are

installing the optional modem kit, locate the CommLink III near the phone line jack for ease of connection.

Technical Data OE361-08 CommLink III Communication Interface

Power 24 Volt AC Computer Connection USB Version 1.1 or 2.0

Plug-in Transformer 110V to 24V (Included) Network Connection RS-485

Power Consumption 14 VA Maximum Protocol HSI Open Protocol Token Passing

Operating Temperature

Operating Humidity 90% RH Non-Condensing Communications RS-485 - 9600 Baud

Three Year Warranty WattMaster reserves the right to change specifications without notice

Form: WMS-OE361-08-CommLinkIII-01A.doc Page 1 of 1

10°F to 140°F

Cabling Included (1) 6 Ft. Long USB Cable

Page 16

1.50

7.00

REAR VIEW

FRONT VIEW

VAV System

Description

The OE361-12 Comm Link IV Communications Interface allows com puter acc es s

into the WattMas ter VAV controls system

and also provides communications

across multiple local communications

loops on the control system.

The CommLink IV comes packaged in

an attractive beige colored plastic enclosure. The Com mLink IV is powered by a

small plug-in transf ormer that is included.

Locally, an optional on-site personal

computer with Prism software installed

may be connected to the CommLink IV

to provide direct access to system control parameters. A USB cable ( 6 ft. long)

is provided with the CommLink IV for

connection to your computer.

Remote telephone acces s to the control

system can be obtained by purchasing

the optional OE419-06 Remote Link II

modem. With the optional Rem ote Link II

modem installed, the c ontrol system can

be accessed remotely by using another

Remote Link II m odem (purchas ed separately) connected to a personal computer

with Prism software installed at the remote location. W ith the Remote Link installed at the job site, the Com mLink IV

can be configured to call a pager or cell

phone number if an alarm condition occurs.

OE361-12 CommLink IV

Communication Interface

5.25

An optional OE415-02 IP Module Kit is

also available that provides an Ethernet

connection to the controls system from

any computer connected to your building’s LAN. It can also be configured to

allow access to the control system from

the Internet if your Ethernet firewall is

configured for this option.

Mounting

If an on-site computer is to be used for direct c onnection and monitoring of the system, the CommLink IV should

be located near the c omputer term inal to m onitor the system . If no on-site com puter is to be used and/or you are

installing the Remote Link II option, locate the CommLink IV near the phone line jack for ease of connection.

Technical Data OE361-12 CommLink IV Communication Interface

Power 24 Volt AC *Remote Link II Conn. RS-232 Serial Port (9 pin)

Plug-in Transformer 120V to 24VAC (Included) **Ethernet Conn. RJ-45 Ethernet Port

Power Consumption 14 VA Maximum Network Loop RS-485 - 19,200 Baud

Operating Temperature

Operating Humidity 90% RH Non-Condensing Cabling Included (1) 6 Ft. Long USB Cable

Computer Conn. USB Version 1.1 or 2.0 Local Loop RS-485 - 9600 Baud

Three Year Warranty

* This Port Is Only Used With The Optional OE419-06 Remote Link II. ** This Port Is Only Used With The Optional OE415-02 IP Module Kit.

Form: WMS-CLKIV-SUB-01A-0907 Page 1 of 1

10°F to 140°F

Protocol HSI Open Protocol Token Passing

WattMaster reserves the right to change specifications without notice

Page 17

VAV System

OE366 USB-Link

Description

The OE366 USB-Link allows com puter access into

the WattMaster VAV controls system and also provides communications across multiple local communications loops on the control system when a

CommLink Communications Interface is installed

on the system.

The USB-Link provides a direct link to enable the

system operator to view the status and to configure

and adjust the setpoints of any controller on the

control system communications loop using the

Prism II computer front end software.

The USB-Link is small in size and is powered by

the USB port of the computer it is plugged into,

making it com pletely portable and allowing connection to the system from any controller.

The USB-Link is supplied with a USB cable, a miniDIN male com munication cable, and two mini-DIN

to terminal adapters. The communication cable

allows the user to walk up to any controller that has

a communication s ocket and plug in the USB-Link

to gain access to the system. The adapters are

used for boards that do not have a f emale mini-DIN

plug connection.

To use the USB-Link, you will need a computer

with an available USB 1.1 or 2.0 port with the included USB drivers installed. You will also need the

Prism II computer front end software installed on

the computer.

CAUTION: The USB-Link does not work with Prism

I software. It only works with Prism II.

Technical Data OE366 USB-Link

Operating Temperature

Operating Humidity 90% RH Non-Condensing Communications RS-485 - 9600 Baud

Computer Connection USB Version 1.1 or 2.0 Adapters Included PL1019054 and PL101905 Mini-DIN

Three Year Warranty

10°F to 140°F

Cabling Included (1) 6 Ft. Long USB Cable and

(1) 7 Ft. Long Communications Cable

Plug Adapters

WattMaster reserves the right to change specifications without notice

Form: WMS-OE366-USB-Link-01A.doc Page 1 of 1

Page 18

VAV System

w

w

Description

The OE419-04 Remote Link is essentially a 14,400 baud modem. The Remote Link is used f or achieving remote

communications with all WattMaster

VAV systems. Built in error correction

(V.42/mnp 2-4) and data compression

(V.42bis/mnp 5) will maximize data

transfer integrity and boost average

throughput up to 57.6 kbps. The Remote Link connects to the Com mLink II

communications interface at the Orion

control system location. A telephone line

connects the Remote Link to the local

phone service. By dialing the telephone

number that the Remote Link is connected to, (using a modem from a remote location) the Orion system can be

monitored and controlled using the

WattMaster Prism computer front end

software package.

OE419-04 Remote Link

1

4

5"

R

em

ote

Lin

k

SIG

DET

RDY

SND

REC

PWR

Front Vie

7"

1

2

1"

Mounting

The Remote Link should be mounted

close to a serviceable telephone outlet.

It connects via a serial data cable to the

CommLink II communications interface

and via a telephone cable to the telephone outlet jack. A molded cable for

connection from the CommLink to the

Remote Link is supplied with the

CommLink . If an on-site com puter is required, it should be connected to the

CommLink at or near the location where

the Remote Link is located. If for any

reason you use cables of greater length

than those provided with the CommLink

II (6 ft. long) be sure the cables that

connect the CommLink II to the Remote

Link and the Comm Link II to the on-site

computer do not exceed twenty-five feet

in length.

SERIAL #

TELCO

LINE

SERIAL DATA

POW

ER

Rear Vie

Technical Data

OE419-04 Remote Link

Power 9 Volt DC Computer Connection RS-232, 25 Pin DB25 Female

Plug-in Transformer 110V to 9V (Included) Phone Connection RJ-11 Female

Power Consumption 500mA Maximum Line Speed 14,400 bps

Operating Temperature

10°F to 140°F

Data Compression V.42bis/MNP 5

Operating Humidity 90% RH Non-Condensing Error Correction V.42/MNP 2-4

WattMaster reserves the right to change specifications without notice

3 Year Warranty

Form: WMS-OE419-SUB-01B Page 1 of 1

Page 19

1.50

7.00

REAR VIEW

FRONT VIEW

VAV System

OE419-06 Remote Link II

Description

The OE419-06 Remote Link II is essentially

a 14,400 baud modem that connects to the

CommLink IV via a serial cable. W hen it is

5.25

used as a modem ( at the remote com puter

location) it connects to the remote computer via a USB cable. The Remote Link II

is used to provide for rem ote dial-up communications with the CommLink II or

CommLink IV communication interfaces.

The Remote Link II connects to the

CommLink II or IV communications interface at the control system loc ation. A telephone line connects the Remote Link II to

the local phone service. By dialing the telephone number at the job site that the Remote Link II is connected to (using another

Remote Link II m odem from a r em ote location), the control system can be monitored

and controlled using the Prism computer

front end software package.

Mounting

The Remote Link II should be mounted

close to a serviceable telephone outlet. The

CommLink II or CommLink IV communications interface connects to the Remote Link

II with the supplied 6 ft. long serial cable.

It is recommended that a second Remote

Link II be used as the dial out modem at

the remote computer location. WattMaster

will not support any other internal or external modems by other manuf ac turer s. A 6 ft.

long USB cable is supplied with the Remote Link II to connect to the remote computer USB port when the Remote Link II is

used at the remote c omputer loc ation. If an

on-site computer at the job location is required, it should be connected to the

CommLink II or IV at or near the location

where the Remote Link II is located, f or ease of connection. If you need to use a longer serial or USB cable, you

will need to purchase these from an elec tronics supply store. Do not use any USB or serial cables longer than 25

ft.

Technical Data

Power 9 VDC

Plug-in Transformer 120 VAC to 9 VDC

Power Consumption 500mA Maximum Phone Connection RJ-11 Female

Operating Temperature

Operating Humidity 90% RH Non-

CommLink Connection 6 ft. - Serial Cable Error Correction V.42/MNP 2-4

3 Year Warranty

Form: WMS-OE419-06-RemoteLnkII-01A.doc Page 1 of 1

OE419-06 Remote Link II

(Included)

10°F to 140°F

Condensing

Computer Connection

For Remote Modem Use

Line Speed 14,400 bps

Data Compression V.42bis/MNP 5

WattMaster reserves the right to change specifications without notice

6 ft. USB Cable For Use With

USB Version 1.1 or 2.0 Ports

Page 20

VAV System

9VDC

10BaseT

OE415 IP-Link Kit

Description

The OE415 IP-Link Kit is used to provide

TCP/IP Internet and/or intranet connection for Ethernet networked computer

systems allowing them to communicate

with the WattMaster VAV System through

V

R

T

K

C

C

E

N

R

A

S

L

the Commlink. The OE415 IP-Link Kit

Includes the IP-Link device with serial

cable, 110/9 Volt power supply, iLan

EPROM for the CommLink, WattMaster

Prism software CD and documentation,

Connect One firmware and documentation CD, and the IP-Link Technical Guide

Computer Front End

Software & Manual

and installation instructions.

The TCP/IP connection provided on the

IP-Link is a TCP connection on a single

port number and is static in nature.

Firewall and proxy servers can easily be

configured to allow traffic to and from the

IP-Link. The nature of the data is raw in

form and comprised of packets native to

WattMaster Prism software. The IP-Link

device will respond to ICMP traffic (PING)

for verification of proper configuration.

Prism software is required in order to

read and send data to the IP-Link and

through the CommLink to the WattMaster

VAV system. The CommLink must have

the included iLan EPROM chip installed to

communicate with the WattMaster VAV

system. The IP-Link connects to the CommLink via the supplied RS232 DB9 Serial Cable. The IP-Link connects

to the host Ethernet system by means of a 10BaseT, RJ-45 jack on the back of the IP-Link. Power is provided to

the IP-Link by the 110/9 Volt Power supply furnished in the kit. The kit also contains a firmware CD used for setting up the IP-Link. Setup of the IP-Link requires a knowledgeable IT person familiar with configuring network

adapters and TCP/IP systems. WattMaster Prism software is included for installation to the local intranet or remote Internet PC(s) that will be used to program and monitor the WattMaster VAV system.

onnect

C

Documentation

C

ne

PWR

Firmware &

onnect

www.connectone.com

ne

3.25”

onnect

”

0

5

T

.

C

A

1

C

V

R

K

C

E

N

R

S

L

ne

PWR

5.25”

Serial

Mode

Technical Data OE415 IP-Link Kit

Power Supply 9 Volt VDC, 350mA System Connection RS-232 DB9 Female Serial Port

Power Consumption 2 Watts Network Connection 10BaseT Ethernet – RJ-45 MDI Socket

Operating Temp

32°F to 158°F

Operating Humidity 90% RH Non-Condensing Standard Compliance Ethernet IEEE 802.3 10BaseT

Data Rate Up to 230 Kbps Flow Control Hardware (DTR, RTS, CTS, DCD) and

1 Year Warranty WattMaster reserves the right to change specifications without notice

Form: WMS-OE415-IP-Link Ki-1A.doc Page 1 of 1

Internet Protocols ARP,IP,ICMP,UDP,TCP,DNS,DHCP,

SMTP, POP3, MIME, HTTP

Software

Page 21

4

”

VAV System

OE415-02 IP Module Kit

Description

The OE415-02 IP Module Kit (when installed and

configured in the Comm Link IV communication interface) provides TCP/IP Internet and/or intranet

1.28”

connection for Ethernet networked computer systems allowing them to comm unicate with your control system. The OE415-02 IP Module Kit consists

of the IP Module and a 10 ft. long CAT5 Ethernet

crossover cable.

1.3

The IP Module plugs into a mating 40 pin (2 x 20)

connector located on the CommLink IV circuit

board. Installation is easily accomplished by re-

IP Module

moving the CommLink IV case cover screws, removing the case cover to acc ess the circuit board,

and then plugging the IP Module into its mating

socket connector. Corr ect alignment is made easy

because of the (4) slot alignment tabs located

around the perimeter of the processor base. It is

not possible to incorrectly align the IP Module to

the socket connector because of this feature.

The TCP/IP connection provided by the IP Module

installed in the CommLink IV is a TCP connection

on a single port number and is static in nature.

Firewall and proxy servers can easily be configured

to allow traffic to and fr om the Comm Link IV when

the IP Module is installed. The nature of the data is

raw in form and comprised of packets native to

Prism software. The IP Module will respond to

ICMP traffic (PING) for verification of proper con-

CAT5 Ethernet Cable

figuration. Prism software is required in order to

read and send data to the IP Module and through

the CommLink IV to the control system. The IP

Module connects to the host Ethernet system by

means of the supplied 10 ft. long CAT 5 Ethernet

crossover cable which plugs into the 10/100 BaseT, RJ-45 jack on the back of the Comm Link IV and into a Ethernet router or Ether net modem on your building’s

LAN. Setup of the Comm Link IV with the IP Module requires a k nowledgeable IT person fam iliar with configuring

network adapters and TCP/IP system s. Prism software must be installed on the local LAN c omputer(s) and/or

remote Internet computers that will be used to program and monitor the control system.

Technical Data

Operating Temperature

Operating Humidity 90% RH Non-Condensing Network Connection 10/100 Base-T Ethernet

Protocols Supported ARP, UDP, TCP, Telnet,

Network Interface IEEE 802.3 RJ45 Ethernet

3 Year Warranty

Form: WMS-OE415-02-IPModuleKit-01A.doc Page 1 of 1

OE415-02 IP Module Kit

10°F to 140°F

ICMP, SNMP, DHCP, BOOTP,

Auto IP, HTTP, SMTP, TFTP

10BASE-T Or 100BASE-TX

(Auto-sensing)

Media Access Control CSMA/CD with ACK

RJ-45 MDI Socket

Flow Control XON/XOFF (Software), CTS/RTS

(Hardware), None

Management Internal Web Server, SNMP (Read

Only), Serial Login, Telnet Login,

Device Installer Software

WattMaster reserves the right to change specifications without notice

Page 22

OE310-21-LP

g

r

VAV System

Description

The OE310-21-LP Lighting Controller

allows an Orion Control System to also

control the building lighting systems

along with the HVAC system. The

Lighting Controller is provided with 7

schedules, each providing 2 start/stop

events per day and 14 start/ stop holiday events. Lighting Controller schedules are designed to operate from a

starting time, a contact closure or a percentage light level as sensed by a (0-

1.5kohm, 0-100%) light level sensor,

thus providing maximum lighting control

flexibility. As an example, a lighting

schedule could be programmed to allow

the lighting circuit to come on at dusk,

based on a light sensor and then turned

off at a given time during the night

based on a time schedule. With the

Lighting Controller, lighting schedules

may be overridden to “on” with a user

provided pushbutton. This pushbutton is

wired to the analog input that corresponds to the schedule number, on the

Lighting Controller. Schedule override

time periods are programmed from the

Orion Prism program. Lighting Controller output relays may be configured for

continuous ON mode during the occupied schedule or a short pulse when the

schedule starts and another short pulse

when the schedule ends. Pulsed output requires an optional Expansion Relay Board and a GE

equivalent lighting relay. The Lighting Controller may be connected to any local loop at any point on the Orion

system. Orion Prism computer front end software is used to interface with the Lighting Panel Controller functions.

The Lighting Controller cannot be programmed through the System Manager operator interface.

9.00

7.63

7.13

CPU

RAM

Li

hting Controlle

GND

+5V

SIG

ANALOG

INPUTS

+V

+V

1

2

3

4

5

6

7

8

G

G

ANALOG

OUTPUTS

EPROM

PIN 1PIN 1

PAL

A1

A2

G

PIN 1PIN 1

8.25

™

RR-7 or RR-9 or

1.00

Mounting

The Lighting Controller is provided with an integral backplate for mounting inside of a control enclosure. It is recommended that Lighting Controller be mounted in the in a control enclosure in the building equipment room. An

optional factory control enclosure for the Lighting Controller is available.

Technical Data OE310-21-GPC

GPC-17 Controller

Power 24 Volt AC Weight 1.5 lb.

Power Consumption 10 VA Maximum Network Connection RS-485

Operating Temp

10°F to 149°F

Protocol HSI Open Protocol Token Passing

Operating Humidity 90% RH Non-Condensing Communications RS-485 - 9600 Baud

Inputs: Outputs:

Types Allowed Type Provided Continuous Contact Closure or

Connected to Analog Input

by Others)

be Programmed to Follow or

Total Inputs Available 1 Total Outputs Available 7

Three Year Warranty WattMaster reserves the right to change specifications without notice

Form: WMS-OE310-21-LightingController-01A.DOC Page 1 of 1

Pushbutton Override

#8 (N.O. Binary Contact

All Schedules May

Not Follow the Override

Start Pulse and Stop Pulse

for Each of the 7 Schedules

(N.O. Binary Contact)

Relay Power Rating 2 Amp @ 24 VAC

Page 23

VAV System

A

OE331-21-GPC Plus

GPC Plus Controller

Description

The OE331-21 General Purpose Controller Plus (GPC Plus) is used for controlling equipment or processes that cannot be controlled using HVAC controllers.

The Prism computer front end software is

used to interface with the GPC Plus controller functions. The GPC Plus Controller

provides the flexibility to control, schedule

and/or monitor equipment such as unit

heaters, exhaust fans, motorized louvers,

etc.. The GPC Plus has (6) configurable

inputs which will accept signals from

thermistor temperature sensors, 4-20mA

or 0-5VDC transmitters or dry contact

closures. An additional modular input is

provided for connection of an OE271

static pressure sensor. The GPC Plus

has (5) relay outputs for on/off control

and (2) analog outputs. With the addition

of the OE352 2 Slot Expansion Base

Board and (1) OE357 4 Relay Expansion

Board, (4) additional relay outputs are

available providing for a maximum of (9)

usable relay outputs. The GPC Plus also

has (5) separate 2 event per day schedules, each with its own optimal start functions built in. In addition the GPC Plus

provides lead/lag start capabilities.

.20 Dia.

Typ. of 4

7.3”

TB1

COMM

T

SHLD

R

LD6

COMM

LD7

PWR

LD8

LED1

LD9

LED2

R1

INPUTS

+VDC

AIN1

AIN2

AIN3

AIN4

AIN5

GND

GND

AOUT1

AOUT2

AIN7

GND

PJ1

TB3

PRESSURE

SENSOR

C21

RN1

1

CX5

1

RN3

+VREF

TEST POINT

U7

RV1

VREF ADJ

EXPANSION

6.2“

CX1

U1

U5

RS-485

COMM

HH

C1

P1

5.11V

EWDOG

R28

RN5

PU1

D6

PU2

D7

PU3

D8

PU4

D9

PU5

D11

PU7

C10

D14

C12

D15

C17

C20

R26

PJ2

U3

CX2

U2

EPROM

RAM

TUC-5R PLUS

(1 MEG)

YS101816 REV. 2

U6

C2

PHILIPS

C3

ADD

DDRESS

1

2

4

8

16

CX10

32

TOKEN

NETWORK

U10

SW1

C11

X2

0-5

0-1

VDC

VDC

JP1

U13

R15

U12

CX14

C14

R19

U14

CX13

U15

C15

R22

R24

R25

CX15

D17

PJ3

T'STAT

6.7”

D1

CX3

CX4

U4

RLY1

RLY2RLY3RLY4RLY5

PAL

1

RN2

CX6

X1

1

RN4

U9

C7

R7

D10

CX12

D12

R13

SC1

D19

D18

C19

C18

VR1

VR2

V1

D2D3D4D5

V2

V3

COM1-3

R1

R2

R3

R4

R5

COM4-5

TB2

V4

V5

U8

NE5090NPB3192

0PS

CX8

R6

L1

C9

R10

D13

9936

R11

U11

MC34064A

C13

C16

TB4

GND

R27

D16

V6

POWER

7824CT

24VAC

M

6.6”

1.1”

Mounting

The GPC Plus is provided with an integral backplate for mounting inside of a control enclosure. It is recommended that the GPC Plus be mounted in the HVAC unit control enclosure, or in a control enclosure in the

building equipment room. An optional factory control enclosure for the GPC Plus is available.

Technical Data OE331-21-GPCPLUS

GPC Plus Controller

Power 24 Volt AC Weight 1.5 lb.

Power Consumption 8 VA Maximum Network Connection RS-485

Operating Temp

10°F to 149°F

Operating Humidity 90% RH Non-Condensing Communications RS-485 - 9600 Baud

Inputs: Outputs:

Types of Allowed

Inputs

Total Inputs Available 7 Analog Output Qty. 2

Static Pressure Inputs 1 (Modular ) Analog Output Signal 0-10 VDC

Configurable Inputs 6 Optimal Start Schedules (5) Total - (1) for Each Schedule

Schedules Available (5) 2 Event per day Lead Lag Scheduling (1) Output can be Configured

Three Year Warranty WattMaster reserves the right to change specifications without notice

Type III-10kohm sensors Total Relay Qty. On Board 5

4-20ma sensors

N.O. Binary Contact

N.C. Binary Contact Relay Power Rating (2 Amp @ 24 VAC)

Protocol HSI Open Protocol Token Passing

Total Relay Qty. Available With

Optional Expansion Board

9

Form: WMS-OE331-21-GPCPlusController-01A.doc Page 1 of 1

Page 24

OE310-21-GPC

r

VAV System

GPC-17 Controlle

Description

The GPC-17 Controller is used for controlling equipment or processes that cannot be controlled using standard HVAC

Unit controllers. The WattMaster Prism

computer front end software is used to

interface with the GPC-17 controller functions. The GPC-17 is designed with 6 universal inputs, 7 binary outputs and 2

analog output. Each input can be configured for use with a Type III-10k ohm

thermistor temperature sensor, 4-20ma

sensor, 0-5 VDC sensor or a N.O. or N.C.

9.00

binary contact closure. Sensor reading

values can be selected for the specific

input type, such as, %RH, Deg. F, RPM,

etc.. If a thermistor type temperature sensor is used, a calibration option is available to offset the actual temperature in

relation to the displayed reading. It also

has one input configures for Duct Static

Pressure and one configured for Building

Pressure. The 7 binary outputs may be

configured to operate based on any of the

8 sensor inputs, outdoor air temperature,

the GPC-17 controller’s internal schedule

or an external schedule. They can also be

configured to use AND/OR logic statements. A Relay Expansion Board can be

connected to the GPC-17 to give it an

extra 8 relay outputs. In addition to the

relay outputs the GPC-17 contains two 010VDC analog outputs which can be configured for simple floating point or PID control. The analog output can

also be configured to operate based on any of the 8 sensor inputs, outdoor air temperature, the GPC-17 controller’s internal schedule or an external schedule. In addition an Analog Output Expansion Board can be connected

to the GPC-17, giving it two additional analog outputs.

7.63

7.13

RAM

CPU

EPROM

PIN 1PIN 1

PAL

GND

+5V

SIG

ANALOG

INPUTS

+V

+V

1

2

3

4

5

6

7

8

G

G

ANALOG

OUTPUTS

A1

A2

G

PIN 1PIN 1

8.25

1.00

Mounting

The GPC-17 is provided with an integral backplate for mounting inside of a control enclosure. It is recommended

that the GPC-17 be mounted in the HVAC unit control enclosure, or in a control enclosure in the building equipment room. An optional factory control enclosure for the GPC-17 is available.

Technical Data OE310-21-GPC

GPC-17 Controller

Power 24 Volt AC Weight 1.5 lb.

Power Consumption 10 VA Maximum Network Connection RS-485

Operating Temp

10°F to 149°F

Protocol HSI Open Protocol Token Passing

Operating Humidity 90% RH Non-Condensing Communications RS-485 - 9600 Baud

Inputs: Outputs:

Types Allowed Type III-10kohm sensors Relay Qty. 7

4-20ma sensors Relay Power Rating (2 Amp @ 24 VAC)

N.O. Binary Contact Analog Output Qty. 2

N.C. Binary Contact Analog Output Signal 0-10 VDC

Total Inputs Available 8

Three Year Warranty WattMaster reserves the right to change specifications without notice

Form: WMS-OE310-21-GPC-17Controller-01A.doc Page 1 of 1

Page 25

A

VAV System

Description

The OE331-21-KWH (Kilowatt Hour)

OE331-21-KWH

KWH Module

Module provides the ability to record and

display KW usage and to limit demand.

Using the Prism Graphical Computer

Front End, a status screen displays current demand, yesterday’s demand, and

the peak demand values and times for

both. Historical logs from the previous

month and the current month are also

available and can be downloaded for

archiving via the PRISM software interface. A running total of power consumption is also displayed on the Status

Screen. This value can be manually reset at any time allowing the user to monitor overall power consumption over long

periods of time.

Analog Input #2 on the KWH Module

monitors all incoming contact closures

from a KW pulse meter (usually provided

by the utility company) and times them to

generate the current KW Demand. A

user adjustable setpoint is provided to

.20 Dia.

Typ. of 4

7.3”

TB1

COMM

T

SHLD

R

LD6

COMM

LD7

PWR

LD8

LED1

LD9

LED2

R1

U7

INPUTS

+VDC

AIN1

AIN2

AIN3

AIN4

AIN5

GND

GND

AOUT1

AOUT2

AIN7

GND

PJ1

TB3

PRESSURE

SENSOR

C21

RN1

1

CX5

1

RN3

+VREF

TEST POINT

RV1

VREF ADJ

C10

EXPANSION

6.2“

CX1

U1

U5

RS-485

COMM

HH

C1

P1

5.11V

EWDOG

R28

RN5

PU1

D6

PU2

D7

PU3

D8

PU4

D9

PU5

D11

PU7

D14

C12

D15

C17

C20

R26

PJ2

U3

CX2

U2

EPROM

RAM

TUC-5R PLUS

(1 MEG)

YS101816 REV. 2

U6

C2

PHILIPS

C3

ADD

DDRESS

1

2

4

8

16

CX10

32

TOKEN

NETWORK

U10

SW1

C11

X2

0-5

0-1

VDC

VDC

JP1

U13

R15

U12

CX14

C14

R19

U14

CX13

U15

C15

R22

R24

R25

CX15

D17

PJ3

T'STAT

6.7”

D1

CX3

CX4

U4

RLY1

RLY2RLY3RLY4RLY5

PAL

1

RN2

CX6

X1

1

RN4

U9

C7

R7

D10

L1

CX12

D12

R13

SC1

D19

D18

C19

C18

VR1

VR2

V1

D2D3D4D5

V2

V3

COM1-3

R1

R2

R3

R4

R5

COM4-5

TB2

V4

V5

U8

NE5090NPB3192

0PS

CX8

R6

C9

R10

D13

9936

R11

U11

MC34064A

C13

C16

TB4

GND

R27

D16

V6

POWER

7824CT

24VAC

M

6.6”

1.1”

define what each pulse represents in

Kilowatts Per Hour. A Demand Factoring

Constant is also provided if it appears that contact bounce may be affecting the operation. The Demand Factor is

simply the number of times to average the current demand reading to create the final Demand Reading. It is normally left at a value of '1' unless a problem is encountered.

Two additional setpoints are provided for the EMS Demand Limiting Broadcast. A Limit Setpoint and a Proportional Reset Range are provided so that the user can adjust when to begin shedding demand and how rapidly

this occurs. Any controllers equipped to "hear" this broadcast begin spreading their heating and cooling setpoints

proportionally until the maximum EMS Adjustment limit is reached. This value is also user adjustable for each

individual controller so that the rate at which demand is shed can be optimally configured for special cases where

not all zones can tolerate a large change in temperature.

Mounting

The KWH Module is provided with an integral backplate for mounting inside of a control enclosure. It is recommended that the KWH Module be mounted in the HVAC unit control enclosure, or in a control enclosure in the

building equipment room. An optional factory control enclosure for the KWH Module is available.

Technical Data OE331-21-KWH

KWH Module

Power 24 Volt AC Weight 1.5 lb.

Power Consumption 8 VA Maximum Network Connection RS-485

Operating Temp

10°F to 149°F

Protocol HSI Open Protocol Token Passing

Operating Humidity 90% RH Non-Condensing Communications RS-485 - 9600 Baud

Input Available Output Available

AIN2 Dry Contact Closure from

KW Pulse Meter (By Others)

Three Year Warranty WattMaster reserves the right to change specifications without notice

Form: WMS-OE331-21-KWH-Module-01A.doc Page 1 of 1

RS-485 Communications Loop EMS Demand Limiting

Broadcast

Page 26

VAV System

Description

The OE510-XX-VAV Pressure Dependent Round Damper consists of a round

air damper, MG320-VAV controller, and

OE282 damper actuator. An optional

auxiliary relay board (OE321) is available for control of auxiliary heat and/or

1/2" Foil Faced

Insulation

OE510-XX-VAV – Pressure

Dependent Round Damper

Round Damper

Blade Assembly

Zone Controller

control of series or parallel flow fan terminal units.

The MG320-VAV Zone Controller is

W

A

O

IR

L

F

F

L

R

I

O

A

W

microprocessor based and communicates with the HVAC Unit Controller on

the WMVAV communications loop. The

VAV Controller monitors the space temperature and allocates the proper air-

Actuator

flow into its assigned space to achieve

the desired comfort and ventilation levels.

Control Enclosure

(Cover Removed)

Pressure Dependent Round Dampers

are used in air conditioning systems

that do not require pressure independent airflow control. If your system requires pressure independent control of

the airflow, see the “OE511 - Pressure Independent Round Damper” data sheet for the correct specifications.

All Round Dampers are tested and certified in accordance with ARI standard 880. An ARI label is affixed to all

units.

Mounting

The Round Damper assembly should be mounted according to standard duct installation practices with airflow

direction as shown in the illustration above. After installation of the Round Damper in the ductwork, insulation

should be applied around any remaining uninsulated surface on the air valve inlet and outlet. The Round Damper

should be mounted so the control enclosure is positioned to the left or right side of the ductwork with the control

enclosure in a vertical plane. Do not mount the Round Damper Assembly with the control enclosure on the top or

bottom of the ductwork. Adequate clearance should be maintained between the control panel and any obstruction to allow for removal of the control panel cover and access to the controls.

Technical Data

OE510-XX-VAV Pressure Dependent

VAV Controller: Air Damper Construction:

Supply Power 24 Volt AC Damper Body 24 Ga. Galv. Steel

Power Consumption 12 VA Maximum Damper Blade Round -18 Ga. Galv. Steel

Operating Temperature

35°F to 125°F

Damper Bearings Oil Impregnated Bronze

Operating Humidity 90% RH Non-Condensing Damper Seal

Communications RS-485 - 9600 Baud Leakage Less Than 1% @ 3” SP

Insulation ½” Foil Faced Fiberglass

Inputs: Dimensions:

Room Temperature Sensor

Setpoint Adjustment OE520-06 (6”) 19.00 5.88 9.38

Actuator Position Feedback OE520-08 (8”) 19.00 7.88 11.38

Outputs:

Expansion Port for Auxiliary Relay Board OE520-14 (14”) 22.00 13.88 17.38

Actuator Port for Connection to Damper Actuator OE520-16 (16”) 22.00 15.88 19.38

WattMaster reserves the right to change specifications without notice

Three Year Warranty On Electronic Components One Year Warranty On Air Damper

Air Damper Model “A” “B” “C”

OE520-10 (10”) 19.00 9.88 13.38

OE520-12 (12”) 22.00 11.88 15.38

Round Damper

Volara® Type A Gasket

Form: WM-OE510-RndDmpr-Sub-01A Page 1 of 2

Page 27

VAV System

OE510-XX-VAV – Pressure

Dependent Round Damper

Round Damper Sizing

Use a load program to determine the peak

load for each zone. These calculations will be

used to select Round Damper sizes.

The WMVAV System utilizes a typical low

pressure duct design. To reduce noise problems, duct pressures should not exceed 1”

W.C.

Primary trunk ducts used with WMVAV systems should not be “undersized”. This is especially true of “pressure dependent” systems. With larger trunk ducts, it is easier to

assure relatively constant pressure to each

Round Damper. Runs should be as short as

possible, and the trunk duct system kept as

symmetrical as possible to facilitate system

balancing. Wherever possible, run the trunk

ducts above corridors and locate the Round