Page 1

Winona, Minnesota USA

ISO 9001

F4T Controller

Installation and Troubleshooting

User’s Guide

TOTAL

CUSTOMER

SATISFACTION

3 Year Warranty

Registered Company

1241 Bundy Boulevard., Winona, Minnesota USA 55987

Phone: +1 (507) 454-5300, Fax: +1 (507) 452-4507

http://www.watlow.com/F4T

1720-6742 Rev. A Made in the U.S.A.

January 2019

Page 2

Safety Information

We use note, caution and warning symbols throughout this document to draw your attention to

important operational and safety information.

A “NOTE” marks a short message to alert you to an important detail.

A “CAUTION” safety alert appears with information that is important for protecting your

equipment and performance. Be especially careful to read and follow all cautions that

apply to your application.

A “WARNING” safety alert appears with information that is important for protecting you,

others and equipment from damage. Pay very close attention to all warnings that apply to

your application.

The safety alert symbol, (an exclamation point in a triangle ç) precedes a general

CAUTION or WARNING statement.

The electrical hazard symbol, (a lightning bolt in a triangleÓ) precedes an electric shock

hazard CAUTION or WARNING safety statement. Further explanations follow:

Symbol Explanation

CAUTION: Warning or Electrical Hazard that needs further explanation than label on unit can provide. Consult QSG for further infor-

ç

Ó

mation.

CAUTION

WARNING

Electrical

or

Shock Hazard

AVERTISSEMENT: mise en garde ou danger qui demande plus de

précisions que l’information sur l’étiquette de l’unité. Consultez le

manuel de l’utilisateur pour plus d’informations.

Unit can be powered with either alternating current (ac) voltage or

direct current (dc) voltage.

ESD Sensitive product, use proper grounding and handling techniques when installing or servicing product.

Do not throw in trash, use proper recycling techniques or consult

manufacturer for proper disposal.

Enclosure made of Polycarbonate material. Use proper recycling

techniques or consult manufacturer for proper disposal.

Unit is a Listed device per Underwriters Laboratories®. It has been

evaluated to United States and Canadian requirements for Process

Control Equipment. CSA 22.2#14, File 158031, UL 61010, File

E185611 QUYX, QUYX7. . See: www.ul.com

Unit is compliant with European Union directives. See Declaration

of Conformity for further details on Directives and Standards used

for Compliance.

Unit has been reviewed and approved by Factory Mutual as a

Temperature Limit Device per FM Class 3545 standard. See: www.

fmglobal.com

Page 3

Symbol Explanation

Unit has been reviewed and approved by CSA International for use

as Temperature Indicating-Regulating Equipment per CSA C22.2 No.

24. See: www.csagroup.org

This F4T User’s Guide is copyrighted by Watlow Electric Manufacturing Company, © May 2016

with all rights reserved.

• © 2010-2012, QNX Software Systems Limited. All rights reserved.

• © 2008 -2014, Crank Software Inc. All rights reserved.

• Watlow® and TRU-TUNE® are registered trademarks of Watlow Electric Manufacturing

Company.

• UL® is a registered trademark of Underwriter's Laboratories Incorporated.

• Modbus® is a registered trademark of Schneider Automation Incorporated.

• Vaisala® is a registered trademark of Vaisala OY Corporation.

• Microsoft® and Windows® are registered trademarks of the Microsoft Corporation.

Quencharc® is a registered trademark of ITW Paktron.

10-07433 Rev. –

Page 4

TC

Table of Contents

Chapter 1: Overview .....................................2

Available F4T Literature and Resources ......................... 2

Chapter 2: Install and Wire .................................4

Getting Started Quickly...The Logical Approach ...................4

Dimensions ............................................... 4

Installing the F4T .......................................... 5

Panel Mounting the Base .................................5

Flush Mounting the Base ................................. 6

Electrical Isolation .........................................8

Wiring the F4T Base ........................................8

Power Requirements .......................................9

Flex Module (FM) Characteristics .......................... 9

Flex Module Installation .....................................9

Wiring the Modules ....................................... 10

Communications Connections ............................ 24

Chapter 3: Connecting a PC ...............................25

Using the User Interface (UI) to Change or View Ethernet Settings ... 25

Understanding the Front Panel Navigational Buttons ..........25

Connecting the F4T Base to a PC .............................27

DHCP Connection ..................................... 27

Fixed IP Connection ....................................27

Composer Software ....................................... 28

Starting Composer Software .............................28

Verifying Pluggable Flex Module Installation Using Composer ...28

Chapter 4: Calibration ...................................30

Calibrating the F4T Inputs ..................................30

Required Equipment When Performing Calibration ............... 30

Calibration of Analog Inputs ................................. 31

Using Composer Software to Calibrate Analog Inputs ............. 32

Using the User Interface to Calibrate Analog Inputs ...............32

Chapter 5: Troubleshooting ................................33

Replacing the Battery ......................................39

Chapter 6: Appendix ....................................41

F4T Base Specifications ....................................41

F4T Base Ordering Information ...........................44

Flex Modules and Limit I/O Specifications ...................... 45

Flex Module - Mixed I/O Ordering Information ............... 48

Flex Module - Limit Ordering Information ................... 49

Flex Modules - High Density I/O Specifications ..................49

Flex Module - High Density Ordering Information ............. 53

Flex Module - Communications Ordering Information .........53

How to Reach Us .........................................56

Watlow F4T Install & Troubleshooting • 1 • Table of Contents

Page 5

1

Chapter 1: Overview

Available F4T Literature and Resources

Document Title and Part Number Description

This document looks deeper at the system

F4T Setup and Operation User Guide,

part number: 1680-2414 Rev. A

configuration using Composer™ software and

the F4T function blocks and their connections.

Common product usage is described and illustrated through application examples.

F4T Specification Sheet, part number:

WIN-F4T-1118

Watlow Application Guide

Watlow Support Tools DVD, part

number: 0601-0001-0000

To acquire one or more of these documents navigate to the Watlow website where you will

have a choice to download free copies or purchase printed versions. Click on the link

below to nd your document of choice: http://www.watlow.com/F4T. For the Application

Guide, click here: http://www.watlow.com/common/catalogs/les/appguide.pdf

Describes F4T hardware options, features,

benefits and technical specifications.

Comprehensive guide to understanding thermal

principles, electrical noise, best practises for

wiring industrial controls and much more.

Contains all related user documents, tutorial

videos, application notes and the application

guide described above.

Your Comments are Appreciated

In an effort to continually improve our technical literature and ensuring that we are

providing information that is useful to you, we would very much appreciate your comments

and suggestions. Please send any comments you may have to the following e-mail address:

TechlitComments@watlow.com

Technical Assistance

If you encounter a problem with your Watlow controller, review your conguration

information to verify that your selections are consistent with your application: inputs,

outputs, alarms, limits, etc. If the problem persists, you should rst contact the Original

Equipment Manufacturer (OEM) for assistance. If that is not an option you can also get

assistance directly from Watlow:

• Contact a local representative: see last page

• Email: wintechsupport@watlow.com

• Call: 1-800-4WATLOW (1-800-492-8569) or +1 (507) 494-5656 from 7 a.m. to 5 p.m. Central

Standard Time (CST) (Select options for Controls & Software and Technical Support)

Please have the following information available when calling:

• Complete model number • User’s Guide • All conguration information

Watlow F4T Install & Troubleshooting • 2 • Chapter 1 Overview

Page 6

Warranty

This product is warranted by Watlow for a period of 36 months in accordance with the

terms and conditions set forth on Watlow's website which can be accessed at

www.watlow.com/terms.

Return Material Authorization (RMA)

1. Call Watlow Customer Service, (507) 454-5300, for a Return Material Authorization (RMA)

number before returning any item for repair. If you do not know why the product failed,

contact an Application Engineer or Product Manager. All RMA’s require:

• Ship-to address

• Bill-to address

• Contact name

• Phone number

• Method of return shipment

• Your P.O. number

• Detailed description of the problem

• Any special instructions

• Name and phone number of person returning the product.

2. Prior approval and an RMA number from the Customer Service Department is required

when returning any product. Make sure the RMA number is on the outside of the carton

and on all paperwork returned. Ship on a Freight Prepaid basis.

3. After we receive your return, we will examine it to verify the reason for the product

failure. Unless otherwise agreed to in writing, Watlow's standard warranty provisions,

which can be located at www.watlow.com/terms, will apply to any failed product.

4. In the event that the product is not subject to an applicable warranty, we will quote

repair costs to you and request a purchase order from you prior to proceeding with the

repair work.

5. Watlow reserves the right to charge for no trouble found (NTF) returns.

Document Overview and Purpose

The purpose of this document is to assist the installer in providing necessary information to

mount, wire and power up the F4T controller. This document also provides information to

assist in the process of diagnosing problems which might occur during or after the

installation process.

Watlow F4T Install & Troubleshooting • 3 • Chapter 1 Overview

Page 7

2

Chapter 2: Install and Wire

Getting Started Quickly...The Logical Approach

The steps below outline installation and wiring for the base alone. More detail for each is

provided in the following sections.

1. Using this document for orientation, nd the base part number and note any installed

options as well as input voltage requirements.

2. Mount/install the base in the panel (see instructions below for panel mount or ush

mount options).

3. Ensure that incoming power is off and connect to the base power supply connector (see

section "Wiring the F4T Base").

4. Make note of any I/O module slot dependencies installing each one into an appropriate

base slot (see graphic entitled F4T Slot Dependencies under "Flex Module Installation").

5. Connect the wires from each eld device to the associated I/O module connector (see

section "Wiring the Modules").

6. Insert all wired I/O connectors onto the applicable modules and apply power to the

base.

7. Connect the controller to a computer running Composer™ software using an Ethernet

cable (see section "Connecting the F4T Base to a PC").

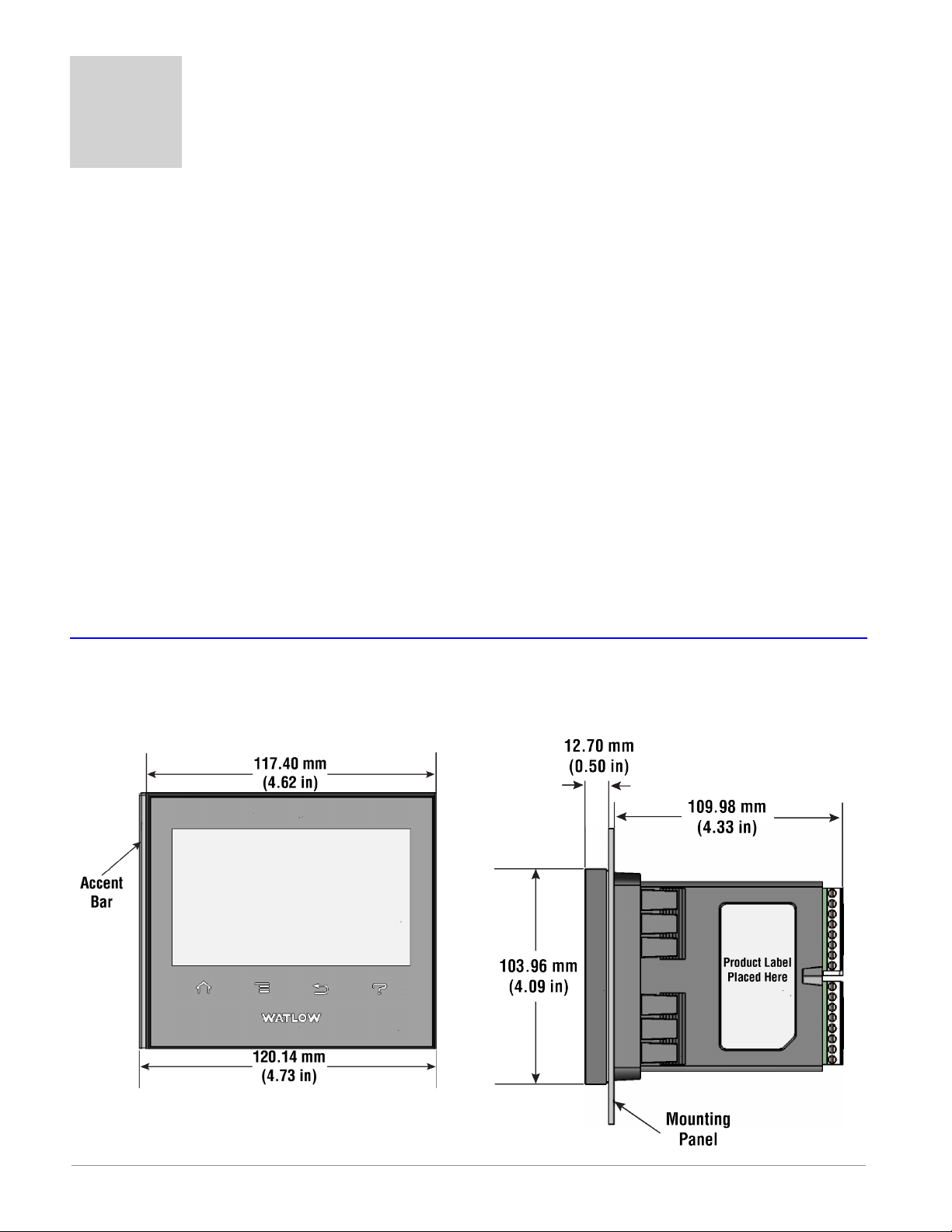

Dimensions

Panel Mount

Front View Side View

Watlow F4T Install & Troubleshooting • 4 • Chapter 2 Install and Wire

Page 8

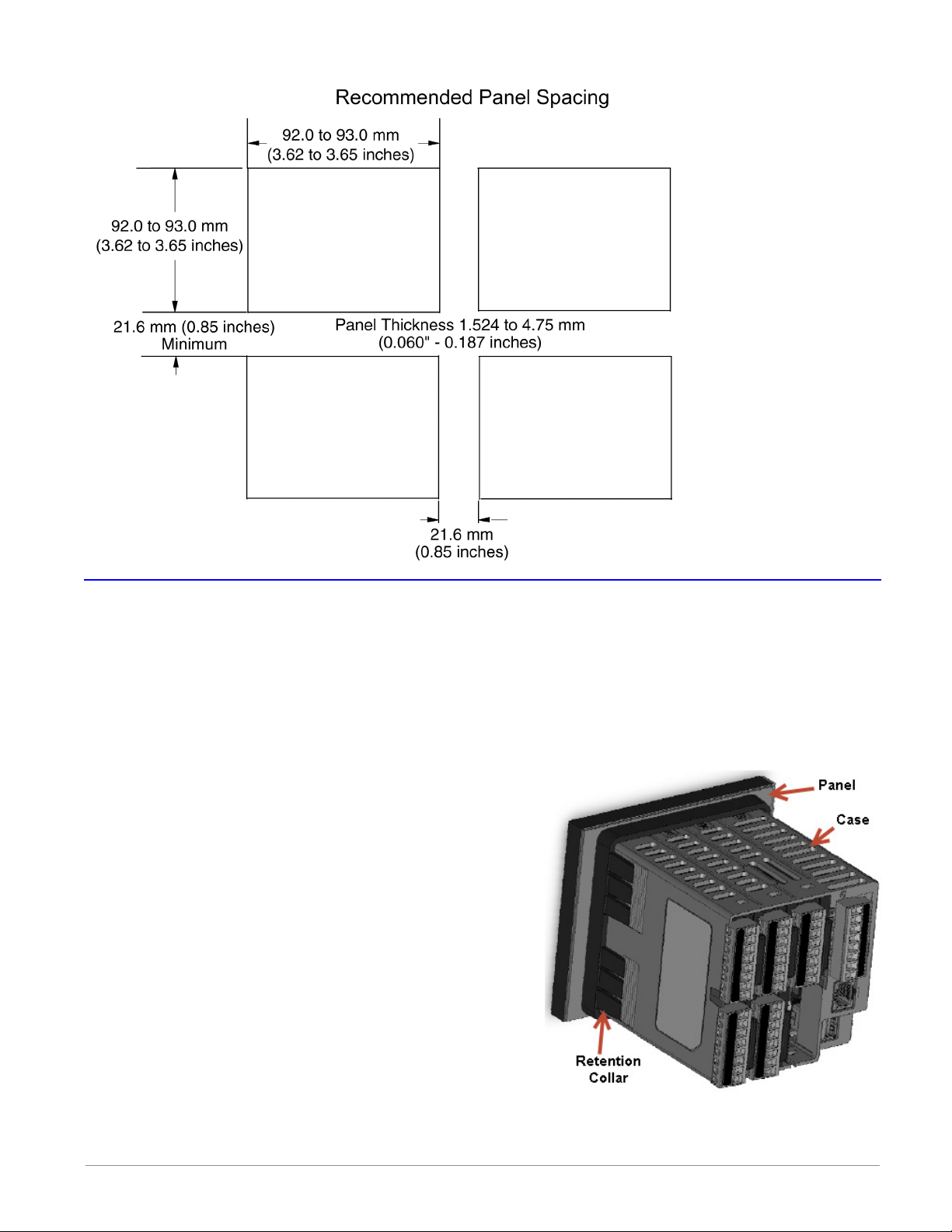

Dimensions (cont.)

Installing the F4T

Panel Mounting the Base

1. Make the panel cutout using the mounting template dimensions above and insert the

case assembly into the panel cutout.

2. While pressing the case assembly rmly against the panel, slide the Retention Collar

over the back of the controller until the gasket is compressed.

3. For an IP65 seal, alternately place and push

the blade of a screwdriver against each of the

the four corners of the retention collar assembly. Apply pressure to the face of the controller while pushing with the screwdriver. Don't

be afraid to apply enough pressure to properly

install the controller. The seal system is compressed more by mating the retention collar

tighter to the front panel. If you can move the

case assembly back and forth in the cutout, you

do not have a proper seal. The tabs on each side

of the retention collar have teeth that latch into

the ridges on the sides of the controller. Each

tooth is staggered at a different depth from the

front so that only one of the tabs, on each side,

is locked onto the ridges at a time.

Watlow F4T Install & Troubleshooting • 5 • Chapter 2 Install and Wire

Page 9

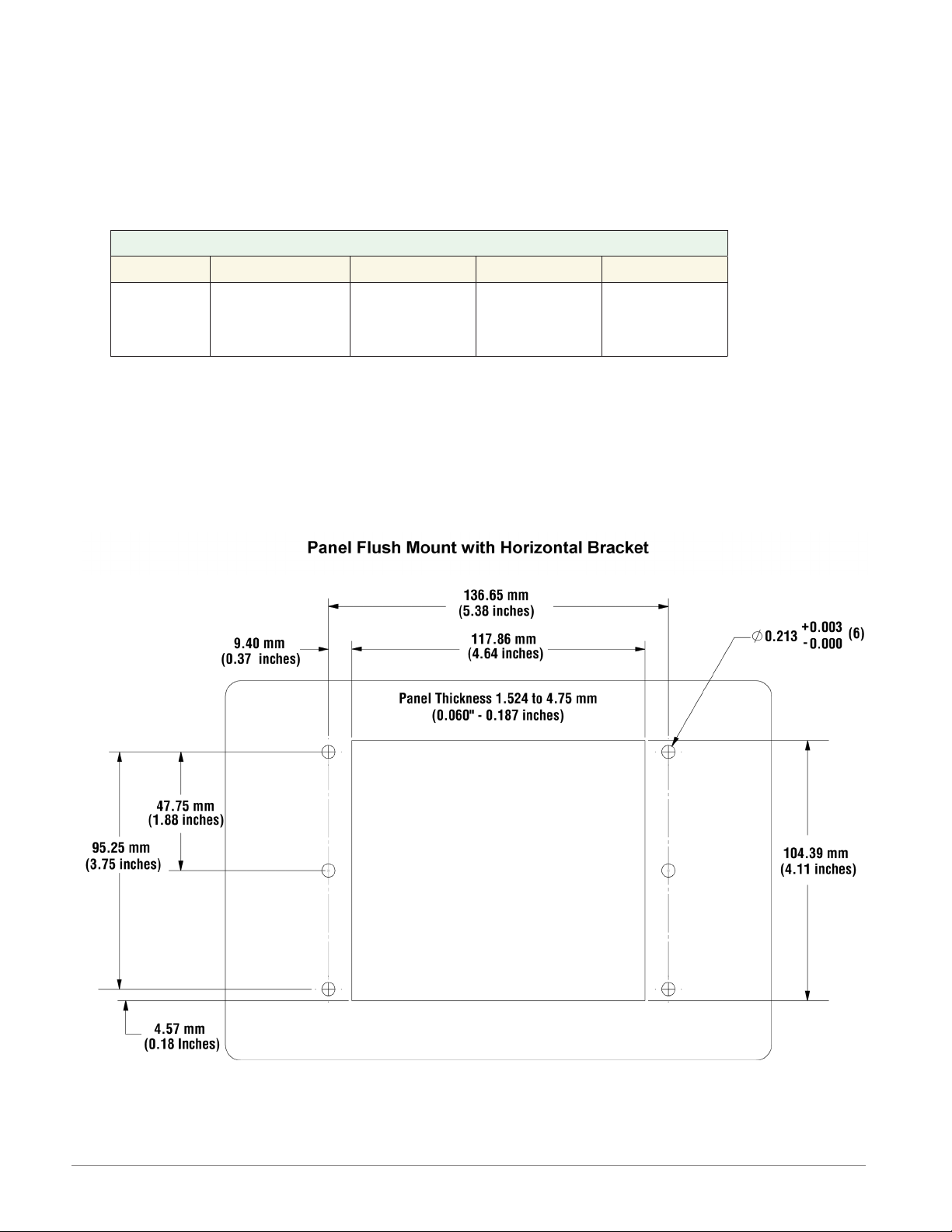

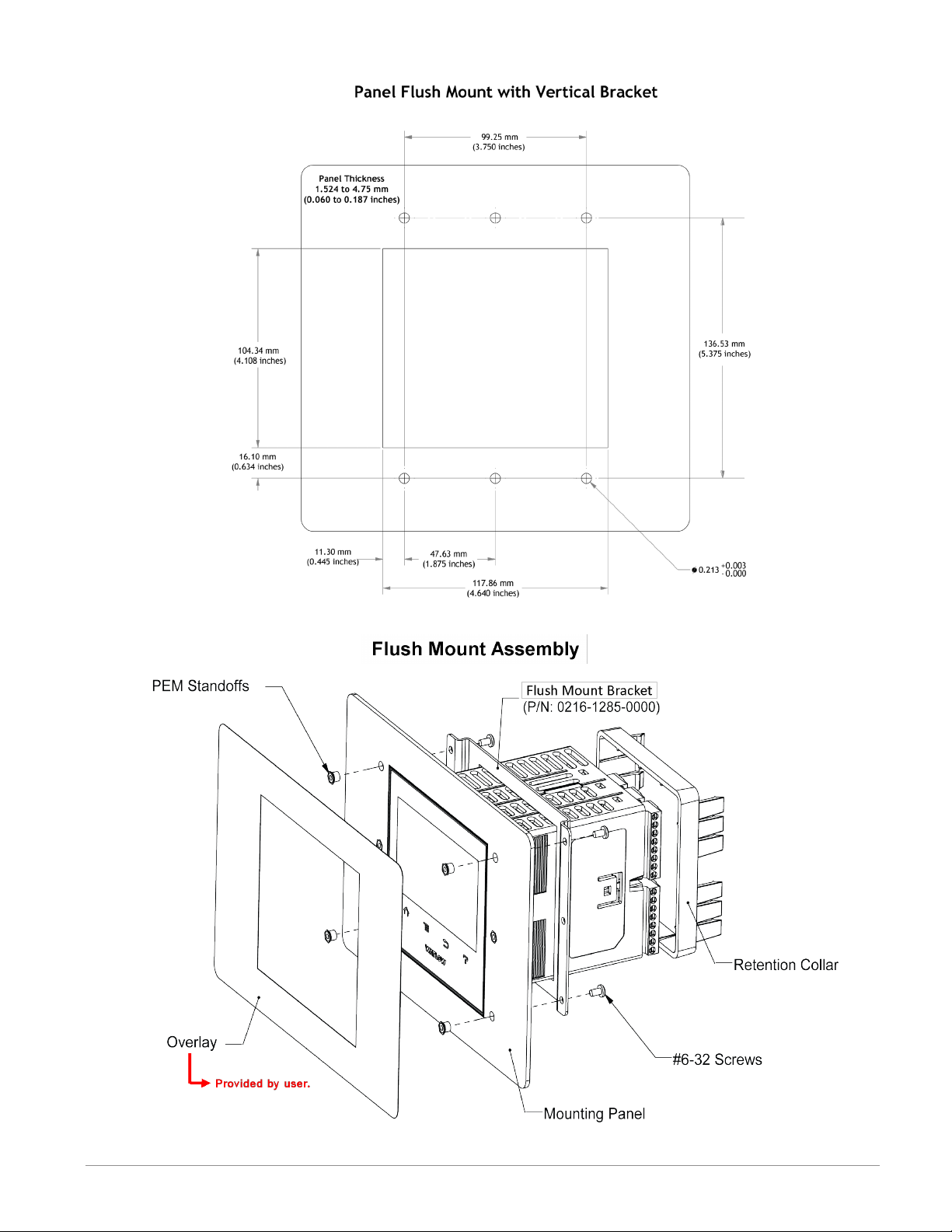

Dimensions (cont.)

Flush Mounting the Base

1. Fabricate the mounting panel per the ush mount vertical or horizontal panel template

(shown below).

2. Press PEM standoffs (based on panel material) into mounting panel per supplier recommendations.

PEM Standoffs

PEM P/N S0-632-6 Z1 S0S-632-6 S0A-632-6 S04-632-6

Material

Steel

(Zinc Plated)

3. Insert the controller through the ush mount bracket and lock it in place with the retention collar.

4. Mount ush mount bracket to back panel with (6) #6-32 screws.

5. Apply overlay to front panel.

Note:

Overlay is provided by the user.

Stainless

Aluminum

Steel

Hardened

Stainless

Steel

Watlow F4T Install & Troubleshooting • 6 • Chapter 2 Install and Wire

Page 10

Dimensions (cont.)

Watlow F4T Install & Troubleshooting • 7 • Chapter 2 Install and Wire

Page 11

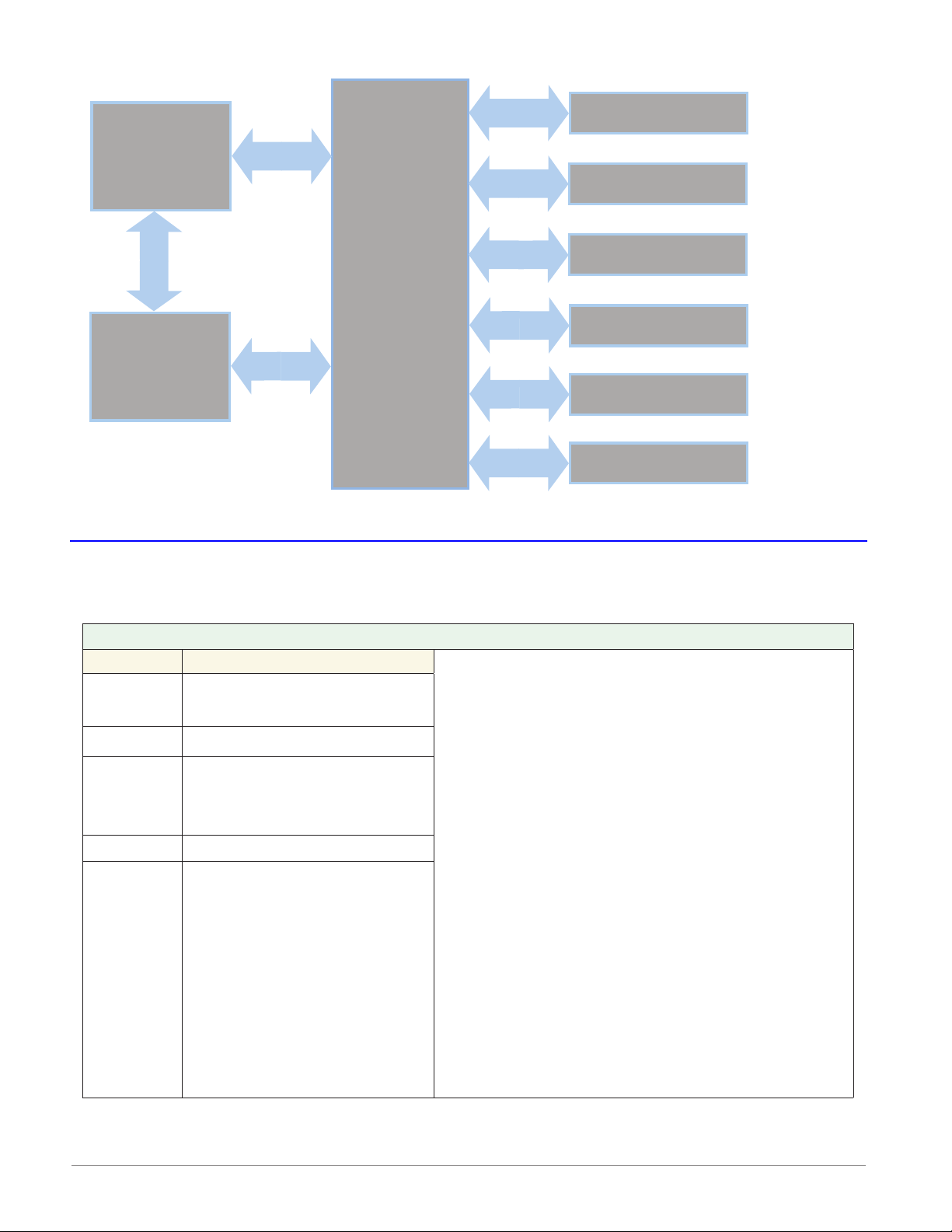

Electrical Isolation

Safety Isolation: 2300VÅ (ac)

Controller Power Supply

24 to 28V

24 to 28VÅ (ac)

100 to 240VÅ (ac)

Mechanical Relay,

Solid-State Relay,

NO-ARC Relay

Î (dc)

Safety Isolation

Outputs

Safety Isolation

Safety Isolation

Controller

Low Voltage Power Bus

Low-voltage Isolation: 42V peak

No Isolation

No Isolation

Low-voltage

Isolation

No Isolation

Low-voltage

Isolation

Low-voltage

Isolation

Digital Inputs & Outputs

Switched DC, Open Collector,

Process outputs

Analog Inputs

USB Host

USB Device

Ethernet Port

Wiring the F4T Base

Identify Connector Pinout

Terminal Function

98

99

- - - - - - - CX

CY

CZ

- - - - - - - -

GND Functional earth ground

Power input: ac or dc+

Power input: ac or dc-

Inter-module Bus A

Inter-module Bus B

Inter-module Bus Common

Power and Communications

Warning:

Óç

Use National Electric (NEC) or other country-

specic standard wiring and safety practices

when wiring and connecting this controller to

a power source and to electrical sensors or

peripheral devices. Failure to do so may result

in damage to equipment and property, and/or

injury or loss of life.

Avertissement :

Óç

Utilisez les pratiques de câblage et de sécurité de National Electric (NEC) ou les normes

spéciques au pays lors du câblage et de

la connexion de ce régulateur à une source

d'alimentation et aux capteurs électriques ou

aux équipements périphériques. Tout manquement à cette règle pourrait provoquer des

dégâts sur l'équipement et le matériel, et/ou

des blessures personnelles ou des décès.

Watlow F4T Install & Troubleshooting • 8 • Chapter 2 Install and Wire

Page 12

Wire Size and Torque for Screw Terminations

YYN

YY

NY

• 0.0507 to 3.30 mm2 (30 to 12 AWG) single-wire termination or two 1.31 mm2 (16 AWG)

• 0.57 Nm (5.0 lb.-in.) torque

Power Requirements

• 85 to 264VÅ (ac), (Models F4T _ _ [1, 2, 3, 4])

• 20.4 to 30.8VÅ (ac) or Î (dc), (Models F4T _ _ [5, 6, 7, 8])

• 50 to 60 Hz

• Power consumption 23W, 54VA

• Inter-module Bus (CX, CY, CZ)

• Do not route network wires with power wires. Connect

inter-module bus wires in daisy-chain fashion when connecting multiple devices in a network

• The power supply within the controller base meets all

power requirements for any and all inserted modules.

Flex Module (FM) Characteristics

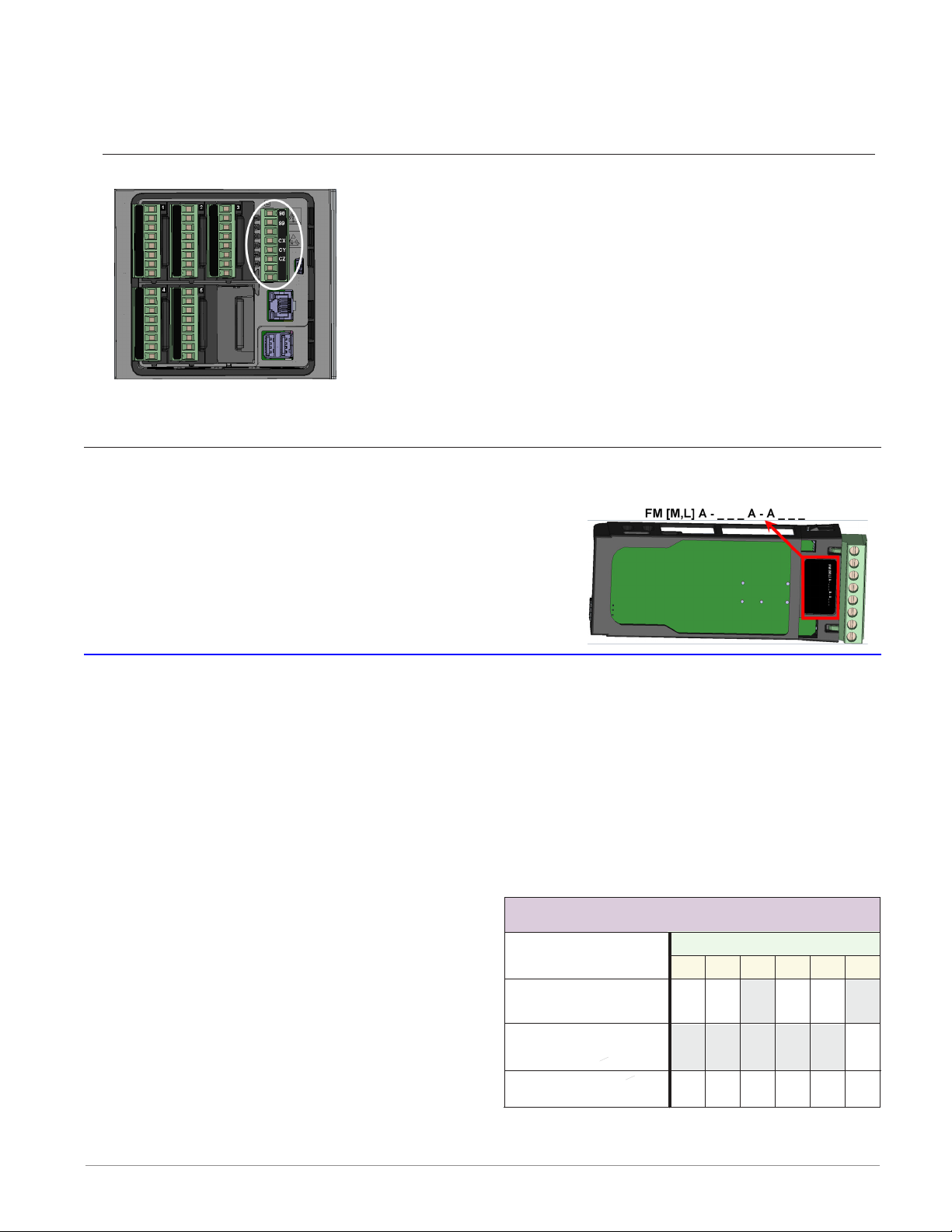

Many of the modules appear to look alike at rst glance, therefore, it is always recommend-

ed that the module part number be noted and veried

prior to plugging it into any of the available slots in a

base. Each module is identied with a part number located on the back side of the assembly right below the connector (black label), as seen in the graphic to the right.

Flex Module Installation - To view video go to www.watlow.com/F4T

Some Flex Modules require that they be installed in specic slots within the base. As an

example, if a communications card is to be installed, it must be placed in slot 6. Slot 6 can

receive and accept any card, however, it is the only slot that allows for a communication

card (see table to the right).

Slots are keyed such that modules cannot be inserted upside down. Insert modules with the

component side facing the right when viewing the controller from the rear.

Installing the modules:

1. Note the part number to determine the

types of inputs and outputs available to be

connected in step 7.

2. Turn off power to the controller.

3. Select a slot for the module (see table to

right). If replacing a module, remove the

old module.

4. Afx corresponding slot number labels

(provided) to the module and to the removable screw terminal block.

Watlow F4T Install & Troubleshooting • 9 • Chapter 2 Install and Wire

Flex Module - Slot Dependencies

Module Type

Dual SSR *

FMHA-K

Communications

FMCA-(2)

All Other Modules

Y = Allowed

* Reguires two adjacent slots

YN

NNNN

YYYY

N = Not allowed

Slot #

Y

456123

Page 13

5. With the component side of the module facing right (viewing the controller from the

rear) insert the module in to the slot until it latches.

6. Remove the screw terminal block from the module.

7. Wire eld devices to the appropriate terminals (see. Wiring details for each input and

output are provided in the following sections.

8. Reconnect the wired screw terminal block to the module. Be sure to reconnect the terminal block to the correct module.

9. Restore power to the controller.

Note:

If a module is swapped out and replaced with a different type or moved to another open

slot after configuration, the controller will no longer function properly without being reconfigured using Composer™ software.

Note:

To minimize the possibility of unwanted downtime due to a module being removed and

installed into the wrong slot, affix the slot number labels (as directed in step 4 above) to

each module (as shown in the graphic below, white circle) and each removable screw terminal block.

Wiring the Modules

Prior to wiring any of the I/O modules described in this document it is recommended that

the warnings and notes listed below be reviewed.

CAUTION:

To prevent damage to the controller, do not connect wires to unused terminals.

AVERTISSEMENT: Pour prévenir tout endommagement du régulateur, ne pas faire de raccor-

dements à des bornes inutilisées.

CAUTION

Switching pilot duty inductive loads (relay coils, solenoids, etc.) with the mechanical relay,

solid-state relay or open collector output options requires the use of an R.C. suppressor for

AC load or a diode for a DC load.

AVERTISSEMENT: les charges inductives de commutation de lampes témoins (bobines de re-

lais, solénoïdes, etc.) avec des options de sortie à relais mécanique, de relais statique ou collecteur ouvert requièrent un dispositif antiparasite R.C.

Watlow F4T Install & Troubleshooting • 10 • Chapter 2 Install and Wire

ç

ç

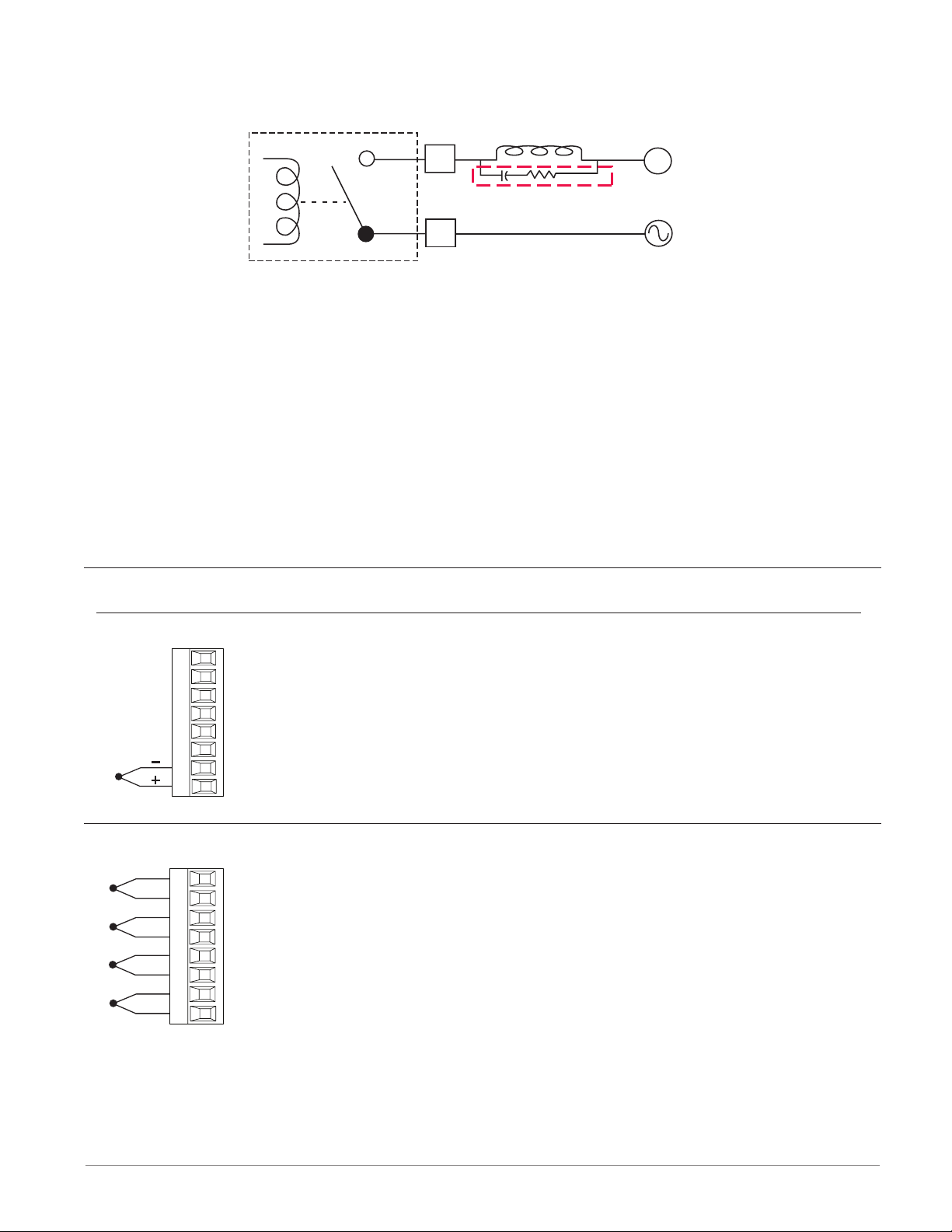

Quencharc Note:

Page 14

Place the Quencharc directly across the external coil as shown below. For a DC load, place

User Load

the cathode of the diode, to the positive voltage of the load and the anode to the ground of

the load.

_

L

Quencharc

Watlow Part #: 0804-0147-0000

_

K

N

Note:

It is possible that the terminal strip labeling for any given module could be the same. For

example, if a Thermocouple input module is installed in slot 1 and 2, each slot would have

S1 and R1 on its label. When referencing either of these inputs the differentiating factor is

the module slot number, therefore the reference should be input 1 of slot number x.

Note:

Maintain electrical isolation between the analog input, digital input-outputs, switched dc/

open collector outputs and process outputs to prevent ground loops.

Note:

The F4T meets IP10 requirements when the empty slots have slot caps installed.

Note:

Maximum wire size and torque for screw terminations:

• 0.0507 to 3.30 mm2 (30 to 12 AWG) single-wire termination or two 1.31 mm2 (16 AWG)

• 0.57 Nm (5.0 lb.-in.) torque

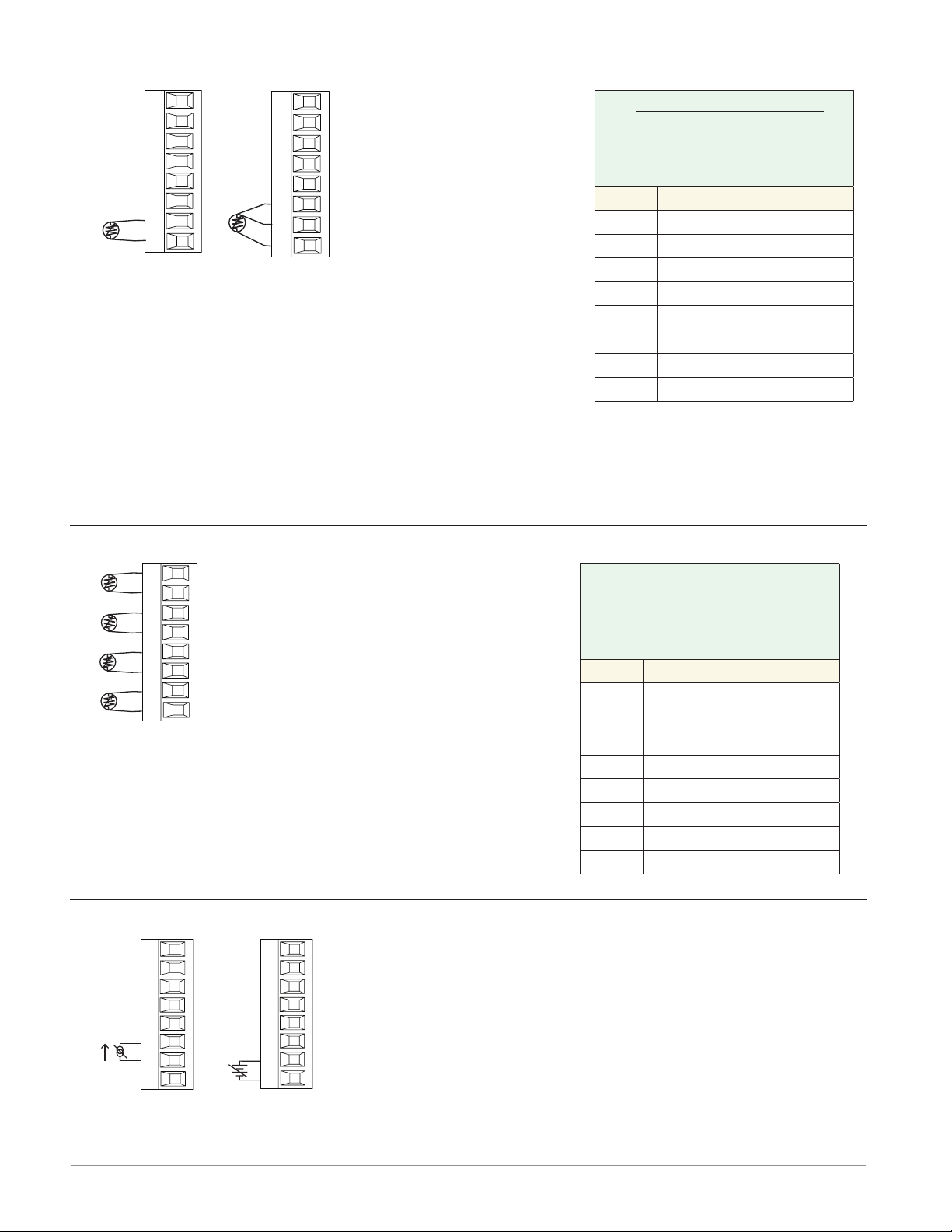

Input Connections

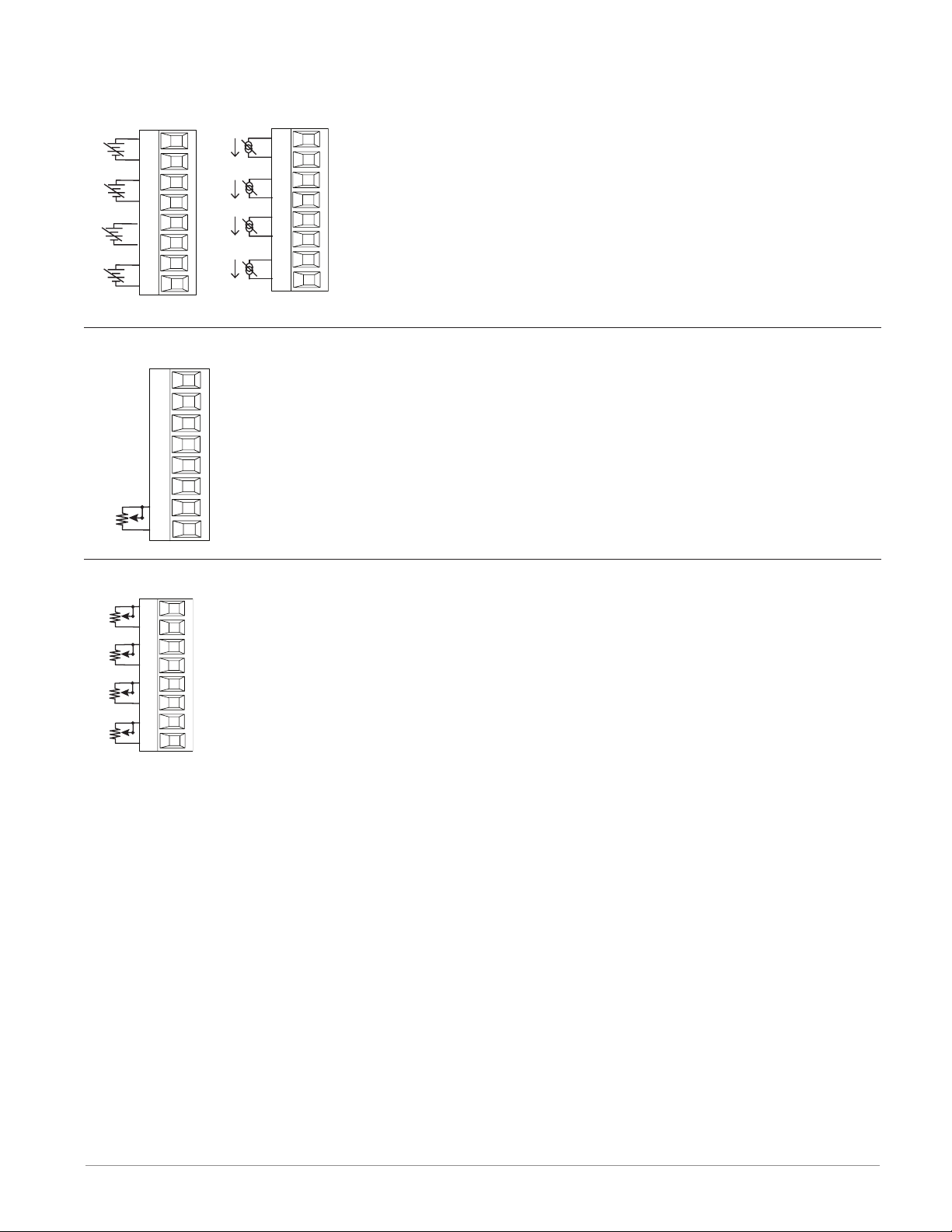

Thermocouple FM [M, L] A - [L, U, Y] _ _ A - A _ _ _

• Grounded or ungrounded sensors, greater than 20MΩ input impedance, 2kΩ source resistance max.

• 3 microampere open-sensor detection

• Thermocouples are polarity sensitive. The negative lead (usually red)

S1

R1

must be connected to S terminal

• To reduce errors, the extension wire for thermocouples must be of the

same alloy as the thermocouple.

Thermocouple (High Density) FMHA - RAAA - A _ _ _

-

S1

+

R1

-

S2

+

R2

-

S3

+

R3

-

S4

+

R4

• Grounded or ungrounded sensors, greater than 20MΩ input impedance, 2kΩ source resistance max

• 3 microampere open-sensor detection

• Thermocouples are polarity sensitive. The negative lead (usually

red) must be connected to S terminal

• To reduce errors, the extension wire for thermocouples must be of

the same alloy as the thermocouple

Watlow F4T Install & Troubleshooting • 11 • Chapter 2 Install and Wire

Page 15

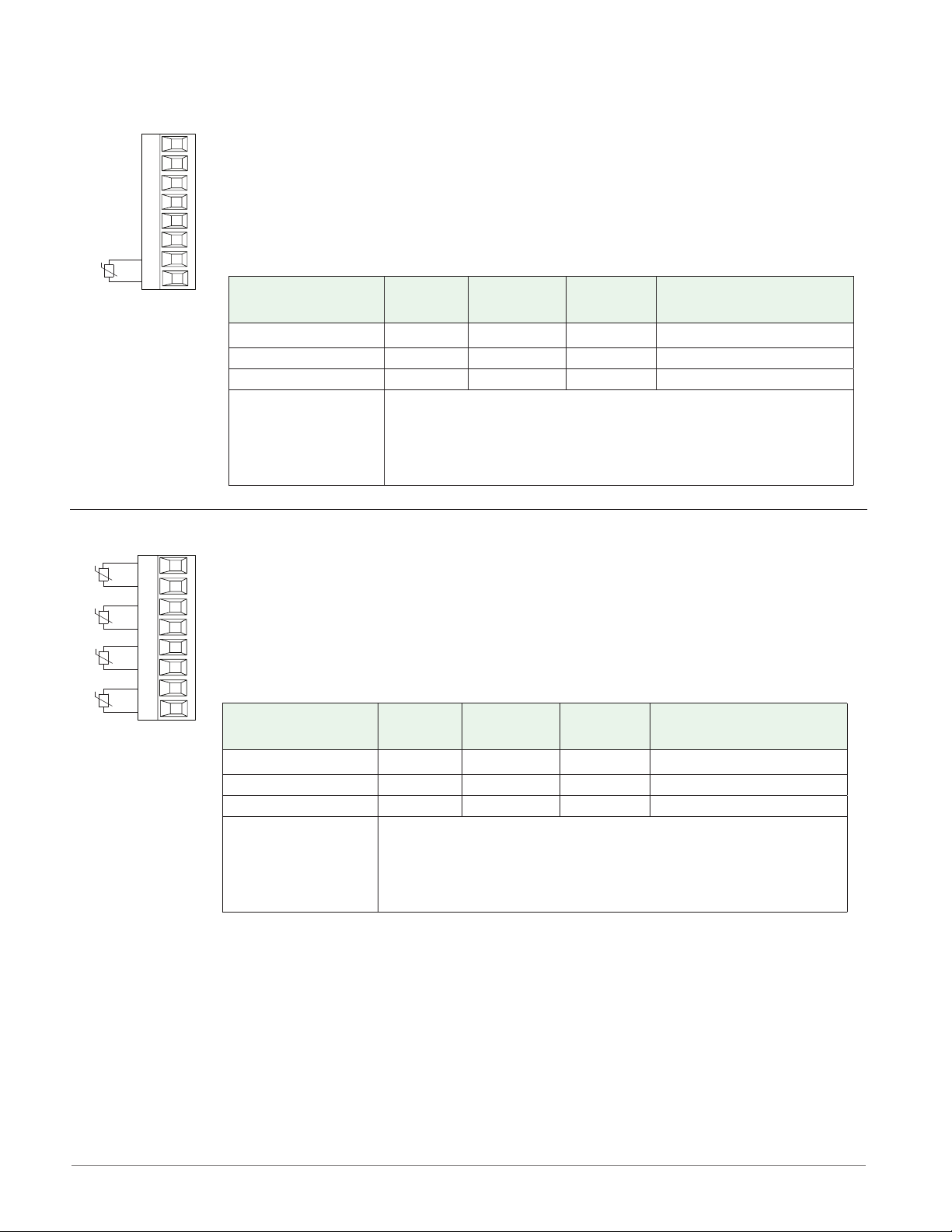

RTD FM [M, L] A - [L, U, Y*] _ _ A - A _ _ _

RTD

RTD

2-wire RTD

• 2 or 3-wire platinum, 100

and 1,000 Ω @ 32°F (0°C)

calibration to DIN curve

(0.00385 Ω/Ω/°C)

T1

S3

S1

R1

S1

2-wire

S2

T1

S3

S1

R1

S1

3-wire

• RTD excitation current

of 0.09 mA typical. Each

ohm of lead resistance

may affect the read-

ing by 2.55°C for a 100

ohm platinum sensor or

0.25°C for a 1000 ohm

sensor.

• For 3-wire RTDs, the S1

lead (usually white) must

be connected to R1.

* This option does not sup-

port 3-wire RTDs

RTD (High Density) FMHA - RAAA - A _ _ _

Lead Wire Resistance

Each wire for 2-Wire

RTDs, not to exceed 10

ohms maximum.

AWG Ohms/1000ft

14 2.575

16 4.094

18 6.510

20 10.35

22 16.46

24 26.17

26 41.62

28 66.17

Note:

3-wire RTD's self-compensate

for lead wire resistance up

to 10 Ω of wire resistance.

S1

R1

S2

R2

S3

R3

S4

R4

• Platinum, 100 and 1,000 Ω @ 32°F

(0°C) calibration to DIN curve

(0.00385 Ω/Ω/°C)

• RTD excitation current of 0.09 mA

typical. Each ohm of lead resistance

may affect the reading by 2.55°C for

a 100 ohm platinum sensor or 0.25°C

for a 1000 ohm sensor (see table to

right)

Process FM [M, L] A - [L, U] _ _ A - A _ _ _

• 0 to 20 mA @ 100 Ω input impedance

• 0 to 10VÎ (dc) @ 20 kΩ input impedance

• 0 to 50 mVÎ (dc) @ 20 MΩ input impedance

+

-

T1

S1

amperes

-

S1

+

R1

volts

• Scalable

Lead Wire Resistance

Each wire for 2-Wire

RTDs, not to exceed 10

ohms maximum.

AWG Ohms/1000ft

14 2.575

16 4.094

18 6.510

20 10.35

22 16.46

24 26.17

26 41.62

28 66.17

Watlow F4T Install & Troubleshooting • 12 • Chapter 2 Install and Wire

Page 16

Input Connections (cont.)

-

-

CW

Process (High Density) FMHA - RAAA - A _ _ _

Volts

S1

+

R1

-

S2

+

R2

-

S3

+

R3

-

S4

+

R4

Potentiometer FM [M, L] A - [L, U] _ _ A - A _ _ _

CW

S_

R_

CCW

Amps

S1

+

R1

-

S2

+

R2

-

S3

+

R3

-

S4

+

R4

• 0 to 20 mA @ 100 Ω input impedance

• 0 to 10VÎ (dc) @ 20 kΩ input impedance

• 0 to 50 mVÎ (dc) @ 20 MΩ input impedance

• Scalable

• Potentiometer: 0 to 1,200Ω

Potentiometer (High Density) FMHA - RAAA - A _ _ _

• Potentiometer: 0 to 1,200Ω

CCW

CW

CCW

CW

CCW

CW

CCW

S_

R_

S_

R_

S_

R_

S_

R_

Watlow F4T Install & Troubleshooting • 13 • Chapter 2 Install and Wire

Page 17

Input Connections (cont.)

Thermistor FM [M, L] A - [M, T] AAA - A _ _ _

• >20 MΩ input impedance

• 0 to 40kΩ, 0 to 20kΩ, 0 to 10kΩ, 0 to 5kΩ

• 2.252kΩ and 10kΩ base at 77°F (25°C)

• Drive current is 109 μA as a constant current source

• User-selectable curves for Alpha Technics, BetaTHERM and YSI

S1

R1

• User-scaling support for Steinhart-Hart coefcients

Thermistor

Curve Setting

Base R

@ 25 ºC

Alpha

Technics

Curve A 2.252K Curve A 2.2K3A 004

Curve B 10K Curve A 10K3A 016

Curve C 10K Curve C 10K4A 006

Use Steinhart-Hart equation coefficients (A, B and

C) from thermistor manufacturer corresponding to

Custom

the terms of the Steinhart-Hart equation:

1 / T = A + Bln(R) + C (ln(R))

Beta

Therm

YSI

3

Thermistor (High Density) FMHA - PAAA - A _ _ _

S1

R1

S2

R2

S3

R3

S4

R4

• >20 MΩ input impedance

• 0 to 40kΩ, 0 to 20kΩ, 0 to 10kΩ, 0 to 5kΩ

• 2.252kΩ and 10kΩ base at 77°F (25°C)

• Drive current is 109 μA as a constant current source

• User-selectable curves for Alpha Technics, BetaTHERM and YSI

• User-scaling support for Steinhart-Hart coefcients

Thermistor

Curve Setting

Base R

@ 25 ºC

Alpha

Technics

Curve A 2.252K Curve A 2.2K3A 004

Curve B 10K Curve A 10K3A 016

Curve C 10K Curve C 10K4A 006

Use Steinhart-Hart equation coefficients (A, B and

C) from thermistor manufacturer corresponding to

Custom

the terms of the Steinhart-Hart equation:

1 / T = A + Bln(R) + C (ln(R))

Beta

Therm

YSI

3

Watlow F4T Install & Troubleshooting • 14 • Chapter 2 Install and Wire

Page 18

Input Connections (cont.)

Int

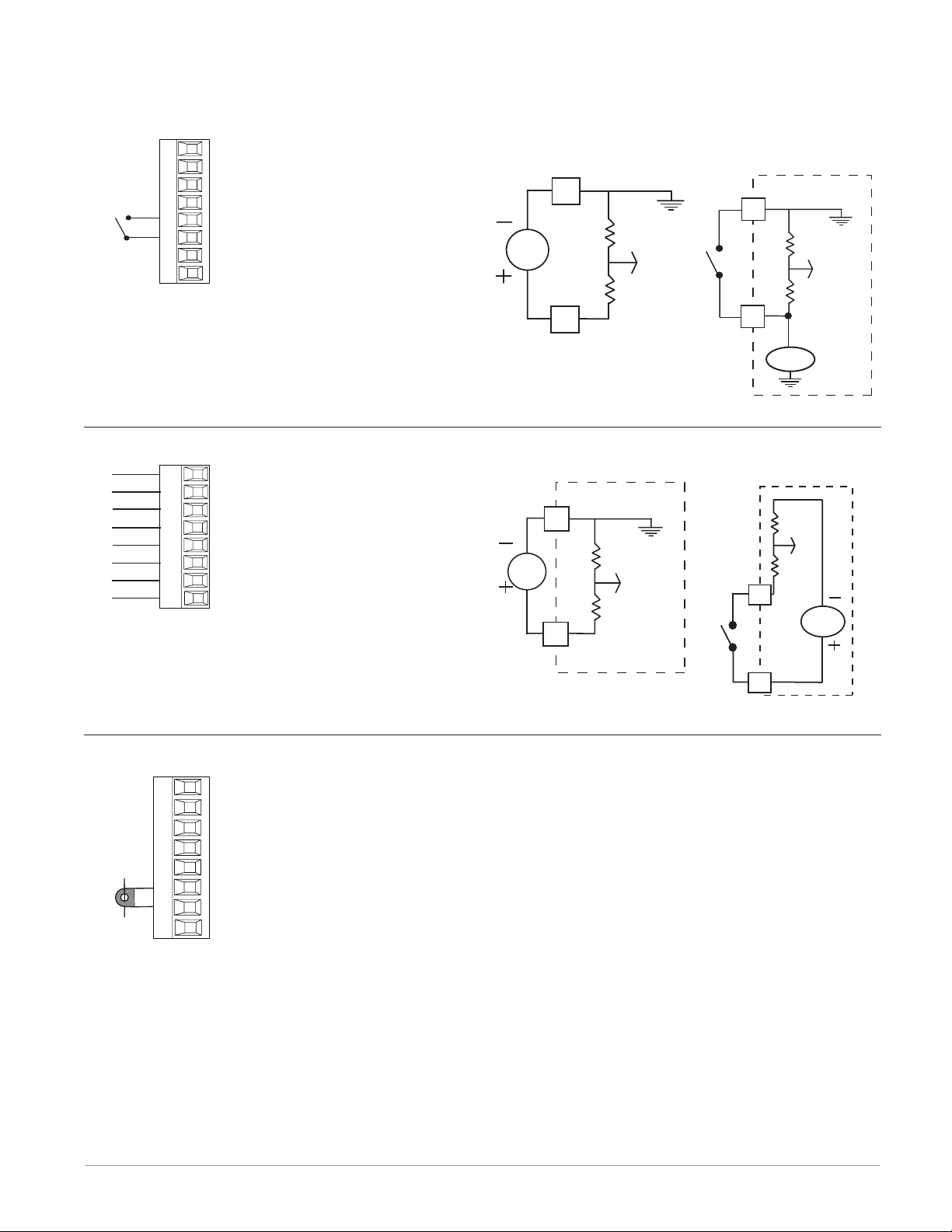

Digital Input FMLA - YEBA - A _ _ _

• Update rate 10Hz

• Voltage

- Max. input 36V at 3mA

- Input inactive when =<

B2

D2

2V

- Input active when =>

Vdc

3V at 0.25mA

• Dry contact

- Input inactive when =>

500Ω

- Input active when =<

100Ω

- Max. short circuit 13mA

Digital Input (High Density) FMHA - CAAA - A _ _ _

ernal

Common

DC Input

DC Input

DC Input

DC Input

DC Input

DC Input

Supply

B1

D1

D2

D3

D4

D5

D6

Z1

• Voltage

- Max. input 36V at 3mA

- Input inactive when =<

2V

- Input active when => 3V

at 0.25mA

• Dry contact

Vdc

- Input inactive when =>

500Ω

- Input active when =<

100Ω

- Max. short circuit 13mA

Voltage Input

common

B2

D2

Dry Contact

common

B2

D2

Vdc

Voltage Input Dry Contact

common

B1

_

D

_

D

Z1

24 Vdc

Current Transformer FMMA - C _ _ A - A _ _ _

• Input range is 0 to 50 mA (ac).

• Current transformer part number: 16-0246

• 100 Ω input impedance

• Response time: 1 second maximum

T1

S1

Watlow F4T Install & Troubleshooting • 15 • Chapter 2 Install and Wire

• Accuracy +/-1 mA typical

Page 19

Example: Using a Current Transformer

12A

Is = IpT/R = 50mA

k)

L2 L1

Fuse

SSR

3A x 4

ISC = Ip(full scale) = 50mA(R)/T

CSI = Output N

s = Current in secondary of current transformer

I

p = Current in primary of current transformer

I

T = Number of turns through the primary of the transformer

R = Number of turns in the secondary of the current

transformer (Turns ratio, assuming one primary turn)

ISC = Input Scaling (parameter found in Current function block)

CSI = Current Output Source Instance (parameter found in Current function bloc

12A

x 4 = 48A

:

Turns around CT

48mA

CT Secondary Current

CT Primary Current

Turns around CT

Total current

Output N

Controller

CT Input

CT Ratio R = 1000:1

48mA

Watlow F4T Install & Troubleshooting • 16 • Chapter 2 Install and Wire

Page 20

Output Connections

Mechanical Relay Form A FM [M, L]A - _ _ JA - A _ _ _

• 5 A at 240VÅ (ac) or 30VÎ (dc) maximum resistive load

normally open

common

L2

K2

NO-ARC Relay Form A FMMA - _ _ HA - A _ _ _

• 20 mA at 24V minimum inductive

load

• 125 VA pilot duty at 120/240V Å(ac),

25 VA at 24V Å(ac)

• 100,000 cycles at rated load

• Output does not supply power

• For use with ac or dc

• See Quencharc note (page 12)

L2

K2

• 12A at 122°F (50°C), 85 to 264VÅ (ac)

resistive load only (see derating curve)

• 2,000,000 cycle rating for rated load

normally open

common

L2

K2

• 100 mA minimum load

• 2 mA maximum off state leakage

• Do not use on dc loads

• Output does not supply power

• Do not drive another relay or solenoid

with this output type

• See Quencharc note (page 12)

Solid-State Relay Form A FMMA - _ KKA - A _ _ _

normally open

common

L1

K1

• 0.5A at 149°F (65°C) to 1A at 50°F

(10°C), 24 to 264VÅ (ac) maximum resis-

tive load

normally open

common

L2

K2

• 20 VA 120/240VÅ (ac) pilot duty

• Opto-isolated, without contact suppression

• Maximum off state leakage of 105 microamperes

• Output does not supply power

• Do not use on dc loads

• See Quencharc note (page 12)

L2

K2

L_

K_

Watlow F4T Install & Troubleshooting • 17 • Chapter 2 Install and Wire

Page 21

Output Connections (cont.)

Open

Four Mechanical Relays Form A (High Density) FMHA - JAAA - A _ _ _

normally open

common

normally open

common

normally open

common

normally open

common

L1

K1

L2

K2

L3

K3

L4

K4

• 5 A at 240VÅ (ac) or 30VÎ (dc) maximum resistive load

• 20 mA at 24V minimum load

• 125 VA pilot duty @ 120/240VÅ (ac),

25 VA at 24VÅ (ac)

• 100,000 cycles at rated load

• Output does not supply power.

• For use with ac or dc

• See Quencharc note (page 12)

1

L

normally open

1

K

common

2

L

normally open

2

K

common

3

L

normally open

3

K

common

4

L

normally open

4

K

common

Dual Solid-State Relays, Form A (High Density) FMHA - KAAA - A _ _ _

normally open

normally open

common

common

normally open

normally open

common

common

L1

L1

K1

K1

L2

L2

K2

K2

• 10 A at 20 to 264VÅ (ac) maximum resistive load

• 10A per output at 240VÅ (ac), max. 20A

per card at 122°F (50°C)

• Opto-isolated, without contact suppression

• Maximum off state leakage of 105 microamperes

• Output does not supply power

• Do not use on dc loads.

Note:

This module requires 2 slots, therefore it

cannot be placed in slot 3 or 6.

L1

Normally

L1

K1

Common

K1

L2

Normally Open

L2

K2

Common

K2

Watlow F4T Install & Troubleshooting • 18 • Chapter 2 Install and Wire

Page 22

Output Connections (cont.)

Open

Open

Open

Open

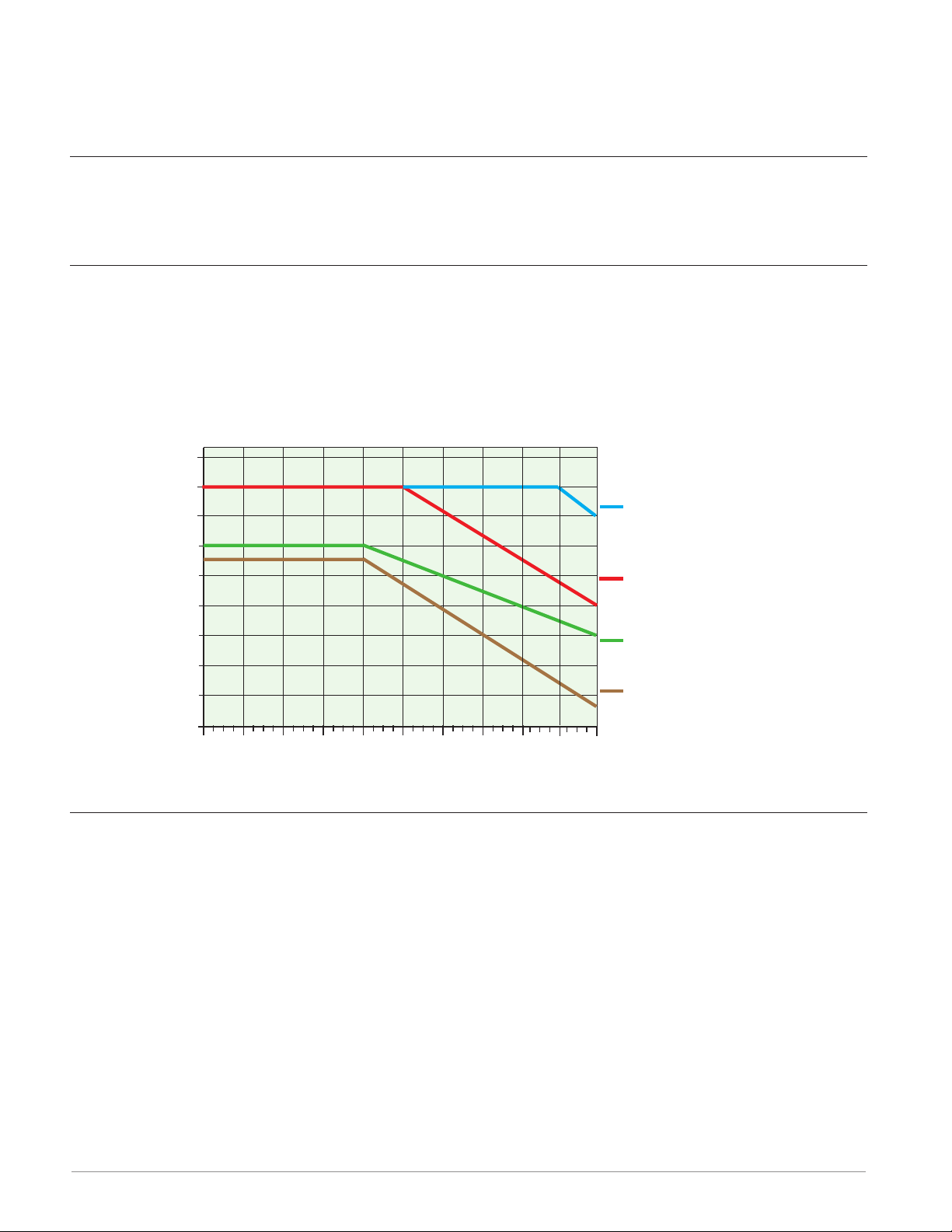

Quad 2 Amp SSR Derating Curve

Amps per Each SSR

SSR FM. All outputs on.

Four 2A Solid-State Relays, Form A (High Density) FMHA - LAAA - A _ _ _

normally open

common

normally open

normally open

common

normally open

L1

K1

L2

L3

K3

L4

• 2A at 20 to 264VÅ (ac) maximum resistive

load

• 50 VA 120/240VÅ (ac) pilot duty

• Optical isolation, without contact suppression

• Maximum off state leakage of 105 µA

• Output does not supply power.

• Do not use on dc loads.

• N.O., COM, N.O wiring (shared common)

between each set of outputs.

• See table below for maximum current output.

All Outputs 100% Duty Cycle

2.2

2.0

1.8

1.6

1.4

1.2

Not Used

Not Used

F4T with 2 FMs: 1 quad

input and 1 quad 2A

SSR FM. Outputs 1 and

3 on.

F4T with 2 FMs: 1 quad

input and 1 quad 2A

1

L

Normally

1

K

Common

2

L

Normally

L3

Normally

K3

Common

L4

Normally

1.0

0.8

0.6

0.4

01510520

25 30 35 40

Ambient Temperature (oC)

F4T with 5 FMs: 1 quad

2A SSR.

F4T with 6 FMs: 1 quad

2A SSR.

45 50

Watlow F4T Install & Troubleshooting • 19 • Chapter 2 Install and Wire

Page 23

Output Connections (cont.)

nor

normally closed

+

3 Mechanical Relays, 2 Form C, 1 Form A (High Density) FMHA - BAAA - A _ _ _

• 5A at 24 to 240VÅ (ac) or 30V

normally open

common

mally closed

normally open

normally open

common

normally closed

Mechanical Relay Form C FM [M, L]A - _ E _ A - A _ _ _

L1

K1

J1

L2

L3

K3

J3

Î (dc) maximum resistive load

• 125VA pilot duty 120/240VÅ

(ac) 25 VA at 24VÅ (ac)

• Output does not supply power

• Form A relay shares common

with one Form C relay.

• See Quencharc note (page 12)

L1

normally open

K1

common

J1

normally closed

L2

normally open

L3

normally open

K3

common

J3

normally closed

normally open

common

normally closed

L1

K1

J1

mum resistive load

• Requires a minimum load of 20 mA at

24V

L1

normally open

• 125 VA pilot duty at 120/240VÅ (ac),

• 5 A at 240VÅ (ac) or 30VÎ (dc) maxi-

25 VA at 24VÅ (ac)

• 100,000 cycles at rated load

• Output does not supply power.

K1

common

J1

• For use with ac or dc

• See Quencharc note (page 12)

Universal Process FMMA - _ F _ A - A _ _ _

• 0 to 20 mA ±30μA into 800 Ω maximum

volts or current -

volts +

current +

F1

G1

H1

load with 5μA nominal resolution

• 0 to 10VÎ (dc) ±15mV into 1 kΩ minimum

load with 2.5mV nominal resolution

• Scalable

0 to 10 V

4 to 20 mA

F1

negative

G1

volts +

• Output supplies power

• Cannot use voltage and current outputs

H1

current

at same time

• Output may be used as retransmit or

control

• Temperature stability 100 ppm/°C

Watlow F4T Install & Troubleshooting • 20 • Chapter 2 Install and Wire

Page 24

Output Connections (cont.)

v

current +

dc

common

Tri-Process/Retransmit (High Density) FMHA - FAAA - A _ _ _

volts - / current -

volts + / current +

F1

H1

• 0 to 20 mA into 400Ω maximum load

• 0 to 10VÎ (dc) into 4 kΩ minimum

load

volts - / current -

olts + / current +

volts - / current -

volts + / current +

F2

H2

F3

H3

• Outputs are scalable

• Output supplies power

• Each output can be independently set

for voltage or current

• Output may be used as retransmit or

control

Switched DC / Open Collector FM [M, L] A - _ CCA - A _ _ _

Switched DC

FM [M, L] A - _ [C] [C] A - A _ _ _

dc -

dc +

W2

Y2

• Output 1 and 2, 30 mA dc

maximum supply current not to

exceed 40 mA combined when

both outputs are used

• Short circuit limited to <50 mA

• 22 to 32VÎ (dc) open circuit

voltage

dc (open collector)

X1

W1

Y1

• Use dc- and dc+ to drive external solid-state relay.

• DIN-A-MITE compatible

Note:

Total current of 40 mA not to be

Open Collector (Output 1 only)

exceeded if both outputs are used.

• 100 mA maximum output current sink

• 30VÎ (dc) maximum supply

FM [M, L] A - _ [C] _A - A _ _ _

voltage

• Any switched dc output can use

the common terminal.

• Use an external class 2 or *SELV

power supply to control a dc

load, with the load positive to

the positive of the power supply, the load negative to the

open collector and common to

the power supply negative.

• *Safety Extra Low Voltage

24V

F

0 to 20 mA

0 to 20 mA

0 to 20 mA

0 to 10 V

H

Not Used

F

0 to 10 V

H

Not Used

F

0 to 10 V

H

Switched DC

X_

common

W_

24V

Y_

Open Collector

common

X1

dc -

W1

Y1

negative

1

volts +

or

1

current +

negative

2

volts +

or

2

current +

negative

3

volts +

3

or

dc -

dc +

Power Supply

Load

Watlow F4T Install & Troubleshooting • 21 • Chapter 2 Install and Wire

Page 25

Output Connections (cont.)

open collect

open collect

open collect

open collect

open collect

open collect

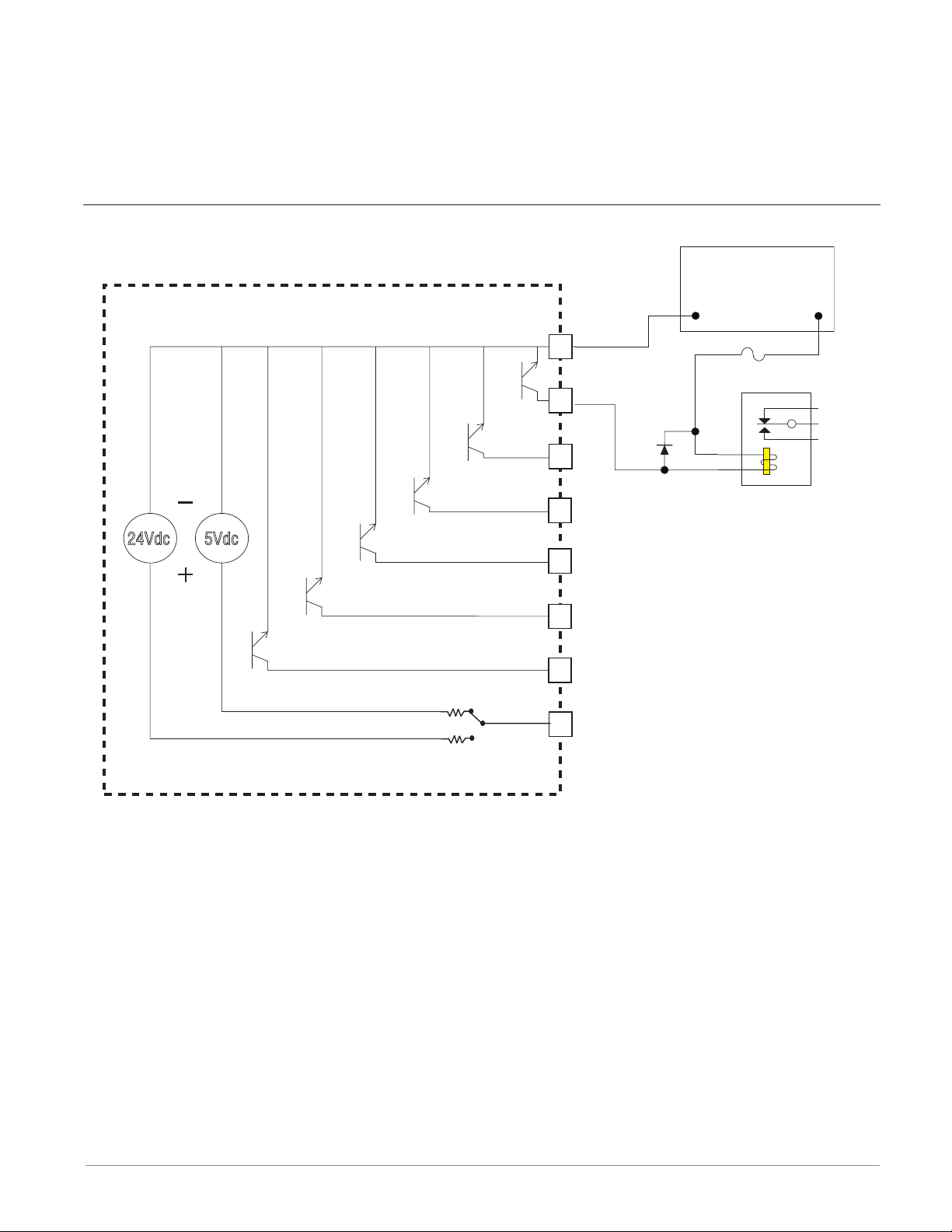

Six Digital Outputs (High Density) FMHA - CAAA - A _ _ _

Common

Internal

or/switched dc

or/switched dc

or/switched dc

or/switched dc

or/switched dc

or/switched dc

Supply

B1

D1

D2

D3

D4

D5

D6

Z1

Open Collector

• Maximum switched voltage is 32VÎ

(dc)

• 400mA, maximum open circuit voltage of 25VÎ (dc), typical 8VÎ (dc)

at 80mA

• Maximum output sink current per

output is 1.5A (external class 2 or

*SELV supply required)

• Total sink current for all outputs not

to exceed 8A

• Do not connect outputs in parallel

• *Safety Extra Low Voltage

Switched DC

• User selectable voltage, 5VÎ (dc) at

130mA or 19 to 22VÎ (dc) at 80mA

Open Collector Outputs

24Vdc

Switched DC Outputs

24Vdc

5Vdc

User Selectable

B1

D1

D2

D3

D4

D5

D6

Z1

B1

D1

D2

D3

D4

D5

D6

Z1

Voltage

Digital Output - Switched DC Wiring Example

B1

D1

24Vdc

5Vdc

D2

D3

D4

D5

Htr 2

Htr 3

Htr 1

+

+

+

-

DC90-60C0-0000

D6

Z1

Internal Supply

User Selectable

Voltage

Note:

As a switched DC output; this output is a constant current output delivering 750 mW, current limited to 150 mA. The internal supply is 5V(dc) open circuit. Pin Z1 is shared to all

digital outputs. This type of output is meant to drive solid state relays, not mechanical

Watlow F4T Install & Troubleshooting • 22 • Chapter 2 Install and Wire

Page 26

Output Connections (cont.)

relays. As an open collector output, use an external power supply with the negative wired

to B1, the positive to the coil of a pilot mechanical relay and the other side of the coil

wired to D_. Each open collector output can sink 1.5 A with the total for all open collector

outputs not exceeding 8 amperes. Ensure that a kickback diode is reverse wired across the

relay coil to prevent damage to the internal transistor.

Digital Output - Open Collector Wiring Example

Power Supply

5 to 32 V(dc)

Open Collector Outputs

Common

B1

D1

D2

-

Fuse

An example fuse is

Bussmann AGC-1 1/2

Diode

+

24Vdc

5Vdc

Internal Circuitry

D3

Relay

D4

D5

D6

Z1

User Selectable

Voltage

Watlow F4T Install & Troubleshooting • 23 • Chapter 2 Install and Wire

Page 27

Communications Connections

Slot B, E

232 (TX)

232 (RD)

EIA-232/485 Modbus RTU Communications

485 T+/R+

485 T-/R-

485 common

485 T+/R+

485 T-/R-

232 common

to DB9 pin 2 (RD)

to DB9 pin 3 (TX)

CB

CA

CC

CB

CA

C5

C3

C2

• Wire T-/R- to the A terminal

of the EIA-485 port.

• Wire T+/R+ to the B terminal

of the EIA-485 port.

• Wire common to the common

terminal of the EIA-485 port.

• Do not route network wires

with power wires. Connect

network wires in daisy-chain

fashion when connecting

multiple devices in a network.

• A termination resistor may be

required. Place a 120 Ω resistor across T+/R+ and T-/R- of

last controller on network.

• Do not wire to both the EIA485 and the EIA-232 pins at

the same time.

• Two EIA-485 terminals of

T/R are provided to assist in

daisy-chain wiring.

• Do not connect more than

one controller on an EIA-232

network.

• Do not connect more than 16

controllers on a Standard Bus

EIA-485 network.

• Maximum number of controllers on a Modbus network is

247.

• Maximum EIA-232 network

length: 15 meters (50 feet)

• Maximum EIA-485 network

length: 1,200 meters (4,000

feet)

• 1/8th unit load on EIA-485

bus.

Modbus-IDA

Terminal

DO A CA or CD T-/R-

D1 B CB or CE T+/R+

common common CC or CF common

Note::

This module must be placed in slot 6.

EIA/TIA-485

Name

Watlow Terminal

Label

Function

Watlow F4T Install & Troubleshooting • 24 • Chapter 2 Install and Wire

Page 28

3

Chapter 3: Connecting a PC

Using the User Interface (UI) to Change or View Ethernet Settings

Understanding the Front Panel Navigational Buttons

When looking at the front panel of the F4T, at the bottom of the display, four push buttons

are displayed as icons shown below. The text in this graphic was placed there for clarity only

and is not present on the front panel.

• Home: regardless of the screen currently in view, when pushed, will always return to

the Home screen which displays the following after personalization:

- Loop name, user designated (Chamber Temp, as shown above).

- Control mode (Auto, as shown above).

- Process Value, input connected to the PV receiver of the loop function block.

- Set Point, which represents the desired value to be maintained by the controller.

- PWR, output power levels for heat and cool if both are congured.

- Output Actions, allows a user to monitor the on/off status of user dened inputs or

outputs.

• Menu: as shown below, will provide access to other settings and functions within the

controller.

• Return: when pushed, this button will take the user back to the previous screen until

the top level of either the home screen or the main menu are reached.

• Help: displays information about the controller such as: part number, software revision

etc...

Note:

Menu buttons can change depending on options ordered (Data Logging) and function blocks

used (Alarm).

Watlow F4T System • 25 • Chapter 3 Connecting to a PC

Page 29

Default Ethernet Parameters and Settings

The bracketed bold settings below represent the defaults as delivered from the factory:

• IP Address Mode: [DHCP], Fixed

- DHCP, Dynamic Host Conguration Protocol, allows for dynamic distribution of network

settings by a DHCP server.

- Fixed, also referred to as a static IP address, is congured manually for a specied network.

• Actual IP Address: [192.168.0.222]

• Actual IP Subnet: [255.255.255.0]

- Subnet, a method used to logically divide and isolate networks.

• Actual IP Gateway: [0.0.0.0]

- Gateway, is a device used on the network to route messages with IP addresses that do not

exist on the local network.

• MAC Address: xx:xx:xx:xx:xx:xx (Will be different and unique for each controller)

- MAC address, is a manufacturer supplied address for the network interface card.

• Display Units: [°F] (Fahrenheit), °C (Celsius)

• Modbus® TCP Enable: [Yes], No

- Modbus is an industrially hardened eld bus protocol used for communications from the

controller to other devices on the network.

• Modbus Word Order: [High], Low

- Modbus allows a user to select the word order of two 16-bit words in oating point values.

• Data Map: [1], 2

- Data Map, the user can switch Modbus registers from the comprehensive listing of F4T

registers to a limited set of the legacy F4 controller registers (1 = F4T, 2 = F4 compatibility).

To change Ethernet parameters:

1. Push the Menu, Settings and Network buttons, in that order.

2. Under "Communications Channels" push Ethernet.

3. Change desired settings.

4. Cycle power to the F4T (changes to IP address will take effect until this step is performed)

Watlow F4T System • 26 • Chapter 3 Connecting to a PC

Page 30

Connecting the F4T Base to a PC

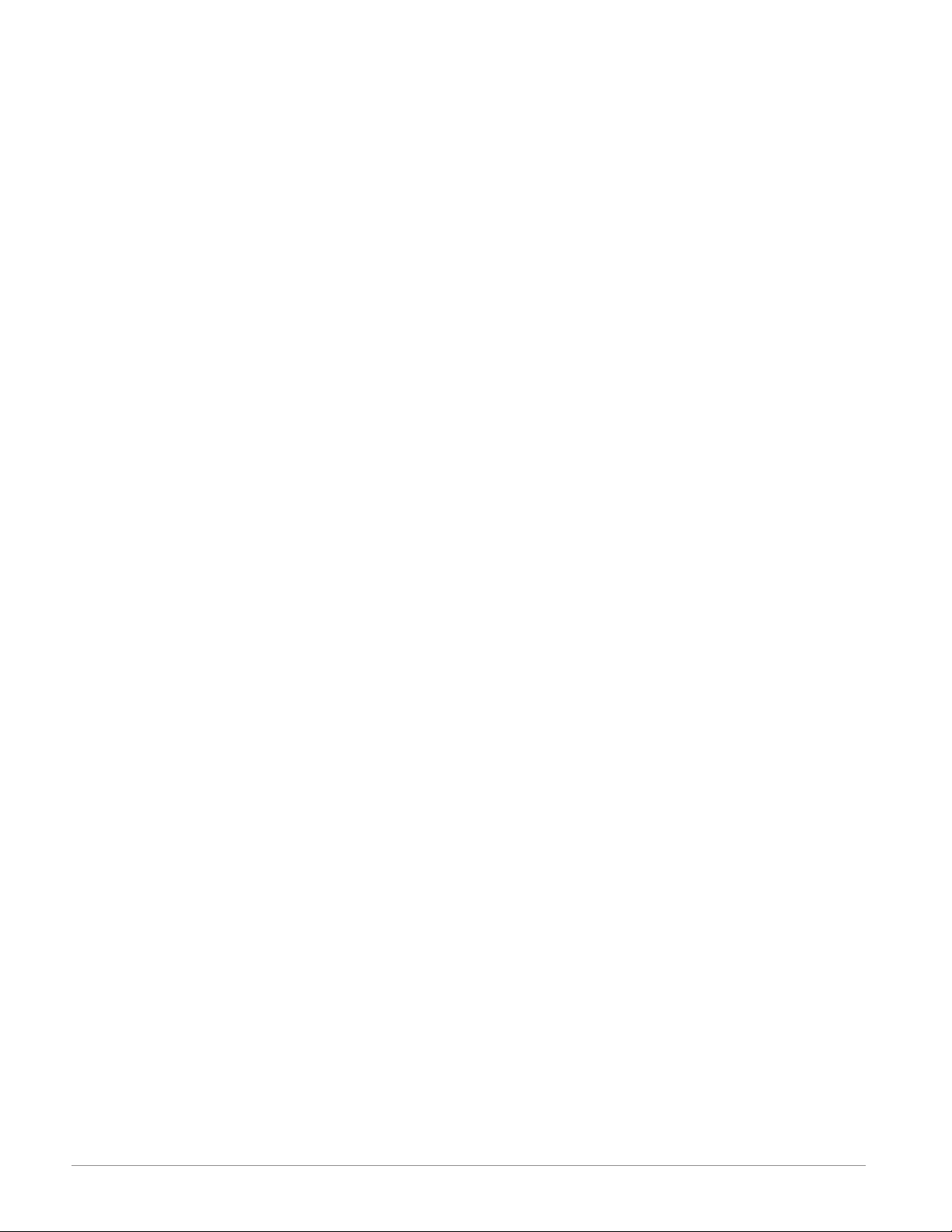

DHCP Connection

There are two ways to connect the F4T over Ethernet to a PC (Fixed IP or DHCP). Because

the F4T is delivered as a DHCP client, we'll take a look at this method rst. The picture

below shows two F4T controllers connected through a switch to a DHCP server. When the

F4Ts are powered up on the network the

DHCP server will assign IP addresses to

them. Using this method allows the F4Ts

to come up in the same network as the PC

with minimal changes to the default F4T

Ethernet conguration.

To connect using DHCP:

1. Connect Ethernet cables from F4T RJ45

connector to the Ethernet switch.

2. Cycle power on the F4T controllers.

3. DHCP server will detect them on the

network and give them IP addresses

automatically.

Fixed IP Connection

If it is desired to connect the F4T directly to a PC as shown in the graphic below follow the

steps below to do so. It should be noted too that there are alternatives to the steps dened

below, this is one way to do this.

To connect using Fixed IP changing PC IP address:

1. Connect Ethernet cables from F4T RJ45 connector

to PC Ethernet port.

2. On the PC navigate to the control panel and click

on Network and Sharing Center

3. Click on Change adapter settings

4. Double-click on the Local Area Connection (the

Ethernet port where cable is connected icon).

5. Click the Properties button.

6. Double-click on Internet Protocol Version 4 (TCP/IPv4) button.

7. Click the radio button identied as Use the following IP address.

8. Change the IP address so that the rst 3 octets match the rst 3 octets of the F4T IP

address while ensuring that the last octet for both the PC and the F4T are unique and

between 0 and 255. If there are other devices on this network all must have a unique address.

9. Change the Subnet mask to match what was entered for the F4T.

10. Click OK when done (this change to the IP address will take effect immediately)

To connect using Fixed IP changing F4T IP address:

1. Push the Menu, Settings and Network buttons, in that order.

2. Under "Communications Channels" push Ethernet.

3. Change desired settings to match the PC ensuring a unique IP address for each.

4. Cycle power to the F4T (changes to IP address will not take effect until this step is pe-

formed).

Watlow F4T System • 27 • Chapter 3 Connecting to a PC

Page 31

Composer Software

Composer™ is the PC-based software used to congure an F4T controller for a specic application. Use Composer to congure which ex modules the controller expects to nd in

each of its slots and to customize the controllers functions for your application. To acquire

Composer software free of charge, point your browser to: http://www.watlow.com/F4T.cfm.

Once there, scroll down to nd and download Composer software.

For detailed instructions in installing and using Composer software see chapter 2 of the F4T

Setup and Operation User Guide.

Starting Composer™ Software

To start the software:

1. Click the Start button and then type composer.exe in the search box to find the executable.

2. Double-click on the file "composer.exe".

Note:

If experiencing difficulties installing or using Composer software, prior to contacting

Watlow technical support, be prepared to send the user log file to the tech support team.

This text file can be found here:

C:\Users\username\AppData\Roaming\Watlow\EZ-Zone Composer\Logs

The red text above will change to the users Windows login name.

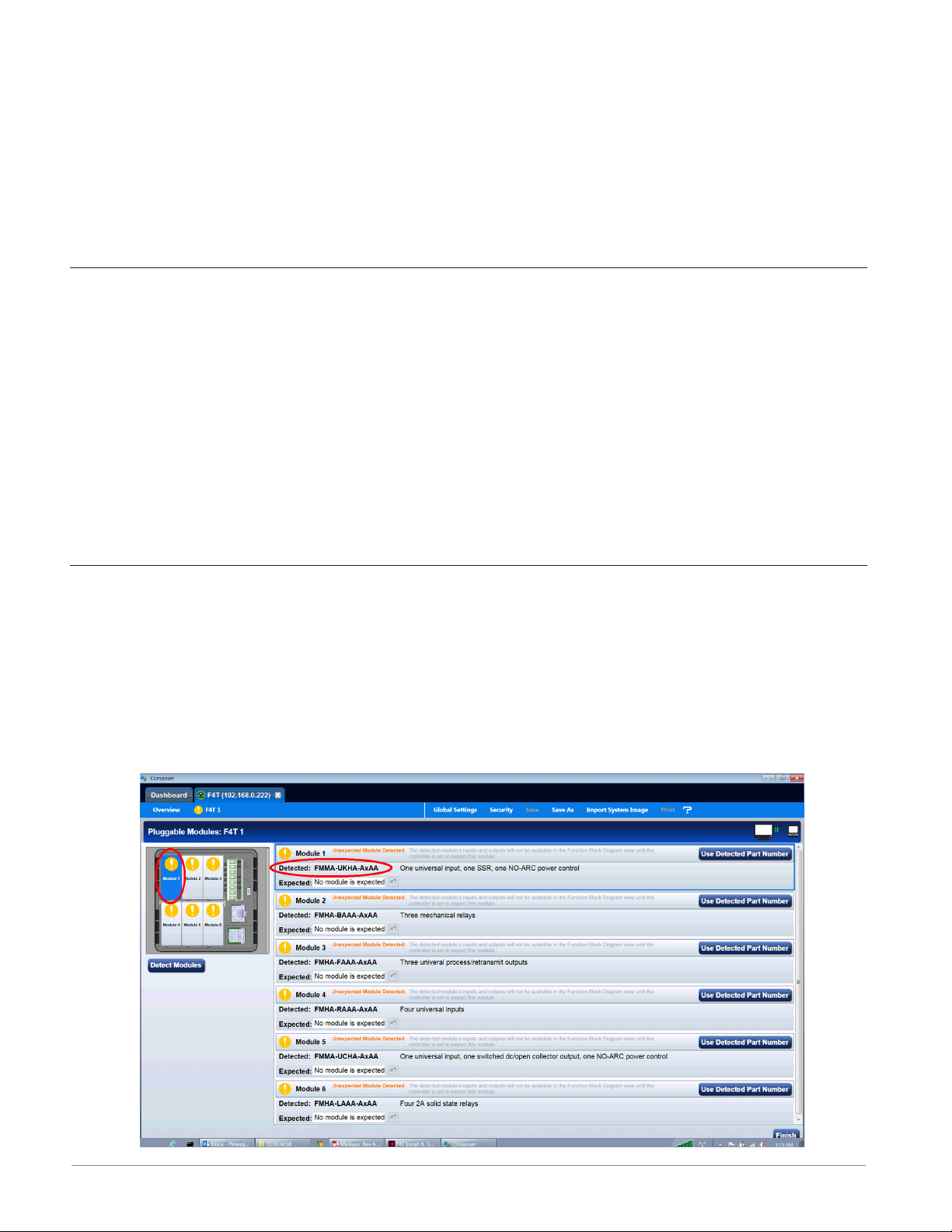

Verifying Pluggable Flex Module Installation Using Composer™

Connect to the desired system:

1. From the systems screen double-click on the online system.

Enter Pluggable Module Screen:

1. Click on the desired Device from the menu bar and then Pluggable Modules.

2. Verify that the detected module (as shown in the graphic below) for each slot matches

what was noted in step 1 (Installing the modules).

Watlow F4T System • 28 • Chapter 3 Connecting to a PC

Page 32

Symbols Related to Pluggable Modules

As viewed from the Menu bar, the symbol that will be displayed to the left of the Pluggable

Modules button will be of the most signicance. The red exclamation will always take precedence.

Symbol Description

The expected module has been detected.

No module has been detected in a slot the controller expects to be empty.

A module has been detected in a slot the controller expects to be empty.

The controller expects a module, but that module is missing or a different

module has been detected.

Watlow F4T System • 29 • Chapter 3 Connecting to a PC

Page 33

4

Chapter 4: Calibration

Calibrating the F4T Inputs

All controllers are calibrated and are accurate to the specied specications (see Appendix

for specications) when they ship from the manufacturing facility.

If an input is suspect as being out of calibration it is recommended that prior to performing any calibration procedure that the user verify that the displayed readings are not within

published specications. Input a known value from a precision source to the analog input and

subtract the displayed value with the known value and compare this difference to the published accuracy range specication (see Appendix for specications) for that type of input.

Use of the Calibration Offset parameter found when viewing the Universal Input parameters

from within Composer™ software or while viewing the input from the front panel Operations

menu, shifts the readings across the entire displayed range by the offset value. Use this parameter to compensate for sensor error or sensor placement error. Typically this value is set

to zero.

Required Equipment When Performing Calibration

Obtain a precision source for millivolts, volts, milliamperes or resistance depending on the

sensor type to be calibrated. Use copper wire only to connect the precision source to the

controller’s input. Keep leads between the precision source and controller as short as possible to minimize error. In addition, a precision volt/ohm meter capable of reading values to 4

decimal places or better is recommended. Prior to calibration, connect this volt/ohm meter

to the precision source to verify accuracy.

Actual input values do NOT have to be exactly the recommended values, but it is critical

that the actual value of the signal connected to the controller be accurately known to at

least four digits.

Watlow F4T Install & Troubleshooting • 30 • Chapter 4 Calibration

Page 34

Calibration of Analog Inputs

To calibrate an analog input, you will need to provide a source of two electrical signals or

resistance values near the extremes of the range that the application is likely to utilize. See

recommended values below:

Sensor Type Precision Source Low Precision Source High

Thermocouple 0.000 mV 50.000 mV

Millivolts 0.000 mV 50.000 mV

Volts 0.000V 10.000V

Milliamps 0.000 mA 20.000 mA

100 Ω RTD 50.00 Ω 350.0 Ω

1,000 Ω RTD 500.0 Ω 3,500 Ω

Thermistor 5 kΩ 50.00 5,000

Thermistor 10 kΩ 150.0 10,000

Thermistor 20 kΩ 1,800 20,000

Thermistor 40 kΩ 1,700 40,000

Potentiometer 0.000 1,200

CAUTION:

Control loops, alarms, limits and any other functions that receive signals from the analog

input will act on the high and low signals applied in this procedure.

Note:

When calibrating a Universal Input configured as a 3-wire RTD, ensure that the calibrated

source is connected across R and both T and S inputs.

Note:

If the user exits this procedure at any point by clicking cancel or simply navigating away

to another screen, the previous calibration for the selected input will be restored.

Note:

The calibration values entered using this procedure will be overwritten whenever the controller has the factory settings restored.

Note:

There are three security settings that can be applied to the calibration screens through

the Diagnostics and Troubleshooting (see the System Overview section of the F4T Setup

and Operation User's Guide for more information) access point:

1. Full Access - full capabilities to calibrate available

2. Read Only - first calibration screen displayed

3. No Access - calibration screens not available

ç

Watlow F4T Install & Troubleshooting • 31 • Chapter 4 Calibration

Page 35

Using Composer™ Software to Calibrate Analog Inputs

To obtain access to the calibration screens:

1. Start Composer software if not already running.

2. From the Dashboard click on Connect to a System and select the appropriate device.

3. From the System Overview screen click on the Device menu button where a drop down

list will appear.

4. Click on Calibrate.

5. Select the appropriate Module and Input and then click on Perform Field Calibration.

6. Follow instructions on the screen.

Using the User Interface to Calibrate Analog Inputs

To calibrate from the F4T front panel:

1. Push the Menu, Service and Calibration buttons, in that order.

2. Select the desired module and input and then push Perform Field Calibration.

3. Follow instructions on the screen.

Note:

At any point in time (using Composer software or the UI) the selected module and input

can be brought back to the factory calibration settings by selecting "Restore Factory Calibration".

Watlow F4T Install & Troubleshooting • 32 • Chapter 4 Calibration

Page 36

5

Chapter 5: Troubleshooting

Indication Description Possible Cause(s) Corrective Action

Alarm won’t

clear or reset

Alarm won’t

occur

Alarm will not clear

or reset with keypad or digital input

Alarm will not activate output

• Alarm latching is active

• Alarm set to incorrect

output

• Alarm is set to incorrect

source

• Sensor input is out of

alarm set point range

• Alarm set point is incorrect

• Alarm is set to incorrect

type

• Digital input function is

incorrect

• Alarm silencing is active

• Alarm blocking is active

• Alarm is set to incorrect

output

• Alarm is set to incorrect

source

• Alarm set point is incorrect

• Alarm is set to incorrect

type

• Reset alarm when process is within range or

disable latching

• Set output to correct

alarm source instance

• Set alarm source to correct input instance

• Correct cause of sensor

input out of alarm range

• Set alarm set point to

correct trip point

• Set alarm to correct

type: process, deviation

or power

• Set digital input function and source instance

• Disable alarm silencing,

if required

• Disable alarm blocking,

if required

• Set output to correct

alarm source instance

• Set alarm source to correct input instance

• Set alarm set point to

correct trip point

• Set alarm to correct

type: process, deviation

or power

Alarm Error Alarm state cannot

be determined due

to lack of sensor

input

Watlow F4T Install & Troubleshooting • 33 • Chapter 5 Troubleshooting

• Sensor improperly wired

or open

• Incorrect setting of sensor type

• Calibration corrupt

• Correct wiring or replace sensor

• Match setting to sensor

used

• Check calibration of

controller

Page 37

Indication Description Possible Cause(s) Corrective Action

Alarm Low Sensor input below

low alarm set point

Alarm High Sensor input above

high alarm set point

Error Input Sensor does not

provide a valid signal to controller

• Temperature is less than

alarm set point

• Alarm is set to latching

and an alarm occurred in

the past

• Incorrect alarm set point

• Incorrect alarm source

• Temperature is greater

than alarm set point

• Alarm is set to latching

and an alarm occurred in

the past

• Incorrect alarm set point

• Incorrect alarm source

• Sensor improperly wired

or open

• Incorrect setting of sensor type

• Calibration corrupt

• Check cause of under

temperature

• Clear latched alarm

• Establish correct alarm

set point

• Set alarm source to

proper setting

• Check cause of over

temperature

• Clear latched alarm

• Establish correct alarm

set point

• Set alarm source to

proper setting

• Correct wiring or replace sensor

• Match setting to sensor

used

• Check calibration of

controller

Limit won’t

clear or reset

Limit will not clear

or reset with keypad or digital input

Limit Error Limit state cannot

be determined due

to lack of sensor

input, limit will trip

Limit Low Sensor input below

low limit set point

• Sensor input is out of

limit set point range

• Limit set point is incorrect

• Digital input function is

incorrect

• Sensor improperly wired

or open

• Incorrect setting of sensor type

• Calibration corrupt

• Temperature is less than

limit set point

• Limit outputs latch and

require reset

• Incorrect alarm set point

• Correct cause of sensor

input out of limit range

• Set limit set point to

correct trip point

• Set digital input function and source instance

• Correct wiring or replace sensor

• Match setting to sensor

used

• Check calibration of

controller

• Check cause of under

temperature

• Clear limit

• Establish correct limit

set point

Watlow F4T Install & Troubleshooting • 34 • Chapter 5 Troubleshooting

Page 38

Indication Description Possible Cause(s) Corrective Action

Limit High Sensor input above

high limit set point

Loop Open

Error

Open Loop Detect

is active and the

process value did

not deviate by a

user-selected value

in a user specied

period with PID

power at 100%.

Loop Reversed

Error

Open Loop Detect is

active and the process value is headed

in the wrong direction when the

output is activated

based on deviation

value and user-selected value.

• Temperature is greater

than limit set point

• Limit outputs latch and

require reset

• Incorrect alarm set point

• Setting of Open Loop

Detect Time incorrect

• Setting of Open Loop Detect Deviation incorrect

• Thermal loop or process

is open

• Open Loop Detect function not required but

activated

• Setting of Open Loop

Detect Time incorrect

• Setting of Open Loop Detect Deviation incorrect

• Output programmed for

incorrect function

• Thermocouple sensor

wired in reverse polarity

• Check cause of over

temperature

• Clear limit

• Establish correct limit

set point

• Set correct Open Loop

Detect Time for application

• Set correct Open Loop

Deviation value for application

• Determine cause of

open thermal loop:

misplaced sensors, load

failure, loss of power to

load, etc.

• Deactivate Open Loop

Detect feature

• Set correct Open Loop

Detect Time for application

• Set correct Open Loop

Deviation value for application

• Set output function correctly

• Wire thermocouple correctly, (red wire is negative)

Ramping Controller is ramp-

ing to new set point

• Ramping feature is activated

• Prole is active

• Disable ramping feature

if not required

• Terminate prole if not

required

Autotuning Controller is

autotuning the control loop

• User started the

autotune function

• Digital input is set to

start autotune

• Wait until autotune

completes or disable

autotune feature

• Connect the digital

input to function other

than autotune, if desired

Watlow F4T Install & Troubleshooting • 35 • Chapter 5 Troubleshooting

Page 39

Indication Description Possible Cause(s) Corrective Action

No heat/cool

action

Output does not

activate load

No Display No display indica-

tion

• Output function is incorrectly set

• Control mode is incorrectly set

• Algorithim is set off

• Output is incorrectly

wired

• Load, power or fuse is

open

• Control set point is incorrect

• Incorrect controller

model for application

• Power to controller is off

• Fuse open

• Breaker tripped

• Safety interlock switch

open

• Separate system limit

control activated

• Wiring error

• Incorrect voltage to controller

• Set output function correctly

• Set control mode appropriately (Open vs Closed

Loop)

• Set heat/cool algorithim

to on/off or PID.

• Correct output wiring

• Correct fault in system

• Set control set point

in appropriate control

mode and check source

of set point: remote,

idle, prole, closed

loop, open loop

• Obtain correct controller model for application

• Turn on power

• Replace fuse

• Reset breaker

• Close interlock switch

• Reset limit

• Correct wiring issue

• Apply correct voltage,

check part number

Watlow F4T Install & Troubleshooting • 36 • Chapter 5 Troubleshooting

Page 40

Indication Description Possible Cause(s) Corrective Action

No Serial

Communication

Cannot establish serial communications

with the controller

• Address parameter incorrect

• Incorrect protocol selected

• Baud rate incorrect

• Parity incorrect

• Wiring error

• EIA-485 converter issue

• Incorrect computer or

PLC communications port

• Incorrect software setup

• Wires routed with power

cables

• Termination resistor may

be required

• Set unique addresses on

network

• Match protocol between

devices

• Match baud rate between devices

• Match parity between

devices

• Correct wiring issue

• Check settings or replace converter

• Set correct communication port

• Correct software setup

to match controller

• Route communications

wires away

from power wires

• Place 120 Ω resistor

across EIA-485 on last

controller

Process

doesn’t control to set

point

Temperature

runway

Process is unstable

or never reaches set

point

Process value continues to increase

or decrease past set

point.

• Controller not tuned correctly

• Control mode is incorrectly set

• Control set point is incorrect

• Controller output incorrectly programmed

• Thermocouple reverse

wired

• Controller output wired

incorrectly

• Short in heater or wiring

• Power controller connection to controller defective

• Controller output defective

• Perform autotune or

manually tune system

• Set control mode appropriately (Open vs Closed

Loop)

• Set control set point

in appropriate control

mode and check source

of set point: remote,

idle, prole, closed

loop, open loop

• Verify output function is

correct (heat or cool)

• Correct sensor wiring

(red wire negative)

• Verify and correct wiring

• Replace heater or repair

wiring

• Replace or repair power

controller

• Replace or repair controller

Watlow F4T Install & Troubleshooting • 37 • Chapter 5 Troubleshooting

Page 41

Indication Description Possible Cause(s) Corrective Action

Heater Error Heater Error • Current through load is

above current trip set

point

• Current through load is

below current trip set

point

Current Error Load current incor-

rect.

• Shorted solid-state or

mechanical relay

• Open solid-state or mechanical relay

• Current transformer load

wire associated to wrong

output

• Defective current transformer or controller

• Noisy electrical lines

• Check that the load current is proper. Correct

cause of over current

and/or ensure current

trip set point is correct.

• Check that the load current is proper. Correct

cause of undercurrent

and/or ensure current

trip set point is correct.

• Replace relay

• Replace relay

• Route load wire through

current transformer

from correct output,

select the output that is

driving the load.

• Replace or repair sensor

or controller

• Route wires appropriately, check for loose

connections, add line

lters

Menus inaccessible

Wrong time

and date

Unable to access

screens or particular parameters of

interest

Real time clock

resets every time

power is lost

• Security set to incorrect

level

• Battery not installed

• Polarity reversed

• Bad battery

• Verify password accuracy

• Login using appropriate

credentials

• Install battery per in-

structions

• Place battery with posi-

tive side of battery facing up in the holder

• Replace battery

Watlow F4T Install & Troubleshooting • 38 • Chapter 5 Troubleshooting

Page 42

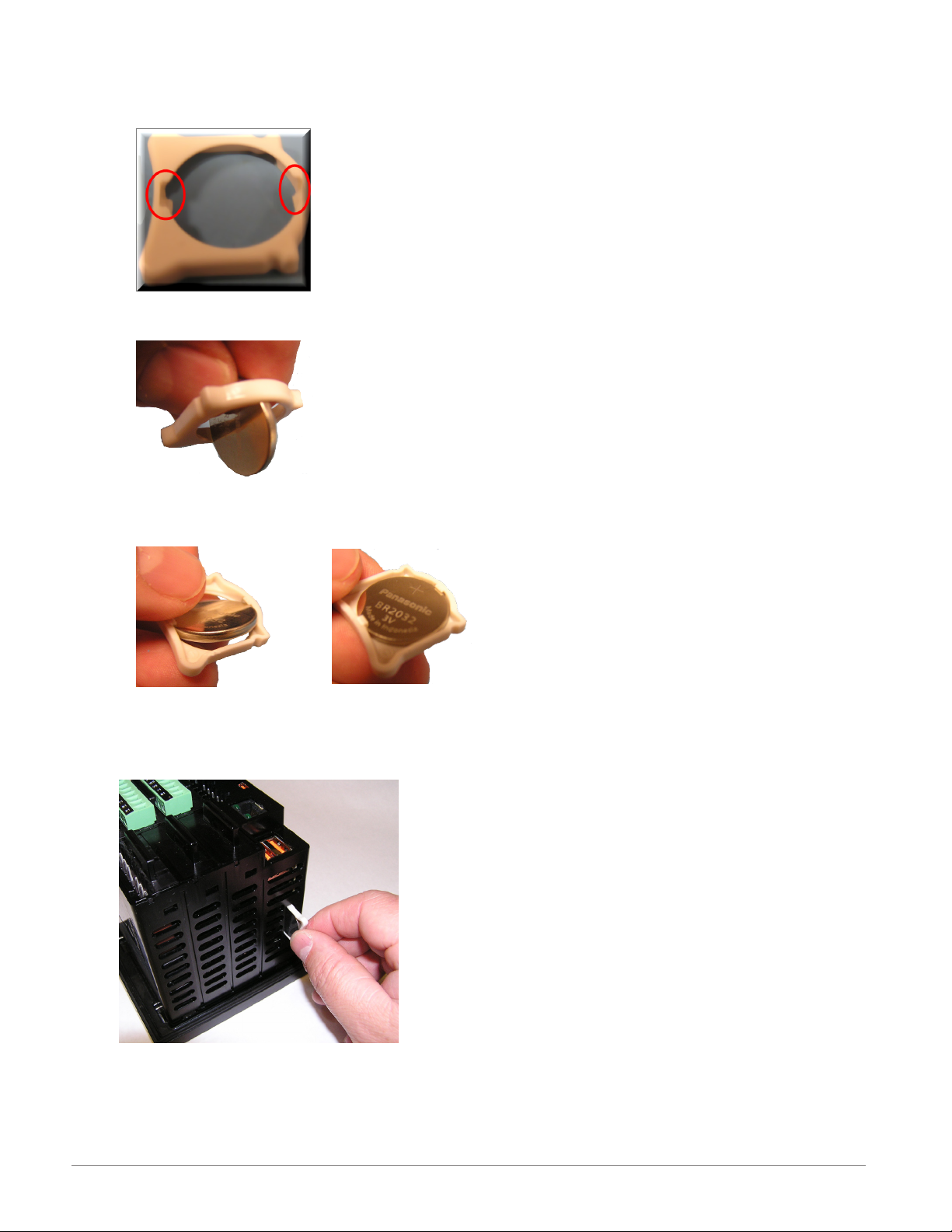

Replacing the Battery

All F4T controllers are equipped with a eld replaceable battery. In a worse case scenario,

the battery should be replaced every 7.5 years. If a replacement is required, the part number for the battery is BR 2032. The Watlow part number for the battery is: 0830-0858-0000

Identifying the battery location:

1. Orient the controller as shown in the picture below.

2. Notice that the battery compartment is located just below the two USB.

Removing the old battery:

1. Ensure all power is off to the F4T.

2. Insert a small screwdriver into the hole provided on the side of the controller as shown

below.

3. Place screwdriver into the bottom of the white battery holder and apply downward

pressure to slide the battery out of the housing. Once removed, make note of the

polarity as seated in the holder.

Watlow F4T Install & Troubleshooting • 39 • Chapter 5 Troubleshooting

Page 43

Installing a new battery:

1. Observing polarity (as shown in the previous graphic), insert the new battery from the

bottom of the holder (2 open slots - red circles as shown in picture below).

2. Insert the battery perpendicular to the plastic housing.

3. Turn and secure the battery so that it sits under the tabs located on the top of the

holder.

4. Insert the holder into the controller housing with the positive side of the battery oriented to the left as shown below.

Note:

If the battery is fully discharged it may be dis-

posed of in normal municipal waste. Because there

will always be some residual metals remaining in

the battery Watlow recommends that this battery

be recycled.

Watlow F4T Install & Troubleshooting • 40 • Chapter 5 Troubleshooting

Page 44

6

Chapter 6: Appendix

F4T Base Specifications

Line Voltage/Power (Minimum/Maximum Ratings)

• High voltage option: 100 to 240V~ (ac) 50/60Hz

• Low voltage option: 24 to 28V (~ ac) (Î dc), 50/60Hz

• Power consumption: 23 W, 54VA maximum

Environment

• NEMA 4X/IP65 - front panel mount conguration only

• 0 to 122°F (-18 to 50°C) operating temperature

• -40 to 185°F (-40 to 85°C) storage temperature

• 0 to 90% RH, non-condensing

Agency Approvals

• UL®/EN 61010 Listed, File E185611 QUYX

• UL® 508 Reviewed

• CSA CC.C#14, File 158031

• FM Class 3545 (congurations with limit modules)

• AMS 2750 E compliant: Analog input process values. Tip: Maximize eld calibration accu-

racy and uniformity by using advanced F4T features such as Calibration Offset and Linearization Function Blocks. Refer to user manual for details.

• RoHS by design, China RoHS Level 2, W.E.E.E.

• CE

• Windows® Hardware Certication

User Interface

• 4.3 inch TFT PCAP color graphic touch screen

• LED backlife >50K hours

• 4 keys: Home, Main Menu, Back, Help

Control Loops

• 1 to 4 PID or ON-OFF control loops

• 0 to 6 Limit loops

• User-selectable action: heat, cool or heat/cool

• Auto-tune with TRU-TUNE+ adaptive control

Control Loops and Over-temperature Limits

• Input sampling: 10Hz

• Output update: 10Hz

Watlow F4T Install & Troubleshooting • 41 • Chapter 6 Appendix

Page 45

Communications

• Ethernet Modbus® TCP

• Isolated communications

Profile Ramp and Soak

• Prole engine affects 1 to 4 loops in sync

• 40 proles with 50 steps per prole

Data Logging

• User selectable parameters: Up to a maximum of 128 active parameters depending on

conguration

• Logging interval: Programmable increments between 0.1 seconds and 60 minutes if

logging to internal memory. Logging directly to USB; 1.0 seconds to 60 minutes

• File types: .CSV for standard data logging or proprietary format for encrypted data log

option

• Storage: 80MB internal memory or to USB memory stick

• File transfer: Internal memory to USB host port or to Ethernet Modbus® TCP

• Transfer options: On demand by user or user programmable based on when a new data log

le record is available. Utilizes TFTP and Samba protocols

• Record: Date and time stamped

Batch Processing with Bar Code Data Entry Via USB Scanner

• Compatible with many bar code types including Code 128, Code 39, Extended Code 39,

Data Matrix, Interleaved 2 of 5, ISSN, SISAC, LOGMARS, QR, UCC/EAN-128

(GS1-128, UPC-A & E)

• Compatible with most USB scanner types such as Zebra DS4308, DS2208, LI2208 and

LS2208

• USB port provides 500mA max. power supply for bar code scanner/base charging

• Display can show bar code elds up to a maximum length of 48 characters.

Characters might wrap to 2 rows after 24 characters

• Part-Prole list entries – approximately 1,000 typical length part numbers of 15 charac-

ters each can be stored. Can easily import different part les via USB thumb drive connection to cover a higher quantity range of part lists

• Program the bar code scanner to add an enter key (carriage return feed) at the end of

each bar code data eld sent to F4T/D4T. Refer to USB scanner user manual.

Trending

• 4 user programmable charts

• 6 pens available per chart

• View analog sensors, process values, set points and power

Watlow F4T Install & Troubleshooting • 42 • Chapter 6 Appendix

Page 46

Number of Function Blocks by Ordering Option

Function Block Basic Set 1 Set 2

Alarm 6 8 14

Compare None 4 16

Counter None 4 16

Linearization 4 4 8

Logic None 12 24

Math None 12 24

Process Value 4 4 8

Special Output

Function

Timer None 6 16

Variable 4 12 24

None 2 4

Real Time Clock with Battery Backup

• Accuracy (typical): +/-3ppm over -15 to 50°C

• Typical battery life: 10 years at 77°F (25°C)

• Field replaceable lithium battery

Compare

• Greater than, less than, equal, not equal, greater than or equal, less than or equal

Counters

• Counts up or down, loads predetermined value on load signal

Linearization

• Interpolated or stepped

Logic

• And, nand, or, nor, equal, not equal, latch, ip-op

Math

• Average, process scale, switch over, deviation scale, differential (subtract), ratio

(divide), add, multiply, absolute difference, minimum, maximum, square root,

sample and hold, pressure-to-altitude and dew point

Process Value

• Sensor backup, average, crossover, wet bulb-dry bulb, switch over, differential

(subtract), ratio (divide), add, multiply, absolute difference, minimum, maximum, square