Page 1

Watlow’s F4T Combines

the Flexibility of a

Modular I/O Controller

with Best-in-Class

Ease of Use

F4T

SPECIFICATION SHEET

1

/4 DIN Process Controller

The F4T temperature process controller from Watlow® offers

a wide range of field removable I/O modules for maximum

design flexibility. Configurations can be custom tailored to

meet the scaling needs of a tremendous range of equipment

and applications while providing exactly the hardware

types required for compatibility. The F4T controller also

features a 4.3 inch, color, graphical touch panel. Combining

power, flexibility and functionality, this new controller offers

unmatched versatility, and its best-in-class ease of use could

very well make user manuals a thing of the past.

Features and Benefits

4.3-inch, color touch panel with high-resolution, graphical

user-interface

• Shortens learning curve and reduces operator errors

• Allows channels, profiles, alarms, inputs and outputs to be

personalized with user defined names

Temperature PID, data logger, trend chart,

over/under-temperature limit, power switching,

math, logic, timers and counters combined into an

integrated system

• Lowers ownership costs

• Eliminates the need for separate discrete components

• Reduces complexity

• Simplifies design, ordering and installation

• Saves money

Robust algorithms for temperature, cascade, altitude,

humidity and compressor

• Improves process control

• Offers one to four channels of control

• Provides multiple PID sets

• Enables TRU-TUNE®+ adaptive control algorithm

• Offers 40 ramp and soak profiles with real-time clock and

battery backup

COMPOSER® graphical configuration PC software

• Speeds up and simplifies commissioning

• Archives and documents controller setup

• Connects with controller easily via Ethernet

Email and text alerts

• Notifies users of an event that has occurred such as a

specific profile or step within a profile, alarm condition,

limit condition or analog input error

Batch processing with bar code data entry

• Easily collects and manages data records

• Inputs information from bar code scan for fast and easy

data entry

• Offers foolproof processing via smart profile to part linkage

• Provides data security through password and data log

encrypted file options

• Improves manufacturing robustness via reminder screens

ensuring all data is entered during processing

• Helps ensure compliance with growing regulations and

minimizes warranty exposure

• Eliminates part processing skips or walk arounds due to

improved quality control

• Produces formatted data record report for easy receipt or

record management uses

Many communications options available including Ethernet

Modbus® TCP and SCPI and EIA-232/485 Modbus® RTU

• Offers two USB host ports and one device port

• Simplifies file transfers

• Connects easily

Modular design

• Adapts quickly to evolving requirements

• Offers numerous types of field pluggable modules for

maximum flexibility and easiest compatibility

• Features scalable and modular firmware functions

• Delivers scalable input/output quantities from 1 to 36

SERIES F4S/F4D/F4P backward compatible

• Provides easy retrofit with minimum pain and disruption

• Ensures proper fit in existing SERIES F4 panel cutout

Page 2

Key Features and Options

• 1 to 4 control loops with TRU-TUNE+ adaptive

control algorithm for superior controllability

• 40 profiles for ramp and soak

• Ethernet Modbus® TCP connectivity

• Multiple high-speed USB host ports

• Over/under-temperature limits for safety shutdown

• Universal, thermistor and ac current measurement inputs

• Inputs and outputs expandable from 1 to 36

• SENSOR GUARD prevents unplanned process shutdowns and

product loss by switching to a backup sensor if the primary

sensor fails

• High current outputs for up to 10A heaters or other loads

• Programmable timers, counters, math and logic

• Temperature, cascade, altitude, relative humidity, compressor

algorithms and Vaisala® humidity compensation

• Sequencer start-up and control

• Retransmit and remote set point

• USB configuration port

• Configuration settings can be stored and recalled

• Removable modules and connectors

• Front-panel mount and flush mounting options

• Right angle and front-screw terminal options

• UL® listed, CSA, CE, RoHS, W.E.E.E., FM

• Multi-language options

• English, German, French, Italian, Spanish, Japanese, Korean

and Chinese

• USB wired or wireless mouse user interface

• Use in hazardous location, dirty environments or

applications with gloves

Common Specifications

Line Voltage/Power

• Data retention upon power failure via nonvolatile memory

Functional Operating Range

• Type J: -346 to 2192°F (-210 to 1200°C)

• Type K: -454 to 2500°F (-270 to 1371°C)

• Type T: -454 to 750°F (-270 to 400°C)

• Type E: -454 to 1832°F (-270 to 1000°C)

• Type N: -454 to 2372°F (-270 to 1300°C)

• Type C: 32 to 4200°F (0 to 2315°C)

• Type D: 32 to 4200°F (0 to 2315°C)

• Type F: 32 to 2449°F (0 to 1343°C)

• Type R: -58 to 3214°F (-50 to 1767°C)

• Type S: -58 to 3214°F (-50 to 1767°C)

• Type B: 32 to 3300°F (0 to 1816°C)

• RTD (DIN): -328 to 1472°F (-200 to 800°C)

• Process: -1999 to 9999 units

Calibration Accuracy

• Calibration accuracy and sensor conformity: ±0.1% of

span, ±1°C at the calibrated ambient temperature and

rated line voltage

• Types R, S, B: ±0.2%

• Type T below -50°C: ±0.2%

• Calibration ambient temperature at 77°F ±5°F (25°C ±3°C)

• Accuracy span: 1000°F (540°C) min.

• Temperature stability: Typical ±0.1°F/°F (±0.1°C/°C) rise in

ambient max.

Conguration Diagnostics

• Indicates if modules present match the expected

conguration settings

USB Host Port

• Total of 2 available

• Version: USB 2.0 hi-speed

• Connector: USB Type A, high-retention

• Flash drive must be FAT32 le system

• Max. current 0.5A/port

System Conguration Requirements

• F4T has 6 slots for ex modules (FM)

• EIA-232/485 Modbus® RTU ex module, if used, must occupy

slot 6 location

• A maximum of two 10A SSR FM modules can be used in the F4T

and each will require space for 2 slots. Valid in slots 1, 2, 4 or 5

Wiring Termination—Touch-Safe Terminals

• Right-angle and front-screw terminal blocks for input, output

and power supply connections

• Input, output and power terminals: touch safe, removable,

12 to 30 AWG

F4T Base Specifications

Line Voltage/Power

• High voltage option: 100 to 240VAC +10/-15%, 50/60Hz ±5%

• Low voltage option: 24 to 28VAC/VDC+10/-15%, 50/60Hz ±5%

• Power consumption: 23 W, 54VA

Environment

• NEMA 4X/IP65 front panel mount conguration only

• Operating temperature: 0 to 122°F (-18 to 50°C)

• Storage temperature: -40 to 185°F (-40 to 85°C)

• Relative humidity: 0 to 90%, non-condensing

Agency Approvals

• UL®/EN 61010 Listed, File E185611 QUYX

• UL® 508 Reviewed

• CSA CC.C#14, File 158031

• FM Class 3545 (congurations with limit modules)

• AMS 2750 E compliant: Analog input process values. Tip: Maximize

eld calibration accuracy and uniformity by using advanced F4T

features such as Calibration Oset and Linearization Function

Blocks. Refer to user manual for details.

• RoHS by design, China RoHS Level 2, W.E.E.E.

• CE

• Windows® Hardware Certication

User Interface

• 4.3 inch TFT PCAP color graphic touch screen

• LED backlife >50K hours

• 4 keys: Home, Main Menu, Back, Help

• Multiple languages

• English, German, French, Italian, Spanish, Japanese, Korean

and Chinese

• USB wired or wireless mouse functionality

• Right click for 4 keys: Home, Main Menu, Back, Help

Control Loops

• 1 to 4 PID or ON-OFF control loops

• 0 to 6 Limit loops

• User-selectable action: heat, cool or heat/cool

• Auto-tune with TRU-TUNE+ adaptive control

Control Loops and Over-temperature Limits

• Input sampling: 10Hz

• Output update: 10Hz

Communications

• Ethernet Modbus® TCP

• Isolated communications

Prole Ramp and Soak Option

• Prole engine aects 1 to 4 loops in sync

• 40 proles with 50 steps per prole

Data Logging

• User selectable parameters: Up to a maximum of 128 active

parameters depending on conguration

• Logging interval: Programmable increments between 0.1 seconds

and 60 minutes if logging to internal memory. Logging directly to

USB; 1.0 seconds to 60 minutes

• File types: .CSV for standard data logging or proprietary format for

encrypted data log option

• Storage: 80MB internal memory or to USB memory stick

• File transfer: Internal memory to USB host port or to Ethernet

Modbus® TCP

• Transfer options: On demand by user or user programmable based

on when a new data log le record is available. Utilizes TFTP and

Samba protocols

• Record: Date and time stamped

Page 3

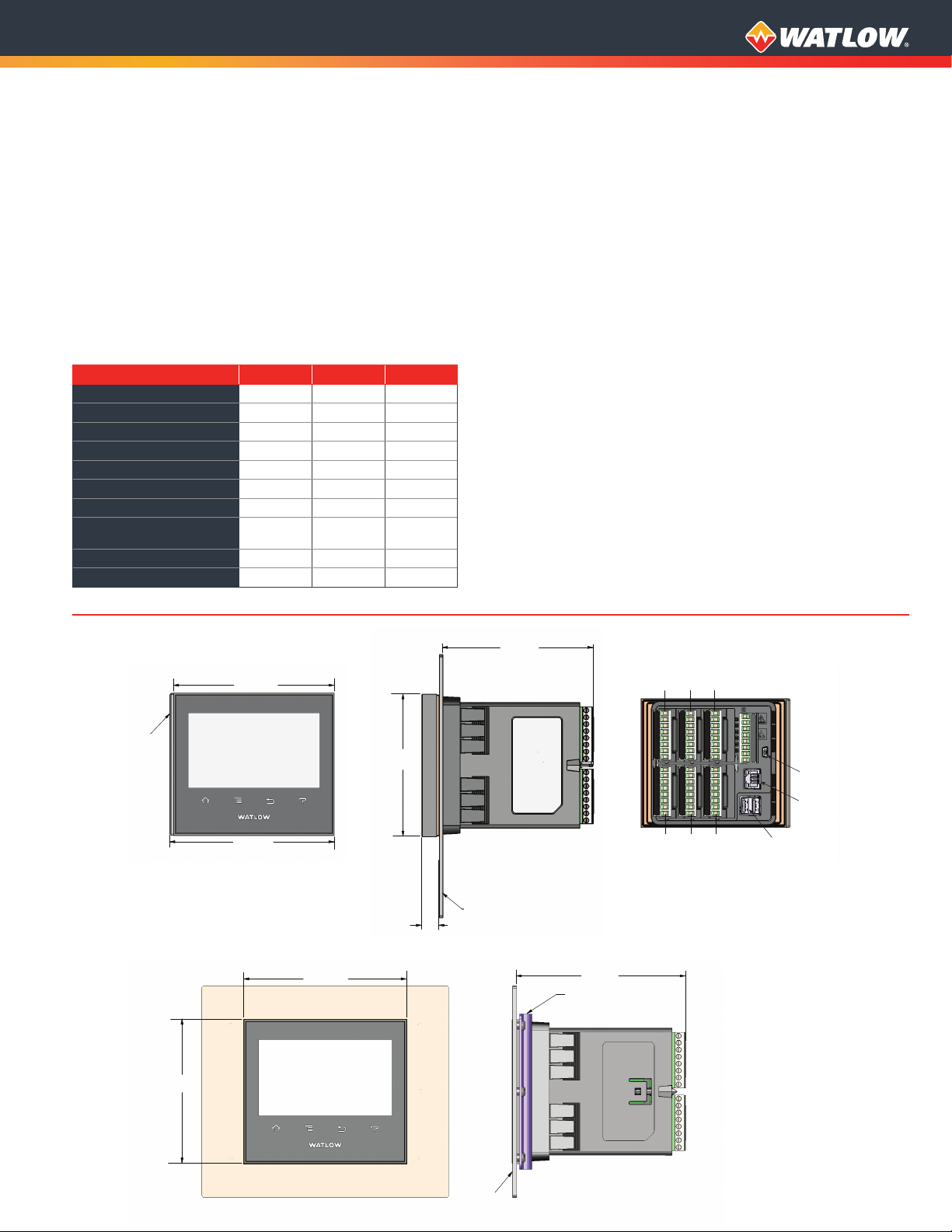

4.09 in.

(103.96 mm)

4.33 in.

(109.98 mm)

(12.7 mm)

Batch Processing with Bar Code Data Entry Via USB Scanner

• Compatible with many bar code types including Code 128,

Code 39, Extended Code 39, Data Matrix, Interleaved 2 of 5, ISSN,

SISAC, LOGMARS, QR, UCC/EAN-128 (GS1-128, UPC-A & E)

• Compatible with most USB scanner types such as Zebra DS4308,

DS2208, LI2208 and LS2208

• USB port provides 500mA max. power supply for bar code

scanner/base charging

• Display can show bar code elds up to a maximum length of

48 characters. Characters might wrap to 2 rows after 24 characters

• Part-Prole list entries – approximately 1,000 typical length part

numbers of 15 characters each can be stored. Can easily import

dierent part les via USB thumb drive connection to cover a

higher quantity range of part lists

• Program the bar code scanner to add an enter key (carriage return

feed) at the end of each bar code data eld sent to F4T/D4T. Refer

to USB scanner user manual.

Number of Function Blocks by Ordering Option

Function Block Basic Set 1 Set 2

Alarm 6 8 14

Compare None 4 16

Counter None 4 16

Linearization 4 4 8

Logic None 12 24

Math None 12 24

Process Value 4 4 8

Special Output Function

(including compressor)

Timer None 6 16

Variable 4 12 24

None 2 4

Trending

• 4 user programmable charts

• 6 pens available per chart

• View analog sensors, process values, set points and power

Real Time Clock with Battery Backup

• Accuracy (typical): +/-3ppm over -15 to 50°C

• Typical battery life: 10 years at 77°F (25°C)

• Field replaceable lithium battery

Compare

• Greater than, less than, equal, not equal, greater than or equal, less

than or equal

Counters

• Counts up or down, loads predetermined value on load signal

Linearization

• Interpolated or stepped

Logic

• And, nand, or, nor, equal, not equal, latch, ip-op

Math

• Average, process scale, switch over, deviation scale,

dierential (subtract), ratio (divide), add, multiply, absolute

dierence, minimum, maximum, square root, sample and hold,

pressure-to-altitude and dew point

Process Value

• Sensor backup, average, crossover, wet bulb-dry bulb, switch over,

dierential (subtract), ratio (divide), add, multiply, absolute

dierence, minimum, maximum, square root, altitude, Vaisala®

relative humidity and pressure-to-altitude

Special Output Function

• Compressor control (cool and/or dehumidify with single

compressor), motorized valve, sequencer

Timers

• On pulse, delay, one shot or retentive

Variable

• User value for digital or analog variable

Panel Mount Dimensions

4.62 in.

(117.4 mm)

Accent

Bar

4.73 in.

(120.14 mm)

Flush Mount Dimensions

4.09 in.

(103.96 mm)

4.62 in.

(117.4 mm)

4.09 in.

(103.96 mm)

0.50 in.

4.33 in.

(109.98 mm)

Slot 1

Slot 2 Slot 3

Slot 4

Slot 5 Slot 6

Mounting Panel

4.81 in.

(122.1 mm)

Flushmount Bracket

USB Type A

(Quantity 2)

USB Mini B

Ethernet

Mounting

Panel

Page 4

F4T Base Ordering Information

Base includes: 4.3 inch color graphical touch panel, 2 USB hosts, USB configuration port, standard bus, Ethernet Modbus® TCP.

SCPI protocol and backwards compatible Modbus® for select key SERIES F4D/P/S parameters.

Part Number

① ②

F4

③

Base

Type

T

④

Application

Type

⑤

Data

Logging

⑥

Power Supply

Connector &

Voltage, Logo

⑦

Profiles &

Function

Blocks

⑧ ⑨

Future

Options

A A

⑩ ⑪

Documentation, Accent

Bar, Replacement

Connector & Custom

⑫

Control

Algorithms

⑬ ⑭ ⑮

Populated

Flex Modules

③

T = Touch screen

④

1 = Standard

X = Custom options, contact factory

⑤

A = None

B =

Graphical trend chart

J =

Data logging

K =

Data logging with encrypted les

L =

Data logging with graphical trend chart

Data logging with encrypted les, graphical trend charts

M =

and batch processing with bar code data entry.

①

Must also order digit 7: Profiles option D, E or F for batch

processing with bar code data entry feature to be enabled.

⑥

1 =

100 to 240VAC Right angle (standard) Yes

2 =

100 to 240VAC Right angle (standard) No

3 =

100 to 240VAC Front screw Yes

4 =

100 to 240VAC Front screw No

5 =

24 to 28VAC or VDC Right angle (standard) Yes

6 =

24 to 28VAC or VDC Right angle (standard) No

7 =

24 to 28VAC or VDC Front screw Yes

8 =

24 to 28VAC or VDC Front screw No

⑦

A =

B =

C =

D =

E =

F =

Note: Refer to top of page 3 “Number of Function Blocks by

Ordering Option”

in each set.

⑧ ⑨

AA =

Future Options

Data Logging and Graphic Trend Charts

Power Supply Connector & Voltage, Logo

Power Supply

Proles Function Blocks

40 Profiles, Battery

None

X X

X X

X X

Backup and

Real-Time Clock

for quantities and types of functions blocks

Base Type

Application Type

Power Supply

Connector

Profiles & Function Blocks

Basic

Set

X X

X X

X X

Future Options

Set 1 Set 2

①

Watlow

Logo

⑩ ⑪

1A =

1B =

1C =

1D =

1E =

1F =

1G =

1H =

1J =

XX =

⑫

1 =

2 =

3 =

4 =

5 =

6 =

7 =

8 =

9 =

A =

B =

C =

Note: Each control loop algorithm requires 1 universal or thermistor

input from a flex module.

Note: Each cascade loop algorithm requires 2 universal or thermistor

inputs from flex modules.

⑬ ⑭ ⑮

AAA =

XXX =

Note: If AAA is selected you will need to order Flex Modules (FM)

next to account for input and output hardware.

Documentation, Accent Bar, Replacement

Documentation

DVD / QSG

Yes X

Yes X

Yes X

Yes X

No X

No X

No X

No X

Replacement connectors only - for the model number

entered

Contact factory, other custom-firmware, preset parameters,

locked code, logo

Control Loop Cascade Loop

No populated flex modules

Contact factory - Populated flex modules

Connector & Custom

Decorated Brush Aluminum

Accent Bar

Gray Blue Red None

Control Algorithms

1 0

2 0

3 0

4 0

0 0

0 1

1 1

2 1

3 1

0 2

1 2

2 2

Populated Flex Modules

Page 5

Flex Modules—High Density I/O Specifications

0 5 10

15

20

25

30

35

40

45

50

Four Universal Inputs (Control Loops, Auxiliary Input)

• Thermocouple: grounded or ungrounded sensors, greater than

20MΩ input impedance, 2kΩ source resistance max.

• RTD: 2-wire, platinum, 100Ω and 1000Ω at 32°F (0°C) calibration to

DIN curve (0.00385Ω/Ω/°C)

• Process: 0-20mA at 100Ω, or 0-10VDC, 0-50mVDC at 20kΩ input

impedance; scalable

• Potentiometer: 0 to 1,200Ω

• Inverse scaling

Four Thermistor Inputs (Control Loops, Auxiliary Input)

• 0 to 40kΩ, 0 to 20kΩ, 0 to 10kΩ, 0 to 5kΩ

• 2.252kΩ and 10kΩ base at 77°F (25°C)

• Preprogrammed Steinhart-Hart coecients for Alpha Techniques

(A curve 2.252k and 10k, C curve 10k), BetaTHERM (2.2K3A, 10K3A

and 10K4A) and YSI (004, 016 and 006)

• User-settable Steinhart-Hart coecients for other thermistors

Three Universal Process/Retransmit Outputs

• Output range selectable

• 0 to 10VDC ±15mV into a min. 4,000Ω load with 2.5mV nominal

resolution

• 0 to 20mA ±30μA into max. 400Ω load with 5μA nominal resolution

• Temperature stability 100ppm/°C

Three Mechanical Relays

• 2 Form C relays, 1 Form A relay. Form A relay shares common with

1 Form C relay

• Each relay is 5A, 24 to 240VAC or 30VDC max., resistive load,

100,000 cycles at rated load. Requires a min. load

of 20mA at 24V, 125VA pilot duty 120/240VAC, 25VA at 24VAC

Four Mechanical Relays

• Form A, 5A ea., 24 to 240VAC or 30VDC max., resistive load, 100,000

cycles at rated load. Requires a min. load of 20mA at 24V, 125VA

pilot duty

Two Solid State Relays

• Form A, 10A max. each SSRs combined at 24VAC min.,

264VAC max., opto-isolated, without contact suppression,

max. resistive load 10A per output at 240VAC, max. 20A per

card at 122°F (50°C), max.

Four Solid State Relays

• Two pairs of SSRs, each pair shares a common

• Form A, 24VAC min., 264VAC max., opto-isolated, without contact

suppression, resistive load 2A per output at 240VAC, max. See table

for max. current per output

Quad 2A SSR Card Derating Curves

2.2

2

1.8

1.6

1.4

1.2

1

Amps Current for each SSR

0.8

0.6

0.4

Ambient Temperature

°C

F4T with 2 ex modules,

1 quad input module and

1 quad 2A SSR module.

Only outputs 1 and 3 ON.

F4T with 2 ex modules,

1 quad input module and

1 quad 2A SSR module. All

4 SSR’s output ON.

F4T with 5 ex modules,

slot below quad 2A SSR

left vacant.

F4T with 6 ex modules,

1 quad 2A SSR card.

Six Digital I/O

• Each independently congurable as input or output

• Dry contact input: update rate 10Hz, min. open resistance 10kΩ,

max. closed resistance 50Ω, max. short circuit 13mA

• DC voltage input: update rate 10Hz, max. input 36V at 3mA, min.

high state 3V at 0.25mA, max. low state 2V

• Switched dc output: max. 5VDC at 130mA, or 19-22VDC at 80mA;

eld selectable

• Open collector output: 32VDC at 1.5A max., 8A max. per 6 outputs

combined

F4T Flex Module—High Density I/O Ordering Information

Part Number

① ②

FM

③

Module ID

Type

H

④

Future

Option

A

③

H = High Density I/O

④

A = Future Option

⑤

R =

4 universal inputs (T/C, RTD 2-wire, 0-10VDC, 0-20mA)

P =

4 thermistor inputs

C =

6 digital I/O

F =

3 universal process/retransmit outputs

3 mechanical relay 5A, 2 Form C and 1 Form A (Form A

B =

Input and Output Hardware

shares a common with one Form C)

J =

4 mechanical relay 5A, Form A

K =

2 SSRs 10A

4 SSRs at 2A each. SSRs grouped in 2 pairs with each pair

L =

①

sharing a common

①

Notes: Input and Output hardware option K: 2 SSR’s 10A.

The 2 SSR’s 10A FM module requires 2 F4T slots. Valid slot locations

are 1, 2, 4 or 5.

The F4T can support a maximum of two total of the K option FM

module types (4 total SSR, 10A).

⑤

⑥ ⑦ ⑧

Input and

Output

Hardware

– –

Future

Options

AAA

Module ID Type

Future Option

⑨

Future

Option

A

⑩

Custom

Options and

Connectors

Firmware, Overlay, Preset

Parameters, Locked Code

⑥ ⑦ ⑧

AAA = Future Options

⑨

A = Future Option

⑩

A =

Right angle screw connector (standard)

F =

Front screw connector

⑪ ⑫

AA =

Standard with quick start guide

AB =

Standard without quick start guide

Replacement connectors hardware only - for the entered

AC =

model number

XX =

Custom

⑪ ⑫

Custom Options-

Future Options

Future Option

Custom Options and Connectors

Custom Options - Firmware, Overlay, Preset

Parameters, Locked Code

Page 6

Flex Modules—Mixed and Limit I/O Specifications

Universal Input

• Thermocouple: grounded or ungrounded sensors, greater than

20MΩ input impedance, 2kΩ source resistance max.

• RTD: 2- or 3-wire, platinum, 100Ω and 1000Ω at 32°F (0°C)

calibration to DIN curve (0.00385Ω/Ω/°C)

• Process: 0-20mA at 100Ω, or 0-10VDC, 0-50mVDC at 20kΩ input

impedance; scalable

• Potentiometer: 0 to 1,200Ω

• Inverse scaling

Thermistor Input

• 0 to 40kΩ, 0 to 20kΩ, 0 to 10kΩ, 0 to 5kΩ

• 2.252kΩ and 10kΩ base at 77°F (25°C)

• Preprogrammed Steinhart-Hart coecients for Alpha Techniques

(A curve 2.252k and 10k, C curve 10k), BetaTHERM (2.2K3A, 10K3A

and 10K4A) and YSI (004, 016 and 006)

• User-settable Steinhart-Hart coecients for other thermistors

Temperature Input

• Thermocouple: grounded or ungrounded sensors, greater than

20MΩ input impedance, 2kΩ source resistance max.

• RTD: 2-wire, platinum, 100Ω and 1000Ω at 32°F (0°C) calibration

to DIN curve (0.00385Ω/Ω/°C)

Digital Input

• Update rate: 10Hz

• DC voltage: max. input 36V at 3mA, min. high state 3V at 0.25mA,

max. low state 2V

• Dry contact input: min. open resistance 10kΩ, max. closed

resistance 50Ω, max. short circuit 13mA

Current Transformer Input

• Accepts 0-50mA signal (user programmable range)

• Displayed operating range and resolution can be scaled and are

user programmable

• Current input range: 0 to 50mA ac, 100Ω input impedance

• Response time: 1 second max., accuracy ±1mA typical

• Use with current transformer (Watlow part number:

16-0246)

Switched DC Output

• Max. 32VDC open circuit

• Max. current 30mA per single output

• Max. current 40mA per pair

Open Collector Output

• Max. 30VDC at 100mA

Solid State Relay (SSR) Output

• Form A, 1A at 50°F (10°C) to 0.5A at 149°F (65°C), 0.5A at 24VAC min.,

264VAC max., opto-isolated, without contact suppression

Form A Electromechanical Relay Output

• 5A, 24 to 240VAC or 30VDC max., resistive load, 100,000 cycles at

rated load, requires a min. load of 20mA at 24V, 125VA pilot duty

Form C Electromechanical Relay Output

• 5A, 24 to 240VAC or 30VDC max., resistive load, 100,000 cycles at

rated load, requires a min. load of 20mA at 24V, 125VA pilot duty

NO-ARC Relay Output

• Form A, 12A at 122°F (50°C), 85 to 264VAC, no VDC, resistive load,

2 million cycles at rated load

Universal Process/Retransmit Output

• Range selectable

• 0 to 10VDC ±15mV into a min. 1,000Ω load with 2.5mV nominal

resolution

• 0 to 20mA ±30μA into max. 800Ω load with 5μA nominal resolution

• Temperature stability 100ppm/°C

Page 7

F4T Flex Module—Mixed I/O Ordering Information

Part Number

① ②

③

④

⑤

⑥ ⑦

⑧

⑨

Output

Future

Option

A

–

Future

Option

A

FM

③

Module ID

Type

M

Future

Option

A

Input

Hardware

–

Module ID Type

Hardware

Options

M = Mixed I/O

④

Future Option

A = Future Option

⑤

A =

None

U =

Universal input - T/C, RTD 2- or 3-wire, 0-10VDC, 0-20mA

T =

Thermistor input

C* =

*

Outputs 1 & 2: FA, FC, FJ and FK.

Current transformer input

Note: If option C is ordered than the following options are NOT valid for

⑥ ⑦

Input Hardware

Output Hardware Options

Output 1 Output 2

AA =

None

AJ =

None Mechanical relay 5A, Form A

AK =

None SSR Form A, 0.5A

CA =

Switched dc/open collector None

CH =

Switched dc/open collector NO-ARC 12A power control

CC =

Switched dc/open collector Switched dc

CJ =

Switched dc/open collector Mechanical relay 5A, Form A

CK =

Switched dc/open collector SSR Form A, 0.5A

EA =

Mechanical relay 5A, Form C None

EH =

Mechanical relay 5A, Form C NO-ARC 12A power control

EC =

Mechanical relay 5A, Form C Switched dc

EJ =

Mechanical relay 5A, Form C Mechanical relay 5A, Form A

EK =

Mechanical relay 5A, Form C SSR Form A, 0.5A

FA =

Universal process/retransmit None

FC =

Universal process/retransmit Switched dc

FJ =

Universal process/retransmit Mechanical relay 5A, Form A

FK =

Universal process/retransmit SSR Form A, 0.5A

KH =

SSR Form A, 0.5A NO-ARC 12A power control

KK =

SSR Form A, 0.5A SSR Form A, 0.5A

None

F4T Flex Module—Limit Ordering Information

Part Number

① ②

③

④

⑤ ⑥ ⑦

Input and

Output Hardware

Options

–

Module ID Type

FM

③

Module ID

Type

L

Future

Option

A

L = Limit

④

Future Option

A = Future Option

⑤⑥⑦

Limit control

with universal

LCJ =

input

Limit control

with universal

LEJ=

input

Limit control

with universal

LAJ =

input

Limit control

YEB =

with thermistor

input

Limit control

with thermistor

input

Limit control

with thermistor

input

Limit control

with temperature input

MCJ =

MEJ =

MAJ =

Notes: Universal input = T/C, RTD 2- or 3-wire, 0-10VDC, 0-20mA

Temperature input = T/C and RTD 2-wire only

Input and Output Hardware Options

Functions

Auxiliary Output

Hardware

Switched dc/

open collector

Mechanical

relay 5A,

Form C

None Mechanical

Switched dc/

open collector

Mechanical

relay 5A,

Form C

None Mechanical

None Mechanical

Limit Output

Mechanical

relay 5A,

Form A

Mechanical

relay 5A,

Form A

relay 5A,

Form A

Mechanical

relay 5A,

Form A

Mechanical

relay 5A,

Form A

relay 5A,

Form A

relay 5A,

Form C

Hardware

⑧

Future

Option

A

⑨

Future

Option

A

–

Auxiliary Input

Hardware

None

None

None

None

None

None

Single digital

input (limit

reset)

Custom

Options and

Connectors

⑩

Custom

Options and

Connectors

⑧

A = Future Option

⑨

A = Future Option

⑩

A =

Right angle screw connector (standard)

F =

Front screw connector

⑪ ⑫

AA =

AB =

AC =

XX =

Custom Options - Firmware, Overlay, Preset

Standard with quick start guide

Standard without quick start guide

Replacement connectors hardware only - for the entered

model number

Custom

⑩

Custom Options-

Firmware, Overlay, Preset

Parameters, Locked Code

⑧

A = Future Option

⑨

A = Future Option

⑩

A =

Right angle screw connector (standard)

F =

Front screw connector

⑪ ⑫

AA =

AB =

AC =

XX =

Custom Options - Firmware, Overlay, Preset

Standard with quick start guide

Standard without quick start guide

Replacement connectors hardware only - for the entered

model number

Custom

⑪ ⑫

Custom Options-

Firmware, Overlay, Preset

Parameters, Locked Code

Future Option

Future Option

Custom Options and Connectors

Parameters, Locked Code

⑪ ⑫

Future Option

Future Option

Custom Options and Connectors

Parameters, Locked Code

Page 8

F4T Flex Modules—Communication Ordering Information

Part Number

① ②

FM

③

C = Communications

④

A = Future Option

⑤

2 =

Notes: EIA-232/485 Modbus® RTU flex module, if used, must occupy

F4T slot 6 location.

⑥ ⑦ ⑧

AAA = Future Options

③

Module ID

Type

C

Modbus® RTU 232/485

④

Future

Option

A

–

Communications Option

Comm.

Option

Module ID Type

Future Option

Future Options

⑤

⑥ ⑦ ⑧

Future

Options

2

AAA

–

⑨

Future

Option

A

⑩

Custom

Options and

Connectors

Custom Options-

Firmware, Overlay, Preset

Parameters, Locked Code

⑨

A = Future Option

⑩

A =

Right angle screw connector (standard)

F =

Front screw connector

⑪ ⑫

AA =

Standard with quick start guide

AB =

Standard without quick start guide

Replacement connectors hardware only - for the entered

AC =

model number

XX =

Custom

⑪ ⑫

Future Option

Custom Options and Connectors

Custom Options - Firmware, Overlay, Preset

Parameters, Locked Code

Accessories

Part Number Description

0830-0870-0000 Protective screen cover (2 per pack)

1

F4T

0822-0705-0000

0216-1285-0000 Flush mount - mounting adapter plate

0847-0400-0000 USB 2.0 to RJ45 Ethernet adapter

0238-1245-ALUM Accent bar (brushed aluminum gray)

0238-1245-REDD Accent bar (brushed aluminum red)

0238-1245-BLUE Accent bar (brushed aluminum blue)

16-0246 Current transformer

0804-0147-0000 RC suppression - Quencharc®

0601-0001-0000 Controller support tools (DVD)

0830-0808-0001

(CAPUSB-MB5)

0830-0808-0002

(CAPUSB-A)

0830-0858-0000 Replacement battery

0822-0769-0000

/4 DIN mounting collar - thru front

panel mount

Rubber plug USB mini

Rubber plug USB host

Module slot plug (for vacant F4T slots

without ex modules

Recommended Third-Party Components

Mfg.

Amphenol USBF 21N SCC

Amphenol

Amphenol RJF 21N SCC

Molex 847290006

Molex 84700-0003 Dust cover www.alliedelec.com

Mfg. Part

Number Description Website

USB - A receptacle

USBBF 21N SCC

with self closing

cap

USB - B receptacle

with self closing

cap

RJ45 receptacle

with self closing

cap

USB type A panel

mount with 2 m

cord

www.alliedelec.com

www.alliedelec.com

www.alliedelec.com

www.alliedelec.com

Documentation

Part Number Description

1720-6742

1680-2414 Setup and Operations User Guide

1440-3329 F4T Controller Quick Start Guide

0600-0095-0000

0600-0096-0000

0600-0097-0000 Mixed I/O Flex Modules Quick Start Guide

Installation and Troubleshooting

User Guide

Communications Flex Modules Quick

Start Guide

High Density Flex Modules Quick

Start Guide

Watlow®, TRU-TUNE®, and COMPOSER® are registered trademarks of Watlow Electric

Manufacturing Company.

UL® is a registered trademark of Underwriter’s Laboratories Incorporated.

Modbus® is a registered trademark of Schneider Automation Incorporated.

Vaisala® is a registered trademark of Vaisala OY Corporation.

Microsoft® and Windows® are registered trademarks of the Microsoft Corporation.

Quencharc® is a registered trademark of ITW Paktron.

Powered by Possibility

To be automatically connected to the nearest

North American Technical Sales Oce:

1-800-WATLOW2 • www.watlow.com

©2020 Watlow Electric Manufacturing Company all rights reserved.

International Technical Sales Offices:

Austria +43 6244 20129 0

China +86 21 3532 8532

France +33 1 41 32 79 70

Germany +49 7253 9400 0

India +91 40 6661 2700

Italy +39 02 458 8841

Japan +81 3 3518 6630

Korea +82 2 2169 2600

Mexico +52 442 256 2200

Singapore +65 6773 9488

Spain +34 91 675 1292

Taiwan +886 7 288 5168

UK +44 115 964 0777

WIN-F4T-0120

Loading...

Loading...