Page 1

ISO 9001

ISO 9001

ER

TISFFAACTCTIIOONN

F4T® Controller

Setup and Operations

User’s Guide

TOTAL

CUCUSSTTOOMMER

SSAATIS

3 Year Warranty

Registered Company

Winona, Minneso ta USA

1241 Bundy Boulevard., Winona, Minnesota USA 55987

Phone: +1 (507) 454-5300, Fax: +1 (507) 452-4507

https://www.watlow.com/f4t

1680-2414 Rev. D Made in the U.S.A.

February 2021

Page 2

Return Material Authorization (RMA)

1. Call Watlow Customer Service, (507) 454-5300, for a Return Material Authorization

(RMA) number before returning any item for repair. If you do not know why the product

failed, contact an Application Engineer or Product Manager. All RMA’s require:

• Ship-to address

• Bill-to address

• Contact name

• Phone number

• Method of return shipment

• Your P.O. number

• Detailed description of the problem

• Any special instructions

• Name and phone number of person returning the product.

2. Prior approval and an RMA number from the Customer Service Department is required

when returning any product. Make sure the RMA number is on the outside of the carton

and on all paperwork returned. Ship on a Freight Prepaid basis.

3. After we receive your return, we will examine it to verify the reason for the product

failure. Unless otherwise agreed to in writing, Watlow's standard warranty provisions,

which can be located at https://www.watlow.com/terms, will apply to any failed product.

4. In the event that the product is not subject to an applicable warranty, we will quote

repair costs to you and request a purchase order from you prior to proceeding with the

repair work.

5. Watlow reserves the right to charge for no trouble found (NTF) returns.

Technical Assistance

If you encounter a problem with your Watlow controller, review your configuration information

to verify that your selections are consistent with your application: inputs, outputs, alarms,

limits, etc. If the problem persists, you can get technical assistance from your local Watlow

representative (see the Appendix in this User's Guide), by e-mailing your questions to

wintechsupport@watlow.com or by dialing +1 (507) 494-5656 between 7 a.m. and 5 p.m.,

Central Standard Time (CST). Ask for for an Applications Engineer. Please have the

following information available when calling:

• Complete model number • User’s Guide • All configuration information

Warranty

This product is warranted by Watlow for a period of 36 months in accordance with the

terms and conditions set forth on Watlow's website which can be accessed at

https://www.watlow.com/terms.

Watlow F4T® • 2 • Chapter 1 Overview

Page 3

Table of Contents

TC

Return Material Authorization (RMA) .............................2

Technical Assistance .........................................2

Warranty ....................................................2

Table of Contents .........................................3

Safety Instructions ........................................6

Chapter 1: Overview .......................................7

Available F4T® Literature and Resources ............................7

Your Comments are Appreciated ...................................7

Document Overview and Purpose ................................7

®

A Conceptual View of the F4T

Inputs .....................................................9

Functions ..................................................9

Outputs ....................................................0

What is a Profile ............................................ 10

Data Logging ..............................................10

Chapter 2: Composer® Software ..............................11

Installing Composer® Software .................................. 11

Using Composer® Software ....................................12

Overview Screen ............................................14

Device Details ...............................................19

Configuring Pluggable Flex Modules .............................. 20

Configuring the Application using the Function Block Diagram .........22

Personalizing the User Interface (UI) Using Composer

Setting Up Data Log Files Using Composer

Creating and Editing Profiles Using Composer

System ............................8

® ..............29

® .......................29

® ....................36

Chapter 3: Using the F4T® Front Panel ..........................44

Navigating and Understanding the User Interface (UI) ................44

Front Panel Navigational Buttons ...............................44

Understanding F4T® Menus ..................................45

Multiple Languages .........................................46

Event Driven Menus .........................................47

Home Screen Described .....................................48

Configuring Ethernet Communications ............................49

Default Ethernet Parameters and Settings ........................49

Personalizing the Home Screen Using the UI .......................50

Front Panel Usage From the Home Screen ........................52

Creating a Profile ...........................................52

Profile Actions From the Home Screen ..........................53

Watlow F4T® Controller • 3 • Table of Contents

Page 4

Table of Contents (cont.)

TC

Starting a Profile Using the Calendar ............................54

Changing Loop Operational Parameters .........................55

Using the Output Widget .....................................55

Data Logging ................................................56

Batch Processing Programming - Batch Menu ......................58

Export Data Log Report via USB Stick ..........................62

Adding a Part Profile List using a PC ............................63

F4T® with the USB Mouse Feature ..............................65

Transferring Data Log Files via the UI ............................. 66

Flashing the Controller Firmware ................................66

Email and Text Alerts ..........................................68

Step 1: Email Server Settings ................................69

Step 2: Send an Alert Test Message ............................70

Step 3: Defining Contacts ...................................71

Step 4: Configuring Alerts ...................................72

Chapter 4: Application Examples ..............................77

Applications .................................................77

Single Loop Control .........................................77

Heat and Cool Control Loop ..................................78

Process Alarm .............................................80

Deviation Alarm ............................................81

Safety Limit ...............................................82

Sensor Backup .............................................83

Profile Ramp and Soak ......................................84

Cascade Control ...........................................85

Compressor Control .........................................87

Chapter 5: Function Block Reference ...........................89

F4T® Functions Described .....................................92

Alarm .....................................................93

Analog Outputs .............................................100

Cascade ..................................................102

Compare .................................................. 117

Control Loop ...............................................121

Counter ................................................... 134

Current Input ...............................................137

Digital Input ................................................139

Digital Inputs/Outputs (I/O) ....................................140

Digital Outputs .............................................. 143

Key ......................................................145

Watlow F4T® Controller • 4 • Table of Contents

Page 5

Table of Contents (cont.)

TC

Limit .....................................................147

Limit Output ................................................ 148

Linearization ............................................... 148

Logic .....................................................154

Math .....................................................163

Profile. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

Process Value ..............................................182

Special Output .............................................. 193

Temperature Input ...........................................198

Thermistor Input ............................................201

Timer .....................................................204

Universal Input ............................................210

Variable ...................................................221

Chapter 6: Communications ................................224

Communications ............................................. 224

Watlow Supplied Software and HMI .............................. 224

Protocols Standard Bus ........................................ 225

Introduction to Standard Commands for Programmable Instruments (SCPI) .... 2

SCPI Command List ......................................... 226

Introduction to the Modbus Protocol ............................. 229

EtherNet/IP ..... .

EtherNet/IP Fundamentals .................................... 23

Setting up implicit data tables in Composer ....................... 23

...........................................232

26

2

3

Adding device to RSLogix 5000 ................................ 23

Interpreting the data ......................................... 237

Explicit Communications ......

EtherNet/IP Summary .......

Troubleshooting ............................................. 24

Chapter 7: Appendix ..................................... 243

F4T® Base Specifications ..................................... 243

Declaration of Conformity ....... .............................. 2

How to Reach Us ........................................... 248

................................ 240

................................ 241

5

2

46

Watlow F4T® Controller • 5 • Table of Contents

Page 6

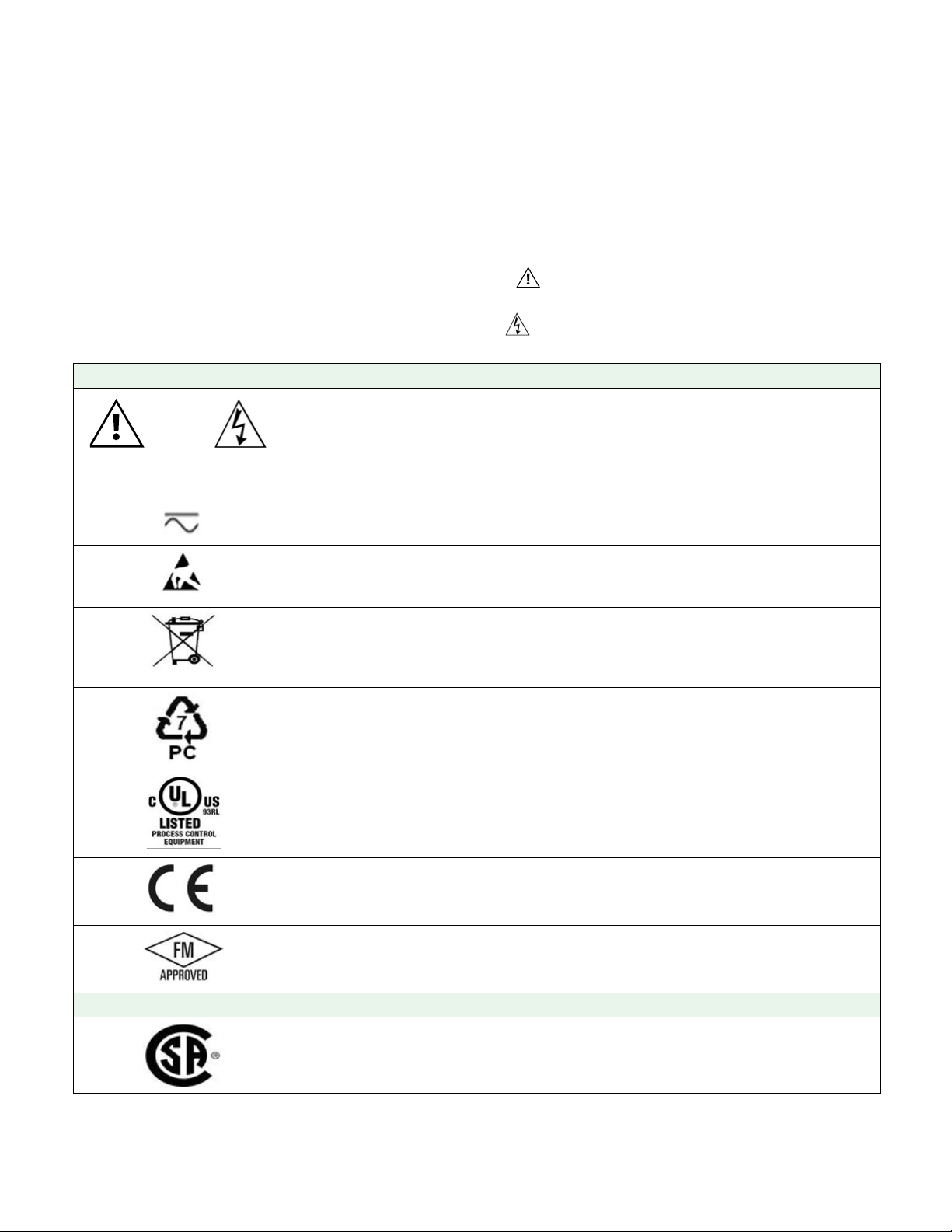

Safety Information

We use note, caution and warning symbols throughout this document to draw your attention to important

operational and safety information.

A “NOTE” marks a short message to alert you to an important detail.

A “CAUTION” safety alert appears with information that is important for protecting your equipment and

perfomance. Be especially careful to read and follow all cautions that apply to your application.

A “WARNING” safety alert appears with information that is important for protecting you, others and equipment

from damage. Pay very close attention to all warnings that apply to your application.

The safety alert symbol, (an exclamation point in a triangle precedes a general CAUTION or WARNING

statement.

The electrical hazard symbol, (a lightning bolt in a triangle

WARNING safety statement. Further explanations follow:

Symbol Explanation

CAUTION: Warning or Electrical Hazard that needs further explanation than label

on unit can provide. Consult QSG for further information.

CAUTION

WARNING

Electrical

or

Shock Hazard

AVERTISSEMENT: mise en garde ou danger qui demande plus de

précisions que l’information sur l’étiquette de l’unité. Consultez le

manuel de l’utilisateur pour plus d’informations.

Unit can be powered with either alternating current (ac) voltage or direct current

(dc) voltage.

ESD Sensitive product, use proper grounding and handling techniques when

installing or servicing product.

Do not throw in trash, use proper recycling techniques or consult manufacturer for

proper disposal.

Enclosure made of Polycarbonate material. Use proper recycling techniques or

consult manufacturer for proper disposal.

precedes an electric shock hazard CAUTION or

Unit is a Listed device per Underwriters Laboratories®. It has been evaluated to

United States and Canadian requirements for Process Control Equipment. CSA

22.2#14, File 158031, UL 61010, File E185611 QUYX, QUYX7. See: www.ul.com

Unit is compliant with European Union directives. See Declaration of Conformity

for further details on Directives and Standards used for Compliance.

Unit has been reviewed and approved by Factory Mutual as a Temperature Limit

Device per FM Class 3545 standard. See: www.fmglobal.com

Symbol Explanation

Unit has been reviewed and approved by CSA International for use as

Temperature Indicating-Regulating Equipment per CSA C22.2 No. 24.

See: www.csa-international.org

Page 7

1

Chapter 1: Overview

Available F4T® Literature and Resources

Document Title and Part Number Description

F4T Installation and Troubleshooting

User Guide, part number:

0600-0092-0000

F4T Specification Sheet, part

®

number: WIN-F4T

Watlow Application Guide

Watlow Support Tools DVD, part

number: 0601-0001-0000

To acquire one or more of these documents navigate to the Watlow website where you will

have a choice to download free copies or purchase printed versions. Click on the link below to

find your document of choice: https://www.watlow.com/literature/index.cfm

-0419

Provides detailed specifications and information

regarding mounting the F4T® base, flex module

wiring and troubleshooting.

Describes F4T hardware options, features, benefits

and technical specifications.

Comprehensive guide to understanding thermal

principles, electrical noise, best practises for wiring

industrial controls and much more.

Contains all product related user documents and

software (Composer™), video tutorials, application

notes and more.

Your Comments are Appreciated

In an effort to continually improve our technical literature and ensuring that we are providing

information that is useful to you, we would very much appreciate your comments and

suggestions. Please send any comments you may have to the following email address:

TechlitComments@watlow.com

Document Overview and Purpose

This document looks deeper at the system configuration using Composer™ software and the

F4T® function blocks and their associated connections. Common product usage is described

and illustrated through application examples.

Watlow F4T® • 7 • Chapter 1 Overview

Page 8

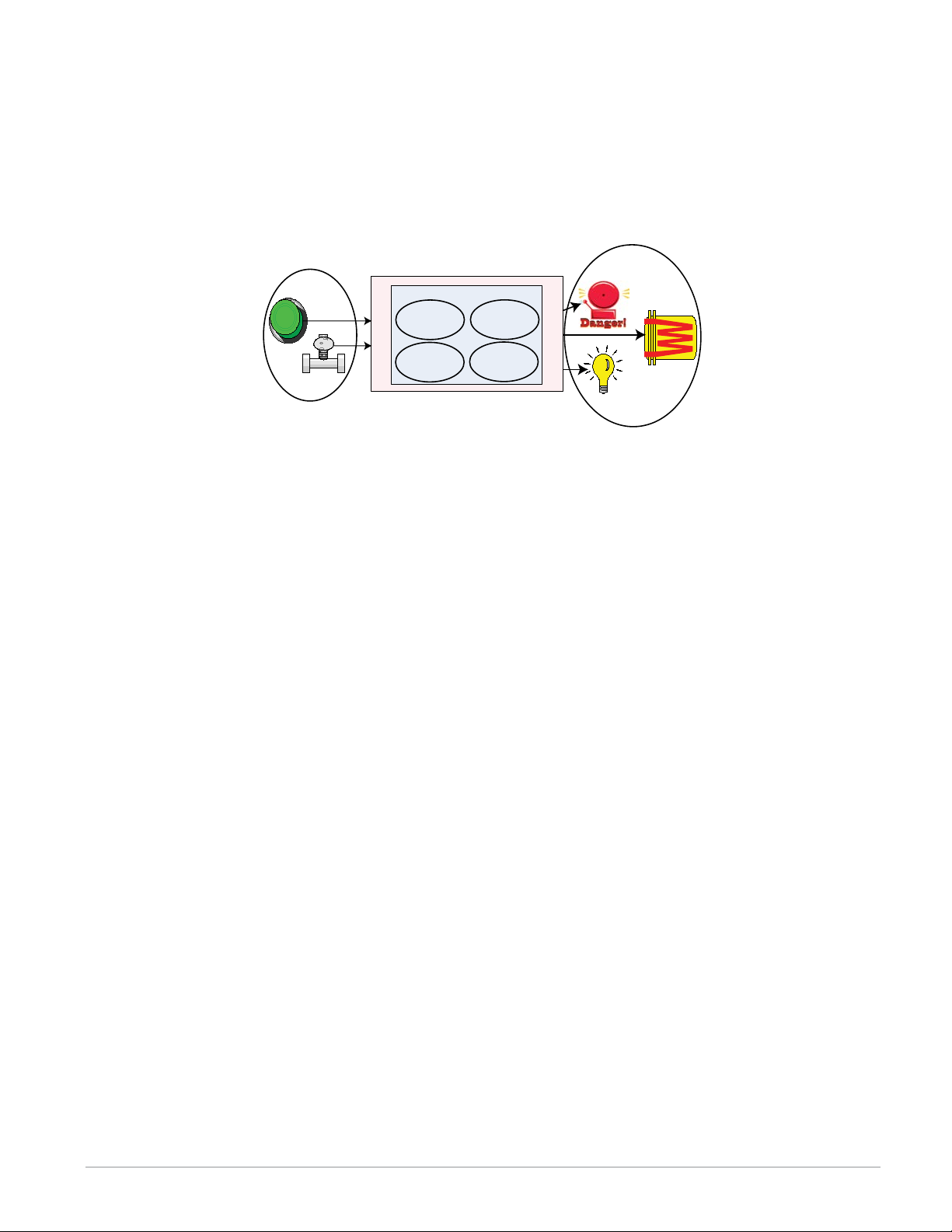

A Conceptual View of the F4T

®

System

The flexibility of the F4T® controller hardware and software (Composer™) allows for a large

range of configurations. Composer software is a graphically based tool used to program the

®

F4T

controller in its entirety. To learn more about installing and using Composer software see

Chapter 2 of this document in the section titled "Installing Composer Software".

Acquiring a better understanding of the controller’s overall functionality and capabilities while at

the same time planning out how the controller can be used will deliver maximum effectiveness

in your application.

Outputs

Inputs

Functions

PID

Heat

Power

Silence

Alarms

Process

Alarm

High

Sequencing

Outputs

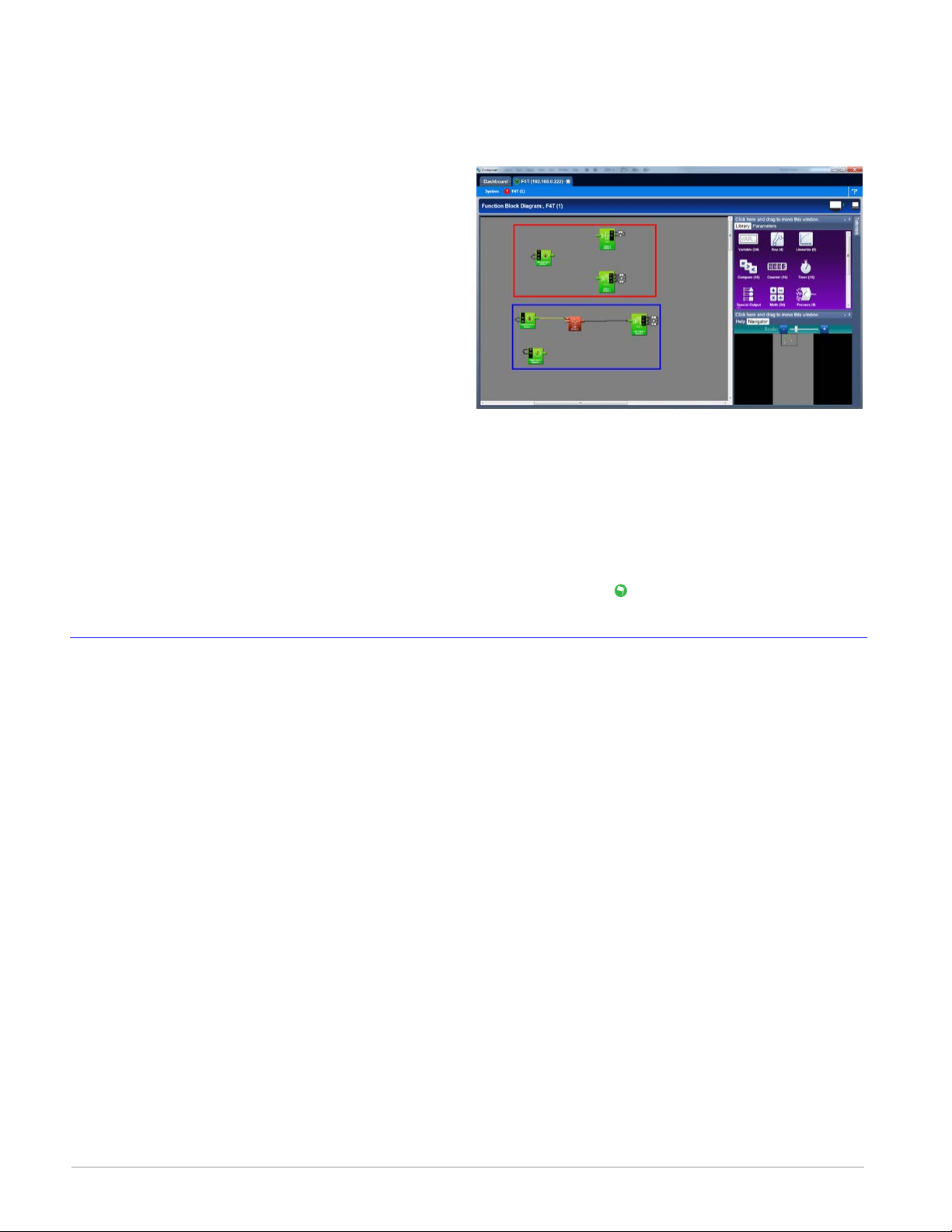

It is useful to think of the controller in three parts: inputs, functions and outputs. For the control

itself, information flows from an input to a function to an output when the controller is properly

configured. The F4T

®

system can carry out several functions at the same time; such as,

monitoring and acting upon various inputs (temperature sensing devices, pressure transducers

and digital inputs), PID control, monitoring for several different alarm situations and then driving

output devices such as heaters, audible alarms, and lights. Each process needs to be thought

out carefully and the controller’s inputs, functions and outputs set up properly. As an example,

the graphic below illustrates the Function Block Diagram as seen when using Composer

software. The application requirements in this example are simple and defined below:

• Need two thermocouple inputs.

• Monitor both thermocouple inputs for high process alarms.

• Drive an output (alarm) device if either input is higher than expected.

• Use one thermocouple input to drive the PID loop (Heat output) with a switched DC

output.

In the graphic below the following is true:

Watlow F4T® • 8 • Chapter 1 Overview

Page 9

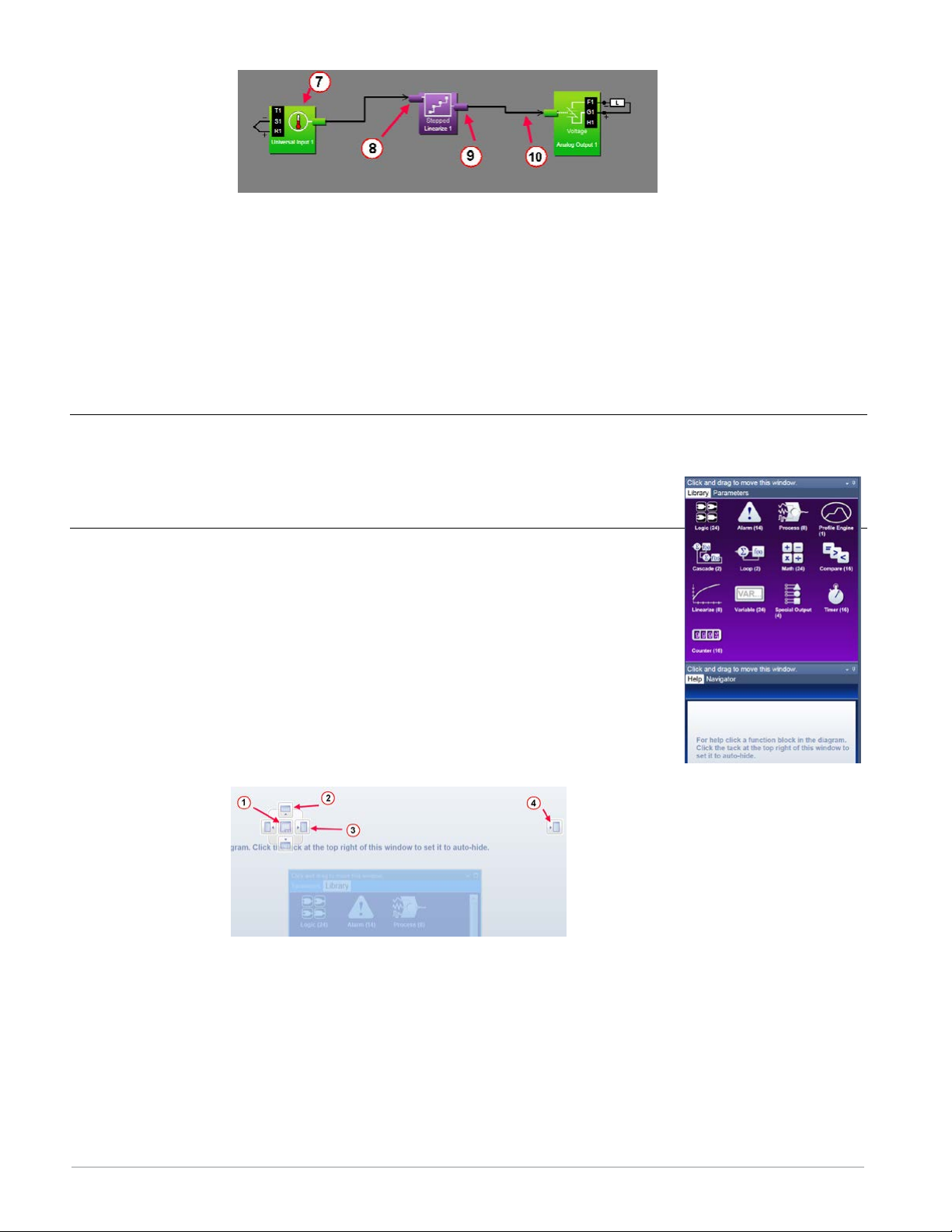

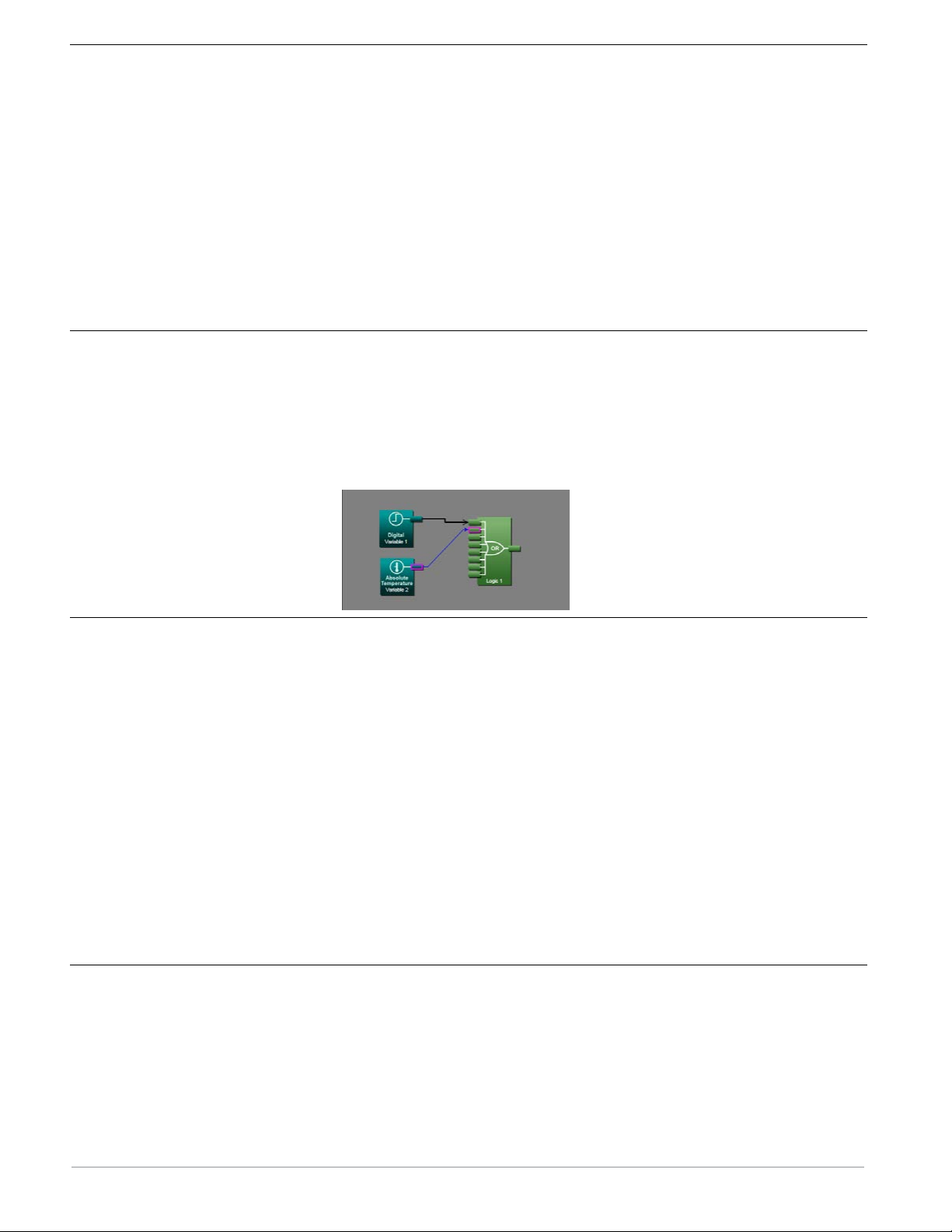

• Universal Input 1 is connected to the Process Value (PV) input of the control loop.

• When the control loop sees that the PV

is less than the user defined set point it

will drive the output to the load through

its heat (HT) output.

• Two unique high process alarms are

configured to monitor Universal Inputs

1 and 2.

• The logic function block (FB) is

configured as an OR where its output

will come on if either input comes on

driving the real-world digital output (alarm) it's connected to.

Note:

In this configuration, the heat output of the control function would be uninterrupted if an

alarm were to occur.

You will find more detailed information regarding the function blocks and how they work further

on in this document.

Inputs

The inputs provide the information that any given programmed function can act upon. In a

simple form, this information may come from an operator pushing a button, or as part of a

more complex function it may represent a remote set point being received from another zone.

Each universal input can be configured for thermistors, thermocouples, or RTDs to read the

process variable. They can also read mV/volts, current or resistance, enabling usage of various

devices to read humidity, air pressure, operator inputs and other values. The settings

associated to each analog input must be

input.

Each digital input reads whether a device is on or off (voltage or resistance) and each system

can be equipped with multiple digital I/O modules. Each I/O point must be configured to

function as either an input or output.

configured to match the device connected to that

Functions

Functions use input signals to calculate a value and or performs an action. A function may be

as simple as reading a digital input as on or off, or reading an analog value (temperature) to

set an alarm state to on or off. As an example, a user could use sensor backup to avoid an

unwanted shutdown if a failure with the primary sensing device should occur.

Watlow F4T® • 9 • Chapter 1 Overview

Page 10

Keep in mind that a FB can be a purely internal function (i.e., control loop, alarm, logic, etc...),

while they can also serve as a connection point between real-world devices

(i.e. thermocouple, heater etc...) and internal functions like a Universal Input connected to the

Control Loop PV input. To have an effect outside of the controller, an output FB must be

configured to respond to some other function. Functions and all associated dependencies

would be configured using Composer software. To learn more about setting up function blocks

see Chapter 2 of this ocument in the section titled "Configuring the Application with the Func-

tion Block Diagram View".

Outputs

Outputs respond to information provided by a function such as, heat power from the output of

the control loop, driving a digital output based on a profile event, turn a light on or off,

unlocking a furnace door or turning on a buzzer.

More than one output can be assigned to respond to any given function, i.e., more than one

output device could be connected to the heat output of the control block. Another example (not

shown), could use the (internal) output of the alarm function and connect it to any available

real-world output to trigger a flashing light and another real-world output that might be

connected to a siren.

What is a Profile

A profile is a set of instructions consisting of a sequence of steps. When a profile runs, the

controller automatically executes its steps in sequence. The step type determines what action

the controller performs. Steps can change temperatures and other process values gradually

over time, maintain the temperatures and process values for specific periods, or repeat a

sequence of steps numerous times. At each step the profile can activate or deactivate outputs

that control other equipment. Also a step can have the controller wait for specific conditions

before proceeding such as, waiting for a switch closure and/or a specific process value to be

detected by a sensor.

Data Logging

Controllers equipped with this feature will have the letter [J, K, L or M] in the fifth character of

its part number (see: F4T® Ordering Information). Logging can be enabled at any time and is

intended to capture real-time data for a user selectable list of data points. With firmware

revision 3.0 and above, several new features are available.

1. User can determine if logged files will be moved automatically and or manually.

2. Destination of the saved file can be directed to internal memory, USB thumb drive, TFTP

server or a Samba shared drive.

3. Based on user choice, files can now be encrypted (filename.enc) for security purposes and

or saved as comma separated values (filename.csv). Creating both file types allows

viewing of the csv file while maintaining the integrity of the encrypted file.

To learn more about configuring these options see the section in this user's guide entitled

Setting Up Data Log Files Using Composer.

Watlow F4T® • 10 • Chapter 1 Overview

Page 11

2

Chapter 2: Composer® Software

Controller Configuration and Setup

Installing Composer® Software

Locating the Software and System Requirements

Composer software is included on the "Watlow Support Tools" DVD which ships with the

product. As an alternative, the software can also be downloaded at: https://www.watlow.com/f4t

In order to install and run this software successfully there are some baseline requirements for

PC hardware and operating systems that must be observed. These requirements are listed

below:

• 250 Megabytes or more of available hard disk drive space

• 300 Megabytes of available RAM

• Supported operating systems include: Windows

• Requires Microsoft® .NET Framework 4.0 (this installs automatically if not already on

target machine)

®

7 / 8 / 8.1 / 10 (32 or 64 bit)

Installing the Software

To install the software:

1. Double-click the Setup.exe.

2. Select the language of choice and click the OK to proceed.

3. Click the Next button to proceed.

4. After reading the Composer

the License Agreement radio button and then click on the Next button to proceed.

5. The next dialog box that will appear shows the default directory in which the software will

be installed. The install location can be changed by clicking the Browse button and then

point to the preferred location.

6. Click Next and then Install.

7. Clicking the Finish button will conclude the installation.

Note:

If experiencing difficulties installing or using Composer software, prior to contacting Watlow

technical support, be prepared to send the user log file to the tech support team. This text

file can be found here: C:\Users\username\AppData\Roaming\Watlow\Composer\Logs

®

software license agreement click the I accept the terms in

The red text above will change to the user's Windows login name.

Watlow F4T® Controller • 11 • Chapter 2 Configuration Using Composer

Page 12

Using Composer® Software

Connecting the PC to the Controller (System) - Physical Connections

Physical connections (hardware and cabling) will vary depending on the controller in use.

1. To find instructions connecting an F4T® controller to a PC see: Chapter 3 of the F4T

Installation and Troubleshooting User's Guide.

2. To find instructions connecting a Rail Mount (RM) control to a PC see: Chapter 2 Install

and Wire, of the RMC Module User's Guide

®

Starting Composer Software:

1. Click the Start button and then type composer.exe in the search box.

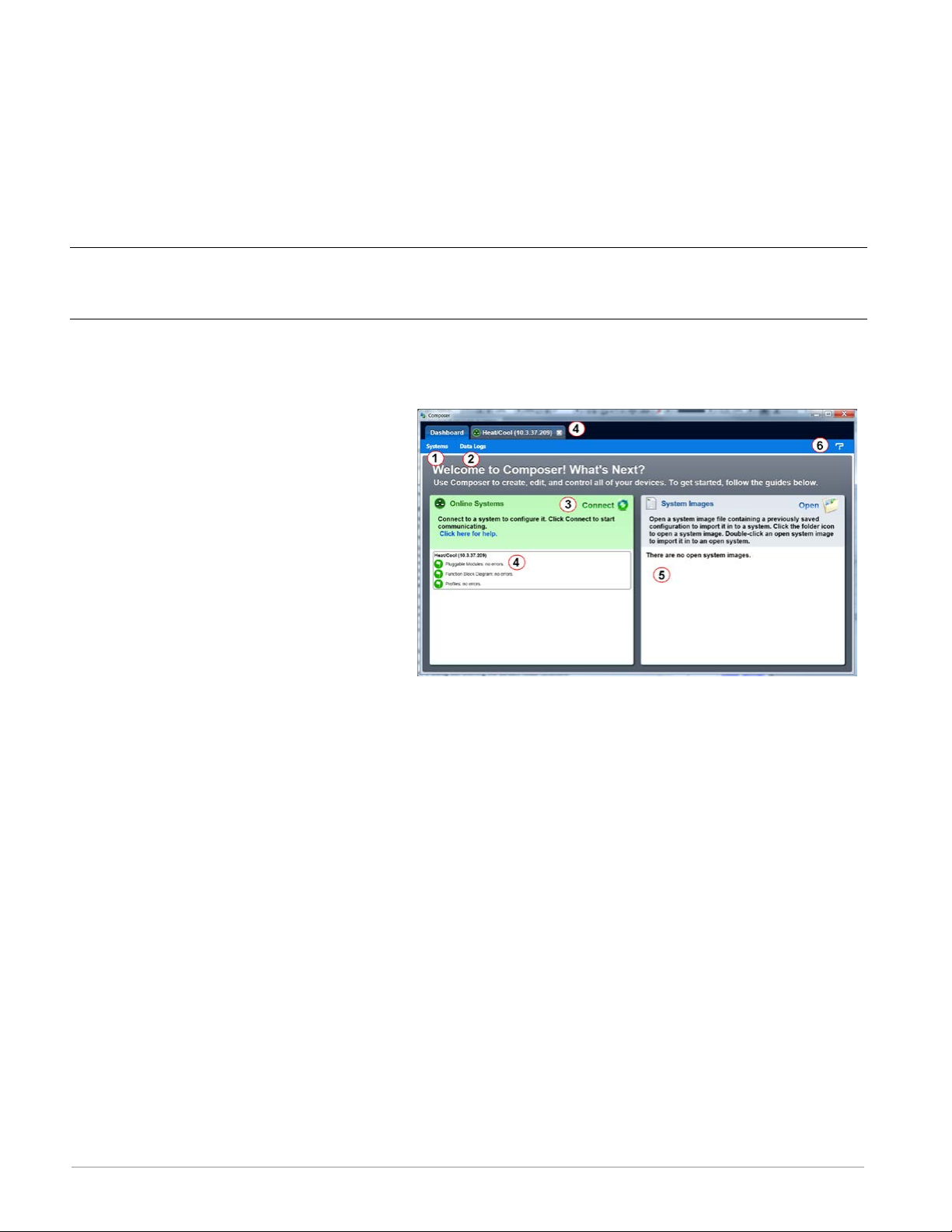

Composer Welcome Screen Orientation

The graphic below illustrates and defines some points of interest as seen on the Composer

Dashboard screen and describes the functionality, numbered correspondingly.

Dashboard (Systems)

• Displays options for

online connections between PC

and a controler or opening

previously saved system image.

Data Logs Menu

• Decrypt Log File: allows for

decryption of an encrypted data

log file.

• View: displays the contents tents

of a data logged file (enc or csv).

Depending on files size this may take several minutes to open.

To decrypt an encrypted file follow the steps below:

1. If data logging has not yet been stopped do so now by pushing: Main Menu -> Data

Logging -> Stop buttons.

Note:

When data logging is stopped, allow at a minimum, six minutes for closure of all files

and movement of those files to the selected destination before attempting decryption.

2. Open up Composer software and click on Data Logs and then Decrypt Log Files.

3. Locate the encrypted files and open them one-by-one (click on one *.enc file and click

Open), or by selecting more than one and click the Open button.

Note:

If logged file is sent to USB, the *.csv and the *.enc file are written directly to USB

constantly. If the File Size Limit is set to 10MB or larger, the csv will continue to be

written continuously while the encrypted portion (*.enc) is chunked into 7.5MB files,

buffered internally and then written out as 7.5MB chunks. If the maximum file size is set

to 10MB, there will be two *.enc files for each csv (7.5MB and 2.5MB). If File Size Limit

is set to 15MB, there would be two 7.5MB *.enc files for each *.csv file.

Note:

As noted above, if a csv file is greater than 10MB there will be more than one

Watlow F4T® Controller • 12 • Chapter 2 Configuration Using Composer

Page 13

encrypted file for the associated csv file. When decrypting these files, it is

recommended that all encrypted files be selected in the decryption process. Each of

the encrypted files will be concatenated into one csv file.

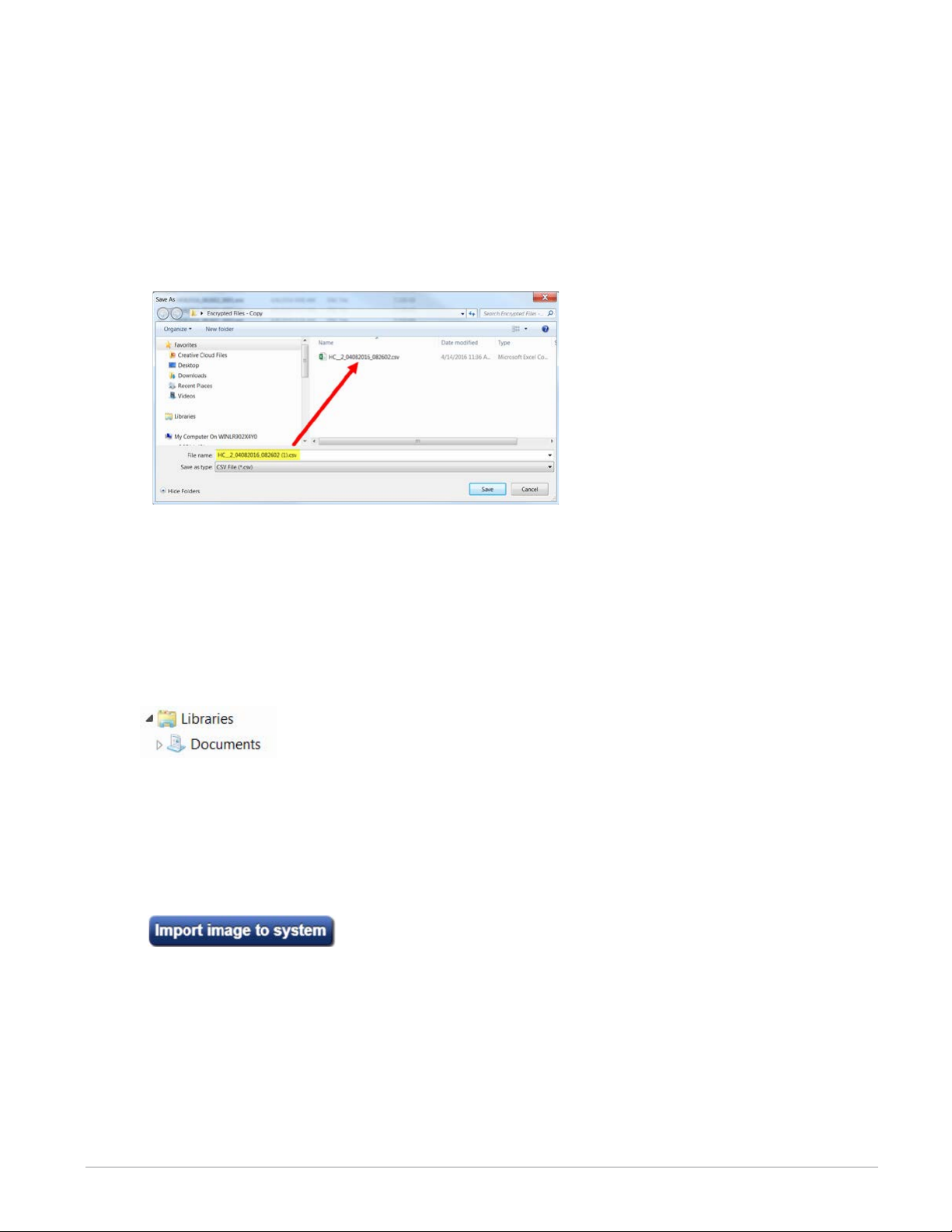

4. After selecting the desired encrypted files and then clicking Open, the window below will

appear. Notice the filename of the original csv and the one suggested in the dialog box

highlighted yellow below. The one within parentheses (1) is inserted to avoid overwriting

the original csv file. You may name the file to your liking.

Note:

The largest file size allowed is 1GB. If decrypting a file of this size it could take up to

10 minutes to complete.

Connect to a System

• Opens a window showing all available communications ports.

Online Systems

• Displays all connected systems.

Open a System Image

• Opens a dialog box showing the default folder structure.

To import a system image follow the steps below:

1. Connect to the desired online system described above

2. Click Open to search storage device and find the desired system image

4. Double-click on the desired system image

5. Once the system image is opened click on the button below:

6. Select the system to be configured and click continue

Note:

Use caution when considering this option, once initiated, controller memory will be

overwritten in its entirety and replaced with the new system image.

System Images

• Displays all opened system images.

Question Mark (?)

Watlow F4T® Controller • 13 • Chapter 2 Configuration Using Composer

Page 14

• Allows a user to do the following:

- Update Settings, Change automatic software update settings

- Check For Updates, Initiate an immediate check for software updates (internet

connection is required)

- Dashboard Help, Provides description and information pertaining to the Dashboard

- About, Displays technical support contact information as well as the current versions of

the installed software and installed modules.

Overview Screen

Topics discussed in this section follow:

Connecting to an Online System: from the Dashboard connect to an online system.

Overview Screen Orientation: visually identifies all devices connected to the system.

System Menu: when clicked, a drop down submenu will appear.

Device Menus: when clicked, a unique drop down submenu will appear for each device or

controller on the system. The menus provide access to device specific screens.

Global Settings: set temperature units and AC line frequency for the system (all controllers).

Security: allows for multiple levels of password protection.

Saving a System Image: save a system image to a storage device.

Import System Image: restore a system image from a storage device to the controller.

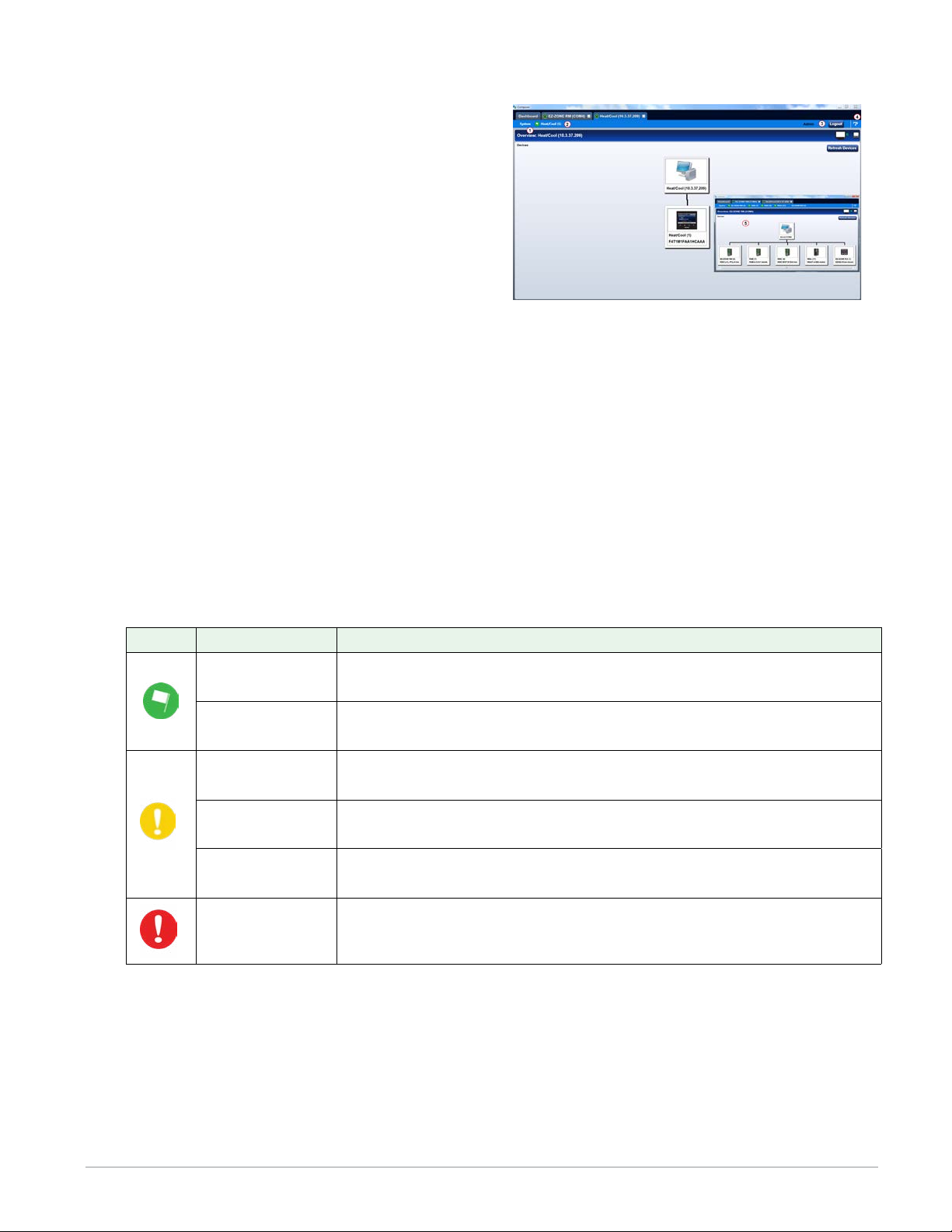

The graphic below, shows the first displayed screen (System Overview) after connecting to a

system.

Connecting to an Online System

To connect to a system:

1. On the Dashboard screen click Connect.

2. Select the communications port that the system is connected to and then click Continue.

3. Double-click on the desired online system.

To view the system overview:

1. On the Dashboard under Online Systems, double-click the desired system.

Overview Screen Orientation

The graphic below illustrates and defines some points of interest as seen in the system

overview with each identified by a corresponding circled number. Further information for each

can be found just below the orientation.

This screen can be accessed from within any Composer

display of all devices connected on the system while also providing navigation to and from

each device.

Watlow F4T® Controller • 14 • Chapter 2 Configuration Using Composer

®

view always rendering a visual

Page 15

System Menu

• Overview: displays the screen shown at the right.

• Save Image: saves a

previously saved system

image using the same

name folder and the

same destination folder.

• Save Image As: saves

system image with a new

name to the user specified

folder.

• Import Image: select a previously saved

system image to download to the device.

• Print: active when viewing the function block diagram. What's printed will be exactly what

can be seen on the canvas. If all FBs are not visible, scale the canvas using the

• Navigator plus and minus buttons and then click the System tab and then Print.

• Global Settings: for use throughout the controller changes settings for Temperature

units, AC Line Frequency, and Date and Time.

• Security: allows the administrator to determine and set security privileges to avoid

• unwanted changes.

Device Menus

• When clicked, a drop down submenu will appear allowing navigation to device level

menus. Each device will have one of three flags displayed immediately to its left. Those

flags are described in the following table.

Symbol Menu Item Description

Pluggable

Modules

Function Block

Diagram

Pluggable

Modules

Function Block

Diagram

Profile Editor

Pluggable

Modules

All expected modules and no unexpected modules are present

®

(F4T

only).

No signals have errors.

A module has been detected in a slot the controller expects

to be empty (F4T

®

only).

At least one unexpected module has been detected, however,

all expected modules are present.

One or more of the profiles were created for a different

®

configuration and cannot be run (F4T

At least one expected module is missing (F4T

only).

®

only).

Security

• When enabled, displays current level of access with the ability to logout.

Question Mark (?)

• Provides help for each of the options mentioned above.

Inset Picture of Rail Mount (RM) modules connected as a system.

Watlow F4T® Controller • 15 • Chapter 2 Configuration Using Composer

Page 16

Global Settings

Each of the settings below will be used and applied throughout the controller.

• Temperature Units: will determine how the temperature is displayed (Fahrenheit or

• Celsius) on the front panel of the controller as well as throughout all configuration

®

screens within Composer

.

• AC Line Frequency: set this to the line frequency of the power applied to loads such as

heaters (50 Hz or 60 Hz) so that the current sensing and variable time-base features will

work correctly.

• Date and Time: sets the date, time and time zone to the current computer settings or

whatever the user enters.

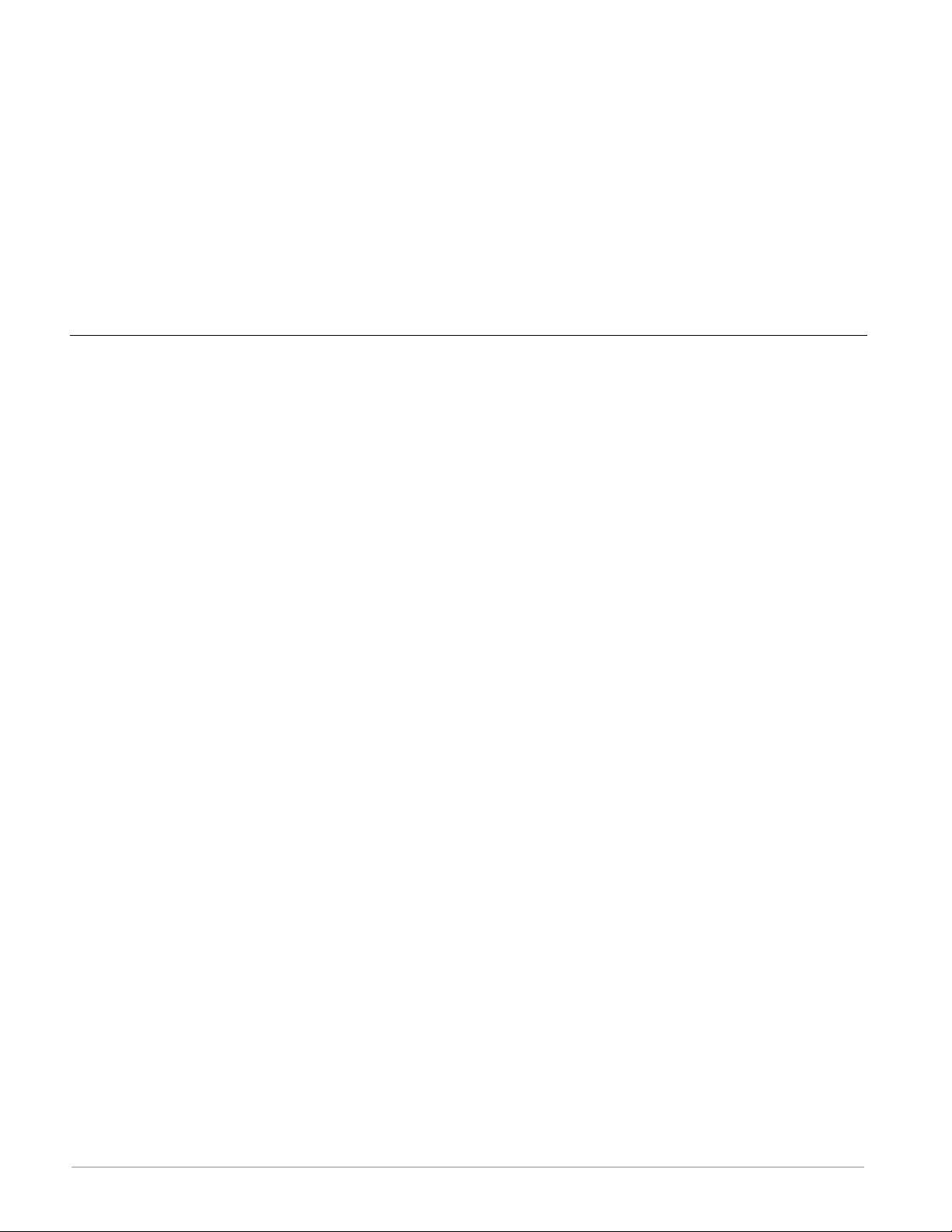

Security

The security feature is used to protect the system's configuration and settings from unwanted

changes. The Admin user sets what access other users have to the system's features. When

security is enabled, a user must enter a password to gain access to protected features through

the controller's user interface or Composer software.

There are three configurable user groups and an admin account:

• User: no password required, Admin sets feature access

• User with Password: requires a password, Admin sets feature access, is permitted to

change the password for this user group.

• Maintenance User: requires a password, Admin sets feature access, is permitted to

change the password for this user group.

• Admin: requires a password, has unlimited access to features, sets permissions and

passwords for all user groups.

The Admin user can set permissions for each user group to allow full, read-only or no access

to the following features:

• Home: controls access to controller's home screen.*

• Control Mode: controls access to setting the control mode, set points and PID

parameters.

• Autotune: controls access to running the autotune feature.

• PID Settings: controls access to the PID settings.

• Profiles: controls access to creating and editing ramp and soak profiles.

• Global Settings: controls access to the system's global settings, temperature units, AC

line frequency and real time clock setting.

• Network: controls access to communications settings.

• Operations: controls access to operational parameter settings.*

• Personalization: controls access to customizing the controller's home screen.

• Data Logging Setup: determines frequency of logging, location of saved files and other

general information.

• File Transfer: allows a user to transfer files (Configuration, Profile and Data log) to/from

the controller.

Watlow F4T® Controller • 16 • Chapter 2 Configuration Using Composer

Page 17

• Diagnostics and Troubleshooting: controls access to the device details and calibration.

• Setup: controls access to the pluggable module configuration and the function block

diagram.

*This setting limits access to the controller's User Interface (UI) only, not via Composer

®

Note:

After making all of the desired security settings, ensure that the security enabled radio button

(top left in the graphic above) is selected Enabled.

.

Note:

If the passwords have been misplaced or forgotten it will be necessary to contact the OEM

or as a last resort Watlow Technical Assistance.

Note:

Once security is applied to the controller, only the administrator (Admin) can reconfigure or

remove the security.

Note:

When the system file is saved, any applied security will be saved with it.

Save Image

After clicking on save image as, the save button will become active (gray to white). This allows

a user to make changes to the system image and simply save it to the same location using the

same filename. Everything that will be saved is as listed below:

• Device Details

• Pluggable Modules (F4T

®

only)

• Function Block Diagram in its entirety

• System Security

®

• Profiles (F4T

with profile option only)

• Profile passwords (F4T® with profile option only)

• All parameters that can be read and written to

Watlow F4T® Controller • 17 • Chapter 2 Configuration Using Composer

Page 18

Save Image As

• Allows user to specify a name and storage location while saving everything in the list

above.

Saving a System Image

To save a system image the first time:

1. From any screen click on the System Menu tab to drop down a submenu.

2. Click the Save Image As button.

3. Use the save as dialog to select the destination folder for the image.

4. Enter the desired filename.

5. Click Save.

Note:

The system image filename will always have the extension wsi for Watlow System Image and

cannot be changed.

Note:

The real-time clock values are not saved or imported.

Import Image

• Restore a system image from a storage device to the controller. The list below shows

what is restored:

- Device Details

®

- Pluggable Modules (F4T

only)

- Function Block Diagram in its entirety

- System Security

- Profiles (F4T

- Profile passwords (F4T

®

with profile option only)

®

with profile option only)

- All parameters that can be read and written to

Watlow F4T® Controller • 18 • Chapter 2 Configuration Using Composer

Page 19

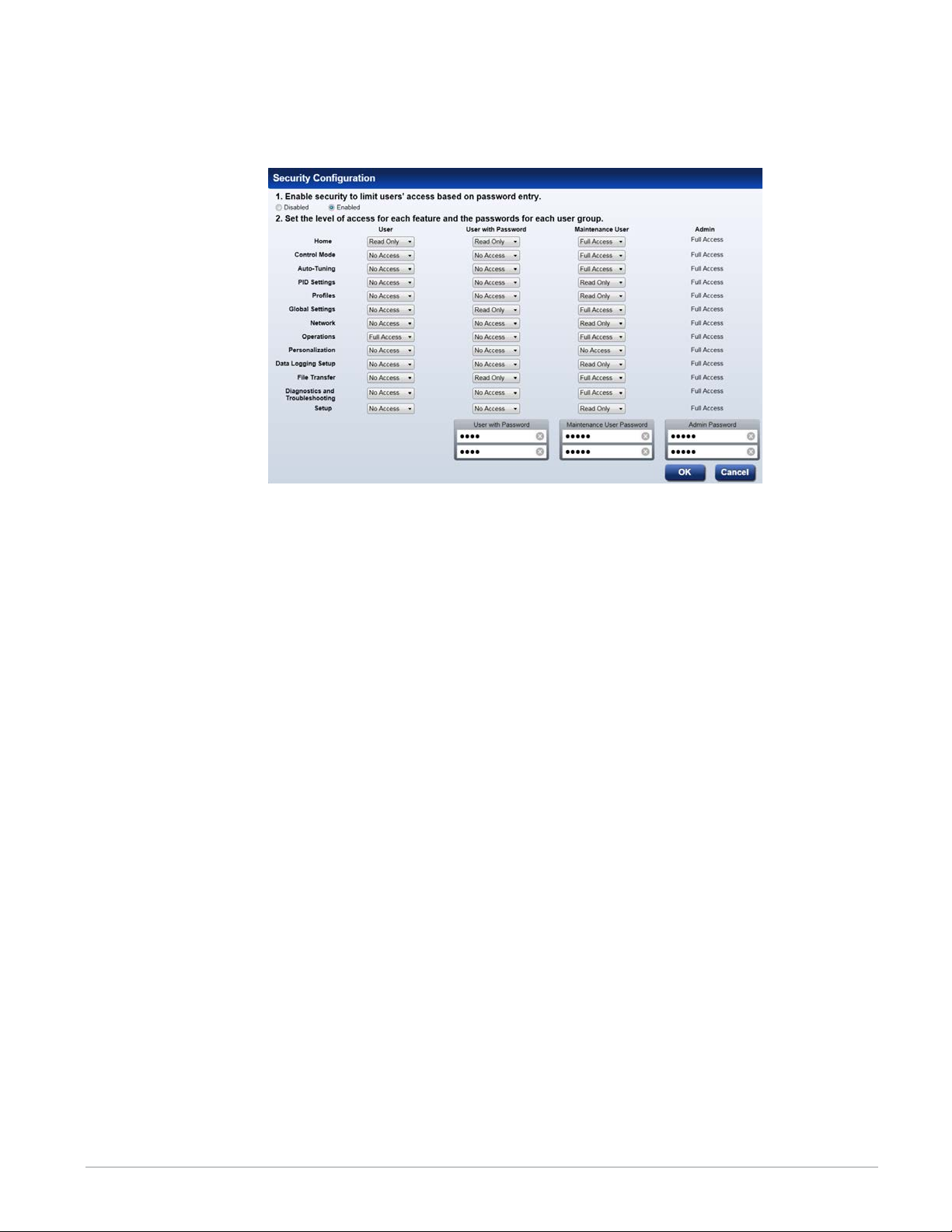

Importing a System Image

To import a system image:

1. From any screen click on the System menu tab to drop down a submenu.

2. Click the Import Image button.

2. Use the open dialog to select the folder location for the previously saved system image.

3. Double-click the desired filename or single-click the filename and then click the Open

button.

Note:

Importing a system image will overwrite the controller in its entirety. Careful thought should

be applied prior to importing.

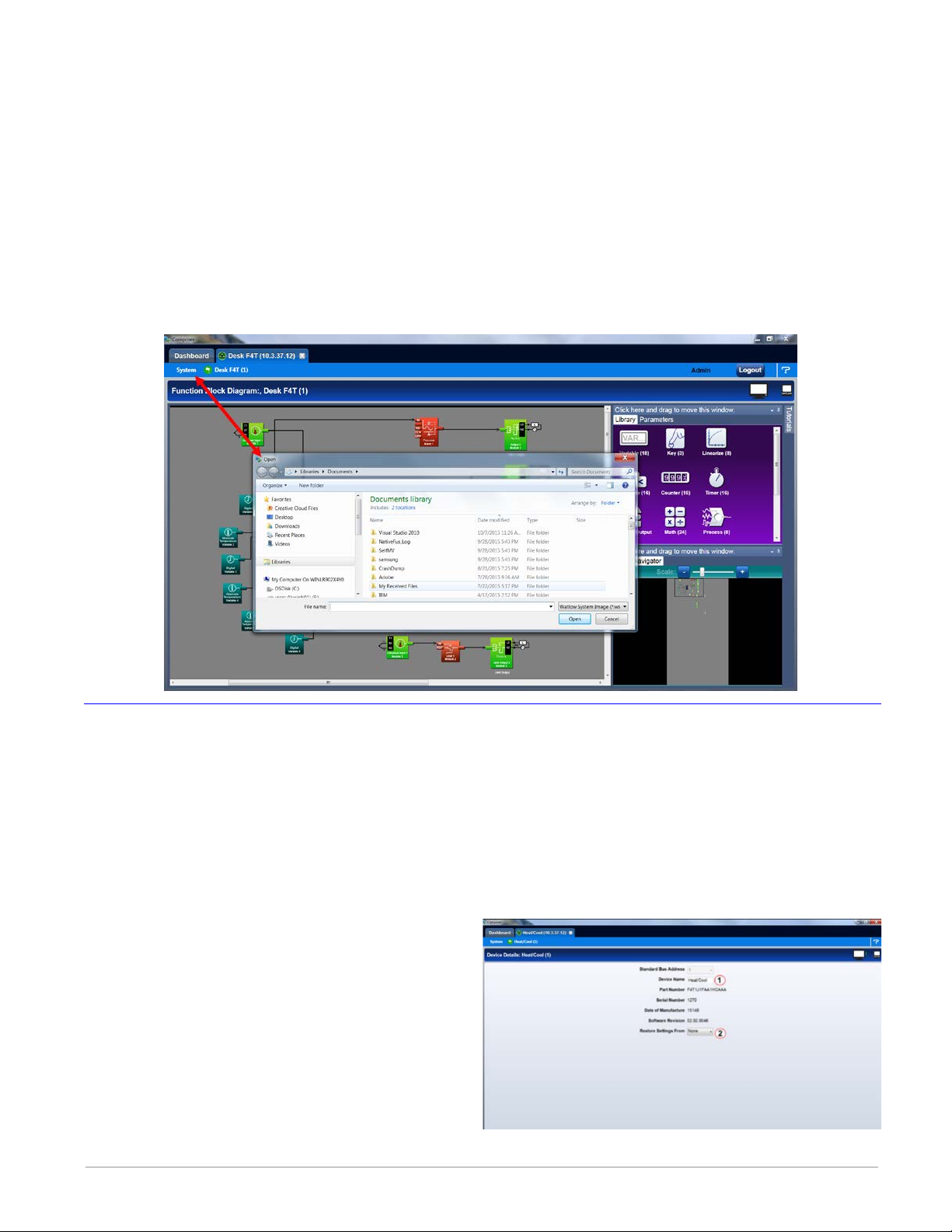

Device Details

The Device Details allows a user to make changes to the system settings described below.

Descriptions are numbered correspondingly in the graphic that follows.

Navigate to Device Details:

1. From any screen click on the Device menu tab to drop down a submenu.

2. Click the Device Details button.

Device Name - change the name (32 characters maximum) of the controller for easy

identification.

Note:

This name will also be displayed in the

upper left corner of the user interface.

Restore Settings From

• None: no action.

• Factory: allows a user to bring the

controller back to the factory default

state.

Watlow F4T® Controller • 19 • Chapter 2 Configuration Using Composer

Page 20

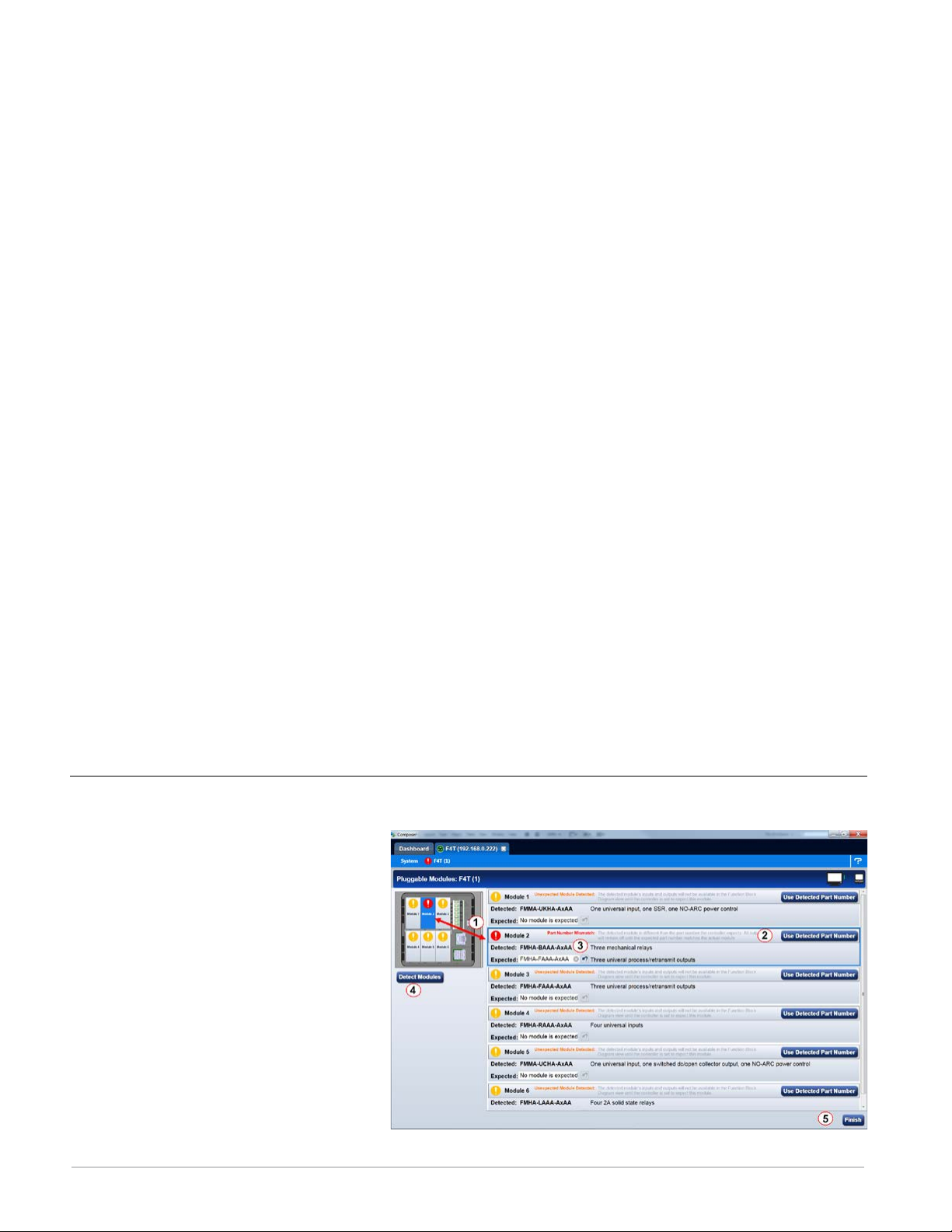

Configuring Pluggable Flex Modules

This controller can have up to six Flex Modules (FM) installed in the chassis. The presence of

each FM must be confirmed and accepted using Composer

configured as installed hardware or the user can type in a valid FM part number for late

installation. For more detail regarding the module installation process, see the Installation and

Troubleshooting User's Guide for the controller in use.

Note:

Typing in a valid part number without the presence of the module is intended for the sole

purpose of building the FBD (connecting function blocks on the canvas). Errors may be

generated and all outputs will be off until the module is inserted.

Topics discussed in this section follow:

Screen Orientation: detailed description of the Pluggable Module configuration screen and

associated characteristics.

Symbols Related to Pluggable Modules: description of the symbols that may be displayed

when using Composer software.

Configuring Flex Modules: configuration process described.

Entering FM Information Before Module Installation: detailed description of the why and how a

user would do this prior to acquiring the module.

®

software. FMs can be fully

Note:

The graphic below represents a controller that first had its flex modules installed with the

controller then being connected to a computer. Because of this scenario each slot appears

with no expected modules. This screen and symbols that are displayed will look different

using a different scenario.

Navigate to Pluggable Modules screen:

1. From any screen click on the Device Menu tab to drop down a submenu.

2. Click the Pluggable Modules button.

Pluggable Flex Modules - Screen Orientation

Module Slot - Location

• The blue box (on the right) and

the slot highlight will move with

the mouse to bring focus to the

slot/module.

Use Detected Part Number

• Click this button to accept the

module that the system sees

as being present in the slot

and displayed in the field

identified as "Detected Part

Number".

Set Expected To None

Watlow F4T® Controller • 20 • Chapter 2 Configuration Using Composer

Page 21

• Click on the X to tell the system there will be no module installed in this slot. Taking this

action will turn the power off for this slot after the controller is reset.

Detect Modules

• The controller will shut off all outputs and initiate an evaluation of each slot to see if any

modules are present.

Note:

In the graphic above, if a module were inserted in slot 3, clicking detect modules will turn the

power on for the slot and report back with the module part number installed.

Finish

• Will cause the controller to restart and take the user to the Function Block Diagram.

Note:

There are some FM slot dependencies. If there is a question as to whether or not an FM is

in an acceptable slot, refer to the Installation and Troubleshooting Guide for the controller in

use.

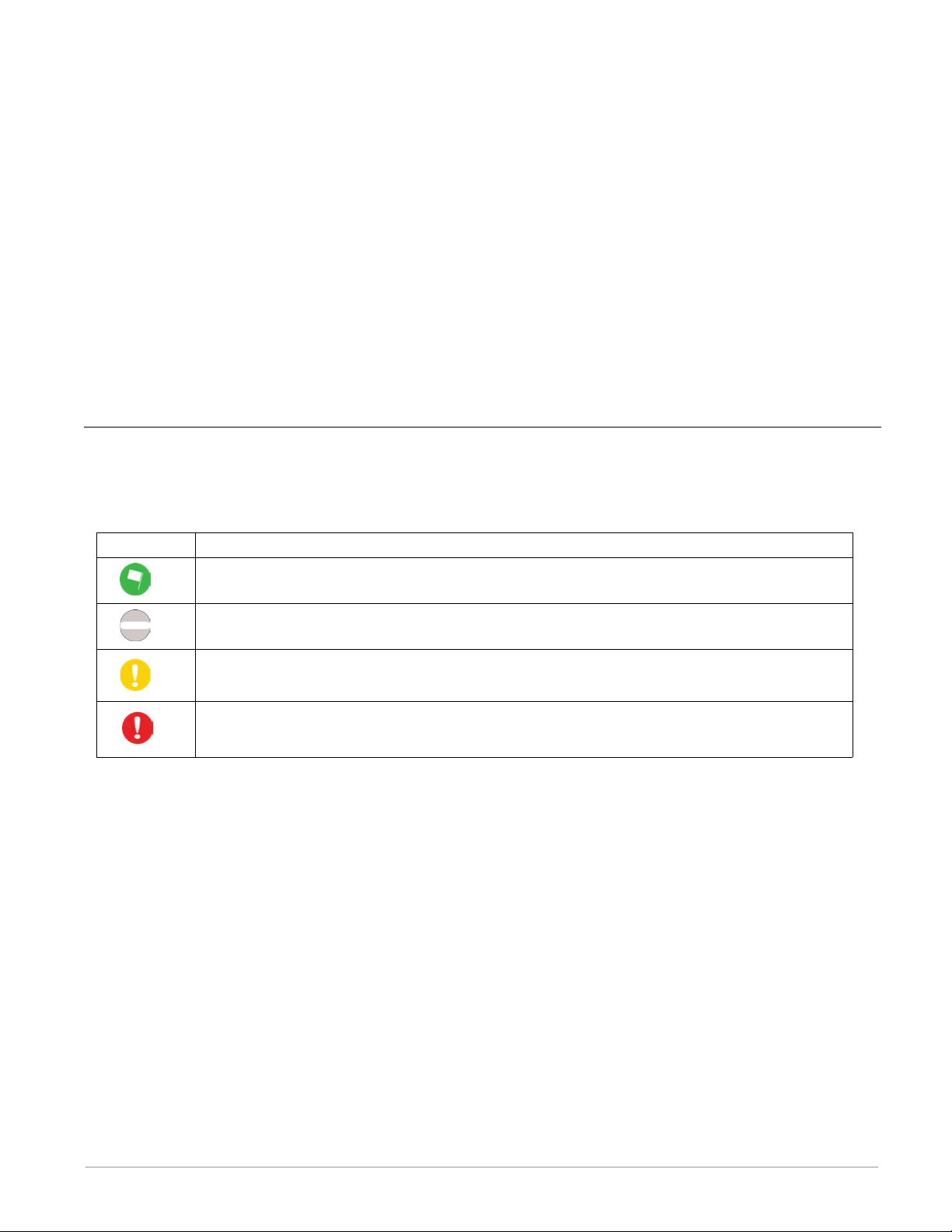

Symbols Related to Pluggable Modules

As viewed from the Menu bar, the symbol that will be displayed to the left of the Pluggable

Modules button will be of the most significance. The red exclamation will always take

precedence.

Symbol Description

The expected module has been detected.

No module has been detected in a slot the controller expects to be empty.

A module has been detected in a slot the controller expects to be empty.

The controller expects a module, but that module is missing or a different

module has been detected.

Configuring Flex Modules

To accept the detected modules:

Note:

If modules were plugged in after powering up or resetting the controller, click on the Detect

Modules button to restart the controller and detect all of the modules that are present.

1. On the right side of the screen click the Use Detected Part Number button.

2. Repeat step 1 for each slot to be configured.

3. Click the Finish button to restart the controller and exit to the Function Block Editor.

Note:

Exiting the pluggable modules screen after any changes are made will cause the controller

to restart. A restart will stop all controller activities while turning off all outputs.

Watlow F4T® Controller • 21 • Chapter 2 Configuration Using Composer

Page 22

Entering Flex Module Information Prior to Installation

Function blocks associated with hardware will not be available until the hardware is expected

to be present. Entering a part number for any slot (even though the module is not currently

installed) allows the programmer access to the associated function blocks. As an example, if

an FMMA-UEKA-AAAA is installed in slot one,

the function blocks that would be available are

shown in the red box. After entering a part

number such as FMLA-YEBA-AAAA in slot 2,

additional hardware dependent function blocks

will appear as shown in the blue box.

Note:

When configuring modules as described

above (not installed), the controller will not be

able to control any outputs. All outputs will be

off.

To configure the controller to expect a module that is not yet installed:

1. Select the desired slot and enter a valid part number in the Expected Part Number field.

2. On the keyboard, push the Enter key.

3. Click Finish when complete to restart the controller. After the restart process is complete

the Function Block Diagram will appear.

Once the module is acquired, simply plug it into its assigned slot and click the Detect Modules

button. After doing so, the controller will restart and a green flag

number.

will be displayed for that slot

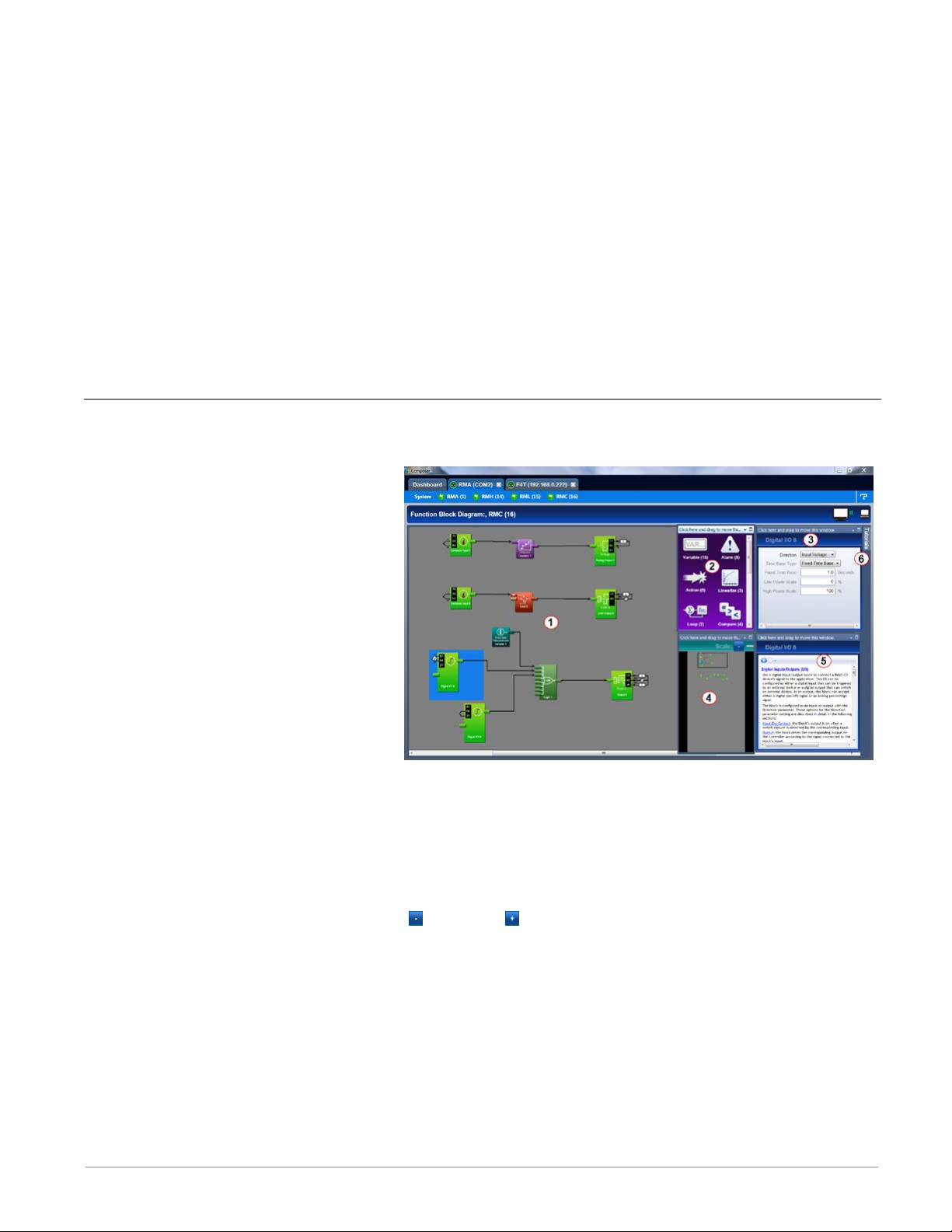

Configuring the Application using the Function Block Diagram

The Function Block Diagram (FBD) view is used to connect the real-world inputs and outputs

to internal controller functions, such as alarms, control loops and ramp and soak profiling.

To enter the Function Block Diagram:

1. Click on the desired Device menu.

2. From the drop down menu click Function Block Diagram.

Topics discussed in this section follow:

Screen Orientation: detailed description of the FBD screen and associated characteristics.

Customizing the FBD Environment: change default canvas settings to user preference.

Window Anchor Points: defines a new docking location.

Getting Started: things a user will encounter on the canvas while building the application.

Selecting and Placing FBs on the Canvas: describes where to find and then place selected

FBs on the canvas.

Moving FBs on the Canvas: describes how to move selected FBs on the canvas.

Connecting FBs Together: describes how to make the application come to life by

interconnecting FBs.

Viewing Signal Values and Errors: describes how to view signal values and errors as they

occur.

Watlow F4T® Controller • 22 • Chapter 2 Configuration Using Composer

Page 23

Troubleshooting Signal Errors: suggestions in how to evaluate a signal error.

Adjusting FB Behavior with Parameter Settings: change the functionality of a FB based on its

parameter settings.

Finding Help for FBs: describes how to acquire embedded help for each FB.

Changing and Deleting Signals: making modifications to the program through new and revised

FB connections.

Removing FBs from the Canvas: describes how to delete FBs on the canvas.

Using Auto Hide: maximize visibility of available screen space by hiding infrequently used

windows.

Floating a Window: move a window from its docked location to a user defined location.

Docking a Window: describes how to create new or return to previous docking locations.

Turning Floating Windows Off and On: describes how to enable and disable floating screens.

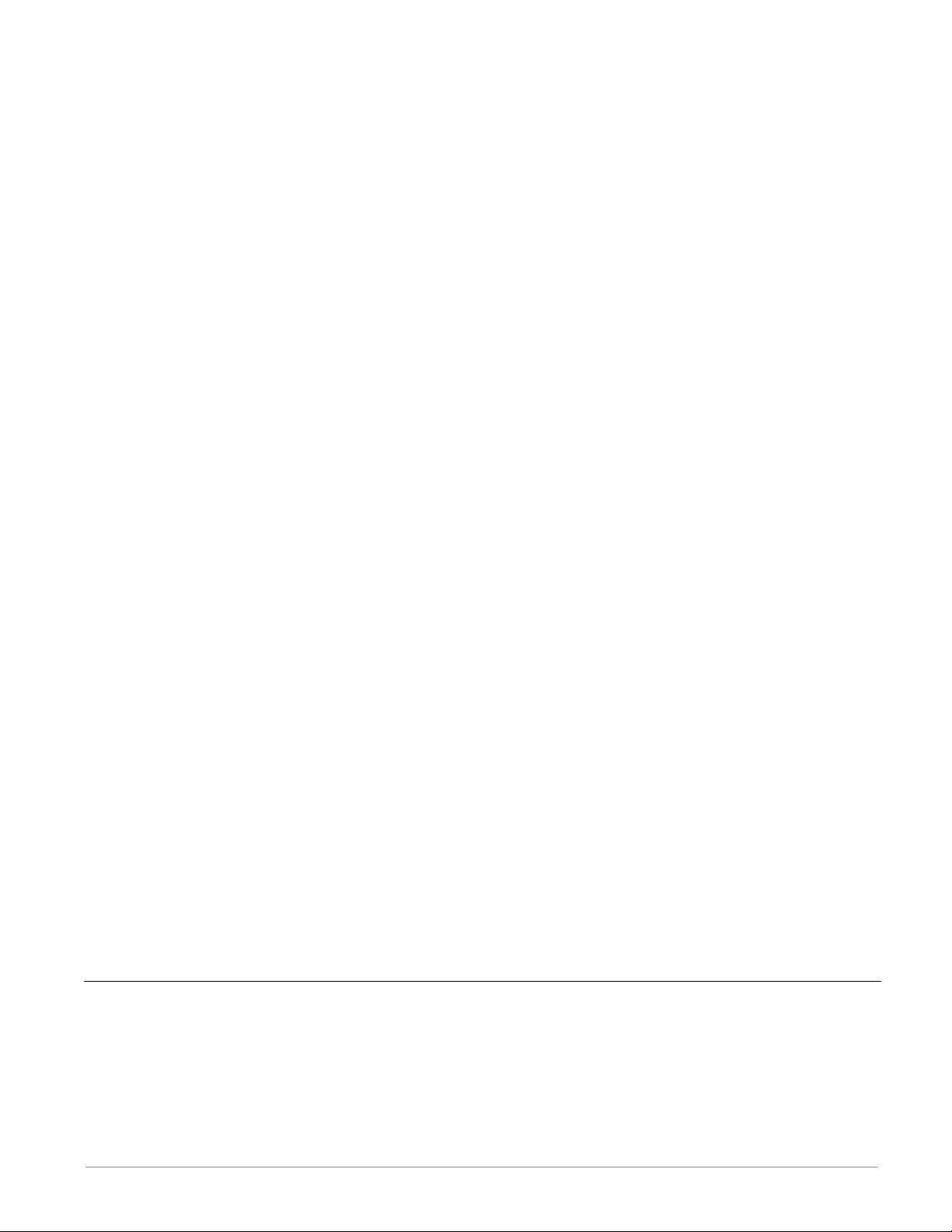

Function Block Diagram View - Screen Orientation

The FBD View has the following features, numbered correspondingly in the graphic below.

Function Block Diagram

• All FBs are placed and

connected on the canvas.

Function Block Library

• Shows the available FBs for

this controller. The number

below each icon indicates how

many FBs of that type remain

available for use with this

controller. As is displayed in

this graphic, this window is

movable and dockable.

Parameter List

• Used to view and set the FBs parameters customizing its behavior for the application.

This window is movable and dockable.

Navigator

• Allows the user to adjust the view of the canvas. Drag the box to reposition the view.

• Use the slide bar or the min+us

window is movable and dockable.

Help

• To view detailed FB information click on any FB. This window is movable and dockable.

and plus

buttons to adjust the zoom level. This

Tutorials

• Topic based video help files.

Function Blocks (FBs)

• Allows the user to customize the functionality of the controller for a specific application.

Some FBs are interfaces to real-world I/O devices and some serve as the interface to

internal functions such as, the compare, logic and math FBs.

Watlow F4T® Controller • 23 • Chapter 2 Configuration Using Composer

Page 24

Receiver

• The part of a FB to which a signal can be connected in order to supply data to the

function.

Transmitter

• The part of a FB from which a signal can be connected in order to carry data to another

FB.

Signal

• A line that represents the connection of data from one FB to another.

Customizing the Function Block Diagram Environment

The Parameter, Help, Library and Navigator windows can be moved from their default locations

to allow a user to maximize the visibility of the FBD diagram. See the

procedures below regarding how to float, hide and dock these windows.

Window Anchor Points

While dragging a window or a grouping of windows to a new docking

location Anchor Points will appear on the screen. The anchor points in

the graphic are numbered corresponding to their associated descriptions

below:

• Drag

•

•

•

the window here to add to the window group.

Drag window here to dock above the window group.

Drag window here to dock to the right of the window group.

Drag window here to dock at the right of the screen.

Getting Started with the Function Block Diagram (FBD)

The basic steps for creating the function block diagram for any application are:

1. Add the function blocks from the library to the canvas that are needed to interpret the

signals from the physical inputs and set the physical outputs. Typically, these will include

Loop, Alarm and Profile Engine function blocks.

2. Connect the transmitters on the FBs that source data to the receivers on the FBs that need

the data.

3. Set each function block's parameters as needed for the application to perform as expected.

Watlow F4T® Controller • 24 • Chapter 2 Configuration Using Composer

Page 25

Detailed descriptions of each function block including all the function block's parameters can

be accessed in the online help for the function block and in the User's Guide, chapter entitled

Function Block Reference.

The FBs that represent the physical inputs and outputs from the controller and are associated

with the flex modules that are expected in the configuration are always on the canvas. These

FBs can only be removed by changing which modules are expected using the Pluggable

Modules view.

Other FBs can be added to the canvas from the library. Some of these FBs such as Loop,

Cascade, Alarm and Profile Engine perform sophisticated functions. See the Application

Examples chapter in this User's Guide for more on these functions. Other function blocks such

as Math and Logic perform fundamental functions that can be combined to add custom

behaviors to the controller for specific applications.

The signals that carry data between function blocks normally appear as black lines in the

diagram, but when the block that transmits the signal cannot determine what the correct value

should be, the signal changes to yellow indicating the error. Each FB's response to errors

received is explained in the description of the function block.

Warning:

Once an output FB receiver is connected to another block, the output on the flex module

turns on according to the received signal. Do not connect outputs until it is safe to do so.

Notable facts about the FBD:

• How a FB responds to its inputs and drives its output is dependent on its parameter

settings. Set the parameters for each function block as needed for the application.

• Signals cannot be moved after they are created; to change where a signal gets data or

where it delivers it, delete the signal and create the desired connection.

• There are several ways to do many things. Try right-clicking to see options or short cuts.

• FBs from the library that have no signals connected are returned to the library when

®

Composer

is closed.

• The location of dockable windows is not saved; windows return to their default locations

when the system is closed.

• The selection of signal values displayed in the diagram is not saved; all signal value

displays are turned off when the system is closed.

Hints:

• Click-and-drag any blank spot on the canvas to change the view.

• Use the scroll bars.

• Use the Navigator to reposition the view of the canvas and to zoom in or out.

• Use the mouse wheel to scroll the view. Hold the shift key to use the mouse wheel to

pan. Hold the Control key to use the mouse wheel to zoom.

Selecting and Placing Function Blocks on the Canvas

To place a FB on the Canvas:

1. Find the desired FB within the library (using scroll bars if present).

2. Click-and-drag the FB to the canvas.

Watlow F4T® Controller • 25 • Chapter 2 Configuration Using Composer

Page 26

Moving Function Blocks

To move a FB on the Canvas:

• Click-and-drag the FB to the desired location on the canvas.

Hints:

• Click the main body of the FB not one of its transmitters or receivers. Clicking a transmitter

or receiver begins to draw a signal rather than move the FB.

• The canvas will scroll if the mouse pointer is close to the edge but not outside the diagram

window.

• To make a long move, click the block to select it, then zoom out to make it easier to move

the block to the desired location.

Connecting Function Blocks Together

To connect a transmitter to a receiver:

• Click and drag a signal from a FB's transmitter to a receiver on another FB.

Hint:

• This can also be accomplished in reverse, i.e., click and drag from a receiver to a

transmitter.

Viewing Signal Values and Errors

To momentarily display a signal's value:

• Mouse over (point the mouse cursor at) the signal.

To display a signal's value continuously:

1. Right-click the signal.

2. Click Show/Hide Data

To cancel (turn off) the signal display:

1. Right-click the signal.

2. Click Show/Hide Data

Note:

The values displayed are not in real-time.

Troubleshooting Signal Errors

While building the FB diagram, or during operation, there may be occasions when the signal

from the transmitter of a FB is displayed yellow. This may reflect that the FB has encountered

an error or some other anomaly has occurred. From the user perspective, an evaluation of the

cause should be done to ensure that unexpected operation does not occur. Suggested steps to

evaluate the cause of a yellow link are listed below:

Watlow F4T® Controller • 26 • Chapter 2 Configuration Using Composer

Page 27

To evaluate the cause of a yellow signal:

1. Trace the yellow signal back to the source

(first occurrence of a yellow link) FB.

2. Place the mouse over the signal which will

display the error.

3. In this particular example, the error is identified as an Open sensor.

4. Click on the selected FB and view the Help window.

5. Search ("Ctrl-F") the help file for the word "Open".

6. Once found, evaluate, make note or correct the cause of the problem.

If further assistance is needed review the associated product User's Guides or contact the

Watlow Technical Support team (1-800-492-8569 or 1-507-494-5656).

Adjusting Function Block Behavior with Parameter Settings

To change a FB parameter:

1. Double-click on the FB.

2. In the Parameters window locate and change the parameter.

Note:

If names are applied here, those names will appear on the FBD

and if selected, the output view of the Personalization screen.

Finding Help for Function Blocks

To locate the help topic for a FB on the Canvas:

• Click the FB and view the help window.

Hints:

• Many function blocks can be configured to perform one of several functions. For these

FBs, the help topic has a section for each function. Locate and click the link for the desired

function.

Changing and Deleting Signals

To delete a signal:

1. Click the signal to select it.

2. Press the Delete key on the keyboard.

Note:

To change where a signal connects, first delete it then make the desired connection.

Watlow F4T® Controller • 27 • Chapter 2 Configuration Using Composer

Page 28

Removing Function Blocks from the Canvas

To remove a FB from the Canvas:

1. Delete all signals connected to the FB.

2. Click the FB to select it.

3. Press the Delete key on the keyboard.

Using Auto Hide

To toggle the auto hide option for a window or a group of windows:

• Click the pin (auto hide) icon in the window's title bar.

To use a window that is hidden:

• Mouse over (point the mouse cursor at) the window name.

Floating Windows

To float a window or a group of windows:

• Click-and-drag the window's title bar to the desired location.

To separate a window from a group:

• Click-and-drag the window name to the desired location.

Docking Windows

To return a floating window or a group of windows to its previous docking location:

• Double-click the title bar.

To change where a window or a group of windows is docked:

1. Click-and-drag the window's title bar until the anchor points appear

2. Drag the window until the mouse pointer is at the desired anchor point.

3. Release the mouse.

Hint:

• Some anchor points dock the window at the sides of the FBD view and others dock or

group the window with other windows.

Turn Floating Windows Off or On

To avoid the possibility of inadvertent window movement, this feature can be turned off.

To turn floating windows off:

• Right-click anywhere on the canvas and choose Turn off float in the pop-up menu.

To turn floating windows on:

• Right-click anywhere on the canvas and choose Turn on float in the pop-up menu.

Watlow F4T® Controller • 28 • Chapter 2 Configuration Using Composer

Page 29

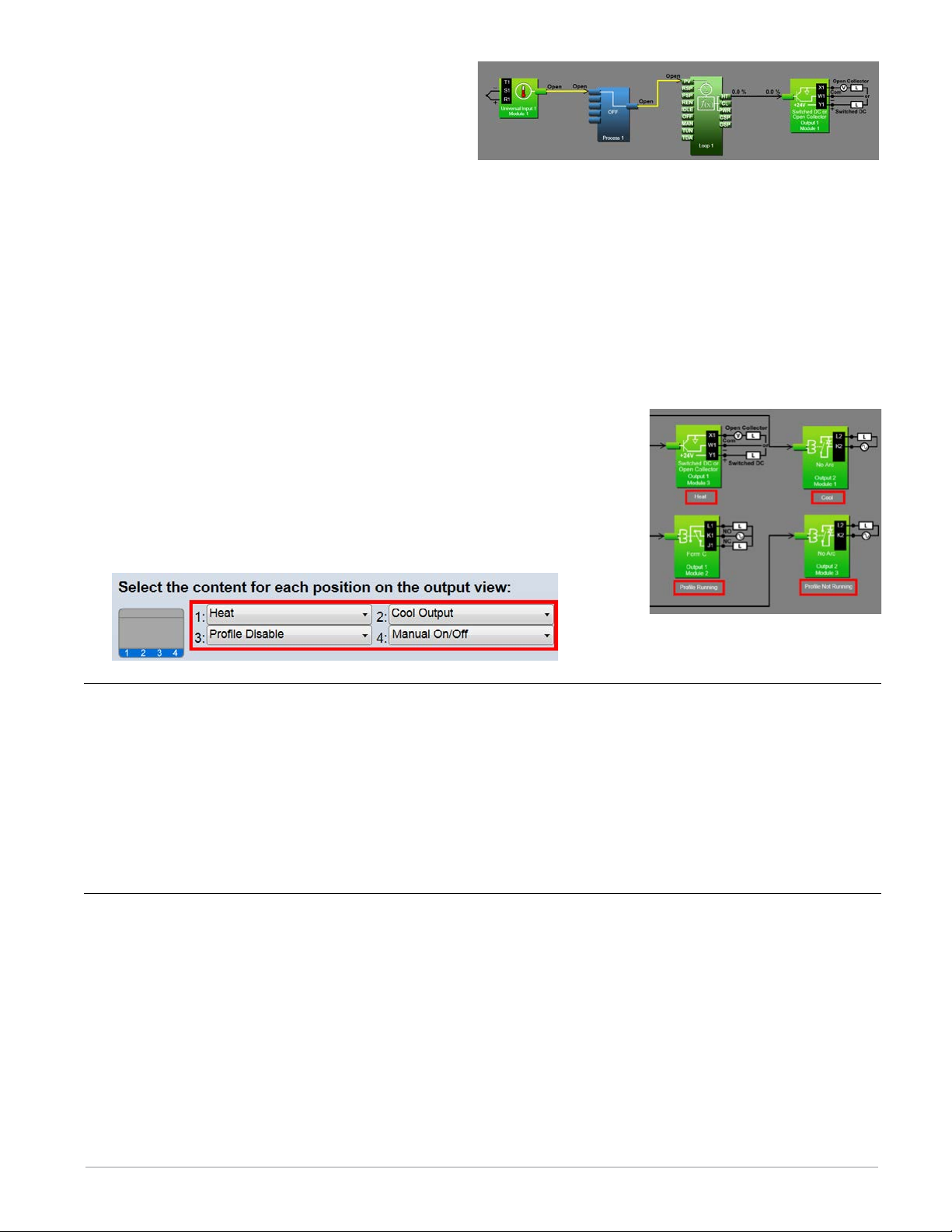

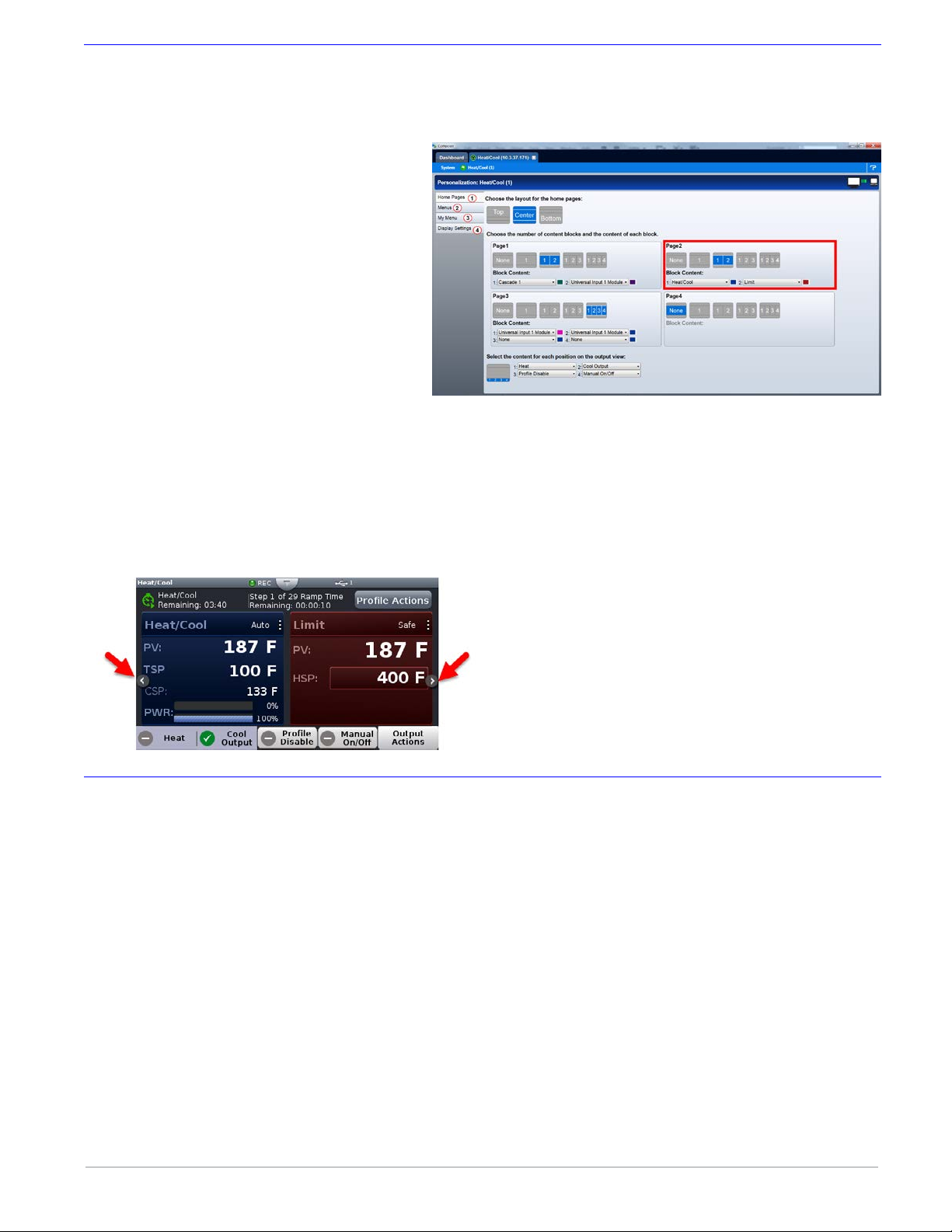

Personalizing the User Interface (UI) Using Composer

The home screen of the F4T® controller can be personalized to show multiple pages and

multiple content blocks within each (4 maximum). Until personalized, the home

screen will be blank. Features that are available on the Personalization screen

are numbered corresponding to their

associated descriptions below:

Home screen can be modified in

accordance with installed hardwar

and named FBs on the FBD

.

®

Modify user interface (UI) button colors

Create a customized menu to be viewed

on the UI.

Change the user interface screen

brightness.

To personalize the home screen:

• From the device menu choose Personalization from the drop down menu.

Much, if not all of what is displayed on the home pages comes from the FBD. Therefore, it

would make sense to first configure the FBD prior to personalizing the home screen.

The personalization settings shown above would produce a home page like the one below.

Because it was the second page configured as shown above (red box), notice the arrow

buttons on the right and left of screen capture below allowing navigation to page 1 and 3.

.

Setting Up Data Log Files Using Composer

Data Logging can be enabled at any time and will log a user selectable list of data points.

While data logging is enabled, the data log file is stored within either the USB device memory

or internal memory. Once the file reaches a specified size (if being transferred automatically), it

will be sent directly to one of three other destinations (USB, TFTP server or a Samba server).

The file transfer can also be initiated manually at any time. The file transfer process from

internal memory, whether completed automatically or manually, will move all log files from

internal memory to the selected destination. To learn more about data logging see

"Data Logging" in the Overview Section of this User Guide.

Note:

Data logging can also be enabled/configured through Modbus. There are specific Modbus

registers for each of the parameters defined below.

Watlow F4T® Controller • 29 • Chapter 2 Configuration Using Composer

®

Page 30

Topics discussed in this section follow:

Setup Data Logging: discusses required fields that must be set prior to starting data logging.

Configuring a Samba Shared Folder: identifies and gives illustrations in defining the necessary

user account and the shared folder.

Configuring a TFTP Server: details required setup fields while illustrating steps to successfully

move files from the F4T® to the TFTP destination.

Note:

Data logging is terminated when power is lost while the data log file itself will be maintained

where it was captured.

Setup Data Logging

To setup data logging, follow the steps below:

1. Click on the Device Menu tab.

2. From the drop down menu click on Data Logging.

3. Select and add all of the desired Data Points for the data log file.

Note:

Selected data points will be used whenever data logging is enabled.

4. Click on the Setup button.

- Logging Status: indicates whether or not recording is active or not.

- File Name: any alphanumeric characters, 63 maximum.

Note:

When transferring files via TFTP, do not create a file on the server called "testfile".

Communications between the F4T® and the TFTP server is tested prior to starting a

transfer using this filename while then verifying the response from the server.

- Log To: USB or Internal Memory.

Note:

When transferring files via TFTP or Samba, internal memory must be selected here.

Note:

There are many USB memory devices available. Watlow does not recommend using

micro SD or SD card to USB adapters in the USB slots. Be aware that we have not

tested all of the variations of USB memory devices but we have tested and validated

those that are listed below:

• Lexar, Kingston, Toshiba and Verbatim

Note:

Supported USB file systems: FAT16 and FAT32.

Note:

Due to wear-leveling operations of flash memory devices (internal - F4T® and external

- USB), there may be some gaps within the data logged file.

Note:

If logged file is sent to USB, the *.csv and the *.enc file are written directly to USB

constantly. If the File Size Limit is set to 10MB or larger, the csv will continue to be

written continuously while the encrypted portion (*.enc) is chunked into 7.5MB files,

buffered internally and then written out as 7.5MB chunks. If the maximum file size is

set to 10MB, there will be two *.enc files for each csv (7.5MB and 2.5MB). If File Size

Limit is set to 15MB, there would be two 7.5MB *.enc files for each *.csv file.

Watlow F4T® Controller • 30 • Chapter 2 Configuration Using Composer

Page 31

- Log Interval: defines the frequency in which the log will be written, 0.1 second to 60

minutes.

- File Type: Encrypted (filename.enc), comma separated values (filename.csv) or Both.

- File Size Limit: 20MB maximum when using internal memory, 1GB when using USB.

- Memory Full Action: when selected log to device is full, Overwrite or Stop.

Note:

Logging to USB allows for Stop only, when memory is full.

- Date Format: MM/DD/YYYY or DD/MM/YYYY.

Note:

Applies to each individual log entry alone, does not apply to filename.

- Time Format: 12 or 24 hour clock.

Note:

Applies to each individual log entry alone, does not apply to filename.

5. Click on the File Transfer button.

- Auto Transfer Type: None, TFTP, Samba or USB.

Note:

When automatic file transfer is enabled, the file as it's being created, will be buffered

in internal memory. The file will be moved to its destination when it either reaches the

maximum file size setting or the user stops data logging. If automatic transfer fails for

any reason, data logging will continue and the files will be stored in internal memory

until internal memory fills up. The setting for Memory Full Action (Overwrite or Stop)

will then be implemented.

Note:

A user can initiate a file transfer manually at any time if one or more of the available

destinations (USB, TFTP or Samba) have been configured.

- Samba User Name: Windows user account name with access to shared directory.

Note:

If using Asian fonts, you may need to create a Latin character set login for use with

Samba transfers.

- Samba Password: Windows user account password.

Note:

If using Asian fonts, you may need to create a user, and password, using the Latin

character set.

- Samba Path: shared directory path and name.

Note:

If using Asian fonts in the path name, please try using latin characters, or numbers as

your folder name, and share name.

- Remote IP Address: the IP address of the remote computer.

- Remote Host Name: the name of the remote computer.

- Transfer Progress: when a transfer is initiated this will reflect its progress from 0% to

100%.

Watlow F4T® Controller • 31 • Chapter 2 Configuration Using Composer

Page 32

Note:

If an error were to occur, as described below, this value could exceed 100.

- Transfer Results, will return the enumerated values shown below:

Enumerated Value Description Possible Causes Corrective Action

• Not configured, no

Blank Nothing to report

No Files to Transfer

Transfer Complete

Transferring Files

Server Down

Need Host IP IP address not present

No data log files in

internal memory

All data log files have

been moved from

internal memory

Data log files being

moved from internal

memory

Connectivity from client

to server not present

activity.

• Transfer not initiated.

• Data logging has not yet

been started.

• Files have already been

moved from internal

memory.

• File transfer initiated and

completed successfully.

• File transfer initiated and

in progress.

• Server not present.

• Server not configured or

configured incorrectly.

• No connectivity between

PC and F4T®.

• Incorrect IP address

entered.

- - - -

- - - -

- - - -

- - - -

Samba

• Check and ensure user account info

(name and password) is correct.

• Check and ensure that the shared

folder name is correct and shared

with the user account mentioned

above.

TFTP

• Ensure server is running and

configured for read/write capability.

TFTP

• Verify a physical connection between

PC and F4T®.

• Check the controller IP address from

the F4T® front panel: push Main Menu

> Settings > Network > Ethernet.

• Ping the F4T® to verify its presence

on the network.

Need Host Name

and IP

Error

Check Directory

Permissions, Host

Name and IP Address

Missing host name or IP

address

File transfer did not

occur successfully

• Not configured.

• Incorrect IP address or

host name entered.

• TFTP server configuration

not correct.

• Not configured.

• Incorrect IP address or

host name entered.

• Shared folder does not

have correct permissions.

Samba

• Ensure the computer name (Host) is

correct. Click on the Windows Start

button and type my computer in the

search field.

• Verify IP address (see: Need IP

Address above).

TFTP

• Server not configured with overwrite

capability, reconfigure server.

• Ensure server is not set for read only.

Samba

• Ensure the shared folder name exists

and that it is being shared with the

user account (Samba User Name).

• Verify IP address (see: Need IP

Address above).

• See the section entitled Configuring a

Samba Shared Folder below.

Watlow F4T® Controller • 32 • Chapter 2 Configuration Using Composer

Page 33

Configuring a Samba Shared Folder

Samba, also known as Server Message Block (SMB)/Common Internet File System (CIFS), is

fully supported by Windows File Sharing. Within this document, SMB/CIFS will be referred to

as Samba.

Samba, when in use, creates a directory on the F4T

®

device that maps to a shared directory

on the user’s PC. There are several ways that a Windows shared drive can be configured. With

this is mind, one of those ways will be discussed and used for demonstration purposes below.

Note:

If a user account already exists with full Administrator rights, steps 1 through 12 can be

skipped.

Setting up a Windows shared drive:

1. Click the Windows Start button and type user

accounts in the search box.

2. When the Make changes to your user account

window opens, click on Manage User Accounts.

3. When the User Accounts window opens, click on the

Advance tab.

4. Under Advance user management, click on the

Advance button.

5. Under the Name column right-click on Users and

then New User.

6. In this example the new user will be identified as "Samba" and will be entered into the User

name field as shown to the right.

Note:

To ensure that there will be no changes required regarding

the password, check Password never expires.

7. Click on Create and then Close.

8. Click on the X (top right corner) to close the

users w indow.

9. If not already open, navigate to Manage user

accounts and click on it. Once there, the new

user account should be visible as shown to the right.

10. Click the OK button.

11. Click on the X (top right corner) to close the User Account window.

12. Navigate to Windows Explorer and create a new folder.

Note:

The name of the shared folder must not contain any slashes, or back-slashes.

Note:

If the folder being created is a sub-folder off of the root directory, right click on the created

folder > select Properties > Sharing > Advanced Sharing and check Share this folder.

Doing this will allow the sub-folder path to be defined as if it were in the root directory of the

selected domain. Lastly, click on Permissions and ensure that all boxes under Allow are

checked as shown below.

Watlow F4T® Controller • 33 • Chapter 2 Configuration Using Composer

Page 34

13. Right-click on the folder created above and then mouse over Share with and click on

Specific People.

14. Click on the drop down button and then Find people.

15. Enter the object name "Samba" and then

click on the Check Names button.

16. Click the OK button.

17. Click on the drop down button and ensure

the folder is set for Read/Write capabilities

as shown below.

18. Click Share.

The graphic below shows the folder as being shared.

Watlow F4T® Controller • 34 • Chapter 2 Configuration Using Composer

Page 35

After the user account has been identified or created and the shared folder has been setup it

is time to configure the File Transfer function within the controller. The graphics below show all

fields that must be filled in to do an automatic transfer of the data logged file to the shared

folder identified in this example as SambaStore.

Note:

Transferring files via Samba may be accomplished by 2 methods; Auto-transfer, and a user

initiated transfer. Once the automatic transfer is enabled this function will move the file to the

remote computers shared folder whenever data logging is running and the set file size has

been reached. The graphics that follow illustrate automatic transfer.

First, a couple of fields (parameters) within Setup must be addressed, identified in the red

boxes below.

Log to - must be set to internal memory to automatically move the files to the shared folder.

File Size Limit - defines the maximum file size that will be moved to the shared drive.

Second, based on the example entries made above, the File Transfer fields need to be filled in

accordingly.

After these screens have been populated as shown, data logged files, once they reach

approximately 1MB in size, will be moved from internal memory to the shared folder

(SambaStore).

Configuring a Trivial File Transfer Protocol (TFTP) Server

In order to use the TFTP file transfer option, a TFTP server must be setup and running on your

computer to service the TFTP transfers from the F4T®. The user will need to specify the IP

address of the remote computer, and also the remote computer name.

TFTP requires no authentication and can transfer a file as large as 20MB to a remote host

computer. There are many TFTP servers available and many can be downloaded off the

internet free of charge. To enable a TFTP transfer, within Composer or via the UI, simply enter

the IP address for the remote computer and ensure the TFTP server is running on the remote

computer.

Watlow F4T® Controller • 35 • Chapter 2 Configuration Using Composer

Page 36

Configuring the TFTP Transfer:

1. Because there are several TFTP servers available note that naming may be different. What

is most important from the server standpoint is that the appropriate IP bindings are set

while the security allows for read/write capability as shown below.

2. Navigate back to the section entitled Setup Data Logging and follow the procedure to

define what it is to be captured within the file. Within this same procedure (step 5), it will be

important to define the IP address of the remote computer while also determining whether

the file will be transferred manually or automatically.

3. Start the TFTP server and then start data logging by pushing the following buttons on the

F4T® front panel: Main Menu > Data Logging > Start

If the file does not seem to be transferring as expected check out the parameter identified

above as Transfer Results and the table that follows it for some assistance.

Creating and Editing Profiles Using Composer

This section describes the features of the Profile View and includes instructions for using it. To

learn about profiles see "What is a Profile" in the Overview Section of this User Guide.

Note:

The Profile Engine function block must have one or more of its receivers (PV1 through PV4)

connected prior to creating or editing profiles with this view. To learn more about how to set

up the Profile Engine, see the Profile Ramp and Soak section in Chapter 4 Applications

Examples and the Profile section in Chapter 5 in this User's Guide.

Profile View Orientation: describes the layout of the profile screens.

Profile Parameters: settings that apply to a profile.

Step Parameters: settings that apply to a step.

Opening the Profile View: displays the list of profiles in the device.

Creating Profiles: up to 40 profiles can be created.

®

Saving a profile: store profiles on the computer to make it easy to load them in other controllers

or to restore one that was inadvertently changed or deleted from the controller.

Loading a Profile: loads a profile that was previously saved to the controller's memory.

Duplicating a Profile: is an easy way to create a new profile similar to one that was created

previously.