Page 1

ISO 9001

EZ-ZONE® RMA (Access) Module

User’s Guide

RMA Module

TOTAL

CUSTOMER

SATISFACTION

3 Year Warranty

Registered Company

Winona, Minnesota USA

1241 Bundy Boulevard., Winona, Minnesota USA 55987

Phone: +1 (507) 454-5300, Fax: +1 (507) 452-4507 http://www.watlow.com

0600-0072-0000 Rev. B Made in the U.S.A.

March 2016

Page 2

Safety Information

• We use note, caution and warning symbols throughout this book to draw your attention to

important operational and safety information.

• A “NOTE” marks a short message to alert you to an important detail.

• A “CAUTION” safety alert appears with information that is important for protecting your

equipment and performance. Be especially careful to read and follow all cautions that

apply to your application.

• A “WARNING” safety alert appears with information that is important for protecting you,

others and equipment from damage. Pay very close attention to all warnings that apply to

your application.

• The safety alert symbol, (an exclamation point in a triangle) precedes a general

CAUTION or WARNING statement.

• The electrical hazard symbol, (a lightning bolt in a triangle) precedes an electric shock

hazard CAUTION or WARNING safety statement. Further explanations follow:

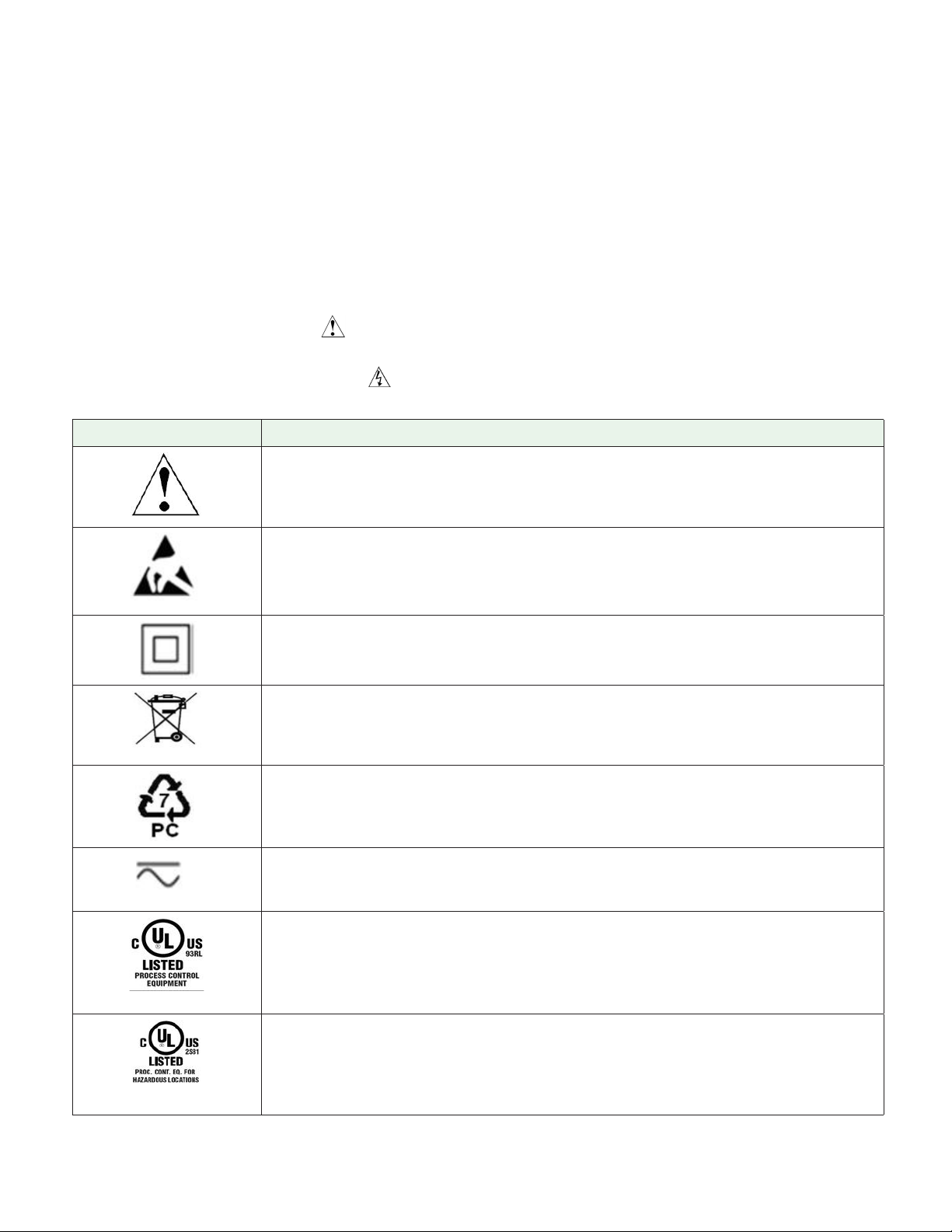

Symbol Explanation

CAUTION – Warning or Hazard that needs further explanation than label

on unit can provide. Consult User's Guide for further information.

ESD Sensitive product, use proper grounding and handling techniques

when installing or servicing product.

Unit protected by double/reinforced insulation for shock hazard prevention.

Do not throw in trash, use proper recycling techniques or consult manufacturer for proper disposal.

Enclosure made of Polycarbonate material. Use proper recycling techniques or consult manufacturer for proper disposal.

Unit can be powered with either alternating current (ac) voltage or

direct current (dc) voltage.

Unit is a Listed device per Underwriters Laboratories®. It has been evaluated to United States and Canadian requirements for Process Control

Equipment. UL 61010 and CSA C22.2 No. 61010. File E185611 QUYX,

QUYX7. See: www.ul.com

Unit is a Listed device per Underwriters Laboratories®. It has been evaluated to United States and Canadian requirements for Hazardous Locations Class 1 Division II Groups A, B, C and D. ANSI/ISA 12.12.01-2007.

File E184390 QUZW, QUZW7. See: www.ul.com

Page 3

Unit is compliant with European Union directives. See Declaration of

Conformity for further details on Directives and Standards used for Compliance.

Unit has been reviewed and approved by Factory Mutual as a Temperature Limit Device per FM Class 3545 standard. See: www.fmglobal.com

Unit has been reviewed and approved by CSA International for use as

Temperature Indicating-Regulating Equipment per CSA C22.2 No. 24.

See: www.csa-international.org

Unit has been reviewed and approved by ODVA for compliance with DeviceNet communications protocol. See: www.odva.org

Unit has been reviewed and approved by ODVA for compliance with Ethernet/IP communications protocol. See: www.odva.org

Warranty

The EZ-ZONE® RMA (Access) module is manufactured by ISO 9001-registered processes and is

backed by a three-year warranty to the first purchaser for use, providing that the units have

not been misapplied. Since Watlow has no control over their use, and sometimes misuse, we

cannot guarantee against failure. Watlows’ obligations hereunder, at Watlows’ option, are

limited to replacement, repair or refund of purchase price, and parts which upon examination prove to be defective within the warranty period specified. This warranty does not apply

to damage resulting from transportation, alteration, misuse or abuse. The purchaser must use

Watlow parts to maintain all listed ratings.

Technical Assistance

If you encounter a problem with your Watlow controller, review your configuration information to verify that your selections are consistent with your application: inputs, outputs,

alarms, limits, etc. If the problem persists, you can get technical assistance from your local

Watlow representative (see back cover), by e-mailing your questions to wintechsupport@watlow.com or by dialing +1 (507) 494-5656 between 7 a.m. and 5 p.m., Central Standard Time

(CST). Ask for for an Applications Engineer. Please have the following information available

when calling:

• Complete model number

• All configuration information

• User’s Guide

• Factory Page

1. Call Watlow Customer Service, (507) 454-5300, for a Return Material Authorization (RMA)

number before returning any item for repair. If you do not know why the product failed,

contact an Application Engineer or Product Manager. All RMA’s require:

• Ship-to address

• Bill-to address

• Contact name

• Phone number

Page 4

• Method of return shipment

• Your P.O. number

• Detailed description of the problem

• Any special instructions

• Name and phone number of person returning the product.

2. Prior approval and an RMA number from the Customer Service Department is required when

returning any product for credit, repair or evaluation. Make sure the RMA number is on the

outside of the carton and on all paperwork returned. Ship on a Freight Prepaid basis.

3. After we receive your return, we will examine it and try to verify the reason for returning

it.

4. In cases of manufacturing defect, we will enter a repair order, replacement order or issue

credit for material returned. In cases of customer misuse, we will provide repair costs and

request a purchase order to proceed with the repair work.

5. To return products that are not defective, goods must be in new condition, in the original boxes and they must be returned within 120 days of receipt. A 20 percent restocking

charge is applied for all returned stock controls and accessories.

6. If the unit cannot be repaired, you will receive a letter of explanation. and be given the

option to have the unit returned to you at your expense or to have us scrap the unit.

7. Watlow reserves the right to charge for no trouble found (NTF) returns.

This EZ-ZONE RMA User’s Guide is copyrighted by Watlow Electric, Inc., © March 2016 with all

rights reserved.

EZ-ZONE RM is covered by U.S. Patent No. 6,005,577 and Patents Pending

Page 5

TC

Table of Contents

Table of Contents .......................... 1

Chapter 1: Overview ........................ 3

A Conceptual View of the RM System .................6

Chapter 2: Install and Wire ....................10

Dimensions ...............................10

Power Supplies ............................11

RM Installation and Removal on a DIN Rail ............14

Wiring ........................................16

Conventions Used in the Menu Pages ................24

Chapter 3: Operations Page ...................27

Data Logging Menu ..............................28

Backup Menu ...................................29

Backup Status Menu .............................30

Chapter 4: Setup Pages ......................31

Global Menu ....................................33

Communications Menu ...........................33

Local Remote Gateway Menu ......................38

Real Time Clock Menu ............................41

Profile Menu ...................................43

Data Logging Menu ..............................43

Log Point Menu .................................46

Backup Menu ...................................48

Variable Menu ..................................50

Chapter 5: Factory Pages .....................51

RMA Module - Factory Page Parameters ..............51

Remote User Interface (RUI) Security Settings .........52

Remote User Interface (RUI) Security Settings .........54

Diagnostics Menu ...............................54

Chapter 6: RMA Features .....................56

Saving and Restoring Settings Using an RUI .....57

Using Password Security .........................57

Real Time Clock (RTC) ............................58

Data Logging ...................................59

Backup ........................................60

Restore .......................................60

Software Configuration ...........................61

Using EZ-ZONE® Configurator Software .............61

Function Block Descriptions .......................66

Backup / Restore Function .......................66

Communications ...............................67

Modbus® RTU ................................68

Data Logging .................................69

Diagnostics Function ...........................71

Watlow EZ-ZONE® RMA Module • 1 • Table of Contents

Page 6

TC

Table of Contents (cont.)

Gateway Function ..............................72

Global Function ................................76

Real Time Clock Function ........................76

Security Function ..............................77

Variable Function ..............................78

Chapter 7: RMA Communications ...............79

EZ-ZONE RMA & Communications ..................79

Protocols ....................................79

Modbus .......................................79

Common Industrial Protocol (CIP) ..................88

Compact Implicit Assembly Class ...................89

Profibus DP ....................................96

Chapter 8: Appendix ........................99

Modbus - User Programmable Memory Blocks .........99

CIP Implicit Assembly Structure ...................102

Compact Class Assembly Structure .................106

RMA Specifications .............................113

RMA Ordering Information .......................116

How to Reach Us ...............................118

Watlow EZ-ZONE® RMA Module • 2 • Table of Contents

Page 7

1

Chapter 1: Overview

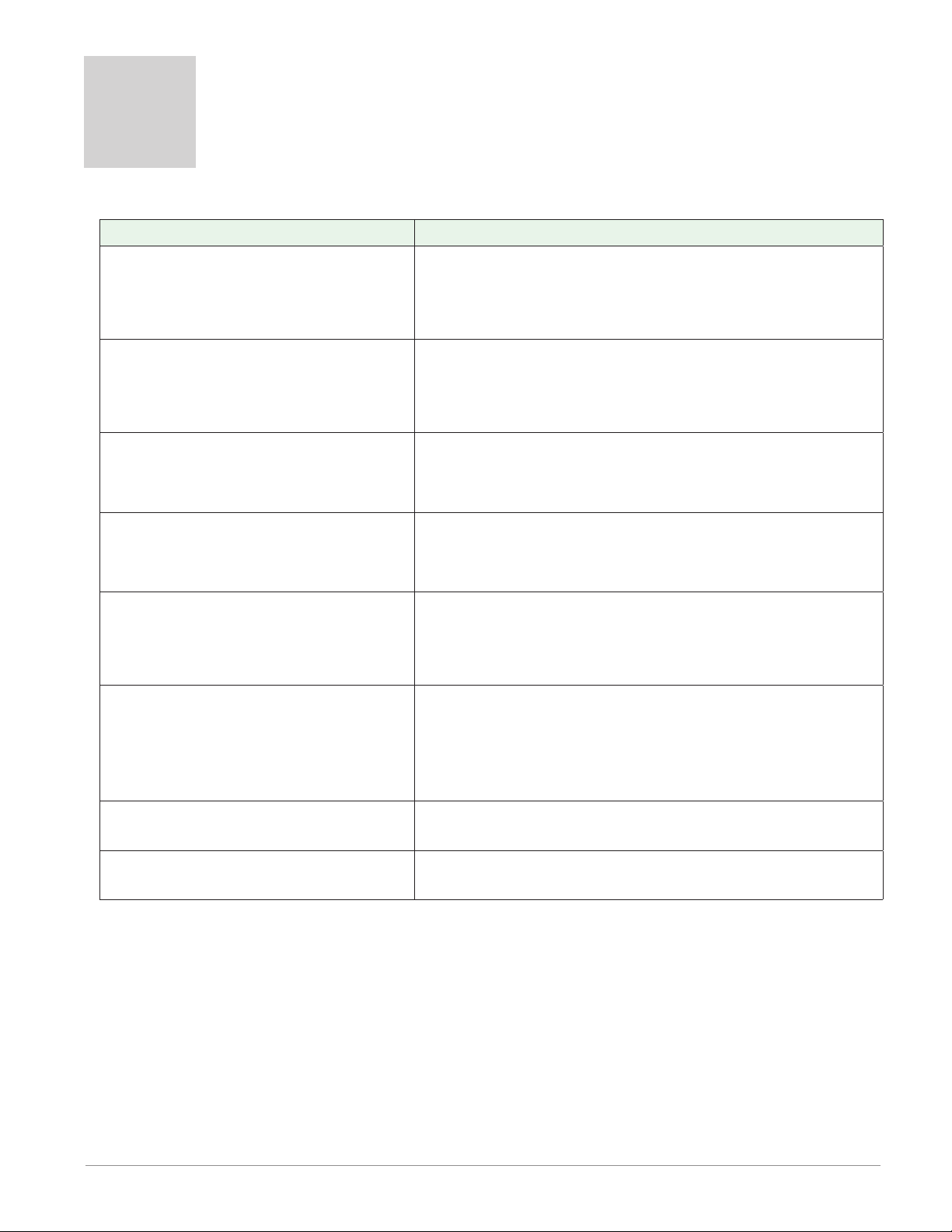

Available EZ-ZONE RM System Literature and Resources

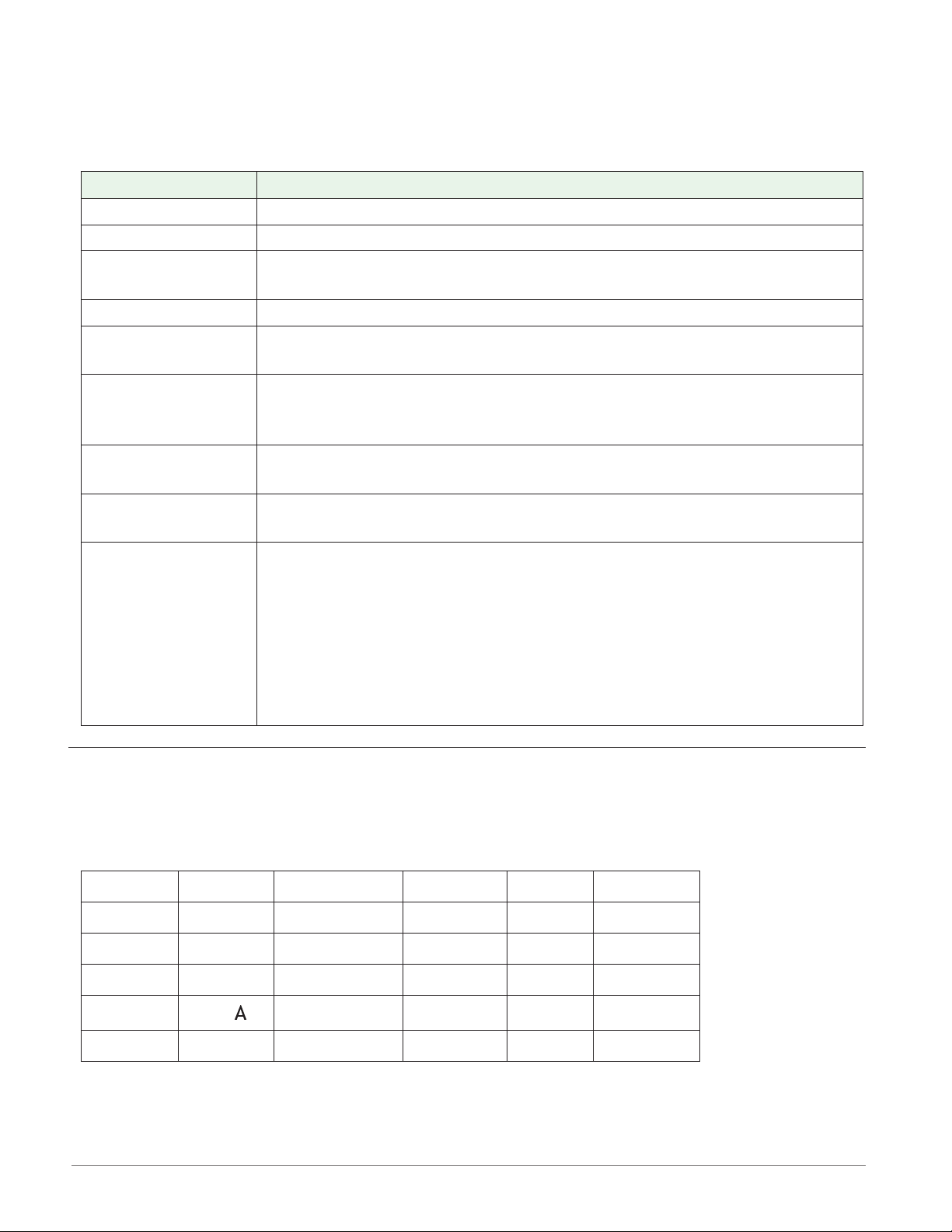

Document Title and Part Number Description

EZ-ZONE Rail Mount High Density

(RMH) User's Guide, part number:

0600-0074-0000

EZ-ZONE Rail Mount Controller

(RMC) User's Guide, part number:

0600-0070-0000

This module extends the density of the standard RM

modules (number of control loops and I/O points).

The User Guide describes common usage, communications and the number I/O points available.

The RMC module is an advanced integrated controller capable of PID and limit control. This document

describes how to configure and program all loops of

control and communications.

EZ-ZONE Rail Mount Scanner (RMS)

User's Guide, part number: 0600-

0071-0000

EZ-ZONE Rail Mount Expansion

(RME) User's Guide, part number:

0600-0073-0000

EZ-ZONE Rail Mount Limit (RML)

User's Guide, part number: 0600-

0075-0000

EZ-ZONE Remote User Interface

(RUI) User's Guide, part number:

0600-0060-0000

EZ-ZONE RM Specification Sheet,

part number: WIN-EZRM-0414

Watlow Support Tools DVD, part

number: 0601-0001-0000

This module adds monitoring points to the RM system. This document describes common usage and

the various types of I/O available.

When additional I/O is needed the Expansion module

fills the gap. This document describes common usage

and the various types of I/O available.

The RML module will protect against unwanted thermal runaway and over temperature conditions. The

User Guide describes configuration, programming

and communications capabilities.

The RUI provides a visual LED display to the RM

configuration and setup menus. This document illustrates and describes connections and also describes

the Home Page for each RM module as viewed from

the RUI.

Describes RM hardware options, features, benefits

and technical specifications.

Contains all related user documents, tutorial videos,

application notes, utility tools, etc...

The DVD described above ships with the product and as stated contains all of the literature

above as well as much more. If the DVD is not available one can be acquired by contacting

Watlow Customer Service at 1-507-454-5300.

As an alternative to the DVD, all of the user documentation described above can also be

found on the Watlow website. Click on the following link to nd your document of choice:

http://www.watlow.com/literature/index.cfm. Once there, simply type in the desired part

number (or name) into the search box and download free copies.

Watlow EZ-ZONE® RMA Module • 3 • Chapter 1 Overview

Page 8

Your Comments are Appreciated

In an effort to continually improve our technical literature and ensure that we are providing information that is useful to you, we would very much appreciate your comments and

suggestions. Please send any comments you may have to the following e-mail address:

TechlitComments@watlow.com

Introduction

The EZ-ZONE® RM Access (RMA) module provides several features (if ordered) for the entire

RM product family. To name a few:

• Multiple eld bus protocols

• Data logging capabilities (up to 200 data points)

• Real Time Clock with Battery Backup

• Automatically (upon power restoration) re-enable a prole to run after a power loss

• Auto-Conguration Backup

Standard Features and Benefits

Communication Capabilities

• Provides a wide range of protocol choices including Modbus® RTU, EtherNet/IP™, Modbus®

TCP, DeviceNet™ and Profibus DP

• Serves as a configuration station

• Provides communication capabilities between the other modules and the PC or PLC

• Stores corresponding module parameter settings for easy auto-configuration of other additional modules or replacement modules

• Serves as a configuration station, which programs initial module setup or automatic programming of modules if swapping out after initial installation

• Provides a USB port for uploading and download-ing configuration or datalog files directly

to a PC

• Saves time and increases reliability of parameter setting

On-board Data Logging Memory

• Ensures vital data is retained

• Downloads data files from the controller when-needed eliminating the need for a separate

chart recorder

Off-the-Shelf Designed System Solution

• Improves system reliability with a factory inte-grated solution that minimizes inter-module

con-nections and potential problems at screw termina-tion points.

• Reduces installation cost

• Eliminates compatibility headaches often encoun-tered with using many different components and brands

Memory for Saving and Restoring User-Defined Parameter Default Settings

• Allows customers to save and restore their own defined defaults for machine parameter

settings

• Reduces service calls and downtime due to inad-vertent end user parameter adjustments

Watlow EZ-ZONE® RMA Module • 4 • Chapter 1 Overview

Page 9

System Integration is Made EZ with Unmatched Flexibility

• Comes with a wide range of communication op-tions such as Ethernet which makes connecting to PLC’s and touchpanel products a snap

• Provides plug and play capabilities with basic Re-mote User Interface (RUI’s), see EZK accessory listings

• Free standard bus communications port and free PC software (EZ-ZONE Configurator and

Composer)

Modules Allow for Greater Design Flexibility

• The RM System allows for 17 total modules in-cluding an Access module)

• Saves money because you do not pay for any more than you need and don’t settle for any

less func-tionality than you need

Split-Rail Control (SRC)

• Allows modules to be mounted together or mount-ed remotely from one another

• Shares control operation via Synergistic Module Control (SMC) capability

• Allows individual modules to be mounted closer to the physical input and output devices

to which they are wired

• Improves system reliability and lowers wiring costs

Agency Certifications: UL® listed, CE, RoHS, W.E.E.E. SEMI F47-0200, Class 1 Div. 2 Rating

on Selected Models

• Assures prompt product acceptance

• Reduces panel builder's documentation and agency costs

Removable Connectors

• Assures reliable wiring and reduces service calls

• Simplifies installation

• Provides a terminal option for accepting ring lug connection

Three-Year Warranty

• Demonstrates Watlow’s reliability and product support

Watlow EZ-ZONE® RMA Module • 5 • Chapter 1 Overview

Page 10

A Conceptual View of the RM System

The exibility of the RM family modules and software allows for a large range of congurations. Acquiring a better understanding of the application requirements and then the overall

functionality and capabilities of each RM module will help to ensure maximum system performance.

The RM system at a high level can have a total of 17 modules installed, only one of which

can be an RMA module and the others (16 maximum) can be any combination of available RM

modules. Each installed RM module must have a unique Standard Bus address (factory default

for an RMA is J while all other RM modules would be 1) ranging from 1-я, A-F (10 -15) and h

(16). Default zone addresses can be changed on any RM module using the button on the face

of each module. Ensure that each module has a unique address.

The RMA can be considered an accessory RM module in that by itself it has no PID control

loops. However, used in conjunction with an RM Control (RMC), RM High Density (RMH) or

an RM Expansion (RME) module, it could be placed in a remote location up to 200 feet away

from any of the other RM modules on the network. While in a remote location, the RMA is

still fully capable of using all of its features, such as, the real time clock (used with proles)

and data logging. This can be done while also providing communications to / from a master

device on the eldbus network.

Some of the user selectable ordering options are listed below:

1. Class 2 or SELV (Saftey Extra Low Voltage) equivalent Power Supplies:

• 90-264 Vac to 24Vdc @ 31 watts

• 90-264 Vac to 24Vdc @ 60 watts

• 90-264 Vac to 24Vdc @ 91 watts

2. The RMA Module can provide:

• Multiple eld bus protocols

• Data logging capabilities (up to 200 data points)

• Real Time Clock with Battery Backup

• Automatically (upon power restoration) re-enable a prole to run after a power loss

• Auto-Conguration Backup

Note:

All RM modules can share data over the backplane (local and split rail). Once the system is

configured and running, changing zone addresses without careful deliberation may cause

disruption in operation.

RM System Configurations Using and RMA

Due to the scalability and exibility in the system components a user has several options

available in the way that the hardware can be connected.

Watlow EZ-ZONE® RMA Module • 6 • Chapter 1 Overview

Page 11

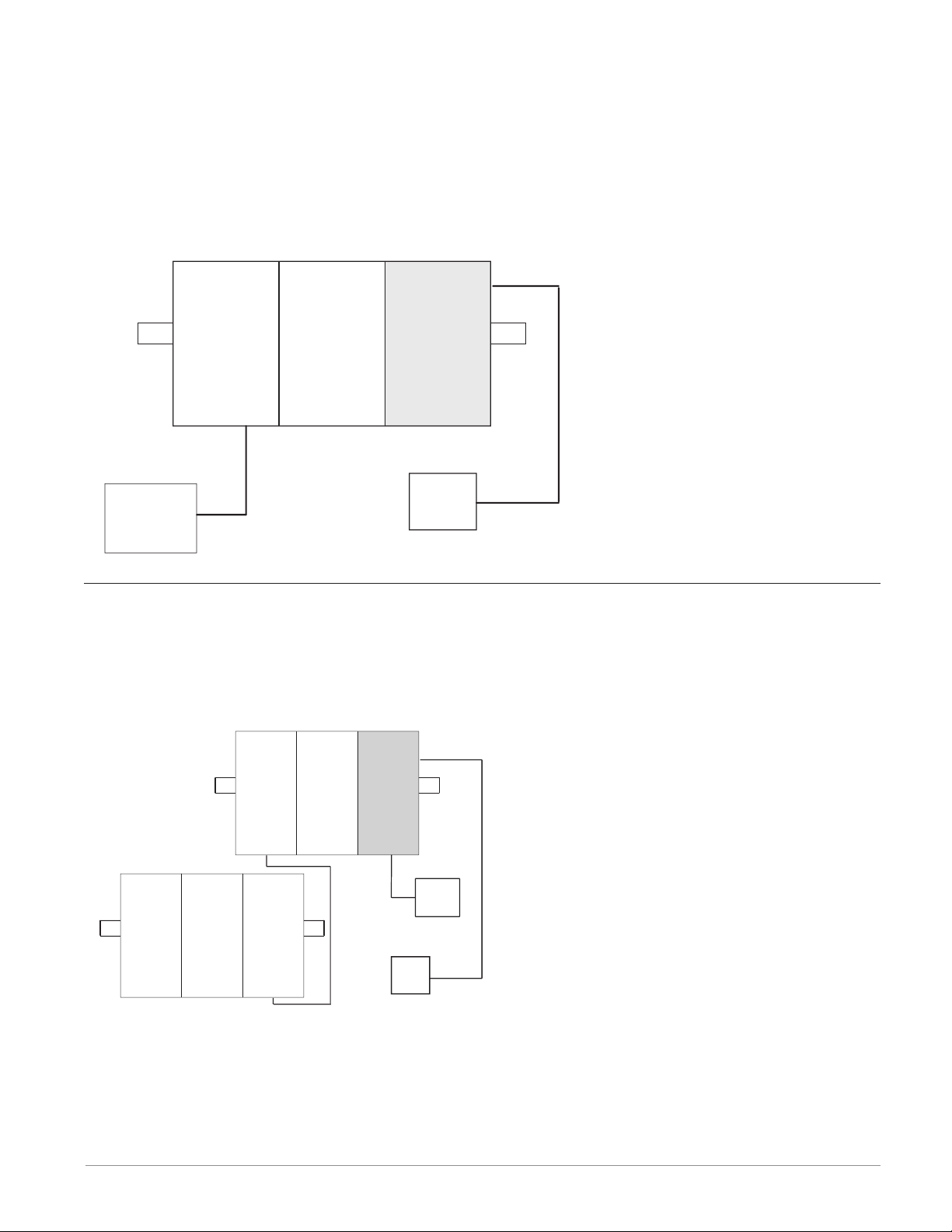

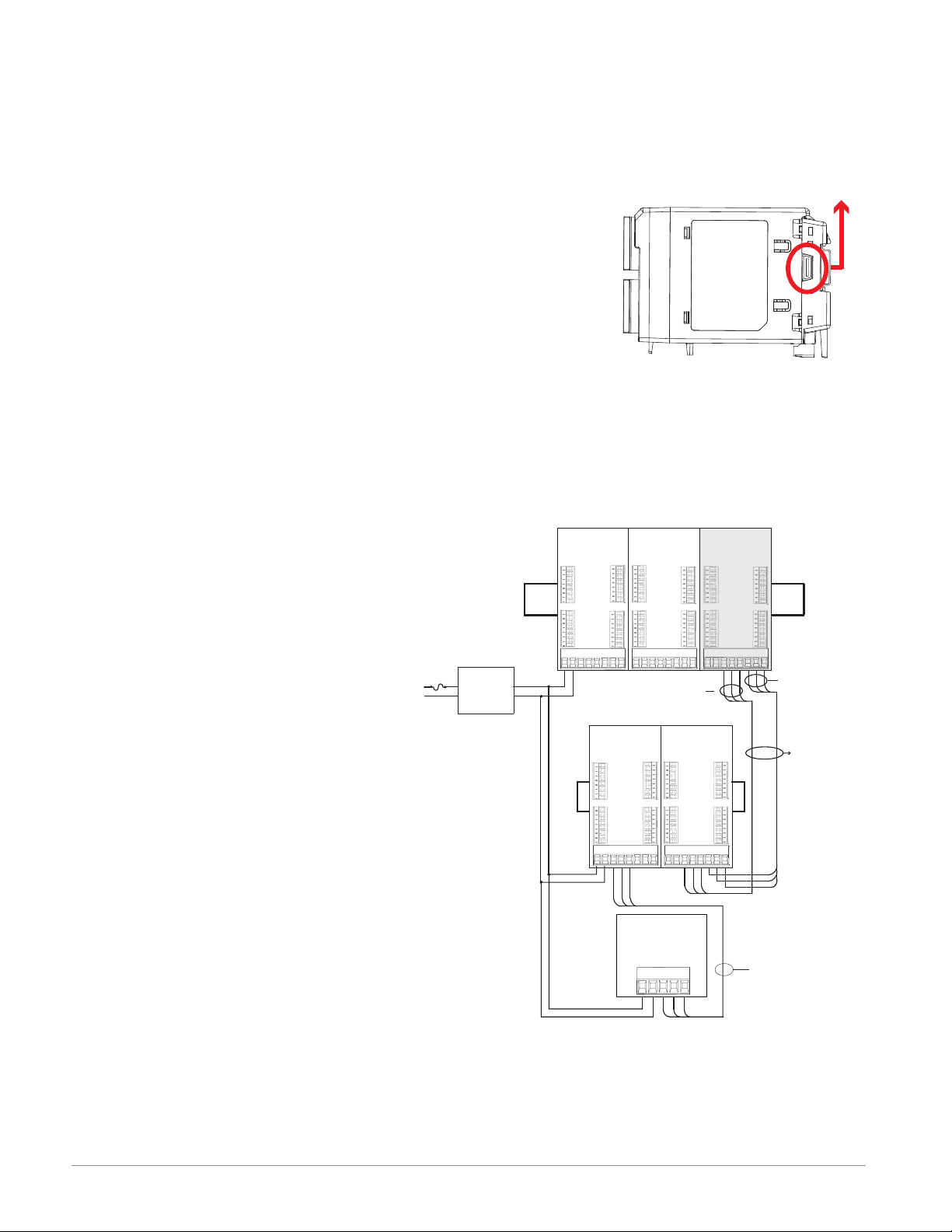

RM System Connected to a Programmable Logic Controller (PLC) on a DIN Rail

In this conguration, the PLC can be connected to the RM system via the RMA module using

one or more available protocols:

1. EtherNet/IP and or Modbus TCP

2. DeviceNet

3. Modbus RTU

4. Probus DP

Slot E

RM

RM

RM

Control

Expansion

Access

Slot CSlot CSlot C

Power

PLC

Supply

RM System Connected to a Split Rail with an Operator Interface Terminal (OIT)

In this conguration both the Inter-module Bus (backplane communications) and Standard

Bus are connected between rails to allow for remote capabilities. It is recommended that

the split rail connection not exceed 200 feet. In this conguration the OIT can communicate

with all modules (maximum 16 modules any combination with one Access module).

RM

Control

RM

Expansion

RM

Access

Slot E

Slot C

RM

Control

Slot C

Watlow EZ-ZONE® RMA Module • 7 • Chapter 1 Overview

RM

Expansion

Slot C

RM

Expansion

Slot C

Slot C

Slot C

Power

Supply

OIT

Page 12

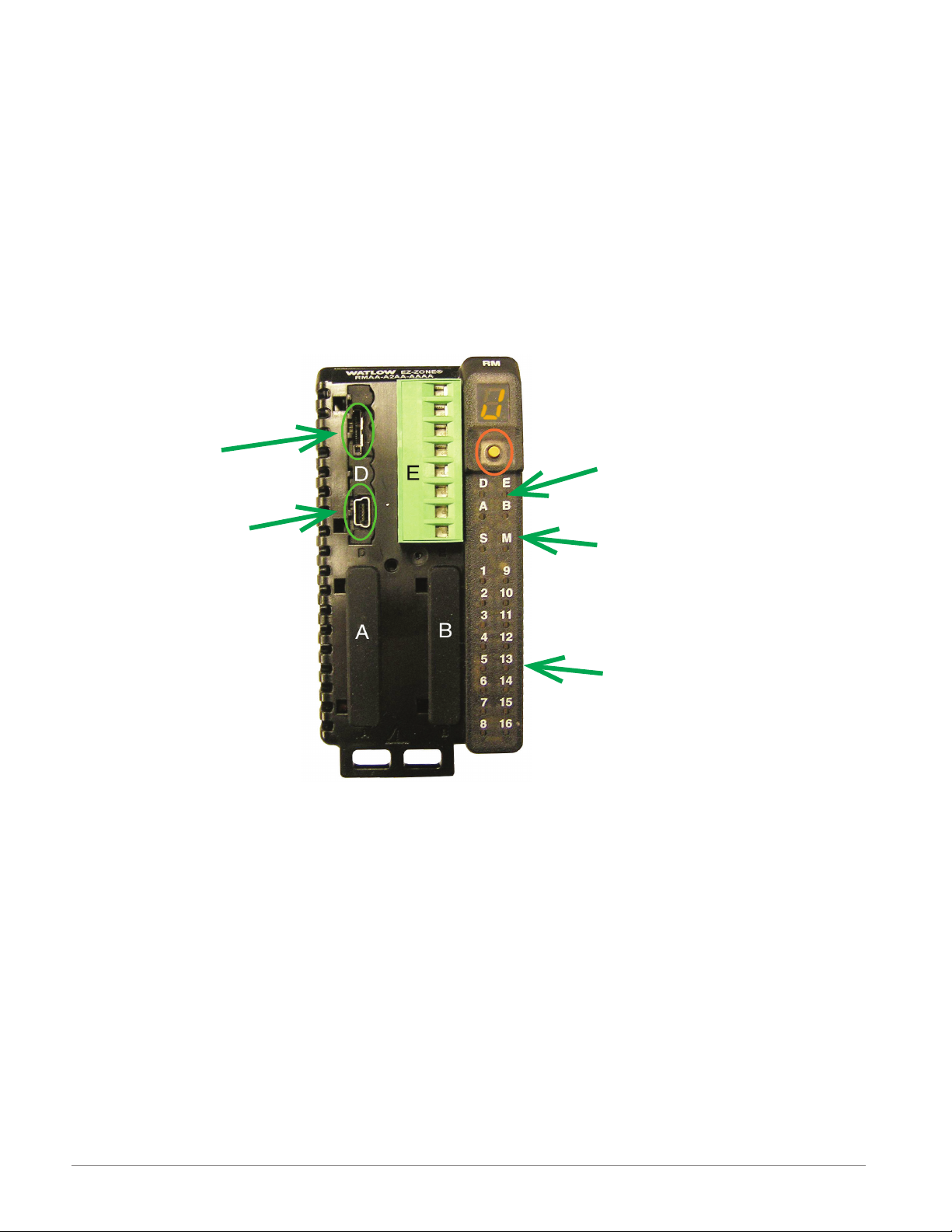

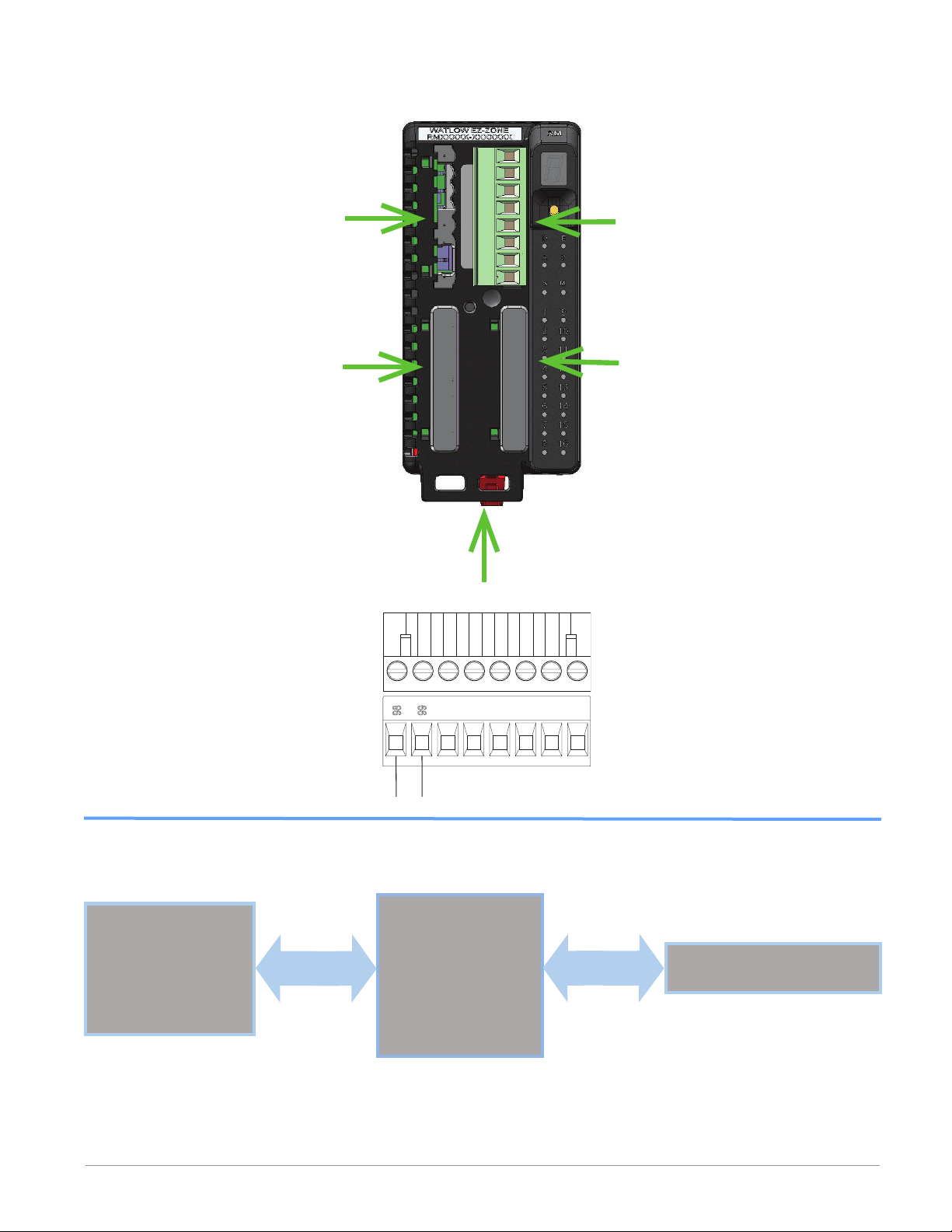

Module Orientation

The picture below reects a front view of an RMA module. Like all RM modules, there are

four slots that appear on the face (slot A, B, D, and E) of the module and one on the bottom

(slot C) not shown. For this particular module only slots D and E can be used. On the face of

the module there is a button (orange circle) under the Zone address J that when pushed and

held has the following function:

1. Push and hold for ~ 2 seconds to change the Zone address. Valid addresses range from 1

to 17 (1 - я, a is 10, b is 11, C is 12, d is 13, E is 14, f is 15, and h is 16). The Access

module is shipped (default factory address) at address J or 17

Note:

For correct operation and accuracy, the module must be mounted in a vertical orientation

as shown.

SD Card

USB, Mini Type B

connector

Module Status (Slot

A, B, D or E not used

on this module

Backplane protocol

(for this module always

set to Standard Busred)

Output indicators (1 to

16) not used on this

module.

Watlow EZ-ZONE® RMA Module • 8 • Chapter 1 Overview

Page 13

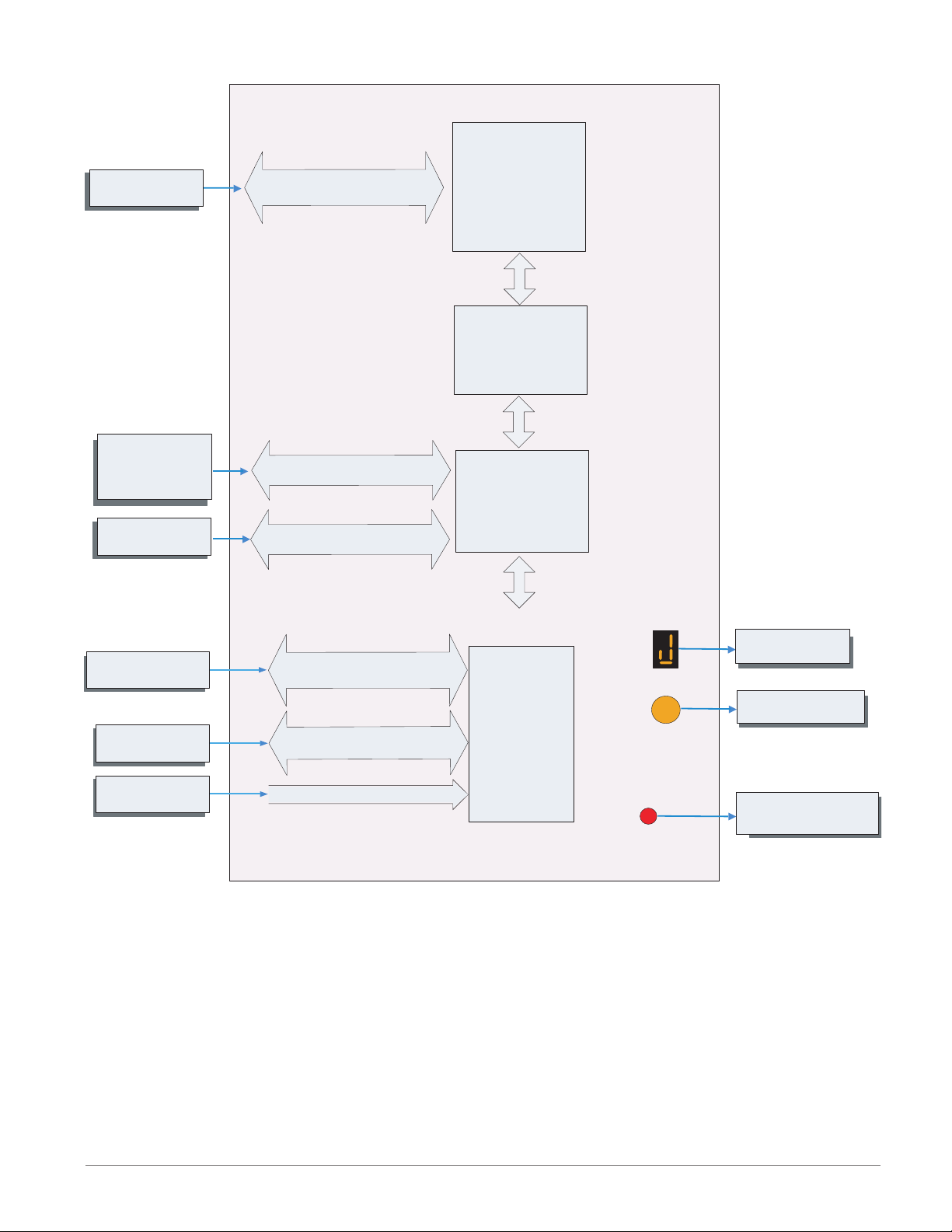

EZ-ZONE RM-Access Module - System Diagram

Input

Function

PLC, PC or OIT

Storage Device

(Configuration,

Memory and Data

Logging)

EIA - 232/485 or Ethernet

Fieldbus Protocol

Micro SD

Memory Socket

Output

Function

Protocol of Choice

- EtherNet/IP

- DeviceNet

- Modbus RTU

- Modbus TCP

- Profibus DP

Slot E

(optional)

Profile Ramp & Soak

Battery Backup &

Real Time Clock

(optional)

Auto Configuration,

Backup, USB Port

and Data Logging

PC

RUI, PC

Other RM Modules

Power Supply

Mini Type B USB Port v1.1

(as device only)

EIA - 485 Communications

Standard Bus

Inter-module Bus

20.4 to 30.8 Vac or Vdc

Slot D

(optional)

Standard Bus

Zone 1 - 17

Supervisory &

Power Board

Slot C

Zone Selection

Button

S

Indicates Zone

Address

Push to select Zone

Address

Indicates Standard Bus

communications activity

Watlow EZ-ZONE® RMA Module • 9 • Chapter 1 Overview

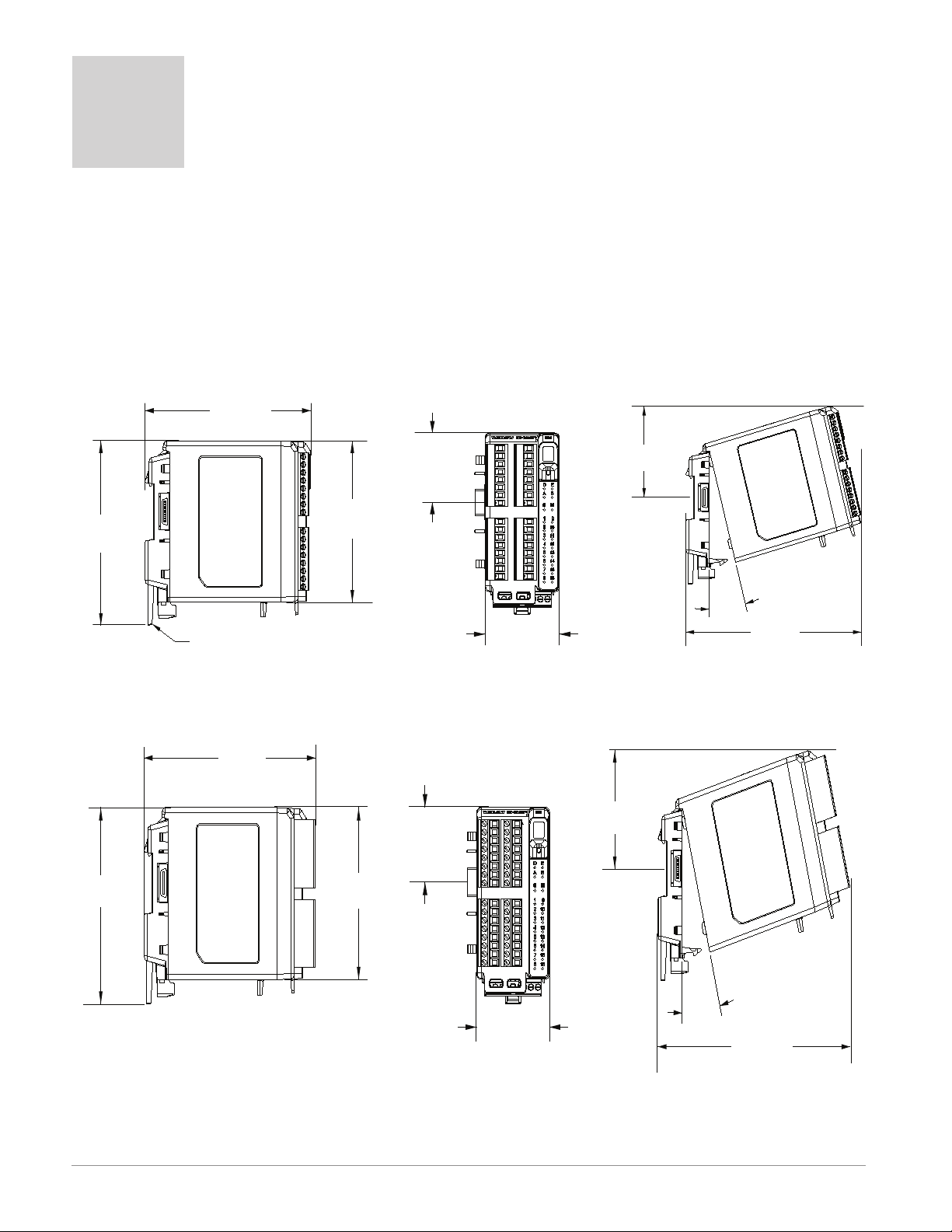

Page 14

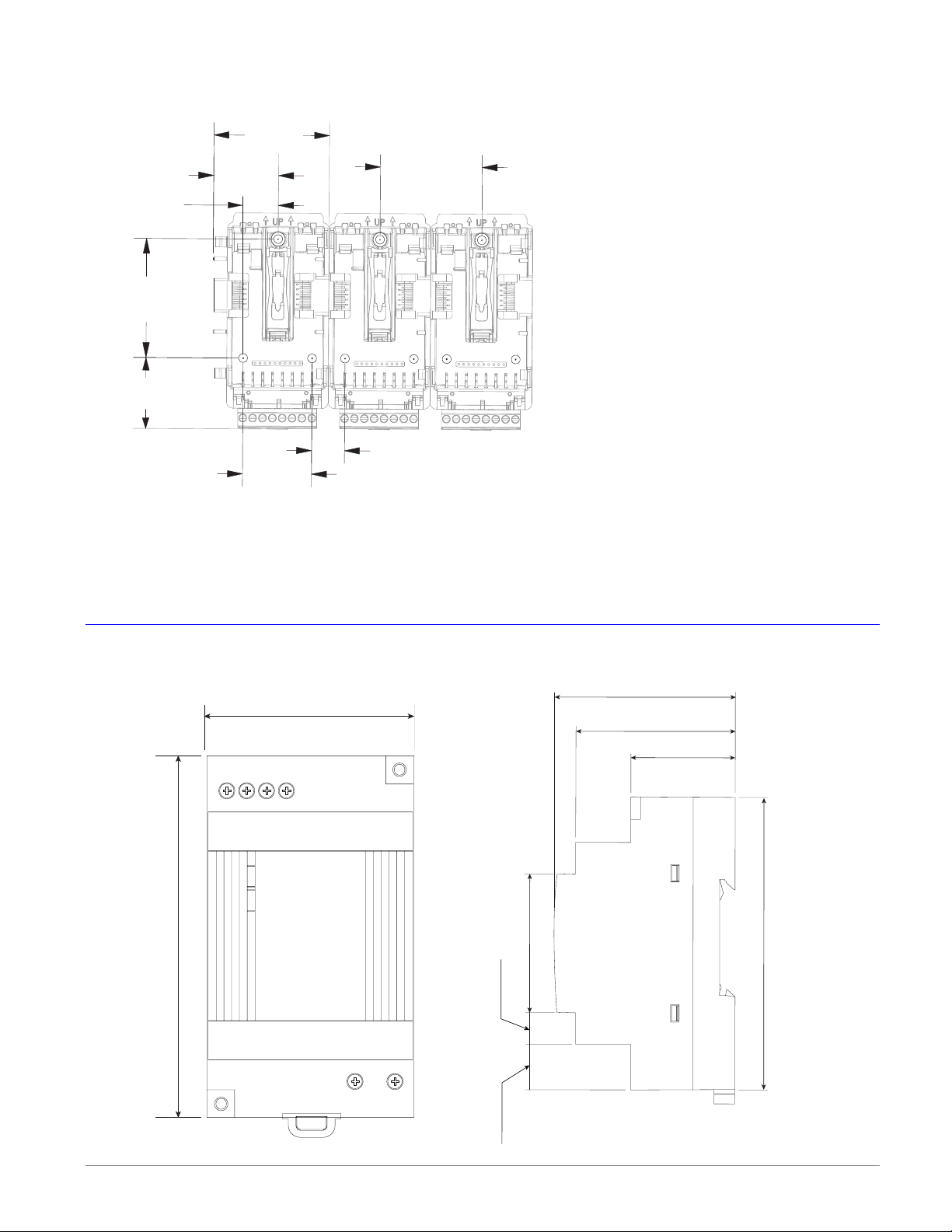

147.07 mm

( 5.8 in )

116.08 mm

( 4.57 in )

101.60 mm

( 4.00 in )

44.45 mm

( 1.75 in )

51.56 mm

( 2.03 in )

75.08 mm

( 3.0 in )

15

165 mm

( 6.50 in )

Module Removal Displacement

Latch in open position

155 mm

( 6.10 in )

116.08 mm

( 4.57 in )

101.60 mm

( 4.00 in )

44.45 mm

( 1.75 in )

51.56 mm

( 2.03 in )

75.08 mm

( 3.0 in )

15

°

173.90 mm

( 6.85 in )

Module Removal Displacement

2

Chapter 2: Install and Wire

Dimensions

As can be seen below the dimensions of the RM system will change slightly based on the type

of connector used.

Note:

Modules should always be mounted vertically. For easy removal and placement of modules

it is recommended that there be a 76.2 mm (3.00 in) clearance on the top, bottom and

front of each module.

Module Removal Clearance Standard Connectors

Module Removal Clearance Straight Connectors

Watlow EZ-ZONE® RMA Module • 10 • Chapter 2 Install and Wire

Page 15

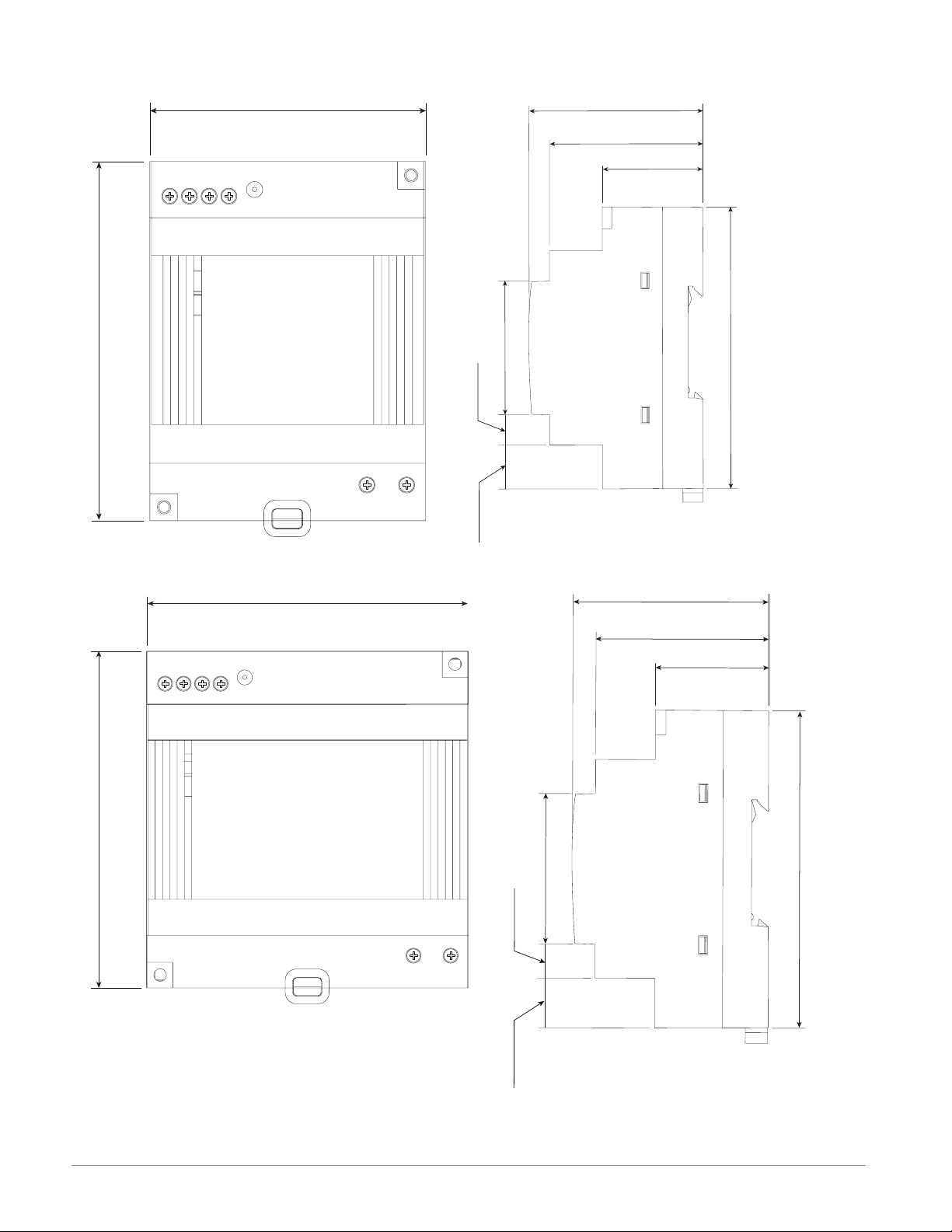

Dimensions (cont.)

56

53.00 mm

91.00 mm

14.20 mm

9.75 mm

55.6 mm

0.559 in

Chassis Mount Front View (Module Removed) - Screw Connection Pattern

58.67 mm

(2.31 in)

32.77 mm

(1.29 in)

17.53 mm

(.69 in)

60.45 mm

(2.38 in)

35.81 mm

(1.41 in)

35.05 mm

(1.38 in)

The view above is representative of the modular backplane without the module.

51.56 mm

(2.03 in)

16.76 mm

(.66 in)

Recommended chassis mount hardware:

1. #8 screw, 3/4" long

2. Torque to 10 -15 in-lb

3. No washers of any kind

Power Supplies

2.087 in

1234

-

++

-

DC LO

DC OK

DSP30

3.583 in

DSP 30

1.697 in

43.1 mm

49.00 mm

1.929 in

2.189 in

32.10 mm

1.264 in

3.583 in

91.00 mm

0.384 in

LN

Watlow EZ-ZONE® RMA Module • 11 • Chapter 2 Install and Wire

Page 16

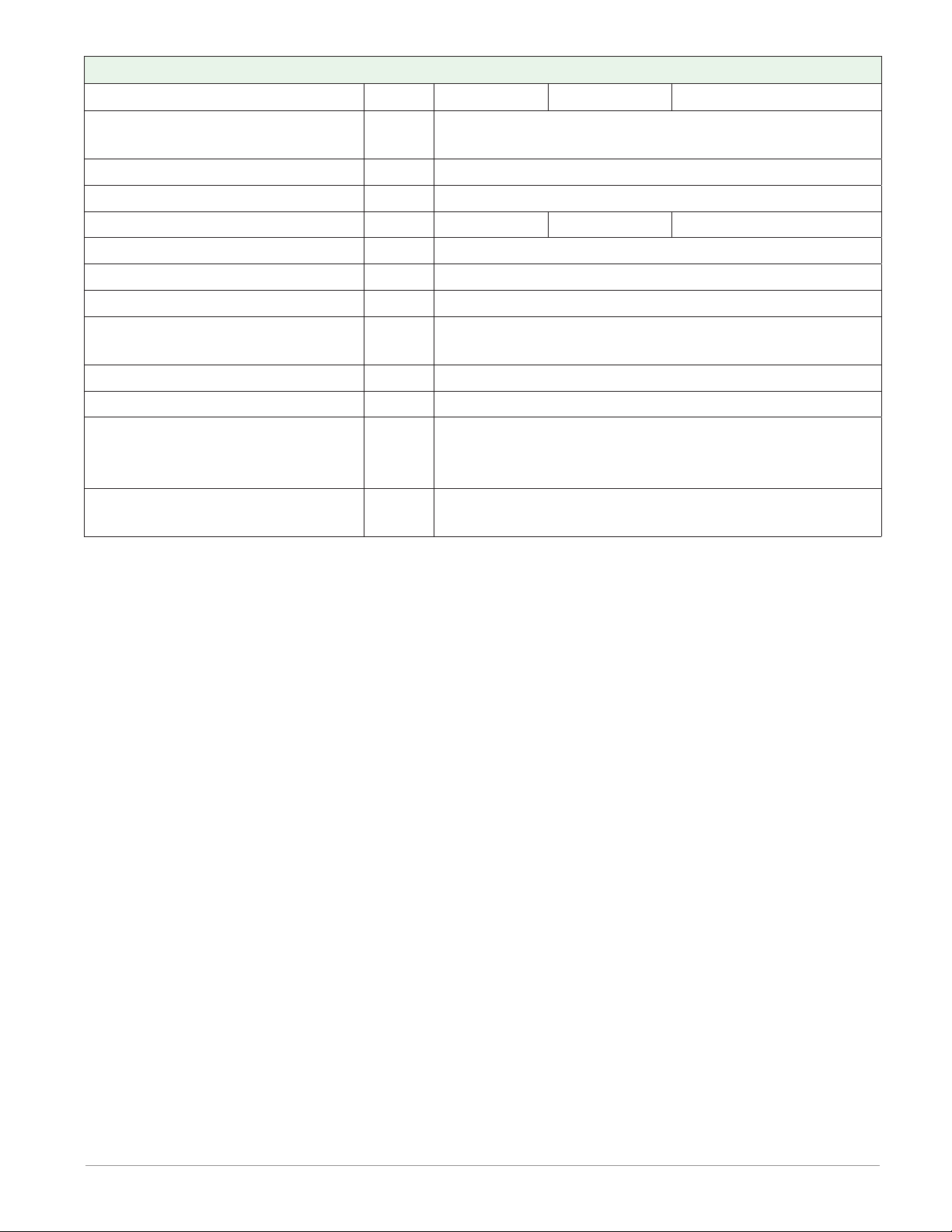

DSP 60

56

71.00 mm

91.00 mm

14.20 mm

9.75 mm

55.6 mm

0.559 in

LN

56

89.9 mm

91.00 mm

14.20 mm

9.75 mm

56.8 mm

0.559 in

1234

++

3.583 in

-

-

DC LO

DC OK

2.795 in

vout ADJ.

DSP60

LN

DSP 100

1.697 in

43.1 mm

0.384 in

49.00 mm

1.929 in

2.189 in

32.10 mm

1.264 in

3.583 in

91.00 mm

1234

++

3.583 in

-

-

DC LO

DC OK

3.539 in

vout ADJ.

DSP100

1.697 in

43.1 mm

0.384 in

49.00 mm

1.929 in

2.236 in

32.10 mm

1.264 in

3.583 in

91.00 mm

Watlow EZ-ZONE® RMA Module • 12 • Chapter 2 Install and Wire

Page 17

Power Supply Specifications

DSP 30 DSP60 DSP100

AC Input Voltage Range VAC

Input Frequency Hz 47 - 63Hz

DC Input Voltage range VDC 120 - 370VDC

Inrush Current (115 / 230VAC) A 25 / 50A 30 / 60A 30 / 60A

Output Voltage Accuracy % ±1% of Nominal

Over voltage Protection V 120 - 145%

LED Indicators - - - - Green LED = On, Red LED = DC Output Low

Operating Temperature - - - -

Storage Temperature - - - - -25 to +85°C

Operating Humidity - - - - 20 - 95% RH (non condensing)

Vibration (Operating) - - - -

Safety Agency Approvals

90 - 264VAC, Class II double insulated (No ground

connection required)

-25 to +71°C (Derate linearly 2.5%/°C from 55 to

71°C)

IEC 60068-2-6 (Mounting by rail: Random wave,

10-500 Hz, 2G, ea. along X, Y, Z axes 10 min/

cycle, 60 min)

UL1310 Class 2(1), UL508 Listed, UL60950-1,

EN60950-1, CE

For a comprehensive listing of these specications point your browser to: http://us.tdk-

lambda.com/lp/products/dsp-series.htm

Watlow EZ-ZONE® RMA Module • 13 • Chapter 2 Install and Wire

Page 18

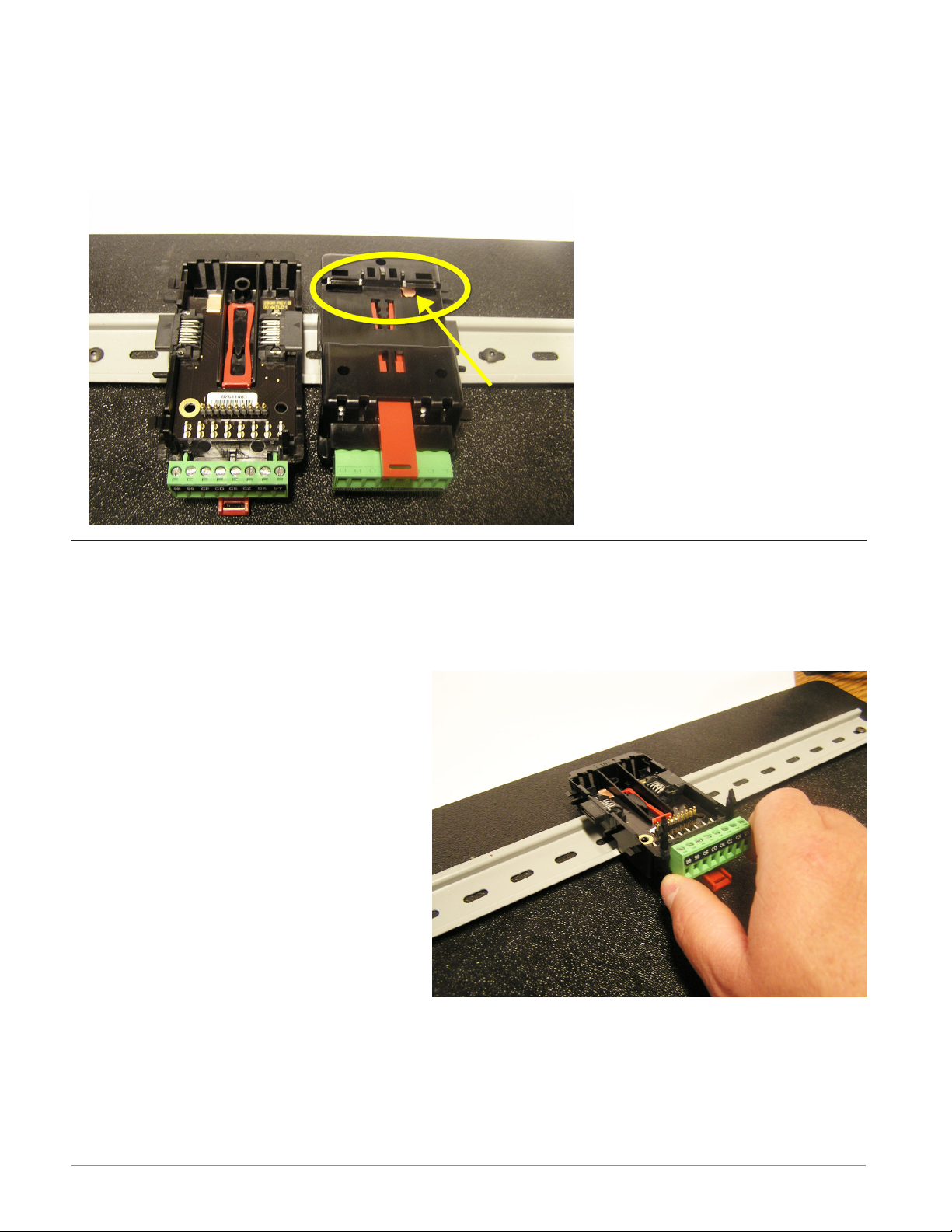

RM Installation and Removal on a DIN Rail

Modular Backplane Connector

The picture on the right shows the Modular Backplane Connector, both front and rear view.

The rear view is bringing in to focus a metal clip. If the DIN rail is grounded the Modular

Backplane Connector and the module connected to it will be also (recommended).

Installing the Modular Backplane Connector

To install the backplane follow the steps below:

1. Hook backplane assembly to upper edge of DIN rail, (see rear view above, backplane hook

detail that mates with upper rail edge is circled)

2. Next, rotate back plane assembly downward to engage the lower edge of the rail.

Note:

Din Rail clipping distance ranges from

1.366 -1.389 inches. The back plane

assembly will not latch onto the rail

successfully if the rail is out of dimension.

3. For nal positioning and locking, the

red tab is to be pushed upward to further engage the bottom edge of the

rail with an over center snap action

latch. (The red locking tab protrudes

from the bottom side of the back

plane assembly).

Note:

For easy removal and placement of modules it is recommended that there be a 76.2 mm

(3.00 in) clearance on the top, bottom and front of each module.

Watlow EZ-ZONE® RMA Module • 14 • Chapter 2 Install and Wire

Page 19

Installing Multiple Modular Backplane Connectors

Multiple modules are easily aligned and latched together. Each module includes matched

mating geometry that facilitates accurate and consistent interconnections.

To install backplane connectors follow the steps below:

1. Attach individual modules to the rail separately.

2. Laterally slide the modules together until

they touch.

3. When the multi-module system is attached

and laterally positioned to the desired placement the locking tab should be engaged to

secure the control system to the rail.

Module Installation

In the picture to the right notice that the arrow

is pointing at the top lip of the module (on side).

To install modules on the backplane follow the steps below:

1. Slide the lip of the module over the top of the Modular Backplane Connector and then

push down on the rear of the module. The module will then slide over the two posts just

above the green connector (see pictures below).

Watlow EZ-ZONE® RMA Module • 15 • Chapter 2 Install and Wire

Page 20

Wiring

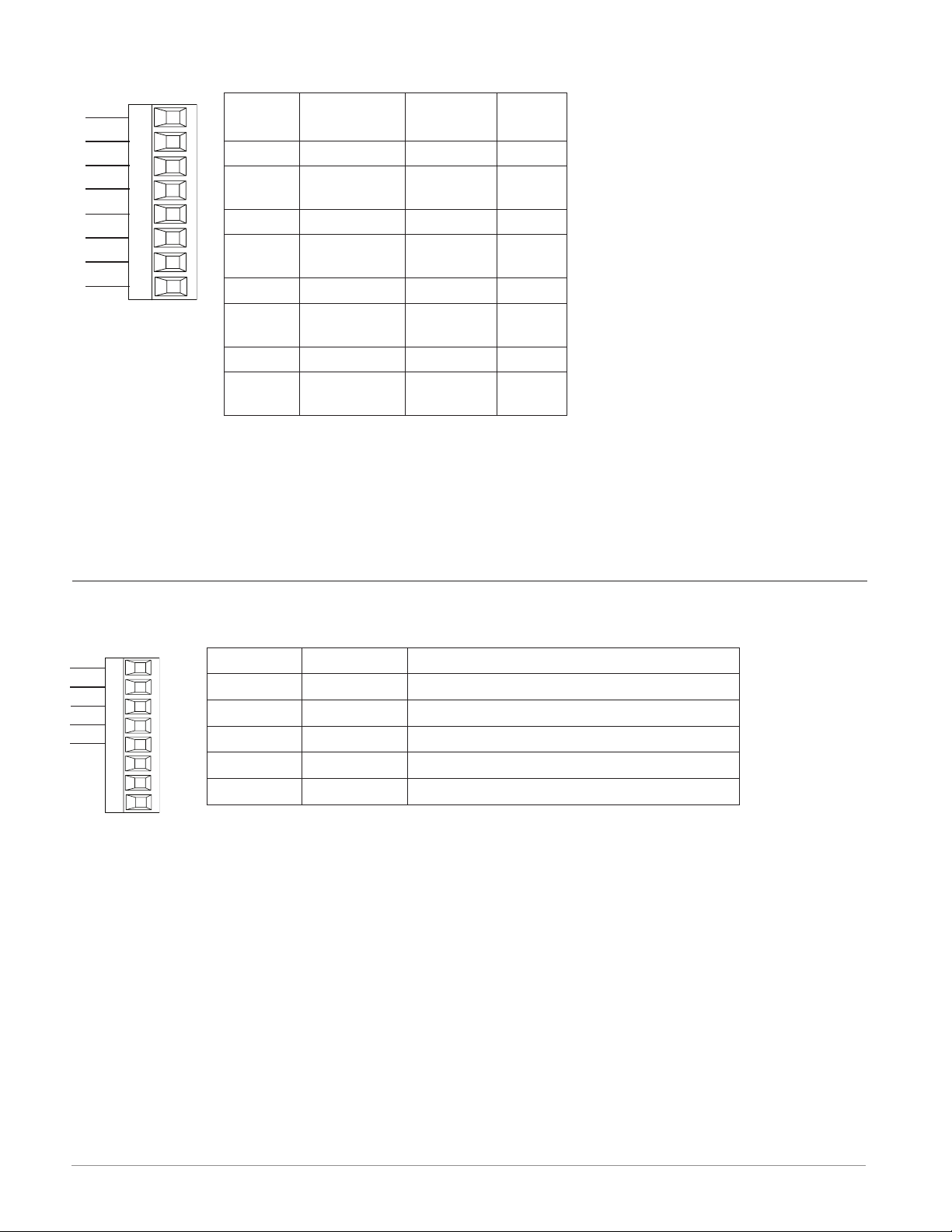

Access Module (RMAx-Axxx-xxxx)

Slot A Slot B Slot D Slot E Terminal Function Configuration

Modbus RTU

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

CB

CA

CC

CB

CA

C5

C3

C2

E8

E7

E6

E5

E4

E3

E2

E1

V+

CH

SH

CL

V-

- - -

- - -

- - -

VP

B

A

DG

trB

B

A

trA

Modbus RTU EIA-485 T+/R+

Modbus RTU EIA-485 T-/RModbus RTU EIA-485 common

Modbus RTU EIA-485 T+/R+

Modbus RTU EIA-485 T-/RModbus RTU EIA-232 common

Modbus RTU EIA-232 DB9/pin 2

Modbus RTU EIA-232 DB9/pin 3

EtherNet/IP and Modbus TCP 10/100

EtherNet/IP™ and Modbus TCP unused

EtherNet/IP™ and Modbus TCP unused

EtherNet/IP™ and Modbus TCP receive EtherNet/IP™ and Modbus TCP unused

EtherNet/IP™ and Modbus TCP unused

EtherNet/IP™ and Modbus TCP receive +

EtherNet/IP™ and Modbus TCP transmit EtherNet/IP™ and Modbus TCP transmit +

DeviceNet

DeviceNet™ power

Positive side of DeviceNet™ bus

Shield interconnect

Negative side of DeviceNet™ bus

DeviceNet™ power return

Profibus DP

Voltage Potential

EIA-485 T+/R+

EIA-485 T-/RDigital ground (common)

Termination resistor B

EIA-485 T+/R+

EIA-485 T-/RTermination resistor A

Part # Digit 6

Slot E: RMAx-A(2)xx-xxxx

Part # Digit 6

Slot E: RMAx-A(3)xx-xxxx

Part # Digit 6

Slot E: RMAx-A(5)xx-xxxx

Part # Digit 6

Slot E: RMAx-A(6)xx-xxxx

Power & Standard Bus Communications

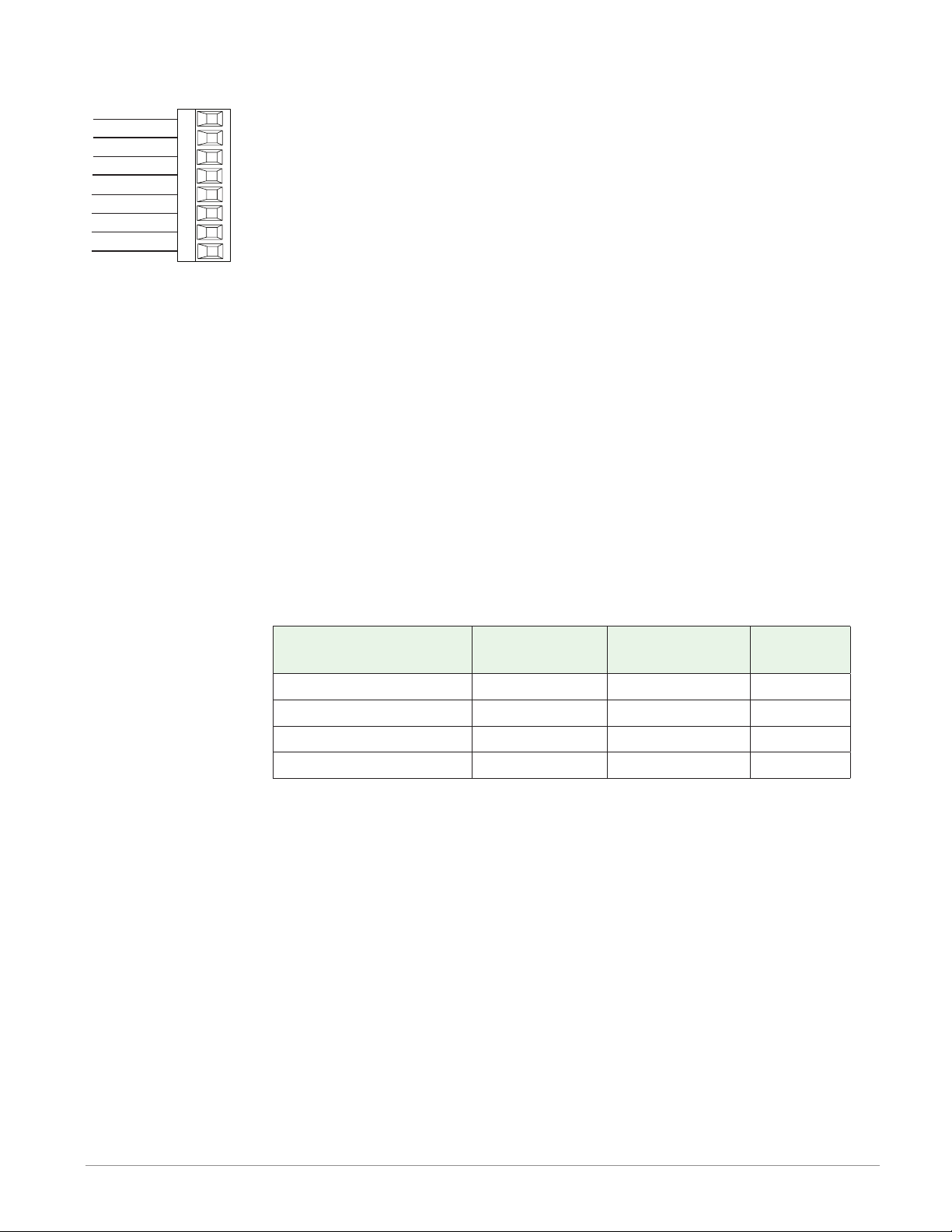

Slot C Terminal Function Configuration

98

99

CF

CD

CE

CZ

CX

CY

Watlow EZ-ZONE® RMA Module • 16 • Chapter 2 Install and Wire

Power input: ac or dc+

Power input: ac or dc-

Standard Bus EIA-485 common

Standard Bus EIA-485 T-/RStandard Bus EIA-485 T+/R+

Inter-module Bus

Inter-module Bus

Inter-module Bus

All

Standard Bus

Inter-module Bus

Page 21

RMA Module - Front View

Standard Connector

Slot D

Slot A

Slot E

Slot B

Slot C

Controller Power Supply

20.4 to 30.8VÎ (dc)

20.4 to 30.8VÅ (ac)

Safety Isolation

98

99

power

RMA Isolation Block

RMA

Low Voltage Power Bus

Low-voltage Isolation: 42V peak

Safety Isolation: 1,528VÅ (ac)

Low-voltage

Isolation

Communications Ports

Watlow EZ-ZONE® RMA Module • 17 • Chapter 2 Install and Wire

Page 22

Warning:

Use National Electric (NEC) or

other country-specific standard

wiring and safety practices when

wiring and connecting this controller to a power source and to

electrical sensors or peripheral

devices. Failure to do so may

result in damage to equipment

and property, and/or injury or

loss of life.

Note:

Maximum wire size termination

and torque rating:

• 0.0507 to 3.30 mm2 (30 to 12

• 0.56 Nm (5.0 in-lb.) torque

Note:

Adjacent terminals may be labeled differently, depending on

the model number

Note:

To prevent damage to the controller, do not connect wires to

unused terminals.

Note:

Maintain electrical isolation

between digital input-outputs,

switched dc/open collector

outputs and process outputs

prevent ground loops.

Note:

If the last two digits of the part

number are "12", this equipment

is suitable for use in CLASS I,

DIVISION 2, Groups A, B, C and

D or Non-Hazardous locations

only. Temperature Code T4

Warning:

Explosion Hazard – Substitution

of component may impair suitability for

Warning:

Explosion Hazard - Do not disconnect while the circuit is live

or unless the area is known to be

free of ignitable concentrations

of flammable substances.

ç

AWG) single-wire termination

or two 1.31 mm

2

(16 AWG)

.

to

ç

CLASS I, DIVISION 2.

ç

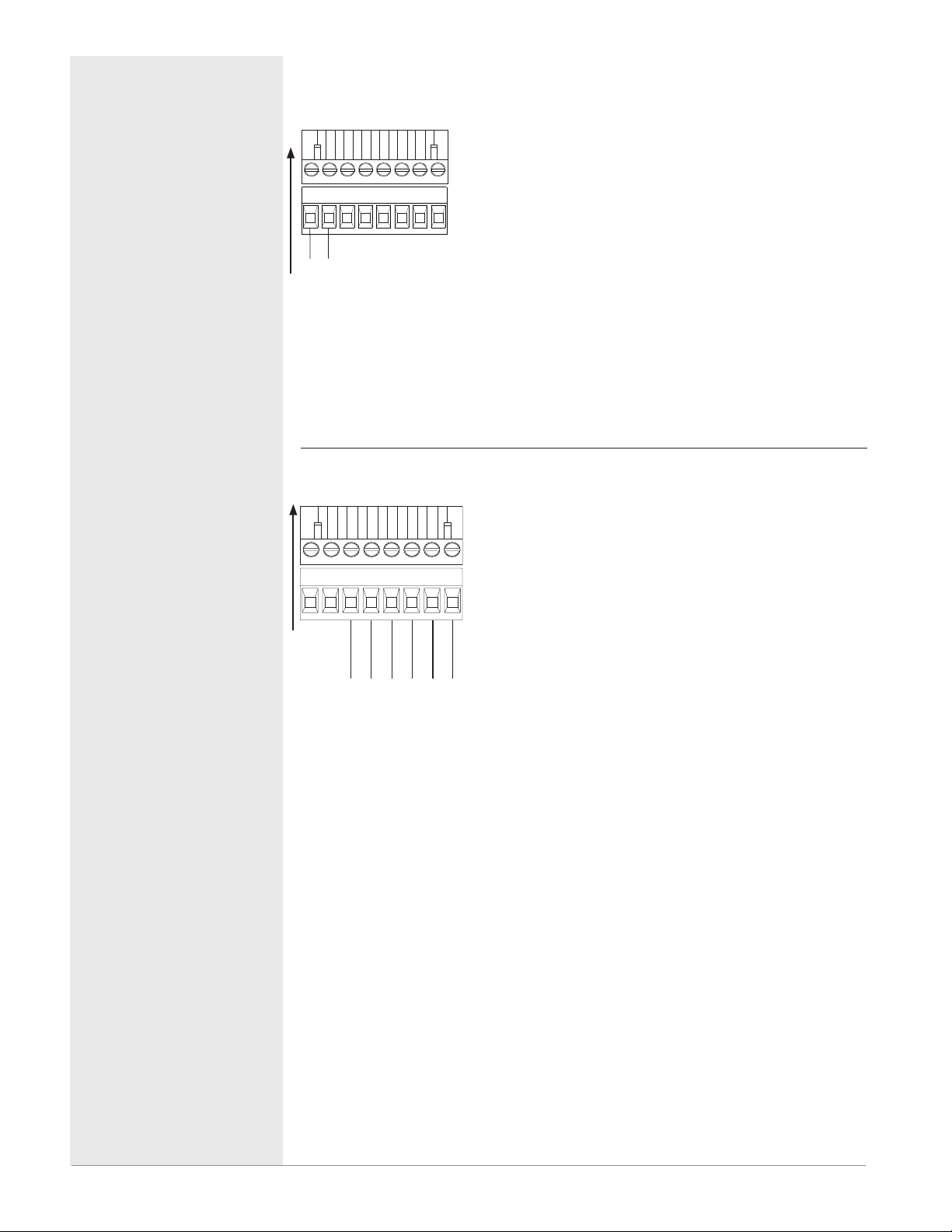

Access Module Wiring (RMAx-xxxx-xxxx)

Low Power

Slot C

99

98

power

Standard Bus EIA-485 Communications

Slot C

CE

CZ

CD

CF

Standard Bus

Common

Note:

Do not connect

unpowered USB

to EIA-485 converter. Communications may be

affected while

converter is not

connected to the

PC.

T- / R-

Common

T+ / R+

• 20.4 to 30.8 V Å (ac) / Î (dc) 9VA

• 47 to 63 Hz

• RMA module power consumption, 4 Watts

maximum

• 31 Watts maximum power available for P/S

part #:0847-0299-0000

• 60 Watts maximum power available for P/S

part #:0847-0300-0000

• 91 Watts maximum power available for P/S

part #:0847-0301-0000

• Class 2 or Safety Extra Low Voltage (SELV)

power source required to meet UL compliance standards

• CF, CD, CE - Standard Bus EIA485 Communications

• CZ, CX, CY - Inter-module Bus EIA485 Com-

CX

CY

munications

• Do not route network wires with power

Inter-module Bus

-

wires. Connect network wires in daisy-chain

+

fashion when connecting multiple devices in

a network

• Wire T-/R- to the A terminal of the EIA-485

port.

• Wire T+/R+ to the B terminal of the EIA-485

port.

• Wire common to the common terminal of

the EIA-485 port.

• Do not route network wires with power

wires. Connect network wires in daisy-chain

fashion when connecting multiple devices in

a network.

• A 120 Ω termination resistor may be required

across T+/R+ and T-/R-, placed on the last

controller on the network.

• Do not connect more than 16 EZ-ZONE RM

controllers on a network.

• Maximum network length: 1,200 meters

(4,000 feet)

• 1/8th unit load on EIA-485 bus

Watlow EZ-ZONE® RMA Module • 18 • Chapter 2 Install and Wire

Page 23

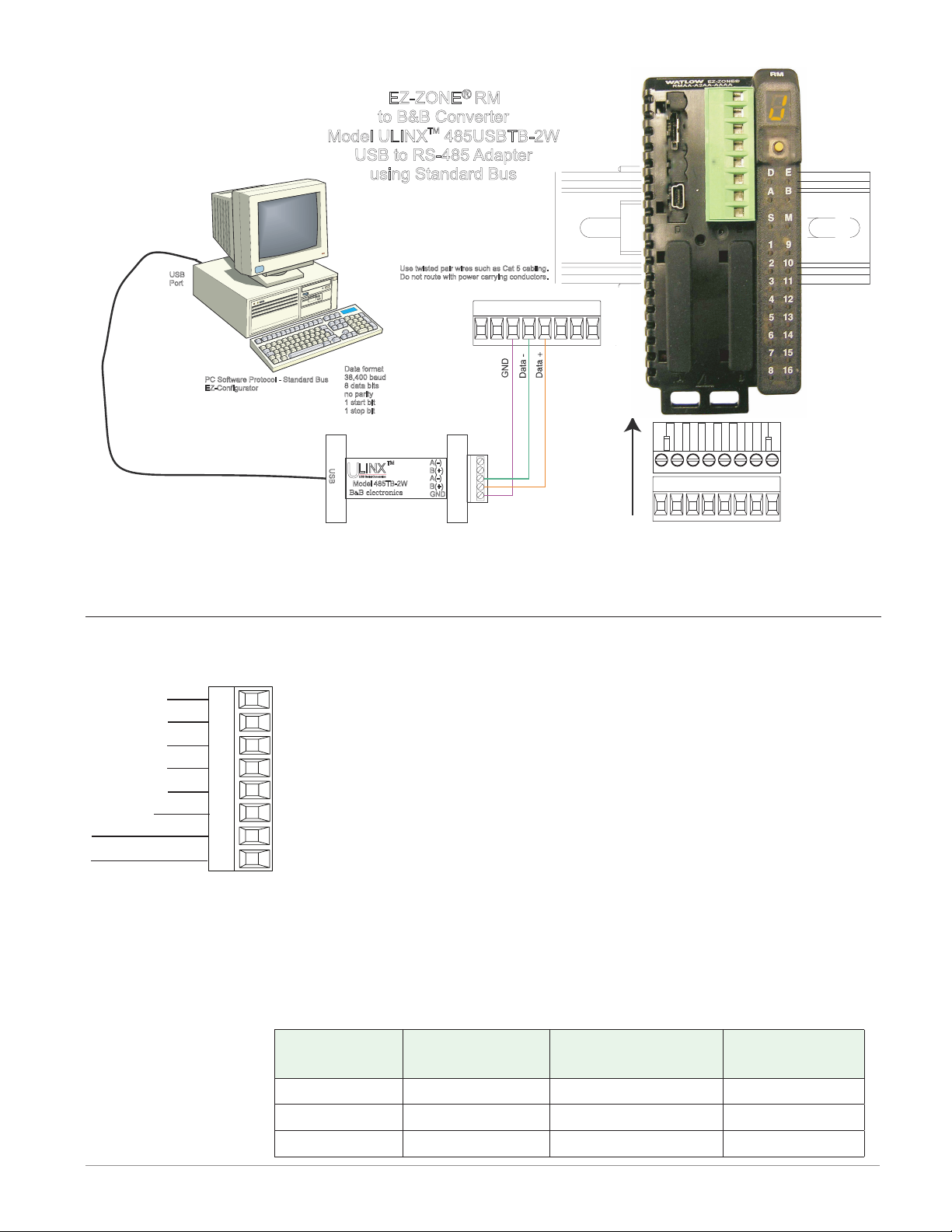

EZ-ZONE® RM

232 (Tx)

to B&B Converter

Model ULINX 485USBTB-2W

TM

USB to RS-485 Adapter

using Standard Bus

USB

Port

PC Software Protocol - Standard Bus

EZ-Configurator

Data format

38,400 baud

8 data bits

no parity

1 start bit

1 stop bit

U

S

U

B

Model 485TB-2W

B B electronics

Use twisted pair wires such as Cat 5 cabling.

Do not route with power carrying conductors.

TM

LINX

USB Serial Conversion

&

0847-0326-0000

A(-)

B(+)

A(-)

B(+)

GND

98 99

CF CD CE CZ CW CY

98 99

CF CD CE CZ CW CY

S

l

o

Note:

Do not connect USB to EIA-485 converter without power. Communications may be affected while converter is not connected to the PC.

EIA-232/485 Modbus RTU Communications

• Wire T-/R- to the A terminal of

T+/R+

T-/R-

common

T+/R+

T-/R-

232 common

to DB9 pin 2 (RD)

232 (RD) to DB9 pin 3 (Tx)

Slot E

CB

CA

CC

CB

CA

C5

C3

C2

the EIA-485 port.

• Wire T+/R+ to the B terminal of

the EIA-485 port.

• Wire common to the common

terminal of the EIA-485 port.

• Do not route network wires with

power wires. Connect network

wires in daisy-chain fashion

when connecting multiple devices in a network.

• A termination resistor is re-

quired. Place a 120 Ω resistor

across T+/R+ and T-/R- of last

controller on network.

RMA Part # Digit 5 and 6 is A2

a Modbus network is 247.

• Maximum network length: 1,200

meters (4,000 feet)

• Maximum EIA-232 network

length: 15 meters (50 feet)

• Do not connect more than one

EZ-ZONE RM controller on an EIA232 network.

• Do not wire to both the EIA-485

and the EIA-232 pins at the same

time.

• Two EIA-485 terminals of T/R are

provided to assist in daisy-chain

wiring.

• 1/8th unit load on EIA-485 bus.

• Maximum number of devices on

t

C

Modbus-IDA

Terminal

EIA/TIA-485

Name

Watlow Terminal

Label

Function

DO A CA or CD T-/R-

D1 B CB or CE T+/R+

common common CC or CF common

Watlow EZ-ZONE® RMA Module • 19 • Chapter 2 Install and Wire

Page 24

Slot E

Slot E

EtherNet/IP™ and Modbus TCP Communications

RMA Part # Digit 5 and 6 is A3

unused

unused

receive -

unused

unused

receive +

transmit -

transmit +

E8

E7

E6

E5

E4

E3

E2

E1

RJ-45

pin

T568B wire

color

Signal Slot E

8 brown unused E8

7

brown and

white

unused E7

6 green receive - E6

5

white and

blue

unused E5

4 blue unused E4

3

white and

green

receive + E3

• Do not route network wires with

power wires.

• Connect one Ethernet cable per

controller to a 10/100 mbps Ethernet switch. Both Modbus TCP

and EtherNet/IP™ are available

on the network.

2 orange transmit - E2

1

white and

orange

transmit + E1

Notes:

EtherNet/IP™ and Modbus TCP communications to connect with a 10/100 switch.

Notes:

When using EtherNet/IP the RMA module supports implicit and unconnected explicit messaging.

DeviceNet™ Communications

V+

CAN_H

shield

CAN_L

V+

CH

SH

CL

V-

V-

T2

S2

R2

Terminal Signal Function

V+ V+ DeviceNet™ power

CH CAN_H Positive side of DeviceNet™ bus

SH shield Shield interconnect

CL CAN_L Negative side of DeviceNet™ bus

V- V- DeviceNet™ power return

RMA Part # Digit 5 and 6 is A5

Watlow EZ-ZONE® RMA Module • 20 • Chapter 2 Install and Wire

Page 25

Profibus DP Communications

Slot E

RMA Part # Digit 5 and 6 is A6

+5Vdc Voltage Potential

485 T+/R+

485 T-/R-

Digital ground

Ter mination resistor B

485 T+/R+

485 T-/R-

Ter mination resistor A

VP

DG

trB

trA

• Wire T-/R- to the A terminal of

B

A

the EIA-485 port.

• Wire T+/R+ to the B terminal of

the EIA-485 port.

• Wire Digital Ground to the com-

B

A

mon terminal of the EIA-485 port.

• Do not route network wires with

power wires. Connect network

wires in daisy-chain fashion when

connecting multiple devices in a

network.

• A termination resistor should be

used if this control is the last one

on the network.

• If external termination is to be

used with a 150 Ω cable place a

390 Ω resistor across pins VP and

B, a 220 Ω resistor across pins B

and A, and lastly, place a 390 Ω

resistor across pins DG and A.

• Do not connect more than 16 EZZONE RM modules on any given

segment.

• Maximum EIA-485 network

length: 1,200 meters (4,000 feet)

• 1/8th unit load on EIA-485 bus.

• Communications instance 2

• RMAX - A [6] X X - A A X X

• If using a 150 Ω cable Watlow

provides internal termination.

Place a jumper across pins trB

and B and trA and A.

Note:

When termination jumpers are in place, there is 392 ohm pull up resistor to 5V and 392 ohm pull down resistor to DP. There is also a 221

ohm resistor between A and B.

Profibus Terminal

EIA/TIA-485

Name

Watlow Termi-

nal Label

Function

VP (Voltage Potential) - - - - VP +5Vdc

B-Line B B T+/R+

A-Line A A T-/R-

DP-GND common DG common

Watlow EZ-ZONE® RMA Module • 21 • Chapter 2 Install and Wire

Page 26

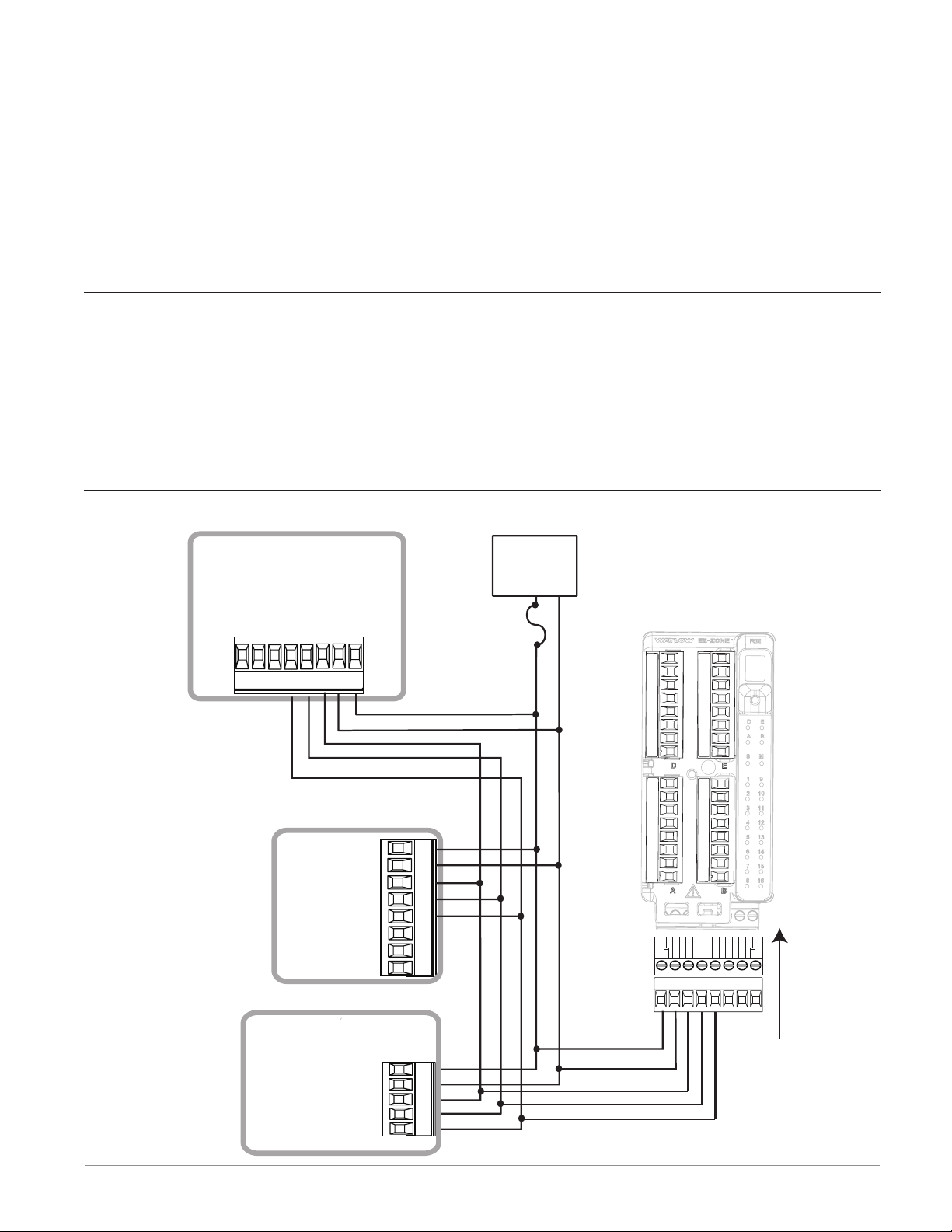

Connecting and Wiring the Modules

Use twisted pair

sheilded wire for

RM System Connections

Components of a RM system can be installed as stand alone modules or can be interconnected on the DIN rail as shown below. When modules are connected together, power and communications are shared between modules over the modular backplane interconnection.

Therefore, bringing the necessary power and communications

wiring to any one connector in slot C is sufcient. The modular

backplane interconnect comes standard with every module

ordered and is generic in nature, meaning any of the RM modules shown below on the DIN rail can use it.

Notice in the split rail system diagram that a single power supply is being used across both DIN rails. One notable consideration when designing the hardware layout would be the available power supplied and the loading affect of all of the modules

used. Watlow provides three options for power supplies listed below:

1. 90-264 Vac to 24Vdc @ 31 watts (Part #: 0847-0299-0000)

2. 90-264 Vac to 24Vdc @ 60 watts (Part #: 0847-0300-0000)

3. 90-264 Vac to 24Vdc @ 91 watts (Part #: 0847-0301-0000)

With regards to the modular loading affect, maximum power for each is listed below:

1. RMCxxxxxxxxxxxx @ 7 watts

2. RMEx-xxxx-xxxx @ 7 watts

3. RMAx-xxxx-xxxx @ 4 watts

So, in the split rail system diagram, the

maximum current draw on the supply

would be 38 Watts.

- 2 RMC modules consumes 14W

- 2 RME modules consumes 14W

- 1 RMA module consumes 4W

- 1 Remote User Interface consumes 6W

With this power requirement the second

or third power supply could be used.

Another hardware conguration scenario

that could present itself (graphic not

shown) would be a conguration that re-

Low Voltage

Class 2

Power Supply

RM Controller

Module

RMCxxxxxxxxxAxx

Slot D

_

_

_

Standard Bus

_

_

Address 1

_

_

_

Slot A

_

_

_

_

_

_

_

_

Slot C

98 99 CFCECZ CX CY

CD

RM Controller

Module

RMCxxxxxxxxxAxx

Slot D

_

_

_

Standard Bus

_

_

Address 4

_

_

_

Slot A

_

_

_

_

_

_

_

_

98 99 CFCECZ CX CY

quires more than one supply. Lets make

some assumptions pertaining to the split

rail system diagram shown below. The

power supply used is the 91W supply.

The top DIN rail now has the following

modules:

- 2 RMC modules consumes 14W

- 1 RMA consumes 4W

- 11 RME modules consumes 77W

As can now be seen, the total power requirement exceeds 91W. In this case, another power

supply would be required. To incorporate another supply in this system simply disconnect

pins 99 and 98 on the remote DIN rail and connect another appropriately sized power supply

to those same pins.

Modular Backplane Interconnect

Slot E

_

_

_

_

_

_

_

_

Slot B

_

_

_

_

_

_

_

_

Standard Bus

Address 5

CD

RM Access

Module

Slot D

_

_

_

Standard Bus

_

_

Address 3

_

_

_

Slot A

_

_

_

_

_

_

_

_

98 99 CFCECZ CX CY

Slot E

Slot B

Slot C

CD

Slot C

CD

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

Slot E

Slot B

Standard Bus

RM Expansion

Module

RMEx-xxxx-xxxx RMAx-xxxx-xxxx

Slot D

Slot E

_

_

_

_

_

_

Standard Bus

_

_

_

_

Address 2

_

_

_

_

_

_

Slot A

Slot B

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

Slot C

98 99 CFCECZ CX CY

CD

Standard Bus

Split Rail Conguration

RM Expansion

Module

RMEx-xxxx-xxxx

Slot E

Slot D

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

Slot A

Slot B

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

Slot C

CD

_

98 99 CFCECZ CX CY

RUI

EZKB - _ A_ _-_ _ _ _

98

99 CF CE

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

Inter-module

Bus

each bus.

Watlow EZ-ZONE® RMA Module • 22 • Chapter 2 Install and Wire

Page 27

When using a split rail conguration ensure that the interconnections for the Inter-module

Bus and Standard Bus do not exceed 200 feet.

Note:

Module is not provided with a disconnect, use of an external disconnect is required. It

should be located in close proximity to the module and be labeled as the disconnect for

the module.

Note:

Connecting power supplies in parallel is not allowed. When power consumption is greater

than 91 watts use a split rail configuration.

Wiring a Serial EIA-485 Network

Do not route network wires with power wires. Connect network wires in daisy-chain fashion when connecting multiple devices in a network. A termination resistor may be required.

Place a 120 Ω resistor across T+/R+ and T-/R- of the last con-troller on a on a network.

Note:

Termination resistors when used, require a termination resistor at both ends of the network.

A Network using Watlow's Standard Bus and an RUI/Gateway

EZ-ZONE ST

ST_ _ - (B or F) _ M _ -_ _ _ _

CD

CE

D5

D6

B5

CF

98

99

+ B

- A

power

power

common

EZ-ZONE PM

98

99

CF

CD

CE

B5

D6

D5

power

com

- A

+ B

Power

Supply

fuse

EZ-ZONE RM

t

C

l

o

S

98 99 CF CD CE CZ CX CY

RUI/Gateway

power

EZKB-_ A _ _- _ _ _ _

98

power

99

CF

CD

CE

common

- A

+ B

common

- A

+ B

Watlow EZ-ZONE® RMA Module • 23 • Chapter 2 Install and Wire

Page 28

Conventions Used in the Menu Pages

To better understand the menu pages that follow review the naming conventions used. When

encountered throughout this document, the word "default" implies as shipped from the factory. Each page (Operations, Setup and Factory) and their associated menus have identical

headers dened below:

Header Name Definition

Display Visually displayed information from the control.

Parameter Name Describes the function of the given parameter.

Range

Default Values as delivered from the factory.

Modbus Relative

Address

CIP (Common Industrial Protocol)

Profibus Index

Parameter ID

Data Type and Access (R/W)

Defines options available for this prompt, i.e., min/max values (numerical), yes/no, etc... (further explanation below).

Identifies unique parameters using either the Modbus RTU or Modbus

TCP protocols (further explanation below).

If used in conjunction with an RMA module identifies unique parameters using either the DeviceNet or EtherNet/IP protocol (further explanation below).

If used in conjunction with an RMA module identifies unique parameters using Profibus DP protocol (further explanation below).

Identifies unique parameters used with other software such as, LabVIEW.

uint = Unsigned 16 bit integer

dint = Signed 32-bit, long

string = ASCII (8 bits per character)

float = IEEE 754 32-bit

RWES = Readable

Writable

EEPROM (saved)

User Set (saved)

Display

When a RM module is used in conjunction with the RUI (optional equipment) visual information from the module is displayed to the observer using a fairly standard 7 segment display.

Due to the use of this technology, several characters displayed need some interpretation, see

the list below:

1 = 1 ϯ = 7

, {= c i= i o= o u= u

щ

2 = 2 8 = 8 ц= d J= J P= P v= v

3 = 3 q = 9 E= E H= K q= q ФІ= W

4 = 4 0 = 0 F= F L= L r= r y= y

5 = 5 џ = g= g ЛЏ= M S= S Z= Z

6 = 6 Ѥ= b h= h n= n t= t

Watlow EZ-ZONE® RMA Module • 24 • Chapter 2 Install and Wire

Page 29

Range

Within this column notice that on occasion there will be numbers found within parenthesis.

This number represents the enumerated value for that particular selection. Range selections

can be made simply by writing the enumerated value of choice using any of the available

communications protocols. As an example, turn to the Setup Page and look at the Backup

Menu. To Save a conguration backup of all connected zones using Modbus simply right the

value of 1646 (save) to Modbus register 1270.

Communication Protocols

All RM modules come with the standard offering of Watlow's Standard Bus protocol used primarily for inter-module communications as well as for conguration using EZ-ZONE Congurator and Composer software (free download from Watlow's web site (http://www.watlow.

com). Along with Standard Bus, the RMH module can also be ordered with Modbus RTU (only

one protocol can be active at any given time). The RMA module has options for several different protocols listed below:

- Modbus RTU 232/485

- EtherNet/IP, Modbus TCP

- DeviceNet

- Probus DP

To learn more about any of the available RM modules, click on the link below. Once there

simply type in RM in the Keyword eld. http://www.watlow.com/literature/manuals.cfm

Modbus RTU Protocol

All Modbus registers are 16-bits and as displayed in this manual are relative addresses (actual). Some legacy software packages limit available Modbus registers to 40001 to 49999 (5

digits). Many applications today require access to all available Modbus registers which range

from 400001 to 465535 (6 digits).

Note:

In this User's Guide, all values shown representing Modbus addresses are added to 400,001

or 40,001 to acquire the absolute address.

For parameters listed as oat notice that only one (low order) of the two registers is listed,

this is true throughout this document. By default, the low order word contains the two low

bytes of the 32-bit parameter. As an example, look in the RMA Setup Page for the Analog pa-

rameter under the Variable menu. Find the column identied in the header as Modbus Relative Address, notice that it lists register 1034. Because this parameter is a oat it is actually

represented by registers 1034 (low order bytes) and 1035 (high order bytes). The Modbus

specication does not dictate which register should be high or low order so Watlow provides

the user the ability to swap this order (Setup Page, Communications Menu) from the default

low/high to high/low.

It should also be noted that some of the cells in the Modbus column contain wording pertaining to an offset. Several parameters in the RMA contain more than one instance; such as,

Data Log points (200), Gateway Instances (17), etc... The Modbus register shown always represents instance one. Take for an example the Log Point parameter found in the RMA Setup

Page under the Log Point menu. Instance one for the Source Function is shown as address

1470 and the offset to the next instance is identied as +16. If there was a desire to read or

write to instance 3, simply add 32 to 1470 to nd the appropriate address; in this case, Log

Point Source Function 3 address would be identied as 1502.

Watlow EZ-ZONE® RMA Module • 25 • Chapter 2 Install and Wire

Page 30

RMA _ - A [2, 3] _ _ - A A _ _

To learn more about the Modbus protocol point your browser to http://www.modbus.org.

Common Industrial Protocol (CIP)

DeviceNet & Ethernet/IP

Both DeviceNet and EtherNet/IP use open object based programming tools and are based on

the Common Industrial Protocol (CIP). Due to the use of CIP as the foundation of either protocol (DeviceNet or EtherNet/IP), they both use the same addressing scheme and parameter

addresses can be found in the column header identied as CIP. There you will nd the Class,

Instance and Attribute in hexadecimal, (decimal in parenthesis) for both protocols.

Note:

The RMA module equipped with EtherNet/IP supports implicit and unconnected explicit messages.

Data Types Used with CIP

uint = Unsigned 16 bit integer

int = Signed 16-bit

dint = Signed 32-bits, long

real = Float, IEEE 754 32-bit

string = ASCII, 8 bits per character

sint = Signed 8 bits , byte

RMA _ - A [3] _ _ - A A _ _

To learn more about the DeviceNet and EtherNet/IP protocol point your browser to http://

www.odva.org.

Profibus DP

To accommodate for Probus DP addressing the following menus contain a column identied

as Probus Index. Data types used in conjunction with Probus DP can be found in the table

below.

Data Types Used with Probus DP

word = Unsigned 16 bit

int = Signed 16-bit Integer

dint = Signed 32-bit Integer

real = Float, IEEE 754 32-bit

char = ASCII, 8 bits per character

byte = 8 bits

RMA _ - A [6] _ _ - A A _ _

To learn more about the Prbus DP protocol point your browser to http://www.probus.org

Watlow EZ-ZONE® RMA Module • 26 • Chapter 2 Install and Wire

Page 31

3

Chapter 3: Operations Page

Access Module Operation Page Parameters

To navigate to the Operations Page using the RUI, follow the steps below:

1. From the Home Page, press both the Up ¿ and Down ¯ keys for three seconds. Ai will ap-

pear in the upper display and oPEr will appear in the lower display.

2. Press the Up ¿ or Down ¯ key to view available menus.

3. Press the Advance Key ‰ to enter the menu of choice.

4. If a submenu exists (more than one instance), press the Up ¿ or Down ¯ key to select and

then press the Advance Key ‰ to enter.

5. Press the Up ¿ or Down ¯ key to move through available menu prompts.

6. Press the Infinity Key ˆ to move backwards through the levels: parameter to submenu, sub-

menu to menu, menu to Home Page.

7. Press and hold the Infinity Key ˆ for two seconds to return to the Home Page.

On the following pages, top level menus are identified with a yellow background color.

Note:

Some of these menus and parameters may not appear, depending on the controller's options. See model number information in the Appendix for more information. If there is

only one instance of a menu, no submenus will appear.

Note:

Some of the listed parameters may not be visible. Parameter visibility is dependent upon

controller part number.

dLog

oPEr Data Logging Menu

StAt Status

A.ЛЏE Available Logging Memory

A.ti Available Logging Time

bCUP

oPEr Backup Menu

StAt Status

2onE Zone

b.sta

oPEr Backup Status Menu

b.sta Backup (1 to 24)

StAt Status

Watlow EZ-ZONE® RMA Module • 27 • Chapter 3 Operations Page

Page 32

Dis-

playy

Parameter Name

Description

dLog

oPEr

Data Logging Menu

RM Access Module • Operations Page

Range Default

Modbus

Relative

Address

Class

Instance

Attribute

hex (dec)

CIP

Pro-

fibus

Index

Param-

eter

ID

Data

Type

& Read/

Write

*

Stat

Stat

A.ЛЏE

A.ME

A.ti

A.ti

* R: Read, W: Write, E: EEPROM, S: User Set

Data Logging

Status

Status indicates the

status of the data

logging function. OK

means logging can

be started or can

continue. No Memory

can indicate the

memory card is full

or not present.

Data Logging

Available Memory

Available logging

memory indicates

the remaining space

available for logging

in megabytes.

Data Logging

Available Logging

Time

Available Logging

Time when logging is

active, indicates the

remaining time that

logging can continue

in hours. When logging is not active,

indicates zero.

no.ЛЏ No Memory

(1637)

oH OK (138)

0 to 9,999 - - - - 1456 0x89 (137)

0 to 9,999 hours - - - - 1458 0x89 (137)

- - - - 1452 0x89 (137)

1

2

1

4

1

5

50 37002 uint

R

52 37004 uint

R

53 37005 uint

R

Watlow EZ-ZONE® RMA Module • 28 • Chapter 3 Operations Page

Page 33

RM Access Module • Operations Page

Display

Parameter Name

Description

Range Default

bCUP

oPEr

Backup Menu

Stat

Stat

2onE

ZonE

* R: Read, W: Write, E: EEPROM, S: User Set

Backup

Status

Status indicates the

status of the configuration backup function.

Off - means no backup or restore action

is running.

Save - indicates the

configuration of a

zone is being saved

to backup memory.

Restore - indicates a

saved configuration

is being restored to a

zone.

Monitor - When

backup is set to restore on a change

the RMA will check

to see if a module

serial number has

changed. If so, a restore will take place

for that module.

Complete - indicates

that the restoration

is complete.

Error - indicates

that the last action

failed.

Backup

Zone

Current Zone indicates which zone’s

configuration is being

saved or restored or

was last saved or restored.

oFF Off (62)

sauE Save (1644)

rEst Restore (1645)

ЛЏon Monitor

(1187)

CpLt Complete (18)

Err Error (28)

1 to 16 1 1276 0x8A

CIP

Modbus

Relative

Address

Off 1274 0x8A

Class

Instance

Attribute

hex (dec)

(138)

1 to 6

3

(138)

1 to 0x10

(16)

4

Pro-

fibus

Index

Param-

eter

ID

60 38003 uint

61 38004 uint

Data

Type

& Read/

Write

*

R

R

Watlow EZ-ZONE® RMA Module • 29 • Chapter 3 Operations Page

Page 34

RM Access Module • Operations Page

Display

Parameter Name

Description

Range Default

b.sta

oPEr

Backup Status Menu

Stat

Stat

* R: Read, W: Write, E: EEPROM, S: User Set

Backup

Status

Status indicates the

status of the current or most recent

backup function performed on the corresponding zone.

None - means no

backup or restore action is running.

OK - indicates the

zone was successfully

restored or saved

depending on the operation.

No Memory - indicates memory is full.

No Module - indicates that a previous

image for the module

had been saved but

while restoring the

module is no longer

present.

No Image - indicates

there is no backed up

image for a module

present on Standard

Bus.

Error - indicates

that the last action

failed.

nonE None (61)

oH OK (1644)

No.ЛЏ No Memory

(1637)

no.ЛЏ No Module

(1664)

no.Lg No Image

(1665)

Err Error (28)

Modbus

Relative

Address

None 1280

[offset 6]

CIP

Class

Instance

Attribute

hex (dec)

0x9A

(154)

1 to 0x18

(24)

1

Pro-

fibus

Index

Param-

eter

ID

94 54001 uint

Data

Type

& Read/

Write

*

R

Watlow EZ-ZONE® RMA Module • 30 • Chapter 3 Operations Page

Page 35

4

Chapter 4: Setup Pages

Access Module Setup Page Parameters

To navigate to the Setup Page using the RUI, follow the steps below:

1. From the Home Page, press and hold both the Up ¿ and Down ¯ keys for six seconds. Ai

will appear in the upper display and SEt will appear in the lower display.

Note:

If keys are released when opEr is displayed, press the Infinity Key ˆ or reset key to exit

and repeat until SEt is displayed.

2. Press the Up ¿ or Down ¯ key to view available menus.

3. Press the Advance Key ‰ to enter the menu of choice.

4. If a submenu exists (more than one instance), press the Up ¿ or Down ¯ key to select and

then press the Advance Key ‰ to enter.

5. Press the Up ¿ or Down ¯ key to move through available menu prompts.

6. Press the Infinity Key ˆ to move backwards through the levels: parameter to submenu, sub-

menu to menu, menu to Home Page.

7. Press and hold the Infinity Key ˆ for two seconds to return to the Home Page.

On the following pages, top level menus are identified with a yellow background color.

Note:

Some of these menus and parameters may not appear, depending on the controller's options. See model number information in the Appendix for more information. If there is

only one instance of a menu, no submenus will appear.

Note:

Some of the listed parameters may not be visible. Parameter visibility is dependent upon

controller part number.

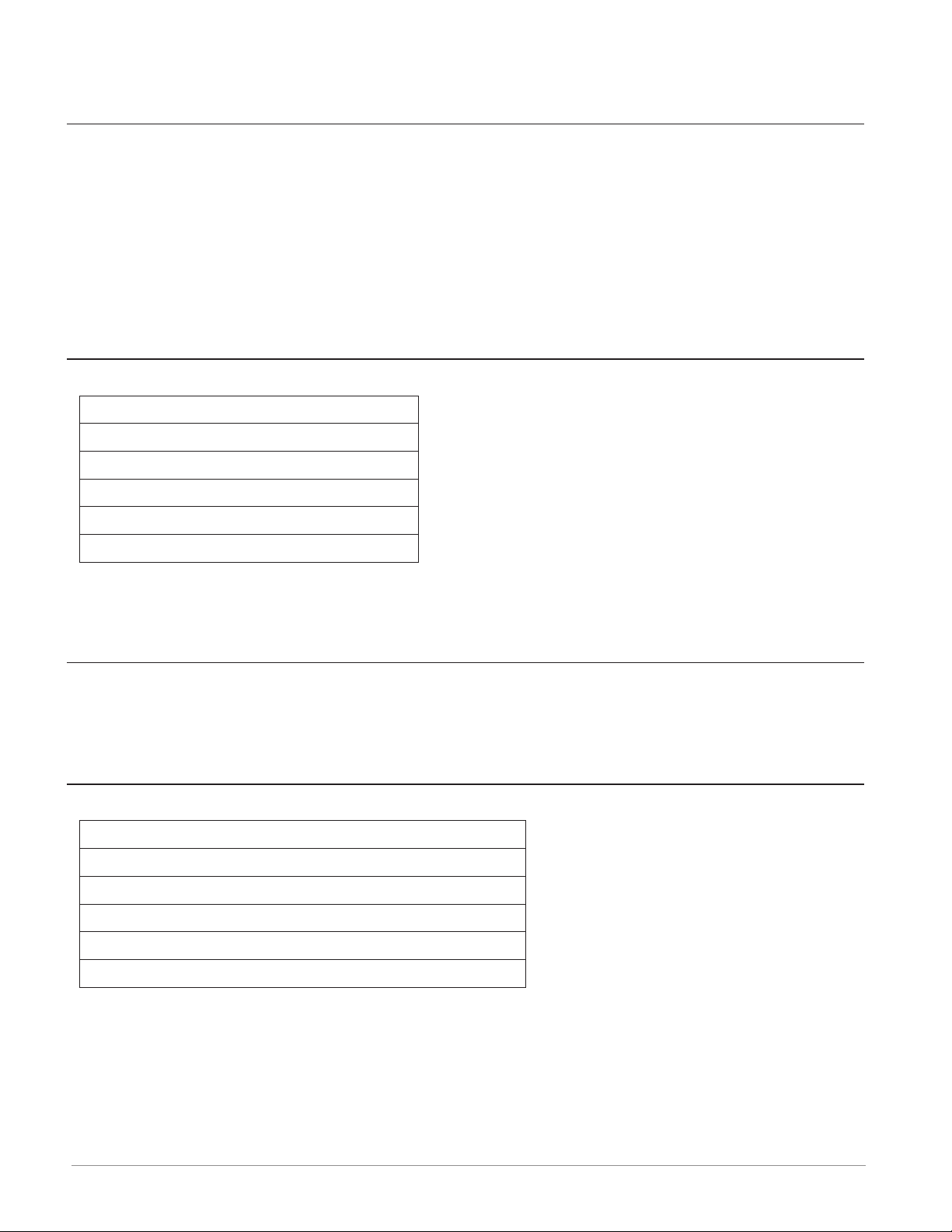

gLbL

SEt Global Menu

d.prs Display Pairs (1 to

10)

Usr.s Save Settings As

Usr.r Restore Settings

From

COЛЏ

SEt Communications Menu

Ad.ЛЏ Modbus Address

bAUd Baud Rate

PAr Parity

ЛЏ.hL Modbus Word Order

iP.ЛЏ IP Address Mode

iP.F1 IP Fixed Address

Part 1

iP.F2 IP Fixed Address

Part 2

iP.F3 IP Fixed Address

Part 3

iP.F4 IP Fixed Address

Part 4

iP.S1 IP Fixed Subnet

Part 1

iP.S2 IP Fixed Subnet

Part 2

iP.S3 IP Fixed Subnet

Part 3

iP.S4 IP Fixed Subnet

Part 4

iP.g1 Fixed IP Gateway

Part 1

iP.g2 Fixed IP Gateway

Part 2

iP.g3 Fixed IP Gateway

Part 3

iP.g4 Fixed IP Gateway

Part 4

ЛЏb.E Modbus TCP Enable

EiP.E EtherNet/IP™ En-

able

Ad.d DeviceNet™ Node

Address

BAUd Baud Rate Device-

Net™

FC.E DeviceNet™ Quick

Connect Enable

P.add Profibus Address

A.LoC Profibus Address

Lock

stat Profibus Status

C_f Display Units

nu.s Non-volatile Save

Watlow EZ-ZONE® RMA Module • 31 • Chapter 4 Setup Page

Page 36

gtФІ

SEt Local Remote Gateway Menu

gtФІ Local Remote Gateway (1 to 17)

du.En Device Enabled

du.St Device Status

ЛЏ.oF Modbus Address Offset

oSt CIP Instance Offset

ao.nb CIP Implicit Assembly Output Mem-

ber Quantity

ai.nb CIP Implicit Assembly Input Member

Quantity

s.of Profibus Slot Offset

rtC

SEt Real Time Clock Menu

hoUr Hours

ЛЏin Minutes

ЛЏon Month

dAtE Date

yEAr Year

doФІ Day of Week

t.For Time Format

d.For Date Format

uAr

SEt Variable Menu

typE Data Type

Unit Units

dig Digital

AnLg Analog

Pro

SEt Profile Menu

Poti Power Off Time

dLog

SEt Data Logging Menu

PErd Period

f.act Full Action

Sfn.A Source Function A

Si.A Source Instance A

S2.A Source Zone A

Lg.pt

SEt Log Point Menu

Lg.pt Log Point (1 to 200)

SFn.A Source Function A

Si.A Source Instance A

S2.A Source Zone A

dEC Display Precision

bCUP

SEt Backup Menu

SAuE Save

rESt Restore

Watlow EZ-ZONE® RMA Module • 32 • Chapter 4 Setup Page

Page 37

RM Access Module • Setup Page

Display

gLbL

SEt

Global Menu

d.prs

dPrS

USr.S

USr.S

USr.r

USr.r

Global

Display Pairs

Defines the

number of Display Pairs.

Global

Save Settings

As

Save all of this

controller's

settings to the

selected set.

Global

Restore Settings From

Replace all of

this controller's settings

with another

set.

Parameter

name

Description

Modbus

Rela-

Range Default

1 to 10 1 - - - - 0x6A

nonE None (61)

- - - -

tive

Ad-

dress

26

SEt1 User Set 1 (101)

SEt2 User Set 2 (102)

nonE None (61)

- - - -

24

SEt1 User Set 1 (101)

SEt2 User Set 2 (102)

FCty Factory (31)

CIP

Class

Instance

Attribute

hex

(dec)

(103)

1

0x1C (28)

0x65

(101)

1

0x0E

(14)

0x65

(101)

1

0x0D

(13)

Data

Pro-

fibus

Index

- - - - 3028 uint

Pa-

ram-

eter

8 1014 uint

7 1013 uint

ID

Type

Read/

Write

RWES

RWE

RWE

&

*

CoЛЏ

SEt

Communications Menu

Ad.ЛЏ

Ad.M

bAUd

bAUd

* R: Read, W: Write, E: EEPROM, S: User Set

Communications

Modbus Address

Set the Modbus

address.

Communications

Baud Rate

Set the speed

of this controller's communications

to match the

speed of the

serial network.

1 to 247 1

9,600 (188)

19,200 (189)

38,400 (190)

9,600

432 0x96

(150)

2

1

434 0x96

(150)

2

3

76 17007 uint

RWE

74 17002 uint

RWE

Watlow EZ-ZONE® RMA Module • 33 • Chapter 4 Setup Page

Page 38

RM Access Module • Setup Page

Display

PAr

PAr

ЛЏ.hL

M.hL

iP.ЛЏ

iP.M

Parameter

name

Description

Communications

Parity

Set the parity

of this controller to match

the parity of

the serial network.

Communications

Modbus Word

Order

Select the

word order of

the two 16-bit

words in the

floating-point

values.

Communications

IP Address Mode

Select DHCP

to let a DHCP

server assign

an address to

this module.

Range Default

nonE None (61)

EuEn Even (191)

odd Odd (192)

hiLo Word High Low (1330)

Lohi Word Low High (1331)

dhCP DHCP (1281)

F.Add Fixed Address (1284)

None

Low

High

DHCP

Modbus

Rela-

tive

Ad-

dress

436 0x96

438 0x96

- - - - - - - - 77 17012 uint

CIP

Class

Instance

Attribute

hex

(dec)

(150)

2

4

(150)

2

5

Pro-

fibus

Index

75 17003 uint

80 17043 uint

Pa-

ram-

eter

ID

RWE

RWE

RWE

Data

Type

&

Read/

Write

*

Note:

Power to the

module must

be cycled after

changing the IP

address.

iP.F1

ip.F1

* R: Read, W: Write, E: EEPROM, S: User Set

Communications

IP Fixed Address Part 1

Set the IP address of this

module. Each

device on the

network must

have a unique

address.

0 to 255 169

- - - - - - - - - - - - 17014 uint

RWE

Watlow EZ-ZONE® RMA Module • 34 • Chapter 4 Setup Page

Page 39

RM Access Module • Setup Page

Display

iP.F2

ip.F2

iP.F3

ip.F3

iP.F4

ip.F4

iP.S1

ip.S1

iP.S2

ip.S2

iP.S3

ip.S3

Parameter

name

Description

Communications

IP Fixed Address Part 2

Set the IP address of this

module. Each

device on the

network must

have a unique

address.

Communications

IP Fixed Address Part 3

Set the IP address of this

module. Each

device on the

network must

have a unique

address.

Communications

IP Fixed Address Part 4

Set the IP address of this

module. Each

device on the

network must

have a unique

address.

Communications

IP Fixed Subnet

Part 1

Set the IP subnet mask for

this module.

Communications

IP Fixed Subnet

Part 2

Set the IP subnet mask for

this module.

Communications

IP Fixed Subnet

Part 3

Set the IP subnet mask for

this module.

Range Default

0 to 255 254

0 to 255 1

0 to 255 1

0 to 255 255

0 to 255 255

0 to 255 0

Modbus

Rela-

tive

Ad-

dress

- - - - - - - - - - - - 17015 uint

- - - - - - - - - - - - 17016 uint

- - - - - - - - - - - - 17017 uint

- - - - - - - - - - - - 17020 uint

- - - - - - - - - - - - 17021 uint

- - - - - - - - - - - - 17022 uint

CIP

Class

Instance

Attribute

hex

(dec)

Pro-

fibus

Index

Pa-

ram-

eter

ID

Data

Type

&

Read/

Write

*

RWE

RWE

RWE

RWE

RWE

RWE

* R: Read, W: Write, E: EEPROM, S: User Set

Watlow EZ-ZONE® RMA Module • 35 • Chapter 4 Setup Page

Page 40

RM Access Module • Setup Page

Display

iP.S4

ip.S4

iP.g1

ip.g1

iP.g2

ip.g2

iP.g3

ip.g3

Parameter

name

Description

Communications

IP Fixed Subnet

Part 4

Set the IP subnet mask for

this module.

Communications

Fixed IP Gateway Part 1

Communications

Fixed IP Gateway Part 2

Communications

Fixed IP Gateway Part 3

Range Default

0 to 255 0

0 to 255 0

0 to 255 0

0 to 255 0

Modbus

Rela-

tive

Ad-

dress

- - - - - - - - - - - - 17023 uint

- - - - - - - - - - - - 17026 uint

- - - - - - - - - - - - 17027 uint

- - - - - - - - - - - - 17028 uint

CIP

Class

Instance

Attribute

hex

(dec)

Pro-

fibus

Index

Pa-

ram-

eter

ID

RWE

RWE

RWE

RWE

Data

Type

&

Read/

Write

*

iP.g4

ip.g4

ЛЏb.E

Mb.E

EiP.E

EiP.E

Ad.d

Ad.d

* R: Read, W: Write, E: EEPROM, S: User Set

Communications

Fixed IP Gateway Part 4

Communications

Modbus TCP Enable

Activate Modbus TCP.

Communications

EtherNet/IP™

Enable

Activate Ethernet/IP™.

Communications

DeviceNet™

Node Address

Set the DeviceNet™ address for this

gateway.

0 to 255 0

no No (59)

yES Yes (106)

no No (59)

yES Yes (106)

0 to 63

Yes

Yes

63

- - - - - - - - - - - - 17029 uint

RWE

- - - - - - - - 78 17041 uint

RWE

- - - - - - - - 79 17042 uint

RWE

- - - - - - - - 83 17052 uint

RWE

Watlow EZ-ZONE® RMA Module • 36 • Chapter 4 Setup Page

Page 41

RM Access Module • Setup Page

Display

bAUd

bAUd

FC.E

FC.E

p.add

P.Add

a.Loc

A.Loc

stat

Stat

Parameter

name

Description

Communications

DeviceNet™

Baud Rate

Set the speed

of this gateway's communications

to match the

speed of the

serial network.

Communications

DeviceNet™

Quick Connect

Enable

Allows for immediate communication

with the scanner upon power

up.

Communications

Profibus DP Address

Set the Profibus address for

this gateway.

Communications

Profibus Address Lock

When set to

yes the Profibus address

cannot be

changed using

software. Can

be changed

from the optional RUI.

Communications

Profibus DP

Status

Current Profibus status.

Range Default

125 125 kb

250 250 kb

500 500 kb

no No (59)

yES Yes (106)

0 to 126

no No (59)

yEs Yes (106)

rEdy Ready (1662)

rng Running (149)

125

No

126

No

- - - -

Modbus

Rela-

tive

Ad-

dress

- - - - - - - - 84 17053 uint

- - - - - - - - - - - - 17054 uint

- - - - - - - - - - - - 17060 uint

- - - - - - - - - - - - 17061 uint

- - - - - - - - - - - - 17062 uint

CIP

Class

Instance

Attribute

hex

(dec)

Pro-

fibus

Index

Pa-

ram-

eter

ID

Data

Type

&

Read/

Write

*

RWE

RWE

RWE

RWE

R

* R: Read, W: Write, E: EEPROM, S: User Set

Watlow EZ-ZONE® RMA Module • 37 • Chapter 4 Setup Page

Page 42

RM Access Module • Setup Page

Display

C_F

C_F