Page 1

ISO 9001

EZ-ZONE® RM Scanner Module

User’s Guide

RM Scanner Module

TOTAL

CUSTOMER

SATISFACTION

3 Year Warranty

Registered Company

1241 Bundy Boulevard., Winona, Minnesota USA 55987

Phone: +1 (507) 454-5300, Fax: +1 (507) 452-4507

http://www.watlow.com

0600-0071-0000 Rev. D Made in the U.S.A.

Winona, Minnesota USA

March 2016

Page 2

Safety Information

We use note, caution and warning symbols throughout this book to draw your attention to

important operational and safety information.

• A “NOTE” marks a short message to alert you to an important detail.

• A “CAUTION” safety alert appears with information that is important for protecting your

equipment and performance. Be especially careful to read and follow all cautions that

apply to your application.

• A “WARNING” safety alert appears with information that is important for protecting you,

others and equipment from damage. Pay very close attention to all warnings that apply to

your application.

• The safety alert symbol, (an exclamation point in a triangle) precedes a general

CAUTION or WARNING statement.

• The electrical hazard symbol, (a lightning bolt in a triangle) precedes an electric shock

hazard CAUTION or WARNING safety statement. Further explanations follow:

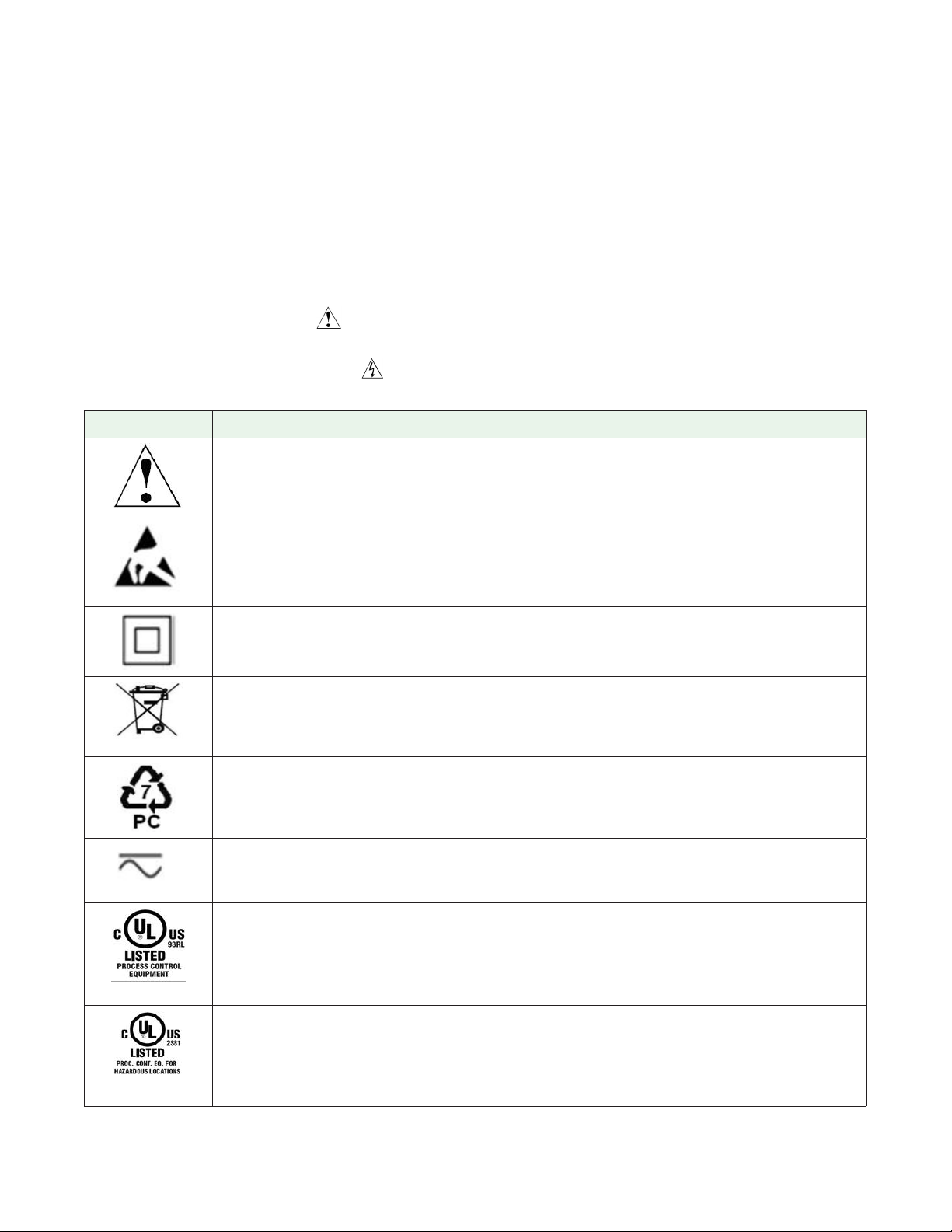

Symbol Explanation

CAUTION – Warning or Hazard that needs further explanation than label on

unit can provide. Consult User's Guide for further information.

ESD Sensitive product, use proper grounding and handling techniques when

installing or servicing product.

Unit protected by double/reinforced insulation for shock hazard prevention.

Do not throw in trash, use proper recycling techniques or consult manufacturer for proper disposal.

Enclosure made of Polycarbonate material. Use proper recycling techniques or consult manufacturer for proper disposal.

Unit can be powered with either alternating current (ac) voltage or direct

current (dc) voltage.

Unit is a Listed device per Underwriters Laboratories®. It has been evaluated to United States and Canadian requirements for Process Control

Equipment. UL 61010 and CSA C22.2 No. 61010. File E185611 QUYX,

QUYX7. See: www.ul.com

Unit is a Listed device per Underwriters Laboratories®. It has been evaluated to United States and Canadian requirements for Hazardous Locations

Class 1 Division II Groups A, B, C and D. ANSI/ISA 12.12.01-2007. File

E184390 QUZW, QUZW7. See: www.ul.com

Page 3

Unit is compliant with European Union directives. See Declaration of

Conformity for further details on Directives and Standards used for

Compliance.

Unit has been reviewed and approved by CSA International for use as

Temperature Indicating-Regulating Equipment per CSA C22.2 No. 24. See:

www.csa-international.org

Warranty

The EZ-ZONE® RM Scanner module is manufactured by ISO 9001-registered processes and is

backed by a three-year warranty to the first purchaser for use, providing that the units have

not been misapplied. Since Watlow has no control over their use, and sometimes misuse, we

cannot guarantee against failure. Watlows' obligations hereunder, at Watlows' option, are limited to replacement, repair or refund of purchase price, and parts which upon examination

prove to be defective within the warranty period specified. This warranty does not apply to

damage resulting from transportation, alteration, misuse or abuse. The purchaser must use

Watlow parts to maintain all listed ratings.

Technical Assistance

If you encounter a problem with your Watlow controller, review your configuration information to verify that your selections are consistent with your application: inputs, outputs,

alarms, limits, etc. If the problem persists, you can get technical assistance from your local

Watlow representative (see back cover), by e-mailing your questions to wintechsupport@watlow.com or by dialing +1 (507) 494-5656 between 7 a.m. and 5 p.m., Central Standard Time

(CST). Ask for for an Applications Engineer. Please have the following information available

when calling:

• Complete model number

• All configuration information

• User’s Guide

• Factory Page

Return Material Authorization (RMA)

1. Call Watlow Customer Service, (507) 454-5300, for a Return Material Authorization (RMA)

number before returning any item for repair. If you do not know why the product failed,

contact an Application Engineer or Product Manager. All RMA’s require:

• Ship-to address

• Bill-to address

• Contact name

• Phone number

• Method of return shipment

• Your P.O. number

• Detailed description of the problem

• Any special instructions

• Name and phone number of person returning the product.

Page 4

2. Prior approval and an Return Merchandise Authorization number from the Customer

Service Department is required when returning any product for credit, repair or evaluation. Make sure the Return Merchandise Authorization number is on the outside of the carton and on all paperwork returned. Ship on a Freight Prepaid basis.

3. After we receive your return, we will examine it and try to verify the reason for returning

it.

4. In cases of manufacturing defect, we will enter a repair order, replacement order or issue

credit for material returned. In cases of customer misuse, we will provide repair costs and

request a purchase order to proceed with the repair work.

5. To return products that are not defective, goods must be in new condition, in the origi-

nal boxes and they must be returned within 120 days of receipt. A 20 percent restocking

charge is applied for all returned stock controls and accessories.

6. If the unit cannot be repaired, you will receive a letter of explanation and be given the

option to have the unit returned to you at your expense or to have us scrap the unit.

7. Watlow reserves the right to charge for no trouble found (NTF) returns.

This EZ-ZONE® RM Scanner User’s Guide is copyrighted by Watlow Electric, Inc., © March 2016

with all rights reserved.

EZ-ZONE RM is covered by U.S. Patent No. 6,005,577 and Patents Pending

Page 5

TC

Table of Contents

Table of Contents ..................................1

Chapter 1: Overview ................................4

Functions ................................................7

Inputs ...................................................7

Outputs .................................................8

Actions ..................................................8

Chapter 2: Install and Wire ...........................18

Dimensions .............................................18

RMS Installation and Removal on a DIN Rail ...................22

Wiring .................................................25

Conventions Used in the Menu Pages .........................46

Chapter 3: Operations Pages .........................49

Analog Input Menu .......................................51

Process Value Menu ......................................52

Digital Input/Output Menu ..................................53

Action Menu .............................................53

Alarm Menu .............................................54

Linearization Menu ........................................55

Compare Menu ..........................................56

Timer Menu .............................................57

Counter Menu ...........................................58

Logic Menu .............................................58

Math Menu ..............................................60

Chapter 4: Setup Pages .............................62

Analog Input Menu .......................................65

Process Value Menu ......................................69

Digital Input/Output Menu ..................................73

Action Menu .............................................76

Output Menu ............................................78

Alarm Menu .............................................82

Linearization Menu ........................................85

Compare Menu ..........................................89

Timer Menu .............................................91

Watlow EZ-ZONE® RMS Module • 1 • Table of Contents

Page 6

TC

Table of Contents (cont.)

Counter Menu ...........................................94

Logic Menu .............................................97

Math Menu .............................................106

Variable Menu ..........................................113

Global Menu ............................................114

Communications Menu ...................................115

Chapter 5: Factory Pages ...........................117

Control Module Factory Page Parameters .....................117

Custom Setup Menu .....................................118

Security Setting Menu ....................................118

Diagnostics Menu .......................................121

Calibration Menu ........................................122

Chapter 6: Features ...............................124

Saving and Restoring Settings Using an RUI ..................125

Inputs .................................................125

10 Point Linearization ...................................128

Alarms ................................................128

Process Alarms ........................................129

Alarm Set Points .......................................129

Alarm Hysteresis .......................................129

Alarm Latching ........................................129

Alarm Silencing ........................................130

Alarm Blocking ........................................130

Using Password Security ..................................130

Modbus - Using Programmable Memory Blocks ................132

Software Configuration ...................................132

EZ-ZONE Configurator Software ...........................133

Function Block Descriptions ...............................137

Action Function ........................................137

Alarm Function ........................................138

Analog Input Function ...................................140

Compare Function ......................................142

Counter Function ......................................144

Watlow EZ-ZONE® RMS Module • 2 • Table of Contents

Page 7

TC

Table of Contents (cont.)

Custom Function .......................................145

Diagnostic Function ....................................145

Digital Input/Output Function .............................146

Global Function ........................................147

Linearization Function ...................................148

Logic Function ........................................150

Math Function .........................................154

Modbus® Function .....................................159

Output Function .......................................160

Process Value Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

Security Function ......................................166

Timer Function ........................................167

Variable Function ......................................173

Chapter 8: Appendix ..............................174

Troubleshooting Alarms, Errors and Control Issues .............174

Modbus® - Programmable Memory Blocks ...................175

Troubleshooting Alarms, Errors and Module Issues .............179

RMS Specifications ......................................184

RMS Ordering Information ................................190

How to Reach Us ........................................192

Watlow EZ-ZONE® RMS Module • 3 • Table of Contents

Page 8

1

Chapter 1: Overview

Available EZ-ZONE RM System Literature and Resources

Document Title and Part Number Description

EZ-ZONE Rail Mount Access

(RMA) User's Guide, part number: 0600-0072-0000

EZ-ZONE Rail Mount Controller

(RMC) User's Guide, part number: 0600-0070-0000

EZ-ZONE Rail Mount High Density

(RMH) User's Guide, part number: 0600-0074-0000

EZ-ZONE Rail Mount Expansion

(RME) User's Guide, part number: 0600-0073-0000

EZ-ZONE Rail Mount Limit (RML)

User's Guide, part number: 0600-

0075-0000

EZ-ZONE Remote User Interface

(RUI) User's Guide, part number:

0600-0060-0000

Describes how to connect the RM system into an industrial network, how to use data logging, module backup

and the real-time clock.

The RMC module is an advanced integrated controller

capable of PID and limit control. This document describes how to configure and program all loops of control and communications.

This module extends the density of the standard RM

modules (number of control loops and I/O points). The

User Guide describes common usage, communications

and the number I/O points available.

When additional I/O is needed the Expansion module

fills the gap. This document describes common usage

and the various types of I/O available.

The RML module will protect against unwanted thermal

runaway and over temperature conditions. The User

Guide describes configuration, programming and communications capabilities.

The RUI provides a visual LED display to the RM configuration and setup menus. This document illustrates

and describes connections and also describes the Home

Page for each RM module as viewed from the RUI.

EZ-ZONE RM Specification Sheet,

part number: WIN-EZRM-0414

Watlow Support Tools DVD, part

number: 0601-0001-0000

The DVD described above ships with the product and as stated contains all of the literature

above as well as much more. If the DVD is not available one can be acquired by contacting

Watlow Customer Service at 1-507-454-5300.

As an alternative to the DVD, all of the user documentation described above can also be

found on the Watlow website. Click on the following link to find your document of choice:

http://www.watlow.com/literature/index.cfm. Once there, simply type in the desired part

number (or name) into the search box and download free copies.

Watlow EZ-ZONE® RMS Module • 4 • Chapter 1 Overview

Describes RM hardware options, features, benefits and

technical specifications.

Contains all related user documents, tutorial videos,

application notes, utility tools, etc...

Page 9

Your Comments are Appreciated

In an effort to continually improve our technical literature and ensure that we are providing

information that is useful to you, we would very much appreciate your comments and suggestions. Please send any comments you may have to the following e-mail address: TechlitCom-

ments@watlow.com

Introduction

The EZ-ZONE® RM Scanner (RMS) is capable of monitoring from 1 to 16 inputs. As is the case

with all of the RM family modules the RMS can be used as a standalone device or it can be

used as part of a larger system of interconnected RM modules. The RMS takes the pain out of

solving your need for high density monitoring requirements as either a stand-alone module or

in applications that require distributed control.

It just got a whole lot easier to solve the thermal requirements of your system. The RMS module is provided in a space-saving, rail-mount package and is highly scalable where you only

pay for what you need. For those applications that require the ability to configure/monitor

the control over a network, Modbus RTU communications is an option. Other communications

protocols are also available (e.g., EtherNet/IP, DeviceNet, Modbus TCP and Profibus DP) when

used in conjunction with an RM Access (RMA) module or when using a Remote User Interface/

Gateway (RUI/GTW).

Standard Features and Benefits

Communication Capabilities

• Supports network connectivity to a PC or PLC

• Watlow Standard Bus or Modbus® RTU

• Provides plug and play capabilities with Remote User Interface (RUI’s) and RMA module

• Free standard bus communications port and free PC software (EZ-ZONE Configurator and

Composer)

Additional Control Integration Options

• Includes programmable timer functions

• Includes programmable counter functions

• Allows for simple math and logic programming options

Integrated Thermal Loop Diagnostics

• Users can easily tell that the entire thermal system is functioning properly

• Provides complete system diagnostics that are far superior to simple discrete level diagnostics

• Allows for flexible synergistic use of hardware, such as using one loop's sensor as a backup

to another loop in the event of sensor failure.

• Helps prevent load loss or allow for maintenance to be scheduled when more convenient.

• Provides notification of system problems to help reduce maintenance and service costs

Off-the-Shelf Designed System Solution

• Improves system reliability with a factory integrated solution that minimizes inter-module

connections and potential problems at screw termination points.

• Reduces installation cost

• Eliminates compatibility headaches often encountered with using many different components and brands

Watlow EZ-ZONE® RMS Module • 5 • Chapter 1 Overview

Page 10

Scanner Handles High Ambient Temperatures

• Operates in an unprecedented temperature range of -18 to 65°C (0 to 149°F) for cabinets

and panel enclosures with elevated temperature levels

Memory for Saving and Restoring User-Defined Parameter Default Settings

• Allows customers to save and restore their own defined defaults for machine parameter

settings

• Reduces service calls and downtime due to inadvertent end user parameter adjustments

Synergistic Module Control (SMC)

• Allows outputs selected for control (heat/cool), alarms or events to be located in any physical module, regardless of which module is connected to the input sensor

Split-Rail Control (SRC)

• Allows modules to be mounted together or mounted remotely from one another (maximum

distance 200 feet or 61 meters)

• Shares control operation via Synergistic Module Control (SMC) capability

• Allows individual modules to be mounted closer to the physical input and output devices

to which they are wired

• Improves system reliability and lowers wiring costs

®

Agency Approvals: UL

listed, CE, RoHS, W.E.E.E. FM, SEMI F47-0200, Class 1 Div. 2 Rating

on Selected Models

• Assures prompt product acceptance

• Reduces panel builder's documentation and agency costs

Removable Connectors

• Assures reliable wiring and reduces service calls

• Simplifies installation

Three-Year Warranty

• Demonstrates Watlow’s reliability and product support

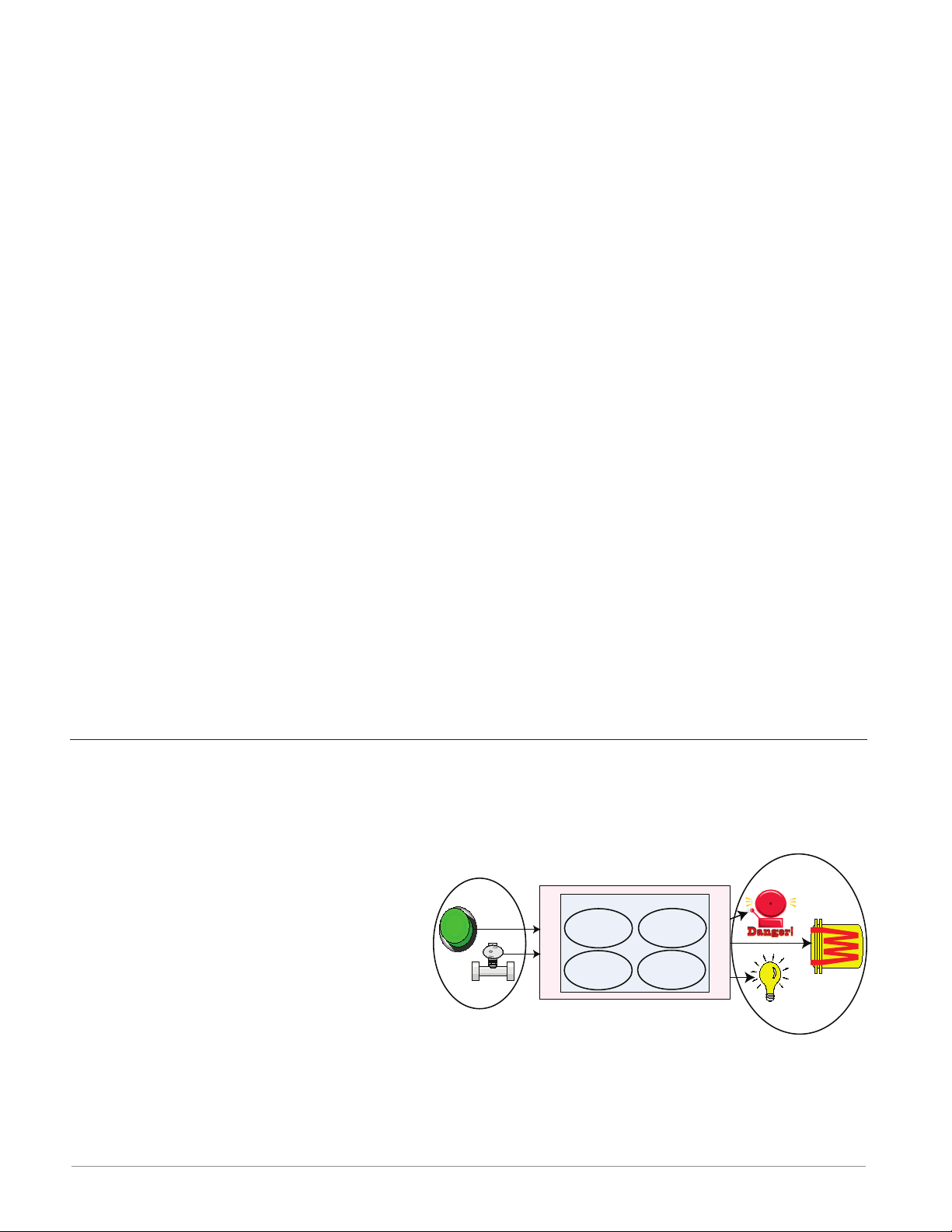

A Conceptual View of the RMS Module

The flexibility of the RMS software and hardware allows for variation in configurations. Acquiring a better understanding of its functionality and capabilities while at the same time planning

out how the controller can be used will deliver maximum effectiveness in your application.

It is useful to think of the scanner in

three parts: inputs, procedures and outputs. Information flows from an input to

a procedure to an output when the scanner is properly configured. An RMS module can carry out several procedures at

Inputs

Prodedures

Process

Alarm

High

Silence

Alarms

Process

Alarm

Low

Tu rn Loop

Alarms off

the same time, e.g., monitoring inputs for

several different alarm situations, monitoring and acting upon digital inputs, and

outputs can be configured to drive devices such as heaters, audible alarms, lights. Each process needs to be thought out carefully and the scanner’s inputs, procedures and outputs set

up properly.

Outputs

Watlow EZ-ZONE® RMS Module • 6 • Chapter 1 Overview

Page 11

Functions

Functions use input signals to calculate a value. A function may be as simple as reading a digital input to set a state to true or false, or reading a temperature to set an alarm state to on

or off. Alternatively, if a failure with the primary sensing device should occur, sensor backup

could be utilized to avoid an unwanted shutdown.

To set up a function, one of the first things that must be considered is the function source

and instance. For example, if the control is equipped with Digital Inputs (source) and it was

decided to use DI 9 (instance) it can then be associated with an Action to reset an individual

alarm or all alarms.

To configure a Digital Input as described above:

1. Navigate to the Setup Page and then to the Digital I/O menu.

2. Select the desired instance and set the direction to input voltage or input dry contact.

3. Navigate to the Setup Page and then the Action menu.

4. Set the Action Function to Alarm

5. Select which alarm instance will be reset (0 equals all)

6. Select the Source Function to Digital I/O

7. Select the Source Instance (step 2 above)

8. Select the Source Zone (0 equals the module being configured).

9. Select the Transmitter Active Level to execute the desired function.

This configuration is now complete. When the selected digital input is active, the alarm or all

alarms that are latched without a currently existing alarm condition will be reset. If a specific

alarm instance (1 - 16) is selected (step 5) it will be that instance alone that will be reset.

Note:

Alarms will reset automatically when the condition that caused the alarm goes back to a

non-alarm state if the Latching prompt is set to non-latching (Setup Page, Alarm Menu).

Keep in mind that a function is a user-programmed internal process that does not execute any

action outside of the controller. To have any affect outside of the controller, an output must

be configured to respond to a function.

Inputs

The inputs provide the information that any given programmed procedure can act upon. Simply stated, this information may come from an operator pushing a button or from a sensor

monitoring the temperature of a part being heated or cooled.

Each analog input typically uses a thermocouple, RTD or thermistor to read the process temperature. It can also read volts, current or resistance, allowing it to use various devices to

read humidity, air pressure, operator inputs and others values. Each analog input must be configured to match the device connected to that input (see: Analog Input Menu, Setup Page).

Each digital input reads whether a device is active or inactive. An RMS module equipped with

digital input/output hardware includes two sets of terminals where each of which can be used

as either an input or an output. Each pair of terminals must be configured to function as either an input or an output with the direction parameter (see: Digital Input/Output Menu, Setup Page).

Watlow EZ-ZONE® RMS Module • 7 • Chapter 1 Overview

Page 12

The inputs provide the information that any given programmed procedure can act upon. Simply stated, this information may come from an operator pushing a button or from a sensor

monitoring the temperature of a part being heated or cooled.

Each analog input typically uses a thermocouple, RTD or thermistor to read the process temperature. It can also read volts, current or resistance, allowing it to use various devices to

read humidity, air pressure, operator inputs and others values. Each analog input must be configured to match the device connected to that input (see: Analog Input Menu, Setup Page).

Each digital input reads whether a device is active or inactive. An RMS module equipped with

digital input/output hardware includes two sets of terminals where each of which can be used

as either an input or an output. Each pair of terminals must be configured to function as either an input or an output with the direction parameter (see: Digital Input/Output Menu, Setup Page).

Outputs

Outputs can perform various functions or actions in response to information provided by a

function, such as removal of the control voltage to a contactor; driving a heater; turning a

light on or off; unlocking a door; or turning on an audible alarm.

Assign an output to a function in the Output Menu or Digital Input/Output Menu. Then select

which instance of that function will drive the selected output. For example, in using an RMS

module, an output can be configured to respond to the output of the PID algorithm from another RM module to drive a heater.

You can assign more than one output to respond to a single instance of a function. For example, alarm 2 could be used to trigger a light connected to output 1 and a siren connected to

digital output 5.

Actions

Based on a given input (Digital I/O, Event output, Logic function, etc..) the Action function

can cause other functions to occur. To name a few, set alarms to off, silencing alarms and re-

storing user memory.

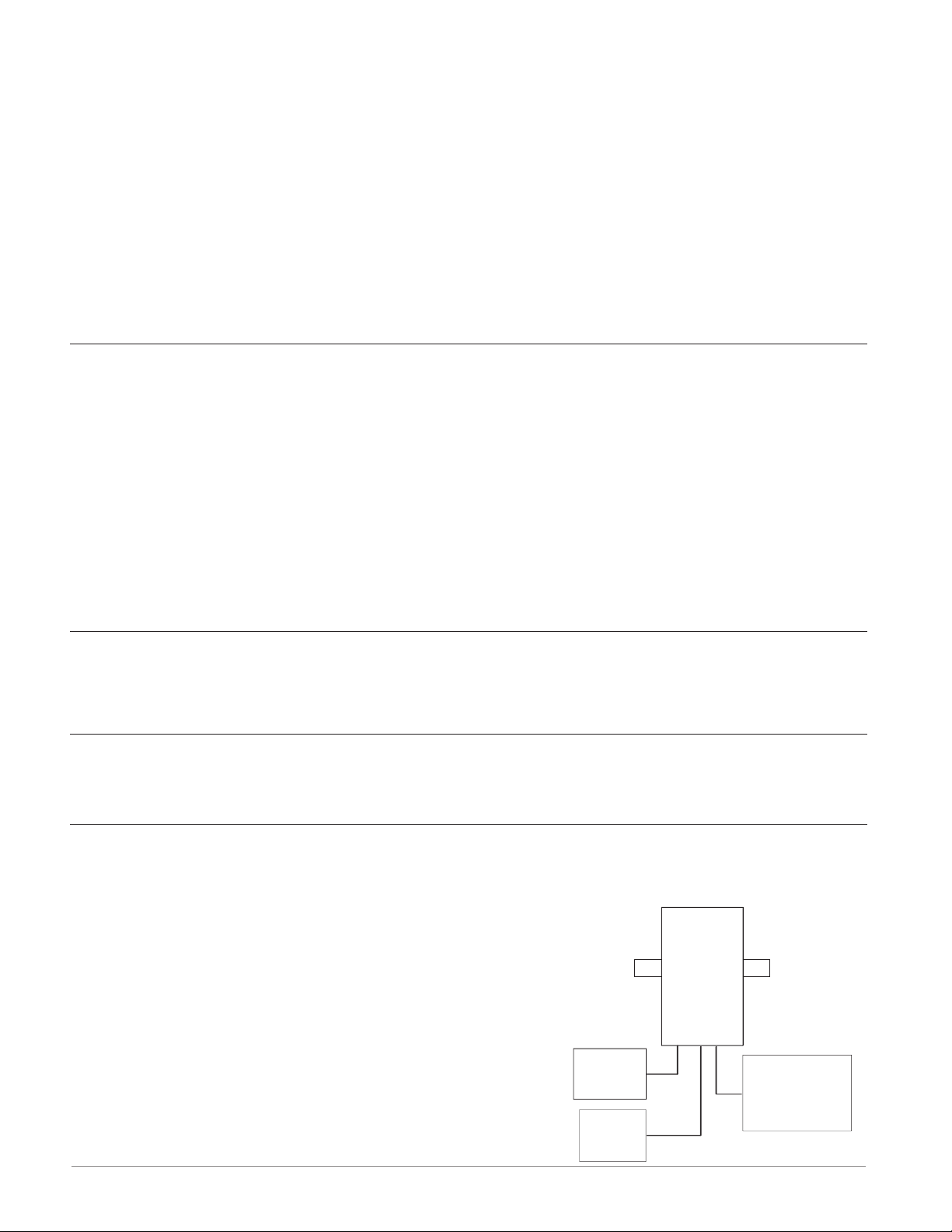

A Conceptual View of RM Hardware Configurations

Due to the scalability and flexibility in the RM system a user has several options available in

the way that the hardware can be connected. Listed below are a few examples.

RMS Connected to a Remote User Interface (RUI) and a Personal Computer (PC)

In this configuration the RUI and PC are connected to the RMS module via Watlow's Standard

Bus where both will be able to talk directly to the RMS module.

In the graphic to the right, the PC running EZ-ZONE

Configurator software and or the RUI can be used to configure and then monitor the RMS and other modules connected to it

RMS

Scanner

Slot C

Power

Supply

RUI

Watlow EZ-ZONE® RMS Module • 8 • Chapter 1 Overview

PC Running

EZ-ZONE

Configurator

Page 13

RMS Module Connected to a Programmable Logic Controller (PLC) on a DIN Rail

In the illustration shown below, the PLC and the RMS module must be equipped with Modbus

RTU.

Note:

If it is intended to use an RUI or a PC using

EZ-ZONE Configurator software it will be necessary to switch the protocol on the RMS to Watlow's

Standard Bus to successfully communicate; follow

the steps below to switch the RMS to the Standard

bus protocol.

1. Disconnect all Modbus devices from the network

2. Push and hold the orange button on the face of

the module for approximately 6 seconds

3. When the LED display (above the orange button)

changes to P, momentarily release the orange

button and then push it again where S will appear (symbol for Standard Bus), release the orange button

4. Push the orange button again for approximately 3 seconds (LED display will become

brighter) to change the Standard Bus address if needed

Power

Supply

PLC

RMS

Scanner

Slot C

PC Running

EZ-ZONE

Configurator

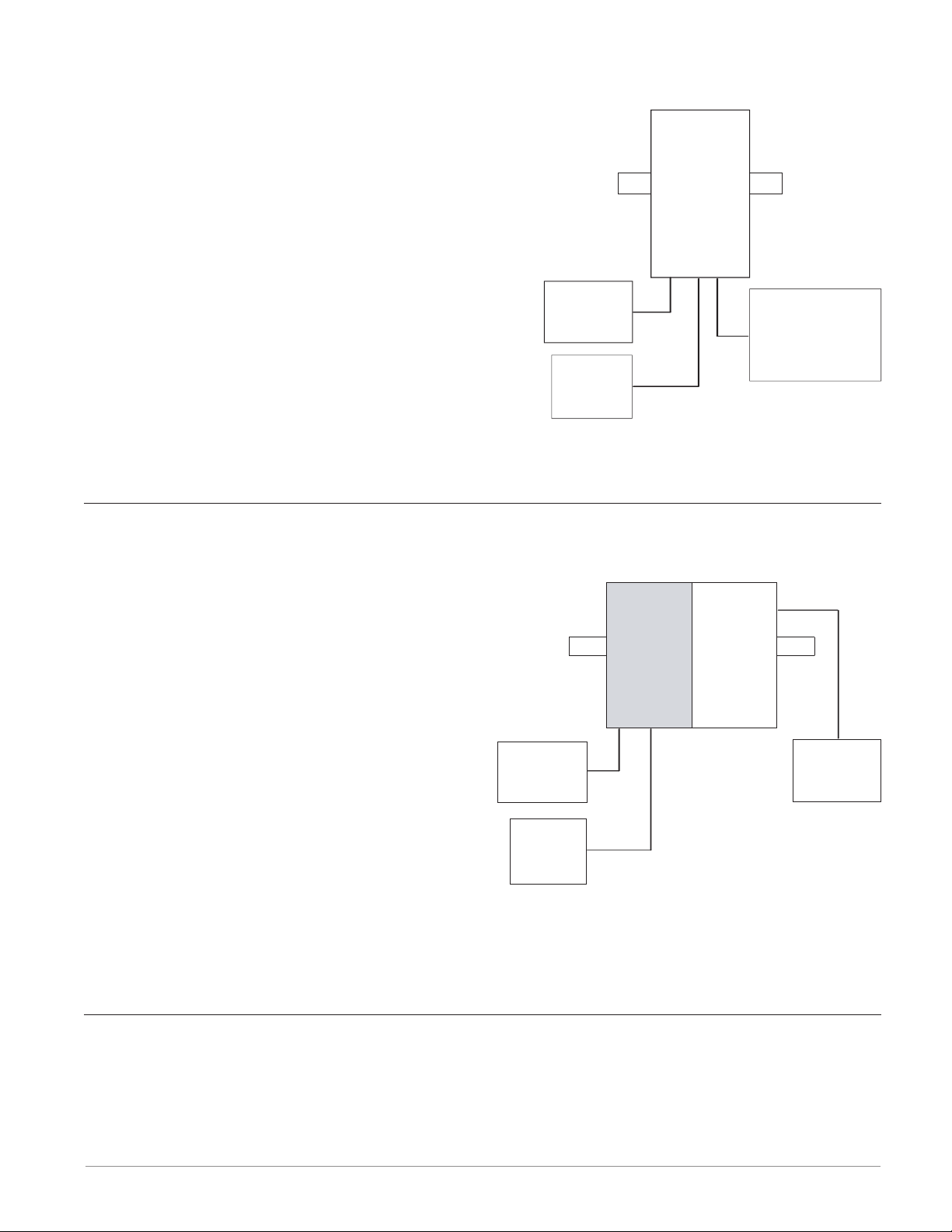

RMS Module Connected to an Operator Interface Terminal (OIT) through an RMA

In this configuration the RMS can be connected to the OIT through the RMA running any of a

number of available protocols. The RMA and the OIT must be using the same protocol while

the communications from RMA to the RMS module is accomplished over the backplane using

Watlow's Standard Bus protocol. Available protocols in the RMA follow:

1. EtherNet/IP and or Modbus TCP

2. DeviceNet

3. Modbus RTU

4. Profibus DP

Notice that in the example to the right that

there is an optional RUI connected to the RMS

module. An OIT is not generally used to configure a control but is used more for run-time

information. As an alternative for configuration

the RUI could be used to configure and monitor in a remote location.

If using Modbus, one advantage in using an RMA module while also having an RUI and a PC

connected is that the RMS could be set for Standard Bus all of the time while the RMA can simultaneously run Modbus and Standard Bus protocols, no protocol switching required.

RUI

Power

Supply

RMS

Scanner

Slot C

RM

Access

Slot C

Slot E

OIT

RMS Connected to a Split Rail with OIT

In this configuration both the inter-module bus (backplane communications) and Standard Bus

are connected between rails to allow for remote capabilities. It is recommended that the split

rail connection not exceed 100 feet. In this configuration the OIT can communicate with all

modules (maximum 16 modules any combination with one Access module).

Watlow EZ-ZONE® RMS Module • 9 • Chapter 1 Overview

Page 14

RMC

Controller

RMS

Scanner

Slot E

RM

Access

RMC

Controller

Slot C

Slot C

RMS

Scanner

Slot C

Slot C

Slot C

Power

Supply

OIT

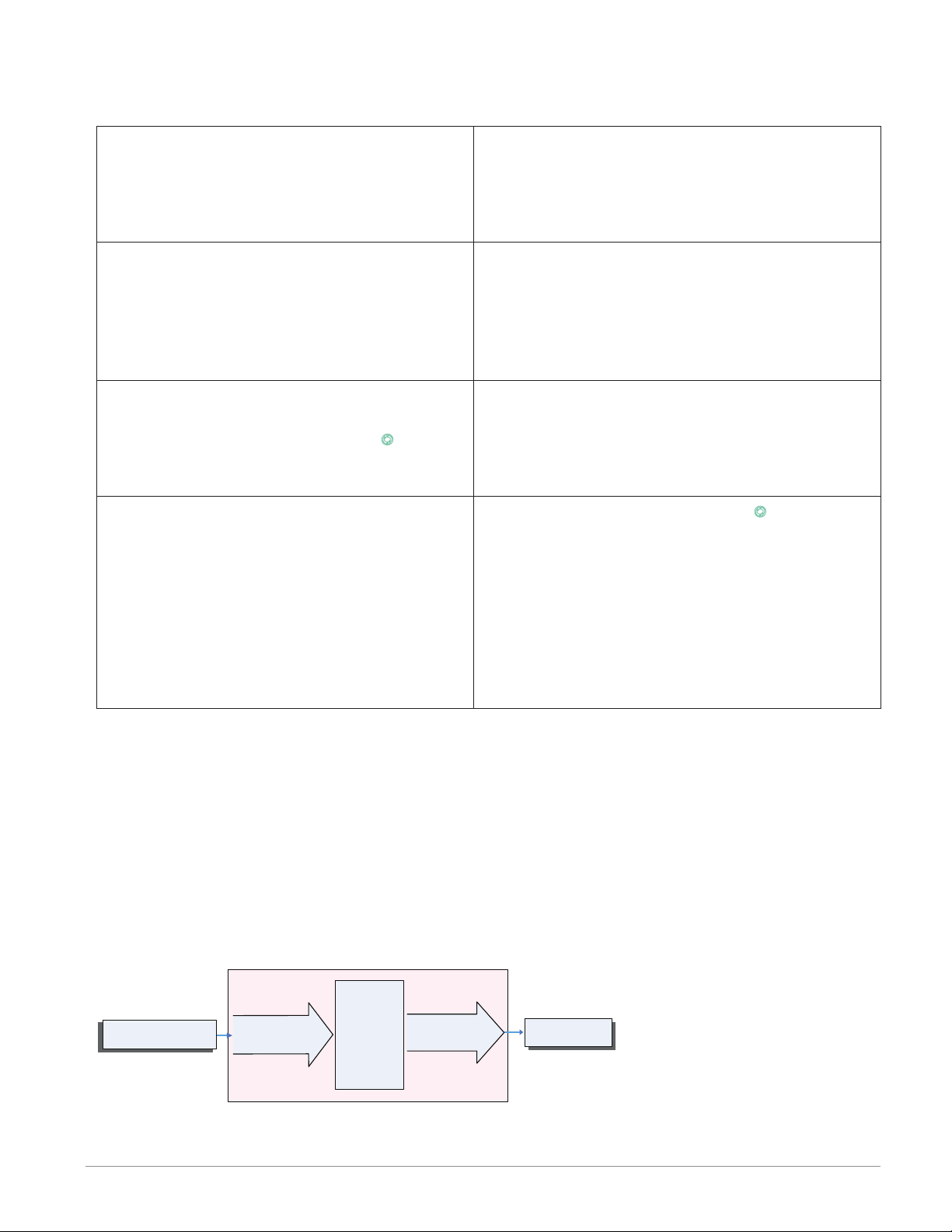

Module Orientation

The picture below represents one of six possible RM modules. All six will have four slots on

the face (slot A, B, D, and E) and one on the bottom (slot C) not shown. All of these slots are

not always used on all modules.

Note:

For correct operation and accuracy, the module must be mounted in a vertical orientation

as shown.

On the face of the module there is a button (white circle) under the Zone address (5) that

when pushed and held has the following functions:

1. For any module, push and hold the orange button for approximately 2 seconds. The address

will intensify indicating that it can now be

E

changed. Release and repeatedly press to change

D

to the desired unique address.

2. For the scanner module, if equipped with the

Modbus protocol (RMSxxxxxxxxx1xx), pushing

B

A

and holding the orange button for approximately

6 seconds will cause the module to display P for

protocol. Releasing the button and then pushing

it again (within 6 seconds), the display will toggle

between N (Modbus) and S (Standard Bus). Valid addresses for Modbus and Standard bus

range from 1 -16 (1 - 9, A is 10, B is 11, C is 12, d is 13, E is 14, F is 15, and h is 16).

The Access module is shipped at address J or 17.

Module Status

(Slot A, B, D, or E)

Protocol

Standard Bus - red

Modbus - green

Module Outputs

1 through 16, all may or

may not be used depending

on module type

Getting Started Quickly

Consider taking the following steps to quickly commission your control:

• Wire and connect the power source to the control

• Wire and connect input and output devices to the control

• Power up the control and navigate to the Setup Page to configure inputs, outputs, adjust

set points, alarms, etc...

The RMS controller has a page and menu structure that is listed below along with a brief description of its purpose. The menu structure can be easily seen and navigated using EZ-ZONE

Configurator software or the Remote User Interface (RUI).

Watlow EZ-ZONE® RMS Module • 10 • Chapter 1 Overview

Page 15

Note:

EZ-ZONE RMS Default Configuration

The menu navigation as described below applies when the RMS is connected to the RUI

which is optional equipment.

Setup Page

Using the RUI, push and hold the up and

down keys (¿ ¯) for 6 seconds to enter.

(See the Setup Page for further information)

Operations Page

Using the RUI push and hold the up and

down keys (¿ ¯) for 3 seconds to enter.

(See the Operations Page for further information)

Factory Page

Using the RUI push and hold the Infinity

and the green Advance keys (ˆ ‰) for 6

seconds to enter. (See the Factory Page

for further information)

Home Page

When using the RUI, the control is at the

Home Page when initially powered up

where it will display the value of Analog

Input 1 in the upper display and the value

of Analog Input 2 in the lower display.

Note:

The Home Page is visible only when using the RUI.

A user would want to setup their control prior

to operation. As an example, define the input

type, alarm sides (high and or low) or set the

output function.

After setting up the control to reflect your

equipment, the Operations Page would be

used to monitor or change runtime settings.

As an example, the user may want to see the

current status (on or off) of an event in the

Action Menu.

For the most part the Factory Page has no

bearing on the control when running. A user

may want to enable password protection,

view the control part number or perhaps create a custom Home Page.

Pushing the green Advance Key ‰ will cause

the display to show the value of Analog Input

1 in the upper display and Analog Input 2 in

the lower display. With each successive push

of the green advance key the display will

sequentially show the value of all remaining

analog inputs in the upper display and the

lower display will show the corresponding LED

display. (e.g., Ain3 for input 3)

The default RMS loop configuration out of the box is shown below:

• All Analog Input functions are set to thermocouple, type J (to change go to the Setup Page,

Analog Input Menu)

• All Process Value functions are set to off (to change go to the Setup Page, Process Value

Menu)

• All outputs are set to off (to change go to the Setup Page, Output Menu)

Once the scanner has been wired and setup, power up the control. If using an RUI the upper

display will show the value of Analog Input 1 and the lower display will show the value of Analog Input 2

.

Input

Function

Input Sensor

All Analog Inputs

Thermocouple Type J

Alarm

Types

All Outputs

Off

Output

Function

Off

Watlow EZ-ZONE® RMS Module • 11 • Chapter 1 Overview

Page 16

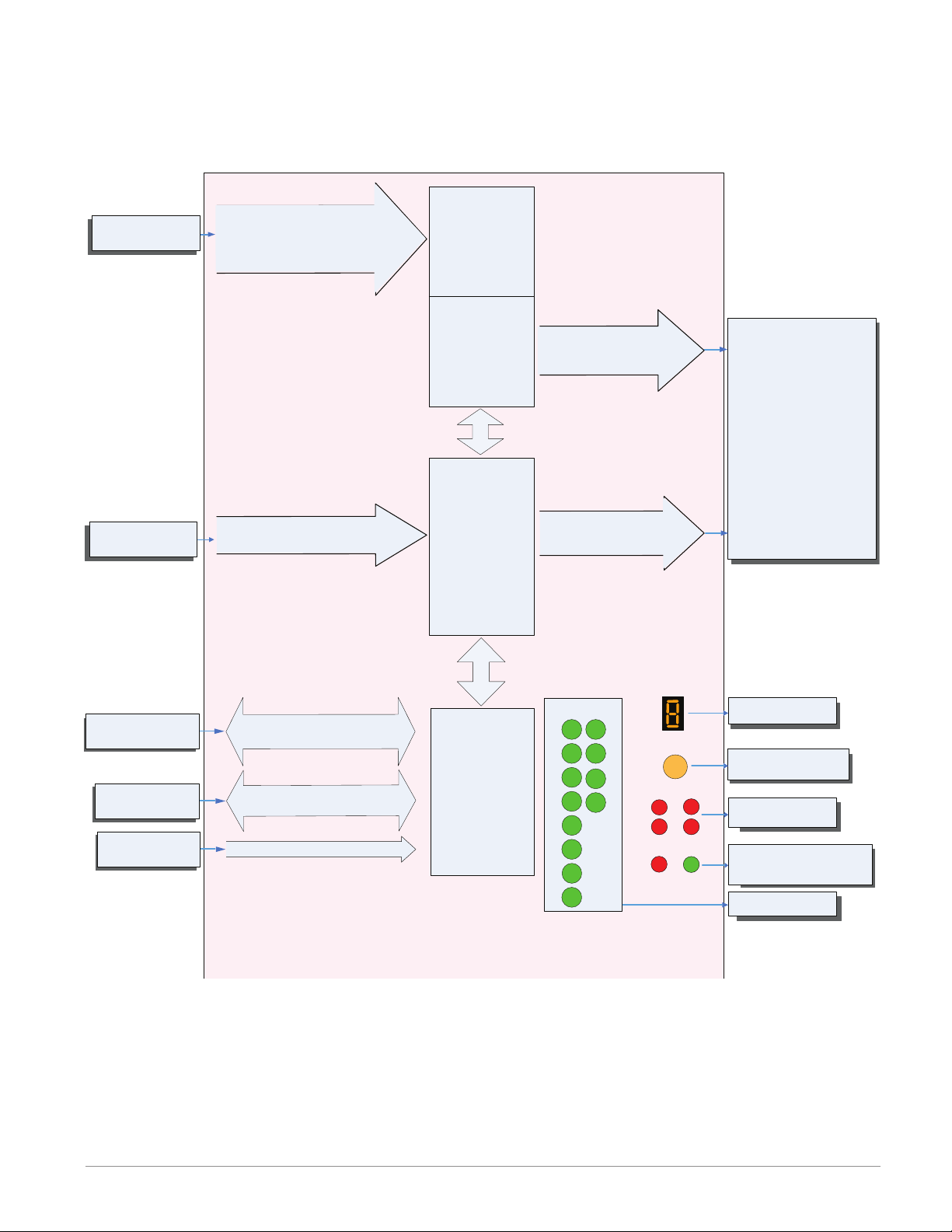

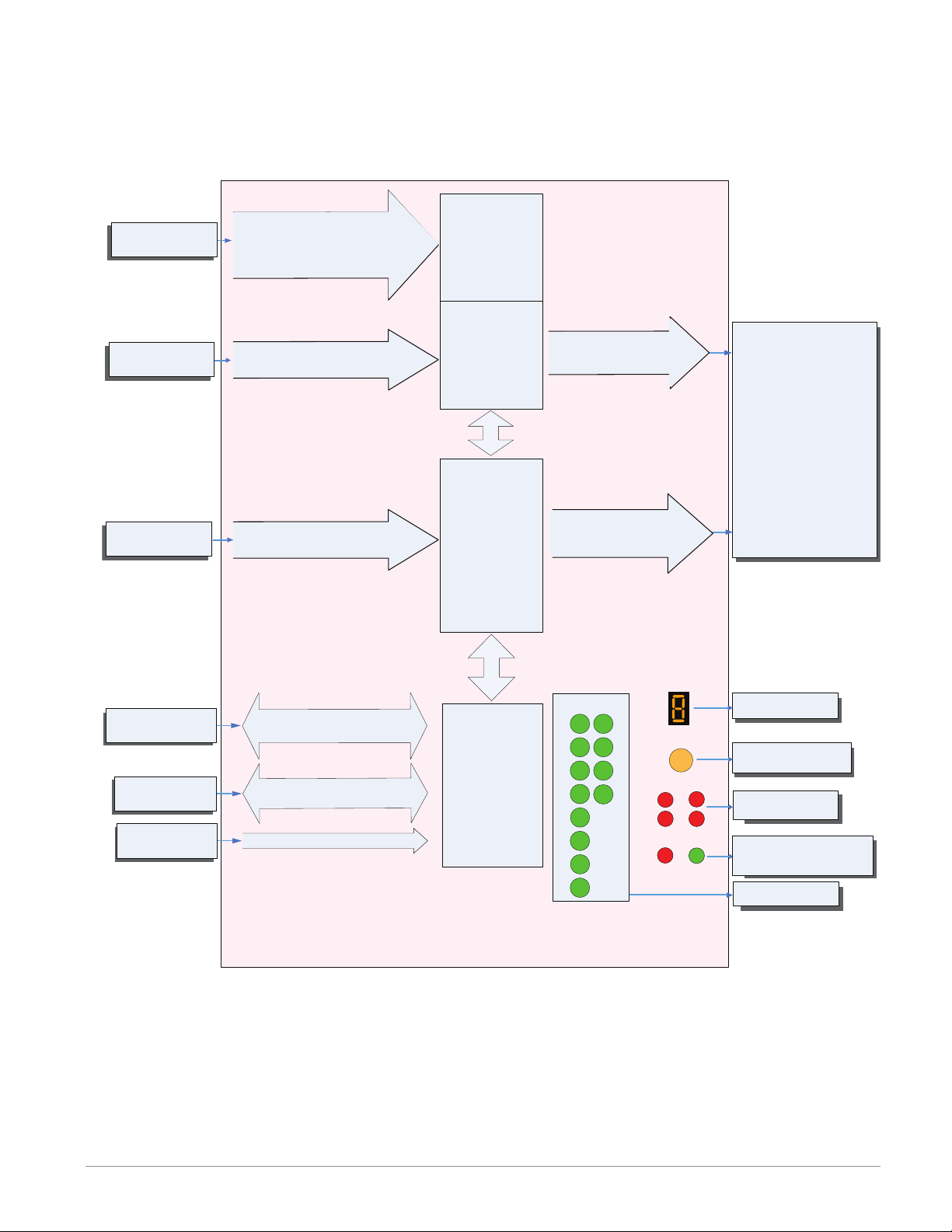

EZ-ZONE RMS Module - System Diagram

16 Scanner Channels - Slots A, B, D and E

R M S x - [R,P] [R,P] [R,P] [R,P] - A A A A

Input

Function

Input Sensor

RUI,

PC, PLC or HMI

Other RM Modules

Power Supply

Analog Input 1 through 16

None, Thermocouple, 2-Wire RTD (100, 1k),

Thermistor (5k, 10K, 20k, 40k), Process

(V, mV, mA) or 1K Potentiometer

EIA - 485 Communications

Standard Bus

(optional Modbus RTU)

Inter-module Bus

20.4 to 30.8 Vac or Vdc

Alarms

Slot A, B, D, E

Modbus RTU

Address 1 - 16

Standard Bus

Zone 1 - 16

Supervisory &

Power Board

Slot C

Zone and Status

LED

Zone Selection

Button

D

A

S

Function

Indicates Zone

Push to select Zone

Address and Protocol

E

B

M

Card Status

Slots A, B, D, E

Indicates communications

activity (Modbus or Standard Bus)

Output

Address

Watlow EZ-ZONE® RMS Module • 12 • Chapter 1 Overview

Page 17

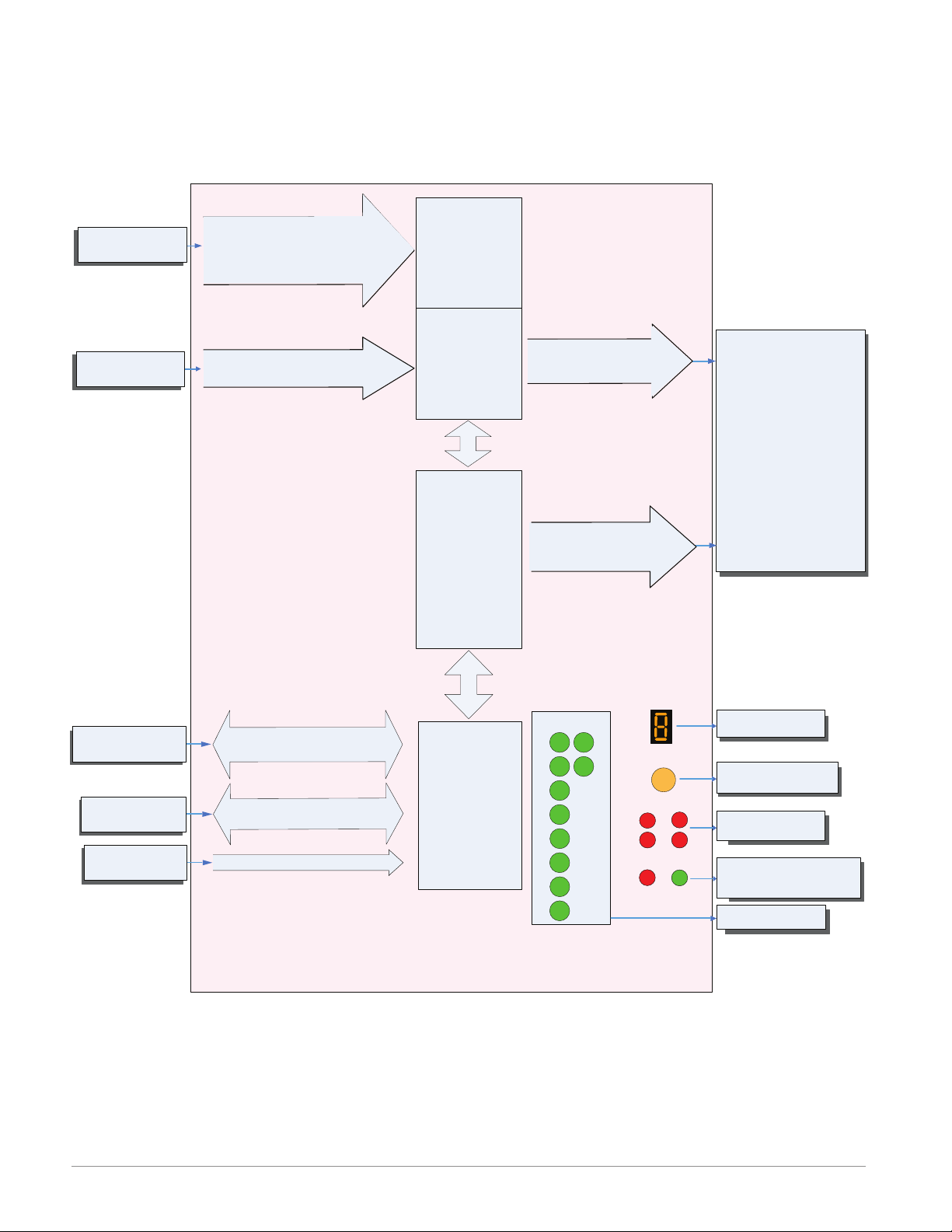

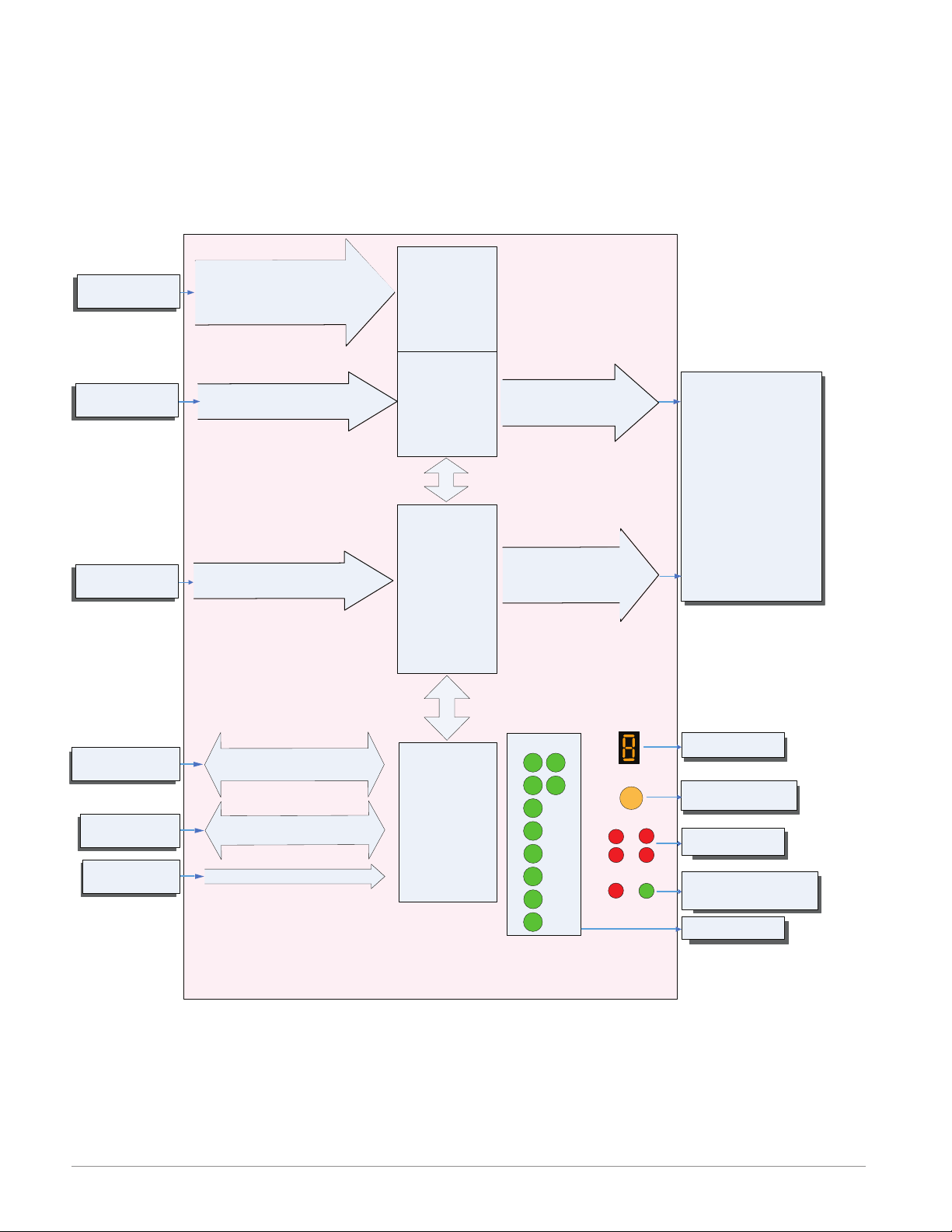

EZ-ZONE RMS Module - System Diagram

Output

Input

8 Scanner Channels - Slots A, B

4 - Form A Mechanical Relays - Slot D

6 - Digital I/O - Slot E

R M S x - [R,P] [R,P] J C - A A A A

Function

Input Sensor

Input Device

Analog Input 1 through 8

None, Thermocouple, 2-Wire RTD (100, 1k),

Thermistor (5k, 10K, 20k, 40k), Process

(V, mV, mA) or 1K Potentiometer

Digital Input 7, 8, 9, 10, 11 or 12

Switch contact or volts dc

Alarms

Slot A, B

4 - Mechanical

Relay Outputs

Form A

Slot D

6 - Digital

Inputs / Outputs

any combination

Slot E

Output 1, 2, 3, 4

5A Mechanical Relay Form A

Output 7, 8, 9, 10, 11 or 12

switched dc/open collector

Function

Analog Input

Alarm

Cool Power

Heat Power

Compare

Counter

Digital I/O

Profile Event Output A-H

Function Key

Linearization

Logic

Math

Process Value

Special Output Function 1-4

Timer

Variable

Off

RUI,

PC, PLC or HMI

Other RM Modules

Power Supply

EIA - 485 Communications

Standard Bus

(optional Modbus RTU)

Inter-module Bus

20.4 to 30.8 Vac oe Vdc

Some input/output combinations not possible, see ordering matrix

Zone and Status

Output Status

Modbus RTU

Address 1 - 16

Standard Bus

Zone 1 - 16

Supervisory &

Power Board

Slot C

1

2

3

4

5

6

7

8

LEDs

9

10

11

12

LED

Zone Selection

Button

D

A

S

Indicates Zone

Push to select Zone

Address and Protocol

E

B

M

Card Status

Slots A, B, D, E

Indicates communications

activity (Modbus or Standard Bus)

Indicates I/O

Address

Status

Watlow EZ-ZONE® RMS Module • 13 • Chapter 1 Overview

Page 18

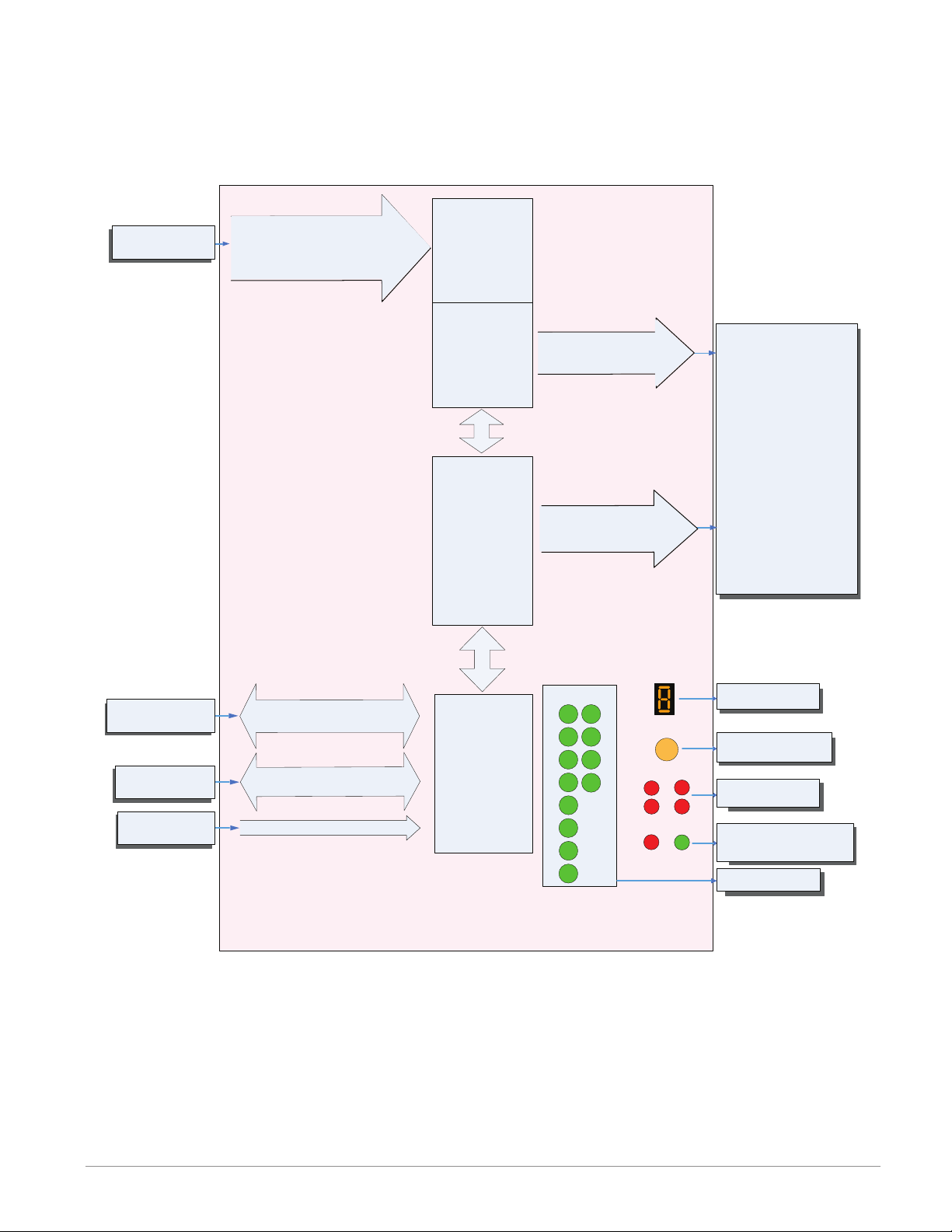

EZ-ZONE RMS Module - System Diagram

Output

Input

8 Scanner Channels - Slots A, B

6 - Digital I/O - Slot D

4 - Form A Mechanical Relays - Slot E

R M S x - [1,2] [1,2] C J - A A A A

Function

Input Sensor

Input Device

Analog Input 1 through 8

None, Thermocouple, 2-Wire RTD (100, 1k),

Thermistor (5k, 10K, 20k, 40k), Process

(V, mV, mA) or 1K Potentiometer

Digital Input 1, 2, 3, 4, 5 or 6

Switch contact or volts dc

Alarms

Slot A, B

6 - Digital

Inputs / Outputs

any combination

Slot D

4 - Mechanical

Relay Outputs

Form A

Slot E

Output 1, 2, 3, 4, 5 or 6

switched dc/open collector

Output 7, 8, 9, 10

5A Mechanical Relay Form A

Function

Analog Input

Alarm

Cool Power

Heat Power

Compare

Counter

Digital I/O

Profile Event Output A-H

Function Key

Linearization

Logic

Math

Process Value

Special Output Function 1-4

Timer

Variable

Off

RUI,

PC, PLC or HMI

Other RM Modules

Power Supply

EIA - 485 Communications

Standard Bus

(optional Modbus RTU)

Inter-module Bus

20.4 to 30.8 Vac oe Vdc

Some input/output combinations not possible, see ordering matrix

Zone and Status

Output Status

Modbus RTU

Address 1 - 16

Standard Bus

Zone 1 - 16

Supervisory &

Power Board

Slot C

LEDs

1

2

3

4

5

6

7

8

9

10

LED

Zone Selection

Button

D

A

S

Indicates Zone

Push to select Zone

Address and Protocol

E

B

M

Card Status

Slots A, B, D, E

Indicates communications

activity (Modbus or Standard Bus)

Indicates I/O

Address

Status

Watlow EZ-ZONE® RMS Module • 14 • Chapter 1 Overview

Page 19

EZ-ZONE RMS Module - System Diagram

Output

Input

8 Scanner Channels - Slots A, B

6 - Digital I/O - Slot D

6 - Digital I/O - Slot E

R M S x - [1,2] [1,2] C C - A A A A

Function

Input Sensor

Input Device

Input Device

Analog Input 1 through 8

None, Thermocouple, 2-Wire RTD (100, 1k),

Thermistor (5k, 10K, 20k, 40k), Process

(V, mV, mA) or 1K Potentiometer

Digital Input 1, 2, 3, 4, 5, 6

Switch contact or volts dc

Digital Input 7, 8, 9, 10, 11, 12

Switch contact or volts dc

Alarms

Slot A, B

6 - Digital

Inputs / Outputs

any combination

Slot D

6 - Digital

Inputs / Outputs

any combination

Slot E

Output 1, 2, 3, 4, 5, 6

switched dc/open collector

Output 7, 8, 9, 10, 11, 12

switched dc/open collector

Function

Analog Input

Alarm

Cool Power

Heat Power

Compare

Counter

Digital I/O

Profile Event Output A-H

Function Key

Linearization

Logic

Math

Process Value

Special Output Function 1-4

Timer

Variable

Off

RUI,

PC, PLC or HMI

Other RM Modules

Power Supply

EIA - 485 Communications

Standard Bus

(optional Modbus RTU)

Inter-module Bus

20.4 to 30.8 Vac oe Vdc

Some input/output combinations not possible, see ordering matrix

Zone and Status

Output Status

Modbus RTU

Address 1 - 16

Standard Bus

Zone 1 - 16

Supervisory &

Power Board

Slot C

1

2

3

4

5

6

7

8

LEDs

9

10

11

12

LED

Zone Selection

Button

D

A

S

Indicates Zone

Push to select Zone

Address and Protocol

E

B

M

Card Status

Slots A, B, D, E

Indicates communications

activity (Modbus or Standard Bus)

Indicates I/O

Address

Status

Watlow EZ-ZONE® RMS Module • 15 • Chapter 1 Overview

Page 20

EZ-ZONE RMS Module - System Diagram

8 Scanner Channels - Slots A, B

6 - Digital I/O - Slot D

1 - Digital Input/2 Mechanical Relays - Slot E

R M S x - [1,2] [1,2] C B - A A A A

Input

Function

Input Sensor

Input Device

Input Device

Analog Input 1 through 8

None, Thermocouple, 2-Wire RTD (100, 1k),

Thermistor (5k, 10K, 20k, 40k), Process

(V, mV, mA) or 1K Potentiometer

Digital Input 1, 2, 3, 4, 5 or 6

Switch contact or volts dc

Digital Input 9

Switch contact or volts dc

Alarms

Slot A, B

6 - Digital

Inputs / Outputs

any combination

Slot D

1 - Digital Input

2 - Mechanical

Relay Outputs

Slot E

Output 1, 2, 3, 4, 5 or 6

switched dc/open collector

Output 7

5A Mechanical Relay Form C

Output 8

5A Mechanical Relay Form A

Output

Function

Analog Input

Alarm

Cool Power

Heat Power

Compare

Counter

Digital I/O

Profile Event Output A-H

Function Key

Linearization

Logic

Math

Process Value

Special Output Function 1-4

Timer

Variable

Off

RUI, EZ-ZONE PM/ST,

PC, PLC or HMI

Other RM Modules

Power Supply

EIA - 485 Communications

Standard Bus

(optional Modbus RTU)

Inter-module Bus

20.4 to 30.8 Vac oe Vdc

Some input/output combinations not possible, see ordering matrix

Zone and Status

Output Status

Modbus RTU

Address 1 - 16

Standard Bus

Zone 1 - 16

Supervisory &

Power Board

Slot C

LEDs

1

2

3

4

5

6

7

8

9

10

LED

Zone Selection

Button

D

A

S

Indicates Zone

Push to select Zone

Address and Protocol

E

B

M

Card Status

Slots A, B, D, E

Indicates communications

activity (Modbus or Standard Bus)

Indicates I/O

Address

Status

Watlow EZ-ZONE® RMS Module • 16 • Chapter 1 Overview

Page 21

EZ-ZONE RMS Module - System Diagram

Output

Input

8 Scanner Channels - Slots A, B

3 - Process Outputs - Slot D or E

4 - SSR Outputs - Slot D or E

R M S x - [R, P] [R, P] [F, L] [F, L] - A A A A

Function

Input Sensor

Analog Input 1 through 8

None, Thermocouple, 2-Wire RTD (100, 1k),

Thermistor (5k, 10K, 20k, 40k), Process

(V, mV, mA) or 1K Potentiometer

Alarms

Slot A, B

3 - Universal/

Retransmit

or

4 - 2A SSR

Outputs

Slot D

3 - Universal/

Retransmit

or

4 - 2A SSR

Outputs

Slot E

Output 1, 2, 3, 4

Process, 2A Solid-State

Relay Form A

** The functions listed to the right

with purple text apply to the

Process output only, where

the orange text applies to the

SSR output only. All others

apply to both output types.

Output 7, 8, 9, 10

Process, 2A Solid-State

Relay Form A

Function

Off

Analog Input

Current*

Alarm*

Cool Power

Heat Power

Power*

Compare*

Counter*

Digital I/O*

Profile Event Output A-H*

Function Key*

Linearization

Logic

Math

Process Value

Set Point Closed*

Set Point Open*

Special Output Function 1-4

Timer*

Variable

RUI,

PC, PLC or HMI

Other RM Modules

Power Supply

EIA - 485 Communications

Standard Bus

(optional Modbus RTU)

Inter-module Bus

20.4 to 30.8 Vac or Vdc

Some input/output combinations not possible, see ordering matrix

Zone and Status

Output Status

Modbus RTU

Address 1 - 16

Standard Bus

Zone 1 - 16

Supervisory &

Power Board

Slot C

LEDs

1

2

3

4

5

6

7

8

9

10

11

12

LED

Zone Selection

Button

D

A

S

Indicates Zone

Push to select Zone

Address and Protocol

E

B

M

Card Status

Slots A, B, D, E

Indicates communications

activity (Modbus or Standard Bus)

Indicates I/O

Address

Status

Watlow EZ-ZONE® RMS Module • 17 • Chapter 1 Overview

Page 22

2

Chapter 2: Install and Wire

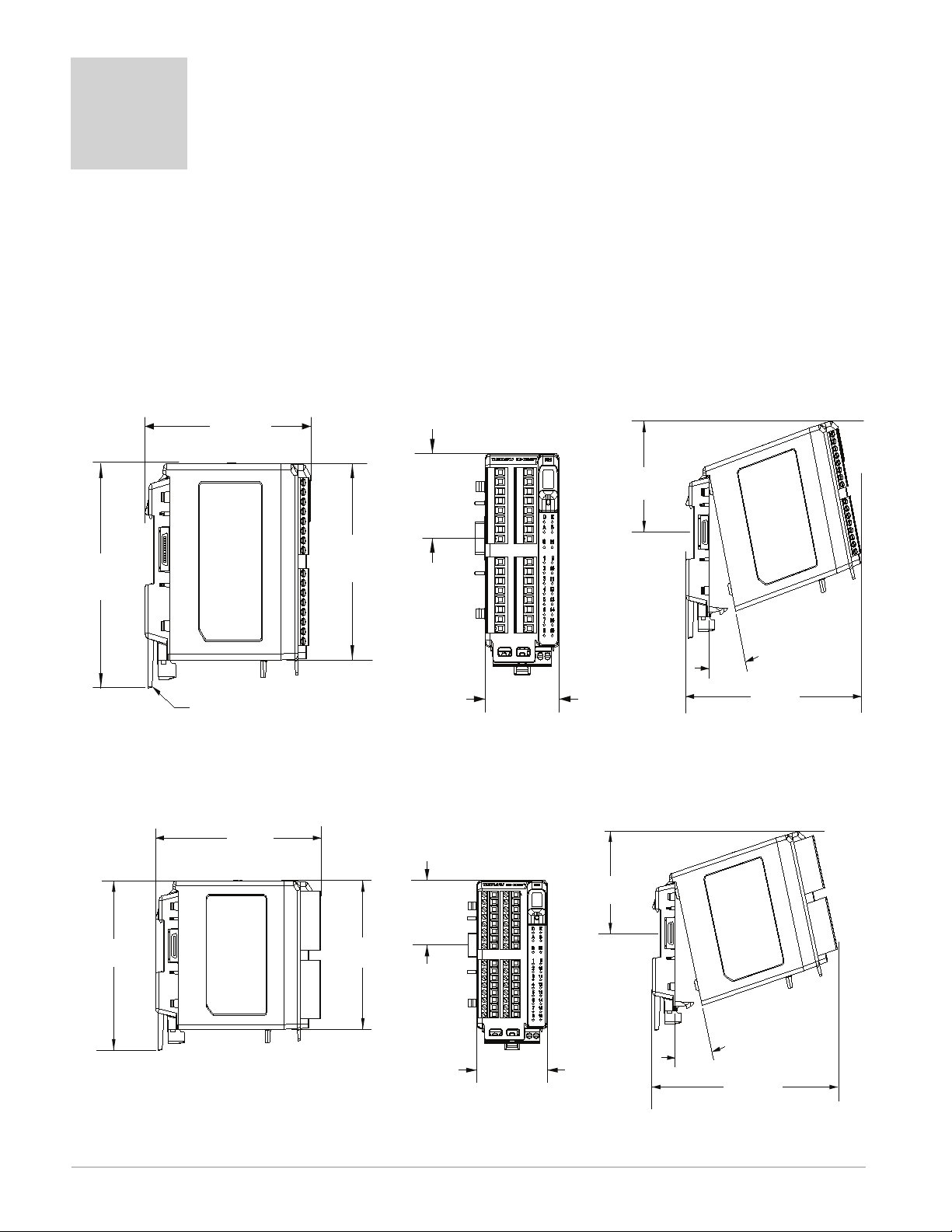

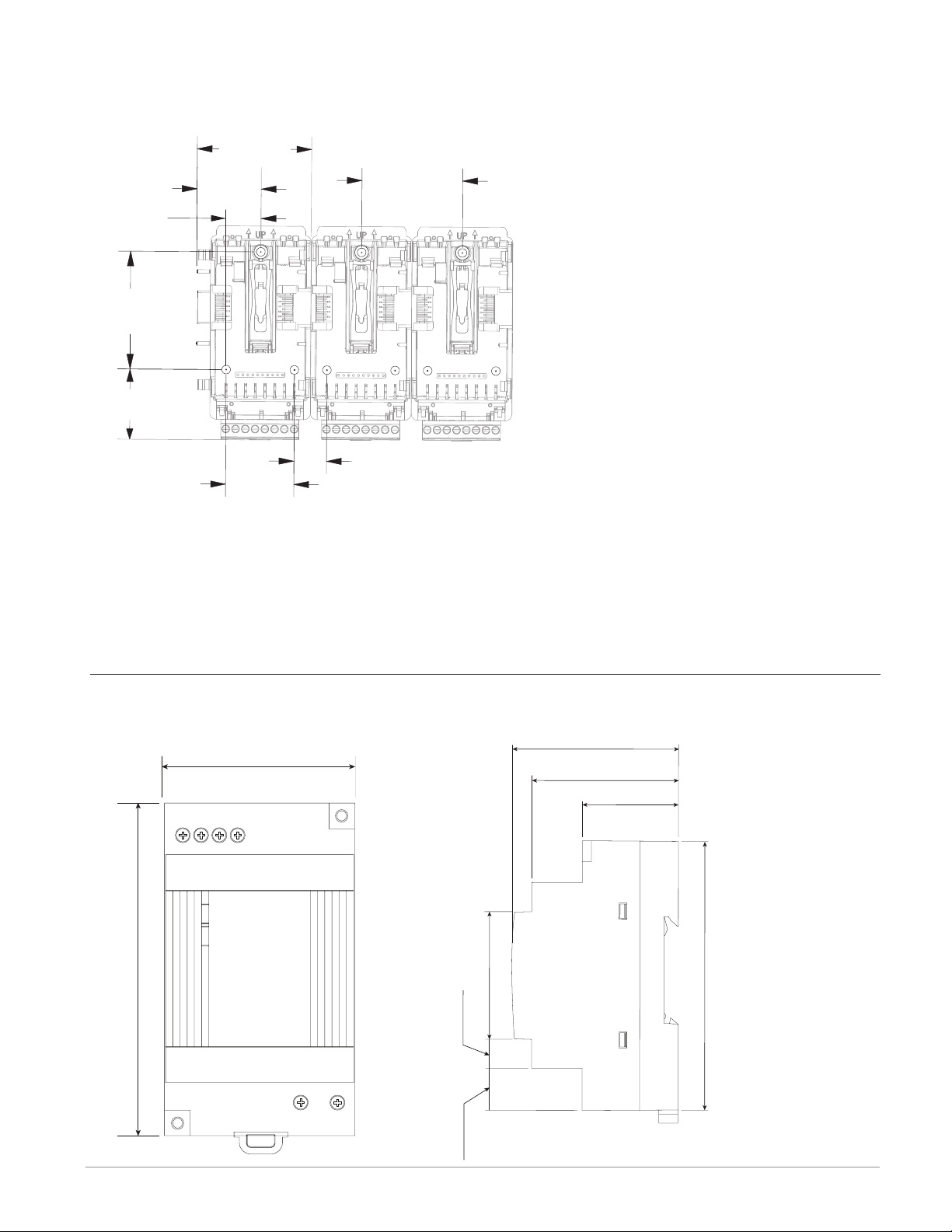

Dimensions

As can be seen below the dimensions of the RMS module will change slightly based on the

type of connector used.

Note:

Modules should always be mounted vertically. For easy removal and placement of modules

it is recommended that there be a 76.2 mm (3.00 in) clearance on the top, bottom and

front of each module.

Module Removal Clearance Standard Connectors

147.07 mm

( 5.8 in )

75.08 mm

( 3.0 in )

116.08 mm

( 4.57 in )

44.45 mm

( 1.75 in )

101.60 mm

( 4.00 in )

51.56 mm

Latch in open position

( 2.03 in )

Module Removal Clearance Straight Connectors

155 mm

( 6.10 in )

44.45 mm

( 1.75 in )

116.08 mm

( 4.57 in )

101.60 mm

( 4.00 in )

51.56 mm

( 2.03 in )

75.08 mm

( 3.0 in )

15

165 mm

( 6.50 in )

Module Removal Displacement

15

°

173.90 mm

( 6.85 in )

Module Removal Displacement

Watlow EZ-ZONE® RMS Module • 18 • Chapter 2 Install and Wire

Page 23

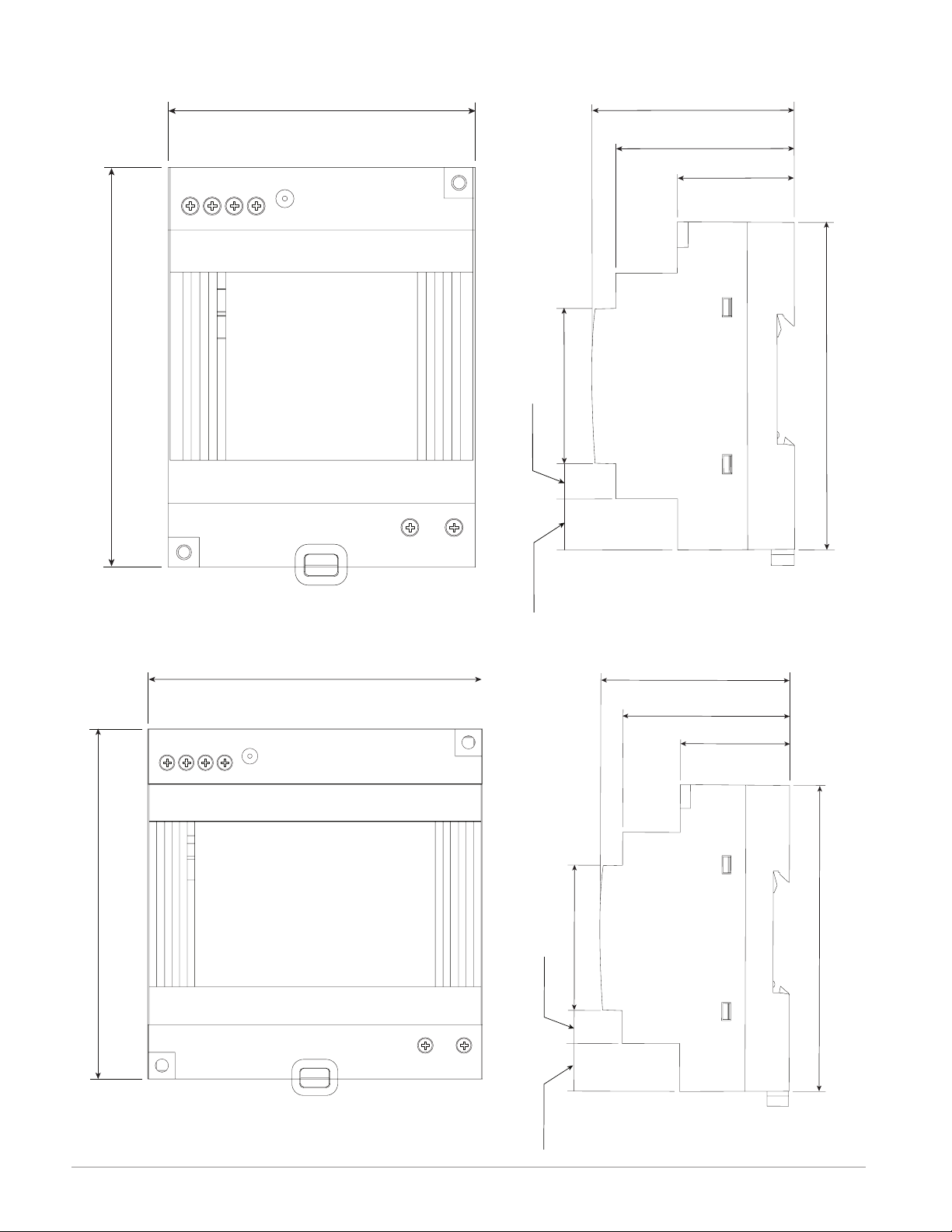

Dimensions (cont.)

56

53.00 mm

91.00 mm

14.20 mm

9.75 mm

55.6 mm

0.559 in

Chassis Mount Front View (Module Removed) - Screw Connection Pattern

58.67 mm

17.53 mm

( 0.69 in )

60.45 mm

( 2.38 in )

35.81 mm

( 1.41 in )

( 2.31 in )

32.77 mm

( 1.29 in )

35.05 mm

( 1.38 in )

51.56 mm

( 2.03 in )

16.76 mm

( 0.67 in )

The view above is representative of the modular backplane without the module.

Recommended chassis mount hardware:

1. #8 screw, 3/4" long

2. Torque to 10 -15 in-lb

3. No washers of any kind

Power Supplies

DSP 30

2.189 in

32.10 mm

1.264 in

3.583 in

91.00 mm

1234

++

3.583 in

2.087 in

-

-

DC LO

DC OK

DSP30

1.697 in

43.1 mm

49.00 mm

1.929 in

0.384 in

LN

Watlow EZ-ZONE® RMS Module • 19 • Chapter 2 Install and Wire

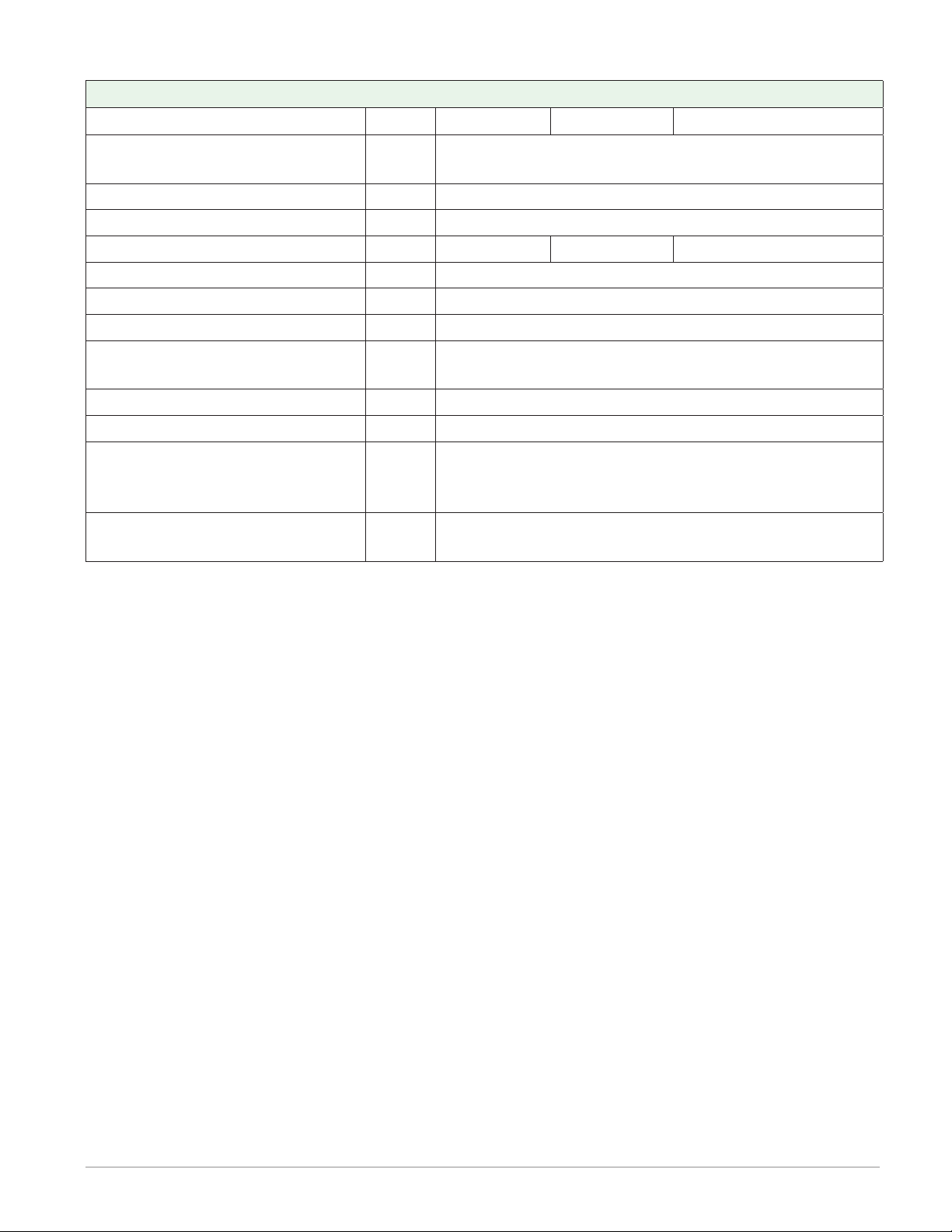

Page 24

DSP 60

LN

56

71.00 mm

91.00 mm

14.20 mm

9.75 mm

55.6 mm

0.559 in

14.20 mm

9.75 mm

56.8 mm

0.559 in

LN

56

89.9 mm

91.00 mm

1

++

3.583 in

2

34

-

-

DC LO

DC OK

2.795 in

vout ADJ.

DSP60

1.697 in

43.1 mm

0.384 in

49.00 mm

1.929 in

2.189 in

32.10 mm

1.264 in

3.583 in

91.00 mm

1234

++

3.583 in

-

-

DC LO

DC OK

3.539 in

vout ADJ.

DSP100

DSP 100

1.697 in

43.1 mm

0.384 in

49.00 mm

1.929 in

2.236 in

32.10 mm

1.264 in

3.583 in

91.00 mm

Watlow EZ-ZONE® RMS Module • 20 • Chapter 2 Install and Wire

Page 25

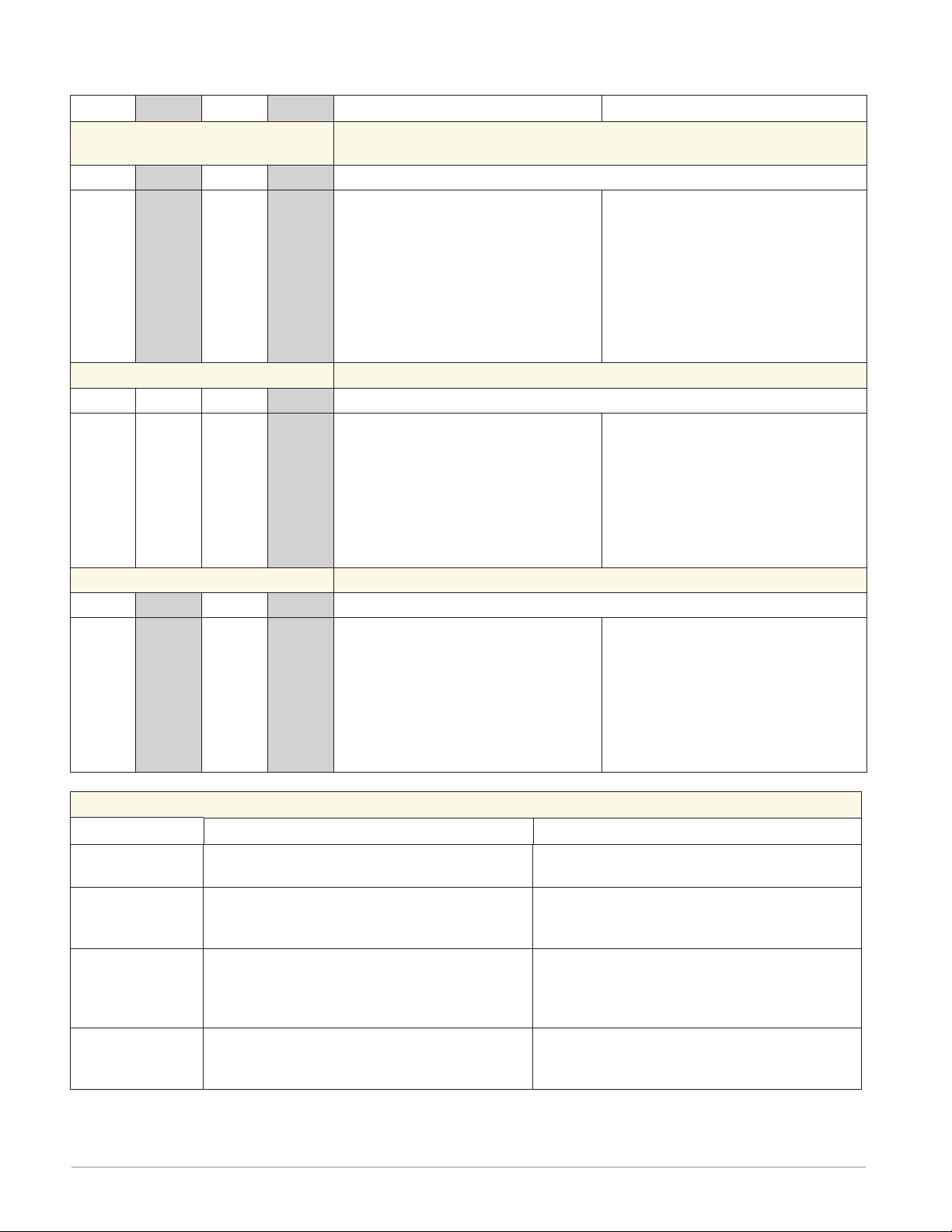

Power Supply Specifications

DSP 30 DSP60 DSP100

AC Input Voltage Range VAC

Input Frequency Hz 47 - 63Hz

DC Input Voltage range VDC 120 - 370VDC

Inrush Current (115 / 230VAC) A 25 / 50A 30 / 60A 30 / 60A

Output Voltage Accuracy % ±1% of Nominal

Over voltage Protection V 120 - 145%

LED Indicators - - - - Green LED = On, Red LED = DC Output Low

Operating Temperature - - - -

Storage Temperature - - - - -25 to +85°C

Operating Humidity - - - - 20 - 95% RH (non condensing)

Vibration (Operating) - - - -

Safety Agency Approvals

90 - 264VAC, Class II double insulated (No ground

connection required)

-25 to +71°C (Derate linearly 2.5%/°C from 55 to

71°C)

IEC 60068-2-6 (Mounting by rail: Random wave,

10-500 Hz, 2G, ea. along X, Y, Z axes 10 min/

cycle, 60 min)

UL1310 Class 2(1), UL508 Listed, UL60950-1,

EN60950-1, CE

For a comprehensive listing of these specifications point your browser to : http://us.tdk-lamb-

da.com/lp/products/dsp-series.htm

Watlow EZ-ZONE® RMS Module • 21 • Chapter 2 Install and Wire

Page 26

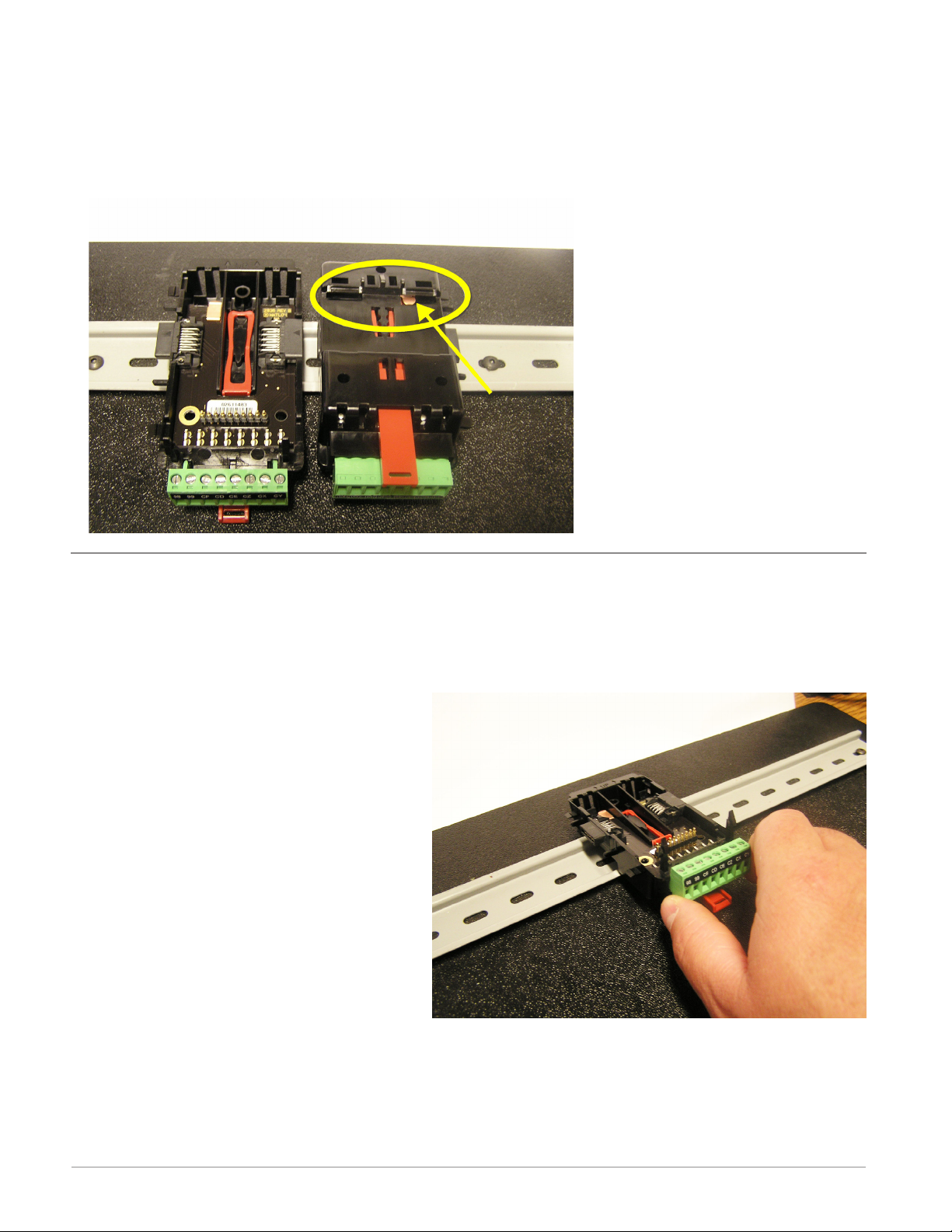

RMS Installation and Removal on a DIN Rail

Modular Backplane Connector

The picture on the right shows the Modular Backplane Connector, both front and rear view.

The rear view is bringing in to focus a metal clip. If the DIN rail is grounded the Modular

Backplane Connector and the module connected to it will be also (recommended).

Installing the Modular Backplane Connector

To install the backplane follow the steps below:

1. Hook backplane assembly to upper edge of DIN rail, (see rear view above, backplane

hook detail that mates with upper rail edge is circled)

2. Next, rotate back plane assembly downward to engage the lower edge of the rail. (Note:

Din Rail clipping distance ranges

from 1.366 -1.389 inches. The back

plane assembly will not latch onto

the rail successfully if the rail is out

of dimension).

3. For final positioning and locking, the

red tab is to be pushed upward to

further engage the bottom edge of

the rail with an over center snap action latch. (The red locking tab protrudes from the bottom side of the

back plane assembly).

Note:

For easy removal and placement of

modules it is recommended that there be a 76.2 mm (3.00 in) clearance on the top, bottom and front of each module.

Watlow EZ-ZONE® RMS Module • 22 • Chapter 2 Install and Wire

Page 27

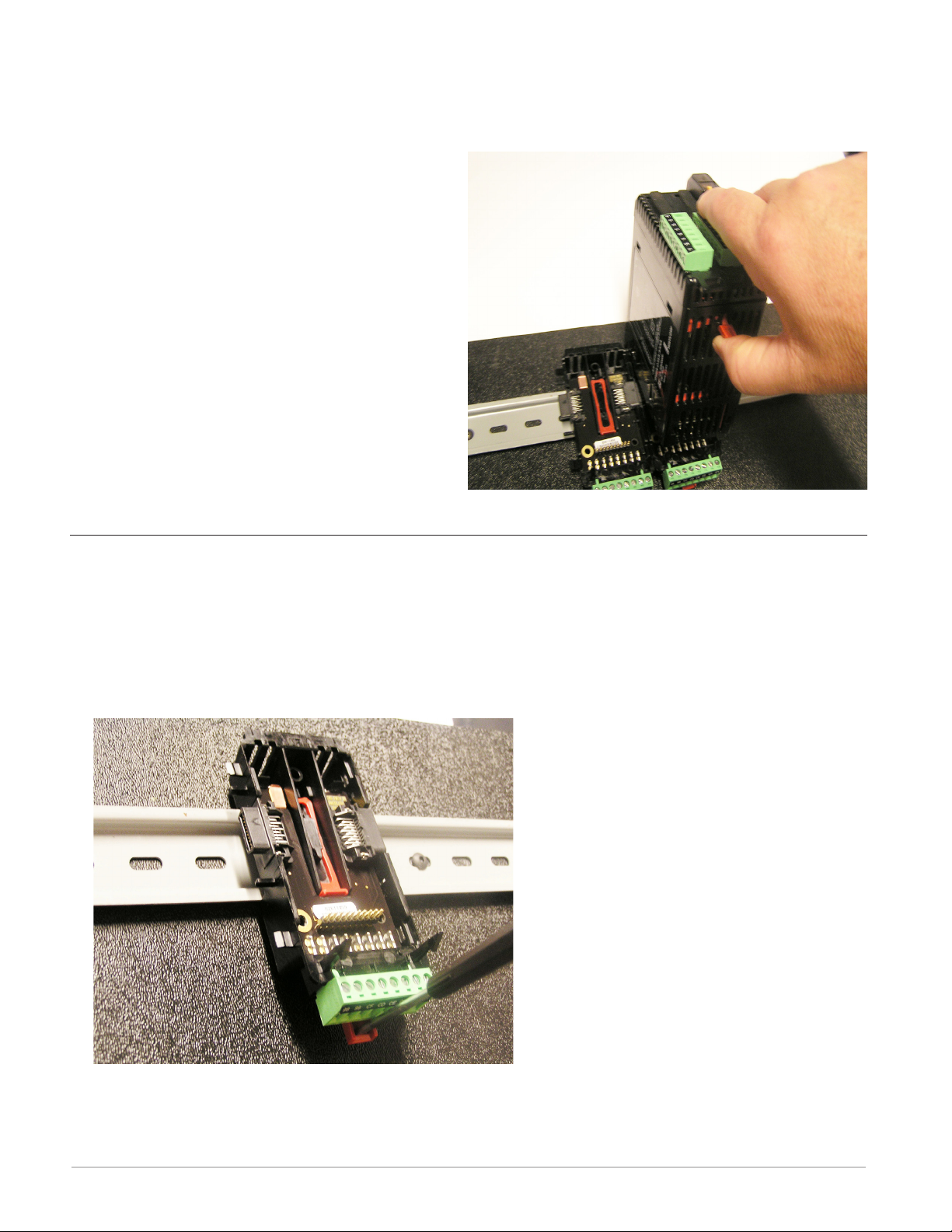

Installing Multiple Modular Backplane Connectors

Multiple modules are easily aligned and latched together. Each module includes matched mating geometry that facilitates accurate and consistent interconnections.

To install backplane connectors follow the steps below:

1. Attach individual modules to the rail separately.

2. Laterally slide the modules together until

they touch.

3. When the multi-module system is attached

and laterally positioned to the desired

placement the locking tab should be engaged to secure the control system to the

rail.

Module Installation

In the picture to the right notice that the arrow is pointing at the top lip of the module (on

side).

To install modules on the backplane follow the steps below:

1. Slide the lip of the module over the top of the Modular Backplane Connector and then

push down on the rear of the module. The module will then slide over the two posts just

above the green connector (see pictures below).

Watlow EZ-ZONE® RMS Module • 23 • Chapter 2 Install and Wire

Page 28

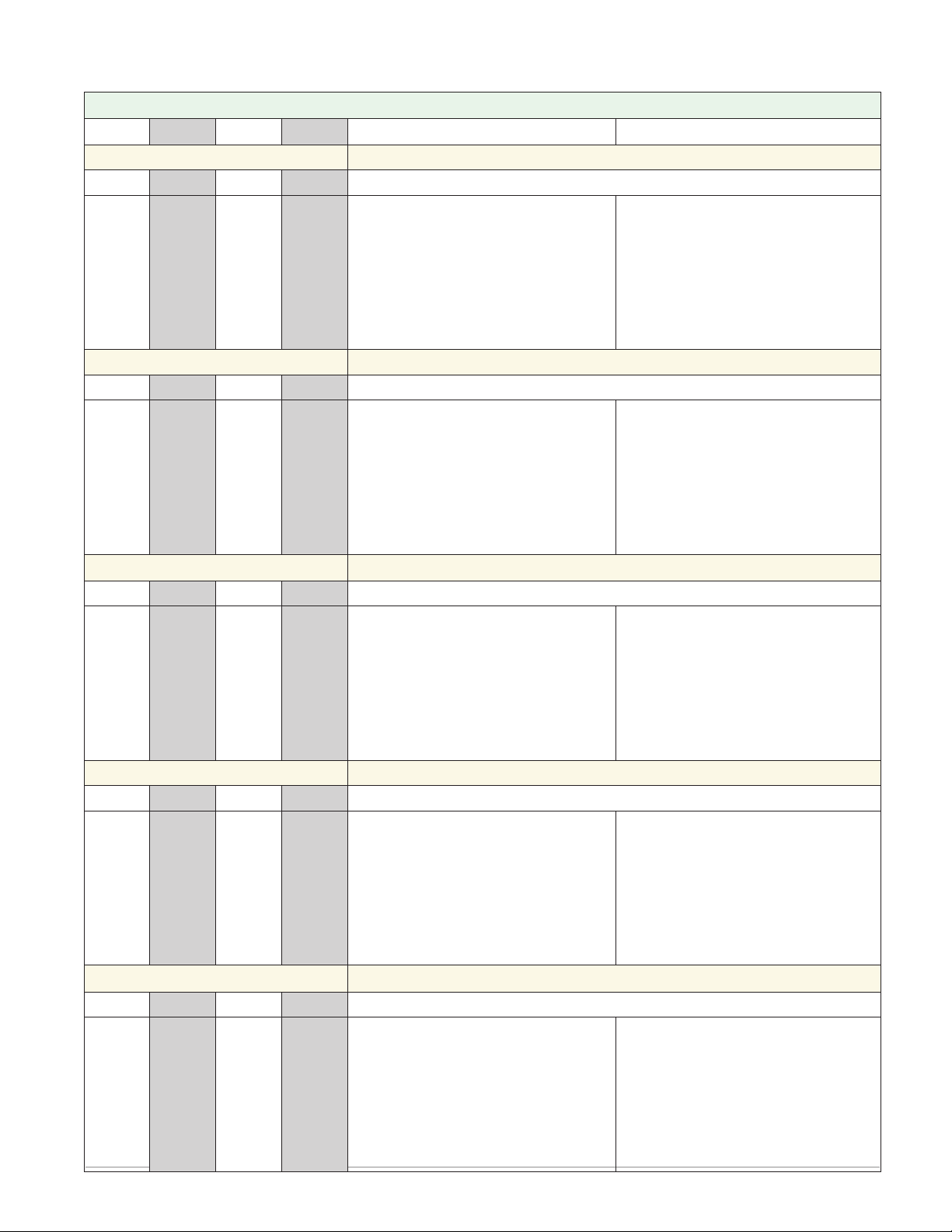

Module Removal

To remove a module from the backplane follow the steps below:

1. Find the red tab protruding from the bottom of the module and pull back on it as shown

to the right.

2. Pull back on the red tab, the two

mounting posts will then release the

module.

3. Lift the module up and slide it up; this

will release the module lip from the

backplane.

Backplane Removal from DIN Rail

To remove a modular backplane connector from the DIN rail follow the steps below:

1. Insert a screw driver into the red locking tab just behind the green connector.

2. Apply downward pressure on the tab by lifting the screwdriver upwards..

3. When released, the tab will move downward and the connector can then be lifted up off

of the DIN rail.

Watlow EZ-ZONE® RMS Module • 24 • Chapter 2 Install and Wire

Page 29

Wiring

Scanner Module (R M S x - x x x x - x x x x)

Slot A Slot B Slot D Slot E Terminal Function Configuration

Inputs Universal, RTD, Potentiometer and Thermistor Inputs 1 - 16

1 - 4 5 - 8 9 - 12 13 - 16

S1

R1

S2

R2

S3

R3

S4

R4

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

S5

R5

S6

R6

S7

R7

S8

R8

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

S9

R9

S10

R10

S11

R11

S12

R12

S13

R13

S14

R14

S15

R15

S16

R16

1 - 6 7-12

B1

D1

D2

D3

D4

D5

D6

Z1

B7

D7

D8

D9

D10

D11

D12

Z7

S_ (RTD), thermocouple -, volts

- , mA -, potentiometer wiper or

thermistor

R_ (RTD), thermocouple +, volts +,

mA +, potentiometer or thermistor

Digital Inputs 1 - 6 and 7 - 12

Common

DC +input

DC +input

DC +input

DC +input

DC +input

DC +input

Internal Supply

Digital Input 9

Universal/Thermistor Input

Part # Digits 5, 6, 7, 8

Input 1-4: RMSx-[R,P]xxx-xxxx

Input 5-8: RMSx-x[R,P]xx-xxxx

Input 9-12: RMSx-xx[R,P]x-xxxx

Input 13-16: RMSx-xxx[R,P]-xxxx

Digital Inputs (DI)

Part # Digit 7, 8

Slot A: Option not valid

Slot B: Option not valid

Slot D: RMSx-xx[C]x-xxxx

Slot E: RMSx-xxx[C]-xxxx

- - - - - - - - - 9

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - B9

D9

Digital Input (DI)

Part # Digit 8

Slot A: Option not valid

Slot B: Option not valid

Slot D: Option not valid

Slot E: RMSx-xxx[B]-xxxx

Common

DC +input

Outputs Form A - Mechanical Relay Outputs 1- 4 and 7 - 10

- - - - - - - 1 - 4 7 - 10

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

L1

K1

L2

K2

L3

K3

L4

K4

L7

K7

L8

K8

L9

K9

L10

K10

normally open

common

normally open

common

normally open

common

normally open

common

Mechanical Relay 5 A, Form A

Part # Digits 7, 8

Slot D: : RMSx-xx[J]x-xxxx

Slot E: : RMSx-xxx[J]-xxxx

Digital Outputs 1 - 6 and 7 - 12

- - - - - - 1 - 6 7 - 12

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

B1

D1

D2

D3

D4

D5

D6

Z1

B7

D7

D8

D9

D10

D11

D12

Z7

Common

open collector/ switched dc

open collector/ switched dc

open collector/ switched dc

open collector/ switched dc

open collector/ switched dc

open collector/ switched dc

Internal Supply

Digital Outputs (DO)

Part # Digit 7, 8

Slot A: Option not valid

Slot B: Option not valid

Slot D: RMSx-xx[C]x-xxxx

Slot E: RMSx-xxx[C]-xxxx

Watlow EZ-ZONE® RMS Module • 25 • Chapter 2 Install and Wire

Page 30

Wiring (cont.)

Slot A Slot B Slot D Slot E Terminal Function Configuration

Outputs (cont.)

- - - - - - - - - - 7, 8

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

L7

K7

J7

L8

K8

- - -

- - -

- - -

- - - - - - 1 - 4 7 - 10

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

L1

K1

L2

- - -

- - L3

K3

L4

L7

K7

L8

- - -

- - L9

K9

L10

- - - - - - 1 - 3 7 - 9

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

F1

H1

- - F2

H2

- - F3

H3

F7

H7

- - F8

H8

- - F9

H9

Form C - Mechanical Relay Output 7 and Form A - Mechanical Re-

lay Output 8

normally open

common

normally closed

normally open

common

Form C and Form A Relay Outputs

Part # Digit 8

Slot A: Option not valid

Slot B: Option not valid

Slot D: Option not valid

Slot E: RMSx-xxx[B]-xxxx

Quad 2A - Solid-State Relay (SSR) Form A Outputs

normally open

common

normally open

not used

not used

normally open

common

normally open

Slot A: Option not valid

Slot B: Option not valid

Slot D: RMS _ - _ _ [L] _ - _ _ _ _

Slot E: RMS _ - _ _ _ [L] - _ _ _ _

2A SSR Outputs

Part # Digits 7, 8

Tri-State Process/Retransmit Outputs

voltage or current voltage + or current +

not used

voltage or current voltage + or current +

not used

voltage or current voltage + or current +

Slot A: Option not valid

Slot B: Option not valid

Slot D: RMS _ - _ _ [F] _ - _ _ _ _

Slot E: RMS _ - _ _ _ [F] - _ _ _ _

Tri-Process Outputs

Part # Digits 7, 8

Power and Communications

Slot C

98

99

CF

CD

CE

CC

CA

CB

CZ

CX

CY

Power input: ac or dc+

Power input: ac or dc-

Standard Bus EIA-485 common

Standard Bus EIA-485 T-/RStandard Bus EIA-485 T+/R+

Standard Bus or Modbus RTU EIA-485 common

Standard Bus or Modbus RTU EIA-485 T-/RStandard Bus or Modbus RTU EIA-485 T+/R+

Inter-module Bus

Inter-module Bus

Inter-module Bus

Terminal Function Configuration

All

Standard Bus

Part # Digit 10

RMSx-xxxx-x[A]xx

Standard Bus or Modbus

Part # Digit 10

RMSx-xxxx-x[1]xx

Inter-module Bus

Watlow EZ-ZONE® RMS Module • 26 • Chapter 2 Install and Wire

Page 31

RMS Module - Front View -

S

l

o

t

C

Standard Connector

Slot D

Slot A

98

Slot E

Slot B

Slot C

99

power

Watlow EZ-ZONE® RMS Module • 27 • Chapter 2 Install and Wire

Page 32

RMS System Isolation Blocks

Controller Power Supply

20.4 to 30.8VÎ (dc)

20.4 to 30.8VÅ (ac)

Safety Isolation

Mechanical Relay,

Outputs

Safety Isolation

Safety Isolation

Controller

Low Voltage Power Bus

Low-voltage Isolation: 42V peak

Safety Isolation: 1,528VÅ (ac)

No Isolation

Low-voltage

Isolation

Low-voltage

Isolation

Digital Inputs & Outputs

Analog Input 1 - 16

Communications Ports

Watlow EZ-ZONE® RMS Module • 28 • Chapter 2 Install and Wire

Page 33

Warning:

ç

Use National Electric (NEC) or

other country-specific standard

wiring and safety practices when

wiring and connecting this controller to a power source and to

electrical sensors or peripheral

devices. Failure to do so may

result in damage to equipment

and property, and/or injury or

loss of life.

Note:

Maximum wire size termination

and torque rating:

• 0.0507 to 3.30 mm2 (30 to 12

AWG) single-wire termination

or two 1.31 mm

2

(16 AWG)

• 0.57 Nm (5.0 in-lb.) torque

Note:

Adjacent terminals may be labeled differently, depending on

the model number

.

Note:

To prevent damage to the controller, do not connect wires to

unused terminals.

Note:

Maintain electrical isolation

between digital input-outputs,

switched dc/open collector

outputs and process outputs

to

prevent ground loops.

Warning:

ç

Explosion Hazard – Substitution

of component may impair suitability for CLASS I, DIVISION 2.

Warning:

ç

Explosion Hazard - Do not disconnect while the circuit is live

or unless the area is known to be

free of ignitable concentrations

of flammable substances.

Scanner Module Wiring (RMSx-xxxx-xxxx)

Low Power RMS- ALL Model Numbers

t

C

l

o

S

99

98

power

Communications RMS Part # Digit 10 is A

t

C

l

o

S

CF

CE

CD

CZ

CY

CX

Standard Bus

Common

T- / R-

Common

T+ / R+

Inter-module Bus

-

Communications RMS Part # Digit 10 is 1

t

C

l

o

S

CC

CB

CA

T- / R-

Common

Modbus

CZ

Common

T+ / R+

CX

CY

Inter-module Bus

-

+

• 20.4 to 30.8 V Å (ac) / Î (dc) 14VA

• 47 to 63 Hz

• Controller module power consumption,

7 Watts maximum

• 31 Watts maximum power available for

P/S part #:0847-0299-0000

• 60 Watts maximum power available for

P/S part #:0847-0300-0000

• 91 Watts maximum power available for

P/S part #:0847-0301-0000

• Class 2 or Safety Extra Low Voltage

(SELV) power source required to meet

UL compliance standards

• CF, CD, CE - Standard Bus EIA485

Communications

• CZ, CX, CY - Inter-module Bus

EIA485 Communications

• Do not route network wires with

power wires. Connect network

+

wires in daisy-chain fashion when

connecting multiple devices in a

network

• CC, CA, CB - Modbus and Standard Bus EIA-485 Communications

(selectable via push button under

zone address)

• CZ, CX, CY - Inter-module Bus EIA485 Communications

• Do not route network wires with

power wires. Connect network

wires in daisy-chain fashion when

connecting multiple devices in a

network

Watlow EZ-ZONE® RMS Module • 29 • Chapter 2 Install and Wire

Page 34

Warning:

Slot A, B, D, E

Slot A, B, D, E

ç

Use National Electric (NEC) or

other country-specific standard

wiring and safety practices when

wiring and connecting this controller to a power source and to

electrical sensors or peripheral

devices. Failure to do so may

result in damage to equipment

and property, and/or injury or

loss of life.

Note:

Maximum wire size termination

and torque rating:

• 0.0507 to 3.30 mm2 (30 to 12

AWG) single-wire termination

or two 1.31 mm

2

(16 AWG)

• 0.57 Nm (5.0 in-lb.) torque

Note:

Adjacent terminals may be labeled differently, depending on

the model number

.

Note:

To prevent damage to the controller, do not connect wires to

unused terminals.

Note:

Maintain electrical isolation

between digital input-outputs,

switched dc/open collector

outputs and process outputs

to

prevent ground loops.

Warning:

ç

Explosion Hazard – Substitution

of component may impair suitability for CLASS I, DIVISION 2.

Warning:

ç

Explosion Hazard - Do not disconnect while the circuit is live

or unless the area is known to be

free of ignitable concentrations

of flammable substances.

Inputs 1 through 16 Thermocouple RMS Part # Digits 5, 6, 7, 8

-

S_

+

R_

-

S_

+

R_

-

S_

+

R_

-

S_

+

R_

• 2K Ω maximum source resistance >20 MΩ in-

put impedance

• 3 microampere open-sensor detection

• Thermocouples are polarity sensitive. The

negative lead (usually red) must be connected to S terminal

• To reduce errors, the extension wire for

thermocouples must be of the same alloy as

the thermocouple.

- Input 1 - 4 (top to bottom): RMSx-(R)xxx-

xxxx

- Input 5 - 8 (top to bottom): RMSx-x(R)xx-

xxxx

- Input 9 - 12 (top to bottom): RMSx-xx(R)x-

xxxx

- Input 13 - 16 (top to bottom): RMSx-

xxx(R)-xxxx

Inputs 1 through 16 Potentiometer RMS Part # Digits 5, 6, 7, 8

CW

S_

R_

CCW

CW

CCW

CW

CCW

CW

CCW

S_

R_

S_

R_

S_

R_

• Use a 1 kΩ potentiometer.

- Input 1 - 4 (top to bottom): RMSx-(R)xxx-xxxx

- Input 5 - 8 (top to bottom): RMSx-x(R)xx-xxxx

- Input 9 - 12 (top to bottom): RMSx-xx(R)x-xxxx

- Input 13 - 16 (top to bottom): RMSx-xxx(R)-xxxx

Watlow EZ-ZONE® RMS Module • 30 • Chapter 2 Install and Wire

Page 35

Warning:

Slot A, B, D, E

Slot A, B, D, E

RTD

Slot A, B, D, E

Use National Electric (NEC) or

other country-specific standard

wiring and safety practices when

wiring and connecting this controller to a power source and to

electrical sensors or peripheral

devices. Failure to do so may

result in damage to equipment

and property, and/or injury or

loss of life.

Note:

Maximum wire size termination

and torque rating:

• 0.0507 to 3.30 mm2 (30 to 12

• 0.57 Nm (5.0 in-lb.) torque

Note:

Adjacent terminals may be labeled differently, depending on

the model number

Note:

To prevent damage to the controller, do not connect wires to

unused terminals.

Note:

Maintain electrical isolation

between digital input-outputs,

switched dc/open collector

outputs and process outputs

prevent ground loops.

Warning:

Explosion Hazard – Substitution

of component may impair suitability for CLASS I, DIVISION 2.

Warning:

Explosion Hazard - Do not disconnect while the circuit is live

or unless the area is known to be

free of ignitable concentrations

of flammable substances.

ç

AWG) single-wire termination

or two 1.31 mm

2

(16 AWG)

.

to

ç

ç

Inputs 1 through 16 Process RMS Part # Digits 5, 6, 7, 8

-

S_

+

R_

-

S_

+

R_

-

S_

+

R_

-

S_

+

R_

volts

-

+

-

+

-

+

-

+

S_

R_

S_

R_

S_

R_

S_

R_

amperes

• 0 to 20 mA @ 100 Ω input impedance

• 0 to 10VÎ (dc) @ 20 kΩ input im-

pedance

• 0 to 50 mVÎ (dc) @ 20 MΩ input

impedance

• Scalable

- Input 1: RMS(1,3,5)xxxxxxxxxxx

(S1-/R1+),(T1+/S1-)

- Input 2: RMSxx(1,5)xxxxxxxxx

(S2-/R 2+),(T2+/S2-)

- Input 3: RMSxxxx(1,5)xxxxxxx

(S3-/R3+),(T3-S3-R3)

- Input 4: RMSxxxxxx(1,5)xxxxx

(S4-/R4+),(T4+/S4-)

Inputs 1 through 16 RTD RMS Part # Digits 5, 6, 7, 8

• Platinum, 100 and

S_

R_

S_

R_

S_

R_

S_

R_

2-wire

1,000 Ω @ 0°C

• Calibration to DIN curve

(0.00385 Ω/Ω/°C)

• RTD excitation current

of 0.09 mA typical.

Each ohm of lead resistance may affect the

reading by 2.55°C for a

100 ohm platinum sensor or 2.5 ohms for a

1000 ohm sensor.

- Input 1 - 4 (top to

bottom): RMSx-(R)

xxx-xxxx

- Input 5 - 8 (top to

bottom): RMSx-x(R)

xx-xxxx

AWG Ohms/1000ft

14 2.575

16 4.094

18 6.510

20 10.35

22 16.46

24 26.17

26 41.62

28 66.17

Watlow EZ-ZONE® RMS Module • 31 • Chapter 2 Install and Wire

- Input 9 - 12 (top to

bottom): RMSx-xx(R)

x-xxxx

- Input 13 - 14 (top

to bottom): RMSxxxx(R)-xxxx

Page 36

Warning:

Slot A, B, D, E

Slot D, E

Int

Slot E

ç

Use National Electric (NEC) or

other country-specific standard

wiring and safety practices when

wiring and connecting this controller to a power source and to

electrical sensors or peripheral

devices. Failure to do so may

result in damage to equipment

and property, and/or injury or

loss of life.

Note:

Maximum wire size termination

and torque rating:

• 0.0507 to 3.30 mm2 (30 to 12

AWG) single-wire termination

or two 1.31 mm

2

(16 AWG)

• 0.57 Nm (5.0 in-lb.) torque

Note:

Adjacent terminals may be labeled differently, depending on

the model number

.

Note:

To prevent damage to the controller, do not connect wires to

unused terminals.

Note:

Maintain electrical isolation

between digital input-outputs,

switched dc/open collector

outputs and process outputs

prevent ground loops.

Warning:

ç

Explosion Hazard – Substitution

of component may impair suitability for CLASS I, DIVISION 2.

Warning:

ç

Explosion Hazard - Do not disconnect while the circuit is live

or unless the area is known to be

free of ignitable concentrations

of flammable substances.

Inputs 1 through 16 Thermistor RMS Part # Digits 5, 6, 7, 8

• >20 MΩ input impedance

S_

R_

S_

R_

S_

R_

S_

R_

Thermistor

- Input 1 - 4 (top to bottom): RMSx-(P)

xxx-xxxx

- Input 5 - 8 (top to bottom): RMSx-x(P)

xx-xxxx

- Input 9 - 12 (top to bottom): RMSxxx(P)x-xxxx

- Input 13 - 16 (top to bottom): RMSxxxx(P)-xxxx

Digital Inputs 1 through 12

RMS Part # Digit 7, 8 is C and or B Respectively

Digital Input

Event Conditions

• Voltage

- Input inactive

when < 2V

- Input active

when > 3V

• Dry Contact

- Input inactive

when > 100KΩ

- Input active

when < 50Ω

• Six user configurable digital

inputs/outputs

per slot

- Slot D DI 1 - 6

RMSx-xx(C) xxxxxx

- Slot E DI 7

- 12, RMSxxxx(C)-xxxx

- Slot E DI 9,

RMSx-xxx(B)xxxx

Voltage Input

common

_

B

Vdc

_

D

Dry Contact

Slot D

_

D

24 Vdc

_

Z

RMSx-xxx(C)-xxx

RMSx-xxx(B)-xxx

Note:

For part number RMSxxxx(B)-xxxx connection is

made between pins B9 and

D9 when configured as a

dry contact (Digital Input 9

Slot E).

to

Common

DC Input

DC Input

DC Input

DC Input

DC Input

DC Input

ernal

Supply

Common

DC Input

B_

D_

D_

D_

D_

D_

D_

Z_

B9

D9

Slot E

_

B

_

D

24 Vdc

Watlow EZ-ZONE® RMS Module • 32 • Chapter 2 Install and Wire

Page 37

Warning:

witched dc

Slot D, E

witched dc

witched dc

witched dc

witched dc

witched dc

D_

D_

Zone 1 Zone 2

ç

Use National Electric (NEC) or

other country-specific standard

wiring and safety practices when

wiring and connecting this controller to a power source and to

electrical sensors or peripheral

devices. Failure to do so may

result in damage to equipment

and property, and/or injury or

loss of life.

Note:

Maximum wire size termination

and torque rating:

• 0.0507 to 3.30 mm2 (30 to 12

AWG) single-wire termination

or two 1.31 mm

2

(16 AWG)

• 0.57 Nm (5.0 in-lb.) torque

Note:

Adjacent terminals may be labeled differently, depending on

the model number

.

Note:

To prevent damage to the controller, do not connect wires to

unused terminals.

Note:

Maintain electrical isolation

between digital input-outputs,

switched dc/open collector

outputs and process outputs

prevent ground loops.

Note:

If the last two digits of the part

number are "12", this equipment

is suitable for use in CLASS I,

DIVISION 2, Groups A, B, C and

D or Non-Hazardous locations

only. Temperature Code T4

Warning:

ç

Explosion Hazard – Substitution

of component may impair suitability for

Warning:

Explosion Hazard - Do not dis-

CLASS I, DIVISION 2.

ç

connect while the circuit is live

or unless the area is known to be

free of ignitable concentrations

of flammable substances.

Quencharc Note:

Switching pilot duty inductive

loads (relay coils, solenoids,

etc.) with the mechanical relay,

solid state relay or open collector

output options requires use of an

R.C. suppressor.

to

Connecting a Digital Output from One Zone (RMC - Zone 1) to a

Digital Input of Another Zone (RMS - Zone 2)

RMC Part # Digit 11 is C

Slot D

Slot A Slot B

Slot E

B7

D7

D8

D9

D10

D11

Digital Output

D12

Z7

In the example above, digital output D8 from Zone 1 is connected

to digital input D8 of Zone 2.

Note:

As shown in the graphic above, for this configuration, a pull-up

resistor is required.

RMS Part # Digit 8 is C

Slot D

Slot A Slot B

Slot E

B7

D7

D8

D9

D10

Digital Input

D11

D12

Z7

Pull-up resistor

required 1K

to 10K Ohms

Digital Outputs 1 - 12 RMS Part # Digit 7, 8 is C

B_

D_

D_

D_

D_

D_

D_

Z_

Common

open collector/s

open collector/s

open collector/s

open collector/s

open collector/s

open collector/s

Internal

Supply

• Maximum switched

voltage is 32VÎ(dc)

• Internal supply