Watlow EZ-ZONE PM Data sheet

EZ-ZONE® PM Panel Mount Controller

EZ-ZONE® PM Controllers

Take the Pain Out of

Meeting Your Thermal

Loop Requirements

SPECIFICATION SHEET

The EZ-ZONE® PM panel mount controller from Watlow®

offers control options to reduce system complexity and the

cost of thermal loop ownership. It can be ordered as a PID

controller, an over/under limit controller or its functions can

be combined into an integrated controller. An option to

integrate a high amperage power controller output with a

high-performance PID controller and an over/under limit

controller in one space-saving, panel mount package is also

available. Many communication options are offered to

support connectivity needs.

Because the EZ-ZONE PM controller is highly scalable, you

pay only for what is needed. This controller is available in

1

/16, 1/8 and 1/4 DIN panel mount packages. The EZ-ZONE PM

controller is easy to use and is ideal for PID, over/under limit

or integrated controller needs.

1

/32,

Features and Benefits

Integrated PID and limit controller

• Reduces wiring time and termination complexity compared

with connecting discrete products

• Decreases required panel space

• Lowers installation costs

• Increases user and equipment safety for over/under

temperature conditions

High amperage power control output

Drives 15 ampere resistive loads directly

•

• Reduces component count

• Decreases cost of ownership

Current monitoring

• Detects heater current flow and provides alarm indication

of a failed output device or heater load

• Drives output on open or shorted heater

Serial communication capabilities

• Provides a wide range of protocol choices including

Modbus® RTU, EtherNet/IP™, Modbus® TCP, PROFIBUS DP,

DeviceNet™

• Supports network connectivity to a PC or PLC

Dual-channel controller

• Provides two PID controllers in one space-saving package

Enhanced control options

• Easily handles complex process problems such as cascade,

ratio, differential, square-root, motorized valve control

without slidewire feedback, wet-bulb/dry-bulb, compressor

control and peltier loads

Countdown timer option

Provides batch process control

•

• Supports set point change during countdown

10-point linearization curve

• Improves sensor accuracy

and J1939 CAN bus

EZ-LINK™ mobile application for iPhone® and Android™

• Expedites controller setup with intuitive navigation

• Simplifies setting parameters with plain text names

and descriptions

• Connects quickly and easily via Bluetooth® wireless

communications

Configuration communications with software

Includes Watlow standard bus communications used by

•

COMPOSER® or EZ-ZONE configurator software

Saves time and improves reliability of controller setup

•

Advanced PID control algorithm

• Offers TRU-TUNE®+ adaptive control to provide tighter

control for demanding applications

Provides auto-tune for fast, efficient start-up

•

Built-in sensor compensation curves

• Saves cost of buying compensated sensors

• Includes Vaisala RH and altitude (pressure) curves

Remote set point operation

• Supports convenient set point manipulation from a remote

device such as a master control or PLC

Profile capability

Offers pre-programmed process control

•

• Allows ramp/soak programming with 40 total steps, battery

backup and real time clock

Retransmit output

Supports industry needs for recording

•

Factory Mutual (FM) approved over/under limit with

auxiliary outputs

• Increases user and equipment safety for over/under

temperature conditions

Memory for saving and restoring parameter settings

Decreases service calls and time down

•

Agency approvals: UL® listed, CSA, CE, RoHS, W.E.E.E., FM,

SEMI F47-0200, Class 1, Div. 2 rating on selected models

• Assures prompt product acceptance

• Reduces end product documentation costs

Touch-safe package

• Increases safety for installer/operator

• Complies with IP2X requirements

EZ-KEY

• Enables simple, one-touch operation of user-defined,

repetitive activities

Programmable menu system

Reduces setup time and increases operator efficiency

•

Three-year warranty

• Provides product support and reliability

Specifications

Controller

• User-selectable heat/cool, on-off, P, PI, PD, PID or alarm action,

not valid for limit controllers

• Auto-tune with TRU-TUNE+ adaptive control algorithm

• Control sampling rates: input = 10Hz, outputs = 10Hz

Profile Ramp/Soak - Real Time Clock and Battery Backup

• 4 profiles, 40 total steps

• Accuracy (typical): ±30 PPM at 77°F (25°C)

+30/-100 PPM at -4 to 49°F (-20 to 65°C)

• Battery type/typical life: lithium, three cumulative years

unpowered at 77°F (25°C)

Isolated Serial Communications

• EIA 232/485, Modbus® RTU

• EtherNet/IP™/Modbus® TCP

• DeviceNet™

• PROFIBUS DP

• SAE J1939 CAN bus

Wiring Termination—Touch-Safe Terminals

• Input, power and controller output terminals are touch safe,

removable, 12 to 22 AWG

Universal Input

• Thermocouple, grounded or ungrounded sensors greater than

20MΩ input impedance, 3µA open sensor detection,

2kΩ source resistance max.

• RTD 2- or 3-wire, platinum, 100Ω and 1000Ω @ 32°F (0°C)

calibration to DIN curve (0.00385 Ω/Ω/°C)

• Process, 0-20mA @ 100Ω, or 0-10VDC @ 20kΩ, 0-50mV at 20MΩ,

0-1000Ω potentionmeter; scalable; inverse scaling

Functional Operating Range

Type J: -346 to 2192°F (-210 to 1200°C)

Type K: -454 to 2500°F (-270 to 1371°C)

Type T: -454 to 750°F (-270 to 400°C)

Type E: -454 to 1832°F (-270 to 1000°C)

Type N: -454 to 2372°F (-270 to 1300°C)

Type C: 32 to 4200°F (0 to 2315°C)

Type D: 32 to 4200°F (0 to 2315°C)

Type F: 32 to 2449°F (0 to 1343°C)

Type R: -58 to 3214°F (-50 to 1767°C)

Type S: -58 to 3214°F (-50 to 1767°C)

Type B: 32 to 3300°F (0 to 1816°C)

RTD (DIN): -328 to 1472°F (-200 to 800°C)

Process: -1999 to 9999 units

Accuracy

• Calibration accuracy and sensor conformity: ±0.1% of span,

±1°C @ the calibrated ambient temperature and rated line

voltage

• Types R, S, B; 0.2%

• Type T below -50°C; 0.2%

• Calibration ambient temperature @ 77°F ±5°F (25°C ±3°C)

• Accuracy span: 1000°F (540°C) min.

• Temperature stability: ±0.1°F/°F (±0.1°C/°C) rise in ambient max.

Thermistor Input

• 0 to 40kΩ, 0 to 20kΩ, 0 to 10kΩ, 0 to 5kΩ

• 2.252kΩ and 10kΩ base at 77°F (25°C)

• Linearization curves built-in

Current Transformer Input

• Accepts 0-50mA signal (user-programmable range)

• Displayed operating range and resolution can be scaled and are

user-programmable

Digital Inputs (DC Voltage)

• Max. input: 36V at 3mA

• Logic: min. high state 3V at 0.25mA, max. low state 2V

Digital Inputs (Dry Contact)

• Logic: min. open resistance 10kΩ, max. closed resistance 50Ω

• Max. short circuit: 20mA

2 Digital I/O (ordered with power supply option)

• Update rate: 10Hz

• Input type: user-selectable, dc voltage or dry contact

• Output type: switched dc

• Output voltage: 24V

• Output 5: 24mA max. or drive one 3-pole DIN-A-MITE®

• Output 6: 10mA max.

6 Digital I/O (ordered with communications option)

• Update rate: 10Hz

• Input type: user-selectable, dc voltage or dry contact

• Output type: user-selectable, switched dc or open collector

• Switched dc output voltage: 12 to 24VDC, depending on

current draw

• Switched dc max. supplied current: 40mA at 20VDC and 80mA

at 12VDC

• Switched dc max. low state: 2V

• Open collector max. switched voltage: 32VDC

• Open collector max. switched current: 1.5A per output;

8A total for all 6 outputs

Output Hardware

• Switched dc: 22 to 32VDC @ 30mA max. per single output and

40mA max. total per paired outputs (1 & 2, 3 & 4)

• Open collector: 30VDC max. @ 100mA max.

• SSR, Form A, 24 to 240VAC, 1A at 50°F (10°C) to 0.5A at 149°F

(65°C) resistive load, 264VAC max., opto-isolated, without contact

suppression, 120/240VAC @ 20VA pilot duty

• Electromechanical relay, Form A, 24 to 240VAC or 30VDC max.,

5A resistive load, 100,000 cycles at rated load, 120/240 @ 125VA

or 24VAC @ 25VA pilot duty

• Electromechanical relay, Form C, 24 to 240VAC or 30VDC max.,

5A resistive load, 100,000 cycles at rated load, 120/240 @ 125VA

or 24VAC @ 25VA pilot duty

• NO-ARC relay, Form A, 85 to 264VAC, 15A @ 122°F (50°C), resistive

load, no VDC, 2,000,000 cycles at rated load

• Universal process output: range selectable; 0 to 10VDC ±15mV

into a min. 1,000Ω load with 2.5mV nominal resolution; 0 to 20mA

±30μA into max. 800Ω load with 5μA nominal resolution;

temperature stability 100ppm/°C

Operator Interface

• Dual 4-digit, 7-segment LED displays

• Advance, infinity, up and down keys, plus a maximum of

2 programmable EZ-KEY(s) depending on model size

• Typical display update rate: 1Hz

• RESET key substituted for infinity on all models with limit

controller

Line Voltage/Power

• High voltage option: 85 to 264VAC, 47 to 63Hz

• Low voltage option: 20 to 28VAC, +10/-15%; 50/60Hz, ±5% or

12 to 40VDC

• Max. power consumption: 10VA (1/32 and 1/16 DIN); 14VA

1

/8 and 1/4 DIN)

(

• Data retention upon power failure via nonvolatile memory

• Compliant with SEMI F47-0200, Figure R1-1 voltage sag

requirements @ 24VAC or higher

Environment

• Operating temperature: 0 to 149°F (-18 to 65°C)

• Storage temperature: -40 to 185°F (-40 to 85°C)

• Relative humidity: 0 to 90% RH, non-condensing

Agency Approvals

• cULus® UL®/EN/CSA C22.2 No 61010-1 Listed, File E185611

• CSA C22.2 No. 24, File 158031 (1/32 and 1/16 DIN sizes)

• UL® 50 4X indoor locations, NEMA 4X, UL® 50E, Type 4X front seal

• cULus® ANSI/ISA 12.12.01-2012, CSA-C22.2 No. 213-1987, Class 1,

Div. 2, Groups A, B, C and D, Temperature Code T4A, File E184390

(optional)

• FM Class 3545 (limit controls)

• CE, RoHS by design, W.E.E.E.

• EtherNet/IP™ and DeviceNet™ ODVA Conformance Tested

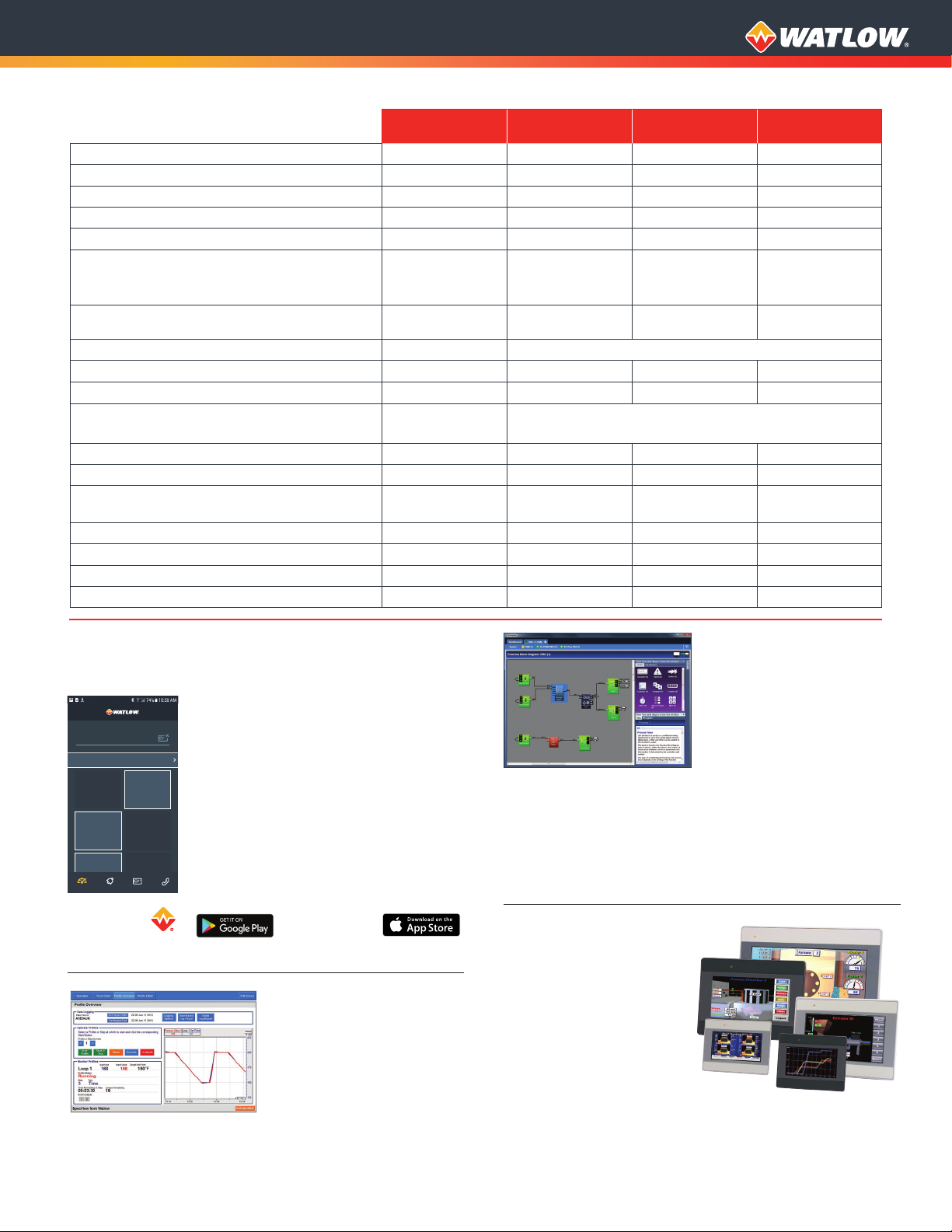

Comparison of Available Features

1

⁄32 DIN

PID Loops 1 1 1 to 2 1 to 2

Profile Ramp/Soak 40 total steps 40 total steps 40 total steps 40 total steps

Profile Battery Backup and Real Time Clock None None Yes Yes

Number of Digital Inputs/Outputs 0 to 2 0 to 2 0 to 8 0 to 8

Number of Outputs 1 to 4 1 to 6 1 to 12 1 to 12

Limit must be

Integrated Safety Limits

ordered as separate

device

Maximum Power Output 5A mechanical relay 15A NO-ARC 15A NO-ARC 15A NO-ARC

Current Measurement None Accepts 0-50mA signal from external current transformer

Standard Bus Communications Yes Yes Yes Yes

Bluetooth® Technology (PM6 Only) No Yes

Field Bus Communications Modbus® RTU 485

10-Point Calibration Offset Yes Yes Yes Yes

Ratio, Differential and Square-Root None Yes Yes Yes

Sensor Compensation Curves - Altitude (Pressure)

and Vaisala RH

None Yes Yes Yes

Motorized Valve Control (without Feedback) None Yes Yes Yes

Wet Bulb/Dry Bulb None Yes Yes Yes

Cascade None None Yes Yes

Countdown Timer Yes Yes Yes Yes

1

⁄16 DIN

1

⁄8 DIN

1

⁄4 DIN

1 1 1

No No

Modbus® RTU 232/485, EtherNet/IP™, Modbus® TCP,

DeviceNet™, PROFIBUS DP, SAE J1939 CAN bus

Compatible Accessories

More information is available on these products at

www.watlow.com

Watlow’s new EZ-LINK app allows users to

Connected Device

1 EZ-ZONE PM

All Parameters

Value

No

75°F

Active Set Point

0.0%

Heat Power

0.0%

Heat Power

70°F

Active Process

Auto

Control Mode

Control Mode

EZ-Link App at for Android™ or

for iPhone®.

historical replay option, easy-to-use recipe features and remote

access options, including LAN, Internet and modem.

easily setup, monitor and adjust Watlow

EZ-ZONE PM controllers via Bluetooth®.

The app is available free-of-charge from

the app store for phones and tablets,

and provides access to the controller’s

parameters with fully spelled out names

in plain text with help topics that explain

each parameter and option. EZ-LINK

mobile application connects quickly

ContactDeviceAlertsDashboard

ContactDeviceAlertsDashboard

and easily via Bluetooth® wireless

communications. Download the

EZ-LINK

SpecView is designed for

industrial users with features

such as data logging, trending

and support for bar code

readers and touch screens. Errors

are reduced, for any process, by

creating application-specific

screens. The software provides a

COMPOSER with INTUITION® is

Watlow’s new, easy-to-use

software for configuring and

customizing controllers. Use it

to optimize Watlow’s F4T and

EZ-ZONE PM and RM controllers

for specific applications.

Task-specific views simplify all

aspects of commissioning new controllers including managing

the inputs and outputs from pluggable flex modules, setting

up functions such as control loops and alarms and creating

and editing profiles. COMPOSER software is included on the

“Watlow Support Tools” DVD and available for download at

www.watlow.com.

Silver Series EM touch

screen operator interface

terminals provide a

customizable user

interface, email event

notifications and log and

graph data for Watlow

controllers and other

devices. A Silver Series EM

operator interface terminal

paired with Watlow

controllers is the perfect solution for your industrial

process or machine control application.

Loading...

Loading...