Watlow EZ-ZONE PM Operating Manual

EZ-ZONE

User's Guide

®

PM Express

L

I

M

I

T

L

I

RESET

M

I

T

L

I

M

I

T

RESET

RESET

Limit Controller

TOTAL

CUSTOMER

SATISFACTION

3 Year Warranty

ISO 9001

Registered Company

Winona, Minnesota USA

1241 Bundy Boulevard., Winona, Minnesota USA 55987

Phone: +1 (507) 454-5300, Fax: +1 (507) 452-4507 http://www.watlow.com

0600-0066-0000 Rev. E Made in the U.S.A.

April 2013

Safety Information

We use note, caution and warning symbols throughout this book to draw your attention to important operational

and safety information.

A “NOTE” marks a short message to alert you to an important detail.

A “CAUTION” safety alert appears with information that is important for protecting your equipment and performance. Be especially careful to read and follow all cautions that apply to your application.

A “WARNING” safety alert appears with information that is important for protecting you, others and equipment

from damage. Pay very close attention to all warnings that apply to your application.

The electrical hazard symbol, (a lightning bolt in a triangle) precedes an electric shock hazard CAUTION or

WARNING safety statement. Further explanations follow:

Symbol Explanation

CAUTION – Warning or Hazard that needs further explanation than label on unit can provide.

Consult users manual for further information.

ESD Sensitive product, use proper grounding and handling techniques when installing or

servicing product.

Unit protected by double/reinforced insulation for shock hazard prevention.

Do not throw in trash, use proper recycling techniques or consult manufacturer for proper

disposal.

Unit can be powered with either alternating current (ac) voltage or direct current (dc) voltage.

Unit is a Listed device per Underwriters Laboratories®. It has been evaluated to United

States and Canadian requirements for Process Control Equipment. UL 61010 and CSA C22.2

No. 61010. File E185611 QUYX, QUYX7. See: www.ul.com

Unit is compliant with European Union directives. See Declaration of Conformity for further

details on Directives and Standards used for Compliance.

Unit has been reviewed and approved by Factory Mutual as a Temperature Limit Device per

FM Class 3545 standard. See: www.fmglobal.com

Unit has been reviewed and approved by CSA International for use as Temperature

Indicating-Regulating Equipment per CSA C22.2 No. 24. See: www.csa-international.org

Warranty

This EZ-ZONE® PM is manufactured by ISO 9001 registered processes and is backed by a three year warranty to

the first purchaser for use, providing that the units have not been misapplied. Watlow's obligations hereunder, at

Watlow's option, are limited to replacement, repair or refund of purchase price, and parts which upon examination prove to be defective within the warranty period specified. This warranty does not apply to damage resulting

from transportation, alteration, misuse or abuse. The purchaser must use Watlow parts to maintain all listed

ratings.

EZ-ZONE PM Limit Express • 2 •

Technical Assistance

You can get assistance from your local Watlow representative (see back cover), send an email with your questions to: wintechsupport@watlow.com or dial +1 (507) 494-5656 between 7 a.m. and 5 p.m. Central Standard

Time (CST) and ask for an Applications Engineer. Please have the following information available when calling:

• Complete model number

• All configuration information

• User's Manual

• Factory Page

The EZ-ZONE PM Controller User’s Guide is copyrighted by Watlow Electric, Inc., © April 2013 with all rights

reserved. The EZ-ZONE PM is covered by U.S. Patent No. 6,005,577 and Patents Pending

Product Overview

The EZ-ZONE PM Express single loop Limit controller is available in 1/4, 8th, 16th or 32nd DIN panel-mount packages. Ordering options include high or low voltage units with up to two outputs.

EZ-ZONE PM Limit Express • 3 •

Installation and Wiring

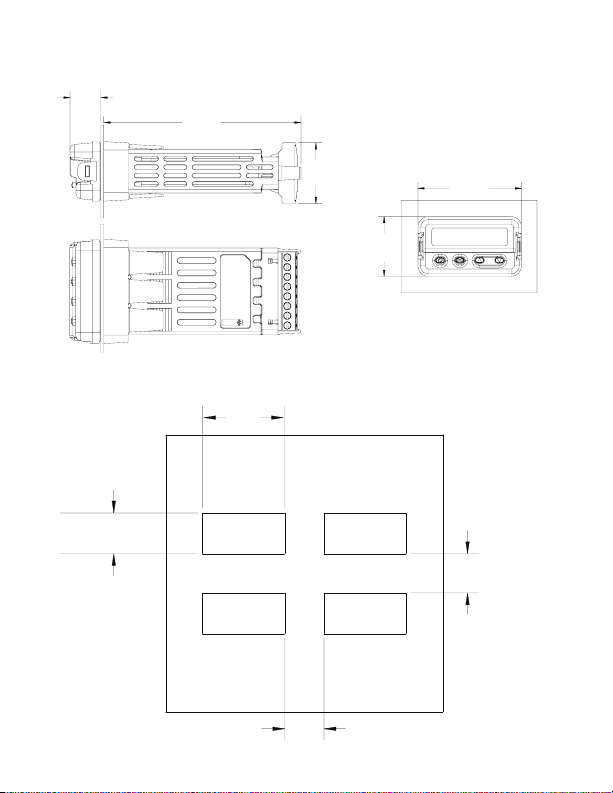

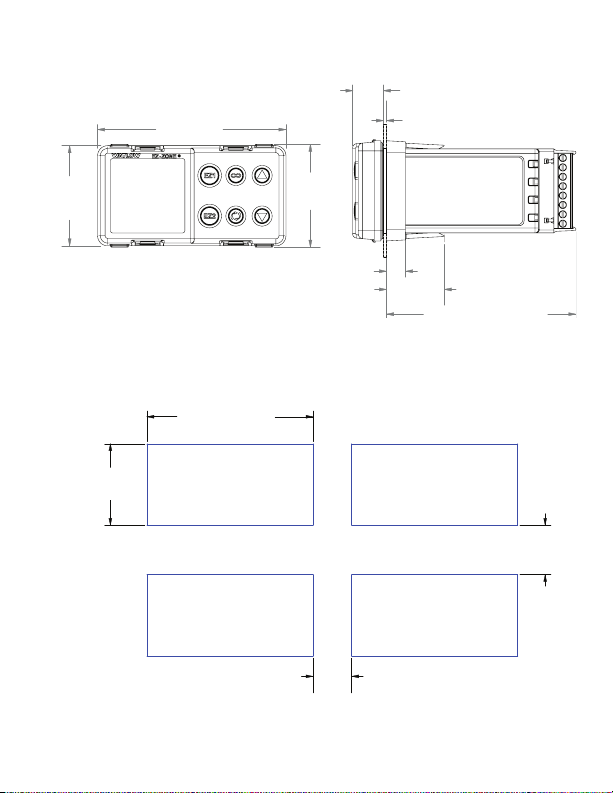

1/32 DIN (PM3) Dimensions

15.9 mm

(0.63 in)

Side

Top

1/32 DIN (PM3) Recommended Panel Spacing

22.2 to 22.5 mm

(0.87 to 0.89 in)

101.6 mm

(4.00 in)

31.2 mm

(1.23 in)

30.9 mm

(1.22 in)

44.96 to 45.47 mm

(1.77 to 1.79 in)

53.3 mm

(2.10 in)

Front

21.6 mm

(0.85 in)

minimum

21.6 mm

(0.85 in)

EZ-ZONE PM Limit Express • 4 • Install & Wiring

15.8 mm

(0.62 in)

1/16 DIN (PM6) Dimensions

101.6 mm

(4.00 in)

53.3 mm

(2.10 in)

53.3 mm

(2.10 in)

Side

Front

51.2 mm

(2.02 in)

Top

1/16 DIN (PM6) Recommended Panel Spacing

44.96 to 45.47 mm

(1.77 to 1.79 in)

44.96 to 45.47 mm

(1.77 to 1.79 in)

panel thickness 1.53 to 9.52 mm

(0.060 to 0.375 in)

21.6 mm

(0.85 in)

minimum

21.5 mm

(0.85 in)

EZ-ZONE PM Limit Express • 5 • Install & Wiring

100.33 mm

(3.95 in)

92.00 to 92.80 mm

(3.62 to 3.65 in)

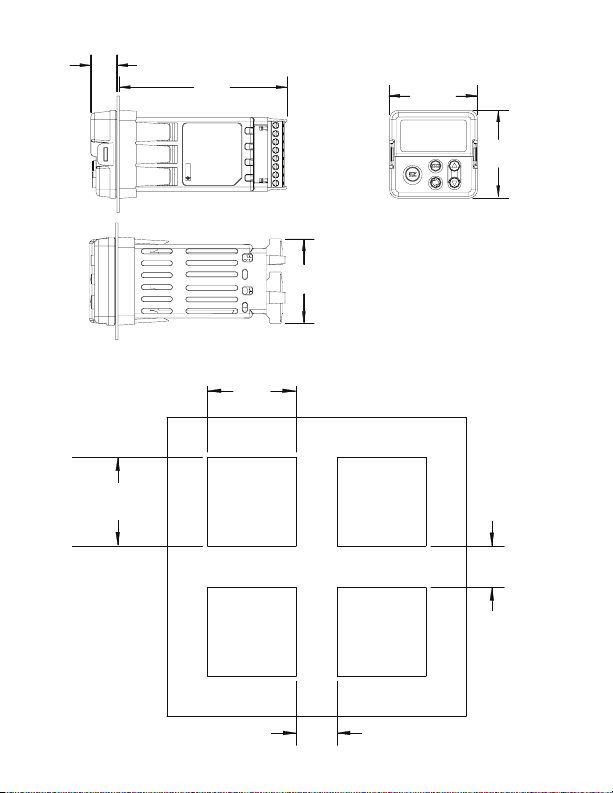

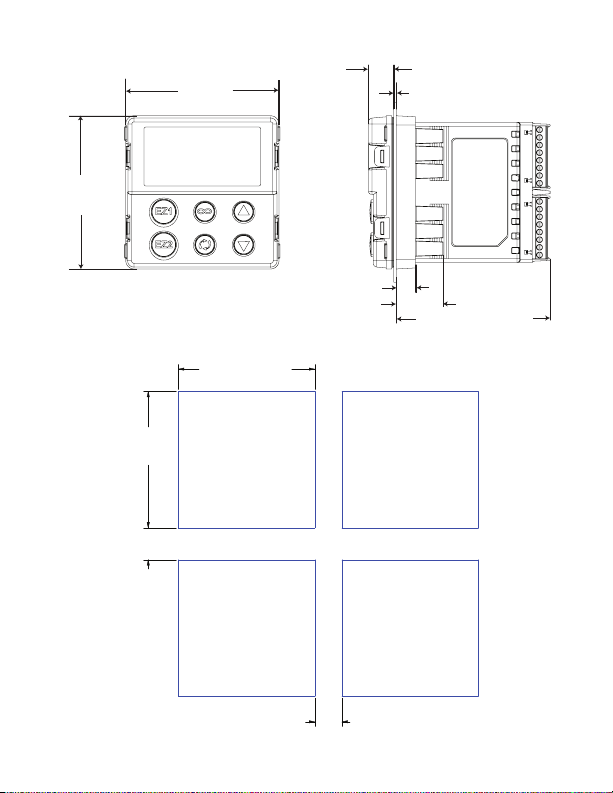

1/8 DIN (PM8) Vertical Dimensions

53.34 mm

(2.10 in)

15.75 mm (0.62 in)

1.52 mm (0.06 in)

54.8 mm

(2.16 in)

10.16 mm

(0.40 in)

30.73 mm (1.21 in)

101.60 mm (4.00 in)

1/8 DIN (PM8) Vertical - Recommended Panel Spacing

44.96 to 45.60 mm

(1.77 to 1.79 in)

panel thickness 1.53 to 9.52 mm

(0.060 to 0.375 in)

21.6 mm

(0.85 in)

Minimum

21.6 mm

(0.85 in)

EZ-ZONE PM Limit Express • 6 • Install & Wiring

Minimum

1/8 DIN (PM9) Horizontal Dimensions

100.33 mm

(3.95 in)

15.75 mm (0.62 in)

1.52 mm (0.06 in)

53.34 mm

(2.10 in)

53.8 mm

(2.16 in)

10.16 mm

(0.40 in)

30.73 mm (1.21 in)

101.60 mm (4.00 in)

1/8 DIN (PM9) Horizontal Recommended Panel Spacing

92.00 to 92.80 mm

(3.62 to 3.65 in)

44.96 to 45.6 mm

(1.77 to 1.79 in)

panel thickness 1.53 to 9.52 mm

(0.060 to 0.375 in)

21.6 mm

(0.85 in)

Minimum

21.6 mm

(0.85 in)

Minimum

EZ-ZONE PM Limit Express • 7 • Install & Wiring

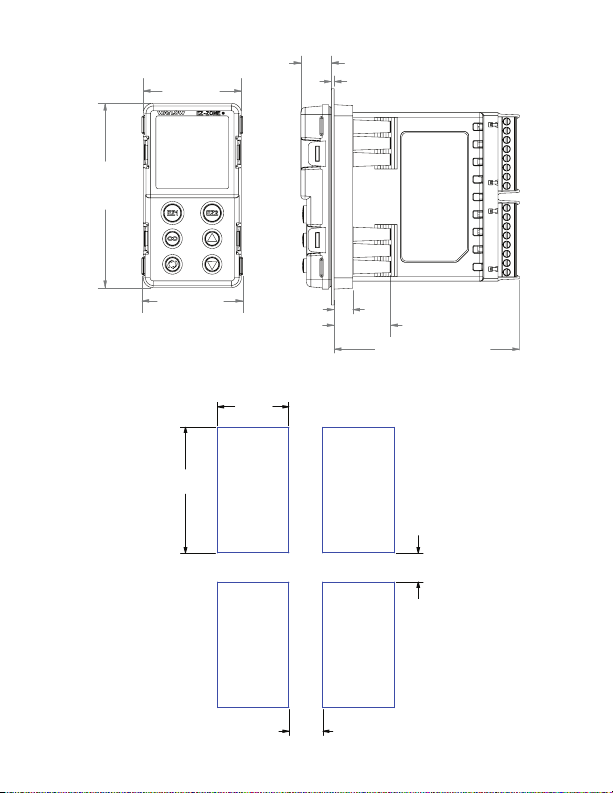

100.33 mm

(3.95 in)

92.00 to 93.0 mm

(3.62 to 3.65 in)

Dimensions 1/4 DIN (PM4) Dimensions

100.33 mm

(3.05 in)

12.70 mm

(0.50 in)

92.00 to 93.0 mm

(3.62 to 3.65 in)

15.75 mm (0.62 in)

1.52 mm (0.06 in)

30.73 mm (1.21 in)

100.84 mm (3.97 in)

21.6 mm

(0.85 in)

Minimum

panel thickness 1.53 to 9.52 mm

(0.060 to 0.375 in)

21.6 mm

(0.85 in)

Minimum

EZ-ZONE PM Limit Express • 8 • Install & Wiring

Installation

CASE

BEZEL

RETENTION COLLAR

PANEL

1. Make the panel cutout using the mounting

template dimensions in this chapter. Insert the

case assembly into the panel cutout.

2. While pressing the case assembly firmly

against the panel, slide the mounting collar

over the back of the controller.

If the installation does not require a NEMA 4X seal,

slide the mounting collar up to the back of the panel

tight enough to eliminate the spacing between the

gasket and the panel.

GASKET

the ridges on the sides of the controller. Each

tooth is staggered at a different depth from the

front so that only one of the tabs, on each side,

is locked onto the ridges at a time.

Removing the Mounted Controller from Its Case

1. From the controller's face, pull out the tab on

each side until you hear it click.

Pull out the tab on

each side until you

hear it click.

2. Once the sides are released, grab the unit

above and below the face with two hands and

pull the unit out. If it is difficult to pull the unit

out, remove the connectors from the back of

the controller. This should make it easier to

remove.

Grab the unit above

and below the face

and pull forward.

Ó Warning:

All electrical power to the controller and con trolled circuits must be disconnected before

removing the controller from the front panel

or disconnecting other wiring.

Returning the Controller to its Case

1. Ensure that the orientation of the controller is

Slide the mounting collar over the back of the

controller.

3. For a NEMA 4X seal, place the blade of a

screwdriver in the notch of the mounting collar

assembly and push toward the panel while

applying pressure to the face of the controller.

Don't be afraid to apply enough pressure to

properly install the controller.

The seal system is compressed more by mat ing the mounting collar tighter to the front

panel (see picture). If you can move the case

assembly back and forth in the cutout, you do

not have a proper seal. The tabs on each side

of the mounting collar have teeth that latch into

Place the blade of a

screwdriver in the

notch of the mounting collar assembly.

correct and slide it back into the housing.

2. Using your thumbs push on either side of the

controller until both latches click.

Note:

The controller is keyed so if it feels that it will

not slide back in do not force it. Check the orientation again and reinsert after correcting.

Chemical Compatibility

This product is compatible with acids, weak alkalis,

alcohols, gamma radiation and ultraviolet radiation.

This product is not compatible with strong alkalis,

organic solvents, fuels, aromatic hydrocarbons, chlorinated hydrocarbons, esters and keytones.

EZ-ZONE PM Limit Express • 9 • Install & Wiring

Terminal Definitions

Slot C Terminal Function Model

9899power input: ac or dc+

power input: ac or dc-

CF

Standard Bus EIA-485 common

CD

Standard Bus EIA-485 T-/R-

CE

Standard Bus EIA-485 T+/R+

Slot A

Input 1

T1

S2 (RTD) or current +,

S1

S3 (RTD), thermocouple -, current - or

volts -, thermistor

R1

S1 (RTD), thermocouple + or volts +,

thermistor

Outputs Terminal Function Configuration

1 2

X1

W1

Y1

L1

K1

J1

common (Any switched dc output can

use.)

dc- (open collector)

dc+

normally open

common

normally closed

L2K2normally open

common

PM _L_ _ _ - AAAAB _ _

PM _L_ _ _ - AAAAB _ _

Universal Sensor

input 1: all configurations

Switched dc/open collector, output 1:

PM _L_ (C) _-_ AAAB _ _

Mechanical Relay 5 A, Form C, output 1:

PM _L_ (E) _-_ AAAB _ _

Mechanical Relay 5 A, Form A, output 2:

PM _L_ _ (J)-_ AAAB _ _

EZ-ZONE PM Limit Express • 10 • Install & Wiring

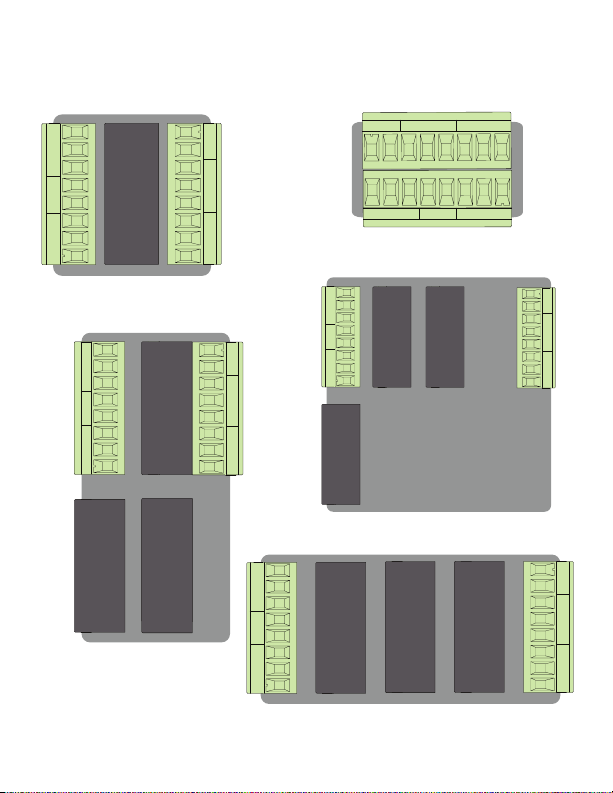

Note:

In the graphics below notice that the Slot A connector does not show labeling for the outputs. Labeling for Slot

A outputs is based on the controller part number.

PM6

Output 1

Output 2

T1

98

99

CF

CD

CE

98 99

PM3

CF CD CE

C

A

T1 S1 R1Output 1 Output 2

S1

R1

A

B

C

PM8

Output 1

Output 2

T1

S1

R1

A

Output 3

Output 4

Input 2

B

E

Digital I/O 7 - 12

D

D

98

99

CF

CD

CE

C

Output 1

Output 2

T1

S1

R1

Output 1

Output 2

T1

S1

R1

A

Output 3

Output 4

Input 2

B

A

B

Digital I/O 7 - 12

D

PM9

D

PM4

Communications Card

E

C

E

C

98

99

CF

CD

CE

98

99

CF

CD

CE

EZ-ZONE PM Limit Express • 11 • Install & Wiring

Loading...

Loading...