Page 1

Series D8

User’s Guide

Watlow Anafaze

1241 Bundy Blvd.

Winona, MN 55987

Customer Service:

Phone....... 1-800-414-4299

Fax ........... 1-800-445-8992

Technical Support:

Phone....... (507) 494-5656

Fax ........... (507) 452-4507

Email ........ wintechsupport@watlow.com

Part No. 0600-3120-2000 Rev. B

November 2008

Page 2

Copyright © 2005, Watlow Anafaze, Incorporated

Information in this manual is subject to change without notice. No part of this publication may be

reproduced, stored in a retrie val system, or transmitted in an y form without written permission

from Watlow Anafaze.

Anafaze is a re gistered trademark of Watlow Electric Manuf acturing Compan y. De viceNet is a

trademark of the Open DeviceNet Vendor Association, Inc. UL is a registered trademark of Underwriters Laboratories, Inc. All other trademarks are the property of their respective owners.

RSNetWorx, RSLinx and RSLogix are trademarks of Rockwell Software Inc.

DeviceNet is a trademark of the Open DeviceNet Vendors Association.

Warranty

Watlow Anafaze, Incorporated w arrants that the products furnished under this Agreement will be

free from defects in material and w orkmanship for a period of three years from the date of shipment. The Customer shall provide notice of any defect to Watlow Anafaze, Incorporated within one

week after the Customer's disco very of such defect. The sole obligation and liability of Watlow

Anafaze, Incorporated under this w arranty shall be to repair or replace, at its option and without

cost to the Customer, the defective product or part.

Upon request by Watlow Anafaze, Incorporated, the product or part claimed to be defecti ve shall

immediately be returned at the Customer's e xpense to Watlow Anafaze, Incorporated. Replaced or

repaired products or parts will be shipped to the Customer at the e xpense of Watlow Anafaze,

Incorporated.

There shall be no w arranty or liability for an y products or parts that ha ve been subject to misuse,

accident, negligence, failure of electric power or modification by the Customer without the writte

approval of Watlow Anafaze, Incorporated. Final determination of w arranty eligibility shall be

made by Watlow Anafaze, Incorporated. If a w arranty claim is considered in valid for an y reason,

the Customer will be char ged for services performed and e xpenses incurred by Watlow Anafaze,

Incorporated in handling and shipping the returned unit.

If replacement parts are supplied or repairs made during the original w arranty period, the warranty

period for the replacement or repaired part shall terminate with the termination of the w arranty

period of the original product or part.

The foregoing warranty constitutes the sole liability of Watlow Anafaze, Incorporated and the Customer's sole remedy with respect to the products. It is in lieu of all other w arranties, liabilities, and

remedies. Except as thus pro vided, Watlow Anafaze, Inc., disclaims all w arranties, e xpress or

implied, including any warranty of merchantability or fitness for a particular purpose

Please Note

: External safety devices must be used with this equipment.

Page 3

Table of Contents

List of Figures ix

List of Tables xiii

1 System Overview 1

Manual Contents 1

Getting Started 2

Safety Symbols 2

Initial Inspection 2

Product Features 2

D8 Parts List 5

Technical Description 6

D8 6

TB50 8

D8 Cabling 8

Safety 8

External Safety Devices 8

Power-Fail Protection 9

2 Installation 11

Typical Installation 12

Mounting Controller Components 12

Recommended Tools 13

Mounting the Controller 13

Mounting the TB50 16

Mounting the Power Supply 18

Mounting the Dual DAC or Serial DAC Module 19

System Wiring 20

Wiring Recommendations 20

Noise Suppression 21

Ground Loops 22

Power Connections 23

Wiring the Power Supply 23

Connecting the TB50 to the D8 25

Testing the System 26

TB50 or TB18 Test 26

Digital Output Test 26

Digital Input Test 27

Sensor Wiring 27

Input Wiring Recommendations 28

Thermocouple Connections 29

Doc. 0600-3120-2000 Watlow Anafaze i

Page 4

Table of Contents Series D8 User’s Guide

RTD Input Connections 30

Voltage Input Connections 30

Current Input Connections 30

Wiring Control and Digital I/O 31

Output Wiring Recommendations 31

Cable Tie Wraps 31

Digital Outputs 31

Digital Inputs 35

TB18 Connections 36

TB50 Connections 37

Analog Outputs 38

Wiring the Dual DAC 38

Wiring the Serial DAC 39

Connecting the D8 to a DeviceNet Network 40

Connector Type 40

Pinout 41

Network Length 42

Baud Rate (Data Rate) 42

Node Address (MAC ID) 42

Status Indicators 43

3 Communicating by DeviceNet 45

Accessing Data with a DeviceNet Master 45

Software 45

About The Electronic Data Sheet (EDS) 46

Configuring a D8 Using RSNetWorx 46

Registering the D8 without an EDS File 47

Registering the D8 with the Watlow EDS File 48

Mapping Polled I/O Data 50

Adding the D8 to the Master's Scanlist 50

Assigning PLC Addresses 51

Sample Ladder Logic 53

Accessing Polled I/O Data 53

Setting a Value with an Explicit Message 55

Reading a Value with an Explicit Message 57

Setting Parameters via DeviceNet 58

Non-Numeric Settings 58

Bit-Wise Values 59

Decimal Placement for Numeric Values 59

Decimal Placement for Percentage Values 60

D8 DeviceNet Overview 60

Master/Slave Connections 60

Addressing 61

Data Types 61

DeviceNet Objects 61

Identity Object 61

Message Router Object 62

DeviceNet Object 63

Assembly Object 63

Connection Object 66

Input Object 67

Output Object 68

Control Object 70

Alarm Object 71

ii Watlow Anafaze Doc. 0600-3120-2000

Page 5

Series D8 User’s Guide Table of Contents

PV Retransmit Object 72

Ratio Object 73

Cascade Object 74

Global Object 75

4 Operation and Setup 77

General Navigation Map 77

Keypad 79

Displays 80

Loop Display 80

Alarm Displays 81

Job Display 83

Changing the Set Point 84

How to Manually Change the Set Point 84

Other Methods of Changing the Set Point 84

Changing the Control Mode and Output Power 85

Accessing and Navigating the Setup Menus 86

How to Access the Setup Menus 86

How to Edit a Setup Parameter 86

Setting Up Closed-Loop Control 87

Feedback 87

Control Algorithm 87

Control Output Signal Forms 87

Heat and Cool Outputs 87

How to Set Up Closed-Loop Control 88

Setting Up a Process Input 88

Input Scaling 88

Input Scaling Example: 4 to 20 mA Sensor 89

Input Scaling Example: 0 to 5 Vdc Sensor 90

Autotuning 91

How Does Autotuning Work? 91

Prerequisites 92

How to Autotune a Loop 92

Setting Up Alarms 93

Failed Sensor Alarms 93

Process Alarms 95

Global Alarm 97

Setting Up Process Variable Retransmit 97

How to Set Up Process Variable Retransmit 98

Process Variable Retransmit Example: Data Logging 98

Setting Up Cascade Control 100

How the Secondary Set Point is Determined 100

Proportional-Only Control on the Primary Loop 101

How To Set Up Cascade Control 102

Cascade Control Example: Water Tank 102

Setting Up Ratio Control 104

How to Set Up Ratio Control 105

Ratio Control Example: Diluting KOH 105

Setting Up Differential Control 106

How to Set Up Differential Control 107

Differential Control Example: Thermoforming 107

Setting Up Remote Analog Set Point 107

How to Set Up a Remote Analog Set Point 108

Remote Analog Set Point Example: Changing a Set Point with a PLC 108

Doc. 0600-3120-2000 Watlow Anafaze iii

Page 6

Table of Contents Series D8 User’s Guide

5 Tuning and Control 111

Control Algorithms 111

On/Off Control 112

Proportional Control (P) 112

Proportional and Integral Control (PI) 113

Proportional, Integral and Derivative Control (PID) 114

Heat and Cool Outputs 114

Setting Up and Tuning PID Loops 115

Proportional Band Settings 115

Integral Settings 115

Derivative Settings 116

General PID Constants by Application 117

Proportional Band Only (P) 117

Proportional with Integral (PI) 117

Proportional and Integral with Derivative (PID) 117

Control Outputs 118

Output Control Signals 118

Output Filter 120

Reverse and Direct Action 120

6 Menu and Parameter Reference 121

Operator Parameters 121

Set Point 122

Mode 122

Heat/Cool Output 122

Process Variable 123

Overview of the Setup Menus 123

Global Setup Menu 125

Load Setup From Job 125

Save Setup As Job 125

BCD Job Load 126

BCD Job Load Logic 126

Mode Override 127

Mode Override Digital Input Active 128

Power Up Alarm Delay 128

Power Up Loop Mode 128

Keypad Lock 129

Thermocouple Short Alarm 129

AC Line Frequency 129

Digital Output Alarm Polarity 129

MAC ID 130

Baud Rate 130

Module LED 130

Network LED 130

Bus Off Count 130

Model and Firmware Version 131

Input Menu 131

Input Type 131

Loop Name 132

Input Units 132

Calibration Offset 132

Reversed Thermocouple Detection 133

Display Format 133

Input Range High 134

iv Watlow Anafaze Doc. 0600-3120-2000

Page 7

Series D8 User’s Guide Table of Contents

Input High Signal 134

Input Range Low 135

Input Low Signal 135

Input Filter 135

Control Menu 136

Heat/Cool Proportional Band 136

Heat/Cool Integral 137

Heat/Cool Derivative 137

Heat/Cool Manual Reset 137

Heat/Cool Filter 137

Hysteresis 138

Restore Automatic Mode 138

Output Menu 139

Heat/Cool Output Type 139

Heat/Cool Cycle Time 140

Heat/Cool SDAC Signal 140

Heat/Cool SDAC Low Signal 140

Heat/Cool SDAC High Signal 140

Heat/Cool Action 141

Heat/Cool Power Limit 141

Heat/Cool Power Limit Time 141

Sensor Fail Heat/Cool Output 142

Open Thermocouple Heat/Cool Output Average 142

Heat/Cool Output Curve 143

Alarms Menu 143

Alarm High Set Point 143

Alarm High Function 144

Alarm High Output 144

High Deviation Value 145

High Deviation Function 145

High Deviation Output 145

Low Deviation Value 145

Low Deviation Function 145

Low Deviation Output 146

Alarm Low Set Point 146

Alarm Low Function 146

Alarm Low Output 146

Alarm Hysteresis 147

Alarm Delay 147

Process Variable Retransmit Menu 148

Heat/Cool Output Retransmit 148

Heat/Cool Retransmit Low Process Variable 148

Heat/Cool Retransmit High Process Variable 148

Cascade Menu 149

Cascade Primary Loop 149

Cascade Low Set Point 149

Cascade High Set Point 149

Ratio Menu 150

Ratio Master Loop 150

Ratio Low Set Point 150

Ratio High Set Point 151

Control Ratio 151

Ratio Set Point Differential 151

I/O Tests Menu 151

Doc. 0600-3120-2000 Watlow Anafaze v

Page 8

Table of Contents Series D8 User’s Guide

Digital Inputs 152

Keypad Test 152

Display Test 152

Test Digital Output 1 to 20 153

Parameters Only Available via Communications 153

Alarm Acknowledge 153

Alarm Enable 153

Alarm Function 154

Alarm Status 154

Ambient Sensor Reading 155

Heat/Cool Output Action for Watchdog Inactivity Fault 156

7 Troubleshooting and Reconfiguring 157

When There is a Problem 157

Returning a Unit 158

Troubleshooting the Controller 158

Process Alarms 159

Ambient Warning 160

Failed Sensor Alarms 160

System Alarms 160

Other Behaviors 161

Reading the DeviceNet Indicator Lights 162

Corrective and Diagnostic Procedures 163

Low Power 163

Battery Dead 163

H/W Error: Gain or Offset 164

H/W Error: Ambient 165

Keys Do Not Work 166

Checking Analog Inputs 166

Earth Grounding 167

Testing Control Output Devices 168

Testing the TB18 and TB50 168

Testing Control and Digital Outputs 168

Testing Digital Inputs 169

Clearing the RAM 169

Replacing the Flash Memory Chip 170

Installing Scaling Resistors 172

Input Circuit 172

Current Inputs 173

Voltage Inputs 174

RTD Inputs 175

Scaling and Calibration 176

Configuring Serial DAC Outputs 176

Configuring Dual DAC Outputs 177

8 Specifications 179

System Specifications 179

Physical Specifications 179

Inputs 185

Outputs 187

Power Supply 189

Dual DAC Specifications 191

Dual DAC Inputs 192

Dual DAC Analog Outputs 192

vi Watlow Anafaze Doc. 0600-3120-2000

Page 9

Series D8 User’s Guide Table of Contents

Serial DAC Specifications 193

Serial DAC Inputs 194

Serial DAC Analog Outputs 195

Glossary 197

Index 205

Menu Structure 213

Doc. 0600-3120-2000 Watlow Anafaze vii

Page 10

Table of Contents Series D8 User’s Guide

viii Watlow Anafaze Doc. 0600-3120-2000

Page 11

1 System Overview

Figure 1.1—D8 Standard Parts List 5

Figure 1.2—D8 Special Inputs Parts List 6

Figure 1.3—D8 Rear Views 6

Figure 1.4—D8 Front Panel 7

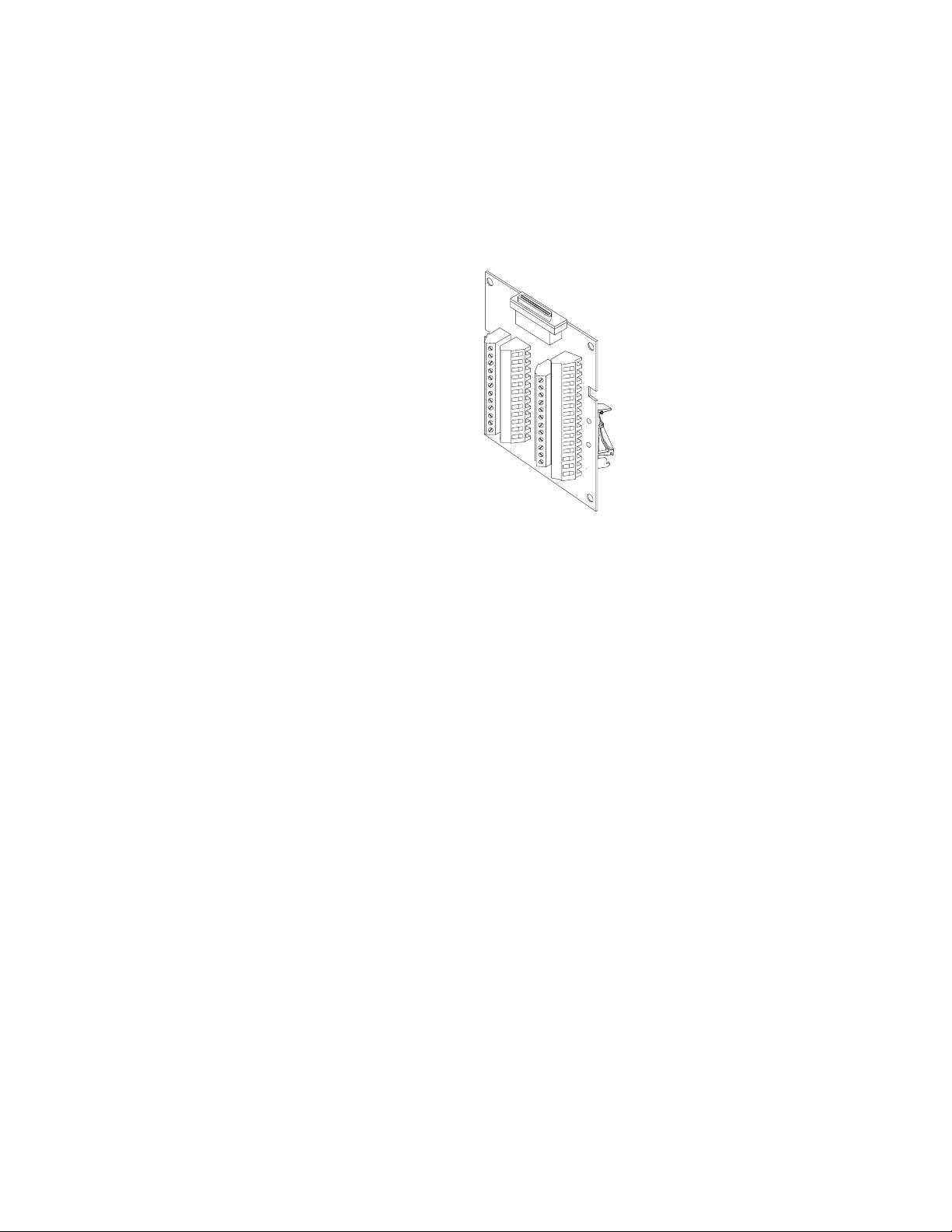

Figure 1.5—TB50 8

List of Figures

2 Installation

Figure 2.1—D8 System Components 12

Figure 2.2—Module Dimensions and Clearance 14

Figure 2.3—Wiring Clearances 14

Figure 2.4—Mounting Bracket 15

Figure 2.5—Mounting the TB50 16

Figure 2.6—TB50 Mounted on a DIN Rail (Front) 16

Figure 2.7—TB50 Mounted on DIN Rail (Side) 17

Figure 2.8—Mounting a TB50 with Standoffs 17

Figure 2.9—D8 Power Supply Mounting Bracket 18

Figure 2.10—Dual DAC and Serial DAC Dimensions 19

Figure 2.11—D8 Series Controller with TB50 23

Figure 2.12—Power Connections with the D8 Power Supply 25

Figure 2.13—Thermocouple Connections 29

Figure 2.14—RTD Connections 30

Figure 2.15—Voltage Signal Connections 30

Figure 2.16—Current Signal Connections 30

Figure 2.17—Digital Output Wiring 32

Figure 2.18—Sample Heat, Cool and Alarm Output Connections 33

Figure 2.19—Output Connections Using External Power Supply 34

Figure 2.20—TB50 Watchdog Timer Output 34

Figure 2.21—TB18 Watchdog Timer Output 34

Figure 2.22—Wiring Digital Inputs 35

Figure 2.23—Dual DAC with Current Output 38

Figure 2.24—Dual DAC with Voltage Output 39

Figure 2.25—Single/Multiple Serial DACs 40

Figure 2.26—DeviceNet Connector 40

Figure 2.27—DeviceNet Connector 41

Figure 2.28—Pinout 41

Figure 2.29—D8 Side with Rotary Switches 43

0600-3120-2000 Watlow Anafaze ix

Page 12

List of Figures Series D8 User’s Guide

3 Communicating by DeviceNet

Figure 3.1—RSNetWorx On-line with Found Devices 47

Figure 3.2—The D8 Registered in RSNetWorx 48

Figure 3.3—D8 Properties in RSNetWorx 49

Figure 3.4—Parameters Tab 50

Figure 3.5—Adding the D8 to the Scanlist 51

Figure 3.6—Scanner Input Properties 52

Figure 3.7—Advanced Mapping Dialog Box 53

Figure 3.8—Using Scanned Data in Logic 54

Figure 3.9—Contents of the PLC Memory 55

Figure 3.10—Explicit Write in Ladder 56

Figure 3.11—Explicit Read in Ladder 58

Figure 3.12—D84 Produced Static Input 65

Figure 3.13— D84 Consumed Static Output 65

Figure 3.14—D88 Produced Static Input 65

Figure 3.15—D88 Consumed Static Output 66

4 Operation and Setup

Figure 4.1—General Navigation Map 78

Figure 4.2—Keypad Navigation 79

Figure 4.3—Loop Display 80

Figure 4.4—Loop Display with Alarm Code 81

Figure 4.5—Display for Failed Sensor Alarm 81

Figure 4.6—Input Scaling 89

Figure 4.7—Activation and Deactivation of Process Alarms 96

Figure 4.8—Application Using Process Variable Retransmit 99

Figure 4.9—Secondary Set Point When Primary Loop Has Heat and Cool Outputs

101

Figure 4.10—Secondary Set Point When Primary Loop Has Heat Output Only 101

Figure 4.11—Example Application Using Cascade Control 103

Figure 4.12—Relationship of Secondary Loop Set Point to Primary Loop Process

Variable in Cascade Example 104

Figure 4.13—Relationship Between the Process Variable on the Master Loop and the

Set Point of the Ratio Loop 105

Figure 4.14—Application Using Ratio Control 106

5 Tuning and Control

Figure 5.1—On/Off Control 112

Figure 5.2—Proportional Control 113

Figure 5.3—Proportional and Integral Control 113

Figure 5.4—Proportional, Integral and Derivative Control 114

Figure 5.5—Time Proportioning and Distributed Zero Crossing Waveforms 118

6 Menu and Parameter Reference

Figure 6.1—Operator Parameter Navigation 121

Figure 6.2—Setup Menus and Parameters 124

Figure 6.3—Linear and Nonlinear Outputs 143

x Watlow Anafaze Doc. 0600-3120-2000

Page 13

Series D8 User’s Guide List of Figures

7 Troubleshooting and Reconfiguring

Figure 7.1—Removal of Electronics Assembly from Case 170

Figure 7.2—Screw Locations on PC Board 171

Figure 7.3—Location of Flash Memory Chip 171

Figure 7.4—Input Circuit 173

Figure 7.5—Serial DAC Voltage and Current Jumper Positions 176

Figure 7.6—Dual DAC 177

8 Specifications

Figure 8.1—D8 Module Dimensions 180

Figure 8.2—Module Dimensions and Clearance 181

Figure 8.3—TB50 Dimensions 182

Figure 8.4—TB50 Dimensions with Straight SCSI Cable 183

Figure 8.5—TB50 Dimensions with Right-Angle SCSI Cable 184

Figure 8.6—Power Supply Dimensions (Bottom View) 190

Figure 8.7—Dual DAC Dimensions 191

Figure 8.8—Serial DAC Dimensions 193

Glossary

Index

Menu Structure

Doc. 0600-3120-2000 Watlow Anafaze xi

Page 14

List of Figures Series D8 User’s Guide

xii Watlow Anafaze Doc. 0600-3120-2000

Page 15

2 Installation

Table 2.1—Cable Recommendations 21

Table 2.2—Power Connections 24

Table 2.3—TB1 Connections 28

Table 2.4—Digital Output States and Values Stored in the Controller 32

Table 2.5—Digital Input States and Values Stored in the Controller 35

Table 2.6—TB18 Connections 36

Table 2.7—TB50 Connections 37

Table 2.8—DeviceNet Connector 41

Table 2.9—Maximum Network Speed 42

Table 2.10—Module Status Indicator Light 44

Table 2.11—Network Status Indicator Light 44

List of Tables

3 Communicating by DeviceNet

Table 3.1—Number of Bytes 48

Table 3.2—Outbound Transaction Header 57

Table 3.3—Explicit Message Body 57

Table 3.4—Number of Decimal Places for Numeric Values via Logic 59

Table 3.5—Address Components 61

Table 3.6—Elementary Data Types 61

Table 3.7—Identity Class and Services 62

Table 3.8—Identity Instance Attributes 62

Table 3.9—Message Router Class and Services 62

Table 3.10—Message Router Instance Attributes 62

Table 3.11—DeviceNet Class and Services 63

Table 3.12—DeviceNet Class Attributes 63

Table 3.13—DeviceNet Instance Attributes 63

Table 3.14—Assembly Class and Services 64

Table 3.15—Assembly Instance Attributes 64

Table 3.16—Connection Class and Services 66

Table 3.17—Connection Instance Attributes 66

Table 3.18—Input Class and Services 67

Table 3.19—Input Class Attributes (Instance 0) 67

Table 3.20—Input Instance Attributes (Instances 1 to 4 or 8) 68

Table 3.21—Output Class and Services 68

Table 3.22—Output Class Attributes (Instance 0) 69

Table 3.23—Output Instance Attributes (Instances 1 to 4 or 8) 69

Doc. 0600-3120-2000 Watlow Anafaze xiii

Page 16

List of Tables Series D8 User’s Guide

Table 3.24—Control Class and Services 70

Table 3.25—Control Class Attributes (Instance 0) 70

Table 3.26—Control Instance Attributes (Instances 1 to 4 or 8) 70

Table 3.27—Alarm Class and Services 71

Table 3.28—Alarm Class Attributes (Instance 0) 71

Table 3.29—Alarm Instance Attributes (Instances 1 to 4 or 8) 71

Table 3.30—PV Retransmit Class and Services 72

Table 3.31—PV Retransmit Class Attributes (Instance 0) 72

Table 3.32—PV Retransmit Instance Attributes (Instances 1 to 4 or 8) 73

Table 3.33—Ratio Class and Services 73

Table 3.34—Ratio Class Attributes (Instance 0) 73

Table 3.35—Ratio Instance Attributes (Instances 1 to 4 or 8) 74

Table 3.36—Cascade Class and Services 74

Table 3.37—Cascade Class Attributes (Instance 0) 74

Table 3.38—Cascade Instance Attributes (Instances 1 to 4 or 8) 75

Table 3.39—Global Class and Services 75

Table 3.40—Global Class Attributes (Instance 0) 75

Table 3.41—Global Instance Attributes (Instance 1) 76

4 Operation and Setup

Table 4.1—Control Modes 80

Table 4.2—Alarm Codes and Messages for Process and Failed Sensor Alarms 82

Table 4.3—System Alarm Messages 83

Table 4.4—Input Readings 90

Table 4.5—Scaling Values 90

Table 4.6—Input Readings and Calculations 91

Table 4.7—Scaling Values 91

Table 4.8—Parameters Settings for Process Variable Retransmit Example 99

Table 4.9—Parameter Settings for the Primary Loop in the Cascade Example 103

Table 4.10—Parameter Settings for the Secondary Loop in the Cascade Example

103

Table 4.11—Ratio Control Settings for the Ratio Loop (Loop 2) in the Example 106

Table 4.12—Parameter Settings for the Ratio Loop (Loop 2) for the Example 107

Table 4.13—Parameters Settings for the Master Loop (Loop 1) in the Example 108

Table 4.14—Parameter Settings for the Ratio Loop (Loop 2) in the Example 109

5 Tuning and Control

Table 5.1—Proportional Band Settings 115

Table 5.2—Integral Term and Reset Settings 116

Table 5.3—Derivative Term Versus Rate 116

Table 5.4—General PID Constants 117

6 Menu and Parameter Reference

Table 6.1—Control Modes 122

Table 6.2—D8 Setup Menus 123

Table 6.3—Values for BCD Job Load 126

Table 6.4—Digital Input States Required to Load Each Job 127

xiv Watlow Anafaze Doc. 0600-3120-2000

Page 17

Series D8 User’s Guide List of Tables

Table 6.5—Power Up Loop Modes 128

Table 6.6—Digital Output Alarm Polarity 130

Table 6.7—Input Types and Ranges 131

Table 6.8—Characters for the Loop Name and Input Units Parameters 132

Table 6.9—Calibration Offset Ranges 133

Table 6.10—Display Formats 134

Table 6.11—Proportional Band Values 136

Table 6.12—Values for the Control Hysteresis and Deviation Alarm Parameters 138

Table 6.13—Heat and Cool Output Types 139

Table 6.14—Alarm Functions 144

Table 6.15—Values for Alarm Hysteresis 147

Table 6.16—Bit Positions for Alarm Enable and Alarm Function 154

Table 6.17—Bit Positions for Alarm Status and Alarm Acknowledge 155

Table 6.18—System Status Bits 155

Table 6.19—DeviceNet Value for Watchdog Inactivity Fault 156

7 Troubleshooting and Reconfiguring

Table 7.1—Operator Response to Process Alarms 160

Table 7.2—Other Symptoms 161

Table 7.3—Module Status Indicator States and Descriptions 162

Table 7.4—Network Status Indicator Light 163

Table 7.5—Resistor Values for Current Inputs 173

Table 7.6—Resistor Locations for Current Inputs 173

Table 7.7—Resistor Values for Voltage Inputs 174

Table 7.8—Resistor Locations for Voltage Inputs 174

Table 7.9—Resistor Locations for RTD Inputs 175

Table 7.10—Dual DAC Jumper Settings 177

8 Specifications

Table 8.1— Agency Approvals / Compliance 179

Table 8.2—Environmental Specifications 179

Table 8.3—D8 with Straight SCSI 180

Table 8.4—D8 Connections 181

Table 8.5—TB50 Physical Dimensions 181

Table 8.6—TB50 Connections 182

Table 8.7—TB50 with Straight SCSI 182

Table 8.8—TB50 with Right Angle SCSI 183

Table 8.9—Analog Inputs 185

Table 8.10—Thermocouple Range and Resolution 186

Table 8.11—RTD Range and Resolution 186

Table 8.12—Input Resistance for Voltage Inputs 186

Table 8.13—Digital Inputs 187

Table 8.14—Digital Outputs Control / Alarm 188

Table 8.15—5 Vdc Output (Power to Operate Solid-State Relays) 188

Table 8.16—Communications 188

Table 8.17—D8 Power Requirements 188

Table 8.18—Power Supply Environmental Specifications 189

Table 8.19—Power Supply Agency Approvals / Compliance 189

Doc.0600-3120-2000 Watlow Anafaze xv

Page 18

List of Tables Series D8 User’s Guide

Table 8.20—Power Supply Physical Specifications 189

Table 8.21—Power Supply with Mounting Bracket 189

Table 8.22—Power Supply Inputs and Outputs 190

Table 8.23—Dual DAC Environmental Specifications 191

Table 8.24—Dual DAC Physical Specifications 191

Table 8.25—Dual DAC Power Requirements 192

Table 8.26—Dual DAC Specifications by Output Range 192

Table 8.27—Serial DAC Environmental Specifications 193

Table 8.28—Serial DAC Physical Specifications 193

Table 8.29—Serial DAC Agency Approvals / Compliance 194

Table 8.30—Serial DAC Inputs 194

Table 8.31—Serial DAC Power Requirements 194

Table 8.32—Serial DAC Analog Output Specifications 195

xvi Watlow Anafaze Doc. 0600-3120-2000

Page 19

1

System Overview

Manual Contents

This manual describes how to install, set up, and operate a D8

series controller. Each chapter covers a different aspect of

your control system and may apply to different users:

• Chapter 1: System Overview provides a component list

and summary of features for the D8 series controllers.

•

Chapter 2: Installation

on installing the D8 series controller and its peripherals.

•

Chapter 3: Communicating via DeviceNet

how to add the D8 controller to a network and how to access controller data via DeviceNet.

•

Chapter 4: Operation and Setup

about operating and setting up the D8.

•

Chapter 5: Tuning and Control

control algorithms and provides suggestions for applications.

•

Chapter 6: Menu and Parameter Reference

detailed descriptions of all menus and parameters for

controller setup.

•

Chapter 7: Troubleshooting and Reconfiguring

cludes troubleshooting, upgrading and reconfiguring

procedures for technical personnel.

•

Chapter 8: Specifications

the controller and optional components.

provides detailed instructions

explains

provides instructions

describes available

provides

in-

lists detailed specifications of

Doc. 0600-3120-2000 Watlow Anafaze 1

Page 20

Chapter 1: System Overview Series D8 User’s Guide

Getting Started

Safety Symbols

These symbols are used throughout this manual:

Initial Inspection

WARNING!

CAUTION!

NOTE!

Indicates a potentially hazardous situation

which, if not avoided, could result in death or

serious injury.

Indicates a potentially hazardous situation

which, if not avoided, could result in minor or

moderate injury or property damage.

Indicates pertinent information or an item

that may be useful to document or label for

later reference.

Accessories may or may not be shipped in the same container

as the D8, depending upon their size. Check the shipping invoice against the contents received in all boxes. If you are uncertain whether you have received all of the items you

ordered, contact your vendor or Watlow Anafaze.

Product Features

D8 series controllers offer high-performance closed-loop control.

The D8 provides four or eight independent control loops with

analog inputs — thermocouples, RTDs and process — and

features DeviceNet communications.

When used as a stand-alone controller, you may operate the

D8 via the two-line 16-character display and touch keypad.

You can also use it as the key element in a computer-supervised data acquisition and control system. The D8 can be locally or remotely controlled via its DeviceNet communications interface.

D8 features include:

2 Watlow Anafaze Doc. 0600-3120-2000

Page 21

Series D8 User’s Guide Chapter 1: System Overview

•

Direct Connection of Mixed Thermocouple Sensors:

Connect most thermocouples to the controller with no

hardware modifications. Thermocouple inputs feature

reference junction compensation, linearization, offset

calibration to correct for sensor inaccuracies, detection of

open, shorted or reversed thermocouples, and a choice of

Fahrenheit or Celsius display.

•

Accepts Resistive Temperature Detectors (RTDs):

, platinum, 0.00385-curve sensors.

Use three-wire, 100

Ω

Special inputs must be installed.

•

Automatic Scaling for Process Analog Inputs:

The D8

series automatically scales process inputs used with industrial process sensors. Enter two points, and all input

values are automatically scaled. Special inputs must be

installed.

•

Dual Outputs:

The D8 series includes both heat and cool

control outputs for each loop. Independent control parameters are provided for each output.

•

Independently Selectable Control and Output

Modes:

Set each control output to on/off, time proportioning, Serial DAC (digital-to-analog converter) or distributed zero crossing mode. Set up to two outputs per

loop for on/off, P, PI or PID control with reverse or direct

action.

•

Boost Output Function:

Set digital outputs to function

as boost on/off control in association with any alarm.

•

Flexible Alarms:

Independently set high and low alarms

and high and low deviation alarms for each loop. Alarms

can activate a digital output by themselves, or they can be

grouped with other alarms to activate an output.

•

Global Alarm Output:

Any alarm event activates the

global alarm output.

•

CPU Watchdog:

The CPU watchdog timer output noti-

fies you of system failure.

•

Keypad or DeviceNet Operation:

Set up and run the

controller from the keypad or via the DeviceNet interface.

•

DeviceNet Communications:

Connect software, programmable logic controllers and other master devices using the widely supported DeviceNet protocol. The D8 is

compliant with both the ODVA DeviceNet specification

and the Interface Guidelines for DeviceNet on Semiconductor Manufacturing Tools.

•

Multiple Job Storage:

Store up to eight jobs in the controller’s battery-backed memory. Load a job through the

keypad, digital inputs or software. Each job is a set of operating conditions, including set points and alarm limits.

Doc. 0600-3120-2000 Watlow Anafaze 3

Page 22

Chapter 1: System Overview Series D8 User’s Guide

•

Nonlinear Output Curves:

Select either of two nonlin-

ear output curves for each control output.

•

Autotuning: Use the autotune feature to set up your system quickly and easily. The internal expert system table

finds the correct PID parameters for your process.

• Low Power Shutdown: The controller shuts down and

turns off all outputs when it detects the input voltage drop

below the minimum safe operating level.

• Process Variable Retransmit: Scale a temperature or

process and convert it to an analog output for external devices such as chart recorders.

• Two-Zone Cascade Control: Control thermal systems

with long lag times, which cannot be accurately controlled with a single loop.

• Ratio or Offset Control: Control one process as a ratio

or offset of another process.

• Remote Analog Set Point: Scale an external voltage or

current source to provide a set point for a loop.

4 Watlow Anafaze Doc. 0600-3120-2000

Page 23

Series D8 User’s Guide Chapter 1: System Overview

D8 Parts List

You may have received one or more of the following components. See Figure 2.1 on page 12 for D8 configuration information.

• D8 series controller with mounting collar and brackets

• TB50 with 50-pin SCSI cable

• Power supply with mounting bracket and screws

• Serial DAC (digital-to-analog converter)

• Special input resistors (installed in D8)

• User’s guide

D8x0-0000-xx0x

Number of Loops

4 = 4-loop controller

8 = 8-loop controller

Digital I/O Termination

0 = TB18

1 = SCSI connector, no terminal board or cable

2 = SCSI connector, TB50 and 3-foot cable

3 = SCSI connector, TB50 and 6-foot cable

4 = SCSI connector, TB50 and 3-foot right angle cable

5 = SCSI connector, TB50 and 6-foot right angle cable

Power Supply

0 = No power supply

1 = CE Power Supply

2 = Wall mount power supply

Special Inputs

0 = Thermocouples and -10 to 60mV inputs only

X = Number of current, voltage and RTD inputs

Figure 1.1 D8 Standard Parts List

Doc. 0600-3120-2000 Watlow Anafaze 5

Page 24

Chapter 1: System Overview Series D8 User’s Guide

D8SI _ _ - _ _ - _ _

Special/Process Input Type

(Not required for thermocouple sensor inputs)

23 = RTD

43 = 0 to 10 mA dc

44 = 0 to 20 mA dc or 4 to 20 mA dc

50 = 0 to 100 mV dc

52 = 0 to 500 mV dc

53 = 0 to 1 Vdc

55 = 0 to 5 Vdc

56 = 0 to 10 Vdc

57 = 0 to 12 Vdc

Start Loop

XX = Loop number XX

End Loop

XX = Loop number XX

Figure 1.2 D8 Special Inputs Parts List

Technical Description

This section contains a technical description of each component of the D8 series controller.

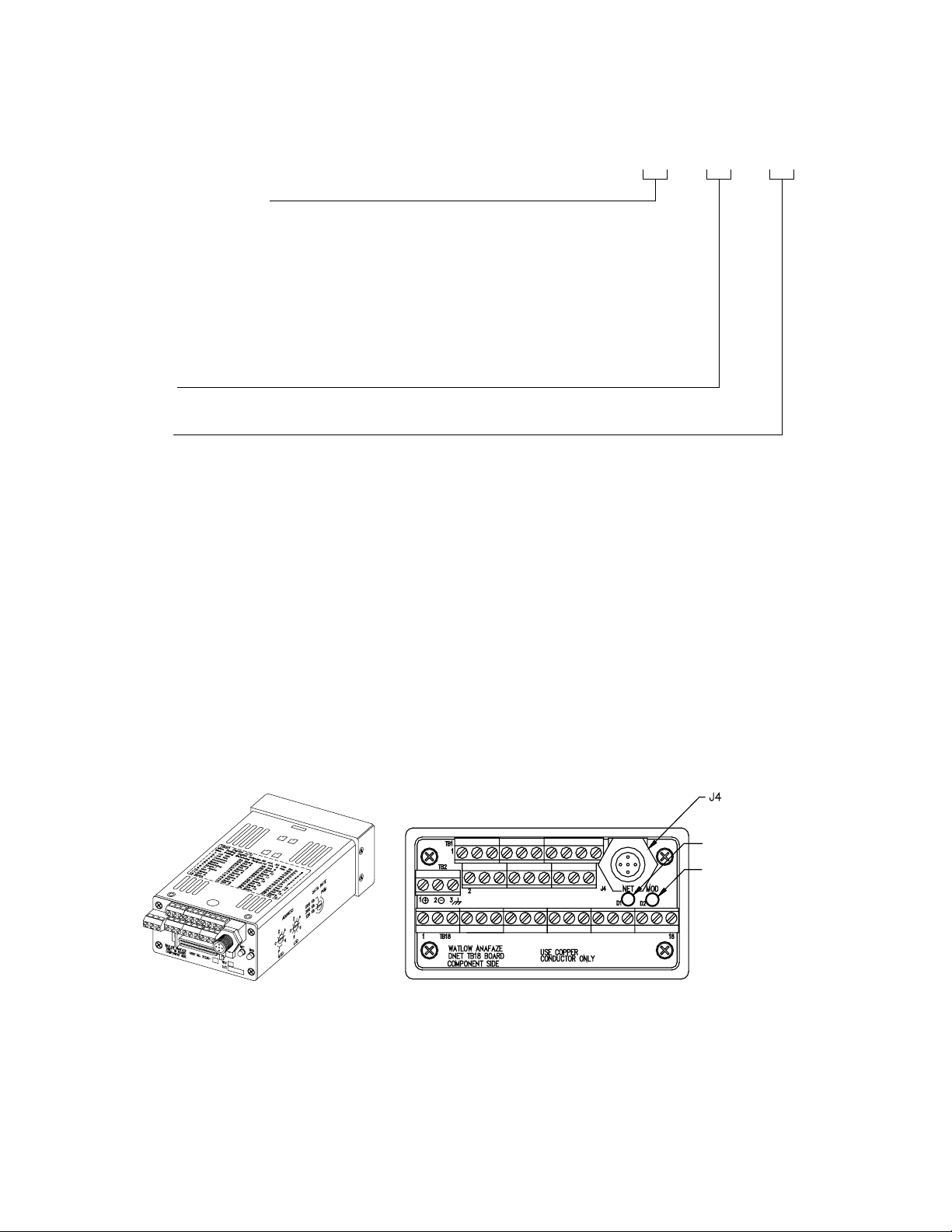

D8

The D8 is housed in a 1/8-DIN panel mount package. It contains the central processing unit (CPU), random access memory (RAM) with a built-in battery, flash memory, communications, digital I/O, analog inputs, display and touch keypad.

Series D8 with SCSI Connector. Series D8 with TB18 Connector.

DeviceNet

Connector

Network LED

Indicator Light

Module LED

Indicator Light

Figure 1.3 D8 Rear Views

6 Watlow Anafaze Doc. 0600-3120-2000

Page 25

Series D8 User’s Guide Chapter 1: System Overview

The D8 has the following features:

• Keypad and two-line, 16-character display.

• Screw terminals for the power and analog inputs.

• Micro-style connector for DeviceNet.

• Input power of 12 to 24 Vdc at 1 Amp.

• 50-pin SCSI cable to connect the digital inputs and outputs to the 50-terminal block (TB50). The D8 is available

with an 18-terminal block (TB18) in place of the SCSI

connector, as shown in Figure 1.3 on page 6.

• Nonvolatile flash memory for storage of firmware and

programmable logic.

• Battery-backed storage of operating parameters. If a

power loss occurs, the operating parameters are stored in

memory. The battery has a ten-year shelf life, and it is not

used when the controller is on.

• Microprocessor control of all calculations for input signal linearization, PID control, alarms, and communications.

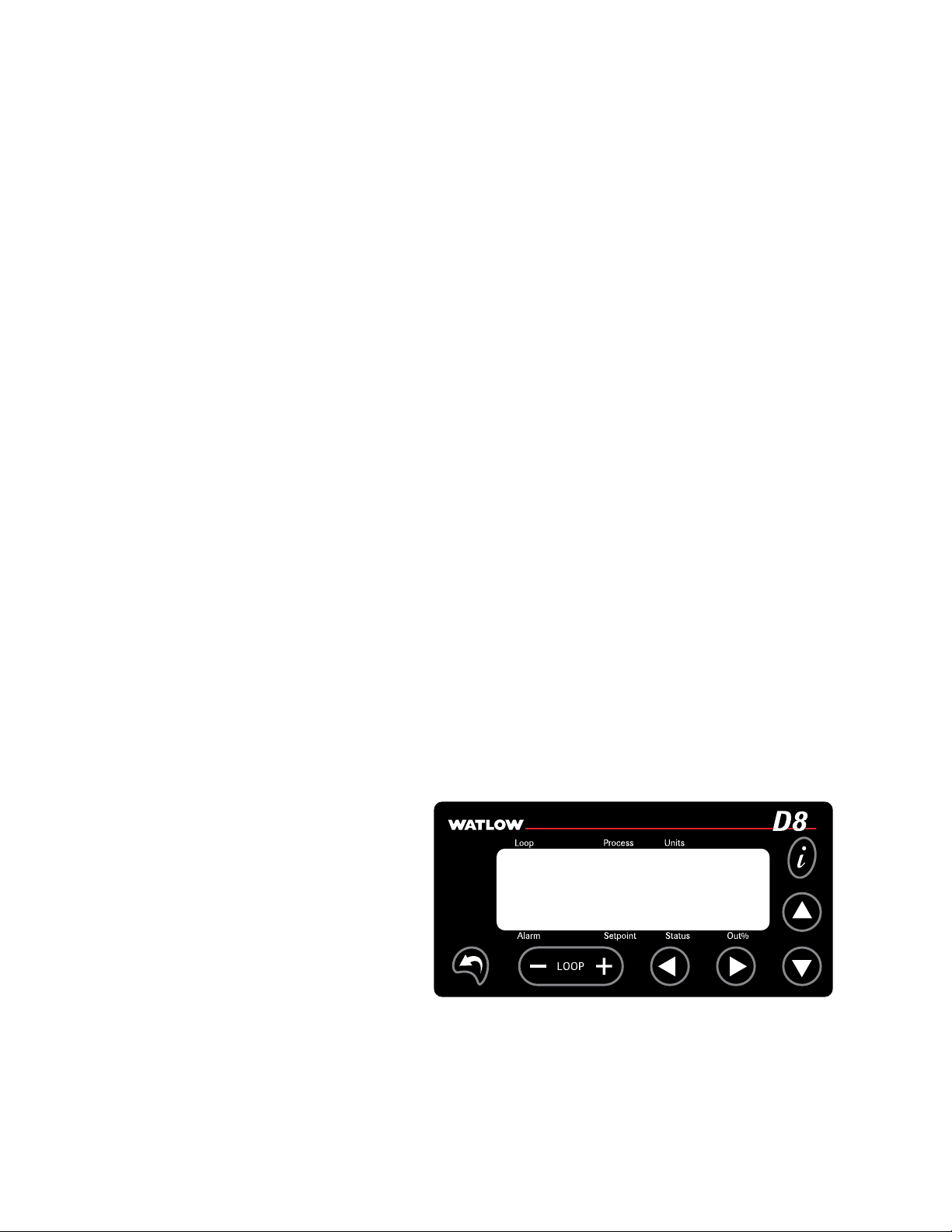

Front Panel Description

The display and keypad provide an intelligent way to operate

the controller. The display has 16 alphanumeric or graphic

characters per line. The eight-key keypad allows you to

change the operating parameters, controller functions and displays.

The displays show process variables, set points and output

levels for each loop. A single-loop display, scanning display

and alarm display offer a real-time view of process conditions.

For useful tips, help and menu information, press

i from any

screen.

Figure 1.4 D8 Front Panel

Doc. 0600-3120-2000 Watlow Anafaze 7

Page 26

Chapter 1: System Overview Series D8 User’s Guide

TB50

The TB50 is a screw-terminal interface for control wiring. It

allows you to connect power controllers and other discrete I/O

devices to the D8. The screw terminal blocks accept wires as

large as 18 AWG (0.75 mm

the TB50 to the D8.

2

). A 50-pin SCSI cable connects

D8 Cabling

Safety

External Safety Devices

Figure 1.5 TB50

Watlow Anafaze provides cables required to install the D8. A

50-pin SCSI cable connects the TB50 to the D8.

Watlow Anafaze has made every effort to ensure the reliability and safety of this product. In addition, we have provided

recommendations that will allow you to safely install and

maintain this controller.

The D8 controller may fail full-on (100 percent output power)

or full-off (0 percent output power), or may remain full-on if

an undetected sensor failure occurs.

Design your system to be safe even if the controller sends a 0

percent or 100 percent output power signal at any time

independent, external safety devices such as the Watlow

Anafaze TLM-8 that will shut down the system if a failure occurs.

. Install

Typically, a shutdown device consists of an agency-approved

high/low process limit controller that operates a shutdown de-

8 Watlow Anafaze Doc. 0600-3120-2000

Page 27

Series D8 User’s Guide Chapter 1: System Overview

vice such as an mechanical contactor. The limit controller

monitors for a hazardous condition such as an under-temperature or over-temperature fault. If a hazardous condition is detected, the limit controller sends a signal to open the contactor.

The safety shutdown device (limit controller and contactor)

must be independent from the process control equipment.

WARNING! The controller may fail in a 0 percent or 100

percent output power state. To prevent

death, personal injury, equipment damage or

property damage, install external safety shutdown devices that operate independently

from the process control equipment.

With proper approval and installation, thermal fuses may be

used in some processes.

Power-Fail Protection

In the occurrence of a sudden loss of power, the D8 controller

can be programmed to reset the control outputs to off (this is

the default). The controller can also be configured to restart to

data stored in memory.

A memory-based restart might create an unsafe process condition for some installations. Use a memory-based restart only

if you are certain your system will safely restart. See Power

Up Loop Mode on page 128.

When using the controller with a computer or other master device, you can program the software to automatically reload

desired operating constants or process values on powerup.

These convenience features do not eliminate the need for independent safety devices.

Contact Watlow Anafaze immediately if you have any questions about system safety or system operation.

Doc. 0600-3120-2000 Watlow Anafaze 9

Page 28

Chapter 1: System Overview Series D8 User’s Guide

10 Watlow Anafaze Doc. 0600-3120-2000

Page 29

2

Installation

This chapter describes how to install the D8 series controller

and its peripherals. Installation of the controller involves the

following procedures:

• Determining the best location for the controller

• Mounting the controller and TB50

• Power connection

• Input wiring

• Communications wiring

• Output wiring

WARNING! Risk of electric shock. Shut off power to your

entire process before you begin installing

the controller.

WARNING! The controller may fail in a 0 percent or 100

percent power output state. To prevent

death, personal injury, equipment damage or

property damage, install external safety shutdown devices that operate independently

from the process control equipment.

Doc. 0600-3120-2000 Watlow Anafaze 11

Page 30

Chapter 2: Installation Series D8 User’s Guide

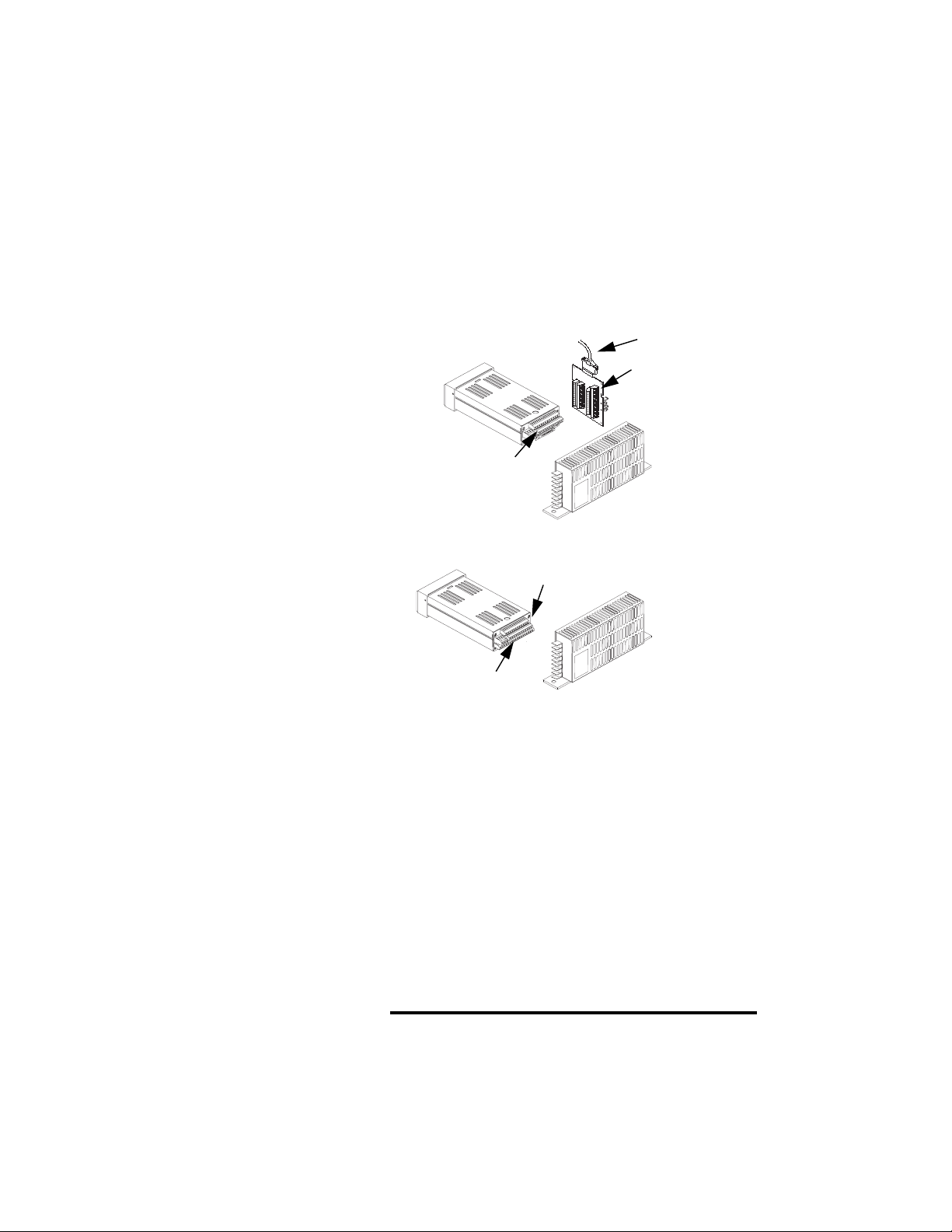

Typical Installation

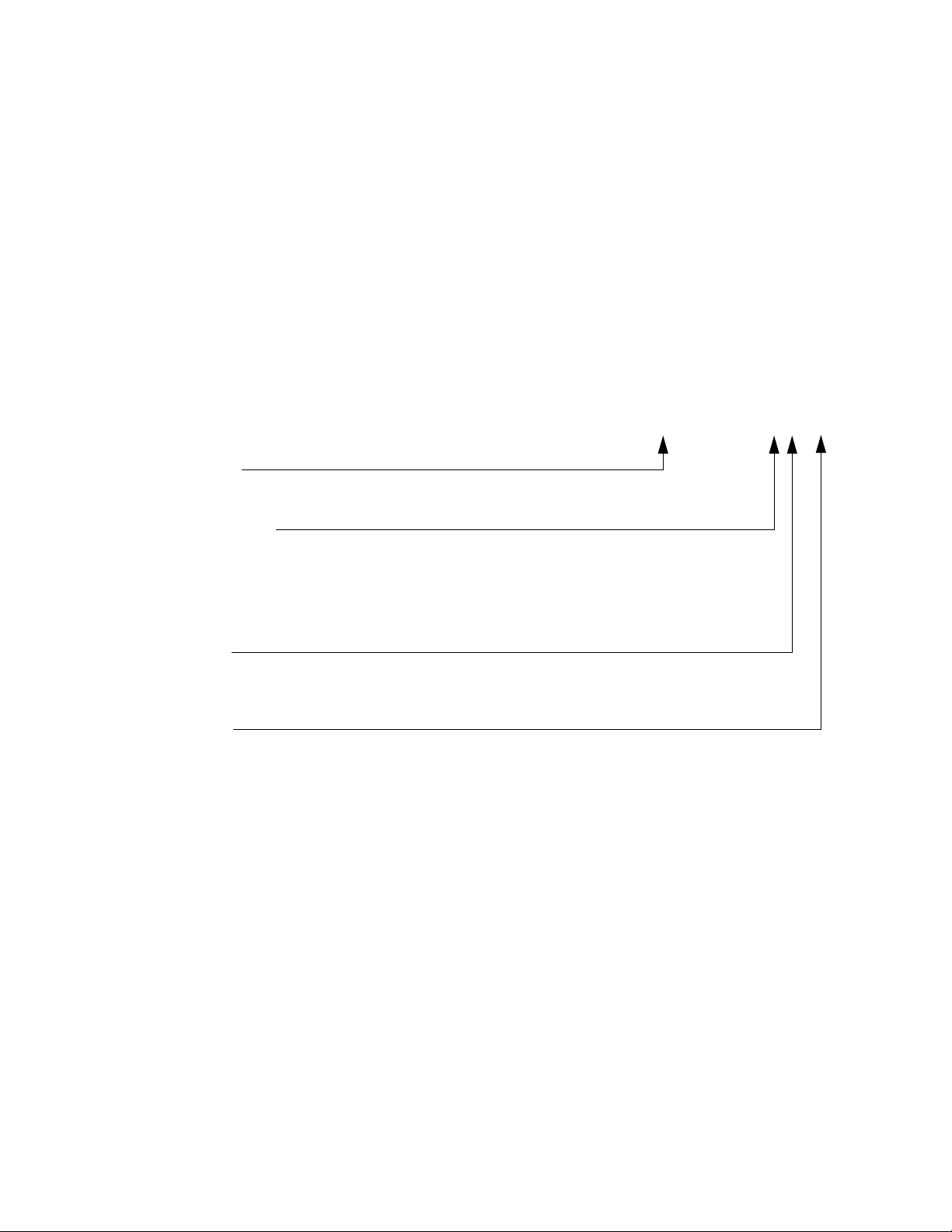

Figure 2.1 shows typical installations of the controller with

the TB50 and the TB18 terminal blocks. The type of terminal

block you use greatly impacts the layout and wiring of your

installation site. See Figure 2.2 to Figure 2.10 to determine potential space requirements.

We recommend that you read this entire chapter before beginning the installation procedure. This will help you to carefully

plan and assess the installation.

D8 with TB50

Signal Inputs

D8 with TB18

Signal Inputs

3 Digital Inputs

11 Digital Outputs (Control, Alarm, Watchdog)

SCSI Cable

8 Digital Inputs

20 Digital Outputs

(Control Alarm,

Watchdog)

D8

Power Supply

D8

Power Supply

Figure 2.1 D8 System Components

Mounting Controller Components

Install the controller in a location free from excessive heat

(>50º C), dust and unauthorized handling. Electromagnetic

and radio frequency interference can induce noise on sensor

wiring. Choose locations for the D8 and TB50 such that wiring can be routed clear of sources of interference such as high

voltage wires, power switching devices and motors.

NOTE! For indoor use only.

12 Watlow Anafaze Doc. 0600-3120-2000

Page 31

Series D8 User’s Guide Chapter 2: Installation

WARNING! To reduce the risk of fire or electric shock, in-

stall the D8 in a controlled environment, relatively free of contaminants.

Recommended Tools

Use any of the following tools to cut a hole of the appropriate

size in the panel.

• Jigsaw and metal file, for stainless steel and heavyweight

panel doors.

• Greenlee 1/8-DIN rectangular punch (Greenlee part

number 600-68), for most panel materials and thicknesses.

• Nibbler and metal file, for aluminum and lightweight

panel doors.

Mounting the Controller

You will also need these tools:

• Phillips head screwdriver

• 1/8-inch (3 mm) flathead screwdriver for wiring

• Multimeter

Mount the controller before you mount the other components,

such as the power supply or TB50, or do any wiring. The controller’s placement affects placement and wiring considerations for the other components of your system.

Ensure that there is enough clearance for mounting brackets,

terminal blocks, and cable and wire connections. The controller extends 191 mm (7.5 inches) behind the panel face and the

collar and brackets extend 7 mm (9/32 inches) on the sides and

12 mm (15/32 inches) above and below it. Allow an additional

Doc. 0600-3120-2000 Watlow Anafaze 13

Page 32

Chapter 2: Installation Series D8 User’s Guide

41 mm (1.6 inches) for a right-angle DeviceNet connector and

SCSI connector. Refer to Figure 2.2.

188 mm (7.4 in)

25 mm

41 mm to 54 mm

(1.6 in to 2.1 in) for cables and clearance

(1.0 in)

Figure 2.2 Module Dimensions and Clearance

1.80 ± 0.020 inch

(45.7 ± 0.5 mm)

Figure 2.3 Wiring Clearances

Maximum Panel Thickness

0.2 inch (5 mm)

3.63 ± 0.020 inches

(92.2 ± 0.5 mm)

We recommend you mount the controller in a panel not more

than 0.2 inch (5 mm) thick.

1. Choose a panel location free from excessive heat (more

than 50°C), dust, and unauthorized handling. (Make sure

there is adequate clearance for the mounting hardware,

14 Watlow Anafaze Doc. 0600-3120-2000

Page 33

Series D8 User’s Guide Chapter 2: Installation

terminal blocks, and cables. The controller extends 188

mm (7.4 in.) behind the panel. Allow for an additional 41

to 54 mm (1.6 to 2.1 in.) beyond the connectors.

2. Temporarily cover any slots in the metal housing so that

dirt, metal filings, and pieces of wire do not enter the

housing and lodge in the electronics.

3. Cut a hole in the panel 46 mm (1.80 in.) by 92 mm (3.63

in.) as shown below. (This picture is NOT a template; it

is for illustration only.) Use caution; the dimensions given here have 1 mm (0.02 in.) tolerances.

4. Remove the brackets and collar from the controller, if

they are already in place.

5. Slide the controller into the panel cutout.

6. Slide the mounting collar over the back of the controller,

making sure the mounting screw indentations face toward the back of the controller.

Bracket (top and bottom)

25

23

21

19

17

15

13

11

9

7

5

3

1

+

26

24

22

20

18

16

14

12

10

8

6

4

2

Bezel

Panel

Mounting Collar

Figure 2.4 Mounting Bracket

7. Loosen the mounting bracket screws enough to allow for

the mounting collar and panel thickness. Place each

mounting bracket into the mounting slots (head of the

screw facing the back of the controller). Push each bracket backward then to the side to secure it to the controller

case.

8. Make sure the case is seated properly. Tighten the installation screws firmly against the mounting collar to secure

the unit. Ensure that the end of the mounting screws fit

into the indentations on the mounting collar.

Doc. 0600-3120-2000 Watlow Anafaze 15

Page 34

Chapter 2: Installation Series D8 User’s Guide

Mounting the TB50

There are two ways to mount the TB50: Use the pre-installed

DIN rail mounting brackets or use the plastic standoffs.

TB50

Mounted

with Standoffs

TB50

Mounted to

DIN Rail

Figure 2.5 Mounting the TB50

DIN Rail Mounting

Snap the TB50 on to the DIN rail by placing the hook side on

the rail first, then pushing the snap latch side in place. See Figure 2.6.

Figure 2.6 TB50 Mounted on a DIN Rail (Front)

16 Watlow Anafaze Doc. 0600-3120-2000

Page 35

Series D8 User’s Guide Chapter 2: Installation

To remove the TB50 from the rail, use a flathead screw driver

to unsnap the bracket from the rail. See Figure 2.7.

Removal

Catch for

Screwdriver

DIN Rail

Snap Latch

Hook Side

Figure 2.7 TB50 Mounted on DIN Rail (Side)

Mounting with Standoffs

1. Remove the DIN rail mounting brackets from the TB50.

2. Choose a location with enough clearance to remove the

TB50, its SCSI cable and the controller itself.

3. Mark the four mounting holes.

4. Drill and tap four mounting holes for #6 (3.5 mm) screws

or bolts.

5. Mount the TB50 with four screws or bolts.

There are four smaller holes on the terminal board. Use these

holes to secure wiring to the terminal block with tie wraps.

0.7 in

(18 mm)

4 Holes for

#6 (3.5 mm)

Bolts or Screws

3.4 in

(86 mm)

0.2 in

(5 mm)

2.6 in

(66 mm)

SCSI Connector

0.2 in

0.2 in

(5 mm)

3.6 in

(91 mm)

(5 mm)

Figure 2.8 Mounting a TB50 with Standoffs

Doc. 0600-3120-2000 Watlow Anafaze 17

Page 36

Chapter 2: Installation Series D8 User’s Guide

Mounting the Power Supply

If you use your own power supply for the D8, refer to the power supply manufacturer’s instructions for mounting information. Choose a Class 2 power supply that supplies an isolated,

regulated 12 to 24 Vdc at 1 A.

Mounting Environment

Leave enough clearance around the power supply so that it

can be removed.

18 Watlow Anafaze Doc. 0600-3120-2000

Page 37

Series D8 User’s Guide Chapter 2: Installation

Mounting the Dual DAC or Serial DAC Module

This section describes how to mount the optional Dual DAC

and Serial DAC digital-to-analog converters.

Mounting of the Dual DAC and Serial DAC is essentially the

same, except that the dimensions differ.

Jumpers

The output signal range of the Dual DAC and Serial DAC

modules is configured with jumpers. See Configuring Dual

DAC Outputs on page 177 and Configuring Serial DAC Outputs on page 176 for information about setting these jumpers.

Mounting

1. Choose a location. The unit is designed for wall mounting. Install it as close to the controller as possible.

2. Mark and drill four holes for screw mounting. Holes accommodate #8 (3.5 mm) screws. See Figure 2.10 for

screw locations. Install the unit with the four screws.

Dual DAC

4 Holes for #8 (3.5 mm)

Screws or Bolts

3.62 in

(91 mm)

Electrical

Connectors

Electrical

Connectors

3.7 in

(94 mm)

4.40 in

(112 mm)

0.3 in

(8 mm)

3.00 in

(76 mm)

0.65 in

(17 mm)

1.75 in

(44 mm)

0.37 in

(9 mm)

4 Holes for #8 (3.5 mm)

Screws or Bolts

3.62 in

(91 mm)

Electrical

Connectors

Serial DAC

Electrical

Connectors

4.7 in

(119 mm)

5.40 in

(137 mm)

0.3 in

(8 mm)

3.00 in

(76 mm)

0.37 in

(9 mm)

0.65 in

(17 mm)

1.75 in

(44 mm)

Figure 2.10 Dual DAC and Serial DAC

Dimensions

Doc. 0600-3120-2000 Watlow Anafaze 19

Page 38

Chapter 2: Installation Series D8 User’s Guide

System Wiring

Successful installation and operation of the control system can

depend on placement of the components and on selection of

the proper cables, sensors and peripheral components.

Routing and shielding of sensor wires and proper grounding

of components can insure a robust control system. This section includes wiring recommendations, instructions for proper

grounding and noise suppression, and considerations for

avoiding ground loops.

WARNING! To reduce the risk of electrical shock, fire,

and equipment damage, follow all local and

national electrical codes. Correct wire sizes,

fuses and thermal breakers are essential for

safe operation of this equipment.

CAUTION! Do not wire bundles of low-voltage signal

Wiring Recommendations

and control circuits next to bundles of highvoltage ac wiring. High voltage may be inductively coupled onto the low-voltage circuits,

which may damage the controller or induce

noise and cause poor control.

Physically separate high-voltage circuits

from low-voltage circuits and from D8 hardware. If possible, install high-voltage ac power circuits in a separate panel.

Follow these guidelines for selecting wires and cables:

• Use stranded wire. (Solid wire can be used for fixed service; it makes intermittent connections when you move it

for maintenance.)

• Use 20 AWG (0.5 mm

Larger or smaller sizes may be difficult to install, may

break easily or may cause intermittent connections.

• Use shielded wire. The electrical shield protects the signals and the D8 from electrical noise. Connect one end of

the input and output wiring shield to earth ground.

• Use copper wire for all connections other than thermocouple sensor inputs.

2

) thermocouple extension wire.

20 Watlow Anafaze Doc. 0600-3120-2000

Page 39

Series D8 User’s Guide Chapter 2: Installation

Table 2.1 Cable Recommendations

Analog Inputs

RTD Inputs

Thermocouple Inputs

Control Outputs and

Digital I/O

Analog Outputs

Noise Suppression

Function Mfr. P/N

Belden 9154

Belden 8451

Belden 8772

Belden 9770

thermocouple

Ext. Wire

Belden 9539

Belden 9542

Ribbon Cable

Belden 9154

Belden 8451

The D8 outputs are typically used to drive solid state relays.

These relays may in turn operate more inductive types of

loads such as electromechanical relays, alarm horns and motor starters. Such devices may generate electromagnetic interference (EMI, or noise). If the controller is placed close to

sources of EMI, it may not function correctly. Below are some

tips on how to recognize and avoid problems with EMI.

No. of

Wires

2

2

3

3

2 20 0.5

9

20

50

2

2

AWG

20

22

20

22

24

24

22 to 14

20

22

2

mm

0.5

0.5

0.5

0.5

0.2

0.2

0.5 to 2.5

0.5

0.5

Symptoms of Noise

Avoiding Noise

For earth ground wire, use a large gauge and keep the length

as short as possible. Additional shielding may be achieved by

connecting a chassis ground strap from the panel to D8 case.

If your controller displays the following symptoms, suspect

noise:

• The display screen blanks out and then reenergizes as if

power had been turned off for a moment.

• The process variable value is incorrect on the controller

display.

Noise may also damage the digital output circuit such that the

digital outputs will not turn on. If the digital output circuit is

damaged, return the controller to Watlow Anafaze for repair.

To avoid or eliminate most RFI/EMI noise problems:

Doc. 0600-3120-2000 Watlow Anafaze 21

Page 40

Chapter 2: Installation Series D8 User’s Guide

• Connect the D8 case to earth ground. The D8 system includes noise suppression circuitry. This circuitry requires

proper grounding.

• Separate the 120 Vac and higher power leads from the

low-level input and output leads connected to the D8 series controller. Do not run the digital I/O or control output leads in bundles with ac wires.

• Where possible, use solid state relays (SSRs) instead of

electromechanical relays. If you must use electromechanical relays, avoid mounting them in the same panel

as the D8 series equipment.

• If you must use electromechanical relays and you must

place them in a panel with D8 series equipment, use a

0.01 microfarad capacitor rated at 1000 Vac (or higher)

in series with a 47

Ω, 0.5 watt resistor across the normal-

ly-open contacts of the relay load. This is known as a

snubber network and can reduce the amount of electrical

noise.

• You can use other voltage suppression devices, but they

are not usually required. For instance, you can place a

metal oxide varistor (MOV) rated at 130 Vac for 120 Vac

control circuits across the load, which limits the peak ac

voltage to about 180 Vac (Watlow Anafaze part number

26-130210-00). You can also place a transorb (back-toback zener diodes) across the digital output, which limits

the digital output voltage.

Additional Recommendations for a Noise Immune System

We strongly recommended the following:

• Isolate outputs through solid state relays, where possible.

• Isolate RTDs or “bridge” type inputs from ground.

• Isolate digital inputs from ground through solid state relays. If this is not possible, then make sure the digital input is the only connection to earth ground other than the

chassis ground.

Ground Loops

Ground loops occur when current passes from the process

through the controller to ground. This can cause instrument

errors or malfunctions.

A ground loop may follow one of these paths, among others:

• From one sensor to another.

• From a sensor to the dc power supply.

22 Watlow Anafaze Doc. 0600-3120-2000

Page 41

Series D8 User’s Guide Chapter 2: Installation

The best way to avoid ground loops is to minimize unnecessary connections to ground. Do not connect any of the follow-

ing terminals to earth ground:

• Power supply dc common

• TB1 terminals 9, 10, 19 (analog common)

• TB2 terminal 2 (dc power common)

Do not connect the analog common terminals to the other terminals listed above.

Power Connections

This section explains how to make power connections to the

D8 and the TB50.

DEVICENET

CONNECTOR

NETWORK LED

INDICATOR LIGHT

MODULE LED

INDICATOR LIGHT

Wiring the Power Supply

WARNING! Use a power supply with a Class 2 rating

Figure 2.11 D8 Series Controller with TB50

only. UL approval requires a Class 2 power

supply.

Connect power to the controller before any other connections,

This allows you to ensure that the controller is working before

any time is taken installing inputs and outputs.

Doc. 0600-3120-2000 Watlow Anafaze 23

Page 42

Chapter 2: Installation Series D8 User’s Guide

Table 2.2 Power Connections

Function Power Supply D8 TB2

DC Power

(Controller)

DC Common

Earth Ground Ground

+12 to 24 Vdc +

12 to 24 Vdc

Common

-

1. Connect the dc common terminal on the power supply to

the dc common (-) terminal on D8 TB2.

2. Connect the positive terminal on the power supply to the

dc positive (+) terminal on D8 TB2.

3. If using an isolated dc output or another power supply to

power the loads, connect the dc common of the supply

powering the loads to the dc common of the supply powering the controller.

4. Use the ground connector on TB2 for chassis ground.

This terminal is connected to the D8 chassis and must be

connected to earth ground.

5. Connect 120/240 Vac power to the power supply.

NOTE! Connect the dc common of the power supply

used for loads to the dc common of the supply powering the controller. If the supplies

are not referenced to one another, the controller’s outputs will not be able to switch the

loads.

NOTE! When making screw terminal connections,

tighten to 4.5 to 5.4 in.-lb. (0.5 to 0.6 Nm).

CAUTION! Without proper grounding, the D8 may not

operate properly or may be damaged.

24 Watlow Anafaze Doc. 0600-3120-2000

Page 43

Series D8 User’s Guide Chapter 2: Installation

CAUTION! To prevent damage from incorrect connec-

tions, do not turn on the heater power or other output power before testing the

connections as explained in Testing the System on page 26.

NOTE! Do not connect the controller’s dc common

(COM) to earth ground . Doing so will defeat

the noise protection circuitry, making measurements less stable.

solid-state relay (ssr)

+

-

ssr

+

ssr

-

+

-

+5V

5V COM

+15V

15V COM

-15V

Ground

AC Line

AC Neutral

green

black

white

add jumper

D8

Controller

L1

L2

V+

common

ground

digital-to-analog

converter

120/240VÅ (ac)

ssr

1 2 3 4

Serial

+

-

Figure 2.12 Power Connections with the D8

Power Supply

Connecting the TB50 to the D8

1. Connect the SCSI cable to the controller.

2. Connect the SCSI cable to the TB50.

Doc. 0600-3120-2000 Watlow Anafaze 25

Page 44

Chapter 2: Installation Series D8 User’s Guide

Testing the System

This section explains how to test the controller after installation and prior to making field wiring connections.

TB50 or TB18 Test

Use this procedure to verify that the TB50 or TB18 is properly

connected and supplied with power:

1. Turn on power to the D8. The display should first show

Calculating checksum, and then show the single-loop

display. If you do not see these displays, disconnect power and check wiring and power supply output.

2. Measure the +5 Vdc supply at the TB50 or TB18:

a) Connect the voltmeter’s common lead to TB50 ter-

minal 3 or TB18 terminal 2.

b) Connect the voltmeter’s positive lead to TB50 or

TB18 terminal 1. The voltage should be +4.75 to

+5.25 Vdc.

Digital Output Test

Use this procedure to test the controller outputs before loads

are connected. If using it at another time for troubleshooting,

disconnect loads from outputs before testing.

1. Connect a 500

TB18 terminal 1 and a digital output terminal. See

Table 2.6 on page 36 for TB18 connections or Table 2.7

on page 37 for TB 50 connections.

2. Connect the voltmeter’s positive lead to terminal 1 on the

TB50 or TB18.

3. Connect the voltmeter’s common lead to the digital output terminal.

4. Use the digital output test in the I/O tests menu to turn the

digital output on and off (see Test Digital Output 1 to 20

on page 153). When the output is off, the output voltage

should be less than 1 V. When the output is on, the output

voltage should be between 4.75 and 5.25 V.

Ω to 100 k Ω resistor between TB50 or

NOTE! By default, heat outputs are enabled. Only

disabled outputs may be turned on using the

manual I/O test. To test heat outputs, set the

corresponding loop to manual mode 100 percent output. See Changing the Control Mode

and Output Power on page 85.

26 Watlow Anafaze Doc. 0600-3120-2000

Page 45

Series D8 User’s Guide Chapter 2: Installation

Digital Input Test

Use the following procedure to test digital inputs before connecting to field devices:

1. Disconnect any system wiring from the input to be tested.

2. Go to the Digital inputs test in the I/O tests menu. This

test shows whether the digital inputs are off (open) or on

(closed).

3. Attach a wire to the terminal of the digital input you want

to test. See Table 2.6 on page 36 for TB 18 connections

or Table 2.7 on page 37 for TB50 connections.

a) When the wire is connected only to the digital input

terminal, the digital input test should show that the

input is off (open).

b) When you connect the other end of the wire to the

controller common (TB50 terminal 3 or TB18 terminal 2), the digital input test should show that the

input is on (closed).

Sensor Wiring

CAUTION! Never run input leads in bundles with high

This section describes how to properly connect thermocouples, RTDs, current and voltage inputs to the controller. The

controller can accept any mix of available input types. Some

input types require that special scaling resistors be installed

(generally done by Watlow Anafaze before the controller is

delivered).

All inputs are installed at the “CH” input connectors (TB1) at

the back of the controller. The illustrations below show the

connector locations for all D8 series controllers.

power wires or near other sources of EMI.

This could inductively couple voltage onto

the input leads and damage the controller, or

could induce noise and cause poor measurement and control.

Doc. 0600-3120-2000 Watlow Anafaze 27

Page 46

Chapter 2: Installation Series D8 User’s Guide

Table 2.3 TB1 Connections

Terminal Number Label Function

1 CH 1 IN+ Channel 1 positive input

2 CH 1 IN- Channel 1 negative input

3 CH 2 IN+ Channel 2 positive input

4 CH 2 IN- Channel 2 negative input

5 CH 3 IN+ Channel 3 positive input

6 CH 3 IN- Channel 3 negative input

7 CH 4 IN+ Channel 4 positive input

8 CH 4 IN- Channel 4 negative input

9 Com Analog Common

10 Com Analog Common

11 CH 5 IN+

12 CH 5 IN-

13 CH 6 IN+

14 CH 6 IN-

15 CH 7 IN+

16 CH 7 IN-

17 CH 8 IN+

18 CH 8 IN-

Channel 5 positive input

Channel 5 negative input

Channel 6 positive input

Channel 6 negative input

Channel 7 positive input

Channel 7 negative input

Channel 8 positive input

Channel 8 negative input

1

1

1

1

1

1

1

1

19 Com Analog Common

NOTE!

1

Terminals 11 to 18 are not used with a 4-channel controller.

Input Wiring Recommendations

Use multicolored stranded shielded cable for analog inputs.

Watlow Anafaze recommends that you use 20 AWG wire (0.5

2

). If the sensor manufacturer requires it, you can also use

mm

24 or 22 AWG wiring (0.2 mm

twisted pair; some require a three-wire input.

The controller accepts the following inputs without any special scaling resistors:

• J, K, T, S, R, B and E thermocouples.

• Process inputs with ranges between -10 and 60 mV.

To avoid thermocouple open alarms on unused inputs, either

set the Input type parameter to skip or jumper the input.

28 Watlow Anafaze Doc. 0600-3120-2000

2

). Most inputs use a shielded

Page 47

Series D8 User’s Guide Chapter 2: Installation

Thermocouple Connections

Connect the positive lead of the thermocouple to the IN+ terminal for one of the loops, and connect the negative lead to the

corresponding IN- terminal.

2

Use 18 or 20 AWG (0.5 or 0.75 mm

puts. Most thermocouple wire is solid, unshielded wire. When

using shielded wire, ground one end only.

) for all thermocouple in-

CH IN+

CH IN-

White

Red

Shield (if present)

Earth Ground at Process End

Type J thermocouple

Figure 2.13 Thermocouple Connections

CAUTION! Ground loops and common mode noise can

damage the controller or disrupt measurements. To minimize ground loops and common mode noise:

• Do not mix grounded and ungrounded ther-

mocouples. If any thermocouple connected

to the controller is of grounded construction,

all thermocouples should be of grounded

construction and each should be connected

to ground at the process end.

• Connect the earth ground terminal on TB2

to a good earth ground, but do not connect

the analog common to earth ground. The D8

uses a floating analog common for sensor

measurements. The noise protection circuits

on the sensor inputs function correctly only

if the controller is correctly installed. See

Ground Loops on page 22.

Doc. 0600-3120-2000 Watlow Anafaze 29

Page 48

Chapter 2: Installation Series D8 User’s Guide

RTD Input Connections

RTD inputs require accessory resistors. Watlow Anafaze recommends that you use a 100

Ω, three-wire platinum RTD to

prevent reading errors due to cable resistance. If you use a

two-wire RTD, jumper the negative input to common. If you

must use a four-wire RTD, leave the fourth wire unconnected.

IN +

CH

100 Ω RTD

IN -

CH

Com

Figure 2.14 RTD Connections

Voltage Input Connections

Voltage inputs with ranges greater than -10 to 60 mV require

accessory resistors. Special input resistors installed at Watlow

Anafaze divide analog input voltages such that the controller

sees a -10 to 60 mV signal on the loop.

Current Input Connections

CH IN+

CH IN-

Device with

Voltage

Output

Figure 2.15 Voltage Signal Connections

Current inputs require accessory resistors. Special input resistors installed at Watlow Anafaze for analog current signals are

such that the controller sees a -10 to 60 mV signal across its

inputs for the loop.

CH IN+

CH IN-

Device with

Current

Output

Figure 2.16 Current Signal Connections

30 Watlow Anafaze Doc. 0600-3120-2000

Page 49

Series D8 User’s Guide Chapter 2: Installation

Wiring Control and Digital I/O

This section describes how to wire and configure the control

outputs for the D8 series controller. The D8 provides dual

control outputs for each loop. These outputs can be enabled or

disabled, and are connected through a TB50 or TB18.

NOTE! Control outputs are connected to controller

common when the control output is on. If you

connect external devices that may have a low

side at a voltage other than controller

ground, you may create ground loops. To

prevent ground loops, use isolated solid

state relays and isolate the control device inputs.

Output Wiring Recommendations

When wiring output devices, use multicolored, stranded,

shielded cable for analog outputs and digital outputs connected to panel-mounted solid state relays.

Cable Tie Wraps

Digital Outputs

• Analog outputs usually use a twisted pair.

• Digital outputs usually have 9 to 20 conductors, depending on wiring technique.

After you wire outputs to the TB50, install the cable tie wraps

to reduce strain on the connectors. Each row of terminals has

a cable tie wrap hole at one end. Thread the cable tie wrap

through the cable tie wrap hole. Then, wrap the cable tie wrap

around the wires attached to that terminal block.

The D8 provides dual control outputs for up to eight loops. By

default, heat outputs are enabled and cool outputs are disabled. If the heat or cool output is disabled for a loop, then the

output is available for alarms or programmable logic. The

CPU watchdog timer output can be used to monitor the state

of the controller; see CPU Watchdog Timer on page 34.

Doc. 0600-3120-2000 Watlow Anafaze 31

Page 50

Chapter 2: Installation Series D8 User’s Guide

Table 2.4 Digital Output States and Values

Stored in the Controller

State

Off 0 Open circuit

On 1 Sinking current to controller common

1

Read and write these values through communications.

Value

1

Description

All digital outputs sink current to controller common when

on. The load may powered by the 5 Vdc supplied by the controller at the TB50, or by an external power supply. When using an external power supply, bear in mind:

• The D8 power supply available from Watlow Anafaze

includes a 5 Vdc supply. When using it to supply output

loads, connect the 5 Vdc common to the 15 Vdc common

at the power supply.

• Do not exceed +24 volts.

• If you connect the external load to earth ground, or if you

cannot connect it as shown in Figure 2.17, then use a solid state relay.

The outputs conduct current when they are on. The maximum

current sink capability is 60 mA at 24 Vdc. The outputs cannot

“source” current to a load.

Using Internal Power Supply

TB50 or TB18

+5 Vdc

Digital Output 1

Digital Output 2

Figure 2.17 Digital Output Wiring

Loads

Using External Power Supply

External

Power

Supply

to earth ground or

equipment ground

TB50 or TB18

Control Common

Digital Output 1

Digital Output 2

+

-

Do not connect

Loads

32 Watlow Anafaze Doc. 0600-3120-2000

Page 51

Series D8 User’s Guide Chapter 2: Installation

Configuring Outputs

As you choose outputs for control and alarms, bear in mind

the following points:

• You can enable or disable the control outputs. By default,

heat outputs are enabled and cool outputs are disabled.

• You can program each control output individually for on/

off, time proportioning, distributed zero-crossing or Serial DAC control.

• You can individually program each control output for direct or reverse action.

• Alarm outputs other than the global alarm are non-latching. See Global Alarm on page 97.

• Alarms can be suppressed during process start up and for

preprogrammed durations. See Power Up Alarm Delay

on page 128.

• Alarm outputs can be configured, as a group, to sink to

output during an alarm or stop current flow during an

alarm. See Digital Output Alarm Polarity on page 129.

Control and Alarm Output Connections

Typically control and alarm outputs use external opticallyisolated solid state relays (SSRs). SSRs accept a 3 to 32 Vdc

input for control, and some can switch up to 100 Amps at 480

Vac. For larger currents, use silicon control rectifier (SCR)

power controllers up to 1000 Amps at 120 to 600 Vac. You

can also use SCRs and a Serial DAC for phase-angle fired

control.

The control and alarm outputs are open collector outputs referenced in the D8’s common. Each output sinks up to 60

mAdc to the controller common when on.

NOTE! Control outputs are sink outputs. They sink

current when the output is on. Connect them

to the negative side of solid state relays.

Figure 2.18 shows sample heat, cool and alarm output connections.

TB50 or TB18

Heat Output

Cool Output

Alarm Output

+5 Vdc

SSR SSR SSR

+-

+-

+-

Figure 2.18 Sample Heat, Cool and Alarm

Output Connections

Doc. 0600-3120-2000 Watlow Anafaze 33

Page 52

Chapter 2: Installation Series D8 User’s Guide

CPU Watchdog Timer

TB50 or TB18

Heat Output

Cool Output

Alarm Output

Common

SSR

+-

- PS +

SSR

SSR

+-

+-

Figure 2.19 Output Connections Using

External Power Supply

The CPU watchdog timer constantly monitors the microprocessor. It is a sink output located on TB50 terminal 6 or TB18

terminal 3. The output can be connected to an external circuit

or device to monitor whether the controller is powered and operational. The output is on (low) when the microprocessor is

operating; when it stops operating, the output goes off (high).

Figure 2.20 and Figure 2.21 show the recommended circuit

for the watchdog timer output for the TB50 and the TB18.

TB50

+ 5 Vdc

(Terminal 1)

Watchdog Timer

(Terminal 6)

+

SSR

-

Figure 2.20 TB50 Watchdog Timer Output

TB18

+ 5 Vdc

(Terminal 1)

Watchdog Timer

(Terminal 3)

+

SSR

-

Figure 2.21 TB18 Watchdog Timer Output

34 Watlow Anafaze Doc. 0600-3120-2000

Page 53

Series D8 User’s Guide Chapter 2: Installation

Digital Inputs

All digital inputs are transistor-transistor logic (TTL) level inputs referenced to controller common and the internal +5 V

power supply of the D8.

When an input is connected to the controller common, the input is considered on. Otherwise, the input is considered off.

Most features that use the digital inputs can be user-configured to activate when an input is either on or off.

External Switching Device

In the off state, internal 4.7 k

Ω resistors pull the digital inputs

high to 5 Vdc with respect to the controller common.

Table 2.5 Digital Input States and Values

Stored in the Controller

State

Off 0 Open circuit

On 1

1

Read and write these values through communications.

To ensure that the inputs are reliably switched, use a switching

device with the appropriate impedances in the on and off

states and do not connect the inputs to external power sources.

When open, the switching device must provide an impedance

of at least 14 k

than 3.7 Vdc. When closed, the switch must provide not more

than 1.7 k

Ω impedance to ensure the voltage drops below 1.3

Vdc.

1

Value

Digital input connected to controller

common

Ω to ensure that the voltage will rise to greater

Description

To install a switch as a digital input, connect one lead to the

common terminal on the TB50 (terminals 3 and 4) or TB18

(terminal 2). Connect the other lead to the desired digital input

terminal on the TB50 (terminals 43 to 50) or TB18 (terminals

16 to 18).

TB50

Input

Control Com

External

Switching

Device

Figure 2.22 Wiring Digital Inputs

Doc. 0600-3120-2000 Watlow Anafaze 35

Page 54

Chapter 2: Installation Series D8 User’s Guide

Functions Activated by Digital Inputs

Use digital inputs to activate the following functions:

• Load a job that is stored in controller memory. See BCD

Job Load on page 126.

• Change all loops to manual mode at specified output levels. See Mode Override on page 127.

• Enable thermocouple short detection. See Thermocouple

Short Alarm on page 129.

• Restore automatic control after a failed sensor has been

repaired. See Restore Automatic Mode on page 138.