Page 1

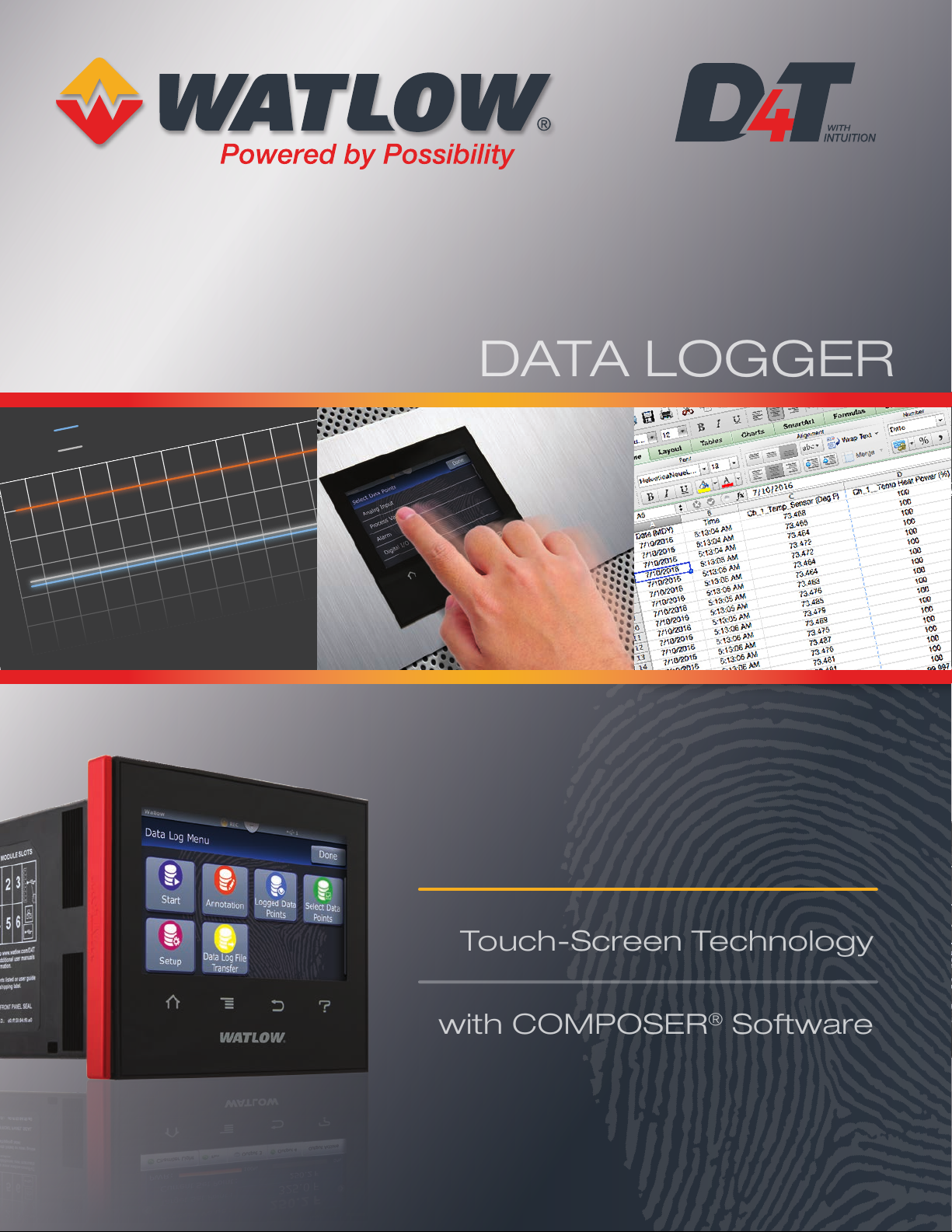

DATA LOGGER

with COMPOSER

®

Software

Touch-Screen Technology

1/4 DIN

Batch 181

Ch_2�Temp Sensor (Deg F)

5:13:05 AM

5:13:05 AM

5:13:05 AM

5:13:06 AM

5:13:06 AM

5:13:06 AM

5:13:06 AM

5:13:06 AM

5:13:07 AM

5:13:07 AM

Ch_1_Temp_Sensor (Deg F)

70

60

50

Ch_1�Temp Heat Power (%)

Page 2

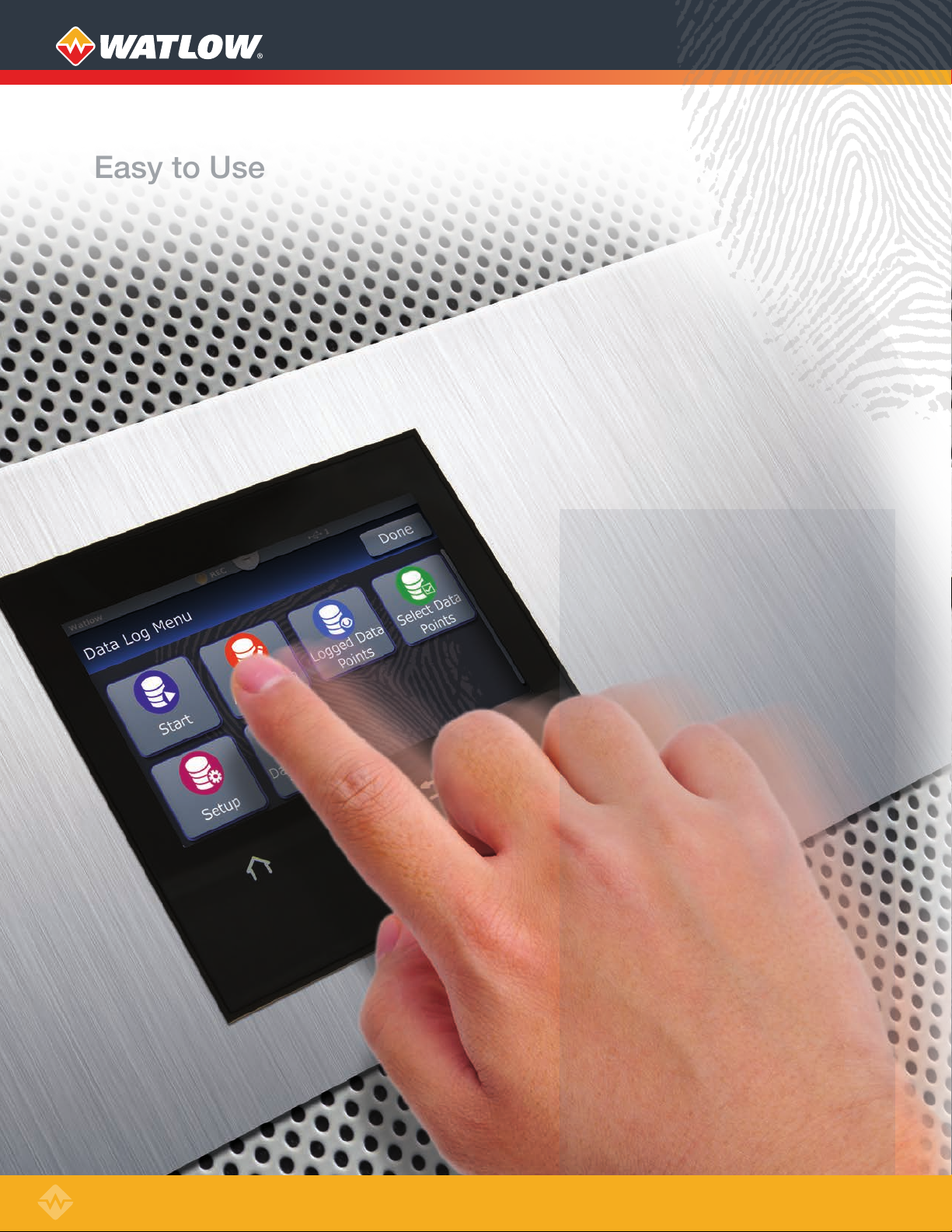

Easy to Use

Touch-Screen Technology

>

4.3-inch color, graphical

touch panel

>

Screen personalization

>

Graphical programming PC

software

>

Multi-language options

> English, German, French,

Italian, Spanish, Japanese

Korean and Chinese

>

Intuitive screen layout and

menu navigation

>

Channels, alarms, inputs and

outputs can all be tailored to

application with user-defined

names

>

USB wired or wireless mouse

user interface

> Use in hazardous location,

dirty environments or

applications with gloves

Page 3

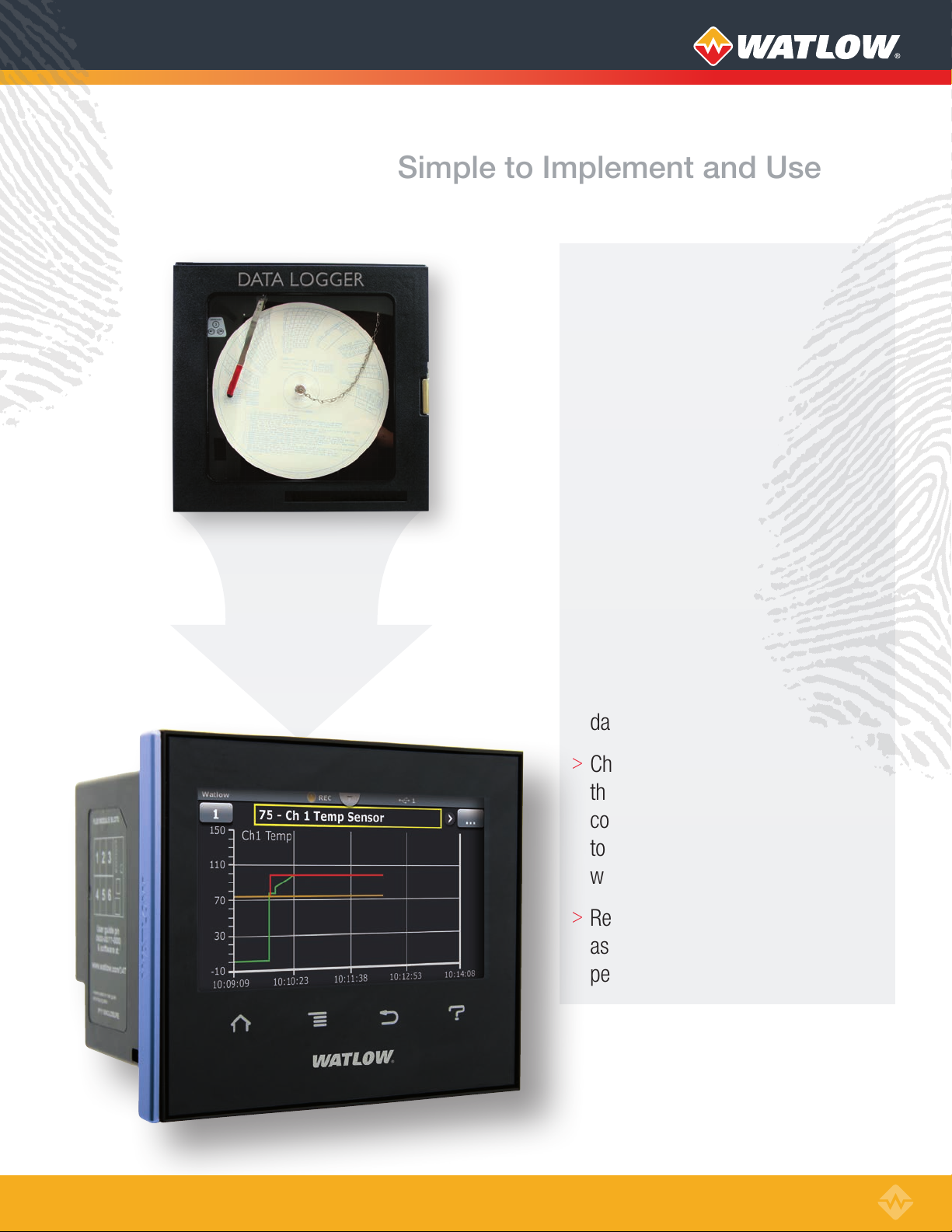

Simple to Implement and Use

Data Logging Functions

>

Easily complies with regulatory

standards with ability to choose

encrypted, .CSV or both types of

file formats for tamperproof record

needs

>

Enables lock-out security levels for

different user groups

>

Simplifies record keeping

management with ability to archive

records to the cloud or a connected

Transition

to the Next

Generation

PC network

>

Flexibility to pick which parameters

to log from

>

Ability to log from one up to 128

data logging points simultaneously

>

Choose where you want to store

the files - inside the controller, on a

connected USB memory device or

to a connected PC anywhere in the

world

>

Recording rate options range from

as fast as 100 milliseconds or once

per hour

Page 4

Manufacturing Environment

Easily Manage Data Records

Scan

paperwork

Scan

individual

parts

The D4T screen

view scanning

part numbers

Batch file report produced

Batch Report

Device Name F4T Station 1 11/6/2018 11:59:45 AM

Lot Number

W030131

Profile Test Trial #1 11/6/2018 12:00:30 AM

Load Operator Robert Henning 11/6/2018 11:59:52 AM

Comment Customer #5739 11/6/2018 11:59:57 AM

Part Number(s) 0004-0329-0000 11/6/2018 12:00:30 AM

0018-0240-0000 11/6/2018 12:00:35 AM

0803-0092-0001 11/6/2018 12:00:40 AM

0843-0041-151R 11/6/2018 12:00:46 AM

Upload Operator Robert Henning 11/6/2018 12:04:41 AM

Comment Batch 3 of 3

Date (MDY) Time Limit_Input

11/6/2018 12:01:57 PM 27.197 23.035 73.563

11/6/2018 12:01:58 PM 27.197 23.04 73.573

complete

11/6/2018 11:59:45 AM

11/6/2018 12:05:23 AM

(Deg C)

Ch_1_Temp PV

(Deg C)

Ch_2_%RH

PV (RH)

>

Bar code scan input for fast and easy

data entry

>

Data security through password and

data log encrypted file options

>

Improve manufacturing robustness

as controller screens ensure all

necessary data is entered during

processing

>

Helps ensure compliance with

growing regulations and minimize

warranty exposure

>

Improved quality control can eliminate

part processing skips or walk around

>

Produces formatted data record

report for easy receipt or record

management uses

Page 5

Design Environment

Supports Fast and Flexible

>

Field pluggable I/O, scalable in

increments of one up to 24

>

Programmable function blocks

>

Wide library of hardware options

for flexibility

>

Support of custom firmware

modifications

>

High and low voltage power

supply options

>

Quick changes, additions or

repair servicing with modular

design

Page 6

COMPOSER® PC Software

Graphical Configuration Tool

and Reliability

>

Speeds up and simplifies

product setup and

commissioning

>

Archives and documents data

logger configuration settings

>

Offers easy plug and play

connection with D4T data

logger

>

Provides read-only view

of encrypted data log file

information

High Quality

High performance validated

with stringent testing

Water test

>

Field-hardened electronics

and robust algorithms already

deployed in hundreds of

thousands of installations

worldwide

>

NEMA 4X/IP65

>

Agency compliance: UL®, FM, CE,

Vibration test

RoHS, W.E.E.E.

>

0 to 122°F / -18 to 50°C

ambient operating temperature

Page 7

Dew Point

Math 2

T

RH

Process

Alarm 1

SIL

OFF

CLR

L

H

IN

Pressure

to Altitude

Math 1

Universal Input 1

Module 1

T1

S1

R1

n

∑

Process 2

n

∑

Average

Process 1

Vaisala®

~

RH

%RH

T

of Process Measurement

Wide Range

File Transfers

>

Process inputs from temperature,

altitude (pressure), humidity,

square-root sensors and other

general process inputs from

analog 0-10VDC or 0-20mA

sensors

>

Battery backup and real-time

clock

>

Monitor up to 24 sensor inputs

>

Math, logic, averaging, minimum,

maximum and other function

Easy Connectivity and Data Mobility with

>

Ethernet Modbus® TCP and SCPI

>

Two USB host ports

>

USB device port

>

232/485 Modbus® RTU

>

USB port for serial communication

access

blocks available

>

LabVIEW™ driver and SCPI

protocol

Page 8

Powered by Possibility

Find out more about Watlow and how we can

provide thermal solutions for your company:

Phone: 1-800-WATLOW2 (1-800-928-5692)

Email: inquiry@watlow.com

Website: www.watlow.com

www.watlow.com/d4t

Watlow Products and Technical Support Delivered Worldwide

North American Technical Support

& Sales Offices

United States & Canada 1-800-WATLOW2

(1-800-928-5692)

For Additional Information

Regarding Watlow’s D4T Process

Controller Visit Our Website At:

www.watlow.com/d4t

Asian Technical Support &

Sales Offices

China +86 21 3532 8532

India +91 40 6661 2700

Japan +81 3 3518 6630

Korea +82 2 2169 2600

Singapore +65 6773 9488

Taiwan +886 7 288 5168

UL® is a registered trademark of Underwriter’s

Laboratories, Inc.

®

Modbus

is a registered trademark of Schneider

Automation Incorporated.

European Technical Support &

Sales Offices

Austria +43 6244 20129 0

France +33 1 41 32 79 70

Germany +49 7253 9400 0

Italy +39 02 4588841

Spain +34 91 675 1292

United Kingdom +44 115 964 0777

Latin American Technical Support

& Sales Office

Mexico +52 442 256 2200

®

, COMPOSER® and INTUITION® are registered

Watlow

trademarks of Watlow Electric Manufacturing Company.

LabVIEW™ is a trademark of National Instruments Corporation.

©2019 Watlow Electric Manufacturing Company WIN-D4T-BROCH-0419

(WP_300)

Loading...

Loading...