Page 1

[ CARE AND USE MANUAL ]

XSELECT HSS XP 2.5 µm COLUMNS

CONTENTS

I. INTRODUCTION

II. GETTING STARTED

a. Column Connection

b. Column Installation

c. Minimizing Band Spread Volume

d. Measuring Band Spread Volume

e. Measuring System Dwell Volume

f. Column Equilibration

g. Solvent Conversion for Normal-Phase Use

h. eCord Installation

i. Initial Column Efficiency Determination

j. VanGuard Pre-Columns

III. COLUMN USE

a. Sample Preparation

b. pH Range

c. Solvents

d. Pressure

e. Temperature

I. INTRODUCTION

Thank you for choosing a Waters XSelect™ High Strength Silica [HSS]

eX tended Performance [XP] 2.5 µm Column. The manufacture of

XSelect HSS XP 2.5 µm Columns begins with ultrapure reagents and

are manufactured in a cGMP, ISO 9001 certified facility to control the

chemical composition and purity of the final product. Well-controlled

manufacturing processes result in industry-leading batch-to-batch

reproducibility. Every column is individually tested. A Performance

Chromatogram and Certificate of Batch Analysis are provided on the

eCord™ Intelligent Chip.

XSelect HSS XP 2.5 µm Columns are based on the same base

particle technology and bonded phase chemistry as 1.8 µm ACQUITY

UPLC® HSS Columns as well as XSelect HSS 3.5 and 5 µm HPLC

Columns, thus enabling seamless transferability between HPLC,

UHPLC and UPLC® platforms.

XSelect HSS XP 2.5 µm Columns will exhibit maximum

chromatographic performance when used on a member of the

ACQUITY UPLC System family.

IV. COLUMN CLEANING, REGENERATION AND STORAGE

a. Cleaning and Regeneration

b. Storage after Reversed-Phase Use

c. Storage after HILIC Use

V. eCORD INTELLIGENT CHIP TECHNOLOGY

a. Introduction

b. Installation

c. Manufacturing

d. Column Use

VI. ADDITIONAL INFORMATION

a. Tips for Maximizing XSelect HSS XP 2.5 µm Column Lifetime

b. Troubleshooting Questions

c. Recommended Flow Rates and Anticipated Backpressures for

Reversed-Phase XSelect HSS XP 2.5 µm Columns

XSelect HSS XP 2.5 µm Columns 1

Page 2

[ CARE AND USE MANUAL ]

II. GET TING STARTED

Each XSelect HSS XP 2.5 µm Column comes with a Certificate of

Analysis and a Performance Test Chromatogram embedded within

the eCord intelligent chip. The Certificate of Analysis is specific to

each batch of packing material contained in the XSelect HSS XP 2.5 µm

Column and includes the gel batch number, analysis of unbonded

particles, analysis of bonded particles and chromatographic results

and conditions. The Performance Test Chromatogram is specific to

each individual column and contains such information as: gel batch

number, column serial number, USP plate count, USP tailing factor,

retention factor and chromatographic test conditions. T hese data

should be recorded and stored for future reference or can be accessed

via the ACQUITY UPLC console.

XP 2.5 µm Columns are designed to operate on any HPLC, UHPLC or

UPLC System. Due to the absence of an industry standard, please be

aware that the type of fittings and connections on each system will

vary by manufacturer and should be mated specifically to a column

when it is installed.

The chromatographic performance can be negatively impacted, or leak-

ing can occur, if the style of the column endfitting does not properly

match that of the compression screw/ferrule tubing depth setting.

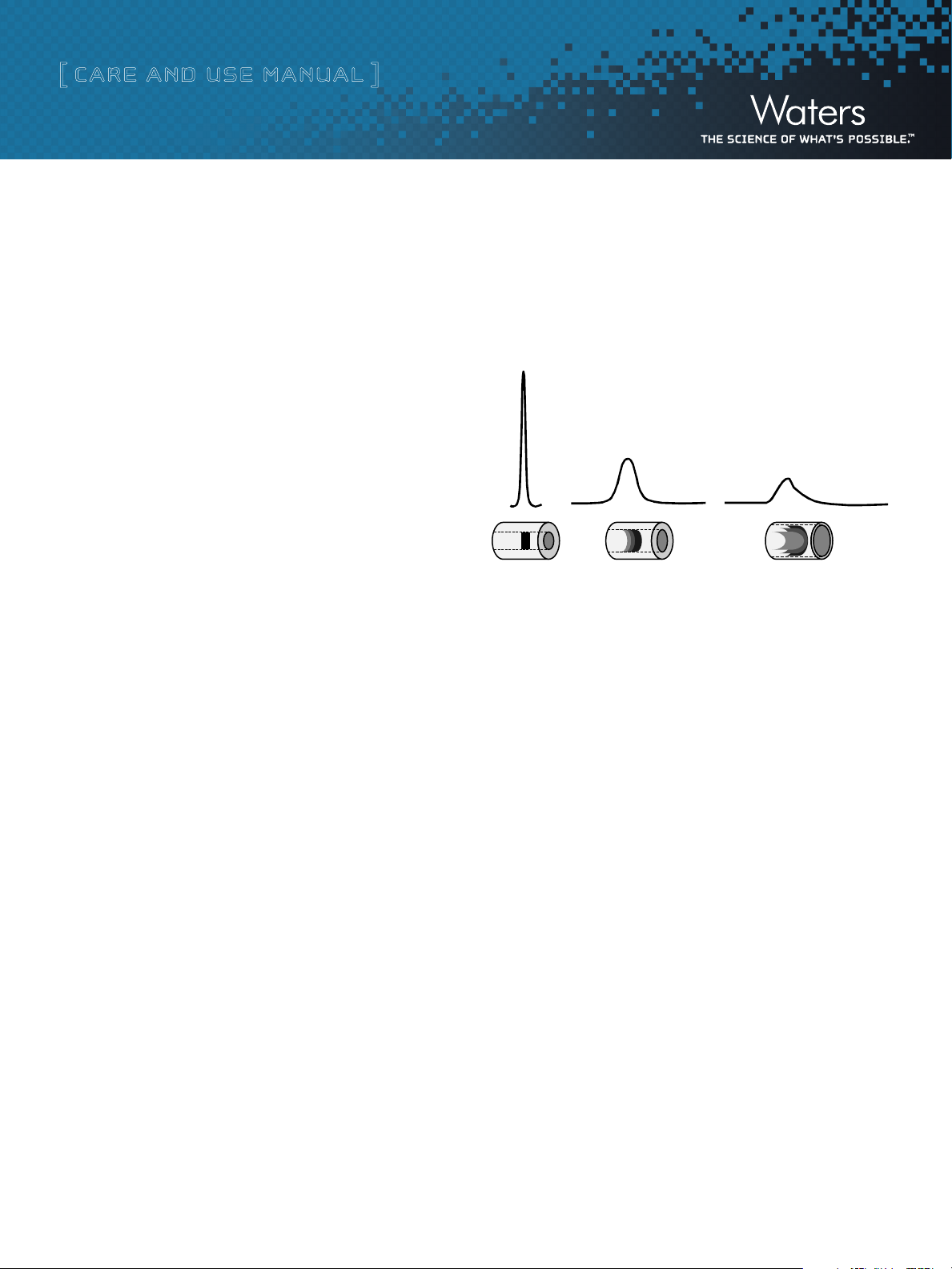

c. Minimizing Band Spread Volume

Band Spreading is a measurement of the system dispersion that

impacts the chromatographic performance. Internal tubing diameter

and fluidic connections can significantly impact system band spreading

and chromatographic performance. Larger tubing diameters cause

excessive peak broadening and reduced sensitivity (Figure 1).

0.005 inches

0.020 inches

0.040 inches

Diluted/Distorted Sample Band

Figure 1: Impact of tubing diameter on band spread.

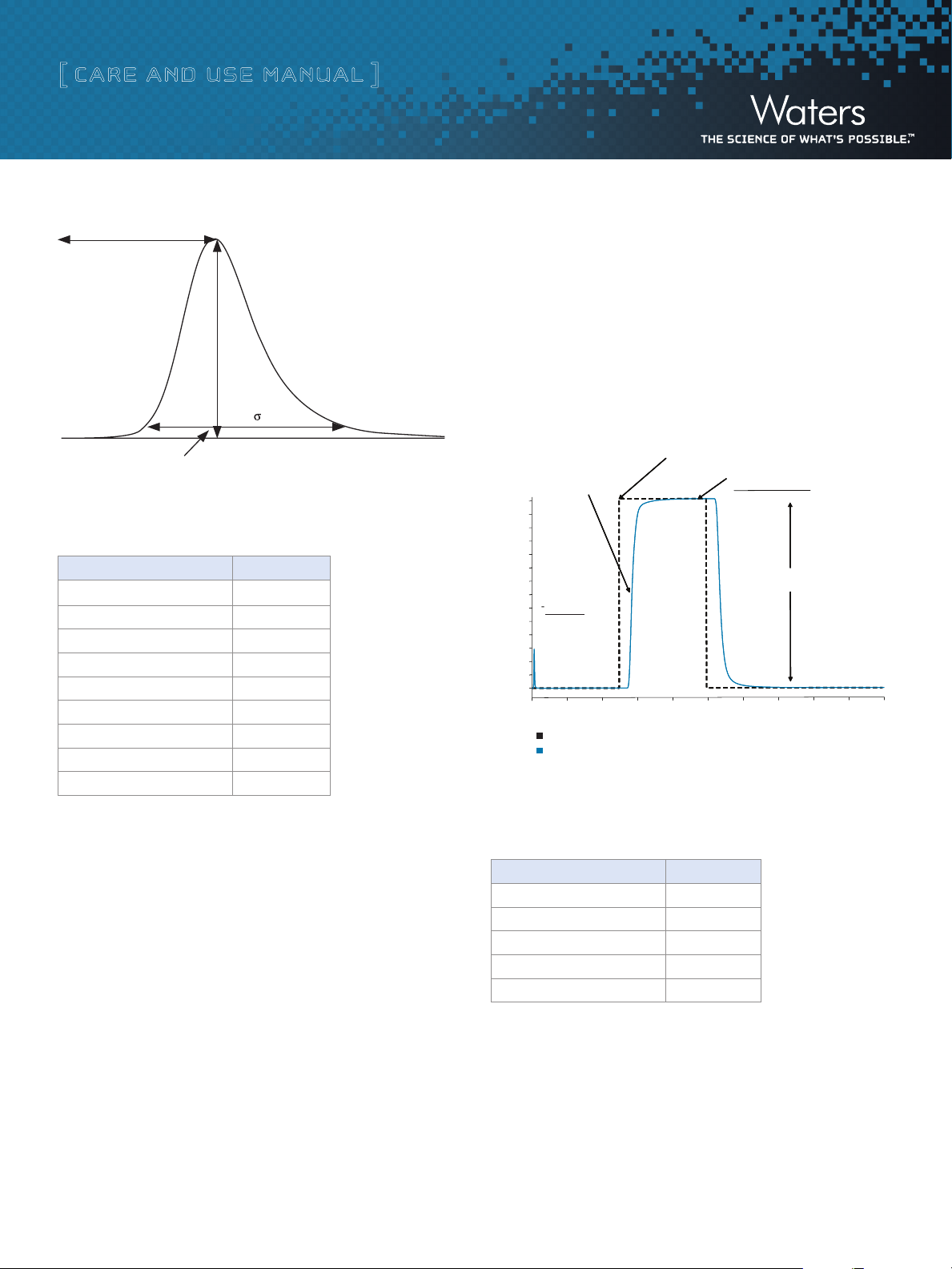

d. Measuring Band Spread Volume

Note: This test should be performed on an LC system equipped with a UV detector.

1. Disconnect the column from the system and replace with a zero

dead volume union.

b. Column Installation

Note: The flow rates given in the procedure below are described for a 2.1 mm ID

column. Scale the flow rate according to the flow rate and pressure guidelines

described in Section VI (Additional Information).

1. Purge the pumping system of any buffer-containing mobile

phases and connect the inlet of the column.

2. Flush the column with 100% organic mobile phase (methanol or

acetonitrile) by setting the pump flow rate to 0.1 mL/min and

increase the flow rate to 0.5 mL/min over 5 minutes.

3. When the mobile phase is flowing freely from the column outlet,

stop the flow and attach the column outlet to the detector. This

prevents air entering the detection system and provides a more

rapid baseline equilibration.

4. Gradually increase the flow rate as described in step 2.

5. Monitor until a steady backpressure and baseline have

been achieved.

2. Set the flow rate to 1 mL/min.

3. Use a test mixture (dissolved in the mobile-phase conditions)

that delivers a maximum peak height of 0.5 – 1.0 AU (System

Start Up Test Mixture can be used, Part No. WAT034544).

4. Inject 2 – 5 µL of this solution.

5. Using the 5-Sigma method, measure the peak width at 4.4% of

peak height:

Band Spreading (µL) = Peak Width (min) x Flow Rate (µL/min)

(For example, if peak width = 0.1 min and flow rate = 1000 µL/min,

band spread = 100 µL)

XSelect HSS XP 2.5 µm Columns 2

Page 3

[ CARE AND USE MANUAL ]

Programmed time = 5 minutes

System Volume

5

4.4 %h

Figure 2: Determination of system band spread volume using 5-Sigma Method.

Table 1: Expected System Band Spread Volumes

System Band Spread

Alliance 2695 HPLC 29 µL

Vendor A HPLC 41 µL

Vendor B UHPLC (600 bar) 28 µL

Vendor C UHPLC 21 µL

Vendor D UHPLC 17 µL

ACQUITY UPLC 12 µL

ACQUITY UPLC H-Class 9 µL

ACQUITY UPLC I-Class (FTN) 7.5 µL

ACQUITY UPLC I-Class (FL) 5.5 µL

6. At 5 minutes, program a step to 100% B, and collect data for an

additional 5 minutes.

7. Measure absorbance difference between 100% A and 100% B.

8. Measure time at 50% of that absorbance difference.

9. Calculate time difference between start of step and 50% point.

10. Multiply time difference by flow rate to calculate system volume.

50% Absorbance = 0.35852 AU

Time = 5.6953 minutes

0.70

0.65

0.60

0.55

0.50

0.45

0.40

5.69

0.35

0.30

5.00

0.25

0.69 min

0.20

0.15

0.10

0.05

0.00

0.00 2.00

= Programmed Gradient

= Actual Gradient

4.00

6.00 8.00

System Volume

0.69 min x 1.5 mL/min = 1.04 mL

Figure 3: Measuring system band spread volume.

100% Asymptotic

Total absorbance = 0.7164 AU

10.00

12.00 14.00

16.00

18.00 20.00

e. Measuring System Dwell Volume

Dwell volume is different than system band spreading. System dwell volume

is a measurement of the volume it takes for the initial gradient conditions to

reach the head of the column. This calculation is particularly useful when it is

necessary to transfer a method between different LC systems.

1. Disconnect the column from the system and replace with a

2. Use acetonitrile as mobile phase A, and acetonitrile with

3. Monitor UV at 254 nm.

4. Use the flow rate in the original method and the intended flow

5. Collect 100% A baseline for 5 minutes.

XSelect HSS XP 2.5 µm Columns 3

zero dead volume union.

0.05 mg/mL uracil as mobile phase B.

rate on the target instrument.

Table 2: Expected System Dwell Volumes

System Dwell Volume

Alliance 2695 HPLC 900 µL

ACQUITY UPLC 120 µL

ACQUITY UPLC H-Class 350 µL

ACQUITY UPLC I-Class (FTN) 100 µL

ACQUITY UPLC I-Class (FL) 95 µL

f. Column Equilibration

XSelect HSS XP 2.5 µm Columns are shipped in 100% acetonitrile. It is

important to ensure mobile-phase compatibility before changing to a

different mobile-phase system. Equilibrate the column with a minimum

of 10 column volumes of the mobile phase to be used (refer to Table

3 for a list of column volumes). The column may be considered fully

equilibrated once a constant backpressure is achieved.

Page 4

[ CARE AND USE MANUAL ]

Table 3: Column Volumes (mL)

Column Length

(mm)

30 0.10 0.21 0.50

50 0.17 0.35 0.83

75 0.26 0.53 1.25

100 0.35 0.71 1.66

To avoid precipitating mobile-phase buffers within the column or

system, flush the column with five column volumes of a waters/

organic solvent mixture using the same, or lower, solvent content

as in the desired buffered mobile phase (i.e., flush the column and

system with 60% methanol in water prior to introducing 60%

methanol/40% buffer mobile phase).

Note: If mobile-phase additives (i.e., ion-pairing reagents) are present in low

concentrations (<0.2% v/v), 100 to 200 column volumes may be required for

complete equilibration. In addition, mobile phases that contain formate (i.e.,

ammonium formate, formic acid) may require extended equilibration times.

2.1 mm 3.0 mm 4.6 mm

Internal Diameter

g. Solvent Conversion for Normal-Phase Use

XSelect HSS Cyano XP 2.5 µm Columns can be used for both reversed-

phase as well as normal-phase separations. The column is shipped in

100% acetonitrile and is ready for use in reversed-phase conditions.

If you intend to use the XSelect HSS Cyano Column for normal-

phase applications, the following solvent conversion procedure

must be followed:

1. Flush the column with a minimum of 20 column volumes of 100%

methanol using a low flow rate to avoid overpressuring the LC system.

Refer to Table 3 for column volume information.

2. Flush the column with a minimum of 20 column volumes of

100% isopropanol using a low flow rate to avoid overpressuring

the LC system. Refer to Table 3 for column volume information.

3. Flush the column with a minimum of 20 column volumes of 100%

dichloromethane using a low flow rate to avoid overpressuring the

LC system. Refer to Table 3 for column volume information.

4. Flush the column with the intended mobile-phase conditions

until a stable baseline is achieved.

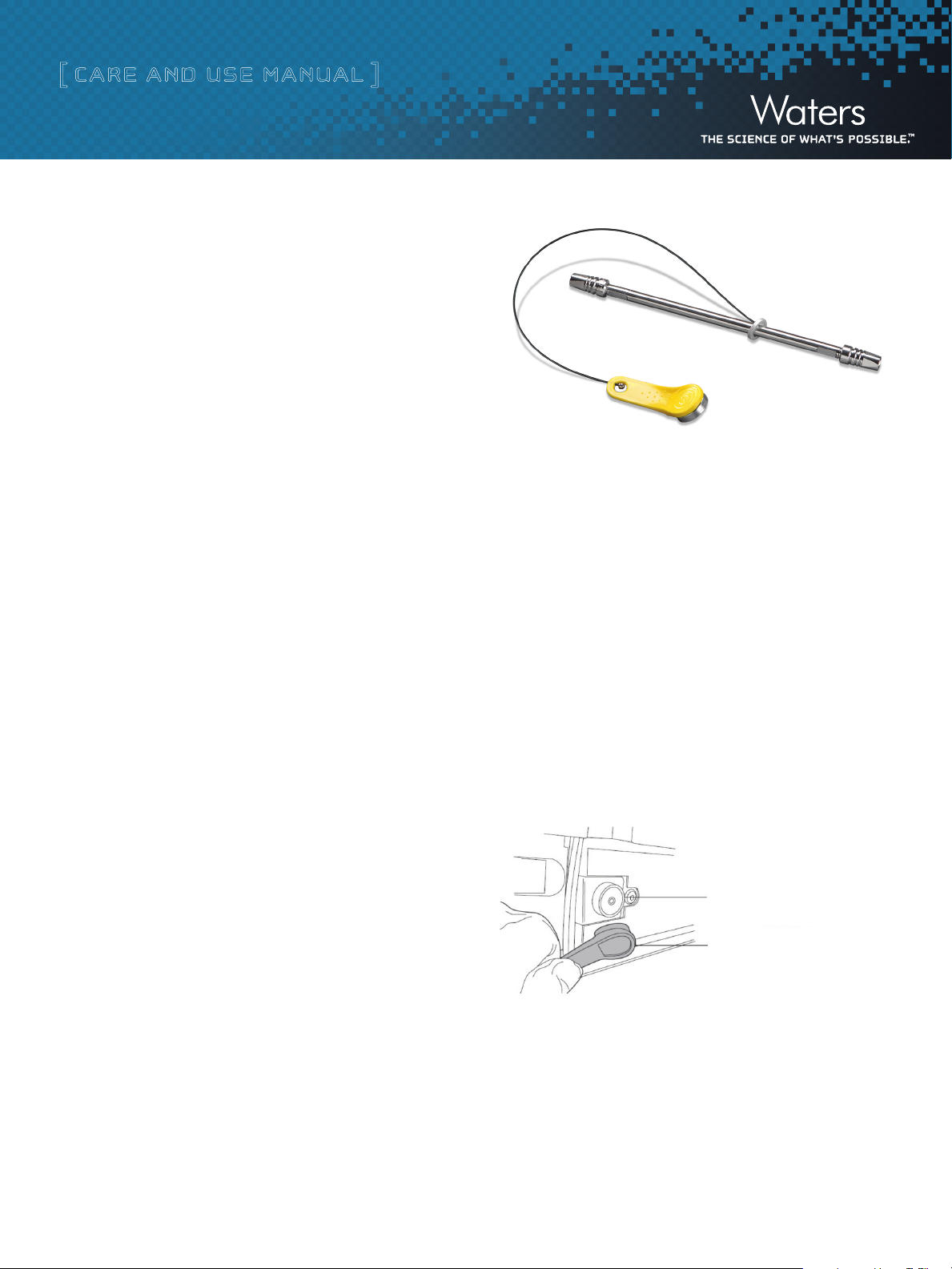

h. eCord Installation

eCord Technology represents a significant advancement in column

usage tracking management which can be realized if the column is

installed on an ACQUITY UPLC System. T he eCord can be read

by connecting the yellow fob to the reader/writer located on the

right-hand side of the ACQUITY UPLC Column heater module.

Embedded information such as the column manufacturing QC data

and Certificates of Analysis may then be accessed via the ACQUITY

UPLC console.

i. Initial Column Efficiency Determination

1. Perform an efficiency test on the column before using it to track

column performance over time. This test may consist of:

a. An analyte test mixture that is commonly used in your laboratory

b. An analyte mixture as found on the ‘Performance Test

Chromatogram’ which can be accessed via the eCord.

Note: If (b) is performed, the isocratic efficiencies measured in your laboratory may

be less than those given on the Waters Performance Test Chromatogram.

This is normal and expected. The Waters isocratic column testing systems

have been modified in order to achieve extremely low system dispersion.

This presents a more challenging test of how well the column was packed. This also

guarantees the highest quality packed column. These special testing systems have

been modified to such an extent that they are not commercially viable and have

limited method flexibility other than isocratic column testing.

2. Determine the number of theoretical plates (N) and use this value for

periodic comparisons.

3. Repeat the test periodically to track column performance over time.

Slight variations may be obtained on different LC systems due to the

quality of the connections, operating environment, system electronics,

reagent quality, column condition and operator technique.

j. VanGuard Pre-Columns

VanGuard™ Pre-Columns are 2.1 mm ID x 5 mm length guard column

devices designed specifically to protect an analytical column

while minimizing the negative dispersion impact of utilizing such a

device. VanGuard Pre-Columns are packed with the same stationary

phases as the XP 2.5 µm Column offering. VanGuard Pre-Columns

are designed to be directly attached to the inlet of a eXtended

Performance [XP] 2.5 µm Column.

XSelect HSS XP 2.5 µm Columns 4

Page 5

[ CARE AND USE MANUAL ]

Note: VanGuard Pre-Columns are shipped with a collet and ferrule that are NOT

pre-swaged. This enables the end user to mate the VanGuard Pre-Column to

a specific XP 2.5 µm Column and ensures void-free and leak-free connections.

Care must be taken when removing the O-ring that holds these two pieces

on the pre-column tubing.

XP 2.5 µm Column

Place wrench here

Ferrule

Flow

Figure 4: Installing a VanGuard Pre-Column.

Collet

VanGuard Pre-Column

Place wrench here

VanGuard Pre-Column Installation Instructions

1. Remove the VanGuard Pre-column from its box and shipping

tube and remove the plastic plug.

2. Orient the pre-column so that the male end is facing up and

carefully remove the black O-ring that holds the collet and

ferrule in place during shipment (collet and ferrule are not

permanently attached).

III. COLUMN USE

To ensure the continued high performance of XSelect HSS XP 2.5 µm

Columns, follow these guidelines:

a. Sample Preparation

1. Sample impurities and/or particulates often contribute to column

contamination. One option to avoid column contamination is to

use Waters Oasis® or Sep-Pak® Solid-Phase Extraction (SPE)

devices. To select the appropriate sorbent for a specific sample

type, visit www.waters.com/sampleprep

2. It is preferable to prepare the sample in the initial mobile-

phase conditions or a weaker solvent for the best peak shape

and sensitivity.

3. If the sample is not prepared in the mobile phase, ensure that

the sample, solvent and mobile phases are miscible in order to

avoid sample and/or buffer precipitation.

4. Filter sample with a 0.2 µm membrane to remove particulates.

If the sample is dissolved in a solvent that contains an organic

modifier (e.g., acetonitrile, methanol, etc.) ensure that the

membrane/filter material is compatible with the solvents

in use. Alternatively, centrifuge the sample for 20 minutes at

8000 rpm, followed by the transfer of the supernatant to an

appropriate vial could be considered.

3. Orient the XP 2.5 µm Column perpendicular to the work surface

so that the column inlet is on the bottom.

4. From below, insert the VanGuard Pre-Column into the column

inlet; turn the assembled column and pre-column 180° so that

the pre-column is now on top.

5. Tighten with two 5/16” wrenches placed onto the XP Column

flats and VanGuard Pre-Column hex nut (male end) as shown in

Figure 4.

6. While keeping pressure on the VanGuard Pre-Column against the

XP 2.5 µm Column, tighten turn to set the collet and ferrule.

7. Check that the ferrule is set by loosening the connection and

inspecting the ferrule depth.

8. Reattach the pre-column to the XP 2.5 µm Column, apply flow

and inspect for leaks.

XSelect HSS XP 2.5 µm Columns 5

b. pH Range

Table 4: Recommended pH Range

Chemistry pH Range

XSelect HSS Cyano 2 - 8

XSelect HSS PFP 2 - 8

XSelect HSS T3 2 - 8

XSelect HSS C18 SB 2 - 8

XSelect HSS C

18

Column lifetime will vary depending on the combination of temperature,

mobile-phase pH and type of buffer/additive used. Table 5 lists the

recommended buffers and additives for XSelect HSS XP 2.5 µm Columns.

Note: Working in combinations of extreme pH, temperature and pressure may result in

reduced column lifetime.

1 - 8

Page 6

[ CARE AND USE MANUAL ]

Table 5: Buffer Recommendations for

XSelect HSS XP 2.5 µm Columns

Buffer

Additive or

Buffer

TFA 0.3 – Volatile Yes

Formic

Acid

Acetic Acid 4.76 – Volatile Yes

Formate

(HCOO-)

Acetate

(CH3COO -)

Phosphate 1 2 .15

Phosphate 2 7.2

Range

pKa

3.75 – Volatile Yes

3.75

4.76

(±1 pH

unit)

2.75 –

4.75

3.76 –

5.76

1.15 –

3.15

6.20 –

8.20

Volatility

Volatile Yes

Volatile Yes

volatile

volatile

Non-

Non-

Used for

Mass

Spec?

No

No

Comments

Ion pair additive, can suppress

MS signal. Used in the 0.01-

0.1% range.

Maximum buffering obtained

when used with ammonium

formate salt. Used in 0.1-1.0 %

range.

Maximum buffering obtained

when used with ammonium

acetate salt. Used in 0.1-1.0%

range.

Used in the 1-10 mM range.

Note: sodium or potassium salts

are not volatile.

Used in the 1-10 mM range.

Note: sodium or potassium salts

are not volatile.

Traditional low-pH buffer, good

UV transparency.

Much shorter colum lifetimes

will be realized using phosphate

at pH 7.

e. Temperature

XSelect HSS XP 2.5 µm Columns can be used up at intermediate

temperatures to enhance selectivity, reduce solvent viscosity and

increase mass transfer rates.

Chemistry Temperature Limit

XSelect HSS Cyano 45 °C

XSelect HSS PFP 45 °C

XSelect HSS T3 45 °C

XSelect HSS C18 SB 45 °C

XSelect HSS C

18

45 °C

Note: Working in combinations of extreme pH, temperature and pressure may

result in reduced column lifetime.

IV. COLUMN CLEANING, REGENERATION AND STORAGE

a. Cleaning and Regeneration

Changes in peak shape, peak splitting, shouldering peaks, shifts

in retention, change in resolution or increasing backpressure may

indicate contamination of the column. Flush with a neat organic

solvent to remove the non-polar contaminant(s), taking care not to

precipitate any buffered mobile-phase components. If this flushing

procedure does not solve the problem, purge the column with the

following cleaning and regeneration procedures.

c. Solvents

To maintain maximum column performance, use high quality HPLC

or MS grade solvents. Filter all aqueous buffers prior to use through

a 0.2 µm filter. Solvents containing suspended particulate materials

will generally clog the outside surface of the inlet of the column. This

may result in higher backpressure or distorted peak shape.

d. Pressure

XSelect HSS XP 2.5 µm Columns are compatible with HPLC, UHPLC

and UPLC pressures. Table 6 depicts the maximum operation pressure

Table 6: Maximum Operation Pressure

Column ID Pressure Range

2.1 mm 18,000 psi [1034 bar]

3.0 mm 18,000 psi [1034 bar]

4.6 mm 9000 psi [620 bar]

XSelect HSS XP 2.5 µm Columns 6

Use a cleaning routine that matches the properties of the samples,

stationary-phase type (reversed-phase, normal-phase or HILIC) and

will solubilize the suspected contaminate. Flush with 20 column

volumes of solvent at an intermediate temperature of 45 °C. Return

to the initial mobile-phase conditions by reversing the sequence.

If using a reversed-phase column, purge the column with a sequence

of progressively more non-polar solvents (i.e., water-to-methanol-to-

tetrahydrofuran-to-methylene chloride).

If using a HILIC column, purge the column with a

sequence of progressively more polar-organic solvents

(i.e., acetonitrile-to-acetonitrile/methanol-to-acetonitrile/

water-to-water).

If column performance has not improved after regeneration/

cleaning procedures, contact your local Waters representative

for additional support.

Page 7

[ CARE AND USE MANUAL ]

Heater compartment receptacle

eCord fob

b. Storage after Reversed-Phase Use

For periods longer than four days, store the XP 2.5 µm Column in

100% acetonitrile. For separations utilizing elevated temperature,

store immediately after use in 100% acetonitrile. Do not store

columns in buffered eluents. If the mobile phase contained a buffer

salt, flush the column with 10 column volumes of HPLC grade water

(see Table 3 for column volume information) followed by 10 column

volumes of acetonitrile. Failure to perform this intermediate step

could result in precipitation of the buffer salt in the column when

100% acetonitrile is introduced. Completely seal the column to avoid

solvent evaporation and drying out of the chromatographic bed.

Note: If a column has been run with a formate-containing mobile phase (e.g.,

ammonium formate, formic acid, etc.) and is purged with 100% acetonitrile,

slightly longer equilibration times may be necessary when the column is re-

installed and re-wetted with that same formate-containing mobile phase.

c. Storage after Normal-Phase Use

For rapid equilibration upon start-up, store the XP 2.5 µm Column in

a mobile phase that is commonly used for your normal-phase separa-

tion (i.e., hexane/isopropanol). Completely seal the column to avoid

solvent evaporation and drying out of the chromatographic bed.

V. e CORD INTELLIGENT CHIP TECHNOLOGY

Figure 5: eCord Intelligent Chip.

At the time of manufacture, information such as the performance test

chromatogram, column manufacturing QC data and Certificates of

Analysis is downloaded onto the eCord. This information may then be

accessed via the ACQUITY UPLC console once the column is installed.

b. Installation

The eCord device can be read by connecting the yellow fob to the

reader/writer located on the right-hand side of the ACQUITY UPLC

Column heater module. Once the eCord is connected to the magnetic

catch on the column heater, column identification and overall column

usage information can be accessed.

a. Introduction

The eCord™ Intelligent Chip Technology represents a significant

advancement in column usage tracking management which can be

realized if the column is installed on an ACQUITY UPLC System.

The eCord Intelligent Chip provides a paperless tracking history of the

column’s performance and usage throughout its lifetime. The eCord

is permanently attached to the column body via a tether that cannot

be removed. T his ensures that the history of the column is always

accessible to the user of that column.

XSelect HSS XP 2.5 µm Columns 7

Figure 6: Installing the eCord Intelligent Chip.

Page 8

[ CARE AND USE MANUAL ]

c. Manufacturing

The eCord provides the user with the Batch Certificate of Analysis and

Performance Test Chromatogram.

d. Column Use

The eCord Intelligent Chip provides the user with specific column

information as well as column use data including: chemistry type,

column dimension, serial number and part number. The overall

column use information includes: total number of samples injected,

total number of injections as well as the maximum pressure and

temperature that the column has been exposed to. Additionally,

detailed column history includes the sample set start date, user name

and system name.

Figure 7: Manufacturing results stored on an eCord.

Figure 8: Column use information.

VI. ADDITIONAL INFORMATION

a. Tips for Maximizing XSelect HSS XP 2.5 µm

Column Lifetime

1. To maximize XP 2.5 µm Column lifetime, pay close attention to:

Water quality (including water purification systems).

Solvent quality.

Mobile-phase preparation, storage and age.

Sample, buffer and mobile-phase solubilities.

Sample quality and preparation.

2. When problems arise, systematically troubleshoot potential causes one

variable at a time in a systematic fashion.

XSelect HSS XP 2.5 µm Columns 8

Page 9

[ CARE AND USE MANUAL ]

3. Always remember to:

Use an in-line filter unit (Part No. 205000343) or a

VanGuard Pre-Column.

Discourage bacterial growth by minimizing the use of

100% aqueous mobile phases where possible.

Discard and re-prepare aqueous mobile phase every

24-48 hours (if 100% aqueous mobile phase is required).

Add 5 – 10% organic modifier to aqueous buffer to

minimize bacterial growth (adjust gradient profile

as necessary).

Filter aqueous portions of mobile phase through a 0.2 µm filter.

Routinely maintain your water purification system to

ensure it is functioning properly.

Only use ultra-pure water (18 MegaOhm-cm) and highest

quality solvent possible.

Consider sample preparation (e.g., solid-phase extraction,

filtration, centrifugation, etc.) when possible.

4. Avoid when possible:

100% aqueous mobile phases

HPLC-grade bottled water

‘Topping off’ your mobile phases

Using phosphate salt buffer in combination with

high acetonitrile concentrations (e.g., >70%) due

to precipitation.

b. Troubleshooting Questions

1. Are you using 100% aqueous mobile phases?

2. What is the age of the mobile phase?

3. Is the mobile phase filtered through a 0.2 µm membrane?

4. Was the mobile phase prepared fresh or topped off?

5. Is the water source of adequate quality?

6. When was the last time the water system was serviced or was

the bottle of water unopened?

7. Is bacterial growth a possibility (pH 7 phosphate buffer is

susceptible to bacterial growth within 24 hours)?

8. If a neat standard is prepared in the initial mobile-phase

conditions and injected, are the problems still observed?

9. If the sample is filtered/purified (i.e., SPE, filtration) is the

problem still observed?

10. Has the quality of the samples changed over time?

5. Don’t assume the column is to blame:

Investigate cause of column failure

Monitor backpressure

Mobile-phase age, bacterial contamination, mobile-phase

precipitation...etc.

Peak splitting

Sample quality

Injection solvent strength.

6. Do not prepare excessive amounts of mobile phase:

To reduce the chances of mobile-phase contamination

or degradation, prepare enough mobile phase to last for

3 – 4 days. Alternatively, store excess bulk quantities in

a refrigerated environment.

XSelect HSS XP 2.5 µm Columns 9

Page 10

[ CARE AND USE MANUAL ]

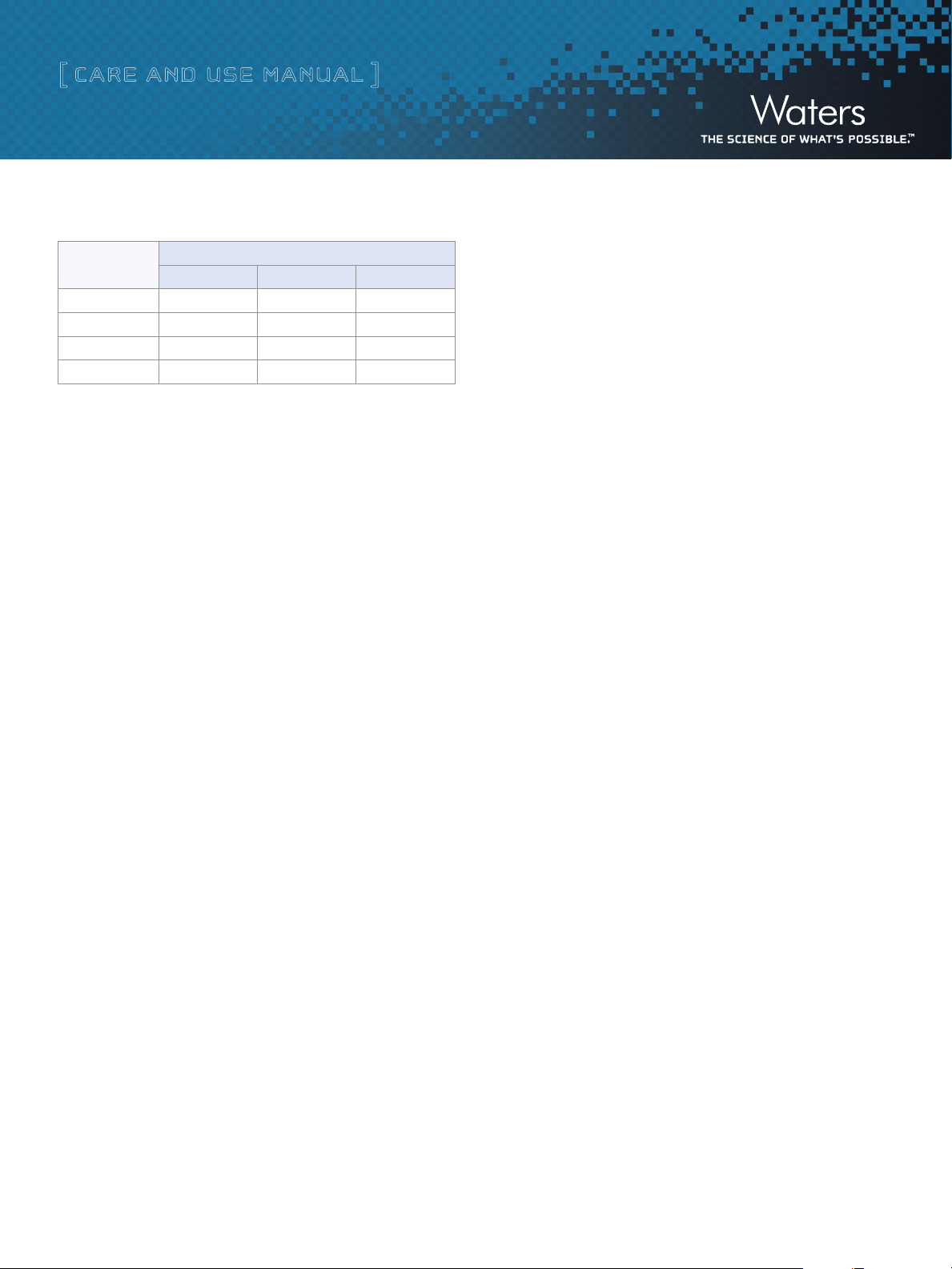

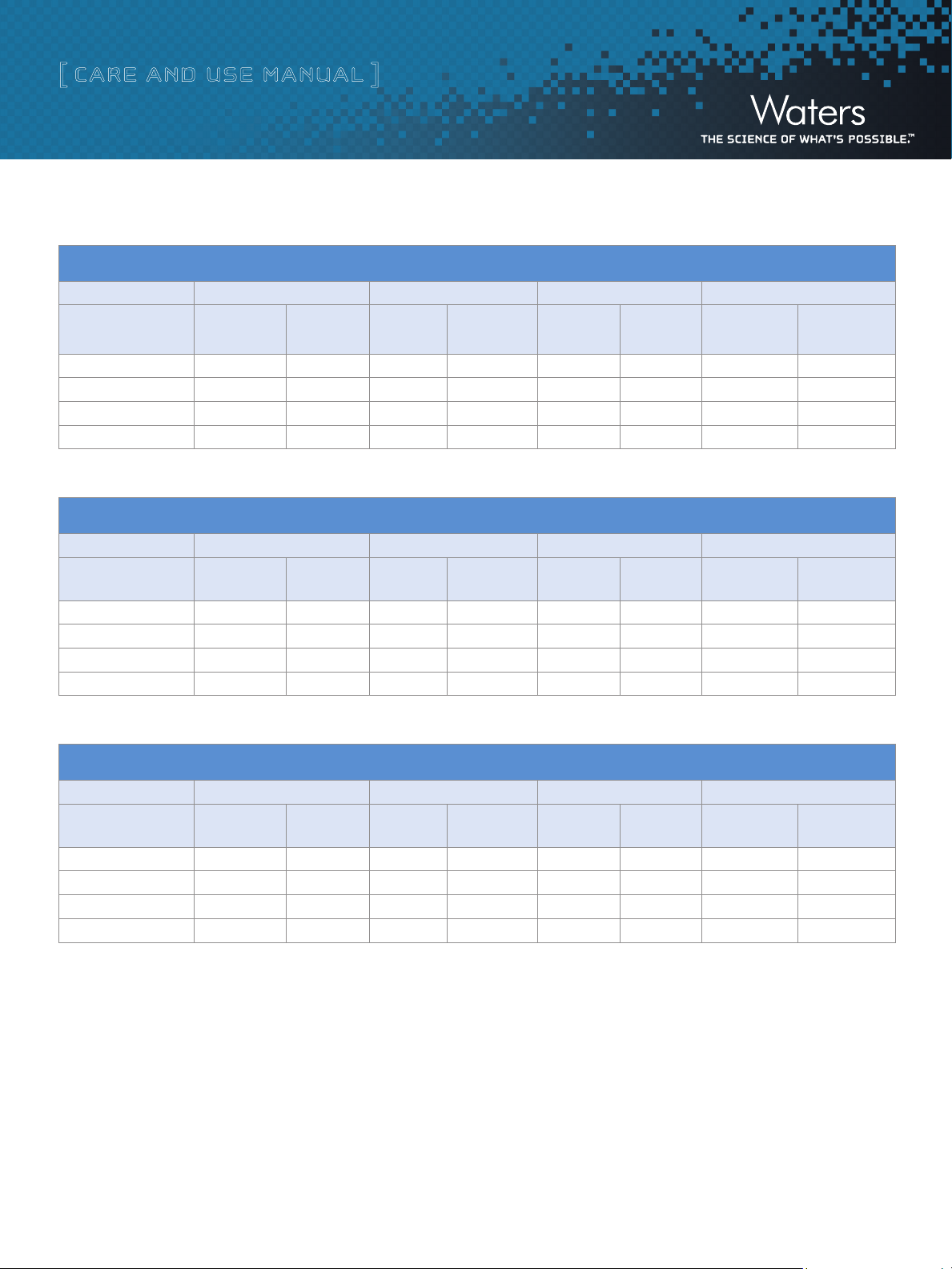

c. Recommended Flow Rates and Anticipated Backpressures for Reversed-Phase XSelect HSS XP 2.5 µm Columns

XP 2.5 µm, 2.1 mm ID Columns (40 °C)

Linear Velocity 3 mm/sec 4 mm/sec 5 mm/sec 6 mm/sec

Column Dimension

2.1 x 30 mm 0.45 1760 0.6 2350 0.75 2940 0.9 3520

2.1 x 50 mm 0.45 2640 0.6 3520 0.75 4400 0.9 5280

2.1 x 75 mm 0.45 3740 0.6 4980 0.75 6230 0.9 7470

2.1 x 100 mm 0.45 4830 0.6 6440 0.75 8055 0.9 9670

Flow Rate

[mL/min]

Backpressure

[psi]

Flow Rate

[mL/min]

XP 2.5 µm, 3.0 mm ID Columns (40 °C)

Backpressure

[psi]

Flow Rate

[mL/min]

Backpressure

[psi]

Flow Rate

[mL/min]

Backpressure

[psi]

Linear Velocity 3 mm/sec 4 mm/sec 5 mm/sec 6 mm/sec

Column Dimension

3.0 x 30 mm 0.9 2180 1.17 2840 1.53 3710 1.8 4360

3.0 x 50 mm 0.9 3040 1.17 3950 1.53 5170 1.8 6080

3.0 x 75 mm 0.9 4120 1.17 5350 1.53 7000 1.8 8230

3.0 x 100 mm 0.9 5190 1.17 6750 1.53 8825 1.8 10380

Linear Velocity 3 mm/sec 4 mm/sec 5 mm/sec 6 mm/sec

Column Dimension

4.6 x 30 mm 2.1 3360 2.8 4480 3.5 5600 4.2 6720

4.6 x 50 mm 2.1 4210 2.8 5620 3.5 7020 4.2 8430

4.6 x 75 mm 2.1 5280 2.8 7040 3.5 8800 4.2 10560

4.6 x 100 mm 2.1 6350 2.8 8460 3.5 10580 4.2 12700

Flow Rate

[mL/min]

Flow Rate

[mL/min]

Backpressure

[psi]

Backpressure

[psi]

Flow Rate

[mL/min]

XP 2.5 µm, 4.6 mm ID Columns (40 °C)

Flow Rate

[mL/min]

Backpressure

[psi]

Backpressure

[psi]

Flow Rate

[mL/min]

Flow Rate

[mL/min]

Backpressure

[psi]

Backpressure

[psi]

Flow Rate

[mL/min]

Flow Rate

[mL/min]

Backpressure

Backpressure

[psi]

[psi]

XSelect HSS XP 2.5 µm Columns 10

Page 11

[ CARE AND USE MANUAL ]

Austria and European Export

(Central South Eastern Europe, CIS

and Middle East) 43 1 877 18 07

Australia 61 2 9933 1777

Belgium 32 2 726 1000

Brazil 55 11 5094-3788

Canada 1 800 252 4752 x2205

China 86 21 6879 5888

CIS/Russia +497 727 4490/290 9737

Czech Republic 420 2 617 1 1384

Denmark 45 46 59 8080

Finland 09 5659 6288

France 33 1 30 48 72 00

Germany 49 6196 400600

Hong Kong 852 2964 1800

The Netherlands 31 76 508 7200

Norway 47 6 384 60 50

Poland 48 22 6393000

Puerto Rico 1 787 747 8445

Singapore 86 21 6879 5888

Spain 34 936 009 300

Sweden 46 8 555 11 500

Switzerland 41 56 676 70 00

Taiwan 886 2 2543 1898

United Kingdom 44 208 238 6100

All other countries:

Waters Corporation U.S.A.

1 508 478 2000

1 800 252 4752

www.waters.com

Hungary 36 1 350 5086

India and India Subcontinent

91 80 2837 1900

Ireland 353 1 448 1500

Italy 39 02 265 0983

Japan 81 3 3471 7191

Korea 82 2 6300 4800

Mexico 52 55 5524 7636

©2012 Waters C orporation. Waters, AC QUIT Y UPLC, UPLC,

Oasis and Sep-Pak are registered trademarks of Waters

Corporation. XSelect, eC ord, VanGuard, and The Science of

What's Possible are trademarks of Waters Corporation. All

other trademarks are the property of ther i respective owners.

March 2012 720004163EN RevB VW-IH -PDF

Waters Corporation

34 Maple Street

Milford, MA 01757 U.S.A.

T: 1 508 478 2000

F: 1 508 872 1990

www.waters.com

XSelect HSS XP 2.5 µm Columns 11

Loading...

Loading...