Page 1

[ CARE AND USE MANUAL ]

XBridge Protein BEH SEC Columns and Standards

CONTENTS

I. INTRODUCTION

II. SYSTEM CONSIDERATIONS FOR

SEC SEPARATIONS

a. Getting Started

b. Column Installation

c. Column Equilibration

d. Useful Functional Tests for Benchmarking LC System

and XBridge Protein BEH SEC Column

III. COLUMN SPECIFICATIONS AND USE

a. SEC Eluent and Needle Wash Preparation

b. Sample Preparation

c. Column Specification

IV. TROUBLESHOOTING

V. COLUMN CLEANING, REGENERATION

AND STORAGE

a. Cleaning and Regeneration

b. Storage

I. INTRODUCTION

Waters family of XBridge® Protein BEH SEC 200Å and 450Å,

3.5 µm Columns was developed to complement the existing line of

UPLC®-based SEC offerings for use where traditional HPLC-based

instrumentation and methods are employed for peptide or protein

size-exclusion chromatography (SEC). These new HPLC-based, SEC

chemistries are based on the same Waters Ethylene Bridged Hybrid

(BEH)-based particle technology and diol-bonded surface coating

as used in our successful line of UPLC-based SEC columns. This

process offers chromatographers the option and ability to easily

transfer methods based on lab instrumentation and component

resolution or sample throughput needs.

All of Waters BEH-based SEC columns are manufactured in a cGMP,

ISO 9001 certified plant using stringent manufacturing protocols

and ultra pure reagents. Each batch of manufactured material

undergoes a series of standard QC measurements (e.g., particle

and pore size distribution) followed by an application specific

test using appropriate peptide and protein test mixture. A packed

column efficiency test is then performed on every batch approved,

packed SEC column to further help ensure reproducible batch to

batch and column to column performance for use in research or in a

demanding validated method.

Page 2

[ CARE AND USE MANUAL ]

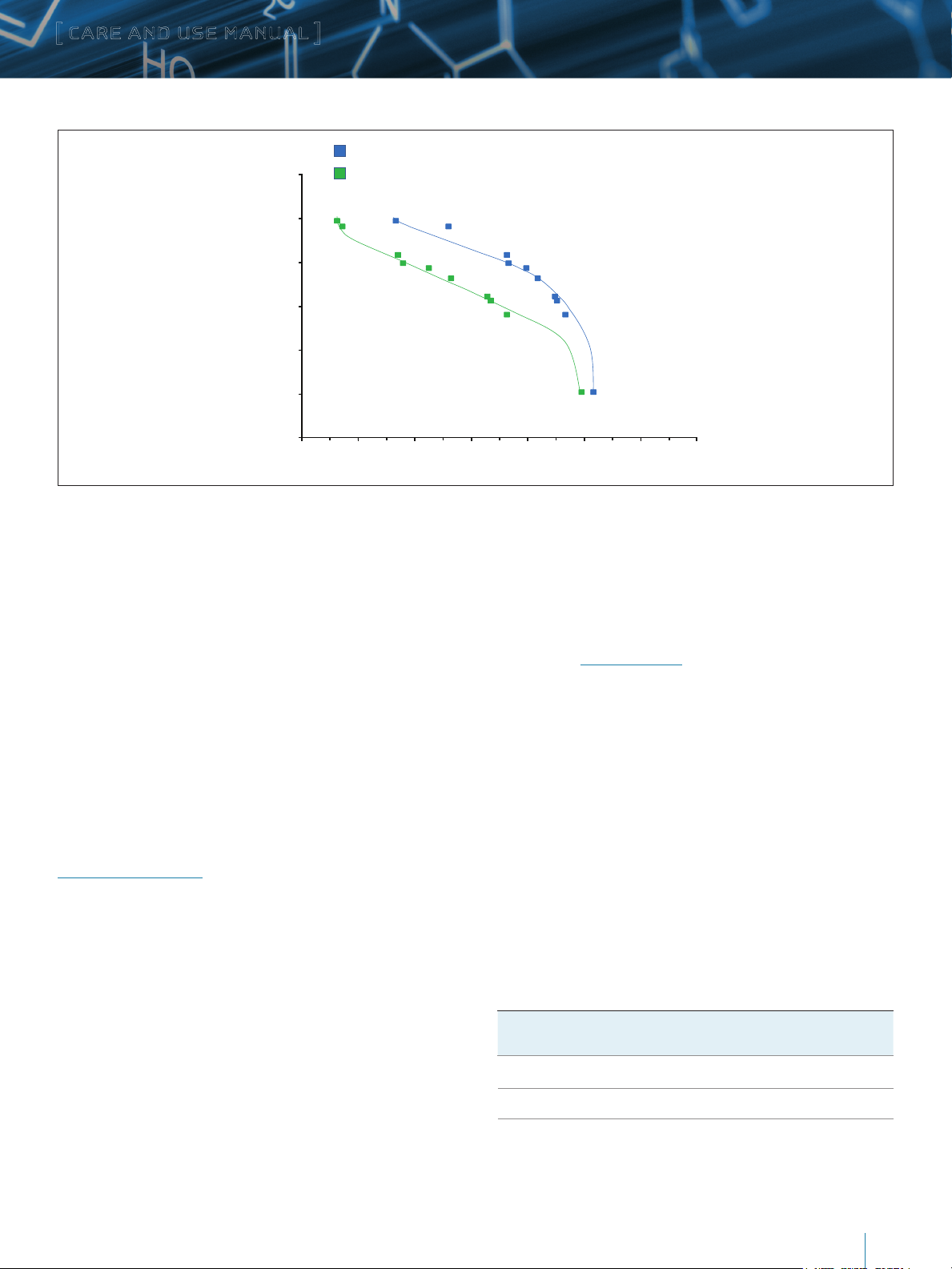

Uracil (112 Da)

Aprotinin (6.5 KDa)

RNAse A (14 KDa)

Myoglobin (17 KDa)

Ovalbumin (44 KDa)

Conalbumin (75 KDa)

Amyloglucosidase (97 KDa)

IgG (150 KDa)

Thyroglobulin (669 KDa)

IgM (900 KDa)

10

100

1,000

10,000

100,000

1,000,000

10,000,000

0.3 0.4 0.5 0.6 0.7 0.8 0.9 1

Protein Molecular Weight (KDa)

Normalized Retention Volume (Vr/VC)

XBridge Protein BEH SEC 450Å, 3.5 µm, 100K – 1,500K Daltons

XBridge Protein BEH SEC 200Å, 3.5 µm, 10K – 450K Daltons

Figure 1: Calibration Curves on XBridge Protein BEH SEC 200Å and 450Å Columns

II. SYSTEM CONSIDERATIONS FOR

SEC SEPARATION

a. Getting Started

In order to obtain the best performance from your Waters XBridge

Protein BEH SEC Column, it is important that your LC system be

properly configured. It is recommended that only pre-cut tubing is

used, and that the ID of all connecting tubing is 0.005” or less for

optimal chromatographic performance.

Size-exclusion chromatography may require modifications to

an existing LC system. Please refer to “Size-Exclusion and IonExchange Chromatography of Proteins using the ACQUITY UPLC

System” (P/N 715002147A that can be obtained at

www.waters.com/chemcu) for examples of LC System components

that can affect SEC results.

The sample loop used may affect the performance of your

separation. Optimally, select the smallest volume sample loop that

is required for the application. Sample loops larger than 20 µL are

not recommended.

b. Column Installation

1. Prior to placing the column on the system, purge the solvent

delivery system of any organic or water-immiscible mobile

phases. When connecting the column, orient it in the proper

direction as noted by the arrow on the column inlet side which

indicates the correct direction of solvent flow.

2. Flush column with 100% aqueous buffer, by pumping at a flow

rate of 0.2 mL/min.

3. Ensure that the mobile phase is flowing freely from the column

outlet. Attach the column outlet to the detector using .004”

ID tubing (P/N 430001562). Monitor the system pressure to

ensure the column is within its pressure limitations.

4. Gradually increase the flow rate, by not more than 0.1 mL/min

at a time, as described in Step 2.

5. Once the system pressure has stabilized, ensure that there are

no leaks at either the column inlet or outlet.

c. Column Equilibration

XBridge Protein BEH SEC Columns are shipped in 20% methanol

in water. It is important to ensure mobile-phase compatibility

before changing to a different mobile-phase system. Equilibrate

the column with a minimum of 10 column volumes of the buffer to

be used (refer to Table 1 for column volumes).

Column Dimension Approximate Volume

7.8 x 150 mm 7 mL

7.8 x 300 mm 14 m L

Table 1. Empty Column Volumes in mL (multiply by 10 for flush solvent volume)

XBridge Protein BEH SEC Columns and Standards

2

Page 3

[ CARE AND USE MANUAL ]

d. Useful Functional Tests for Benchmarking LC System and

XBridge Protein BEH SEC Column

Waters recommends performing a benchmarking test upon

receipt of your column and throughout the lifetime usage. By

using a separation of common proteins with an appropriate

method, you can:

Verify the performance of the column upon receipt.

Monitor the condition of the columns for extended use.

Troubleshoot separation difficulties that may arise.

Waters BEH200 SEC Protein Standard Mix (P/N 186006518)

and BEH450 SEC Protein Standard Mix (P/N 186006842) were

specifically designed for this purpose with carefully chosen

proteins and/or peptides to provide a good representation of the

intended application.

The information below details how to successfully prepare and

use the included BEH SEC Protein Standard for benchmarking or

troubleshooting purposes. Figures 2 and 3 provide separation

conditions and results you should expect to obtain.

Buffer Preparation

Chemicals:

Sodium phosphate monobasic, monohydrate

Sodium phosphate dibasic, anhydrous

HPLC-grade water

1

0.036

0.024

AU

0.012

0.000

0.00 1.00 2.00 3.00 4.00 5.00 6.00 7.00 8.00 9.00 10.00

1.) Thyroglobulin, 2.) IgG FU, 3.) BSA, 4.) Myoglobin, 5.) Uracil

Figure 2: Protein Mixture separation on XBridge Protein BEH SEC 200,

3.5 µm 7.8 x 150

4

3

2

5

Minutes

Analyte pl MW

1. Thyroglobulin, 3 mg/mL 4.6 669,000

2. IgG, 2 mg/mL 6.7 150,000

3. BSA, 5 mg/mL 4.6 66,400

4. Myoglobin, 2 mg/mL 6.8, 7.2 17,000

5. Uracil, 0.1 mg/mL N/A 112

Table 2: BEH200 SEC Test Mix

Conditions:

Instrument: ACQUITY TUV with Tunable UV detector

Column: XBridge Protein BEH SEC, 200Å, 3.5 μm,

7.8 x 150 mm

Preparation of 100 mM sodium phosphate buffer (500 mL):

1. Weigh out 500 ± 0.02 g of water into a 500 mL beaker.

2. Weigh out 3.55 ± 0.02 g of sodium phosphate dibasic and add

to the 500 mL beaker.

3. Weigh out 3.45 ± 0.02 g of sodium phosphate monobasic and

add to the 500 mL beaker.

4. Stir for a minimum of 30 minutes then filter the solution

through a 0.2 µm filter.

5. Take the pH and record the value for reference purposes

(approximate pH: 6.8).

Sample: BEH200 SEC Protein Standard Mix

(P/N 186006518)

Mobile phase: 100 mM sodium phosphate, pH 6.8

Weak needle wash: 100% Milli-Q

®

water

Strong needle wash: 100% Milli-Q water

Seal wash: 90/10 water/methanol

Injection type: Full loop

Injection volume: 2 µL

Flow rate: 0.86 mL/min

Column temp.: Ambient

Detection: UV @ 280 nM

XBridge Protein BEH SEC Columns and Standards

3

Page 4

[ CARE AND USE MANUAL ]

5

0.030

3

0.020

AU

0.010

1

0.000

0.00 1.00 2.00 3.00 4.00 5.00 6.00 7.00 8.00 9.00 10.00

1.) Thyroglobulin dimer, 2.) Thyroglobulin, 3.) IgG FU, 4.) BSA, 5.) Myoglobin, 6.) Uracil

Figure 3: Protein Mixture separation on XBridge Protein BEH SEC 450,

3.5 µm 7.8 x 150 mm

4

6

2

Minutes

Analyte pl MW

1. Thyroglobulin, 0.1 mg/mL 4.6 669,000

2. Thyroglobulin, Approx 3 mg/mL 4.6 669,000

3. IgG, 2 mg/mL 6.7 150,000

4. BSA, 5 mg/mL 4.6 66,400

5. Myoglobin, 2 mg/mL 6.8, 7.2 17,000

6. Uracil, 0.1 mg/mL N/A 112

Table 3: BEH450 SEC Test Mix

Conditions:

Instrument: ACQUITY TUV with Tunable UV detector

Column: XBridge Protein BEH SEC, 450Å, 3.5 μm,

7.8 x 150 mm

III. COLUMN SPECIFICATIONS AND USE

To ensure the continued high performance of XBridge Protein BEH

SEC, 3.5 µm Columns, follow these guidelines:

a. SEC Eluent and Needle Wash Preparation

Use HPLC-grade buffers, water, and organic solvents

when possible.

Filter solutions through a compatible 0.2 µm or smaller pore size

filter. The use of a sterile filtration apparatus is recommended

for buffers capable of supporting microbial growth.

Solutions that are susceptible to microbial growth should be

replaced at regular intervals to avoid column contamination.

Do NOT refill partially full SEC eluent bottles with new eluent.

Rather, when required use new bottle containing freshly

prepared SEC eluent.

Select solvent inlet filters that are compatible with solutions

used, and clean or replace filters regularly when using

solutions that are susceptible to microbial growth.

b. Sample Preparation

Ensure that samples are free of particulates before injecting

onto the SEC column. If samples appear cloudy or turbid,

they should not be injected, as this could lead to column

pressure increases. Sample preparation such as filtration or

centrifugation may be used, if appropriate.

If the sample is not dissolved in the mobile phase, ensure that

the sample, solvent and mobile phases are miscible in order to

avoid sample and/or buffer precipitation.

Sample: BEH450 SEC Protein Standard Mix

(P/N 186006842)

Mobile phase: 100 mM sodium phosphate, pH 6.8

Weak needle wash: 100% Milli-Q water

Strong needle wash: 100% Milli-Q water

Seal wash: 90/10 water/methanol

Injection type: Full loop

Injection volume: 2 µL

Flow rate: 0.86 mL/min

Column temp.: Ambient

Detection: UV @ 280 nM

c. Column Specifications

Shipping solvent: 20% methanol in water

Recommended maximum flow rate and backpressure:

XBridge Protein BEH SEC 200, 7.8 x 150 mm:

4 mL/min/2,600 psi

XBridge Protein BEH SEC 200, 7.8 x 300 mm:

2.7 mL/min/3,200 psi

XBridge Protein BEH SEC 450, 7.8 x 150mm:

4mL/min / 2600psi

XBridge Protein BEH SEC 450, 7.8 x 300mm:

2.7 mL/min / 3200psi

XBridge Protein BEH SEC Columns and Standards

4

Page 5

[ CARE AND USE MANUAL ]

Mass load: < 300 μg for a 7.8 x 150 mm

Volume load: < 60 μL for 7.8 x 150 mm

Recommended pH range: 2 to 8. The column lifetime will vary

depending upon the operating temperature as well as the type

and concentration of buffer used.

Recommended salt conc.: less than or equal to 0.5 M

Recommended organic conc.: < 20% acetonitrile

(Caution: Many proteins are insoluble at elevated organic

concentrations. Prior to chromatography, test to ensure the sample

does not precipitate at the organic concentration to be used for

the chromatography. Also, if column is run under denaturing

conditions (greater than 10% organic), subsequent column

performance under 100% aqueous conditions may be affected.)

Recommended temperature: 4–60 °C. Reduce flow rate when

operating at low temperatures (e.g. 10 °C) to avoid excessive

column pressure.

Recommended storage: For overnight storage, continuously

flush the column with the mobile phase at 10–20% of the

maximum recommended flow rate. Store the column in the

HPLC-grade water when it will be used within 24 hrs or in 20%

methanol for long term storage.

Note: Working at extremes of pressure, pH and/or temperature may

result in shorter column lifetimes.

IV. TROUBLESHOOTING

The first step in systematic troubleshooting is comparison of the

column performance in its current state to the performance when

it was functioning properly. The functional tests with the protein

mixture may reveal subtle changes in surface chemistry that affect

the application.

There are several common symptoms of change in the column.

1. An increase in pressure is often associated with decreased

performance in the application. The first step in diagnosis is

to ensure that the elevated pressure resides in the column

rather than somewhere else in the system. This is determined

by monitoring pressure of the system as each connection

is broken from the outlet end to the inlet. If the system is

occluded, the blockage should be identified and removed. If the

pressure increase resides in the column, it is helpful to know

whether the problem was associated with a single injection or

whether it occurred over a series of injections. If the pressure

gradually built up, it is likely that the column can be cleaned

as described in Section VI. If a single sample caused the

pressure increase, it likely reflects particulates or insoluble

components, such as lipids or higher order aggregates.

Cleaning is still an option, but using the more aggressive

options. If samples appear cloudy or turbid, they should not

be injected, as this will lead to pressure increases. Sample

preparation such as filtration or centrifugation may be used,

but one should first check whether this impacts the results.

2. Loss of resolution and increased peak tailing can be caused

by microbial contamination. It is important to follow

good standard laboratory practices to prevent microbial

contamination. This includes changing buffer bottles

frequently, using high purity water, using a sterile filtration

apparatus, and storing system and column under recommended

conditions. If microbial contamination has occurred, cleaning

the column will have no effect on performance. When changing

the flow rate, ramp it at a rate of 0.1 mL/min and avoid

immediate flow-rate increases greater than 0.1 mL/min.

3. Increased peak tailing can be caused by failure of a tubing

connector or a build-up of material on the column inlet frit.

Before proceeding with diagnostic or corrective measures,

check all connections that the mobile phases have been

correctly prepared and the correct method has been selected.

Then repeat the protein standard test. If the proteins shows

increased peak tailing, it is likely that there is significant

build-up of material on the column inlet and the column will

require replacement.

4. Carryover is defined as the appearance of the constituents

of one sample in the next analysis. In size-exclusion

chromatography carryover is typically due to system

components or improper wash solvents. Run a blank injection.

If the protein peaks only appear when an injection is made,

they likely originate from system component or inadequate

wash solvents. Adsoprtion in the system components most

likely occurs in the loop or needle. In these instances the

component may need to be changed.

Note: Useful general information on column troubleshooting

problems may be found in HPLC Columns Theory, Technology

and Practice, U.D. Neue (Wiley-VCH, 1997), the Waters HPLC

Troubleshooting Guide (Literature code 720000181EN), and the

Waters website, www.waters.com.

XBridge Protein BEH SEC Columns and Standards

5

Page 6

[ CARE AND USE MANUAL ]

V. COLUMN CLEANING, REGENERATION

AND STORAGE

a. Cleaning and Regeneration

Changes in peak shape, such as increased tailing, shoulders on

the peak, shifts in retention, change in resolution, ghost peaks,

or increased backpressure may indicate contamination of the

column. Choose a cleaning option that may be expected to

dissolve the suspected contaminant.

It may be useful to conduct cleaning procedures at one-half

the flow rate typically used with that column. In this way the

possibility of high pressure events is reduced.

Recommended cleaning solvents:

a. A concentrated salt solution at low pH (e.g. 0.5 M Na SO, pH 2.7).

b. A low concentration of methanol (e.g., 20%) in HPLC-grade water.

c. Use of ionic detergents and other surfactants should be

avoided if the SEC column is to be subsequently used to

analyze native proteins.

b. Storage

For overnight storage, continuously flush the column with the

mobile phase at 20% of the maximum recommended flow rate.

Store the column in the HPLC-grade water when it will be used

within 24 hours or in 20% methanol for long term storage.

Note: Working at extremes of pressure, pH and/or temperature may

result in shorter column lifetime.

Note: Choose a cleaning solvent based on sample properties, e.g.

use (a) to remove basic protein and (b) to remove hydrophobic

proteins. Chaotrophic agents can solvate strongly adsorbed

proteins via hydrogen bond disruption.

As a last resort, flow reversal or back flushing can be tried

at a low flow rate (e.g., 0.1 mL/min). However, this approach

may further damage the column or only provide short-lived

improvement in performance.

Waters, The Science of W hat’s Possible, XBridge and UPLC are registered trademarks of Waters Corporation.

All other trademarks are the property of their respective owners.

©2014 Waters Corporation. Produced in the U.S.A. October 2014 720005206EN AW-PDF

Waters Corporation

34 Maple Street

Milford, MA 01757 U.S.A.

T: 1 508 478 2000

F: 1 508 872 1990

www.waters.com

Loading...

Loading...