Page 1

[ Care and Use ManUal ]

VIRIDIs sFC CoLUMns

Contents

I. IntRoDUCtIon

II. GettInG stARteD

a. Safety Considerations

b. Column Installation

c. Column Equilibration

d. Initial Column Efficiency Determination

III. CoLUMn Use

a. Sample Preparation

b. Solvents

c. Pressure

IV. sCALInG UP/DoWn IsoCRAtIC MetHoDs

V. ConneCtInG tHe CoLUMn to tHe sFC sYsteM

I. IntRoDUCtIon

Thank you for choosing a Viridis® SFC column. The Viridis SFC packing

materials are designed to provide excellent stability, minimal column

bleed, and high mass loading. The Viridis SFC packing materials are

manufactured in an ISO 9000 certified plant using ultra-pure reagents.

Each batch of Viridis SFC material is tested and the results are held to

narrow specification ranges to assure excellent, reproducible performance.

Every column is individually tested and a Performance Chromatogram is

provided with each column along with the Certificate of Batch Analysis.

Table 1. Physical Characteristics

Viridis

SFC

Chemistry

2-Ethylpyridine

Silica Spherical 5 10 0 340 0.90 n/a n/a

Particle

Shape

Spherical 5 10 0 340 0.90 8 No

Particle

Size

(µm)

Pore

Size

(Å)

Surface

Area

(m2/g)

Pore

Volume

(cc /g)

Carbon

Load

(%)

End-

capped

a. Column Connectors and System Tubing Considerations

b. Band Spreading Minimization

VI. tRoUBLesHootInG

VII. CoLUMn CLeAnInG, ReGeneRAtInG AnD stoRAGe

a. Cleaning and Regeneration

b. Storage

1Viridis SFC Columns

Page 2

[ Care and Use ManUal ]

II. GettInG stARteD

Each Viridis SFC column comes with a Certificate of Analysis and a

Performance Test Chromatogram. The Certificate of Analysis is specific

to each batch of packing material and includes the gel batch number,

analysis of unbonded particle and analysis of bonded particles. The

Performance Test Chromatogram is specific to each individual column

and contains the gel batch number, column serial number, USP plate

count, USP tailing factor, capacity factor, and chromatographic condi-

tions under normal-phase LC conditions. These data should be stored

for future reference.

a. Safety Considerations

An SFC column while being used is, by design, under pressure. The

major safety concern for even a small leak with just CO

is frostbite.

2

Pay attention to any frosting on the column or system connections.

This indicates a leak, usually with temperatures far below 0 °C. Any

small leak with solvent introduced could produce a situation where

the LEL (lower exposure limit) is reached.

b. Column Installation

Note: Scale the flow rate up or down accordingly based upon the i.d.,

length, particle size, and backpressure of the Viridis SFC column being

installed. See “Scaling Up/Down Isocratic Methods” for calculating

flow rates when changing column i.d. and/or length. See “Connecting

the Column to the SFC system” for a more detailed discussion on SFC

connections.

c. Column Equilibration

Viridis SFC columns are shipped dry. Equilibrate the column with a mini-

mum of 10 column volumes of the mobile phase prior to use. (Refer to

Table 2 for a listing of empty column volumes.)

d. Initial Column Efficiency Determination

1. Perform an efficiency test on the column before using it. Waters

recommends using a suitable solute mixture to analyze the column

upon receipt.

2. Determine the number of theoretical plates (N) and use this value

as a benchmark for periodic comparisons.

3. Repeat the test at predetermined intervals to track column

performance over time. Slight variations may be obtained on

two different SFC systems due to the quality of the connections,

operating environment, system electronics, reagent quality and

column condition.

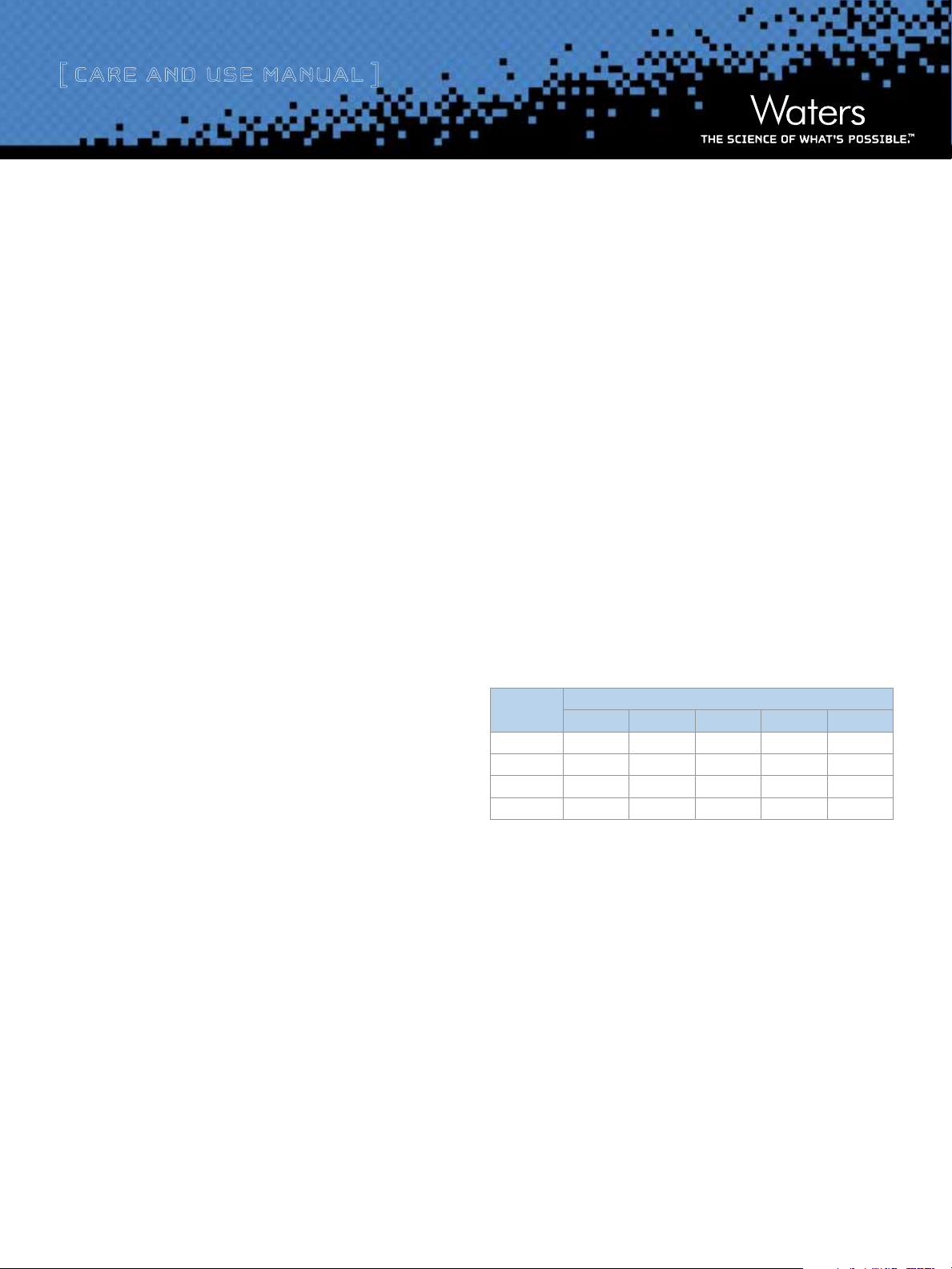

Table 2. Empty Column Volumes in mL (multiply by 10 for flush solvent volumes)

Column

Dimension

50 mm 0.8 4 14 35 98

100 mm 1.7 8 28 70 196

150 mm 2.5 12 42 106 294

250 mm 4 20 70 176 490

4.6 mm 10 mm 19 mm 30 mm 50 mm

Column Internal Diameter (mm)

1. Make sure your co-solvent pump is primed and has an adequate

solvent/modifier supply before performing injections.

2. Connect both the inlet and outlet of the column to the SFC system.

3. If the column is still filled with a solvent, use a low flow rate and

back pressure setting (100 bar) to start pumping CO

and modifier

2

through the column.

4. If you see frosting on the column at the inlet or outlet, tighten the

compression screw on that side. If you see frosting on the column,

turn off the CO

and vent the system. Allow the column to depres-

2

surize fully before disconnecting the inlet or outlet to troubleshoot

the leaking issue.

III. CoLUMn Use

To ensure the continued high performance of Viridis SFC columns,

follow these guidelines:

a. Sample Preparation

1. Sample impurities often contribute to column contamination.

®

Use Oasis

Pak

sample before analysis. Link to www.waters.com/sampleprep.

2. Prepare the sample in the SFC mobile-phase modifier (typically,

methanol) for the best peak shape and sensitivity.

2Viridis SFC Columns

solid-phase extraction cartridges/columns or Sep-

®

cartridges of the appropriate chemistry to clean up the

Page 3

[ Care and Use ManUal ]

3. If the sample is not dissolved in the mobile-phase modifier,

ensure that the sample, solvent and mobile phases are miscible

in order to avoid sample precipitation. Filter sample with 0.2 μm

membranes to remove particulates. If the sample is dissolved in

a solvent, ensure that the membrane material does not dissolve

in the solvent. Contact the membrane manufacturer with solvent

®

compatibility questions. Pall Gelman Laboratory Acrodisc

filters are recommended. (Refer to the Waters Chromatography

Columns and Supplies Catalog for additional information.)

Alternatively, centrifugation for 20 minutes at 8,000 rpm,

followed by the transfer of the supernatant liquid to an appropriate

vial, could be considered.

b. Solvents

To maintain maximum column performance, use high quality chro-

matography grade solvents. Solvents containing suspended particulate

materials will generally clog the outside surface of the inlet distri-

bution frit of the column. This will result in higher operating pres-

sure, reduced column lifetime, and compromised performance.

c. Pressure

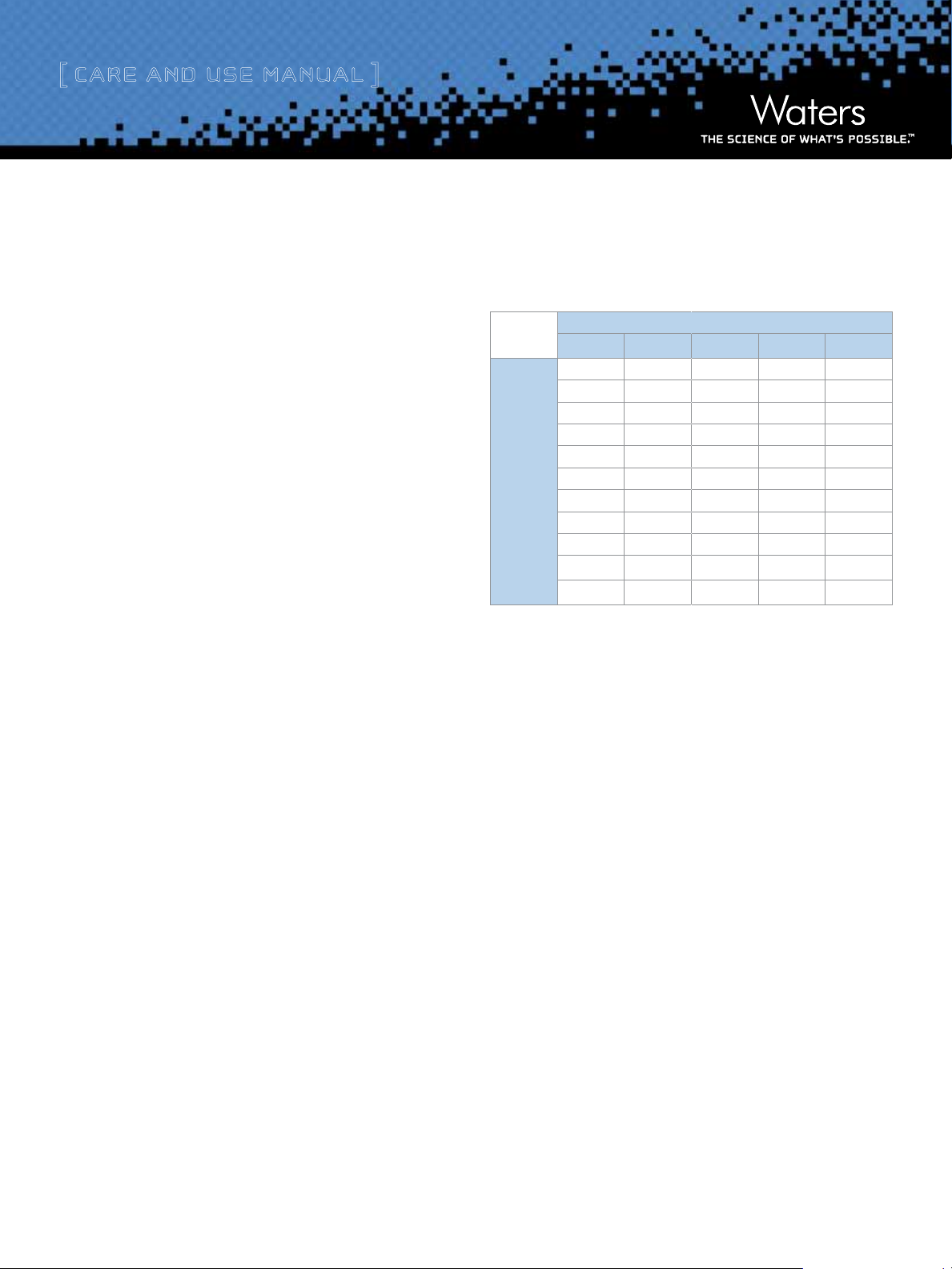

Table 3 may be helpful in scaling-up the flow rate to maintain sepa-

rations in larger column internal diameters.

Table 3. Flow Rate Scaling Chart

Column Diameter (mm)

4.6 10 19 30 50

2.5 11. 8 4 2.7 106.3 295.4

3 14 .2 51.2 127. 6 354.4

3.5 16 .5 59.7 148. 9 413. 5

4 18 .9 68.2 170.1 472.6

4.5 21.3 76.8 191.4 5 31.7

5 23.6 85.3 212.7 590.7

6 28.4 102.4 255.2 708.9

Flow rate (g/min)

7 3 3.1 119.4 297.7 8 27.0

8 37. 8 13 6.5 340.3 945.2

9 42.5 15 3.5 382.8 10 63.3

10 47.3 170.6 425.3 1181. 5

V. ConneCtInG tHe CoLUMn to tHe sFC sYsteM

Viridis SFC columns can tolerate pressures of up to 6,000 psi (400

bar or 40 Mpa) although pressures greater than 4,000 – 5,000 psi

should be avoided in order to maximize column and system lifetimes.

IV. sCALInG UP/DoWn IsoCRAtIC MetHoDs

The following formulas are used for scaling separations.

If column i.d. and length are altered:

F

= F1(r2/r1)

2

or

Injection volume

Where: r = Radius of the column (mm)

F = Flow rate (g/min)

L = Length of column (mm)

1 = Original, or reference column

2 = New column

2

= Injection volume2 (r2/r1)2 (L2/L1)

1

a. Column Connectors and System Tubing Considerations

Tools needed:

3/8 inch wrench

5/16 inch wrench

Handle the column with care. Do not drop or hit the column on a

hard surface as it may disturb the bed and affect its performance.

1. Correct connection of 1/16 inch outer diameter stainless steel

tubing leading to and from the column is essential for high

quality chromatographic results.

2. When using standard stainless steel compression screw fit-

tings, it is important to ensure proper fit of the 1/16 inch

outer diameter stainless steel tubing. When tightening or loos-

ening the compression screw, place a 5/16 inch wrench on the

compression screw and a 3/8 inch wrench on the hex head of

the column endfitting.

Note: If one of the wrenches is placed on the column tube flat

during this process, the endfitting will be loosened and leak.

3Viridis SFC Columns

Page 4

[ Care and Use ManUal ]

0.090 inches

3. If a leak occurs between the stainless steel compression screw

fitting and the column endfitting, a new compression screw

fitting, tubing and ferrule must be assembled.

4. An arrow on the column identification label indicates correct

direction of solvent flow.

Correct connection of 1/16 inch outer diameter stainless steel tub-

ing leading to and from the column is essential for high-quality

chromatographic results. Tubing touches the bottom of the column

endfitting, with no void between them. Extra column peak broadening

can destroy a successful separation. The choice of appropriate column

connectors and system tubing is discussed in detail below.

Figure 1: Waters and Parker Ferrule Types

0.130 inches

Waters Ferrule Settings

Parker Style Ferrule Settings

Various column manufacturers have employed different types of

chromatographic column connectors. The chromatographic performance

of the separation can be negatively affected if the style of the column

endfittings does not match the existing tubing ferrule settings. This

section explains the differences between Waters style and Parker style

ferrules and endfittings (Figure 1). Each endfitting style varies in the

required length of the tubing protruding from the ferrule. The Viridis

SFC column is equipped with Waters style endfittings that require a

0.130 inch ferrule. If a non-Waters style column is presently being

used, it is critical that ferrule depth be reset for optimal performance

prior to installing a Viridis SFC column.

In a proper tubing/column connection (Figure 2), the tubing touches

the bottom of the column endfitting, with no void between them.

The presence of a void in the flow stream reduces column performance.

This can occur if a Parker ferrule is connected to a Waters style end-

fitting (Figure 3).

Figure 3: Parker Ferrule in a Waters Style Endfitting

Void

Note: A void appears if tubing with a Parker ferrule is connected to a

Waters style column.

To fix a void, cut the end of the tubing with the ferrule, place a new

ferrule on the tubing and make a new connection. Before tightening

the screw, make sure that the tubing bottoms out in the endfitting of

the column.

Conversely, if tubing with a Waters ferrule is connected to a column

with Parker style endfitting, the end of the tubing will bottom out

before the ferrule reaches its proper sealing position. This will leave a

gap and create a leak (Figure 4).

Figure 4: Waters Ferrule in a Parker Style Endfitting

Gap

Note: The connection leaks if a Waters ferrule is connected to a column

with a Parker style endfitting.

There are two ways to fix a leak:

Figure 2: Proper Tubing/Column Connection

1. Tighten the screw a bit more. The ferrule moves forward, and

reaches the sealing surface. Do not overtighten since this may

end in breaking the screw.

2. Cut the tubing, replace the ferrule and make a new connection.

4Viridis SFC Columns

Page 5

[ Care and Use ManUal ]

b. Band-Spreading Minimization

Figure 5 shows the influence of tubing internal diameter on system

band-spreading and peak shape. As can be seen, the larger tubing

diameter causes excessive peak broadening and lower sensitivity.

Figure 5: Effect of Connecting Tubing on System

0.005 inches

0.020 inches

0.040 inches

Diluted/Distorted Sample Band

VI. tRoUBLesHootInG

VII. CoLUMn CLeAnInG, ReGeneRAtInG AnD stoRAGe

a. Cleaning and Regeneration

Changes in peak shape, peak splitting, shoulders on the peak, shifts

in retention, change in resolution or increasing backpressure may

indicate contamination of the column. Flushing with a neat organic

solvent, taking care not to precipitate additives, is usually suffi-

cient to remove the contaminant. If the column performance is poor

after regenerating and cleaning, call your local Waters office for

additional support.

b. Storage

1. Ensure all additives are removed from the column by flushing

with an appropriate organic solvent. Allow the column to sta-

bilize at room temperature before pumping the desires single

solvent through the column for storage.

2. Do not store columns that might be under pressure or can

thermodynamically become pressurized.

1. One of the most common problems with regards to columns is

incorrect or non-priming of the co-solvent/modifier pump. If

no peaks are observed after an injection or unusually long

retention times occur, check the priming of the co-solvent/

modifier pump first.

2. If you see frosting on the column at the inlet or outlet, tighten

the compression screw on that side. If tightening doesn’t work,

depressurize the system and the column then replace the fitting

that is not sealing correctly.

3. If you see frosting on the column, turn off the CO

system. Allow the column to depressurize fully before discon-

necting the inlet or outlet. Please contact your Waters repre-

sentative for additional support.

4. Excessive flow rates could damage the internal frits and accel-

erate column failure. Try to keep the pressure drop (∆P) below

100 bar across the column.

and vent the

2

5Viridis SFC Columns

Page 6

[ Care and Use ManUal ]

Sales Offices

Austria and European Export

(Central South Eastern Europe, CIS

and Middle East) 43 1 877 18 07

Australia 61 2 9933 1777

Belgium 32 2 726 1000

Brazil 55 11 5094-3788

Canada 1 800 252 4752 x2205

China 86 21 6879 5888

CIS/Russia +497 727 4490/290 9737

Czech Republic 420 2 617 1 1384

Denmark 45 46 59 8080

Finland 09 5659 6288

France 33 1 30 48 72 00

Germany 49 6196 400600

Hong Kong 852 2964 1800

Hungary 36 1 350 5086

India and India Subcontinent

91 80 2837 1900

Ireland 353 1 448 1500

Italy 39 02 265 0983

Japan 81 3 3471 7191

Korea 82 2 6300 4800

Mexico 52 55 5524 7636

The Netherlands 31 76 508 7200

Norway 47 6 384 60 50

Poland 48 22 6393000

Puerto Rico 1 787 747 8445

Singapore 65 6593 7100

Spain 34 936 009 300

Sweden 46 8 555 11 500

Switzerland 41 56 676 70 00

Taiwan 886 2 2543 1898

United Kingdom 44 208 238 6100

All other countries:

Waters Corporation U.S.A.

1 508 478 2000

1 800 252 4752

www.waters.com

©2011 Waters Corporation. Waters, The Science of W hat’s

Possible, Viridis, Oasis and SepPak are trademarks of Waters

Corporation. Acrodisc is a trademark of Pall Corporation.

May 2011 720003441EN Rev B KK-PDF

Viridis SFC Columns 6

Waters Corporation

34 Maple Street

Milford, MA 01757 U.S.A.

T: 1 508 478 2000

F: 1 508 872 1990

www.waters.com

Loading...

Loading...