Page 1

[ CARE AND USE MANUAL ]

UPLC Intact MASS Analysis Application Kit

(Part Number: 176001519)

CONTENTS

I. UPLC INTACT MASS ANALYSIS APPLICATION

KIT COMPONENTS

II. INSTALLING THE PRE-COLUMN TUBING INTO

MASSPREP MICRO DESALTING COLUMN

III. CONNECTING THE COLUMN TO LCT

PREMIER MS

IV. CONNECTING THE COLUMN TO Q-Tof

PREMIER MS, AND SYNAPT HDMS

V. CONNECTING THE COLUMN TO WATERS SQ

DETECTOR (SQD)

IV. SUGGESTED METHOD FOR MASS ANALYSIS

USING UPLC INTACT MASS ANALYSIS

APPLICATION KIT

a. Intact Antibody Analysis

b. Reduced Antibody Analysis

I. UPLC INTACT MASS ANALYSIS APPLICATION

KIT COMPONENTS

Description Qty Part Number

MassPREP Micro Desalting Column 1 186004032

Desalting Cartridge Manual Assembly,

Cap/Tube/Column

UPLC Intact Mass Analysis Solution 1 715001664

Intact Mass Tubing Kit. Kit contains: 1 205000548

Peek Compression Screw, Long, 10–32 4 410002276

Peek Tubing, 0.062 OD x .004 ID x 8.50 L 1 430001991

Peek Tubing, 0.062 OD x .004 ID x 15.04 L 1 430001992

Peek Tubing, 0.062 OD x .004 ID x 22.20 L 1 430001993

P/N: 430001988

P/N: 410002276

P/N: 186004032

1 430001988

VII. TIPS FOR SUCCESS

P/N: 430001991

P/N: 430001992

P/N: 430001993

Figure 1. UPLC® Intact Mass Analysis Application Kit Components.

Page 2

[ CARE AND USE MANUAL ]

II. INSTALLING THE PRE-COLUMN TUBING INTO

MASSPREP MICRO DESALTING COLUMN

Required materials:

1/4-inch open-end wrench

5/16-inch open-end wrench

Flow

Solvent Inlet Solvent Outlet

Figure 3. Column assembly after attaching the column to the pre-column tubing.

III. CONNECTING THE COLUMN TO LCT

PREMIER MS

Figure 2. Installation of the pre-column tubing into the MassPREP Micro

Desalting Column.

Installation Procedure

1. Place the column on a flat surface (O-ring end facing up).

2. Remove the O-ring from the column.

3. Secure the column (P/N 186004032) with a 5/16-inch wrench

(bottom) as shown in Figure 2.

4. Tighten one end of the pre-column tubing (P/N 430001988)

into the column with a 1/4-inch wrench (a full turn beyond

hand-tight).

5. Connect the marked end (marked as solvent inlet) of the

column tubing assembly to the solvent outlet of the ACQUITY

UPLC® Column Heater (Figure 3).

Note: Proceed from this point to either section III, IV, or V

depending upon the type of mass spectrometer you have.

Installation Procedure

1. Connect one end of the 15.04-inch long PEEK tube (P/N

430001992) to the outlet of the column using a fitting (P/N

410002276).

2. Connect the other end of the tubing to the salt divert valve

(Port 2) using another fitting, as shown in the Figure 4. The

salt divert valve is located at the top-left corner of the LCT

Premier™ front panel.

3. Place the column in the column heater as shown in the Figure 6.

4. Connect one end of the 8.5-inch long PEEK tube (P/N

430001991) to Port 1 of the divert valve using a fitting

5. Connect the other end to the inlet of LCT Premier sample probe

using another fitting (Figure 4).

6. Use a larger diameter PEEK tube (0.062 o.d. x 0.005 or

0.01-inch i.d.) for the waste line (not included in the kit).

UPLC Intact MASS Analysis Application Kit

2

Page 3

[ CARE AND USE MANUAL ]

Column Heater

UPLC

Gradient

Waste

Position 1: Sample loading and salt divert to waste

UPLC

Gradient

Waste

Position 2: Sample elution to MS

Figure 4. Fluidic configuration for LC-MS (UPLC-LCT Premier) analysis. A postcolumn salt diversion valve (top-left corner of the LCT Premier) can be utilized

to divert buffers and nonvolatile salts to waste in the beginning of the LC/MS

analysis.

15.04”

8.5”

15.04”

8.5”

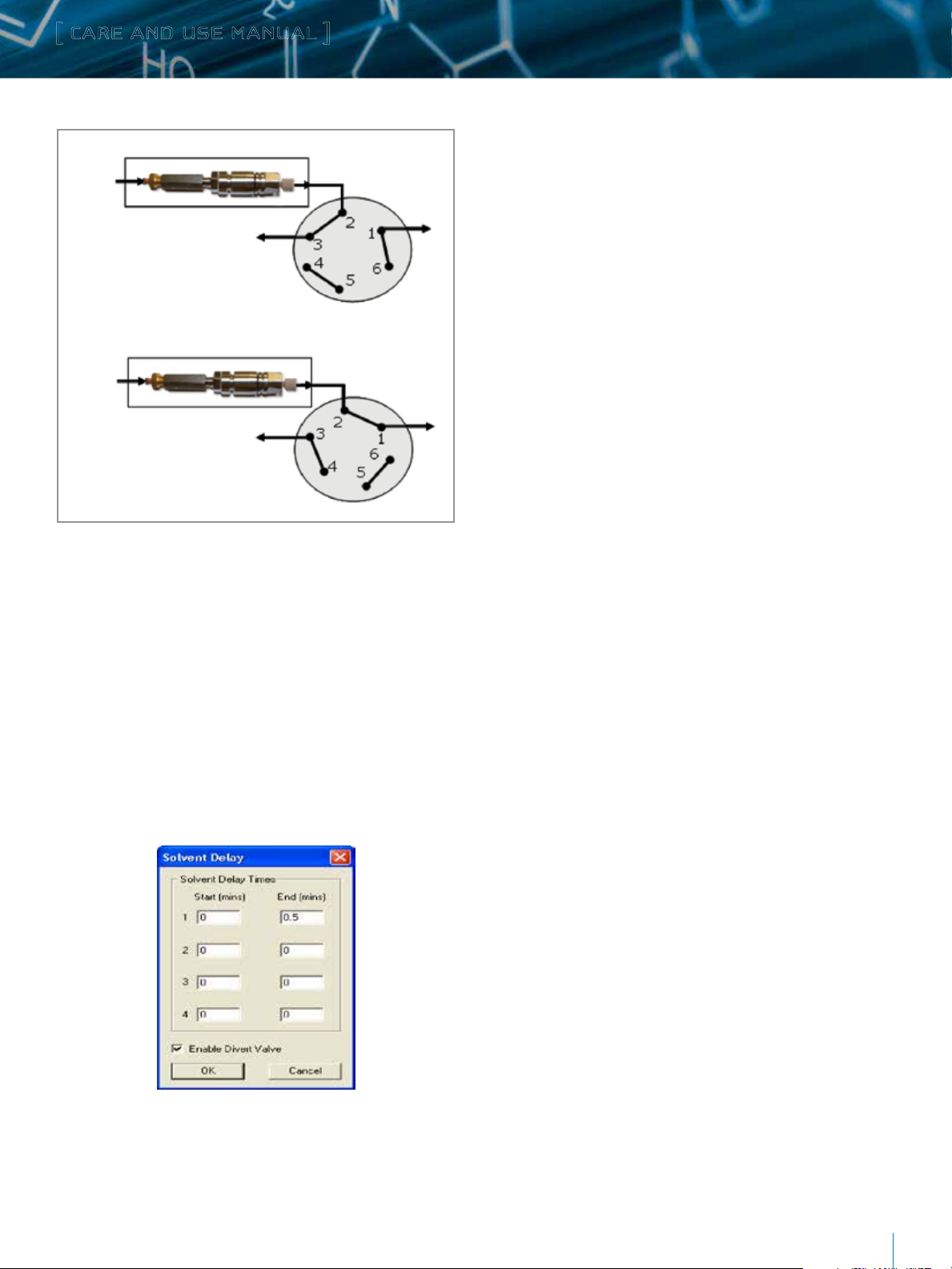

IV. CONNECTING THE COLUMN TO Q-TOF Premier

MS, AND SYNAPT HDMS

Neither Q-Tof Premier™ MS nor SYNAPT® HDMS® has an integrated

divert valve. However, an optional external 2 position valve (P/N

MS

MS

417000118) can be used with Q-Tof Premier and Synapt HDMS

mass spectrometers to divert buffers and nonvolatile salts present

in the sample to waste at the beginning of the LC/MS analysis.

Follow Steps 1–5 in Section II to attach the column to the pre

column tubing. Then follow Steps 12-17 below to connect the

column to the mass spectrometer.

1. Connect one end of the 15.04-inch long PEEK tube

(P/N 430001992) to the outlet of the column using a fitting

(P/N 410002276).

2. Connect the other end of the tubing to the external salt divert

valve (Port 4) using another fitting, as shown in the Figure 5.

3. Connect one end of the 8.5-inch long PEEK tube (P/N

430001991) to the external divert valve (Port 5).

4. Connect the other end to the inlet of MS sample probe (Figure 5).

The divert valve can be programmed from the MS Method Editor in

MassLynx®. To set a salt divert time, open MS Method Editor. Then

select Option> Solvent Delay on the MS Method Editor to open

the Solvent Delay dialog box. To enable the divert/injection valve

to be used as divert valve, select Enable Divert Valve. This diverts

the flow of solvent during a solvent delay period (0.5 min or user

defined value) either to, or away from, the source for the time

period shown in the solvent delay timetable (Table 1).

5. Place the column in the column heater as shown in the Figure 6.

6. Use a larger diameter PEEK tube (0.062 o.d. x 0.005 or

0.01-inch i.d.) for the waste line (not included in the kit).

Table 1. Salt divert timetable.

UPLC Intact MASS Analysis Application Kit

3

Page 4

[ CARE AND USE MANUAL ]

Column Heater

UPLC

Gradient

Position 1: Sample loading and salt divert to waste

UPLC

Gradient

15.04”

Waste

MS

8.5”

Position 2: Sample elution to MS

Figure 5. Fluidic configuration for LC-MS analysis using mass spectrometers with no integrated salt divert valve.

Figure 6. Column placement in the column heater.

15.04”

8.5”

MS

Communications Connections for the External Divert Valve

The optional external divert valve (417000118) can be controlled via line control using the connecting

wires with contact closures. Detailed instructions can be found in the valve operating manual.

1. Connect the red wire to pin #4 and black wire to GND to the terminal block (wires and terminal block

are included in the valve kit), as shown in the table below.

Pin # 1 2 3 4 5 6 GND

Wire - - - Red - - Black

UPLC Intact MASS Analysis Application Kit

4

Page 5

[ CARE AND USE MANUAL ]

2. Plug the terminal block into terminal block I/O (terminal block

I/O is located on the back panel of the external divert valve).

3. Connect the other side of the red wire to pin #6 and black to the

pin #7 of a different terminal block as shown in table below.

1 (+)

2 (-)

3 (+)

4 (-)

5 Ground

6 (Red)

7 (Black)

8

9

10 Ground Out

11 (+)

12 (-)

Gradient Start In

Stop Flow In

Switch 2 Out

Switch 3 Out

0-2 V Analog 2 Out

4. Plug the terminal block into Switch II (Switch II is located on the

back panel of the ACQUIT Y UPLC Binary Solvent Manager [BSM]).

V. CONNECTING THE COLUMN TO WATERS SQ

DETECTOR (SQD)

Follow steps 1-5 in Section II to attach the column to the pre

column tubing. Then follow Steps 18-23 below to connect the

column to the SQD.

1. Connect one end of the 22.20-inch long PEEK tube

(P/N 430001993) to the outlet of the column using a fitting

(P/N 410002276).

2. Connect the other end to the divert valve (Port 1) using another

fitting, as shown in the Figure 7. The divert valve is located at

the top-right corner of the SQD front panel.

3. Place the column in the column heater as shown in the Figure 6.

4. Connect one end of the 8.5-inch long PEEK tube (P/N

430001991) to Port 2 of the divert valve.

5. Connect the other end to the inlet of SQD sample probe (Figure 7).

6. Use a larger diameter PEEK tube (0.062 o.d. x 0.005 or

0.01-inch i.d.) for the waste line (not included in the kit).

The divert valve can be programmed from the ACQUIT Y UPLC

inlet Method Editor in MassLynx. To set a salt divert time, open

inlet Method Editor. Then select Inlet> Events on the ACQUITY

UPLC BSM Instrument Method to open the Events dialog box. To

enable the external divert valve to be used as a divert valve, select

Run Events and enter the events in the events table by clicking

line 1 and 2. Table 2 depicts a salt divert event. When Switch 2 is

in ON position at 0.01 min, the solvent flow is diverted to waste

until 0.51 min, and then the valve is switched to allow the solvent

flow to enter the MS.

Table 2. ACQUITY UPLC BSM console of salt divert timetable/events.

Table 3. Salt divert timetable for SQD.

The divert valve can be programmed from the

MassLynx. To set a salt divert time, open

Option> Method events

select

Method events dialog box. To enable the valve to be used as divert

Enable

valve, select

time period shown in the

defined value) then

. This diverts the flow of solvent to waste for the

the valve is switched allowing the flow to go to

on the

Method events

MS Method editor

MS Method Editor

MS Method Editor

timetable (0.5 min or user

. Then

to open the

the MS (Table 3).

in

UPLC Intact MASS Analysis Application Kit

5

Page 6

[ CARE AND USE MANUAL ]

MS

Column Heater

UPLC

Gradient

Position 1: Sample loading and salt divert to Waste

UPLC

Gradient

Position 2: Sample elution to MS

Figure 7. Fluidic configuration for LC-MS (UPLC-SQD) analysis. A post-column diversion valve located at the top right corner of the SQD

(typically used to direct calibrant for use in automatic tuning), was utilized to divert buffers and non-volatile salts to waste at the beginning

of the LC-MS analysis.

8.5”

22.20”

Waste

MS

8.5”

Waste

SQD Divert Valve

VI. SUGGESTED METHOD FOR MASS ANALYSIS

USING UPLC INTACT MASS ANALYSIS

APPLICATION KIT

Mass Spectrometry has become a powerful tool for therapeutic

proteins analysis. However, most therapeutic proteins are

stored in a matrix of biological buffers and non-volatile salts

and stabilizers. Thus, one of the most significant challenges

encountered during mass analysis of these proteins is processing

of the sample to remove these agents, which often form non-

covalent adducts that reduce MS response and further complicate

the resulting mass spectral data. The following offers two rapid,

sensitive and efficient desalting LC-MS methods that can be

utilized as a starting point with the UPLC Intact Mass Analysis

Application Kit for the characterization of an intact antibody and

its variants, and, constituent heavy and light chain structures.

a. Intact Antibody Analysis

A fast (4-min cycle time) and efficient LC-ESI-MS method was

used to profile multiple structural variants of an IgG. To minimize

cycle time, and maximize system performance, higher flow

rates (0.5 ml/min) were used for loading, desalting, and column

regeneration. A system controlled post-column valve was used

for waste diversion of sample buffers and salts. Additional

sawtooth (rapid) gradient cycles were applied to regenerate the

column to pre-injection conditions as part of each analysis (Table

4). Overlaid TICs (y-axis linked) for this experiment and the

associated summed mass spectra are shown in Figures 8 and 9,

respectively.

Tim e (min) %B Flow (ml /min) Curve

0.00 5 0.5 Initial

0.50 5 0.5 6

Load/WashDivert Flow

0.51 5 0.2 6

2.00 90 0.2 6

Gradient

2.10 5 0.5 6

2.70 90 0.5 6

2.80 5 0.5 6

3.40 90 0.5 6

Column

Washing and

Regeneration

3.50 5 0.5 6

4.00 5 0.5 6

A= 0.1 % Formic acid (Water)

B= 0.1 % Formic acid (ACN) Column temperature: 80 °C

Table 4. Gradient profile used for intact IgG1 analysis.

UPLC Intact MASS Analysis Application Kit

6

Page 7

[ CARE AND USE MANUAL ]

Pre-run Blank

0.5 µg IgG1

Post-run Blank

Figure 8. Total ion chromatograms (TICs) from Waters ACQUITY UPLC-LCT

Premier ESI-TOF MS analyses of an intact IgG1, and pre and post blank runs.

Column temperature was set to 80 °C for these analyses.

Pre-run Blank

0.5 µg IgG1

Max: 2 Counts

754 Counts

Tim e (min) %B Flow (ml /min) Curve

0.00 5 0.2 Initial

0.50 5 0.2 6

Load/WashDivert Flow

0.51 10 0.2 6

7.61 50 0.2 6

Gradient

8.0 90 0.5 6

8.1 5 0.5 6

TIME

8.6 90 0.5 6

8.7 5 0.5 6

9.2 90 0.5 6

Column

Washing and

Regeneration

9.3 5 0.5 6

9.8 5 0.5 6

A= 0.1 % Formic acid (Water)

B= 0.1 % Formic acid (ACN) Column temp.: 80 °C

Table 5. Gradient profile used for reduced IgG1 analysis.

Post-run Blank

Figure 9. Combined ESI-Tof (ACQUITY UPLC-LCT Premier ESI-Tof MS) mass

spectra of an intact IgG1 demonstrating regeneration to pre-injection

conditions.

2 Counts

m/z

b. Reduced Antibody Analysis

A ten minutes LC-ESI-MS method was used to resolve and

characterize IgG heavy and light chain subunits. For efficient

sample desalting, a system controlled post-column valve was used

for waste diversion of sample buffers and salts, prior to initiating

the analysis gradient. Additional sawtooth gradient cycles were

applied following the analysis gradient to regenerate the column

back to pre-injection conditions (Table 5). To minimize run cycle

time, and maximize system performance, higher flow rates

(0.5 ml/min) were applied for column regeneration. T he 10 min

LC-MS run largely resolved the earlier eluting light chain from the

later eluting glycosylated heavy chains (Figure 10).

Blank

MASs Spectrum

Heavy Chain

TIME

MASS Spectrum

Light Chain

Total Ion

Chromatogram

(1:3 µg load)

Figure 10. Total ion chromatograms (TICs) from LC-MS analyses of a reduced

IgG1, and pre and post blank runs. Combined ESI-TOF mass spectra of light and

heavy chains are shown in inset. Column temperature was set to 80 °C for

these analyses.

Pre and Post-run

UPLC Intact MASS Analysis Application Kit

7

Page 8

[ CARE AND USE MANUAL ]

MS Conditions

The MS parameters listed below can vary depending upon the

physical characteristics of the analyzed proteins, flow rate, and

MS probe position.

MS

Conditions

Ionization

Mode

Capillary

Voltage

Cone

Voltage

Desolvation

Temp

Source

Temp

Desolvation

Gas

Acquisition

range (m/z)

LCT Premier

MS

SYNAPT

HDMS

SQD*

ESI Positive ESI Positive ESI Positive

3–3.2 kV 2–3 kV 4.2–4.5 kV

40–50 V 35–37 V 39–45 V

350–450 °C 350–450 °C 350–450 °C

120–150 ° C 120 –150 ° C 120 –150 ° C

800 L/Hr 800 L/Hr 600–800 L/Hr

600–5000

(Intact)/

600–3000

(Reduced)

600–5000

(Intact)/

600–3500

(Reduced)

600–2000

(Reduced)

80–100 V

Ion Guide I

(Intact)/5 V

(Reduced)

Note: Desolvation temp, source temp, and desolvation gas values used in the

above table are based on 0.5 ml/min flow rate.

* Waters SQD parameters can be optimized using IntelliSmart™ software.

Tips for Success

Results obtained with the UPLC Intact Mass Analysis Application

Kit can vary depending upon the physical characteristics of the

analyzed proteins as well as the performance characteristics of

the LC-MS system, injector, and injection wash protocol used.

Additional sawtooth gradient cycles can be applied following

the analysis gradient to regenerate the column back to pre-

injection conditions. Suggested needle wash solvents and column

temperature for antibody LC-MS analysis are listed below:

Needle Weak Wash Solution Composition: 0.1% formic acid

in water

Needle Strong Wash Solution Composition:

65% acetonitrile/5% IPA/30% water in 0.1% formic acid

Column temperature: 80 °C

Separation of light and heavy chains of an antibody can be

obtained by optimizing gradient slope (gradient slope is measured

as percent of organic such as acetonitrile per mobile phase

volume passed through the column), flow rate, initial gradient

strength and column temperature. Set the column temperature to

80 °C. Use the gradient method in Table 5 as a starting point for

optimizing the separation of light and heavy chains of an antibody.

Follow the steps below to further optimize the separation of light

and heavy chains.

1. Find a gradient slope that provides an acceptable resolution

of your reduced antibody.

2. Use the result from the initial separation to design a gradient

(focus gradient slope) that improves the resolution between light

and heavy chains by focusing the gradient (narrow gradient).

3. Then adjust the gradient initial strength (while keeping the

gradient slope constant) to reduce the analysis time without

sacrificing the resolution.

Waters, The Science of W hat’s Possible, UPLC, ACQUIT Y UPLC, HDMS, SYNAPT, and MassLynx are registered trademarks of Waters

Corporation. MassPREP, LCT Premier, Q-Tof Premier, and IntelliStart are trademarks of Waters Corporation. All other trademarks are

property of their respective owners.

©2014 Waters Corporation. Produced in the U.S.A. June 2014 Rev B 715001664EN K P-PDF

Waters Corporation

34 Maple Street

Milford, MA 01757 U.S.A.

T: 1 508 478 2000

F: 1 508 872 1990

www.waters.com

Loading...

Loading...