Page 1

Waters TQ Detector

Quick Start Guide

71500126803/Revision A

Copyright © Waters Corporation 2007.

All rights reserved.

Page 2

Copyright notice

© 2007 WATERS CORPORATION. PRINTED IN THE UNITED STATES OF

AMERICA AND IRELAND. ALL RIGHTS RESERVED. THIS DOCUMENT

OR PARTS THEREOF MAY NOT BE REPRODUCED IN ANY FORM

WITHOUT THE WRITTEN PERMISSION OF THE PUBLISHER.

The information in this document is subject to change without notice and

should not be construed as a commitment by Waters Corporation. Waters

Corporation assumes no responsibility for any errors that may appear in this

document. This document is believed to be complete and accurate at the time

of publication. In no event shall Waters Corporation be liable for incidental or

consequential damages in connection with, or arising from, its use.

Waters Corporation

34 Maple Street

Milford, MA 01757

USA

Trademarks

Connections Insight, ESCi, and Waters are registered trademarks of Waters

Corporation. ACQUITY UPLC, IntelliStart, IonSABRE, MassLynx, T-Wave,

UPLC, and ZSpray are trademarks of Waters Corporation.

Other trademarks or registered trademarks are the sole property of their

respective owners.

Page 3

Customer comments

Waters’ Technical Communications departme nt invites you to tell us of any

errors you encounter in this document or to suggest ide as for otherwise

improving it. Please help us better understand what you expect from our

documentation so that we can continuously improve its accuracy and

usability.

We seriously consider every customer comment we receive. You can reach us

at tech_comm@waters.com.

Waters Corporation

34 Maple Street

Milford, MA 01757

USA

iii

Page 4

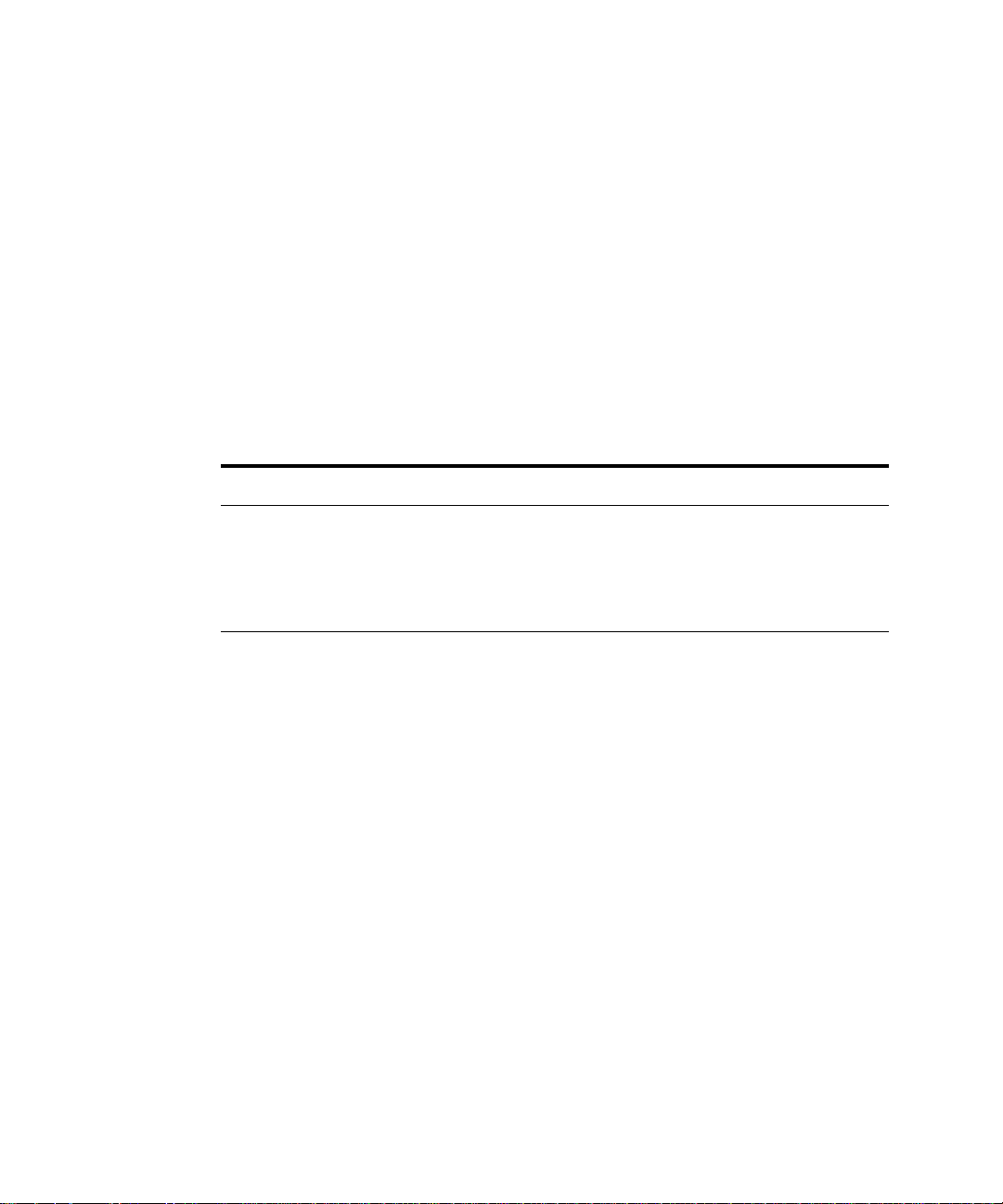

Safety considerations

Some reagents and samples used with Waters® instruments ca n po se

chemical, biological, and radiological hazard s. Be sure you are aware of the

potentially hazardous effects of all substances you work with. Always observe

Good Laboratory Practice (GLP) guidelines, published by the U.S. Food and

Drug Administration, and consult your organization’s safety representative

for guidance.

When you develop methods, follow the “Pro tocol for the Ado ption of Analyt ical

Methods in the Clinical Chemistry Laboratory,” Ame rican Journal of Medical

Technology, 44, 1, pages 30–37 (1978). This protocol addresses good operating

procedures and the techniques necessary to validate system and method

performance.

Instrument-specific safety consideratio ns

Solvent leakage hazard

The source exhaust system is designed to be robust and leak-tight. Waters

recommends you perform a hazard analysis, assuming a maximum leak into

the laboratory atmosphere of 10% HPLC eluate.

Warning:

• To confirm the integrity of the source exhaust system, the

source seals must be renewed at intervals not exceeding one

year.

• The source seals can withs tand exposure only to specific

solvents, see Appendix C in the Wat ers TQ Det ector Oper ator’ s

Guide. If you intend to use solvents other than those listed,

you must first determine whether those solvents are

compatible with the composition of the seals.

iv

Page 5

Flammable solvents hazard

Warning: Where signif icant quantities of flammable solvents are

involved, the source must receive a continuous flow of nitrogen to

prevent possible ignition within that enclos ed space.

Never let the nitrogen supply pressure fall below 400 kPa (4 bar, 58 psi)

during analyses that require flammable solvents. Connect to the LC output

with a gas-f a il co n n e ctor to stop the LC solvent if th e ni t rogen suppl y fa i l s.

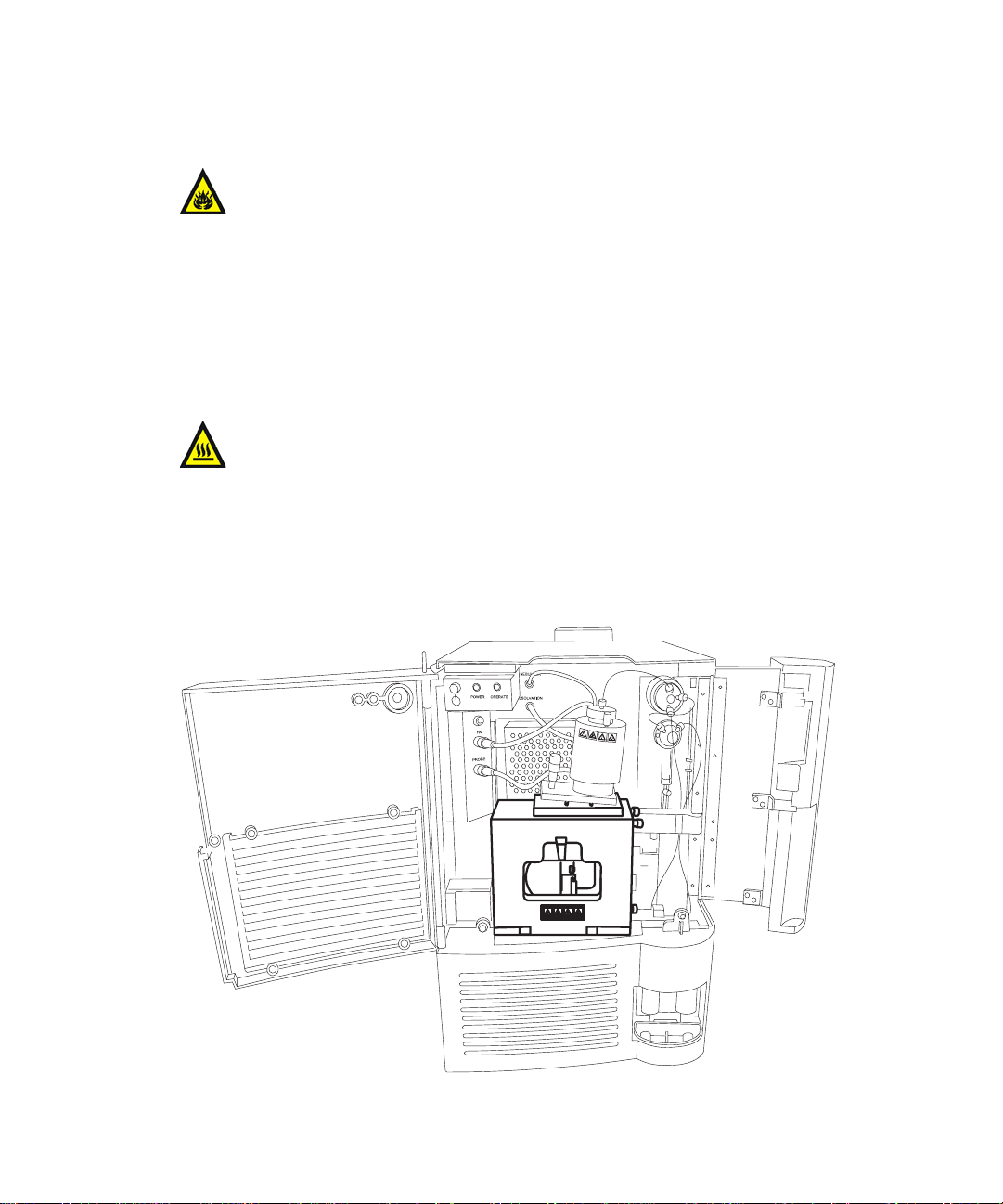

High temperature hazard

Warning: The source enclosure can be hot. To avoid burn injuries,

avoid touching the source enclosure when operating or servicing the

TQ Detector.

Waters TQ Detector high temperature hazard:

Source enclosure ass em bly

v

Page 6

High voltage hazard

Warning:

• To avoid electric shock, do not remove the TQ Detector’s protective

panels. The components they cover are not user-serviceable.

• To avoid non-lethal electric shock, any equipment connected to the

ESI and IonSABRE™ APCI probes must be grounded.

• When the TQ Detector is in Operate mode, certain ext ernal surfaces

can conduct high voltages. To avoid non-lethal electric shock, make

sure the instrument is in Standby mode before touching areas

marked with this high voltage warning symbol.

Safety advisories

Consult Appendix A for a comprehensive list of warning and caution

advisories.

vi

Page 7

Operating this device

When operating this device, follow standard quality cont rol procedures and

the guidelines presented in this section.

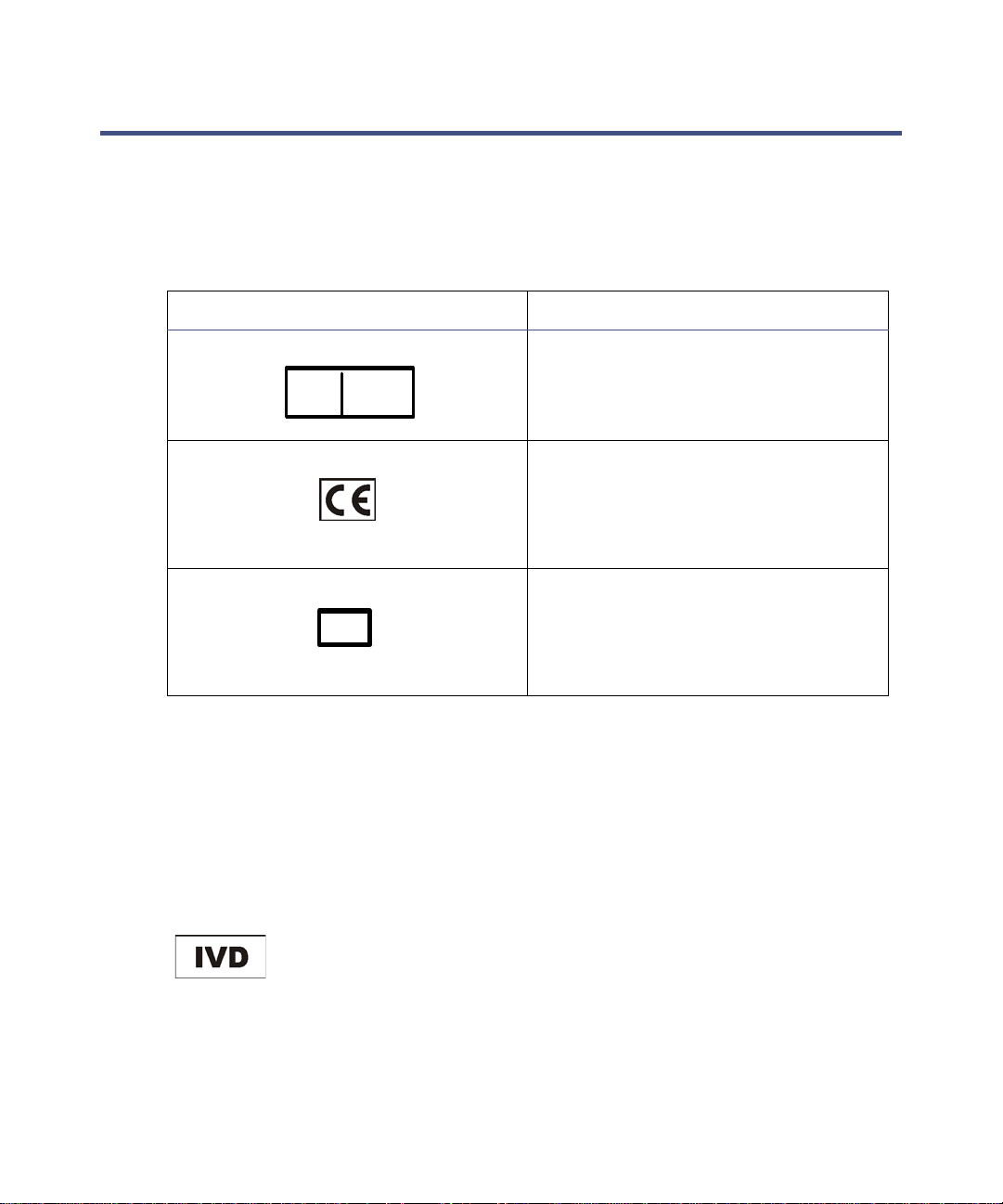

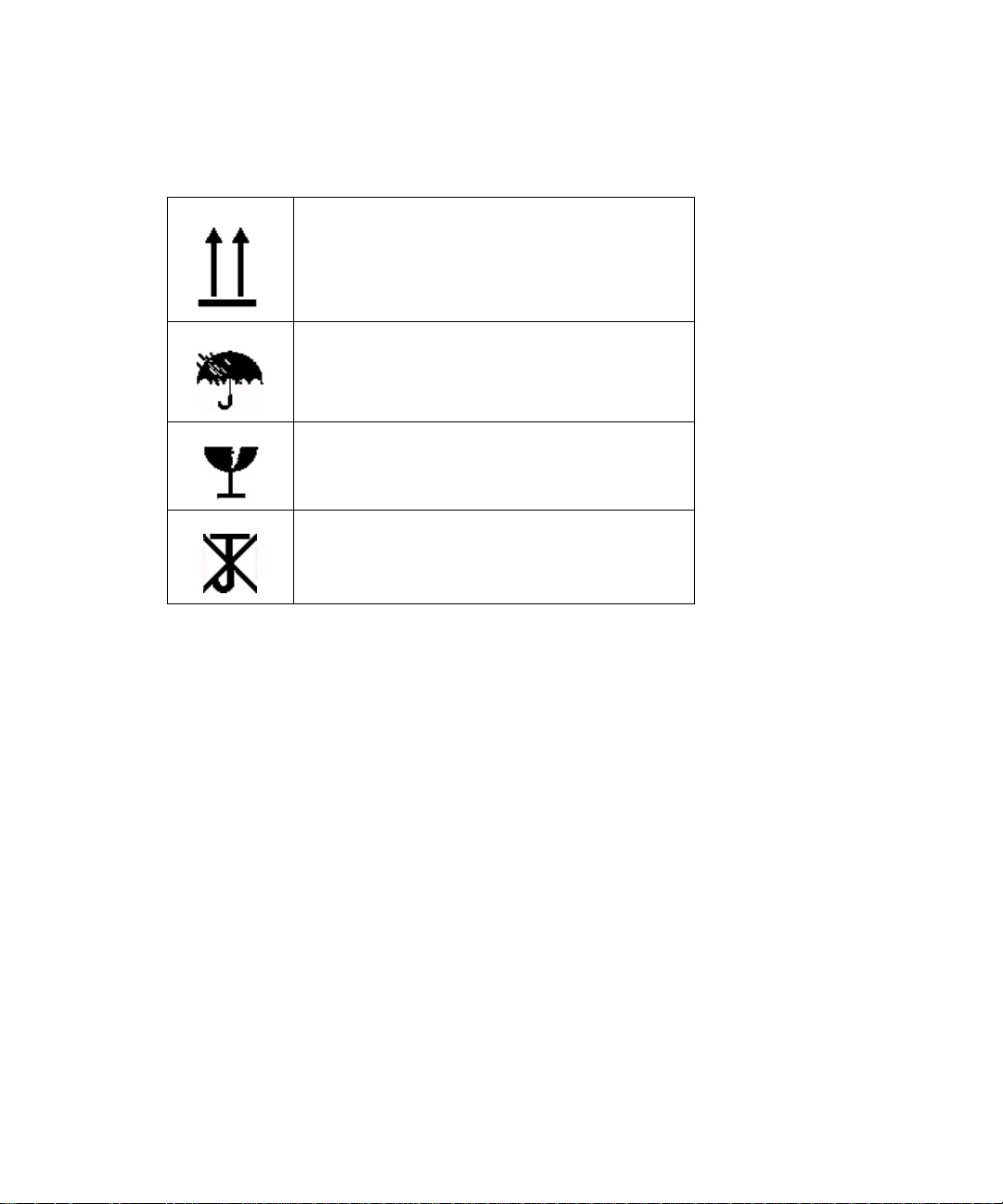

Symbols

Symbol Definition

Intended use

The Waters Tandem Quadrupole (TQ) Detector is intended to be used as a

research tool to deliver authentica ted mass measurement in both MS and

MS/MS modes.

The Waters TQ Detector can be used for general In Vitro Diagnostic

applications, only by professionally trained and qualified laboratory

personnel.

E C RE P

Authorized Representative of the

European Community

The CE symbol serves as

confirmation of the conformity of a

product with all European

Community directives applicable to

that product.

For in vitro diagnostic use.

IV D

The Waters TQ Detector is CE-marked according to the

European Union In Vitro Diagnostic Device Directive 98/79/EC.

vii

Page 8

Calibration

To calibrate LC systems, follow acceptable calibration method s using at least

five standards to generate a standard curve . The concentration range for

standards should cover the entire range of quali ty-control samples, typical

specimens, and atypical specimens.

To calibrate mass spectrometers, consult the calibration section of the

operator’s guide of the instrument you are calibrating.

Quality control

Routinely run three quality-control samples that represent subnormal,

normal, and above-normal levels of a compound. Ensure that quality-control

sample results fall within an acceptable range, and evaluate precision from

day to day and run to run. Data col lected when qualit y control samples are ou t

of range might not be valid. Do not r eport the se dat a until you ar e cert ain that

the instrument performs satisfactorily.

When analyzing samples from a co m plex matrix such as soil, tissue,

serum/plasma, whole blood, etc., note tha t the mat rix components can

adversely affect LC/MS results, enhancing or suppres sing ionization. To

minimize these matrix effects, Wate rs recommends you adopt the following

measures:

viii

• Prior to the instrumental analysis, use appropria te sample

pretreatment such as protein precipitation, liquid/liquid extraction

(LLE), or solid phase extraction (SPE) to remove matrix interferences.

• Whenever possible, verify method accuracy and precision using

matrix-matched calibrators and QC samples.

• Use one or more internal standard compounds, preferably

isotopically-labeled analytes.

Page 9

IVD authorized representative information

IVD authorized representative

Waters Corporation (Micromass UK Limited) is

registered in the United Kingdom with the

Medicines and Healthcare P roducts Regulatory

Agency (MHRA) at market Towers, 1 Nine Elms

Lane, London, SW8 5NQ. The referenc e number

is IVD000167.

Waters Corp o ra tion (Microm a ss UK Ltd.)

Floats Road

Wythenshawe

Manchester M23 9LZ

United Kingdom

Telephone: +44-161-946-2400

Fax: +44-161-946-2480

Contact: Quality manager

ix

Page 10

x

Page 11

Table of Contents

Safety considerations .......................................................................................... iv

Instrument-s pe c if i c sa f et y co n si d erations............. ... ............. .. .......................... iv

Flammable solvents hazard ................................................................................ v

High temperature hazard.................................................................................... v

High voltage haza r d......... .. .......................... ... ............. .. .. ............. ... ................... vi

Safety advisories................................................................................................. vi

Operating this device ......................................................................................... vii

Symbols ............................................................................................................. vii

Intended use...................................................................................................... vii

Calibration ....................................................................................................... viii

Quality control ................................................................................................. viii

IVD authorized representative information ................................................. ix

IVD authorized representative .......................................................................... ix

1 Waters TQ Detector Overview ............................................................ 1-1

Overview ............................................................................................................. 1-2

Waters TQ Dete c to r.......................... ... ............. .. ............. .. .............. .. ............. . 1-2

ACQUITY TQD UPLC/MS system .......... .. .. ................................................... 1-4

MassLynx mass spectrometry software and data system ............................. 1-5

ACQUITY UPLC Console......................................................................... ....... 1-6

Ionization techniques and source probes ................................................... 1-7

Electrospray i on i za tion (ESI)..... .. ............. .. .............. .. ............. .. .............. .. ..... 1-7

Combined electrospray ionization and atmospheric p ressure chemical ionization

(ESCi) ......................................................................................................... 1-7

Atmospheric pressure chemical ionization..................................................... 1-8

Atmospheric pressure photoionization ........................................................... 1-8

Table of Contents xi

Page 12

Ion optics ............................................................................................................. 1-9

MS operating modes ....................................................................................... 1-10

MS/MS operating modes ................................................................................ 1-11

Product (daug h t er) ion mode. .............. .. ............. .. ............. ... ............. .. .......... 1-11

Precursor (pare n t) ion mode...... ............. .. ............. ... ............. .. .. .............. .. ... 1-1 2

Multiple reaction monitoring mode .............................................................. 1-12

Constant neutral loss mode........................................................................... 1-13

Sample inlet ...................................................................................................... 1-14

Vacuum system ................................................................................................ 1-14

Rear panel .. ... ............. .. .. .. ... .. .. ............. ... .. .. .. .. .............. .. .. .. .. ... ............. .. .. ... .. .. . 1-15

IntelliStart fluidics system overview ......................................................... 1-16

IntelliStart fluidics system operation ........................................................ 1-17

Operating the IntelliStart fluidics system from the ACQUITY UPLC

Console . .. ............. .. .............. .. ............. .. .............. .. ............. .. .............. .. .. ... 1-1 7

Operating the IntelliStart fluidics system from the Tune window............. 1-18

Programming the MS method to operate the IntelliStart fluidics system. 1-18

2 Preparing the Waters TQ Detector for Operation ......................... 2-1

Starting the TQ Detector ................................................................................. 2-2

Configuring IntelliStart..................... ............................................... .. ............. 2-6

Verifying the instrument’s state of readiness................................................ 2-6

Tuning and calibration information ............................................................... 2-6

Running the TQ Detector at high flow rates.................................................. 2-7

Monitoring the TQ Detector LEDs.................................................................. 2-8

Preparing the IntelliStart fluidics system .................................................. 2-9

Installing the solvent manifold drip tray........................... .. .......................... 2-9

Installing the reservoir bottles..................... .......................................... ....... 2-10

Diverter valve positions................................................................................. 2-11

Purging the infusion syringe......................................................................... 2-13

Rebooting the TQ Detector ........................................................................... 2-14

Rebooting the TQ Detector by pressing the reset button ............................ 2-14

xii Table of Contents

Page 13

Shutting down the TQ Detector .................................................................. 2-15

Putting the TQ Detector in Standby mode for overnight shutdown........... 2-15

Complete TQ Detector shutdown.................................................................. 2-16

Emergency TQ Detector shutdown............................................................... 2-17

3 ESI and ESCi Modes of Operation ..................................................... 3-1

Introduction ....................................................................................................... 3-2

Installing the ESI probe .................................................................................. 3-2

Required materials .......................................................................................... 3-2

Installing the corona pin ................................................................................. 3-5

Required materials .......................................................................................... 3-5

Optimizing the ESI probe for ESCi operation ........................................... 3-7

Required materials .......................................................................................... 3-7

Removing the corona pin ................................................................................ 3-9

Required materials .......................................................................................... 3-9

Removing the ESI probe ............................................................................... 3-11

Required materials ........................................................................................ 3-11

4 Operating the Waters TQ Detector .................................................... 4-1

Setting-up the instrument .............................................................................. 4-2

Required materials .......................................................................................... 4-2

Performing a sample tune .............................................................................. 4-7

Required materials .......................................................................................... 4-7

Developing experiment methods .................................................................. 4-9

Required materials .......................................................................................... 4-9

Verifying the sys t em us in g Sys t em QC ........... ............. .. ... .. .. .. .. .............. .. . 4-11

A Safety Advisories ..................... ..... ..... ................................................... A-1

Warning symbols ............................................................................................... A-2

Task-specific hazard warnings........................................................................ A-2

Warnings that apply to particular instruments, instrument components, and

sample types............................................................................................... A-3

Table of Contents xiii

Page 14

Caution symbol .................................................................................................. A-5

Warnings that apply to all Waters instruments ......................................... A-5

Electrical and handling symbo l s ............. .. ... .. .. .. ............. ... .. .. .. .. ... ............. . A-13

Electrical symbols.......................................................................................... A-13

Handling symbols .......................................................................................... A-14

xiv Table of Contents

Page 15

1 Waters TQ Detector Overview

This chapter describes the instrument, including its controls and gas

and plumbing connections.

Contents:

Topic Page

Overview 1-2

Ionization techniques and source probes 1-7

Ion optics 1-9

MS operating modes 1-10

MS/MS operating modes 1-11

Sample inlet 1-14

Vacuum system 1-14

Rear panel 1-15

IntelliStart fluidics system overview 1-16

IntelliStart fluidics system operation 1-17

1-1

Page 16

Overview

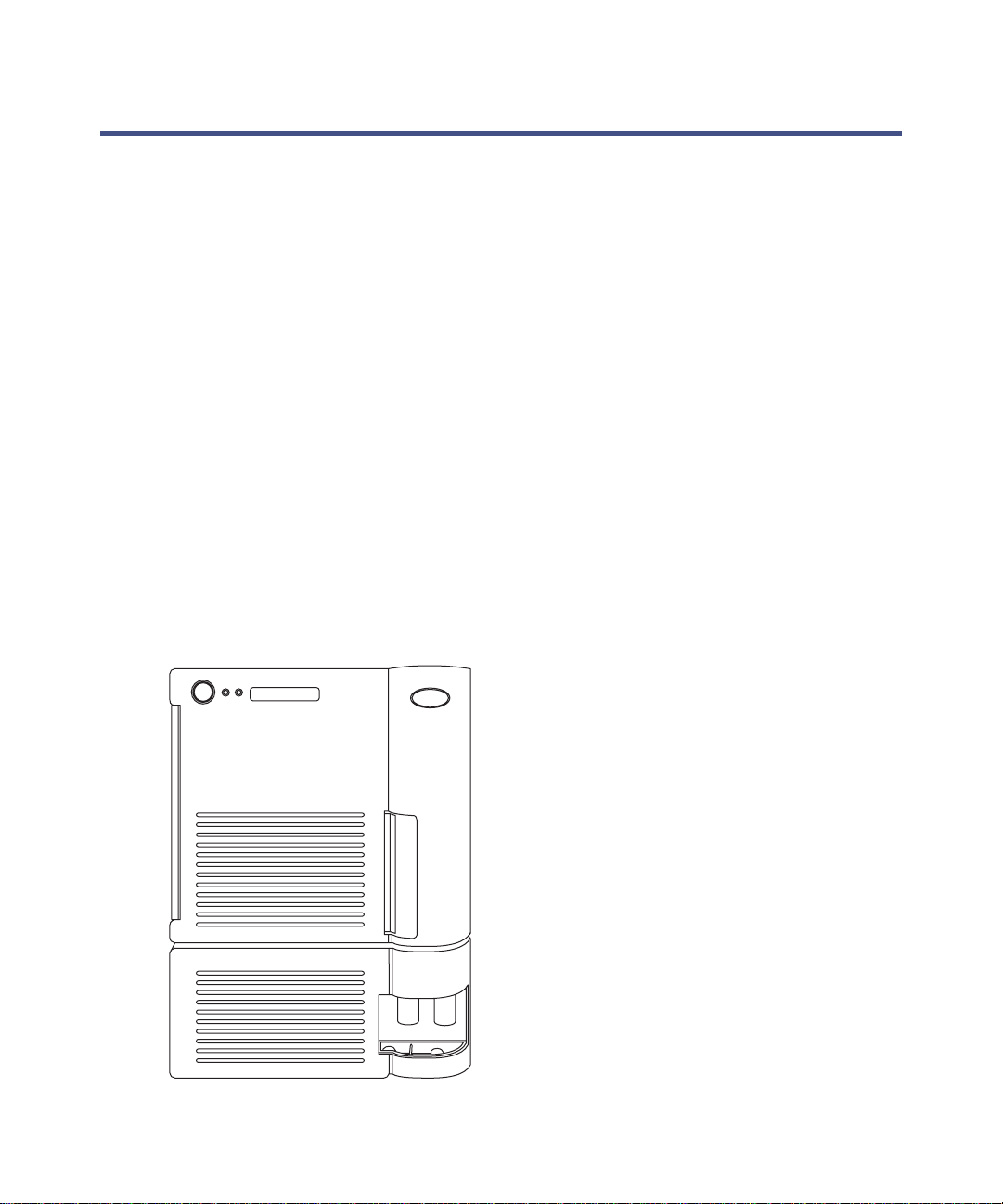

Waters TQ Detector

The Waters® TQ Detector is a tandem quadrupole, atmospheric pressure

ionization (API) mass spectrometer. Designed for routine UPLC™/MS/MS

analyses in quantitative and qualitative applications, it can operate at fast

acquisition speeds compatible with ultra performance LC.

Waters provides these ion sources with the instrument as standard

equipment:

• ZSpray™ (dual orthogonal sampling) interface.

• Multi-mode ESCi

chemical ionization (APCI) and electrospray ionization (ESI).

Optional ionization modes are IonSABRE™ APCI and APPI (atmospheric

pressure photoionization) .

For TQ Detector specifications, see the Waters TQ Detector Site Preparation

Guide.

Waters TQ Detector:

®

ionization switching for atmospheric pressure

1-2 Waters TQ Detector Overview

TP02592

Page 17

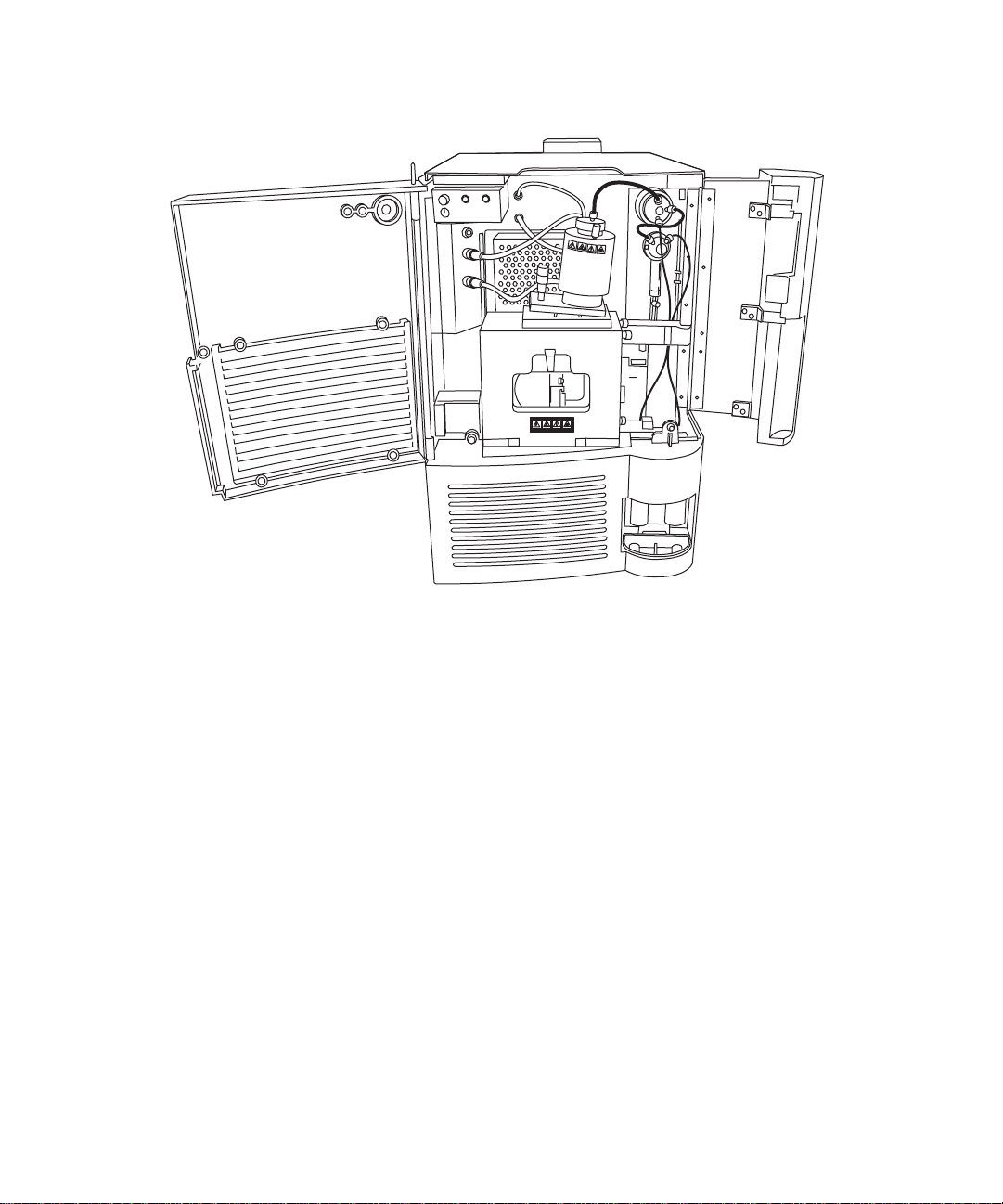

Waters TQ Detector with doors open:

HV

PROBE

NEBULIZER

POWER OPERATE

DESOLVATION

V

H

E

B

O

R

P

IntelliStart technology

TP02627

IntelliStart™ technology monitors LC/MS/MS performance and reports when

the TQ Detect or is ready for use.

The IntelliStart software automatically tune s and mass calibrates the TQ

Detector and displays performance readbacks . In tegrated with MassLynx™

mass spectrometry software and ACQUITY UPLC™ Console software,

IntelliStart enables simplified set-up of the system for use in routine

analytical and open access applications.

The IntelliStart fluidics system is built into the TQ Detector. It delivers

sample directly to the MS probe from the LC column or from two integral

reservoirs. The integral reservoirs can also deliver sample through direct or

combined infusion so that you can optimize instrument performance at

analytical flow rates.

See also: The TQ Detector online Help for further details of IntelliStart.

Overview 1-3

Page 18

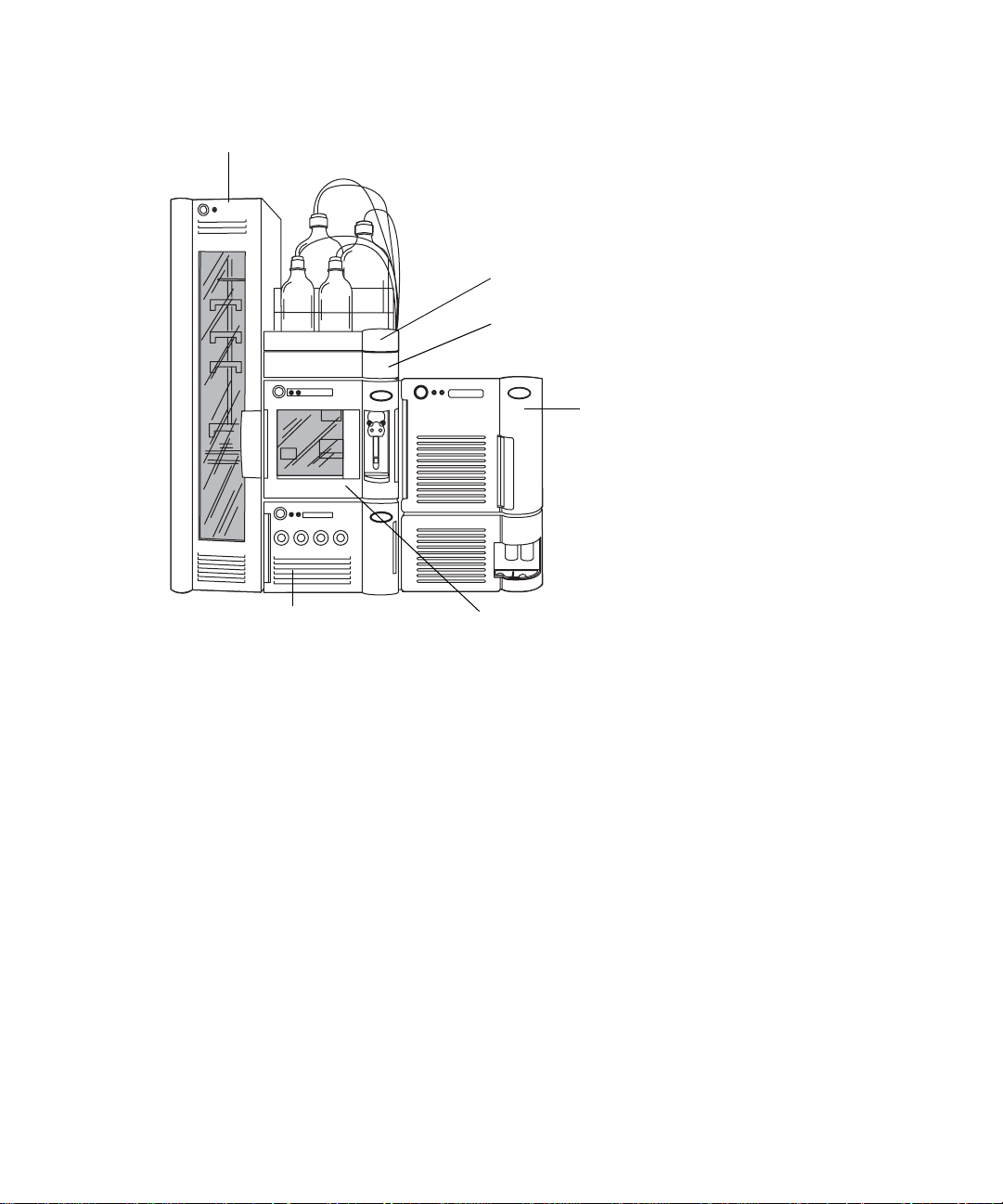

ACQUITY TQD UPLC/MS system

Note: The Waters TQ Detector is designed for compatib ility with the

ACQUITY UPLC system; if you are not using an ACQUITY UPLC system,

refer to the documentation relevant to the LC syst em being used.

The ACQUITY TQD UPLC/MS system includes an ACQUITY UPLC system

and the Waters TQ Detector.

ACQUITY UPLC system

The ACQUITY UPLC system includes a binary solvent manager, sample

manager, column heater, optional sample organizer, op tional detectors, and a

specialized ACQUITY UPLC column. Waters MassLynx mass spectrometry

software controls the system.

See also:

• ACQUITY UPLC System Operator’s Guide

• Controlling Contamination in LC/MS System s (part number

715001307). You can find this document on http: //www.waters.com; click

Services and Support and then Support Center.

1-4 Waters TQ Detector Overview

Page 19

Waters ACQUITY TQD:

Sample organizer (option al)

manager

Solvent tray

Column heater

TP02597

Sample managerBinary solvent

TQ Detector

MassLynx mass spectrometry software and data system

MassLynx is a high-performance mass spect rometry application that acquires,

analyzes, manages, and distributes ultra-violet (UV), evaporative light

scattering, analog, and mass spectrometry data.

MassLynx software permits these major operations:

• Configuring the instrument.

• Creating LC inlet and MS/MS methods that define operating

parameters for a run.

• Using IntelliStart softwar e to tune and m a ss calibrate the TQ Detector.

• Running samples.

• Monitoring the run.

• Acquiring data.

• Processing data.

Overview 1-5

Page 20

•Reviewing data.

•Printing data.

See also: MassLynx 4.1 user documentation and online Help for more

information on installing and using MassLynx software.

ACQUITY UPLC Console

The ACQUITY UPLC Console is a software application with which you

configure settings, monitor perfor manc e, run diagnostic tests, and maintain

the system and its modules. The ACQUITY UPLC Console functions

independently of MassLynx and does not recognize or control the data system.

See also: ACQUITY UPLC System console online Help for details of the TQ

Detector.

TQ Detector ACQUITY UPLC Console page:

1-6 Waters TQ Detector Overview

Page 21

Ionization techniques and source probes

Electrospray ionization (ESI)

In electrospray ionization (ESI), a strong electrical charge is given the eluent

as it emerges from a nebulizer. The droplets that compose the resultant

aerosol undergo a reduction in size (solvent evaporat ion). As solvent continues

to evaporate, the charge density incre ases until the dr oplet su rfac es eject io ns

(ion evaporation). The ions can be singly or multiply charged. The multiply

charged ions are of particular interest because the TQ Detector separates

them according to their mass-to-charge ratios (m/z), permitting the detection

of high-molecular-weight compounds.

The instrument can accommodate eluent flow rates of up to 1 mL/min.

Combined electrospray ionization and atmospheric pressure chemical ionization (ESCi)

Combined electrospray ionization and atmospheric pressure chemical

ionization (ESCi) is supplied as standard equipment on the TQ Detector. In

ESCi, the standard ESI probe is used in conjunction with a corona pi n to allow

alternating acquisition of ESI and APCI ionization data, facilitating high

throughput and wider compound coverage.

Ionization techniques and source probes 1-7

Page 22

ESCi mode:

Corona pin

TP02695

Sample cone tip

See also: “Electrospray ionization (ESI)” on page 1-7.

Atmospheric pressure chemical ionization

A dedicated high performance atmospheric pressure chemical ionization

(APCI) probe is offered as an option.

See also: The Waters TQ Detector Operator’s Guide for full details.

Atmospheric pressure photoionization

Atmospheric pressure photoionization (APPI) is offered as an option. It uses

photons generated by a krypton-dischar ge ultra-violet (UV) lamp ( ∼10.2 eV) to

produce sample ions from vaporized LC eluent.

1-8 Waters TQ Detector Overview

Page 23

Ion optics

The TQ Detector’s ion optics operate as follows:

• Samples from the LC or Intellistart fluidics system are introduced at

atmospheric pressure into the ionization source.

• The ions pass through the sample cone into the vacuum system.

• The ions pass through the transfer optics to the fir st quadrupole where

they are filtered according to their mass-to-charge ratio (m/z).

• The mass-separated ions pass into the T-Wave™ collision cell where

they either undergo collision-induced dissociation (CID) or pass to the

second quadrupole. Any fragment ions are then mass-analyzed by the

second quadrupole.

• The transmitted ions are detected by the photomultiplier detection

system.

• The signal is amplified, digitized, and sent to the MassLynx mass

spectrometry software.

Ion optics overview:

Sample cone

Sample inlet Transfer optics

T-W ave co llision

cell

Conversion dynode

Isolation valve

Z-Spray ion sourc e Quadrupole 1

(MS1)

Quadrupole 2

(MS2)

Detector

Ion optics 1-9

Page 24

MS operating modes

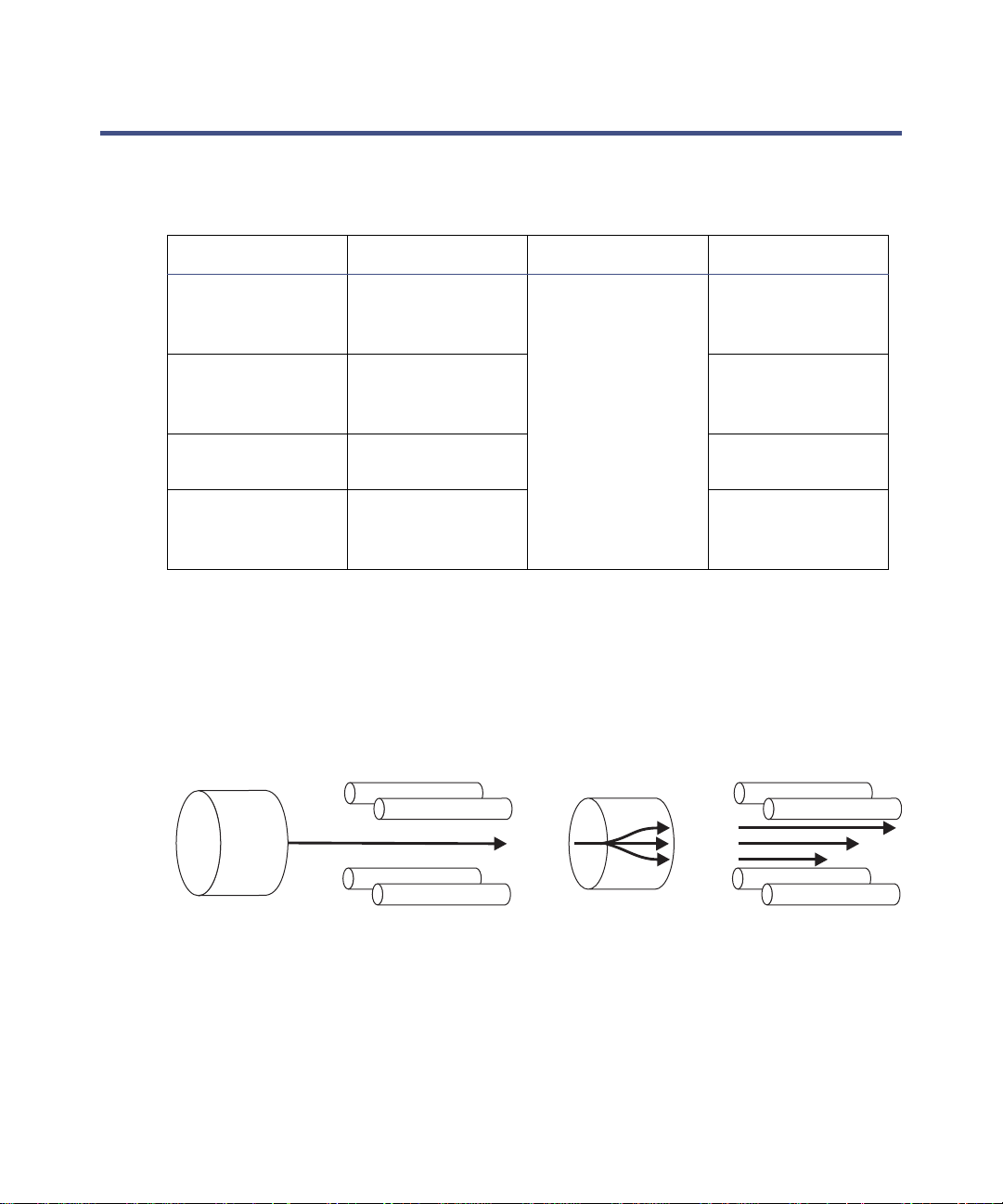

The following table shows the MS operating modes.

MS operating modes :

Operating mode MS1 Collision cell MS2

MS1 Resolving

(scanning)

MS2 Pass all masses Resolving

SIR Resolving (static) Pass all masses

The MS1 mode, in which MS1 is used as the mass filter, is the most common

and most sensitive method of per formi ng MS analysis. It i s di rectly analogous

to using a single-quadrupole mass spectrometer.

The MS2 mode of operation is used, with collision gas p resent, when switching

rapidly between MS and MS/MS operat ion (for example, in survey scan mode).

It also provides a useful tool for instrument tuning and calibration before

MS/MS analysis and for fault diagnosis.

The selected ion recording (SIR) mode of operation is used as a quantitation

mode when no suitable fragment ion can be found to perform a more specific

multiple reaction monitoring (MRM) analysis.

Pass all masses

(scanning)

1-10 Waters TQ Detector Overview

Page 25

MS/MS operating modes

The following table shows the MS/MS operating modes.

MS/MS operating modes :

Operating mode MS1 Collision cell MS2

Product

(daughter) ion

Static (at

precursor mass)

spectrum

Precursor

Scanning Static (at product

(parent) ion

spectrum

MRM Static (at

precursor mass)

Constant neutral

loss spectrum

Scanning

(synchronized

with MS2)

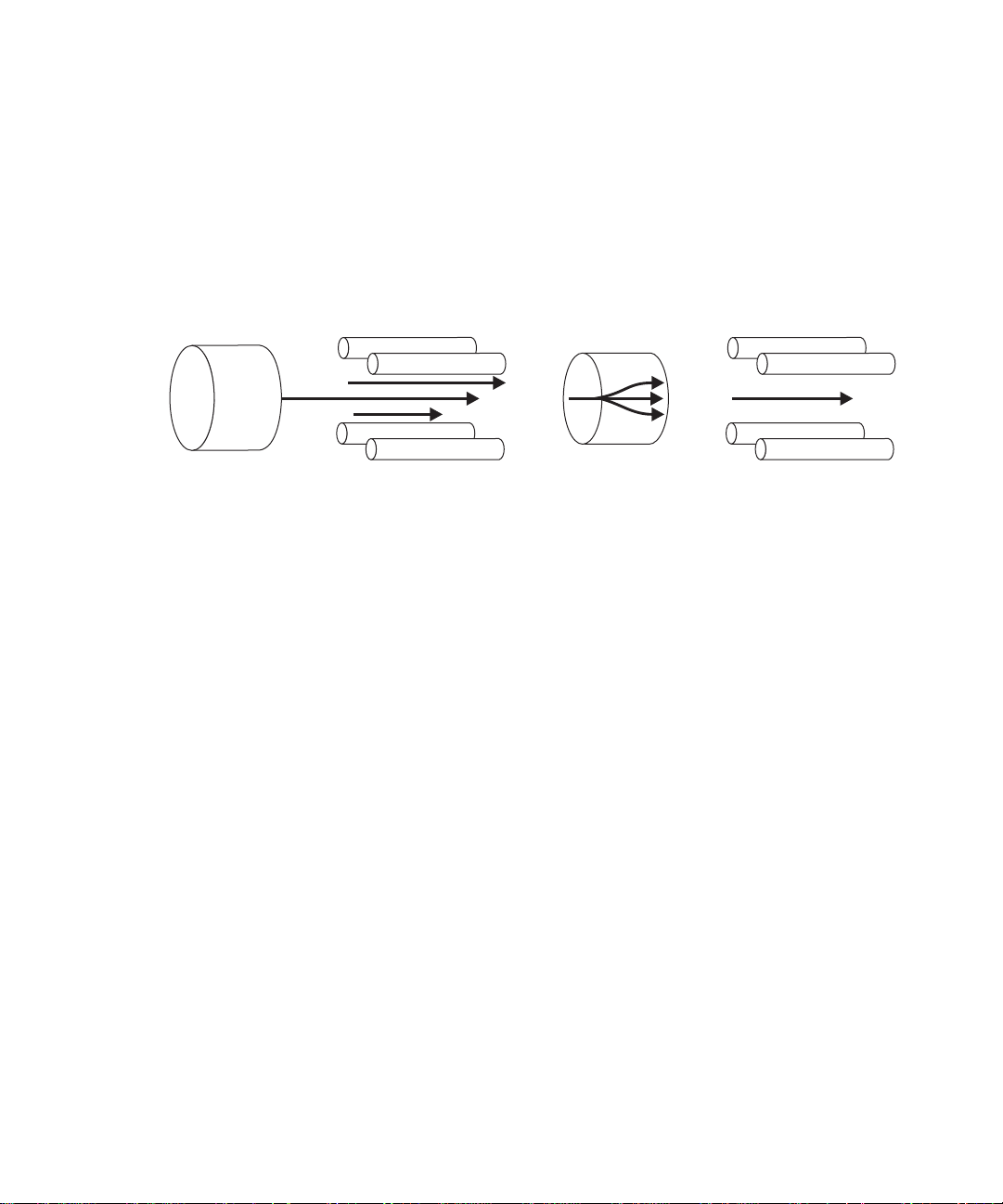

Product (daughter) ion mode

Product ion mode is the most commonly used MS/MS operating mode. An ion

of interest is selected for fragment ation in the collision cell, thus yielding

structural information.

Product ion mode:

Pass all masses Scanning

mass)

Static (at product

mass)

Scanning

(synchronized

with MS1)

MS1

Static (at precursor mass)

Collision cell

Pass all masses

Typical applications

• Structural elucidation (for example, peptide sequencing)

MS/MS operating modes 1-11

MS2

Scanning

Page 26

• Method development for MRM screening studies:

– Identifying product ions for use in MRM transitions.

– Optimizing CID tuning conditions to maximize the yield of a specific

product ion to be used in MRM analysis.

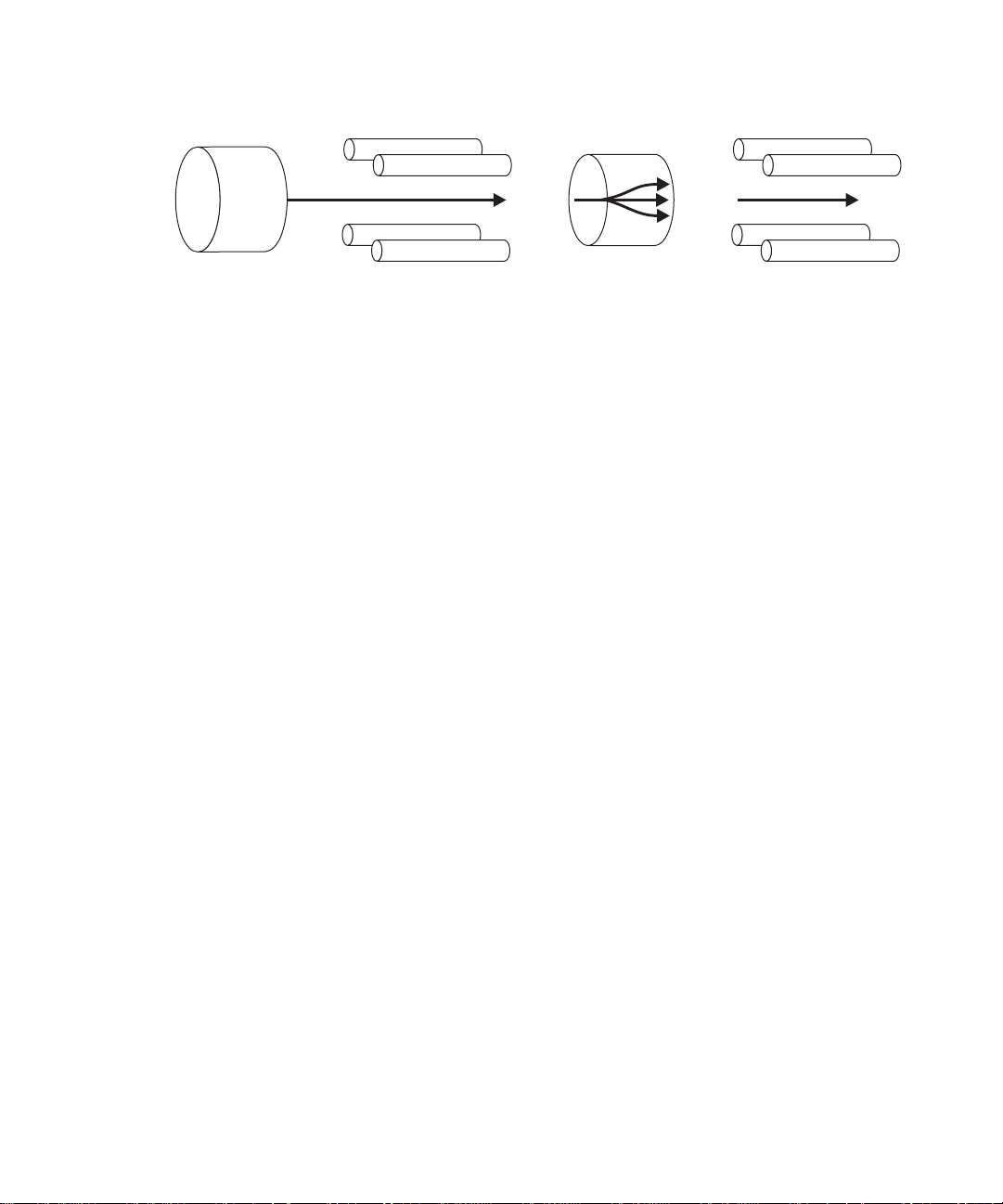

Precursor (par ent) ion mode

Precursor ion mode:

MS1

Scanning

Typical application

You typically use the precursor ion mode for structural elucidation–that is, to

complement or confirm product scan data–by scanning for all the precursors of

a common product ion.

Multiple reaction monitoring mode

MRM mode is a highly selectiv e MS/MS equivalent of SIR. As both MS1 and

MS2 are static, greater dwell time on the ions of interest is allowed, and

therefore better sensitivity compared to scanning MS/MS. This is the most

commonly used acquisition mode for quantitative analysis, allowing the

compound of interest to be isolated from the chemical background noise.

Collision cell

Pass all masses

MS2

Static (at product mass)

1-12 Waters TQ Detector Overview

Page 27

Multiple reaction monitoring mode:

MS1

Static (at precursor mass)

Typical application

You typically use MRM to quantify known analytes in complex samples:

• Drug metabolite and pharmacokinetic studies.

• Environmental, for example, pest icide and herbicide analysis.

• Forensic or toxicology, for example, screening for target drugs in sport.

• MRM does not produce a spectrum because only one transition is

monitore d at a time. As in SI R , a c h romatogram is produce d.

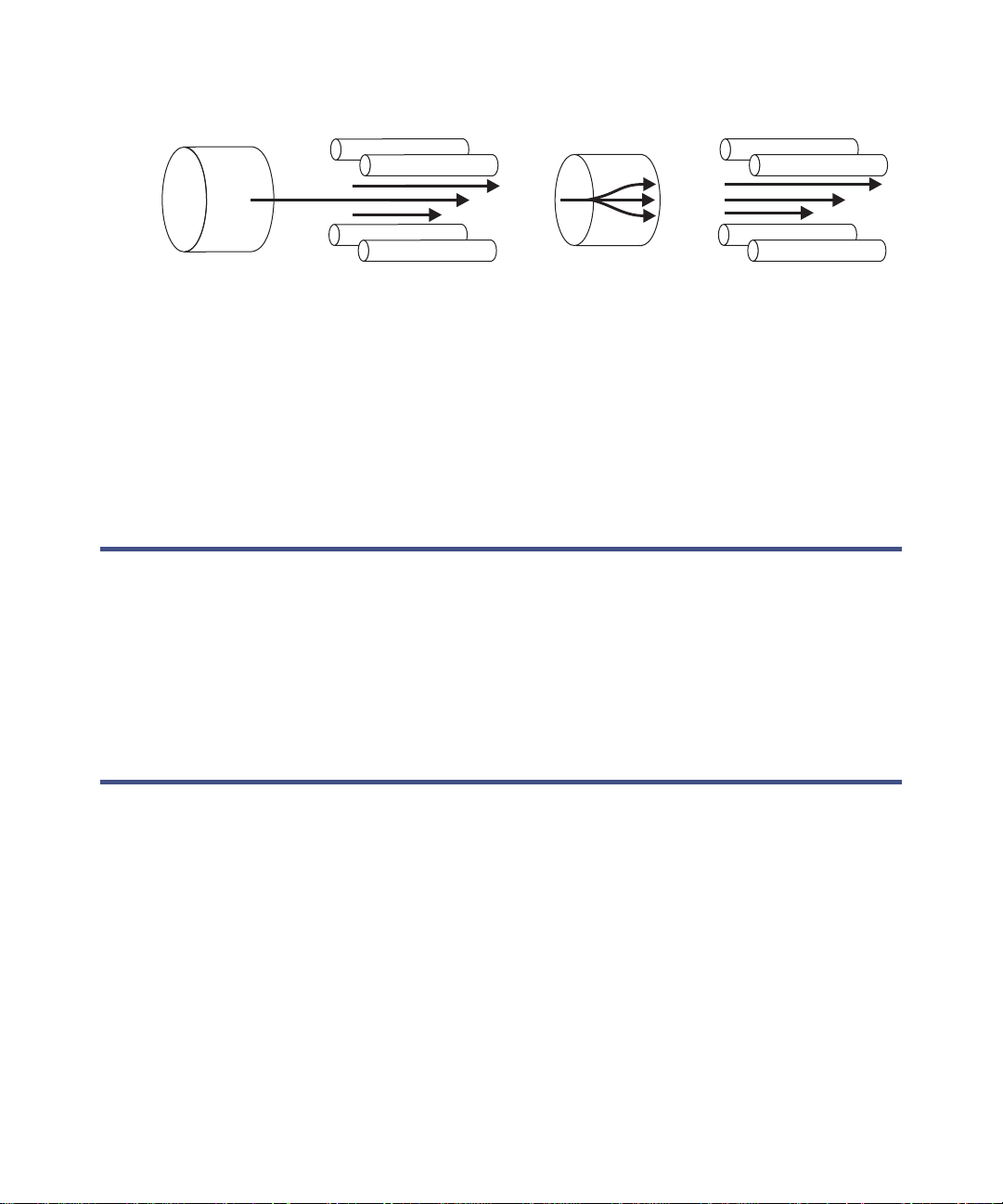

Constant neutral loss mode

Constant neutral loss mode detects the loss of a specific neutral fragment or

functional group from an unspecified precur sor or precursors.

The scans of MS1 and MS2 are synchronized. When MS1 transmits a specific

precursor ion, MS2 “lo oks” to s ee whether that p recu rsor lo ses a fra gment of a

certain mass. If it does, the loss registers at the detector.

In constant neutral loss mode, the spectrum show s the masses of all

precursors that actually lost a fragment of a certain mass .

Collision cell

Pass all masses

MS2

Static (at product mass)

MS/MS operating modes 1-13

Page 28

Constant neutral lo ss mode:

Typical application

You typically use constant neutral loss mode to screen mixtures for a specific

class of compound that is character ized by a common f ragmentat ion pathway,

indicating the presence of compounds containing a common functional group.

Sample inlet

Either of two methods delivers solvent and sample to the installed probe:

• An LC system, which delivers the eluent from an LC analysis.

• IntelliStart fluidics system, which uses on-board solutions to automate

instrument optimization. You can de liver solutions by direct or

combined infusion.

Vacuum system

MS1

Scanning

(synchronized with MS2)

Collision cell

Pass all masses

MS2

Scanning

(synchronized with MS1)

An external roughing (rotary vane) pump and an internal split- flow

turbomolecular pump combine to create the source vacuum. The

turbomolecular pump evacuates the analyzer and ion transfer region.

Vacuum leaks and electrical or vacuum pump failures cause vacuum loss,

which protective interlocks guard against. The system monitors

turbomolecular pump speed and continuously measures vacuum pressure

with a built-in Pirani gauge. The gauge also serves as a switch, discontinuing

operation when it senses vacuum loss.

A vacuum isolation valve isolates the source from the mass analyzer, allowing

routine source maintenance without venting.

1-14 Waters TQ Detector Overview

Page 29

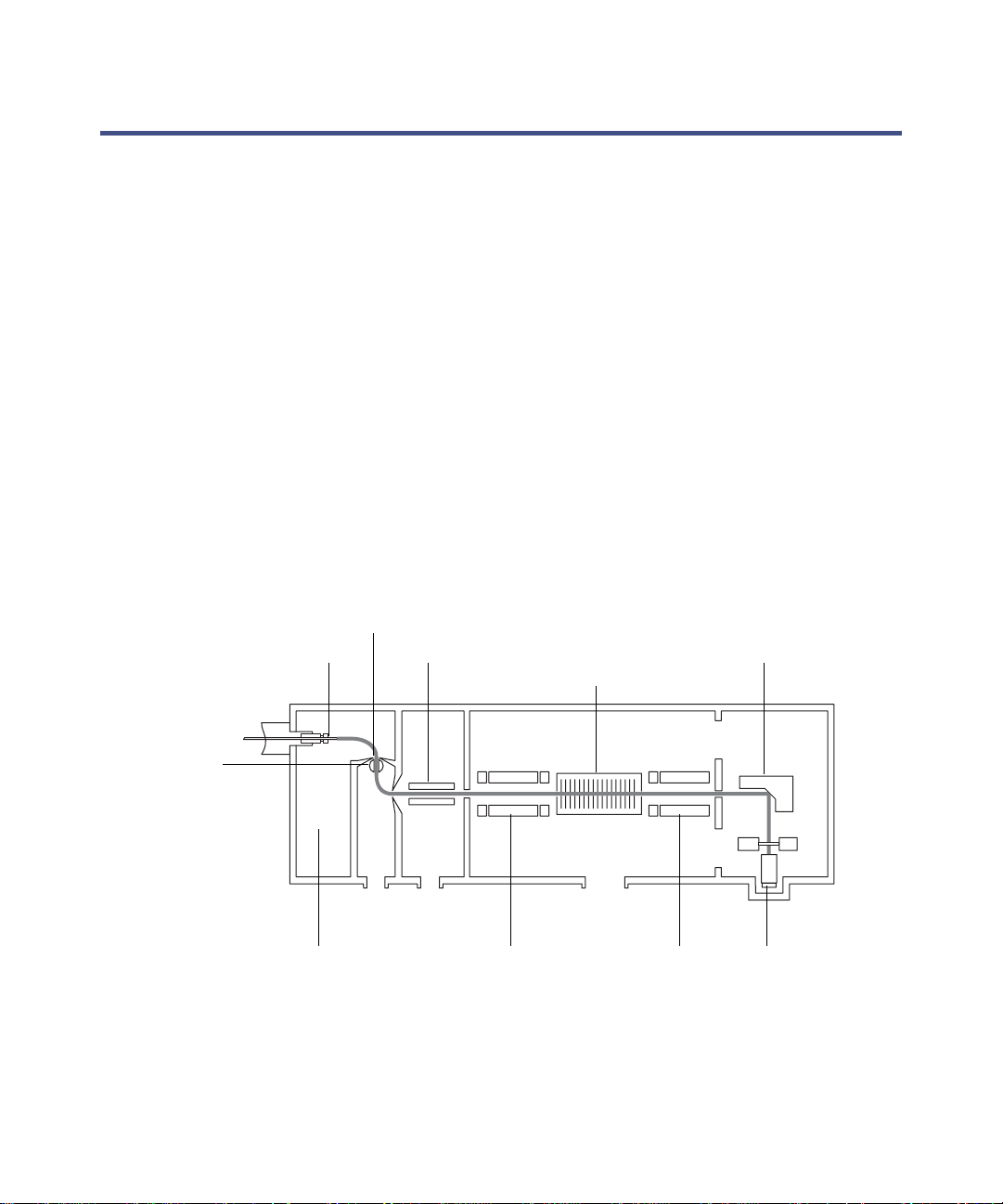

Rear panel

The following figure shows the rear panel locations of the connectors used to

operate the TQ Detector with external devices.

TQ Detector rear panel:

Power cord

Nitrogen inlet

Source vent

Turbo vacuum

Collision cell

gas inlet

V~ 200-240

Hz 50-60

VA 1200

APIGAS

6.9BAR MAXIMUM

SOURCEVENT

Waters Corporation

34 Maple Street Milford, MA01757 U.S.A.

VACUUM

COLLISION

GAS

1.0BAR

MAXIMUM

VACUUM

Serial Number

ACN 065444751

+

+

1

1

InjectStart

In

Analog

Out

2

2

-

-

Ground

3

3

Ground

+

+

4

4

In

Event

NotUsed

-

-

5

5

+

6

6

StopFlow

Switch3

Out

7

7

-

Ground

8

8

Ground

+

9

9

Out Out

Switch4

Switch4

10

10

-

IVD

RS232

ETHERNET

Event inputs

and outputs

Shielded

Ethernet

PUMP

Roughing pump

relay switch

Source vacuum

Rear panel 1-15

Page 30

IntelliStart fluidics system overview

The IntelliStart fluidics system is built into the TQ Detector. The system

delivers sample directly to the MS probe in one of two ways:

• From the LC column

• From two integral reservoirs.

Tip: The integral reservoirs can also deliver sample through direct or

combined infusion to enable optimization at analytical flow rates.

The IntelliStart system incorporates a multi-position valve with these

attributes:

• An input connection from an external LC column.

• An input connection from the TQ Detector’s infusion syringe. (The TQ

Detector’s infusion syringe is also connected to two reservoirs, A and B.

In the software, you specify which reservoir to draw from.)

• An output connection to the TQ Detector’s probe.

• An output connection to a waste line.

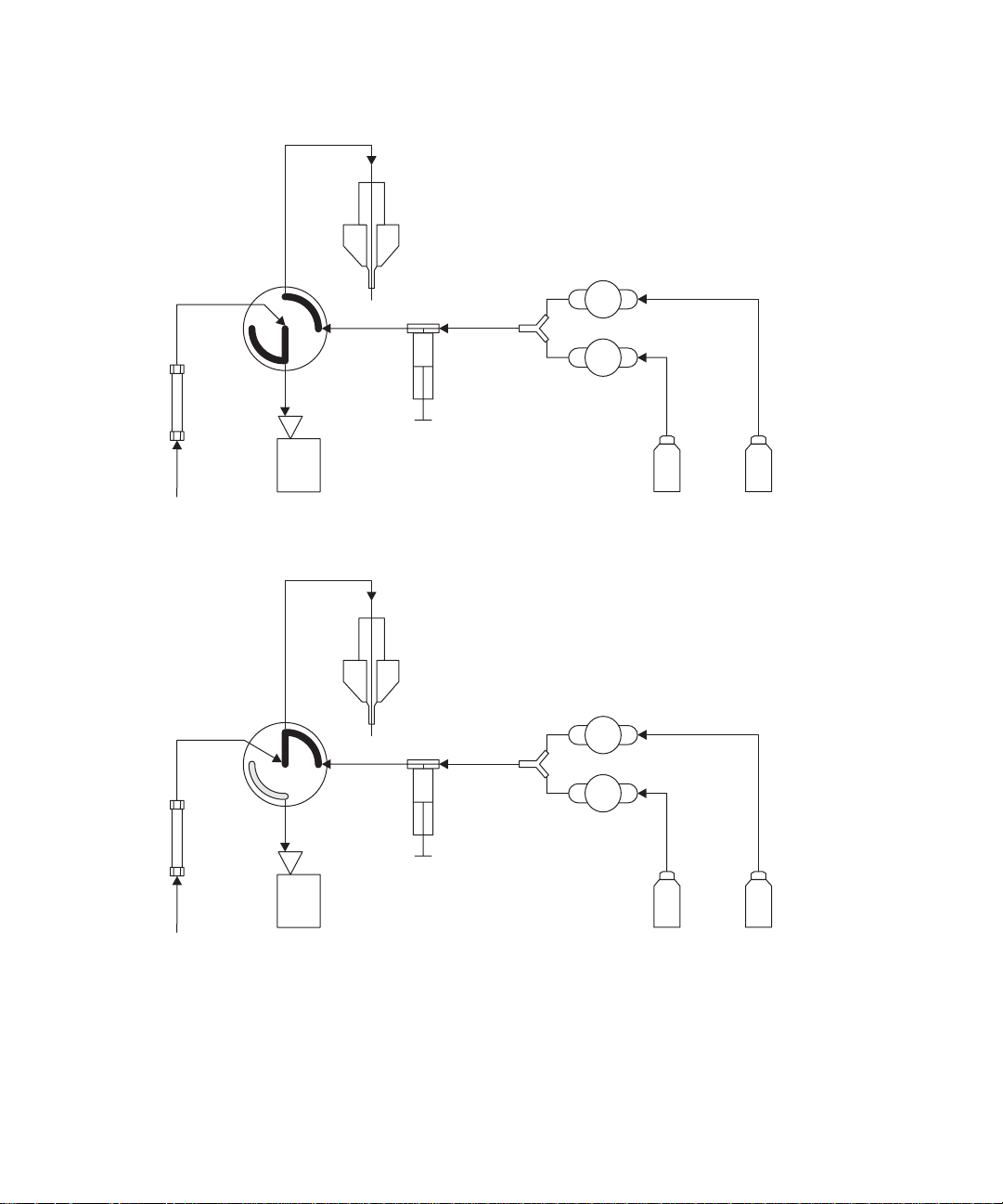

LC flow:

Probe

LC

Column

Syringe

LC Waste

1-16 Waters TQ Detector Overview

Idle

B

Off

A

Off

Reservoir A Reservoir B

Page 31

IntelliStart fluidics system operation

Control of solvent and sample delivery during auto-tuning, auto-calibration,

and method development is automatically performed by the sof tware.

IntelliStart configuration requirements can be set in the system console. You

can edit the parameters, frequency, and extent of the automation you want

IntelliStart to perform.

See also: The TQ Detector online Help for further details of IntelliStart.

Operating the IntelliS tart fluidics system f rom the ACQUITY UPLC Console

To operate the IntelliStart fluidi cs system from the Instrument Console:

1. In the MassLynx window, click MS Console.

2. In the ACQUITY UPLC Console system tree, expand TQ Detector.

3. Click Interactive Display.

4. In the ACQUITY UPLC Console window, click the current flow rate.

5. In the Select Flow Rate dialog box, enter a new flow rate.

IntelliStart fluidics system operation 1-17

Page 32

6. Click OK.

7. Click Reservoir A or B.

8. In the Select Reservoir dialog box, click A or B.

9. Click OK.

Tip: If the selected reservoir is different from the current reservoir, the

system purges as the reservoir changes.

10. Click the current diverter valve position label.

11. In the Select a Flow State dialog box, select the required flow state.

12. Click OK.

13. Click to start.

Tip: A status indicates the amount of fluid in the syringe and the

amount of time remaining before the fluid empties. When the syringe is

empty the system becomes idle.

14. Click to refill the syringe or to purge the system.

15. Click to stop the current action.

Operating the IntelliStart fluidics system from the Tune window

To operate the IntelliStart fluidics system from the Tune window:

1. In the MassLynx window, click MS Tune.

2. In the TQ Detector Tune window, click the Fluidics page.

3. Set the Flow Control parameters according to the instructions in the

MassLynx online Help.

Programming the MS method to operate the IntelliStart fluidics system

In the MS method, you can program the operation of the system’s

multi-position valve to infuse sample during a run. The valve can also divert

LC flow to waste as a timed event.

1-18 Waters TQ Detector Overview

Page 33

To program the MS method:

1. In the MassLynx window, click MS Method.

2. In the MS Methods window, click Options > Method Events.

3. In the Method events dialog box, select the appropriate flow state, as

shown in the following table.

Flow states :

State LC Syringe

LC TQ probe Waste

Combined TQ probe TQ probe

Infusion Waste TQ Probe

Waste Waste Waste

No change No change No change

Tip: At instrument power-up, the LC state is waste.

See also: MassLynx online Help topic “Advanced Methods and Events ”.

IntelliStart fluidics system operation 1-19

Page 34

1-20 Waters TQ Detector Overview

Page 35

2 Preparing the Waters TQ

Detector for Operation

This chapter describes how to start and shut-down the TQ Detector.

Contents:

Topic Page

Starting the TQ Detector 2-2

Preparing the IntelliStart fluidics system 2-9

Rebooting the TQ Detector 2-14

Shutting down the TQ D etector 2-15

2-1

Page 36

Starting the TQ Detector

Note: The Waters TQ Detector is designed for compatib ility with the

ACQUITY UPLC system; if you are not using an ACQUITY UPLC system,

refer to the documentation relevant to the system being used.

Caution: Using incompatible solvents can cause severe damage to the

instrument.

• Refer to Appendix C of the Waters TQ Detector Operator’s Guide for

TQ Detector solvent information.

• Refer to Appendix C of the ACQUITY UPLC System Operator’s

Guide for more information on solvent compatibility with

ACQUITY.

Starting the TQ Detector entails powering-on the ACQUITY workstation,

logging into the workstation, powering-on the TQ Detector and all the other

ACQUITY instruments, and starting the MassLynx software.

Requirement: You must power-on and log in to the ACQUITY workstation

first to ensure that it obtains the IP addresses of the system instrum e nts.

To start the TQ Detector:

Warning: During analyses that require flammable solvents, to avoid

ignition of the solvents, never let the nitrogen supply pressure fall

below 400 kPa (4 bar, 58 psi).

1. Ensure the n i tr o g e n sup p l y i s connected to th e instrumen t’ s AP I g a s

connection.

Note: The nitrogen must be dry and oil-free, with a purity of at least

95%. Regulate the supply at 600 to 690 kPa (6.0 to 6.9 bar, 90 to

100 psi).

See also: Figure titled “TQ Detector rear panel” on page 1-15.

2. Ensure that the collision gas supply is connecte d to the TQ Detector.

Requirement: The collision gas is argon; it must be dry and of high

purity (99.9%). Regulate the supply at 50 kPa (0.5 bar, 7 psi).

3. Power-on the ACQUITY UPLC system workstation, and log in before

powering-on the other instruments.

2-2 Preparing the Waters TQ Detector for Operation

Page 37

4. Press the power switch on the top, lef t-hand s ide of the TQ Dete ctor and

ACQUITY instruments. Each system instrument “beeps” and runs a

series of startup tests.

5. Allow 3 minutes for the embedded PC to initialize. An audible alert

sounds when the PC is ready.

The power and status LEDs change as follows:

• Each system instrument’s power LED shows green.

• During initialization, the binary solvent manager’s and sample

manager’s status LED flashes green.

• After the instruments are successfully powered-on, all power LEDs

show steady green. The binary solvent manager’s flow LED, the

sample manager’s run LED, and the TQ Detector’s operate LED

remain off.

6. Start MassLynx. You can monitor the ACQUITY console for messages

and LED indications.

7. In the MassLynx main window’s lower-left corner, click IntelliSt art.

Result: TQ Detector console IntelliStart appears . The TQ Detector is in

Standby mode.

Starting the TQ Detector 2-3

Page 38

8. Click Control > Pump to start the roughing pump. The operate LED

remains off.

Tip: There is a 20-second delay, during which th e turbop ump is star ting,

before the roughing pump starts. IntelliStart displays “Instrument in

standby”.

2-4 Preparing the Waters TQ Detector for Operation

Page 39

9. Click Resolve or Operate to put the TQ Detector into Operate

mode. When the TQ Detector is in good operating conditi on, IntelliStart

displays “Ready”.

Tip: Clicking Resolve should prepare the system for operation,

putting the TQ Detector into Operate mode. If clic k i ng Resolve fails to

put the instrument into Operate mode, IntelliStart displays corrective

actions.

Starting the TQ Detector 2-5

Page 40

Configuring IntelliStart

To configure IntelliStart:

1. In the ACQUITY UPLC Console system tree, click TQ Detector.

2. Click Configure > IntelliStart Configuration.

3. In the IntelliStart Configuration dialog box, in the Checks list, select the

checkboxes for the items you want checked during TQ Detector startup.

Clear the checkboxes of items you do not want checked.

Tip: To display detailed information for an item, highlight it and click

Properties.

4. Click Apply > OK.

Verifying the instrument’s state of readiness

When the TQ Detector is in good operating condition, the power LED shows

constant green and the operate LED is off. You can view any error messages in

IntelliStart.

To access IntelliStart:

1. In the ACQUITY UPLC Console system tree, select TQ Detector.

2. In the TQ Detector information window, click IntelliStart.

Tuning and calibration information

The TQ Detector must be tuned and calibrated prior to use, tasks normally

performed from IntelliStart.

See also: The online Help topic “Instrument Setup” and Chapter 4,

“Operati n g th e Wa ters TQ Detec tor”.

2-6 Preparing the Waters TQ Detector for Operation

Page 41

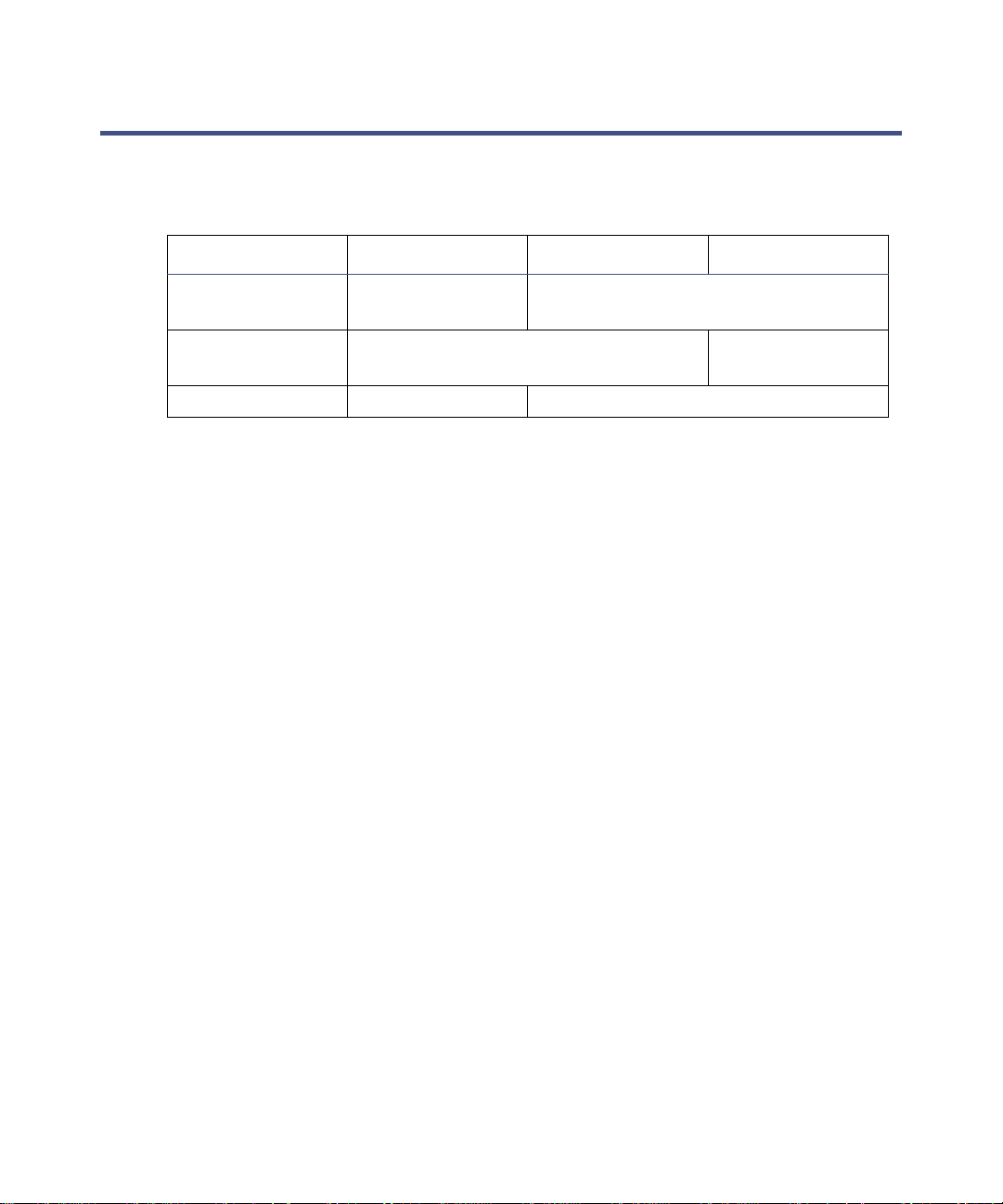

Running the TQ Detector at high flow rates

ACQUITY UPLC is run at high flow rates. To optimize desolvation, and thus

sensitivity, the ACQUITY TQD system should be run at appropriate gas flows

and desolvation temperatures. IntelliStart automatically sets these when you

enter a flow rate, according to the following table.

Flow rate versus temperature and gas flow :

Flow rate

(mL/min)

0.000 to 0.100 120 250 500

0.101 to 0.300 120 350 600

0.301 to 0.500 150 400 800

>0.500 150 450 900

Note: Under low ambient temperature, high moisture, and high flow rate

conditions, condensation can occur in the instrument’s source.

Source temp (°C)

Desolvation

temp (°C)

Desolvation gas

flow (L/hr)

Starting the TQ Detector 2-7

Page 42

Monitoring the TQ Detector LEDs

Light-emitting diodes on the TQ Detector indicate its operational status.

Power LED

The power LED, to the top, left-hand side of the TQ Detector’s front panel,

indicates when the T Q De te c tor is po we r e d- on o r po we r e d- off.

Operate LED

The operate LED, to the right of the power LED, indicates the operating

condition.

Operate LED indications :

LED mode and color Description

Off The instrument is in Standby mode with high

voltages and heaters inoperative.

Constant green The instrument is in Operate mode with heaters

and high voltages operating.

Flashing green Indicates the system is waiting for an instrument

component to reach operational conditio ns. The

LED could, for example, flash while the system

reaches a programmed temperature set point or

vacuum level. The instrument is in work ing

order and Operate mode but not yet ready to

acquire.

Flashing red Indicates that the sys tem stopped due to error

and is no longer processing any samples or other

maintenance requests. Information r egarding the

error appears in the data system's contro l panel

or the ACQUITY UPLC Console software.

Constant red for

3 minutes

Constant red for more

than 3 minutes

2-8 Preparing the Waters TQ Detector for Operation

The instrument is waiting for the instrument to

initialize.

Indicates a serious system failure that prevents

further operation. Power-off the instrument, and

then power-on. If the LED is still steady red for

more than 3 minutes, contact your Waters

service r epresentative.

Page 43

Preparing the IntelliStart fluidics system

See also: Appendix B of the Waters TQ Detector Operator’s Guide .

Installing the solvent manifold drip tray

Required materials

Chemical-resistant, powder-free gloves

To install the solvent manifold drip tray:

Warning: The solvent ma nifold drip tray can be contaminated

with biohazardous and/or toxic materials. Always wear

chemical-resistant, powder-free gloves while performing this

procedure.

Install the solvent manifold drip tray as shown below:

TP02685

Preparing the IntelliStart fluidics system 2-9

Page 44

Installing the reservoir bottles

Required materials

Chemical-resistant, powder-free gloves

To install the reservoir bottles:

Warning: The reservoir bottles can be contaminated with

biohazardous and/or toxic materials. Always wear

chemical-resistant, powder-free gloves while performing this

procedure.

1. Remove the reservoir bottle caps.

2. Screw the reservoir bottles onto the TQ Detector as shown below.

TP02630

2-10 Preparing the Waters TQ Detector for Operation

Page 45

Diverter valve positions

Column and syringe in home position after power-up

After power-up, the flow path between the column and waste is open. The

syringe is empty, and the flow path between it and waste is open.

Waste

Column

Probe

Idle

Syringe

B

Off

A

Off

LC Waste

Reservoir A Reservoir B

LC position

In the LC position, the flow path between the LC and probe is open, and the

flow path between the syringe and waste is also open.

Probe

B

LC

Column

LC Waste

Idle

Syringe

Off

A

Off

Reservoir A Reservoir B

Preparing the IntelliStart fluidics system 2-11

Page 46

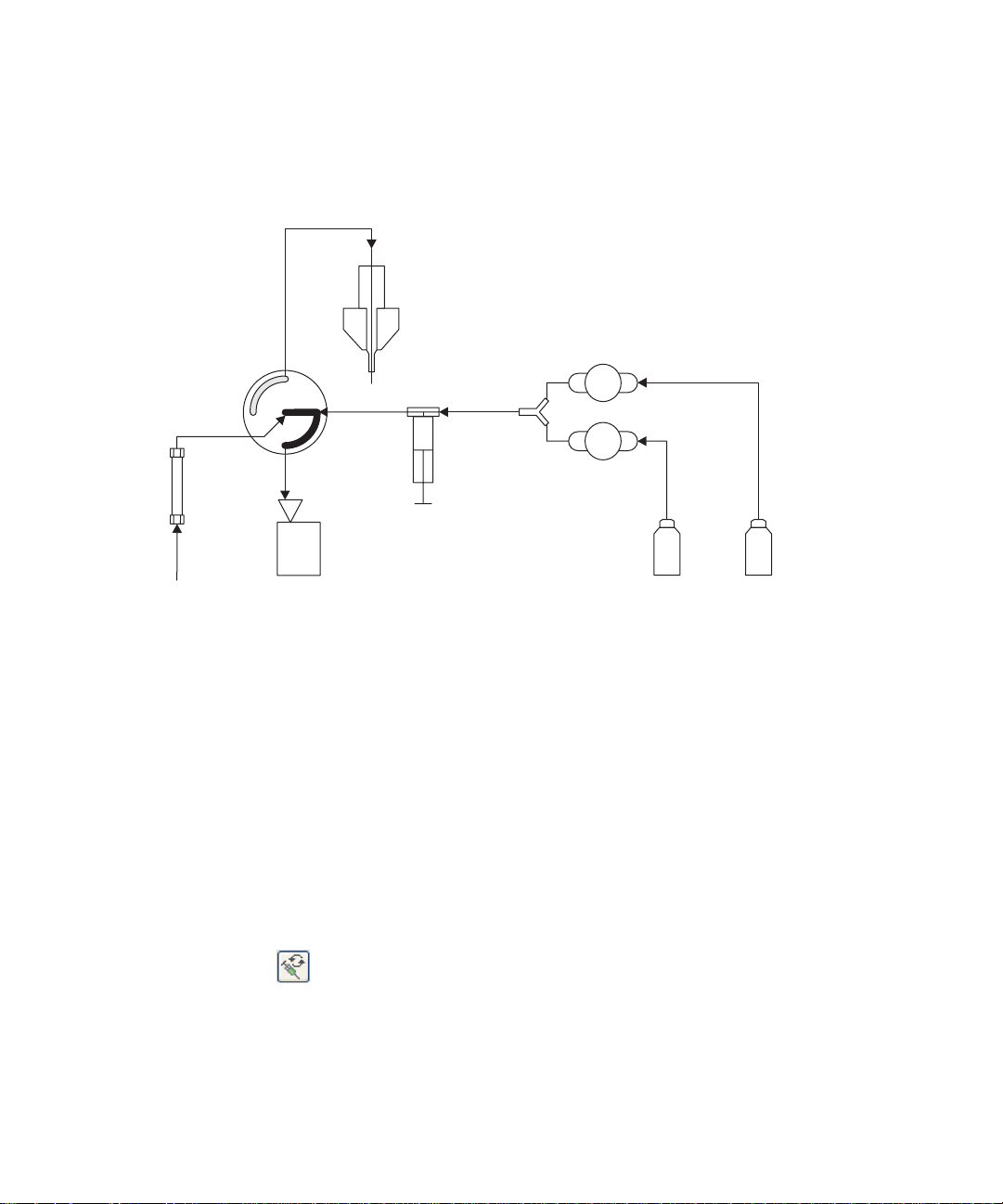

Infusion position in infusion mode

Probe

Infusion

Column

LC Waste

Infusion

Syringe

Reservoir A Reservoir B

B

Off

A

On

Combined position with LC flow and syringe in idle mode

Probe

Combined

Idle

B

Off

A

Off

Column

Syringe

LC Waste

2-12 Preparing the Waters TQ Detector for Operation

Reservoir A Reservoir B

Page 47

Waste position

In the waste position, both the LC flow and the infusion syringe flow are

directed to waste. The syringe mode can be only static or dispensing (that is,

never drawing).

Probe

Waste

Idle

Column

Syringe

LC Waste

Purging the infusion syringe

Whenever you replace a solution bott le, you sho uld purge t he inf usi on syringe

with the solution that you are going to use next.

Tip: Depending on the solutions used, the IntelliStart fluidics system can

require more then one purge cycle to minimize carryover.

To purge the infusion syringe:

1. In the ACQUITY UPLC Console system tree, expand TQ Detector.

2. Click Interactive Display.

B

Off

A

Off

Reservoir A Reservoir B

3. Select the re q u ir e d so l u ti o n reservoir.

4. Click to purge the system.

Tip: System purge takes approximately 2 minutes.

Preparing the IntelliStart fluidics system 2-13

Page 48

Rebooting the TQ Detector

Sometimes you might need to reboot the TQ Detector:

• When the Tune window fails to respond.

• When MassLynx fails to initialize.

• Immediately following software download.

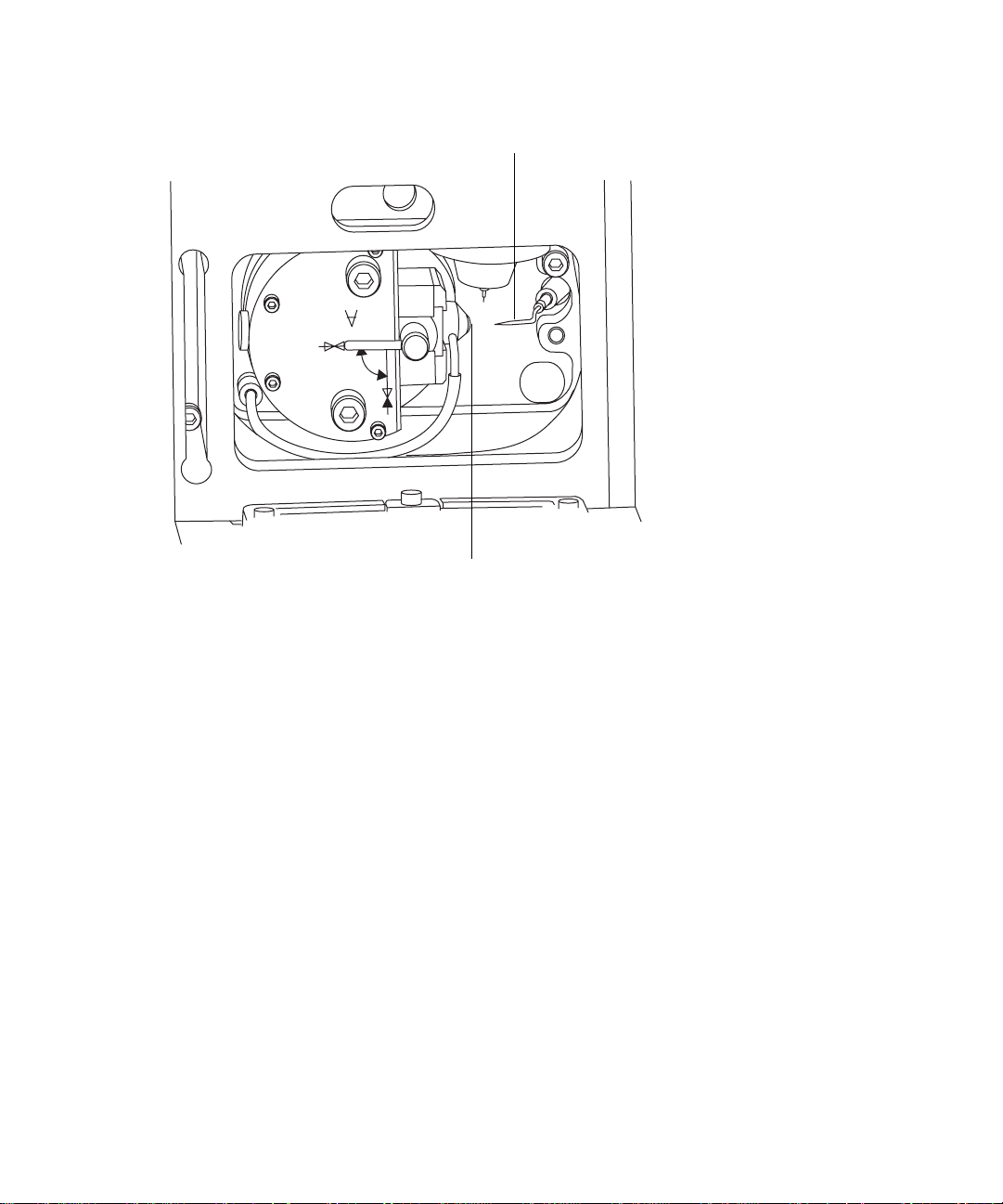

Rebooting the TQ Detector by pressing the reset button

Tip: The reset button shuts down the electronics momentarily and causes the

TQ Detector to reboot.

To reboot the TQ Detector by pressing the reset button:

1. Open the TQ Detector’s front left door.

2. Press the red reset button on the top, left-hand side of the instrument.

TP02687

2-14 Preparing the Waters TQ Detector for Operation

Reset button

Page 49

Shutting down the TQ Detector

Recommendation: You should always leave the TQ Detect or in Operate mode

except when performing routine maintenance. It is not necessary to switch to

Standby mode. However, shutting down the TQ Detector is acceptable

provided that you consider warm-up time on restarting. If you do shut dow n

the TQ Detector, refer to the instructions in this section.

Caution: Buffers left in the system can precipitate and damage

instrument components.

Tip: Set system shutdown parameters in the Shutdown Editor. Consult the

MassLynx online Help for more information.

Putting the TQ Detector in Standby mode for overnight shutdown

You might want to shut down the instrument for a relatively brie f pe riod, like

overnight, while maintaining the LC flow.

To put the TQ Detector in Standby mode:

1. In the ACQUITY UPLC Console, click to stop the LC flow or, if

column flow is required, divert the LC flow to waste as follows:

a. In the ACQUITY UPLC Console system tree, expand TQ Detector.

b. Click Interactive Display.

c. Click the current diverter valve position label.

d. In the Select a Flow State dialog box, select Waste.

e. Click OK.

2. Click Standby to shut off heaters and voltages.

Tip: You can create a method to stop the gas flow or lower the

temperature. See the MassLynx online Help for more infor mation on

creating me t h ods.

Shutting down the TQ Detector 2-15

Page 50

Complete TQ Detector shutdown

To completely shut down the TQ Detector:

1. Put the TQ Detector in Standby mode.

See also: “Putting the TQ Detector in Standby mode for overnight

shutdown” on page 2-15.

2. In the ACQUITY UPLC Console, click API Gas .

3. Click Col Gas .

4. Click Control > Vent.

Result: The turbomolecular pump is switched off. When the

turbomolecular pump runs down to half its normal operating speed, the

vent valve opens and the instrument is automatically vented. The

operate LED changes from green to red and then turns off.

5. Exit MassLynx.

6. After the roughing pump shuts off, operate the power button (on the

front of the instrument) to power-off the TQ Detec tor.

Warning: The TQ Detecto r’s power switch does not isolate the

instrument from the main power supply. To isolate the

instrument, you must disconnect the power cable from the back

of the instrument.

7. Disconnect the power cable from the back of the TQ Detector.

8. Power-off all other instruments and the workstation.

Note: The fans inside some instruments run continuously, even after

you power-off the instruments.

2-16 Preparing the Waters TQ Detector for Operation

Page 51

Emergency TQ Detector shutdown

To shut down the TQ Detector in an emergency:

Warning: The TQ Detecto r’s power switch does not isolate the

instrument from the main power supply. To isolate the instrument,

you must disconnect the power cable from the back of the instrument.

Caution: Data can be lost during an emergency shutdown.

1. Operate the power button on the front of the TQ Detector .

2. Disconnect the power cable from the back of the TQ Detector.

Shutting down the TQ Detector 2-17

Page 52

2-18 Preparing the Waters TQ Detector for Operation

Page 53

3 ESI and ESCi Modes of

Operation

This chapter describes how to prepare the TQ Detector for the following

modes of operation:

• ESI (electrospray ionization)

• ESCi (combined electrospay and atmospheric pres sur e chemical

ionization)

If your system uses APCI mode, refer to Chapter 6 of the Waters TQ

Detector Operator’s Guid e.

Contents:

Topic Page

Introduction 3-2

Installing the ESI probe 3-2

Installing the corona pin 3-5

Optimizing the ESI probe for ESCi operation 3-7

Removing the corona pin 3-9

Removing the ESI probe 3-11

3-1

Page 54

Introduction

The ESI and ESCi ionization mode options use th e standar d ESI probe t hat i s

fitted to the instrument when it is shipped from the factory. For ESCi

operation, the corona pin is used in conjunction with the ESI pr obe. The

following sections explain how to install and remove t he ESI probe and cor ona

pin.

See also:

• “Electro sp ra y i o n iza t i o n (E SI)” on page 1-7.

• Table titled “Combined electrospray ionization and atmospheric

pressure chemical ionization (ESCi)” on page 1-7.

Installing the ESI probe

Required materials

Chemical-resistant, powder-free gloves

To install the ESI probe:

Warning: The ACQUITY UPLC system connections, ESI probe,

and source can be contaminated with biohazardous and/or toxic

materials. Always wear chemical-resistan t, powder-free gloves

while performing this procedure.

Warning: To avoid electric shock, ensure that the instrument is

suitably prepared before commencing this pr ocedure.

1. Prepare the instrument for working on the source.

See also: Chapter 5 of the Waters TQ Detector Operator’s Guide.

Warning: The source can be hot. To avoid burn injuries, take

great care while working with the instrument’s access door open.

2. Open the instrument’s access door.

3-2 ESI and ESCi Modes of Operation

Page 55

Warning: The ESI probe tip is sharp. To avoid puncture wounds,

handle the ESI probe with care.

3. Remove the protective sleeve, if fitted, from the ESI probe tip.

4. Ensure that the contacts o n the ESI probe align with the probe adjuster

assembly contacts, and carefully slid e the ESI probe into the hole in the

probe adjuster assembly.

ESI probe

Probe adjuster assembly

Probe adjuster

assembly contacts

TP02632

5. Secure the ESI probe by tightening the two thumbscrews.

See also: Figure titled “ESI probe mounted on the source enclosure,

showing the connections to the front panel” on page 3-4.

Installing the ESI probe 3-3

Page 56

ESI probe mounted on the source enclosu re, showing th e connections

to the front panel:

Vernier prob e adju ste r

Nebulizer gas connection

Desolvation gas connection

ESI probe

electrical lead

Probe adjuster

assembly

electrical lead

Probe adjuster assembly

Thumbscrew

Diverter valve

ESI probe

6. Connect the ESI probe’s PTFE tube to the nebulizer gas connection.

7. Ensure that the probe adjuste r asse mbly’s e lectric al lead is con nected t o

the instrument’s probe connection.

8. Connect the ESI probe’s electrical lead to the instrument’s HV

connection.

Warning: To avoid electric shock, do not use stainless steel

tubing to connect the diverter valve to the ESI probe; use the

PEEK™ tubing supplied with the instrument.

9. Connect the diverter valve to the ESI probe; use tubing of the

appropriate internal diameter (ID).

Tip: Two tubes of different ID are supplied with the instrume nt.

Requirement: If you are replacing the tubing suppl ied with the

instrument, you must minimize the length of the tube connecting the

diverter valve to the ESI probe. This minimizes delays and dispersion.

10. Close the instrument’s access door.

3-4 ESI and ESCi Modes of Operation

Page 57

Installing the corona pin

Required materials

• Chemical-resistant, powder-free gloves

• Needle-nose pliers

• 80:20 acetonitrile/water

To install the corona pin:

Warning: The ACQUITY UPLC system connections, ESI probe,

and source can be contaminated with biohazardous and/or toxic

materials. Always wear chemical-resistan t, powder-free gloves

while performing this procedure.

Warning: To avoid electric shock, ensure that the instrument is in

Standby mode when commencing this procedure.

1. In the ACQUITY UPLC Console, click Stand by , and confirm that

the Operate indicator is not illuminated.

Warning: The source can be hot. To avoid burn injuries, take

great care while working with the instrument’s access door open.

2. Open the instrument’s access door.

Warning: The probe tip is sharp. To avoid puncture wounds , take

great care while working with the source enclosure door open if

an ESI probe is fitted.

Caution: Do not apply any downward force to the sourc e

enclosure door while the door is open.

3. Unlatch the source enclosure door’s handle and open the door.

Installing the corona pin 3-5

Page 58

4. Use the needle-nose pliers to remove the blanking plug from the corona

pin mounting contact.

Tip: Store the blanking plug in a safe location.

Corona pin mounting contact:

Corona pin mounting

contact blanking plug

TP02660

Warning: The corona pin tip is sharp. To avoid puncture wounds,

handle the corona pin with care.

Caution: To avoid damaging to the corona pin’s tip and bending

the pin, use the needle nose pliers to grip the corona pin at the

end that fits into the mounting contact.

5. Use the needle-nose pliers to fit the corona pin to the mounting contact.

Requirement: Ensure that the corona pin is securely mounted and that

its tip aligns with the sample cone orifice.

3-6 ESI and ESCi Modes of Operation

Page 59

Corona pin:

ESI probe tip

Corona pin

Sample cone tip

TP02695

6. Use the vernier probe adjuster to position the ESI probe tip so that it is

pointing approximately mid-way between the tips of the sample cone

and corona pin.

See also: Figure titled “ESI probe mounted on the source enclosure,

showing the connections to the front panel” on page 3-4.

7. Close the source enclosure door and fasten the handle.

8. Close the instrument’s access door.

Optimizing the ESI probe for ESCi operation

Required materials

80:20 acetonitrile/water

To optimize the ESI probe for ESCi operation:

1. In the MassLynx window, click MS Tune.

2. In the Tune window, click Setup > Inter-scan Setup.

3. In the Inter-scan Setup dialog box, click Reset to Defaults.

Optimizing the ESI probe for ESCi operation 3-7

Page 60

4. Click OK.

5. In the MassLynx Tune window, click Ion Mode > ESCi+.

6. Select box numbers 1 and 2, clear box numbers 3 and 4 (above the peak

display).

7. In row 1, set Ion Mode to ES.

8. In row 2, set Ion Mode to APcI.

9. In each row, set Mass to 42 and Span to 5.

10. Start an infusion of 80:20 acetonitrile/water.

11. Use the vernier probe adjuster to ensure that the ESI pr obe tip is

pointing approximately mid-way between the tips of the sample cone

and corona pin.

12. On the Tune window, observe the 42 Da peak in the ES+ and APcI+

peak displays, and increase the values of Capillary (kV) and Corona

[(µA) in the current mode or kV in the voltage mode] to prod uce the mo st

intense ESI+ and APcI+ signal.

13. Use the vernier probe adjuster to gradually move the probe

bi-directionally to determine the best position for both the ESI+ and

APcI+ signals.

Tip: You can find a position between the two modes that yields a

relatively optimized signal.

14. To determine whether you hav e discrete ionization in the ESI or APcI

mode, set the Capillary parameter to 0 kV and observe that little or no

signal remains in ESI mode. Then set the Corona parameter to 0 µA or

0 kV , and observe that little or no signal remains in APcI mode.

Result: The ESI probe is now optimized for ESCi mode.

Tip: If necessary, repeat the above procedure using the analyte of

interest, since ionization pot entials may vary with different samples.

3-8 ESI and ESCi Modes of Operation

Page 61

Removing the corona pin

Required materials

• Chemical-resistant, powder-free gloves

• Needle-nose pliers

To remove the corona pin:

Warning: The ACQUITY UPLC system connections, corona pin,

ESI probe, and source can be contaminated with biohazardous

and/or toxic materials. Always wear chemical-resistant,

powder-free gloves while performing this procedure.

Warning: To avoid electric shock, ensure that the instrument is in

Standby mode when commencing this procedure.

1. In the ACQUITY UPLC Console, click Stand by , and confirm that

the Operate indicator is not illuminated.

Warning: The source can be hot. To avoid burn injuries, take

great care while working with the instrument’s access door open.

2.

Open the instrument’s access door.

Warning: The probe tip is sharp. To avoid puncture wounds , take

great care while working with the source enclosure door open if

an ESI probe is fitted.

Caution: Do not apply any downward force to the sourc e

enclosure door while the door is open.

3. Unlatch the source enclosure door’s handle and open the door.

Removing the corona pin 3-9

Page 62

Warning: The corona pin tip is sharp. To avoid puncture wounds,

handle the corona pin with care.

Caution: To avoid damaging to the corona pin’s tip and bending

the pin, use the needle nose pliers to grip the corona pin at the

end that fits into the mounting contact.

4. Use the needle-nose pliers to remove the corona pin from its mounting

contact.

Tip: Store the corona pin in a safe location.

See also: Figure titled “Corona pin:” on page 3-7.

5. Use the needle-nose pliers to fit the blanking plug to the corona pin

mounting contact.

See also: Figure titled “Corona pin mounting contact:” on page 3-6.

6. Close the source enclosure door and fasten the handle.

7. Close the instrument’s access door.

3-10 ESI and ESCi Modes of Operation

Page 63

Removing the ESI probe

Required materials

Chemical-resistant, powder-free gloves

To remove the ESI probe:

Warning: The ACQUITY UPLC system connections, ESI probe,

and source can be contaminated with biohazardous and/or toxic

materials. Always wear chemical-resistan t, powder-free gloves

while performing this procedure.

Warning: To avoid electric shock, ensure that the instrument is

suitably prepared before commencing this pr ocedure.

1. Prepare the instrument for working on the source.

See also: Chapter 5 of the Waters TQ Detector Operator’s Guide.

Warning: The ESI probe and source can be hot. To avoid burn

injuries, ta ke g re a t care while wo rking with th e i n st rument’s

access door open.

2. Open the instrument’s access door.

3. Disconnect the diverter valve tubing from the ESI probe.

4. Disconnect the ESI probe’s electrical lead from the high voltage

connection.

5. Disconnect the ESI probe’s PTFE tube from the nebulizer gas

connection.

6. Undo the two thumbsc rews s ecur ing the ESI pro be to the probe adjust er

assembly.

Warning: The ESI probe tip is sharp. To avoid puncture wounds,

handle the probe with care.

7. Carefully remove the ESI probe from the probe adjuster assembly.

Removing the ESI probe 3-11

Page 64

8. If available, fit the protective sl eeve to the ESI probe tip.

9. Close the instrument’s access door.

3-12 ESI and ESCi Modes of Operation

Page 65

4 Operating the Waters TQ

Detector

This chapter is an introduction to operating your TQ Detector; it

explains these tasks:

• Setting-up your TQ Detector.

• Performing a sample tune.

• Developing instrument methods.

• Verifying the system.

Contents:

Topic Page

Setting-up the instrument 4-2

Performing a sample tune 4-7

Developing experiment me thods 4-9

Verifying the system using System QC 4-11

4-1

Page 66

Setting-up the instrument

The IntelliStart instrument setup calibrates the instrument and then, by

default, performs a sample tune. If calibration is unneces sary, you can

perform only a sample tune.

See also: “Performing a sample tune” on page 4-7.

Tip: Instrument setup need only be performed every three to six months,

depending on your usage requirements.

In the following example, sodium cesium iodide is used as the calibrant

solution and sulfadimethoxine the tune sample.

Tip: You can substitute solutions suitable for your requirements.

See also: The TQ Detector online Help for further details of IntelliStart.

Required materials

• Sodium cesium iodide solution (2 ng/µL)

• Sulfadimethoxine solution (100 pg/µL)

To prepare the IntelliStart fluidics system:

See also: “IntelliStart fluidics syst em operation” on page 1-17.

1. Ensure that IntelliStart fluidics system’s reservoir A is filled with

sodium cesium iodide solution.

2. Ensure that reservoir B is filled with sulfadimethoxine solution.

Requirement: Ensure that there is enough soluti on in each r eservoir f or

approximately 5 minutes of operation during the set-up procedure.

Recommendation: In general, place calibrant solution in reservoir A

and tune sample in reservoir B.

3. In the MassLynx window, click MS Console.

4. In the ACQUITY UPLC Console system tree, expand TQ Detector.

5. Click Interactive Display.

6. In the ACQUITY UPLC Console window, click the current flow rate.

7. In the Select Flow Rate dialog box, enter a 50 µL/min flow rate.

4-2 Operating the Waters TQ Detec tor

Page 67

8. Click OK.

9. Click to purge the system.

Tip: System purge takes approximately 2 minutes.

10. Repeat step 9.

Rationale: Purging the IntelliStart fluidics system twice ensures that

any traces of previously used solutions are removed from the system.

11. Click on the currently-selected reservoir display.

12. In the Select Reservoir dialog box, select the reservoir not currently

selected.

13. Click OK.

Result: The other reservoir is selected, and the system is purged.

14. When the purge finishes, click to purge the sys tem again.

To specify the instrument set-up parameters:

1. In the ACQUITY UPLC Console system tree, click TQ Detector.

2. Ensure that Ion Mode is ES+.

3. In the ACQUITY UPLC Console system tree, click IntelliStart.

4. Ensure that Instrument Setup is selected.

5. If you require system pre-checking, click Pre-checks.

Rationale: If Pre-checks is selected, when IntelliStart starts the

instrument set-up, it dete rmines whethe r t he existi ng cali brati on is stil l

valid. If so, it does not perform a full calibration but proc eeds to sample

tuning the instrument.

See also: TQ Detector online Help topic “IntelliStart flow diagram”.

6. Click Start to open the IntelliStart Setup Paramete rs dialog box.

7. In the Instrument Setup tab’s Reference drop-d own li st , click Naics.

Rationale: Naics is the calibration reference file for sodium ces i um

iodide when working in ES+ ion m ode.

Setting-up the instrument 4-3

Page 68

8. Click Fill from reference file.

Result: The default mass values appear in the In strument Tune Mas ses

text boxes.

Rule: You must click Fill from reference file every time you select a new

calibration reference file.

Instrument Setup Parameters dialog box Instrument Setup tab with

default parame ters:

Tip: You can use alternative reference solutions to calibrate at higher

masses.

9. The tune and calibration results are written to the files in the

Instrument Tune and Calibration text boxes; you can use the default

files, enter new names, or Browse for files.

4-4 Operating the Waters TQ Detec tor

Page 69

To specify the sample tune parameters:

1. In the IntelliStart Setup Parameters dialog box, click the Sample Tune

tab.

2. Click Copy Instrument Setup masses.

Rationale: The Tune Masses from the Instrument Setup tab are copied

into the Sample Tune Masses boxes.

Instrument Setup Parameters dialog box Sample Tune tab:

3. In the Tune text box, enter sulfadimethoxine.ipr.

Rationale: The sample tune results are written to this file.

Setting-up the instrument 4-5

Page 70

Instrument Setup Parameters dialog box Sample Tune tab with

example sample tune parameters:

To start instrument set-up:

1. Click Start .

Result: A message appears reminding you to ensure that the calibrant

solutions, calibration parameters and LC flow are set correctly.

2. Click OK.

Result: Instrument set-up starts. An autotune on the calibrant is

followed by automatic calibration. The ACQUITY UPLC Console

displays the progress of the setup.

4-6 Operating the Waters TQ Detec tor

Page 71

Example ACQUITY UPLC Console display during calibration:

IntelliStart creates tune and calibration files , which are saved as

specified on the Instrument Setup Parameters dialog box’s Instrument

Setup tab. Once calibration is complete, the sample tune starts on the

four masses defined in the Intell iStart Setup Parameters dialog box.

When the sample tune is complete, the results are written to the

Sulfadimethoxine.ipr file.

Performing a sample tune

In the following example, sulfadimethoxine is used as the tuning sample.

Required materials

Sulfadimethoxine solution (100 pg/µL)

To perform a sample tune:

1. Prepare the IntelliStart fluidics system with sulfadimethoxine solution

in reservoir B.

See also: “To prepare the IntelliStart fluidics system:” on page 4-2.

Performi ng a sample tune 4-7

Page 72

2. In the ACQUITY UPLC Console system tree, click TQ Detector.

3. Ensure that the Ion Mode is ES+.

4. In the ACQUITY UPLC Console system tree, click IntelliStart.

5. Clear the Instrument Setup check box.

6. If you require system pre-checking, click Pre-checks.

Rationale: If Pre-checks is selected, when IntelliStart starts the sampl e

tune, it determines whether the existing tune is still valid. If so, no

sample tune is performed.

See also: TQ Detector online Help topic “IntelliStart flow diagram”.

7. Click Start .

8. In the IntelliStart Setup Parameters dialog box’s Sample Tune tab,

specify the sample tune parameters as described in “To specify the

sample tune parameters:” on page 4-5.

9. Click Start .

Result: A message appears reminding you to ensure that the tune

solutions, tune parameters, and LC flow are set correctly.

10. Click OK.

Result: Sample tune starts. The ACQUITY UPLC Console displays the

progress of the tune. When the sample tune is complet e , the results are

written to the Sulfadimethoxine.ipr file.

4-8 Operating the Waters TQ Detec tor

Page 73

Developing experiment methods

IntelliStart allows you to automatically develop quantitative MRM or SIR

methods for compounds of interest. Up to four compounds can be handled in a

single process. Up to three transitions can be selected for each compound.In

this example, methods for sulfadimethoxine are create d.

Required materials

Sulfadimethoxine solution (100 pg/µL)

To create a method:

1. Prepare the IntelliStart fluidics system with sulfadimethoxine solution

in reservoir B.

See also: “To prepare the IntelliStart fluidics system:” on page 4-2.

2. In the ACQUITY UPLC Console system tree, click TQ Detector.

3. Ensure that the Ion Mode is ES+.

4. In the ACQUITY UPLC Console system tree, click IntelliStart.

5. Clear the Instrument Setup check box.

6. Click Develop Method.

7. If you require system pre-checking, click Pre-checks.

See also: TQ Detector online Help topic “IntelliStart flow diagram”.

8. Click Start .

9. In the IntelliStart Setup Parameters dialog box, click the Method

Develope r ta b .

Note: The masses, tune file and IntelliStart fluidics system parameters

already set in IntelliStart are used.

10. Select the parameters shown in the following figure.

Developing experiment methods 4-9

Page 74

Instrument Setup Parameters dialog box Method Developer tab:

In this case, Sulfadimethoxine.exp is the method file created.

The Validation pane selections save optimization data for validation

purposes and creates an autotune report file (Sulfadimethoxine.xml).

11. Click Start .

Result: A message appears reminding you to ensure that the sample

solutions, sample tune parameters and LC flow are set correctly.

12. Click OK.

Result: Method development starts. The ACQUITY UPLC Console

displays the progress of the method development. When the method

development is complete, the method is written to the

Sulfadimethoxine.exp file.

The Validation pane selection saves optimization data for validation

purposes, and creates an autotune report file (Sulfadimethoxine.xml).

A green check mark indicates a successful run; a red cross indicates a

failure.

4-10 Operating the Waters TQ Detector

Page 75

Verifying the system using System QC

The System QC function uses pre-defined LC/MS methods to test the system

by injecting a diagnostic sample on-column. The sample helps identify any

problems with the configured system by providing these data:

• Sensitivity (signal-to-noise rat io)

• Response (peak area, peak height)

• Chromatographic performance (peak width, retention time)

System QC can be activated in several ways:

• Manually, from the ACQUITY UPLC Console.

• Manually, as part of an ACQUITY UPLC Console Autotune sequence.

• Automatically, based on a scheduled date and time.

The following example shows you how to perform a manual verification.

See also: The MassLynx online Help for details of how to perform verifica tion

manually, as part of an Autotune sequence or automatically based on a

scheduled dat e and ti me.

Multiple injections are processed using the OpenLynx Application- Ma nager.

Measurements are reported for each chosen parameter across the repeat

analyses. If results are within user-defined tolerances, the LC/MS system is

ready to use.

The System Ready results are logged via the ACQUITY UPLC Console but

can also appear in a printed report. The raw data and OpenLynx browser

report are also stored for re cords.

Requirement: For System QC to work, OpenLynx must be installed with

MassLynx. OpenLynx is normally installed by default. If it has not been

installed, run the installation DVD, select Modify, and select OpenLynx when

prompted.

Before running System QC you need a suitable tune file, method f ile and inle t

file. You can use IntelliSt art to creat e a tune file and devel op a me thod fo r t he

sample you want to use for System QC.

See also: “Performing a sample tune” on page 4-7 and “Developing

experiment methods” on page 4-9.

Verifying the system using System QC 4-11

Page 76

An inlet file must be created independently.

See also: The MassLynx online Help.

Requirement: IntelliStart reads the tune, inlet, and method files from the

System QC project (SystemQC.pro). You must save the tune, inlet, and

method files to the Aqudb folder of the System QC project before performing

the verifica tion.

To perform a manual verification using System QC:

1. In the ACQUITY UPLC Console, click System QC.

2. Click Start .