Page 1

[ Care and Use ManUal ]

styragel column

I. IntroductIon

This manual covers the care and use of the Waters Styragel® HR, HT, and HMW

families of Gel Permeation Chromatography (GPC) columns. Please take a few

moments to read this manual carefully. Follow the recommendations in this

manual to prolong column life and enhance chromatographic reproducibility.

This introduction describes the three families of Waters Styragel columns:

• Styragel HR

• Styragel HT

• Styragel HMW

Waters Styragel columns are packed with high-performance, fully porous, highly

cross-linked styrene-divinylbenzene copolymer particles. Their different charac-

teristics allow you to choose the column optimally suited to your application.

Styragel columns are shipped in three solvents: toluene, tetrahydrofuran (THF),

and dimethylformamide (DMF).

contents

I. IntroductIon

a. Styragel HR

b. Styragel HT

c. Styragel HMW

II. InstallIng the column Bank

a. Preparing the GPC/HPLC System

b. Installing the Columns

c. Repairing Damaged Compression Screw Assemblies

d. Equilibrating the Column Bank

III. PreParIng solvent and samPles

a. Preparing the Solvent

b. Changing Solvents

c. Preparing the Sample

Iv. usIng the column

a. Chromatography Guidelines

b. Calibrating the Column

Styragel Columns 1

v. care and maIntenance

a. Troubleshooting

b. Storing the Column

c. Efficiency Testing

1. Testing Instrument Band Spreading

2. Column Efficiency Test

Page 2

[ Care and Use ManUal ]

a. Waters Styragel HR

Use Waters Styragel HR columns for the high-resolution analysis of low-

molecular weight polymers, oligomers and additives. Packed with 5 µm

particles, Waters Styragel HR columns provide the high plate counts necessary

for this type of analysis.

b. Waters Styragel HT

Use Waters Styragel HT columns for the analysis of polymers with mid-range

molecular-weight distributions. They are the most versatile columns for

molecular-weight analysis. Waters Styragel HT columns are packed with 10 µm

particles to provide dependable performance over a wide range of temperatures

and solvents.

c. Waters Styragel HMW

Waters Styragel HMW columns are designed for the molecular-weight analysis

of ultrahigh-molecular-weight polymers. Their 20 µm particle size together with

the nominally 10 µm HMW frit design prevents the breakdown of ultrahigh

molecularweight polymers due to shear, which can occur with smaller particles.

This manual covers both column sizes 7.8 x 300 mm columns, and the solvent

efficient 4.6 x 300 mm columns. In sections with recommend flow rates or

spare parts, the 4.6 mm column conditions, or spare part follow immediately

after the 7.8 mm recommendations.

3. Flush the system to remove any microparticulates and old solvents.

Flush the injector loop if applicable.

Band spreading

The connection tubing and fittings in any chromatographic system contribute

to extra-column band spreading. Before installing the column, me sure your

system instrument band spreading (see Section on Testing Instrument Band

Spreading). If this test is not possible with your system, refer to your system

operator’s manual.

Narrow-Bore Chromatography for 4.6 mm Solvent Efficient Columns

The peak volume in a narrow-bore system is so small, it is critical to minimize

band spreading. Use the shortest tubing possible for all connections. It is not

necessary to use a microbore flow cell in your detector or to change your

conventional HPLC system in any way. Use 0.009-inch (0.25 mm) i.d. tubing

throughout the system.

b. Installing the Columns

When connecting columns in series, use the 0.009 inch (0.25 mm) i.d.

U-shaped column-joining tube supplied with each column.

Sequence of columns in a column bank

II. InstallIng the column Bank

This chapter describes:

• Preparing the GPC/HPLC system

• Installing the columns

• Repairing damaged compression screw assemblies

• Equilibrating the column

a. Preparing the GPC/HPLC System

Before attaching the columns in the flow path on a GPC/HPLC system, you

must first prepare the system:

1. Directly connect the system injector to the detector by replacing

the old columns with a zero-dead-volume union.

2. Convert the system to the solvent in which the columns have been

stored. For a new column set, this is the shipping solvent.

Generally, the results of an analysis are independent of the sequence in which

a column bank is arranged. However, to improve resolution and column life,

arrange the columns in order of decreasing pore size, with the column with

the largest pore size closest to the injector. This is recommended because:

• The columns with the larger pore sizes are more rugged and are

better able to tolerate the accumulation of extraneous materials.

• The species with the highest molecular-weight in the sample

contributes the most to the viscosity of the sample. If the largest

species is separated first, the viscosity decreases more quickly,

placing less strain on the column bank. In the case of ultrahigh MW

polymers, there is less shear on the sample.

Styragel Columns 2

Page 3

[ Care and Use ManUal ]

Installing columns in a column bank

To install your columns:

1. Remove the end plugs from each column and save them.

2. Connect the first column to the injector outlet tubing. Ensure that

solvent flow is in the direction shown by the arrow on the column

label. Finger-tighten the fittings, then tighten the fittings with a

wrench by another 1/4 turn.

3. Connect the next column to the previous column using the U-tubes

supplied with the columns. Ensure that solvent flow is in the

direction shown by the arrow on the column label. Thread the

inlet and outlet fittings of the U-tube until finger tight, then

tighten the fittings by another turn with a wrench.

4. Repeat step 3, until all columns are connected.

5. Connect the last column to the detector inlet tubing using steps

1 through 4.

c. Repairing Damaged Compression Screw Assemblies

To remove a damaged compression screw or a worn ferrule assembly:

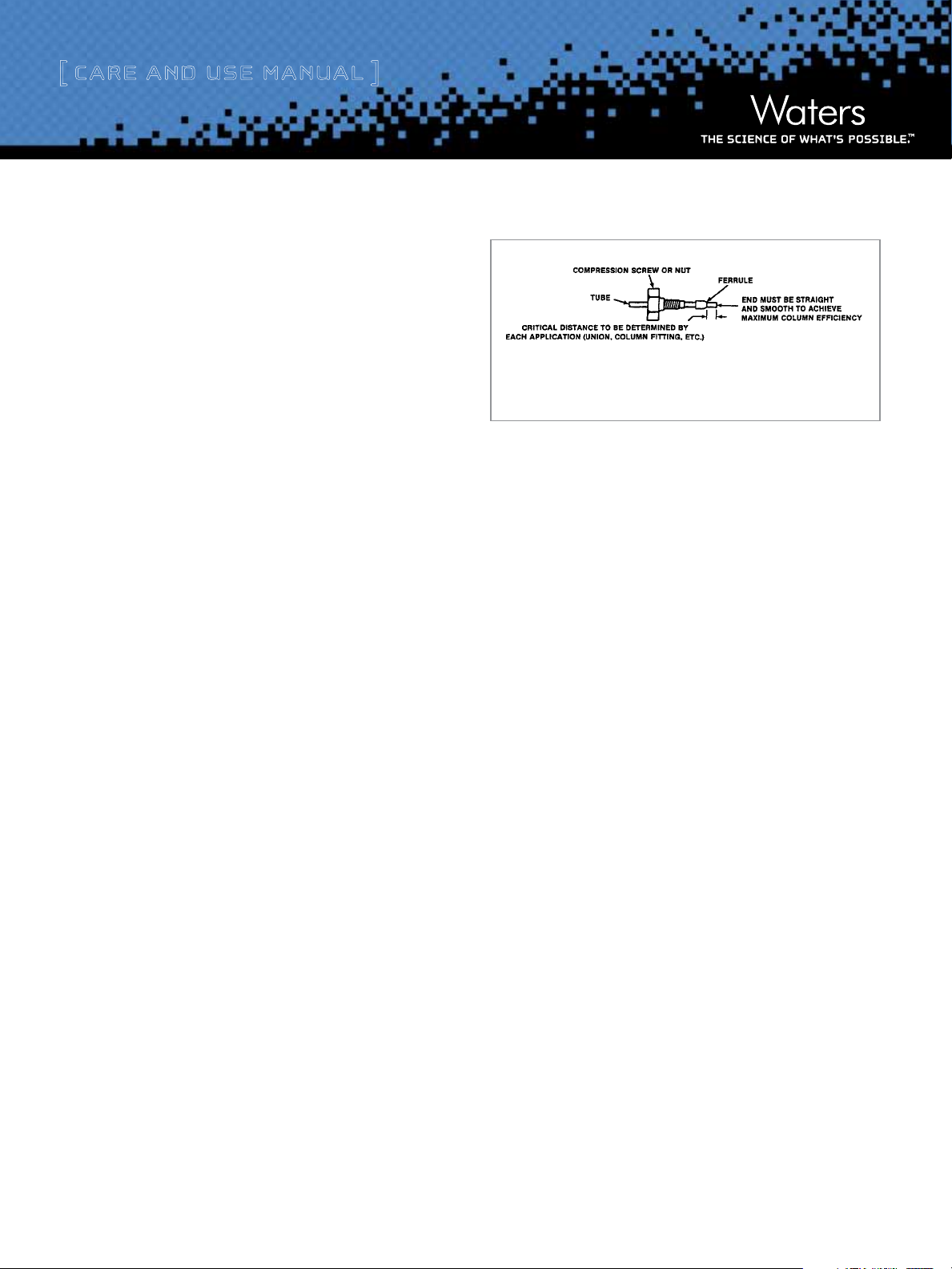

Figure 1. Ferrule and Compression Screw Assembly

Ferrule 0.009-inch I.D. Tubing (0.25 mm) 0.130-inch gap (3.3 mm)

The distance between the end of the ferrule and the end of the U-tube may

differ for different column types. If you have used columns from another

manufacturer, it may be necessary to reset the ferrules, or make up a new

fitting (see Figure 1). Use 0.009-inch (0.25 mm) i.d. tubing for all lines

between the injector and detector. For Waters columns, the critical distance is

0.130 inch (2.25 mm).

d. Equilibrating the Column Bank

Equilibrate the columns when you install them and when you use them after

they have been stored. To equilibrate your column bank:

1. Set the pump flow rate at 0.0 mL/min, then turn on the pump.

1. Scribe the circumference of the tubing at the desired break point

using a tube cutter or a file with a cutting edge.

2. Grasp the tubing on both sides of the scribe mark with cloth-

covered pliers (to prevent marring the tube surface). Gently

work the tube back and forth until it separates at the scribe mark.

Ensure that the tubing end is straight, open, and free of burrs.

3. Slide the compression screw, followed by the ferrule (large end of

the taper first), over the tube. Properly bottom the tubing in the

fitting seat. If the tubing is not completely seated, the resulting

dead volume can lead to poor chromatographic results.

2. Increase the flow rate by 0.1 mL/min at 15 second intervals until

you reach the final flow rate.

3. Purge the columns with the shipping solvent until you obtain a

stable baseline.

Styragel Columns 3

Page 4

[ Care and Use ManUal ]

Flow rate and backpressure for 4.6 mm

Solvent Efficient Columns

For best resolution and maximum column life, do not allow the flow rate to

exceed 0.3 mL/min or the backpressure to exceed 3.5 MPa (500 psi, 35 atm)

per column.

Please note: The flow rate recorded on the Certificate of Analysis, included

with the column, may be higher than the guidelines provided. For maximum

column life in your lab, please follow the flow and back pressure guidance

we provide.

When using the HR 0.5, HR 1, and HR 2 columns, increase the flow rate in 0.1

mL/min increments at 30-second intervals until you reach 0.3 mL/min.

Defective columns

One or more defective columns in a series may cause the entire set of columns

to appear defective. One defective column can cause peak spreading that

cannot be overcome by any number of good columns. See Table 4, Table 5,

or Table 6 for column efficiency data.

Initial efficiency tests

Test your system and columns before the first analysis. Run a test sample

using the recommended parameters for your system and columns, and record

the results. These results serve as a baseline to compare future performance.

See Section on Efficiency Testing, for the procedures to determine the

efficiency of your system and columns.

a. Preparing the Solvent

Use clean solvent for reproducible results and maintenance-free operation. Use

solvents of LC-grade or better, filtered to remove micro particulate matter larger

than 0.45 µm. Refer to Waters catalog, filtration section for filter choice and

solvent compatibility chart.

b. Changing Solvents

Solvent compatibility

Waters Styragel columns are shipped in the solvent of your choice: toluene,

THF or DMF. Some applications require a different solvent. Changing solvents

works best between compatible solvents. Refer to the table below for solvent

compatibilities.

Note: The use of highly aqueous mobile phases may damage the resin and is

not recommended.

Table 1. Solvent Conversion Table

To convert to:

o-Dichlorobenzene Toluene

Trichlorobenzene Toluene Hexafluoroisopropanol THF

Phenol/TCB Toluene N-Methyl pyrrolidone DMF

y-Butyrolactone THF m-Cresol DMF

Use columns

shipped in:

To convert to:

To use Waters Styragel columns for high-temperature chromatography in

solvents like trichlorobenzene (TCB) or orthodichlorobenzene (ODCB), you

must convert the column to the selected solvent at elevated temperature.

Use columns

shipped in:

Save the chromatograms from these tests. For the column-efficiency test,

record the retention times, system settings, and all experimental conditions

so they may be reproduced exactly for future comparison.

III. PreParIng solvent and samPles

This chapter describes:

• Preparing the solvent

• Changing solvents

• Converting columns to high temperature solvents

• Preparing the sample

Styragel Columns 4

High-temperature conversion procedure

To convert the column bank to high-temperature operation:

1. Convert the system to the column shipping solvent at room

temperature.

2. Purge solvent efficient columns at 0.1 mL/min while gradually

increasing the temperature to 90 ˚C over a minimum of 3 hours.

Solvent Efficient Columns

(Purge solvent efficient columns at 0.1 mL/min while gradually

increasing the temperature to 90 ˚C over a minimum of 3 hours.)

Set the system to 55 ˚C when converting columns from THF to

HFIP or Y _ Butyrolactone.

Page 5

[ Care and Use ManUal ]

3. With the system at 90 ˚C, convert to the high-temperature solvent

at 0.1 mL/min using 12 mL per column. Then purge the system

for a minimum of four column volumes at 0.2 mL/min.

When using a bank of columns, multiply the number of column

volumes specified in the procedure by the number of columns

being used.

4. Convert to the high-temperature solvent using a flow rate of 0.1

mL/min. Use at least 20 mL per column.

5. Increase the temperature to the final conditions over a minimum

of four hours while continuing to purge the column at 0.1 mL/min.

Never exceed 150 ˚C.

Increase the temperature to the final conditions over a minimum

of four hours while continuing to purge the column at 0.1 mL/min.

Never exceed 150 ˚C.

6. Adjust the flow rate to the final operating conditions. T he optimal

flow rate is 0.3 ml/min.

Adjust the flow rate to the final operating conditions. The optimal

flow rate is 0.3 ml/min.

Returning to room temperature

To return the columns to room temperature, reverse the above procedure.

Alternatively, set the flow rate to 0.1 mL/min and reduce the temperature by

10 ˚C every 30 minutes.

Restarting the column

To restart the column, maintain a flow rate of 0.1 mL/min and increase the

temperature to the desired temperature over 10 hours. Then program the

desired operating flow rate.

c. Preparing the Sample

Good sample preparation prolongs column life and ensures reproducible

results. Take into account factors such as the capacity of the column,

sample viscosity, and the type and sensitivity of the detector. Remove

micro particulates with a 0.45 µm filter. Refer to Waters catalog for filter

choice and solvent compatibility chart.

Reactive polymers

Some reactive polymers (such as epoxies) may “condition” the column.

Improve column life and reproducibility by dedicating columns to specific

classes of reactive polymers.

Sample concentration

Sample concentration affects both viscosity and injection volume. While small

sample amounts produce narrower peaks, viscous samples may require larger,

more dilute samples. Table 2 lists the recommended concentration of sample

for optimal results.

High-molecular-weight polymers

High-molecular-weight polymers are especially susceptible to viscosity

problems. When analyzing high-molecular-weight polymers, use the con-

centrations indicated in Table 2. Run narrow-distribution polymers, such as

polystyrene standards, with an injection volume of 50 µL per column (20 µL per

column for solvent efficient columns) at a concentration of 0.02 percent.

Polystyrene standards with molecular weights of approximately four million or

greater become increasingly susceptible to degradation by shearing in solu-

tion. Shearing is indicated by molecular-weight distributions that are broader

than expected. With proper handling, polymers with molecular weights as high

as 20 million can be handled successfully.

For maximum column life, avoid temperature cycling. Maintain operating

temperature but reduce flow rate to 0.1 mL/min when columns are not

in use.

Styragel Columns 5

Page 6

[ Care and Use ManUal ]

Styragel® HR

Molecular Weight

Styragel® HR 0.5

Styragel

®

HR 1

Styragel

®

HR 2

Styragel

®

HR 3

Styragel® HR 4

Styragel

®

HR 5

Styragel

®

HR 6

Styragel

®

HR 4E

Styragel

®

HR 5E

Elution Volume (mL)

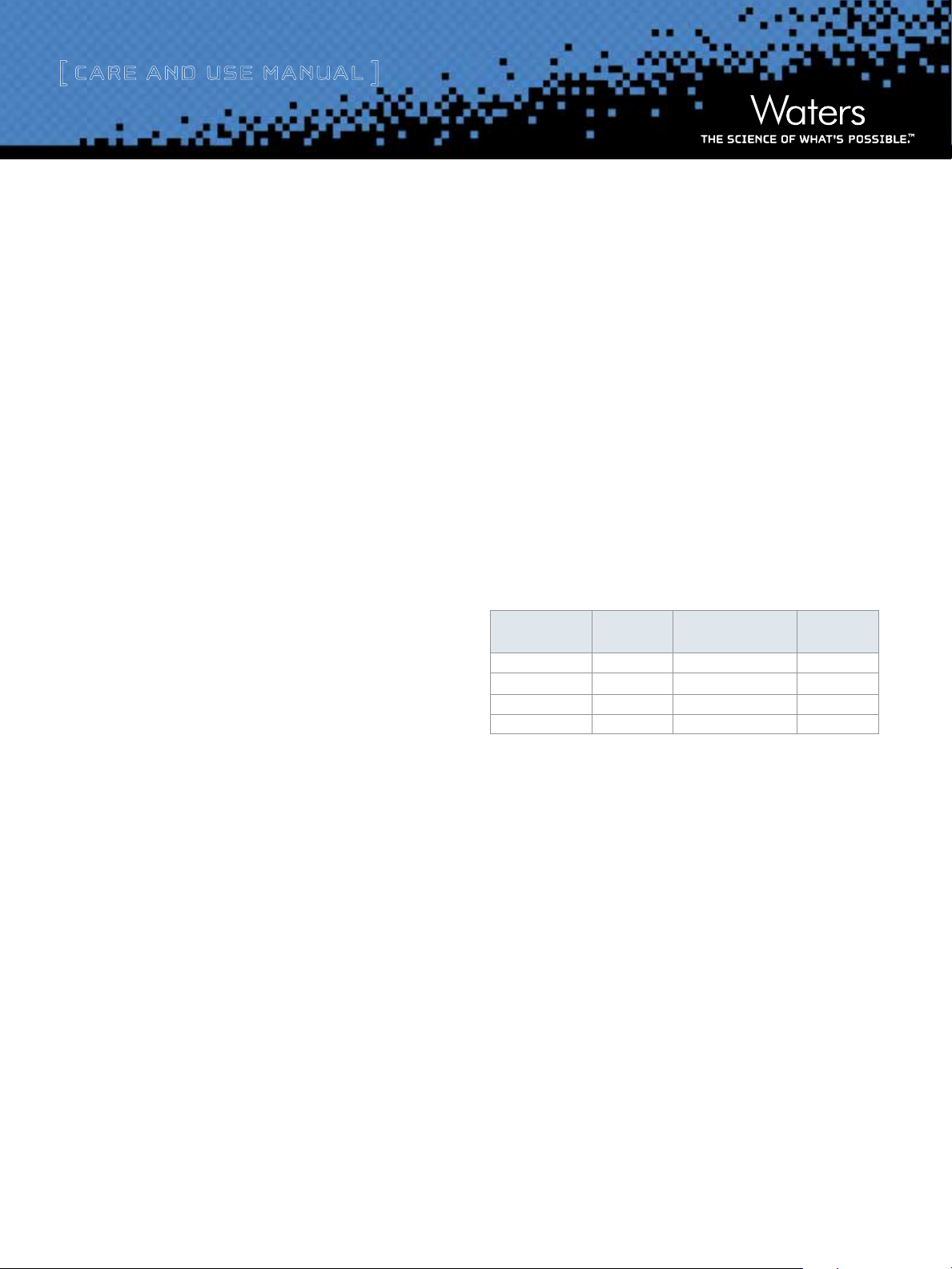

Table 2. Recommended Sample Concentrations

Molecular-weight Range Sample Concentration

0 to 25,000 <0.25%

25,000 to 200,000 <0.1 %

200,000 to 2,000,000 <0.05%

Above 2,000,000 <0.02%

Ultrahigh-molecular-weight polymers

Shearing is also a factor to be considered with most ultrahigh-molecular-weight

polymers. The effect of shearing may not be as easily observed as it is with

narrow molecular-weight standards. Ultrahigh-molecular-weight polyolefin frac-

tions are subject to possible shearing and incipient precipitation. Use especially

dilute solutions of these fractions (for example, 0.02 percent) to minimize

precipitation.

Iv. usIng the column

This chapter describes:

• Chromatography guidelines

• Calibrating the column

a. Chromatography Guidelines

Gel permeation chromatography columns have a finite lifetime directly related

to their care and use. Column life is reduced by contamination from samples

and eluents, frequent solvent changeover, improper handling and storage, and

temperature cycling.

Guidelines for column use

When using Waters Styragel columns, observe the following guidelines:

• Protect the column from rapid changes in pressure that can result

from rapidly changing the composition of the solvent.

• When changing to a solvent with a different viscosity, it may be

necessary to adjust the flow rate to stay below the operating

backpressure specification of 3.5 MPa (500 psi, 35 atm) per

column.

• Avoid precipitation by dissolving samples in the mobile phase.

• Always use high-quality HPLC solvents.

• Dedicate columns to specific applications. Frequent switching of

samples and solvents accelerates column deterioration and loss

of resolution.

• Using highly aqueous mobile phases may damage the resin and is

not recommended.

b. Calibrating the Column

Whenever you replace a single column or a complete column bank, generate a

new calibration curve to ensure the reproducibility of your application. Figure

2, Figure 3, and Figure 4 show typical calibration curves by column family. The

calibration curves were obtained with polystyrene standards.

Figure 2. Calibration Curves for Waters Styragel HR Columns

Elution Volume (mL)

Styragel® HR 0.5

Styragel

Styragel

Styragel

Styragel® HR 4

Styragel

Styragel

Styragel

Styragel

®

HR 1

®

HR 2

®

HR 3

®

HR 5

®

HR 6

®

HR 4E

®

HR 5E

• For best resolution and maximum column life, do not exceed a flow

rate of 1.0 mL/min or the backpressure exceed 3.5 MPa (500 psi,

35 atm) per column (corrected for system backpressure).

• For solvent efficient columns, best resolution and maximum

column life, do not let the flow rate exceed 0.3 mL/min or the

backpressure exceed 3.5 MPa (500 psi, 35 atm) per column

(corrected for system backpressure). Normal flow rate for these

columns is 0.3 mL/min.

• Protect the column from vibration and mechanical shock.

• Minimize temperature cycling.

Styragel Columns 6

Page 7

[ Care and Use ManUal ]

Styragel® HT 2

Elution Volume (mL)

Styragel

®

HT 3

Styragel

®

HT 4

Styragel® HT 5

Styragel

®

HT 6

Styragel

®

HT 6E

Styragel® HMW 2

Elution Volume (mL)

Styragel

®

HMW 6E

Styragel

®

HMW 7

Figure 3. Calibration Curves for Waters Styragel HT Columns

Styragel® HT

Elution Volume (mL)

Styragel® HT 2

Styragel

Styragel

Styragel® HT 5

Styragel

Styragel

Molecular Weight

v. care and maIntenance

This chapter describes:

• Troubleshooting

• Storing the column

®

HT 3

®

HT 4

®

HT 6

®

HT 6E

Figure 4. Calibration Curves for Waters Styragel HMW Columns

Styragel® HMW

Elution Volume (mL)

Styragel® HMW 2

Styragel

Styragel

Molecular Weight

®

HMW 6E

®

HMW 7

• Efficiency testing

a. Troubleshooting

Table 3 describes specific problems, causes, and corrective actions.

Table 3. Column Troubleshooting

Problem Cause Corrective Action

Buildup in system operating

pressure

Loss of resolution, broad peaks,

low plate counts

Styragel Columns 7

Inlet filter insert (from the first column only) plugged with par-

ticulates Injector and pump seal shedding

Clogged tubing Replace the tubing

Filter inserts partially blocked

Failing injector Repair the injector

Insufficient equilibrium Continue equilibrium

Column damaged Replace column

Replace the inlet filter insert.

Install a Styragel Guard column.

Fit an in-line filter between the pump and the

first column.

Replace or clean inlet

and/or outlet filter inserts

Page 8

[ Care and Use ManUal ]

Diluted/Distorted Sample Band

b. Storing the Column

If you will be using the column again in less than 24 hours, special storage

procedures are unnecessary. However, be sure that the columns never dry out.

For longer storage periods, return the column to its box with the end plugs

firmly in place for storage. Do not leave a column at elevated temperatures

without solvent flow.

For maximum column life, avoid temperature cycling. Maintain operating

temperature and reduce flow rate to 0.1 mL/min when columns are not in use.

To restart the column, maintain a flow rate of 0.1 mL/min and, if applicable,

increase the temperature gradually over 10 hours. Then set the flow rate to

the desired operating flow.

c. Efficiency Testing

Waters columns are tested for adherence to our specifications. Slight variations

may occur depending on:

• The type and condition of equipment used

• The nature of the sample

1) Testing Instrument Band Spreading

Test procedure

The band spreading of a properly operating system should be less than

150 µL (75 µL for solvent efficient columns). To determine the band spreading

of your system:

1. Remove the column(s) from the system.

2. Connect the inlet and outlet tubing with a zero dead-volume

union.

3. Set the flow rate to 1.0 mL/min.

4. Use a fast chart speed to obtain a peak of easily measurable

width. If you use a data system, set the sampling rate to at least

10 data points per second. You may need to adjust the detector

sensitivity to keep the peak on scale.

Figure 5. Method for Calculating Band Spreading

Add calculation N= 25 (Vr/W)^2

• Instrument settings

Perform your own efficiency tests. To test both your system and each column

in the system, carry out both of these tests:

• Instrument band-spreading test

• Column-efficiency test

When to perform efficiency tests

Perform efficiency tests each time you add columns or otherwise change your

system. Then, as you use the system, conduct efficiency tests on a regular

schedule.

If problems occur during normal operation of the column, repeat the conditions

for the initial efficiency tests and compare the results. Monitor instrument

band spreading by performing a column efficiency test without the column in

line. Resolve excessive band spreading before installing columns.

5. Inject the same sample as for a plate count determination (see

Table 4, 5, or 6).

6. Measure the width of the resulting peak at 4.4% of the peak height

to obtain a value in µL.

Figure 5 illustrates the 5 sigma method, in which the width of the peak (w) is

measured at 4.4% of the peak height (h).

Styragel Columns 8

Page 9

[ Care and Use ManUal ]

2) Column Efficiency Test

The column-efficiency test described below may be used to calculate a theoreti-

cal plate count, which is a measurement of column efficiency within your system.

Solvents

It is not necessary to use the solvent that your column is shipped in to deter-

mine the efficiency of your column. Initial plate counts that are determined

using different solvents will have different values. Test columns individually

using your normal operating solvent.

Test procedure

To perform a column efficiency test:

1. Slowly increase the flow rate to 1.0 mL/min for the HR 0.5,

HR 1, HR 2, and HR 4E columns, or to 2.0 mL/min for all

other columns.

2. Adjust the detector to an attenuation that achieves a peak of 70

percent full scale (noise level <0.5 percent full scale).

3. Set the recorder chart speed to 50 mm/min, or the data system

sampling rate to at least 5 data points per second.

4. Inject up to 20 µL of marker solution. Use a solution of up to 10

percent marker in solvent. Use up to 5 µL for solvent efficient

columns.

Refer to Table 4, Table 5, or Table 6 for the marker to use when performing

the efficiency test.

5. Record the retention time, instrument settings, and column con-

figuration so you can reproduce them exactly for comparison in

the future.

6. Compute the plate count using the tangent method (see

Figure 6). Use these results for comparison throughout the life

of your column.

7. Replace any column that exhibits a plate count more than 30

percent below the original value.

Table 4. Conditions and sample for 7.8 mm for Column Efficiency Test:

HR Columns

Column

Type

HR 0.5 Acetone Propylbenzene Ethyleneglycol 1.0

HR 1 Acetone Propylbenzene Ethyleneglycol 1.0

HR 2 Acetone Propylbenzene Ethyleneglycol 1.0

HR 3 ODCB Acetone Acetone 2.0

HR 4 ODCB Acetone Acetone 2.0

HR 4E Acetone Propylbenzene Ethyleneglycol 1.0

HR 5E DCHP

1

Toluene THF DMF

2

Acetone Acetone 2.0

Flow Rate

mL/min

Dicyclohexylphthalate

Table 5. Conditions and Sample for 4.6 mm Column Efficiency Test:

HR Columns

Column

Type

HR 0.5 ODCB 0.3 Acetone 0.3 Acetone 0.3

HR 1 ODCB 0.3 Acetone 0.3 Acetone 0.3

HR 2 ODCB 0.3 Acetone 0.3 Acetone 0.3

HR 3 ODCB 0.3 Acetone 0.3 Acetone 0.3

HR 4 ODCB 0.3 Acetone 0.3 Acetone 0.3

HR 4E ODCB 0.3 Acetone 0.3 Acetone 0.3

HR 5E

Toluene THF DMF

Marker

DCHP

Flow Rate

(mL/min)

2

0.3 Acetone 0.3 Acetone 0.3

Marker

Flow Rate

(mL/min)

Marker

Flow Rate

(mL/min)

Styragel Columns 9

Page 10

[ Care and Use ManUal ]

Table 6. Conditions and sample for 7.8 mm for Column Efficiency Test:

HT Columns1

Column Type Toluene THF DMF

HT 3 ODCB Acetone Acetone 2.0

HT 4 ODCB Acetone Acetone 2.0

HT 5 ODCB Acetone Acetone 2.0

HT 6 DCHP Acetone Acetone 2.0

HT 6E DCHP Acetone Acetone 2.0

Flow Rate

(mL/min)

Table 7. Conditions and sample for 4.6 mm for Column Efficiency Test:

HT Columns1

Column

Type

HR 3 ODCB 0.3 Acetone 0.3 Acetone 0.3

HR 4 ODCB 0.3 Acetone 0.3 Acetone 0.3

HR 5 ODCB 0.3 Acetone 0.3 Acetone 0.3

HR 6 DCHP 0.3 Acetone 0.3 Acetone 0.3

HR 6E

Toluene THF DMF

Flow Rate

Marker

(mL/min)

DCHP 0.3 Acetone 0.3 Acetone 0.3

Marker

Flow Rate

(mL/min)

Marker

Flow Rate

(mL/min)

Table 8. Test Condition and Sample for Efficiency Test 7.8 mm HMW

Columns

Column Type Toluene THF DMF

HMW 7 DCHP Acetone Acetone 2.0

HMW 6E DCHP Acetone Acetone 2.0

Flow Rate

(mL/min)

Figure 6. Tangent Method for Calculating Column Efficiency

N = 16 (tR/w)2

tR = Elution distance from injection point to the peak

apex on the chart paper.

W= Peak width of marker measured where tangents

drawn on peak intersect baseline (same units as tRj.

Styragel Columns 10

Page 11

[ Care and Use ManUal ]

Sales Offices

Austria and European Export

(Central South Eastern Europe, CIS

and Middle East) 43 1 877 18 07

Australia 61 2 9933 1777

Belgium 32 2 726 1000

Brazil 55 11 5094 3788

Canada 1 800 252 4752

China 86 10 5293 6688

Czech Republic 420 2 617 11384

Denmark 45 46 59 8080

Finland 358 9 5659 6288

France 33 1 30 48 72 00

Germany 49 6196 400 600

Hong Kong 852 2964 1800

Hungary 36 1 350 5086

Norway 47 6 384 6050

Poland 48 22 833 4400

Puerto Rico 1 787 747 8445

Russia/CIS 7 495 727 4490/ 290 9737

Singapore 65 6593 7100

Spain 34 93 600 9300

Sweden 46 8 555 115 00

Switzerland 41 56 676 7000

Taiwan 886 2 2501 9928

United Kingdom 44 208 238 6100

All other countries:

Waters Corporation U.S.A.

1 508 478 2000

1 800 252 4752

www.waters.com

India 91 80 2837 1900

Ireland 353 1 448 1500

Italy 39 02 265 0983

Japan 81 3 3471 7191

Korea 82 2 6300 4800

Mexico 52 55 52 00 1860

The Netherlands 31 76 508 7200

©2011 Waters Corporation. Waters, The Science of W hat’s Possible, and Styragel are trademarks of Waters Corporation.

January 2011 WAT044491 Rev 4 VW-PDF

Waters Corporation

34 Maple Street

Milford, MA 01757 U.S.A.

T: 1 508 478 2000

F: 1 508 872 1990

www.waters.com

Styragel Columns 11

Loading...

Loading...