Page 1

[ CARE AND USE MANUAL ]

[ CARE AND USE MANUAL ]

Sep-Pak XPoSure Aldehyde Sampler

CONTENTS

I. INTRODUCTION

a. Sep-Pak DNPH-Silica Cartridge Description

II. USING THE SEP-PAK XPOSURE

ALDEHYDE SAMPLER

a. Theory of Operation

b. Preventing Contamination

c. Collecting the Sample

d. Eluting the Derivatives from the Sampler

III. ANALYZING THE DNPH DERIVATIVES

a. Theory of Operation

b. Preventing Contamination

c. Collecting the Sample

d. Calculating Results

IV. APPLICATION EXAMPLES

a. Formaldehyde in Laboratory Air - STEL

b. Glutaraldehyde in Laboratory Air – STEL

I. INTRODUCTION

Waters Sep-Pak® XPoSure™ Aldehyde Samplers are convenient,

reproducible sampling devices for quantifying formaldehyde

concentrations in the workplace and indoor air within a range of

0.001 to 5 parts per million (ppmv).

V. STORAGE AND DISPOSAL OF THE SAMPLERS

a. Storing Unused Samplers

b. Storing Exposed Samplers

c. Disposing of used cartridges

VI. TROUBLESHOOTING

VII. REFERENCES AND BIBLIOGRAPHY

VIII. ORDERING INFORMATION

IX. APPENDIC ES

a. Appendix A: Measuring Acetontrile Purity

b. Appendix B: Synthesizing the DNPH-Derivative Standards

c. Appendix C: Measuring Breakthrough

d. Appendix D: Useful Conversion Factors

d.1. Carbonyl to Hydrazone Conversion Factors

d.2. Equation for converting µg/L to ppmv

d.3. Conversion Factors: µg/L to ppmv

Page 2

[ CARE AND USE MANUAL ]

[ CARE AND USE MANUAL ]

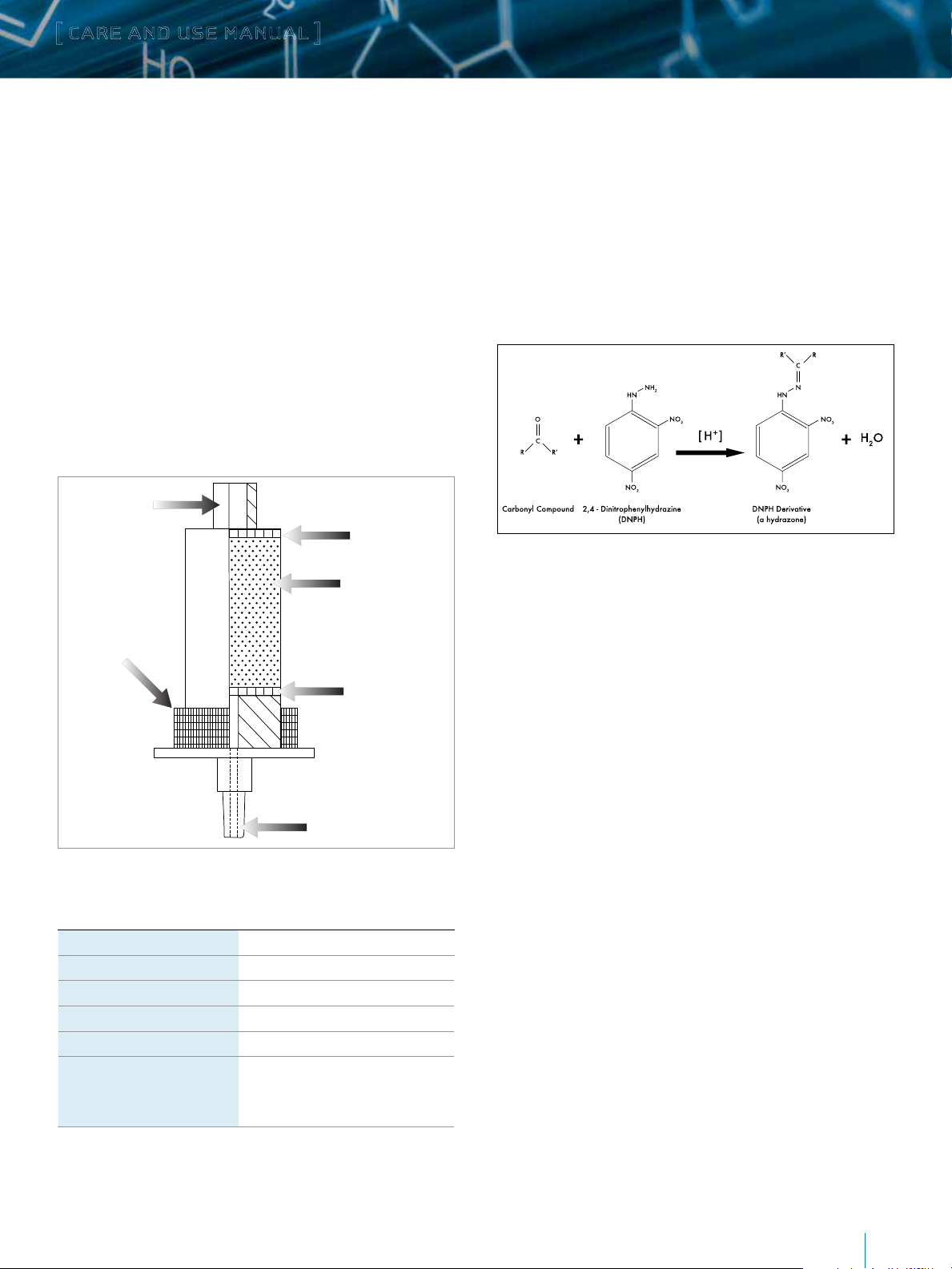

a. Sep-Pak XPoSure Aldehyde Sampler Description

and Features

Sep-Pak XPoSure Aldehyde Samplers contain acidified

2,4-Dinitrophenylhydrazine(DNPH)-coated silica, packed

in Waters Sep-Pak Plus cartridges.

The samplers are constructed from high-purity and high-

density polyethylene components, triaxially-compressed

packed beds and Luer fittings equipped with end caps and

plugs.

The samplers are designed for flow rates of up to 1.5 L/min

with typical personal pumps.

The gold-colored aluminum compression ring on the

Sep-Pak XPoSure Aldehyde Sampler allows for easy

identification.

Luer Connector

Polyethylene Filter

DNPH-Silica

Aluminum

Compression Ring

Polyethylene Filter

II. USING THE SEP-PAK XPOSURE

ALDEHYDE SAMPLER

a. Theory of Operation

Sep-Pak XPoSure Aldehyde Samplers trap aldehydes in air by

reacting them with acidified 2,4-dinitrophenylhydrazine(DNPH),

forming stable hydrazone derivatives. The derivitization reaction,

as shown in Figure 2, takes place during sample collection. T he

derivatives are later eluted and analyzed using HPLC.

Figure 2. Derivitization Reaction.

b. Preventing Contamination

Contamination is most likely to occur during sample collection.

Before eluting the derivatives, clean all glassware by rinsing with

acetonitrile and heating to 60 °C in a vacuum oven for at least

30 minutes. Eluting the samples in a nitrogen-purged glove box

further reduces the risk of contamination.

Luer Connector

Figure 1. Cutaway View.

Table 1: Physical and Chemical Properties

Hold-up Volume

Collection Efficiency

Capacity

Quantity of DNPH Silica

Sampling Temperature

Dimensions

a.

Based on 50% consumption of DNPH.

b

Evaluate sampler performance for individual high-temperature method.

a

b

>95% for sampling rates up to 1.5 L/min

Approximately 70 µg formaldehyde

0.35 g/sampler (~1 mg DNPH)

0.7 mL

10 °C to 100 °C

4.3 cm total length

2.0 cm o.d. at widest point

1.0 cm i.d.

0.9 cm bed length

The acetonitrile you use to elute the DNPH derivatives can also be

a source of contamination. Even HPLC-grade acetonitrile may have

unacceptable levels of carbonyl contaminants and should be stored

in a carbonyl-free environment. A concentration of 10 µg/L of

any aldehyde or ketone contaminant will add 0.1 µg to the blank

values determined for the DNPH-derivatives per cartridge. Follow

the procedure in Appendix A, Measuring Acetonitrile Purity, to

pre-qualify your acetonitrile.

Sep-Pak XPoSure Aldehyde Sampler

2

Page 3

[ CARE AND USE MANUAL ]

[ CARE AND USE MANUAL ]

c. Collecting the Sample

Caution: Beware of unintentional exposure of the samplers and

eluted samples to aldehyde and ketone sources. Laboratory air

often holds high concentrations of acetone. Labeling inks and

adhesives as well as packaging containers (including vials with

plastic caps) are all possible sources of contamination.

Sampling methods have been developed and validated for both 15

minute short-term exposure limit (STEL), and in 8 hour personal

exposure limit (PEL) measurements following the National

Institute for Occupational Safety and Health (NIOSH) guidelines

XPoSure Aldehyde Samplers have been tested under controlled

laboratory conditions. Table 2 lists the equipment needed to

collect air samples using XPoSure Aldehyde Samplers. The

recommended measurement range for formaldehyde is:

STEL: 0.022 to 2 ppmv

PEL: 0.01 to 1 ppmv

Table 2: Sample Collection Equipment

Suggested Personal Pump Specifications

Operating Range 100 to 1,500 mL/min

Compensation Range 1,500 mL/min – 0 to 20 inches water

Flow Control ±5% set point constant flow

Flow Indicatora Built-in flow indicatora

a.

A flow calibrator may also be required.

1,2

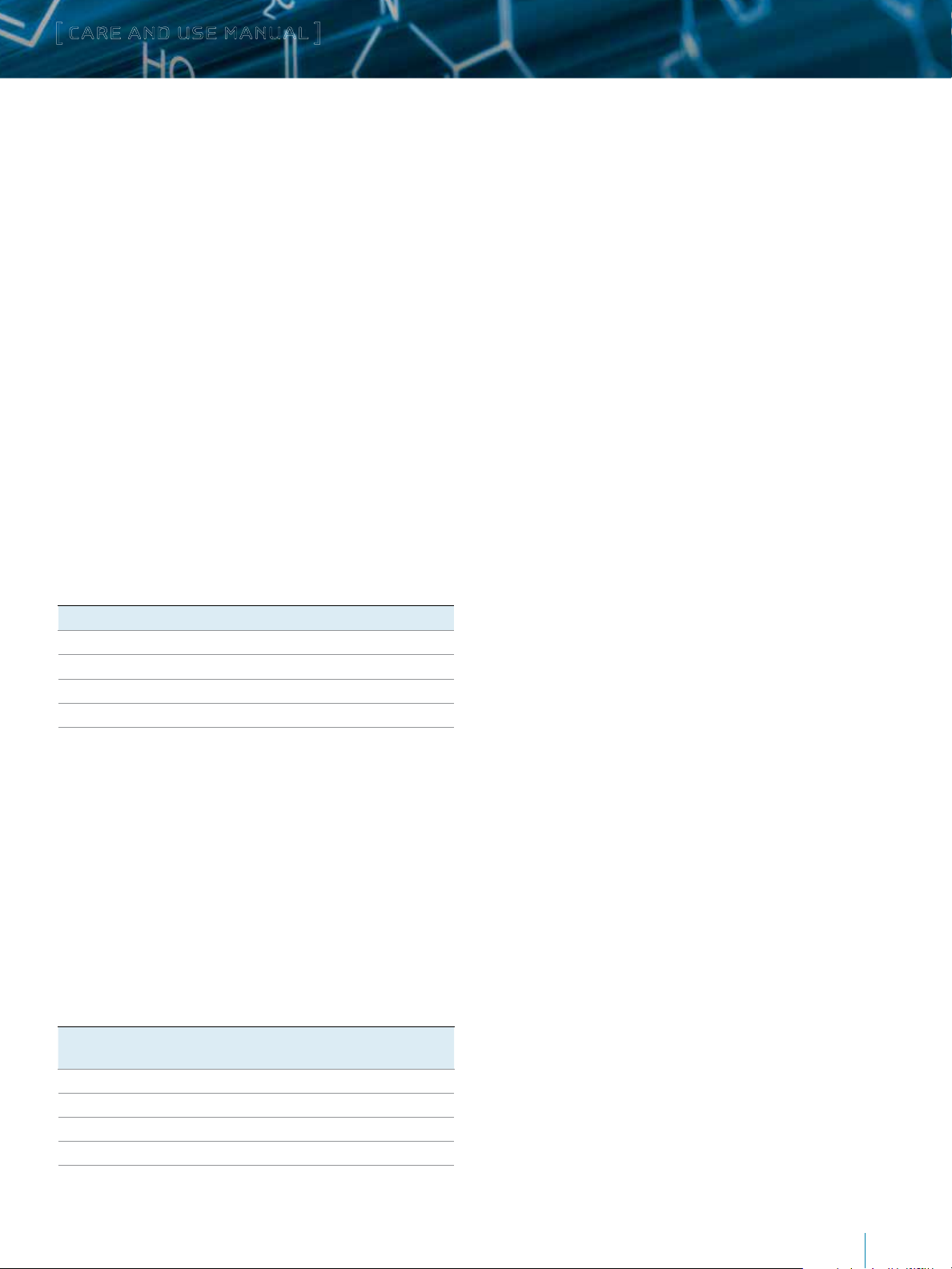

Sample Collection – STEL (0.02 to 2.0 ppmv)

To collect the STEL air sample:

1. 1Calibrate the sampling pump with a representative sampler

in line. Set the flow to 1.5 L/min. Figure 3 shows the flow rate

through a sampler versus applied vacuum. Once calibrated,

remove and store this representative sampler for future

calibrations.

2. Take a fresh sample from its pouch. Remove and save the end

cap and plugs.

.

3. Connect the sampler to a pump with flexible plastic tubing. The

sampler is bidirectional (flow can be in either direction).

4. Draw air for 15 minutes, yielding a sample volume of

22.5 liters.

5. Reseal the sampler with its end cap and plug.

6. Store the sampler in the pouch provided with appropriate

identification. Seal the pouch by folding the edge over twice

and stapling it shut. Avoid exposing the samplers to heat.

A 22.5 L air sample is sufficient for quantifying formaldehyde in

the range of 0.02 to 2 ppmv. Formaldehyde concentrations lower

than 0.02 ppmv in air will require longer sampling times and a

larger air sample. Conversely, formaldehyde concentrations that

exceed 2.0 ppmv will require shorter sampling times or reduced

sampling flow rates in order to avoid overloading the sampler and

obtaining nonlinear results.

The background levels of aldehydes and ketones in the sampler

determine the sensitivity of the method. The volume of air passed

through the sampler must be large enough for the quantity of

DNPH derivatives formed to be several times greater than the

background level. The United States Environmental Protection

Agency (US EPA) recommends that this level be at least 10 times

the background level.3 Table 3 lists the sampler background

specifications.

Table 3: Sampler Background Specifications

Compound

Formaldehyde <0.45 <0.06

Adetaldehyde <0.75 <0.15

Acetone <1.5 <0.38

Othersa <0.75 -

a.

Individually, as acetone-DNPH.

µg DNPH Derivatives

per Sampler

µg Carbonyl Compounds

per Sampler

Note: The maximum recommended sampler capacity is

2.3 µmoles total carbonyl species. This calculates to 50% of

the DNPH consumed. Contaminated air may contain significant

concentrations of other aldehydes and ketones and the total may

exceed the capacity of the sampling device. Follow the procedure in

Appendix C, Measuring Breakthrough for more information.

Sep-Pak XPoSure Aldehyde Sampler

3

Page 4

2.0

[ CARE AND USE MANUAL ]

[ CARE AND USE MANUAL ]

1.8

1.6

1.4

1.2

1.0

Note: The maximum recommended sampler capacity is 2.3 µmoles

total carbonyl species. This calculates to 50% of the DNPH consumed.

Contaminated air may contain significant concentrations of other

aldehydes and ketones and the total may exceed the capacity

of the sampling device. Follow the procedure in Appendix C,

Measuring Breakthrough for more information.

0.8

0.6

0.4

0.2

5

Figure 3: Typical Sampler Backpressure Profile.

15

Vacuum (inches water)

Sample Collection – PEL (0.01 to 1.0 ppmv)

To collect the PEL air sample:

1. Calibrate the sampling pump with a representative sampler in

line. Set the flow to 100 mL/min. Figure 3 shows the flow rate

through a sampler versus applied vacuum. Once calibrated,

remove and store this representative sampler for future

calibrations.

2. Take a fresh sample from its pouch. Remove and save the end

cap and plugs.

3. Connect the sampler to a pump with flexible plastic tubing. The

sampler is bidirectional (flow can be in either direction).

4. Draw air for 8 hours, yielding a sample volume of 48 liters.

5. Reseal the sampler with its end cap and plug.

6. Store the sampler in the pouch provided with appropriate

identification. Seal the pouch by folding the edge over twice

and stapling it shut. Avoid exposing the samplers to heat.

A 48 L air sample is sufficient for quantifying formaldehyde in the

range of 0.01 to 1 ppmv. Formaldehyde concentrations lower than

0.01 ppmv in air will require longer sampling times and a larger

air sample. Conversely, formaldehyde concentrations that exceed

1.0 ppmv will require shorter sampling times or reduced sampling

flow rates in order to avoid overloading the sampler and obtaining

nonlinear results.

d. Eluting the Derivatives from the Sampler

To elute the derivatives from the sampler:

1. Remove the sampler from the stapled pouch.

2. Elute the DNPH derivatives from the sampler with pre-qualified

25

30

acetonitrile directly into a 10 mL volumetric flask. Use a flow

rate of <3 mL/min. Higher flow rates (>3 mL/min) can result in

reduced recovery.

3. Cap the volumetric flask and mix by inverting it several times.

4. Analyze the eluate using HPLC.

Note: Since background levels may change during storage, always

compare samples to a blank sampler from the same lot, stored

under the same conditions.

III. ANALYZING THE DNPH DERIVATIVES

a. Operating Guidelines

To ensure success in your HPLC analysis:

Use a pre-column filter between the injector and column.

Use HPLC-grade water and HPLC-grade acetonitrile.

Degas the mobile phases by simultaneously applying

vacuum and ultrasound to the mobile phases for 30 seconds.

If you are using a low-pressure mixing gradient system,

sparging with helium may be necessary.

Waters Symmetry® C18 columns are shipped containing

water/acetonitrile. Before the first analysis, equilibrate the

column with mobile phase at 1.3 mL/min for 10 minutes in

mobile phase or until the baseline is stable. See Table 4 for

separation conditions.

Sep-Pak XPoSure Aldehyde Sampler

4

Page 5

0246810

12

14

0

.0005

.0010

.0015

.0020

.0025

1. DNPH

2. DNPH-Formaldehyde

3. DNPH-Acetaldehyde

4. DNPH-Acetone

.0030

1

2

3

4

[ CARE AND USE MANUAL ]

[ CARE AND USE MANUAL ]

b. Performing the HPLC Analysis

To analyze the sample:

1. Prepare the standard solution of the DNPH derivatives that you

need to quantify. T he concentrations of the standards should

be in the same range as the expected concentrations in the

sample. To synthesize DNPH derivatives, see Appendix B.

2. Prepare a cartridge blank from the same sample lot as

the cartridge used to collect the sample, using the sample

procedure and same bottled solvent.

3. Analyze the standard solution to determine the response factor

for each derivative. Due to the high linearity of the detector

response, a single point calibration is sufficient for Waters

detectors.

Note: Use an injection volume appropriate for your column.

Inject ≤ 20 µL for a 3.9 x 150 mm Waters Symmetry C18 column,

and ≤ 10 µL for a 3.0 x 75 mm Waters Symmetry C18 column.

4. Analyze the cartridge blank to determine background levels.

Ensure that the blank values are in the normal range (see Table

3). Figures 4 and 5 show a representative separation and blank

sample, respectively.

1. DNPH

2. Formaldehyde-DNPH

3. Acetaldehyde-DNPH

4. Acetone-DNPH

5. Acrolein-DNPH

6. Propionaldehyde-DNPH

Time (minutes)

Figure 4. Isocratic Separation of C1-C3 Hydrazone Derivatives.

5. Analyze the samples.

6. Subtract the blank values from the sample values. Run

standards at regular intervals between samples.

Table 4: HPLC Separation Conditions

Column Waters Symmetry C18, 3.9 x 150 mm

Mobile Phase 45:55 Acetonitrile/Water

Flow Rate 1.3 mL /min

Injection Volume 20 µL

Detection Wavelength

Limit of Detection for

Formaldehyde

Limit of Quantification for

Formaldehyde

Absorbance at 360 nm

(<50 mV of baseline noise)

Based on a signal to noise ration of 3

(55 picograms in 20 µL injection)

Based on a signal to noise ratio of 10

(183 picograms in 20 µL injection)

Figure 5: Typical Sampler Blank.

c. Analyzing a Cartridge Blank

Analyze a blank to determine background levels. Since

background levels may change during storage, always compare

samples to blank cartridges from the same lot stored under the

same conditions.

Note: When preparing a blank sample, ensure that you use the

exact bottled reagents that were used for the preparation of the

sample.

To prepare a cartridge blank:

1. Elute a fresh DNPH-Silica Sep-Pak cartridge from the same lot

as the cartridges used to collect your sample

2. Analyze the solution by HPLC using the same conditions as

those used for the sample.

3. Multiply the concentration of each DNPH derivative by the

volume of the eluate to determine the amount of background

DNPH derivative.

Sep-Pak XPoSure Aldehyde Sampler

5

Page 6

2

de

3

e

e

0

6

0

.002

4

2a

[ CARE AND USE MANUAL ]

[ CARE AND USE MANUAL ]

d. Calculating Results

To calculate the aldehyde concentration in air:

1. Prepare a calibration line of peak area to standard

concentration on µg/mL of analyte as carbonyl compound.

2. Use the calibration line to determine the analyte concentration

in the blank and sample eluates.

3. Determine the mass of each analyte in the blank (Wb) in

µg. This is done by multiplying each analyte concentration

by the eluate volume in mL. Compare these vales to the

specifications listed in Table 3. If these values are higher than

the specifications, contamination occurred during sample

preparation or storage.

4. Determine the mass of each analyte in the sample (Ws) in µg.

This is done by multiplying each analyte concentration by the

eluate volume in mL.

5. Calculate the analyte concentration (C) in µg/L*. This is done

by dividing the weight of the analyte in the air (Ws-Wb) by the

volume of the air sampled (V) in liters.

C = Ws – W

V

*The units, µg/L, is equivalent to mg/m3. For converting µg/L to ppmv at 1 atm

and 20 °C, see Appendix D.

b

b. Glutaraldehyde in Laboratory Air – STEL

The sample in Figure 7 was collected in chemical research

laboratory using a portable sampling pump. The 22.5 liter air

sample was collected at 1.5 L/min. The chromatogram shows

0.02 ppmv of glutaraldehyde. Under these chromatographic

conditions the DNPH-glutaraldehyde diastereomers are resolved.

1

.00

.004

.002

0

0246

Figure 7. Analysis of Glutaraldehyde in Lab Air.

1. DNPH

2a & 2b. DNPH-Glutaraldehyde Diastereomers

2b

2a

8

8

V. STORAGE AND DISPOSAL OF T HE SAMPLERS

a. Storing unused samplers

Always store any unused Waters Sep-Pak XPoSure Aldehyde

Samplers in their protective pouches to prevent contamination.

Store the sealed pouches in a refrigerator at (4 °C ± 2 °C) for up to

six months. Cartridges may be stored in their unopened pouches at

room temperature (20 to 25 °C) for up to two weeks.

IV. APPLICATION EXAMPLES

a. Formaldehyde in Laboratory Air - STEL

The sample in Figure 6 was collected in a chemical research

laboratory using a portable sampling pump. The 22.5 liter air

sample was collected at 1.5 L/min. The chromatogram shows

0.02 ppmv formaldehyde, with trace levels of both acetonitrile

and acetone detected.

1. DNPH

.004

.002

0

02 46810

Figure 8. Analysis of Formaldehyde in Lab Air.

1

2

1. DNPH

2. DNPH-Formaldehyde

3. DNPH-Acetaldehyde

4. DNPH-Acetone

4. DNPH-Aceton

3

. DNPH-Formaldehy

. DNPH-Acetaldehyd

4

12

14

Background levels of hydrazone derivatives increase slightly with

time and temperature. Before using cartridges exposed to high

temperatures or stored longer than the recommended periods, run

a blank.

b. Storing exposed samplers

Once a sampler has been used for collection, be careful to cap

and seal it until it is time to elute it. Inadvertent exposure of an

exposed cartridge can ruin a carefully collected sample. Elute

the derivatives from the cartridge within two weeks. T he sample

eluates are stable at 4 °C ± 2 °C for up to one month.

c. Disposing of used cartridges

Dispose of used cartridges according to applicable government

regulations.

Sep-Pak XPoSure Aldehyde Sampler

6

Page 7

[ CARE AND USE MANUAL ]

[ CARE AND USE MANUAL ]

VI. TROUBLESHOOTING

Table 5 describes solutions to problems that may arise while

using the samplers. Most errors occur as a result of contamination

during sample preparation. To resolve chromatographic problems

not listed, refer to your HPLC system manual.

Table 5: Troubleshooting

Symptom Possible Cause Solution

Contaminated

acetonitrile

High carbonyl values

in sampler blank

High formaldehyde

levels in sampler

blank

Broad peaks

Contaminated

glassware

Air contamination

during elution

Sampler age and

storage conditions

Coelution of

formaldehyde with

an impurity

Injection volume

too high

System or

column failure

4

Certify acetonitrile quality

prior to use, see Appendix A.

Use only pre-cleaned

glassware.

Prepare sample in

a glove box.

Replace samplers.

Refrigerate fresh samplers.

Prepare a fresh mobile

phase or decrease the

acetonitrile content.

Reduce t he

injection volume.

Consult the HPLC

System manual.

To order, contact your Waters representative, call Waters at

(800) 252-4752 or order online at www.waters.com.

Table 6: Ordering Information

Product Part Number

Sep-Pak XPoSure Aldehyde Samplers, 20/box WAT047205

In-Line Pre-Column Filter

Symmetry C

Solvent Filter, PV DF, 47 mm, 0.45 µm, Protein, 100/pkg

Beginners Guide to Liquid Chromatography

Guide to Successful Operation of Your LC System

Column, 3.9 x 150 mm WAT046980

18

WAT084560

WAT200530

715001531

WAT022378T P

IX. APPENDIC ES

a. Appendix A: Measuring Acetontrile Purity

HPLC-grade acetonitrile may contain traces of aldehydes and

ketones, and especially acetone. A concentration of 10 µg/L of

an aldehyde or ketone in the acetonitrile adds 0.1 µg to the blank

values determined for the DNPH-derivatives per cartridge.

VII. REFERENCES AND BIBLIOGRAPHY

1. Committee on Aldehydes, Board of Toxicology and

Environmental Hazards, National Research Council,

Formaldehyde and Other Aldehydes; National Academy Press,

Washington, DC, 1981.

2. Tejada, S. B. “Evaluation of Silica Gel Cartridges Coated in

Situ With Acidified 2,4-Dinitrophenylhydrazine for Sampling

Aldehydes and Ketones in Air”, Intern. J. Environ. Chem.

1986, 26, 167-185.

3. Riggins, R.M. “Compendium of Methods for the Determination

of Toxic Organic Compounds in Ambient Air”, U.S.

Environmental Protection Agency Report EPA-600/4-84-041,

U.S. Environmental Protection Agency; Research Triangle Park,

NC, 1984.

4. Guide to Successful Operation of Your LC System; Waters

Corporation, Milford, MA 1991.

5. ASTM Method E411; Standard Test Method for Trace Quantities

of Carbonyl Compounds with 2,4-Dinitrophenylhydrazine.

If you acetonitrile is unacceptable for your application, contact

your solvent supplier, to purify the acetonitrile. To purify

acetonitrile, distill it from an acidified DNPH solution, using a

procedure analogous to the one described in ASTM Method E411

for the purification of methanol.

5

To measure acetonitrile purity:

1. Clean all glassware by rinsing with acetonitrile and heating

in a 60 °C vacuum oven for at least 30 minutes.

2. Elute a fresh sampler with 3 mL acetonitrile.

3. Within 3 minutes, inject the eluate into the HPLC system to

measure the concentration of DNPH derivatives.

4. Add 1 drop of concentrated HCl to the eluate, and allow to

react at room temperature for 30 minutes.

5. Remeasure the concentration of DNPH derivatives by HPLC.

6. Calculate the difference in the concentration of each DNPH

derivative measured in steps 3 and 5 to yield the contribution

form the acetonitrile.

VIII. ORDERING INFORMATION

Waters Sep-Pak XPoSure Aldehyde Samplers are shipped in boxes

of 20 individually-packaged cartridges. Pouches are supplied for

storage after sampling.

7. Calculate the percent hydrazone contributed by the acetonitrile

relative to the background level. The value for any hydrazone

should not exceed 25% of its value in the blank.

Sep-Pak XPoSure Aldehyde Sampler

7

Page 8

[ CARE AND USE MANUAL ]

[ CARE AND USE MANUAL ]

Example: Measuring Acetonitrile Purity

1. HPLC analysis of a fresh sampler shows the sample contains:

Derivative

FormaldehydeDNPH

AcetaldehydeDNPH

Acetone-DNPH 1.60 ÷ 0.40 x 100 = 400%

Contribution

from

Acetonitrile

0.01 ÷ 0.08 x 100 = 12%

0.02 ÷ 0.12 x 100 = 17%

Divided by

Background

Value

Times

100

Equals

Percent

Relative to

Background

2. Analysis of the concentrations of hydrazones after reacting

with acid yields:

Derivative Concentration (µg/mL)

Formaldehyde-DNPH 0.08

Acetaldehyde-DNPH 0.12

Acetone-DNPH 0.40

All other hydrazones <0.05

3. The difference between the concentrations of hydrazone from

steps 3 and 5 represents the amount of hydrazone

contributed by the acetonitrile:

Derivative Concentration (µg/mL)

Formaldehyde-DNPH 0.09

Acetaldehyde-DNPH 0.14

Acetone-DNPH 2.00

All other hydrazones <0.05

4. The percent of the hydrazones contributed by the acetonitrile is:

Derivative

FormaldehydeDNPH

AcetaldehydeDNPH

Acetone-DNPH 2.00 µg/mL - 0.40 µg/mL = 1.60 µg/mL

Concentration

after Reaction

with Acid

0.09 µg/mL - 0.08 µg/mL = 0.01 µg/mL

0.14 µg/mL - 0.12 µg/mL = 0.02 µg/mL

Minus

Concentration

in Blank

Equals

Contribution

form Acetonitrile

Since the percent for formaldehyde and acetaldehyde arising

from the acetonitrile is less than 25% of the background level

in the sampler, the acetonitrile is considered clean for these

compounds. If the analysis considers only these compounds, the

acetonitrile is acceptable.

However, the amount of acetone arising for the acetonitrile is

4 times the amount found in the the background level. Therefore,

it is suggested that this lot of acetonitrile may be unacceptable

for use in the analysis of acetone.

b. Appendix B: Synthesizing the DNPH-Derivative Standards

High purity (99%) DNPH derivatives are commercially available

or can be synthesized from DNPH supplied by Aldrich Chemical

Company (70% DNPH and 30% water). To synthesize 98-99%

pure hydrozones:

1. Prepare one liter of 2 M HCl solution: Add 172 mL concentrated

reagent-grade hydrochloric acid (HCl) to a 1 L volumetric

flask. Fill the flask to the mark with distilled deionized water.

2. Saturate the 2 M HCl solution with DNPH: Add 8 g DNPH and

stir for one hour at 20 to 25 °C. Filter through a 0.45 µm

hydrophilic membrane (HVLP) filter (Waters Part number:

WAT200530).

3. Form the hydrazone derivative by adding a two-fold molar

excess of reagent-grade aldehyde or ketone to the filtered

2 M HCl DNPH solution. Stir for 30 minutes to one hour at

20 to 25 °C.

4. Filter the hydrazone slurry. Wash the hydrazone with 50 mL

2 M HCl 3 times. Wash with 50 mL water 3 times. Dry the

filter cake in an oven at 50 to 60 °C overnight.

5. Prepare a standard stock solution of the DNPH-derivatives

by dissolving an accurately weighed amount in acetonitrile.

Prepare a set of calibration standards using the stock

solution. The concentration of the standards should be in the

same range as the expected concentration of the samples.

The solutions are stable for at least one month when stored in

tightly-capped glass vials at 4 °C ± 2 °C.

Sep-Pak XPoSure Aldehyde Sampler

8

Page 9

[ CARE AND USE MANUAL ]

[ CARE AND USE MANUAL ]

c. Appendix C: Measuring Breakthrough

Note: If several aldehydes and ketones are present in significant

concentration, estimate the maximum sample size from the total

concentration of all species. Collection efficiency determinations

are best made during times expected to yield peak formaldehyde

concentrations. This will enable appropriate sampling rates and

intervals to be selected to avoid breakthrough.

Figure 8 shows the predicted total carbonyl concentration versus

the range of sample volumes.

To measure Waters Sep-Pak XPoSure Aldehyde Sampler for

collection efficiency:

1. Connect two unused cartridges together by the Luer fittings

and mark each cartridge for identification.

2. Connect the cartridges to a calibrated pump with a short

length of flexible tubing.

3. Collect the sample.

4. Elute both cartridges and a third blank cartridge.

5. Analyze all three cartridges by HPLC.

6. Subtract the blank value from the values determined from the

other two cartridges.

7. Calculate and sum of the total captured DNPH-derivative from

both cartridges.

8. Divide the amount of DNPH-derivative determined from

the first cartridge by the total amount determined form

cartridges 1 and 2. Multiply by 100. This is the percentage of

DNPH-derivatives captured on the first cartridge. This value

should exceed 95%; otherwise, some of the sample broke

through to the second cartridge.

Figure 8. Total Carbonyl Concentration vs. Range of Sample Volumes.

Collection efficiency for Waters Sep-Pak XPoSure Aldehyde

Sampler is greater than 95% for air sampling rates of up to

1.5 L/min. The sampler may exhibit breakthrough if:

The sampling flow rate is greater than 1.5 L/min

The amount of sample collected is enough to react with

more than 50% of the DNPH (~2.3 µmoles)

Example: Measuring Sample Breakthrough

The expected concentration of formaldehyde is 0.66 ppmv (µL/L).

Flow rate is 1.25 L/min for 80 minutes. A sample volume of 100

liters is collected. The theoretical quantity of carbonyl is:

Analyte ppmv Carbonyl Collected

concentration x molecular x air volume = µg Carbonyl

weight

Analyte molar volume at 1 atm/25 °C

This calculates to:

0.66 µL x 30.03 g/mole x 100 L = 81 µg formaldehyde

24.46 L/mole

The actual results are shown in Table 7. To calculate the percent

captured on the first sampler, divide the quantity captured on

sampler 1 by the total quantity captured, then multiply by 100.

Since this value is less than 95%, and the total carbonyl amount

exceeded 2.3 µmoles, breakthrough occurred.

Sep-Pak XPoSure Aldehyde Sampler

9

Page 10

[ CARE AND USE MANUAL ]

[ CARE AND USE MANUAL ]

In the above example, only a single carbonyl source was present.

Under many test conditions more than one carbonyl source may be

present in significant concentrations. These other compounds will

consume DNPH, effectively reducing the capacity of the sampler for

the compound of interest. To assure that the capacity of the sampler

has not been exceeded, compare the DNPH peak areas of the sample

to a similarly eluted blank. T he DNPH peak area in all samples

must be no less than 50% of the DNPH peak area of the blank. This

ensures the sampler capacity has not been exceeded.

Table 7: Breakthrough Example HPLC Results

Sampler

Sampler 1 75.06 75.00 91.8

Sampler 2 6.72 6.66 8.2

Blank 0.06 - -

Amount

(µg)

Quantity Captured

Sampler – blank (µg)

Percent Captured

on Sampler

d. Appendix D: Useful Conversion Factors

This appendix contains:

Carbonyl to hydrazone conversion factors

Equation for converting µg/L to ppmv

Conversion factors: µg/L ppmv

Table 9: Conversion Factors,

Carbonyl Weights ↔ Derivative Weights

Carbonyl

Compounds

Formaldehyde 6.998 0.1429

Adetaldehyde 5.089 0.19 65

Adetone 4.101 0.2438

Glutaraldehyde

Carbonyl → Derivative,

(MWD /MWC)

4.589 0.2175

Derivative → Carbonyl,

(MWC /MWD)

d.2. Equation for converting µg/L to ppmv

Carbonyl concentrations can be converted from µg/L to ppmv

(µL/L) by using the following expression:

(Result in ppmv) = (Result in µg/L) x 22.41 x T2 x P1

MWC T1 P2

Where values are:

22.41 = Molar volume of an ideal gas at STP (273.15 °K and

1 atm), L/mole

MWC = Molecular weight of carbonyl, g/mole

Obtaining carbonyl concentrations in eluates and air samples

required the use of several constants and conversion factors. The

factors described in this appendix can be used when converting

carbonyl weights to:

Equivalent derivative weights for preparing standard

solutions

Volumes for reporting air samples in ppmv

d.1. Carbonyl to Hydrazone Conversion Factors

Table 8 lists the molecular weights (MW) for some carbonyl

compounds. These values were used to derive the conversion

factors listed in Table 9. Multiply the carbonyl or derivative

weights by the appropriate factor for the desired conversion.

Table 8: Carbonyl and Hydrazone Molecular Weights

Carbonyl

Compounds

Formaldehyde 30.03 210.15

Adetaldehyde 44.05 22 4.17

Adetone 58.08 238.20

Glutaraldehyde

Carbonyl Compounds

Molecular Weight, (MWC)

100.12 460.36

Hydrazone Derivative

Molecul ar Weight (MWD)

T1 = Standard temperature, 273.15 °K

T2 = Air sample temperature, ºK

P1 = Standard pressure, 1 atm

P2 = Air sample pressure, atm

d.3. Conversion Factors: µg/L to ppmv

Table 10 lists the factors for converting between µg/L and ppmv at

25 °C and 1 atm. Results are converted between µg/L (or mg/m3)

and ppmv, by multiplying by the appropriate factor.

Table 10: Factors for Converting Between µg/L and ppmv at

25 °C and 1 atm.

Carbonyl

Compounds

Formaldehyde 1.23 0.813

Adetaldehyde 1.8 0 0.555

Adetone 2.38 0.420

Glutaraldehyde

ppmv → µg/L µg/L p → ppmv

4.09 0.244

Sep-Pak XPoSure Aldehyde Sampler

10

Page 11

[ CARE AND USE MANUAL ]

Waters, The Science of W hat’s Possible, Symmetry, and Sep-Pak are registered trademarks of Waters Corporation.

XPoSure is a trademark of Waters Corporation. All other trademarks are the property of their respective owners.

©2014 Waters Corporation. Produced in the U.S.A. March 2014 Rev C WAT047204EN KP-PDF

Waters Corporation

34 Maple Street

Milford, MA 01757 U.S.A.

T: 1 508 478 2000

F: 1 508 872 1990

www.waters.com

Loading...

Loading...