Page 1

[ Care and Use ManUal ]

WAters seP-PAK dnPH-sILICA CArtrIdGe

Contents

I. IntroduCtIon

a. Sep-Pak DNPH-Silica Cartridge Description

II. usInG seP-PAK dnPH CArtrIdGes

a. Theory of Operation

b. Preventing Contamination

c. Collecting the Sample

d. Eluting the Derivatives

III. AnALYZInG tHe dnPH derIVAtIVes

a. Operating Guidelines

b. Performing HPLC Analysis

c. Analyzing a Cartridge Blank

d. Selecting Separation Conditions

IV. APPLICAtIon eXAMPLes

a. Estimating Sample Volume

b. Analysis of Auto Exhaust Emissions

c. Analysis of Residential Air

d. Analysis of Research Lab Air

I. IntroduCtIon

Waters Sep-Pak® DNPH-Silica cartridges are convenient, reproducible

sampling devices for quantifying aldehydes and ketones in gasses,

including air within a range of 1 to 5,000 parts per billion (ppbv).

V. storAGe And dIsPosAL oF used CArtrIdGes

VI. trouBLesHootInG

VII. reFerenCes And BIBLIoGrAPHY

VIII. orderInG InForMAtIon APPendICes

IX. APPendICes

a. Measuring Acetonitrile Purity

b. Synthesizing DNPH Derivative Standards

c. Measuring Sample Breakthrough

Waters Sep-Pak DNPH-Silica Cartridge

1

Page 2

[ Care and Use ManUal ]

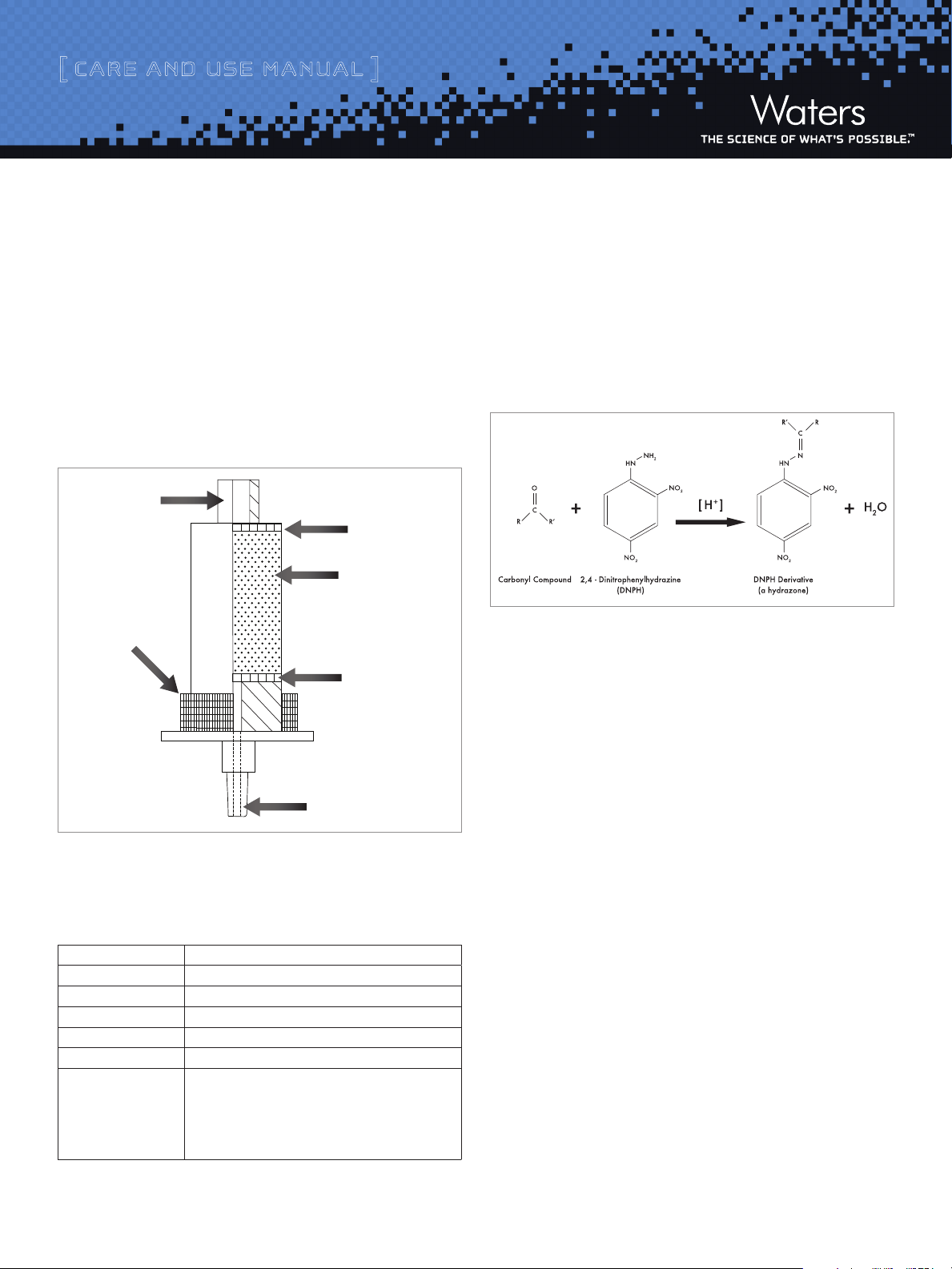

Po lyethylene Filter

DNPH-Silica

Po lyethylene Filter

Luer Connector

Aluminum

Compression Ring

Luer Connector

a. Sep-Pak DNPH-Silica Cartridge Description

• WatersSep-PakDNPH-Silicacartridgesconsistofacidified

2,4-dinitrophenylhydrazine-coated silica packed in Waters

Sep-Pak Plus cartridges.

• WatersSep-PakPluscartridgesareconstructedofhigh-purity

polyethylene components with triaxially-compressed packed

beds and Luer fittings equipped with end caps and plugs.

• T hegold-coloredaluminumcompressionringontheSep-Pak

DNPH-Silica cartridge allows for easy identification.

II. usInG seP-PAK dnPH-sILICA CArtrIdGes

a. Theory of Operation

Waters Sep-Pak DNPH-Silica cartridges trap aldehydes and ketones in

gasses by reacting them with the DNPH in the cartridge to form stable

1,2 ,3

hydrazone derivatives

place during sample collection. The derivatives are later eluted and

analyzed. Analysis should take place within two weeks.

Figure 2: Derivitization Reaction

. The derivitization reaction (Figure 2) takes

Figure 1: Cutaway View

Table 1: Physical/Chemical Properties

Hold-Up Volume 0.7 mL

Particle Size 55 to 105 µm

Collection Efficiency >95% for sampling rates up to 2 L/min

Capacity Approximately 75 µg formaldehyde

Quantity of DNPH-Silica 0.35 g/cartridge (1.0 mg DNPH)

Operating Temperature* 10 °C to 100 °C

Dimensions 4.3 cm total length

2.0 cm o.d. at widest point

1.0 cm i.d.

0.9 cm bed length

* Evaluate cartridge performance for individual high-temperature

methods.

b. Preventing Contamination

Contamination is most likely to occur during sample preparation.

Before eluting the derivatives, clean all glassware by rinsing with

acetonitrile and heating to 60 °C in a vacuum oven for at least

30 minutes. Eluting the samples in a nitrogen-purged glove box

further reduces the risk of contamination.

The acetonitrile used to elute the DNPH derivatives can also be a

source of contamination. Even HPLC-grade acetonitrile may have

unacceptable levels of carbonyl contaminants. A concentration of

10 µg/L of any aldehyde or ketone contaminant will add 0.1 µg to

the blank values determined for the DNPH derivatives per cartridge.

Follow the procedure in Appendix A to test your acetonitrile.

c. Collecting the Sample

Caution: Beware of unintentional exposure of the cartridges and

eluted samples to aldehyde and ketone sources. Laboratory air often

holds high concentrations of acetone. Labeling inks and adhesives as

well as packaging containers (including vials with plastic caps) are all

possible sources of contamination.

Waters Sep-Pak DNPH-Silica Cartridge

2

Page 3

[ Care and Use ManUal ]

Caution: Ozone (usually present in urban air) degrades the hydrazone

4

derivatives

. Place an Ozone Scrubber Cartridge (Waters Part

number: WAT054420) on the inlet of the Sep-Pak DNPH-Silica

cartridge.

Notice: Do not use Sep-Pak DNPH-Silica cartridges to process liquid

samples.

To collect the sample:

1. Take the cartridge from its pouch. Remove and save the end cap

and plug.

2. Connect the cartridge to a pump with flexible plastic tubing.

The cartridge is bidirectional (flow can be in either direction).

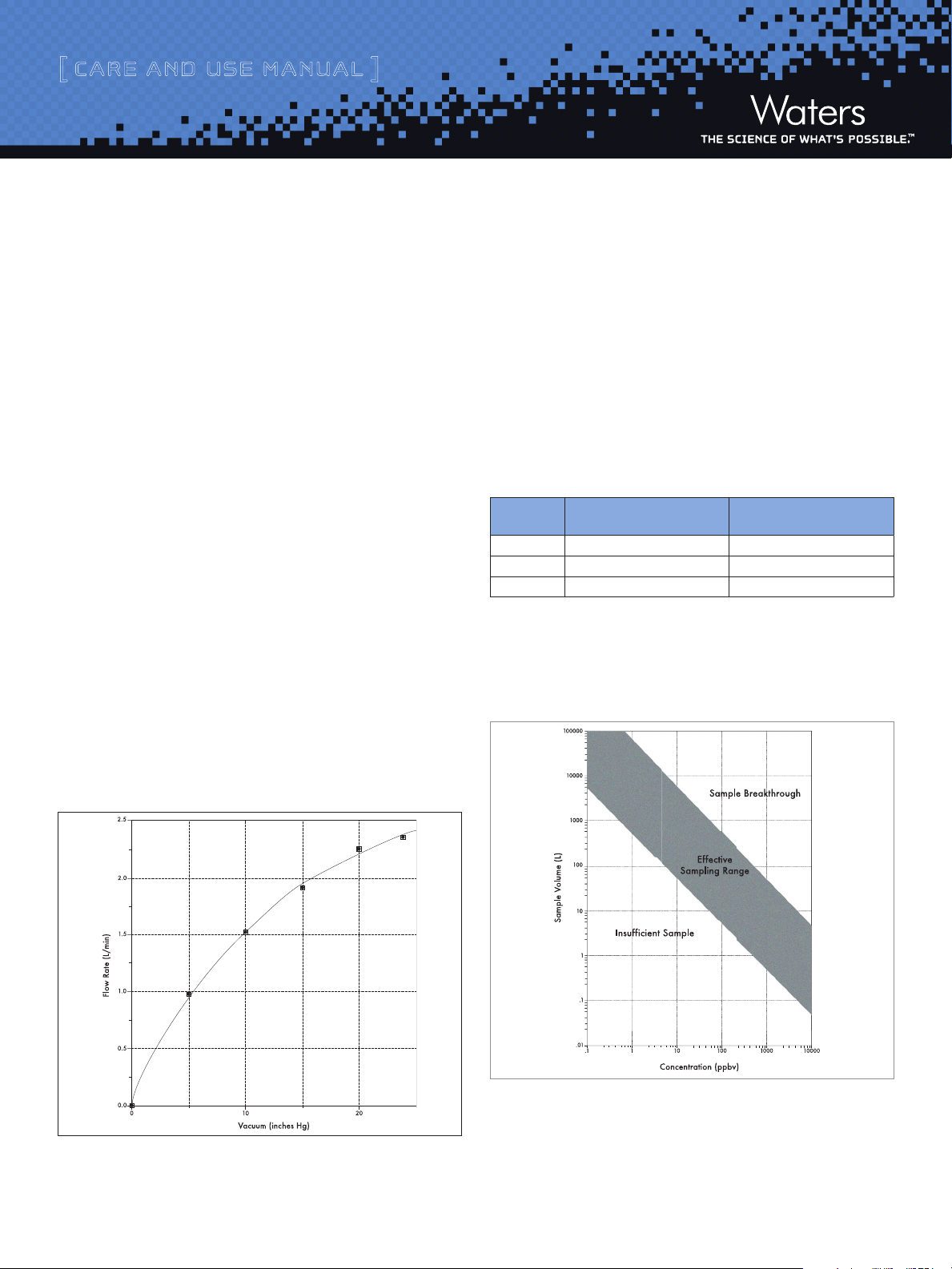

Figure 3 shows the flow rate through a cartridge versus applied

vacuum.

3. Draw the sample through the cartridge. Record the flow rate and

collection time.

4. Reseal the cartridge with its end cap and plug.

5. Store the cartridge in the provided pouch with appropriate

identification. If possible, seal the pouch using a heat sealer,

®

or store the cartridge in a glass container with a Teflon

-lined

cap. Keep the samples cool (<4 °C). Elute the cartridge within

two weeks.

The volume of air passed through the cartridge must be large

enough for the quantity of DNPH derivative formed to be several

times greater than the background level (Table 2). The United

States Environmental Protection Agency (US EPA) recommends

3

that this level be at least 10 times of that of the background

.

Figure 4 shows the ranges of sample volumes to use as a function

of expected concentration. If you can not predict the concentration

of total carbonyl compounds in a sample, follow the procedure in

Appendix C, Measuring Sample Breakthrough.

Table 2: Background Levels of DNPH Derivatives

Compound µg DNPH Derivative per Cartridge µg as Carbonyl Compound per

Cartridge

Formaldehyde <1.0 <0.15

Acetone <2.0 <0.50

Others* <0.75 -

* Individually, as acetone-DNPH, determined using a gradient

from 70/25/5 water/acetonitrile/tetrahydrofuran to 40/60 water/

acetonitrile. Other conditions are as in Section III, d.

Figure 3: Flow Rate versus Applied Vacuum

Waters Sep-Pak DNPH-Silica Cartridge

Figure 4: Range of Sample Volumes vs. Expected Concentration

3

Page 4

[ Care and Use ManUal ]

d. Eluting the Derivatives

There are two recommended methods for elution of the derivatives

from the cartridge:

Volumetric Method:

1. Elute the DNPH derivatives from the cartridge directly into a

5 mL volumetric flask. Use 3 mL HPLC-grade acetonitrile at a

flow rate of less than 3 mL/min. Higher flow rates (>3 mL/min)

can result in reduced recovery.

2. Dilute to volume with HPLC-grade acetonitrile.

Gravimetric Method:

1. Elute the DNPH derivatives from the cartridge directly into a

tared vessel. Weigh the eluate and divide by the density of the

acetonitrile to obtain the sample volume. Acetonitrile has a

density of 0.785 g/mL at 20 °C.

III. AnALYZInG tHe dnPH derIVAtIVes

a. Operating Guidelines

To ensure success in your HPLC analysis:

• Useapre-columnfilterbetweentheinjectorandcolumn.

b. Performing HPLC Analysis

To analyze the sample:

1. Prepare the standard solution of the DNPH derivatives that you

need to quantify. The concentrations of the standards should be

in the same range as the expected concentrations in the sample.

To synthesize DNPH derivatives, see Appendix B.

2. Prepare a cartridge blank from the same sample lot as the

c a r t r i d g e u s e d t o c o l l e c t t h e s a m p l e , u s i n g t h e s a m p l e

procedure and same bottled solvent.

3. Analyze the standard solution to determine the response

factor for each derivative. Due to the high linearity of the

detector response, a single point calibration is sufficient for

Waters detectors.

Note: Use an injection volume appropriate for your column. Inject

≤20 µL for a 3.9 x 150 mm Nova-Pak C

3.0 x 75 mm Nova-Pak C

column.

18

column, and ≤10 µL for a

18

4 . A n a l y z e t h e c a r t r i d g e b l a n k t o d e t e r m i n e b a c k g r o u n d l e v e l s .

Ensure that the blank values are in the normal range

(see Table 2).

5. Analyze the samples.

• UseHPLC-gradeunstabilizedtetrahydrofuranformakingmobile

phases.

• UseHPLC-gradewaterandHPLC-gradeacetonitrile.

• Degasthemobilephasesbysimultaneouslyapplyingvacuum

and ultrasound to the mobile phases for 30 seconds. If you are

using a low-pressure mixing gradient system, sparging with

helium may be necessary.

®

• WatersNova-Pak

C18 columns are shipped containing

water/acetonitrile. Equilibrate the column at 1.5 mL/min for

10 minutes in mobile phase before the first analysis.

Waters Sep-Pak DNPH-Silica Cartridge

6. Subtract the blank values from the sample values. Run standards

at regular intervals between samples.

c. Analyzing a Cartridge Blank

Analyze a blank to determine background levels. Figure 5 shows a

typical result from a blank cartridge extraction. Since background

levels may change during storage (see Section V), always compare

samples to blank cartridges from the same lot stored under the same

conditions.

Note: When preparing a blank sample, ensure that you use the exact

bottled reagents that were used for the preparation of the sample.

4

Page 5

[ Care and Use ManUal ]

1 . DNPH

2. Formaldehyde-DNPH

3. Acetaldehyde-DNPH

4. Acetone-DNPH

5. Acrolein-DNPH

6. Propionaldehyde-DNPH

Time (minutes)

Time (minutes)

1 . DNPH

2. Formaldehyde-DNPH

3. Acetaldehyde-DNPH

4. Acetone-DNPH

5. Acrolein-DNPH

6. Propionaldehyde-DNPH

7 . Crotonaldehyde-DNPH

8. Butanone-DNPH

9. Butyraldehyde-DNPH

1 0 . Benzaldehyde-DNPH

1 1 . Isovaleraldeh yde-DNPH

1 2 . V a leraldehyde-DNPH

1 3 . o-T o lualdehyde-DNPH

1 4 . m-T o lualdehyde-DNPH

1 5 . p-T o lualdehyde-DNPH

1 6 . Hexaldehyde-DNPH

1 7 . 2,5-Dimethylbenzaldehyde-DNPH

1 . DNPH

2. Formaldehyde-DNPH

3. Acetaldehyde-DNPH

4. Acetone-DNPH

Time (minutes)

1

1 . DNPH

2

. Formalde

hyd

e-DNP

H

3

. Acetaldehyde-DNP

H

4. Acetone-DNP

H

Cartridge Blank

234

02681 0

1 2

1 4

To prepare a cartridge blank:

1. Elute a fresh DNPH-Silica Sep-Pak cartridge from the same lot as

the cartridges used to collect your sample.

2. Analyze the solution by HPLC using the same conditions as those

used for the sample.

3. Multiply the concentration of each DNPH derivative by the

volume of the eluate to determine the amount of background

DNPH derivative.

Figure 6: Isocratic Separation of C

Aldehyde and Ketone

1-C3

Derivatives

Gradient Separation of Derivatives

Use the gradient conditions listed in Table 4 to separate DNPH and

DNPH derivatives from a complex mixture of aldehydes and ketones

in 15 minutes. Figure 7 shows an example separation.

Column Nova-Pak C18 3.9 x 150 mm

Mobile Phase A: Water/Acetonitrile/Tetrahydrofuran 60/30/10 v/v

B: Water/Acetonitrile 40/60 v/v

Gradient 100%Afor1min(adjustasnecessarytogivegradientdelay>

Figure 5: Typical DNPH-Silica Sep-Pak Cartridge.

3mL) then a linear gradient from 100% A to 100% B in 10 min

Flow Rate 1.5 mL/min

d. Selecting Separation Conditions

InjectionVolume 20 µL

Detection Adsorbance at 360 nm

Isocratic Separation of Derivatives

Aldehyde and Ketone

1-C9

Use the conditions in Table 3 to separate DNPH and DNPH

derivatives of C

through C3 a l d e h y d e s a n d k e t o n e s i n l e s s t h a n

1

Table 4: Gradient Separation of C

Derivatives

10 minutes. This separation requires a relatively weak mobile phase

(high water content) to separate the formaldehyde-DNPH derivative

from trace impurities. Figure 6 shows a representative chromatogram

using the isocratic conditions listed in Table 3.

Table 3: Isocratic Separation of C

Derivatives

Column Nova-Pak C18 3.9 x 75 mm

Aldehyde and Ketone

1-C3

Mobile Phase Water/Acetonitrile/Tetrahydrofuran 65/30/5 v/v

Flow Rate 1.5 mL/min

InjectionVolume 10 µL

Figure 7: Gradient Separation of C

Derivatives

Aldehyde and Ketone

1-C9

Detection Adsorbance at 360 nm

Waters Sep-Pak DNPH-Silica Cartridge

5

Page 6

[ Care and Use ManUal ]

Time (minutes)

1 . DNPH

2. Formaldehyde-DNPH

3. Acetaldehyde-DNPH

4. Acetone-DNPH

5. Acrolein-DNPH

6. Propionaldehyde-DNPH

7 . Crotonaldehyde-DNPH

8. Butanone-DNPH

9. Butyraldehyde-DNPH

1 0 . Benzaldeh yde-DNPH

1 1 . o-T o lualdehy de-DNPH

1 2 . m, p-T o lualdehy de-DNPH

1 3 . 2,5-Dimethylbenzaldehy de-DNPH

Time (minutes)

Lab Air Sample

Cartridge Blank

1 . DNPH

2. Formaldehyde-DNPH

3. Acetaldehyde-DNPH

4. Acetone-DNPH

5. Butanone-DNPH

6. Isovaleraldeh yde-DNPH

Time (minutes)

Residential Air

Cartridge Blank

1 . DNPH

2. Formaldehyde-DNPH

3. Acetaldehyde-DNPH

4. Acetone-DNPH

5. Hexaldehyde-DNPH

IV. APPLICAtIon eXAMPLes

a. Estimating Sample Volume

An expected formaldehyde concentration in a paper mill is estimated

to be 1000 ppbv. Refer to Figure 4 to find the sample volume to

collect. For this example, a sample volume of 10 liters is sufficient.

The pump used in this example generates 17 inches (Hg) of vacuum,

resulting in a flow rate through the cartridge of 2 L/min. Therefore,

five minutes of pumping at 2 L/min yields the 10 liter sample

required for the analysis.

b. Analysis of Auto Exhaust Emissions

A typical analysis of diluted exhaust emissions from car fueled by

gasoline is shown in Figure 8. The sample* was collected using a

constant volume sampler dilution tunnel. The car was operated on a

prescribed driving schedule on a chassis dynamometer.

The cartridge was connected to a heated (100 °C) sampling manifold

using a short piece of Teflon tubing. The sample was collected using

a metal bellows pump and a mass flow controller.

c. Analysis of Residential Air

A n e x a m p l e o f a n a n a l y s i s o f i n d o o r a i r i n a c o n v e n t i o n a l h o m e i s

s h o w n i n F i g u r e 9 . A 1 0 8 l i t e r s a m p l e w a s c o l l e c t e d a t 0 . 6 L / m i n

us ing a port abl e s amplin g p ump . T he chromat ogr am sho ws

formaldehyde (31 ppbv), acetaldehyde (9 ppbv), acetone (62 ppbv),

and hexaldehyde (2 ppbv).

Figure 9: Analysis of Residential Air

d. Analysis of Research Lab Air

Figure 8 represents an 8.4 liter sample collected at 1 L/min.

F or m al d e hy d e i s t h e m o st a bu n da n t c a rb o ny l c o mp o un d em it te d

(ca. 2000 ppbv). Smaller amounts of other aldehydes and ketones

al so appe ar.

* The sample was provided by Dr. S.B. Tejada of the US EPA

Atmospheric Research and Exposure Assessment Laboratory.

Figure 8: Analysis of Auto Exhaust Emissions

Waters Sep-Pak DNPH-Silica Cartridge

The sample in Figure 10 was collected in a chemical research labora-

tory using a portable sampling pump. A 100 L air sample was drawn

through the cartridge at flow rate 0.65 L/min. The chromatogram

shows formaldehyde (4.8 ppbv), acetaldehyde (1.2 ppbv), acetone

(118 ppbv), butanone (0.8 ppbv), and isovaleradehyde (0.7 ppbv).

Figure 10: Analysis of Research Lab Air

6

Page 7

[ Care and Use ManUal ]

V. storAGe And dIsPosAL oF used CArtrIdGes

Storing unused Cartridges

Always store any unused Waters Sep-Pak DNPH-Silica cartridges in

their protective pouches to prevent contamination.

Store the sealed pouches in a refrigerator at (4 °C or lower) for up to

six months. Cartridges may be stored in their unopened pouches at

room temperature (20 to 25 °C) for up to two weeks.

Background levels of hydrazone derivatives increase slightly with

time and temperature. Before using cartridges exposed to high

temperatures or stored longer than the recommended periods, run a

blank.

Storing Exposed Cartridges

Once a cartridge has been used to collect a sample, be careful to

cap and seal it until it is time to elute it. Inadvertent exposure of an

exposed cartridge can ruin a carefully collected sample. Elute the

derivatives from the cartridge within two weeks.

VI. trouBLesHootInG

Use Table 5 to solve common problems that may arise while using

the cartridges. Most errors occur as a result of contamination during

sample preparation. If resolution problems persist, validate the HPLC

5

.

system

Table 5: Troubleshooting Common Problems

Symptom Possible Cause Solution

High carbonyl values

in unused cartridges

Formaldehyde

coelutes with other

peaks

Broad peaks Injectionvolumetoohigh Useinjectionvolumeappropriate

Contaminated acetonitrile Certify acetonitrile quality prior

to use, see Appendix A

Contaminated glassware Use only pre-cleaned glassware.

Air contamination of

sample during elution

Cartridge age and storage

conditions

Improper mobile phase

composition

Separation conditions Check separation conditions. Use

Prepare sample in a glove box.

Buy new cartridges. Refrigerate

unused cartridges. Rotate stock.

Prepare fresh mobile phase,

decrease acetonitrile content.

a gradient separation.

to column (≤ 20 µL for 150 mm

or ≤ 10 µL for 75 mm Nova-Pak

columns).

C

18

Disposing of Used Cartridges

Dispose of used cartridges according to applicable government

regulations.

VII. reFerenCes And BIBLIoGrAPHY

1. Committee on Aldehydes, Board of Toxicology and

Environmental Hazards, National Research Council,

Formaldehyde and Other Aldehydes; National Academy Press,

Washington, DC, 1981.

2. Tejada,S.B.,“EvaluationofSilicaGelCartridgesCoatedIn

Situ With Acidified 2,4-Dinitrophenylhydrazine for Sampling

Aldehydes with Ketones in Air”, Intern. J. Environ. Chem. 1986,

26 , 167-185.

3. Riggins,R.M.,“CompendiumofMethodsfortheDetermination

of Toxic Organic Compounds in Ambient Air”, US Environmental

Protection Agency Report EPA-600/4-84-041, US

Environmental Protection Agency: Research Triangle Park, NC,

198 4.

Waters Sep-Pak DNPH-Silica Cartridge

7

Page 8

[ Care and Use ManUal ]

4. Arnts,R.R.andTejada,S.B.,“2,4-Dinitrophenylhydrazine-

Coated Silica Gen Cartridge Method for Determination of

Formaldehyde in Air: Identification of an Ozone Interference”,

Environ. Sci. Technol. 1989, 23, 1428-1430.

5. Guide to Successful Operation of Your LC System; Millipore

Corporation, Waters Chromatography Division: Milford, MA

1991. See Appendix E to order.

6. ASTM Method E411; Standard Test Method for Trace Quantities

of Carbonyl Compounds with 2,4-Dinitrophenylhydrazine.

VIII. orderInG InForMAtIon

Waters Sep-Pak DNPH-Silica cartridges are shipped in boxes of 20

individually-packaged cartridges. Pouches are supplied for storage

after sampling.

Table 6: Ordering Information

If your acetonitrile is unacceptable for your application, contact your

solvent supplier, or purify the acetonitrile. To purify acetonitrile,

distill it from an acidified DNPH solution using a procedure

a n a l o g o u s t o t h e o n e d e s c r i b e d i n A S T M M e t h o d E 4 1 1 f o r t h e

6

purification of methanol

.

To measure acetonitrile purity:

1. Clean all glassware by rinsing with acetonitrile and heating in a

60 °C vacuum oven for at least 30 minutes.

Derivative Concentration (µg/mL)

Formaldehyde-DNPH 0.08

Acetaldehyde-DNPH 0.12

Acetone-DNPH 0.40

All other hydrazones <0.05

2. Elute a fresh cartridge with 3 mL acetonitrile.

Derivative Concentration (µg/mL)

Formaldehyde-DNPH 0.09

Acetaldehyde-DNPH 0.14

Acetone-DNPH 2.00

All other hydrazones <0.05

Product Part Number

Sep-Pak DNPH-Silica Cartridges, 20/

box

Sep-Pak DNPH-Silica Long Body

Cartridges, 20/box

Nova-Pak C

Nova-Pak C

In-line Pre-Column Filter (0.5µm) 600000180

HVLP Mobile Phase Filter, 100/pkg WAT200530

Beginners Guide to Liquid

Chromatography

Ozone Scrubber Cartridge, 20/box WAT54420

Column, 3.9 x 75 mm WAT011670

18

Column, 3.9 x 150 mm WAT086344

18

WAT037500

WAT039550

715001531

IX. APPendICes

Appendix A: Measuring Acetonitrile Purity

HPLC-grade acetonitrile may contain traces of aldehydes and

ketones, especially acetone. 10 µg/L of an aldehyde or ketone

i n t h e a c e t o ni t r i l e a d d s 0 .1 µ g D N P H d e r i v a t i v e p e r c a r t r i d g e t o

background values.

3. Within3minutes,injecttheeluateontotheHPLCsystemto

measure the concentration of DNPH derivatives.

Derivative Concentration

after Reaction

with Acid

FormaldehydeDNPH

AcetaldehydeDNPH

Acetone-DNPH 2.00 µg/mL - 0.40 µg/mL = 1.60 µg/mL

0.09 µg/mL - 0.08 µg/mL = 0.01 µg/mL

0.14 µg/mL - 0.12 µg/mL = 0.02 µg/mL

Minus

Concentration in

Blank

Equals

Contribution from

Acetonitrile

4. Add 1 drop of concentrated HCl to the eluate and allow it to

react at room temperature for 30 minutes.

Derivative Contribution

from

Acetonitrile

FormaldehydeDNPH

AcetaldehydeDNPH

Acetone-DNPH

0.01 ÷÷ 0.08 x 100 = 12%

0.02 ÷÷ 0.12 x 100 = 17%

1.60 ÷ ÷ 0.40 x 100 =

Divided by

Background

Value

Times 100 Equals Percent

Relative to

Background

400%

Waters Sep-Pak DNPH-Silica Cartridge

8

Page 9

[ Care and Use ManUal ]

5. Remeasure the concentration of DNPH derivatives by HPLC.

6. Calculate the difference in the concentration of each DNPH

derivative measured in steps 3 and 5 to yield the contribution

from the acetonitrile.

7. Calculate the percent hydrazone contributed by the acetonitrile

relative to the background level. The value for any hydrazone

should not exceed 25% of its value in the blank.

Example: Measuring Acetonitrile Purity

1. HPLC analysis of a fresh cartridge shows the sample contains:

2. Analysis of the concentrations of hydrazones after reacting with

acid yields:

3. The different between the concentrations of hydrazone from

steps 3 and 5 represent the amount of hydrazone contributed by the

acetonitrile.

4. The percent of the hydrazones contributed by the acetonitrile are:

2. Saturate the 2 M HCl solution with DNPH: Add 8 g DNPH and stir

for one hour at 20 to 25 °C. Filter through a 0.45 µm hydrophilic

membrane (HVLP) filter (Waters Part number: WAT200530).

3. Form hydrazone derivative: Add a two-fold molar excess of

reagent-grade aldehyde or ketone to the filtered 2 M HCl DNPH

solution. Stir for 30 minutes to one hour at 20 to 25 °C.

4. Filter the hydrazone slurry. Wash the hydrazone with 50 mL 2 M

HCl 3 times. Wash with 50 mL water 3 times. Dry the filter cake

in an oven at 50 to 60°C overnight.

5. Prepare standard solutions in acetonitrile at concentrations

between 1 to 10 mg hydrazone/L. The solutions are stable for

at least one month when stored in tightly-capped glass vials

at 4 °C.

Appendix C: Measuring Sample Breakthrough

Note: If several aldehydes and ketones are present in significant

concentration, estimate the maximum sample size from the total

concentration of all species.

Since the percent for formaldehyde and acetaldehyde arising from the

acetonitrile is less than 25% of the background level in the cartridge,

the acetonitrile is considered clean for these compounds. If the analysis

considers only these compounds, the acetonitrile is acceptable.

However, the amount of acetone arising from the acetonitrile is four

times the amount in the blank (much higher than the 25% suggested

maximum). Therefore, it is suggested that this lot of acetonitrile may

be unacceptable for the analyses.

Appendix B: Synthesizing DNPH Derivative Standards

DNPH-derivative standards are easily synthesized from DNPH supplied

by Aldrich Chemical Co. (70% DNPH and 30% water). To synthesize

98-99% pure hydrazones:

1. Prepare one liter of 2 M HCl solution: Add 172 mL concentrated

reagent-grade hydrochloric acid (HCl) to a 1 L volumetric flask.

Fill the flask to the mark with distilled deionized water.

The collection efficiency for Waters Sep-Pak DNPH-Silica cartridges is

greater than 95% for gaseous sampling rates of up to 2 L/min. The

sample may exhibit breakthrough if:

• Thesamplingflowrateisgreaterthan2L/min

• Theamountofsamplecollectedisenoughtoreactwithmore

than 50% of the DNPH (equivalent to 0.5 mg DNPH)

To measure DNPH-Silica cartridges for collection efficiency:

1. Connect two unused cartridges together by the Luer fittings and

mark each cartridge for identification.

2. Connect the cartridges to a pump with a short length of flexible

tubing.

3. Collect the sample.

4. Elute both cartridges and an unused third blank cartridge.

Waters Sep-Pak DNPH-Silica Cartridge

9

Page 10

[ Care and Use ManUal ]

5. Analyze all three cartridges by HPLC.

6. Subtract the value from the blank cartridge from the values

determined from the other two cartridges.

7. Calculate and sum of the total captured DNPH-derivative from

both cartridges 1 and 2.

8. Divide the amount of DNPH-derivative determined from the first

cartridge by the total amount determined form cartridges 1 and

2. Multiply by 100. This is the percentage of DNPH-derivatives

captured on the first cartridge. This value should exceed 95%

otherwise, some of the sample broke through to the second

cartridge.

Example: Measuring Sample Breakthrough

To measure breakthrough:

Expected concentration of formaldehyde is 500 ppbv. Flow rate is

2.0 L/min. A sample volume if 100 liters yields:

Table 7: Breakthrough Example HPLC Results

Sampler Amount (µg) Quantity Captured

Sampler – blank (µg)

Sampler 1 75.06 75.00 91.8

Sampler 2 6.72 6.66 8.2

Blank 0.06 - -

In the above example, only a single carbonyl source was present.

Under many test conditions more than one carbonyl source may be

present in significant concentrations. These other compounds will

consume DNPH, effectively reducing the capacity of the sampler for

the compound of interest. To assure that the capacity of the sampler

has not been exceeded, compare the DNPH peak areas of the sample to

a similarly eluted blank. The DNPH peak area in all samples must be

no less than 50% of the DNPH peak area of the blank. This ensures

the sampler capacity has not been exceeded.

Percent Captured on

Sampler

Analyte ppmv Carbonyl Collected

concentration x molecular x air volume = µg Carbonyl

weight

Analyte molar volume at 1 atm/25 °C

This calculates to:

0.66 µL x 30.03 g/mole x 100 L = 81 µg formaldehyde

24.46 L/mole

The actual results are shown in Table 7. To calculate the percent

captured on the first sampler, divide the quantity captured on sampler

1 by the total quantity captured, then multiply by 100. Since this

value is less than 95%, and the total carbonyl amount exceeded

2.3 µmoles, breakthrough occurred.

Waters Sep-Pak DNPH-Silica Cartridge

10

Page 11

[ Care and Use ManUal ]

Austria and European Export

(Central South Eastern Europe, CIS

and Middle East) 43 1 877 18 07

Australia 61 2 9933 1777

Belgium 32 2 726 1000

Brazil 55 11 5094-3788

Canada 1 800 252 4752 x2205

China 86 10 8586 8899

CIS/Russia +7 495 3367000

Czech Republic 420 2 617 1 1384

Denmark 45 46 59 8080

Finland 09 5659 6288

France 33 1 30 48 72 00

Germany 49 6196 400600

Hong Kong 852 29 64 1800

The Netherlands 31 76 508 7200

Norway 47 6 384 60 50

Poland 48 22 833 4400

Puerto Rico 1 787 747 8445

Singapore 65 6273 1221

Spain 34 93 600 9300

Sweden 46 8 555 11 500

Switzerland 41 56 676 70 00

Taiwan 886 2 2543 1898

United Kingdom 44 208 238 6100

All other countries:

Waters Corporation U.S.A.

1 508 478 2000

1 800 252 4752

www.waters.com

Hungary 36 1 350 5086

India and India Subcontinent

91 80 2837 1900

Ireland 353 1 448 1500

Italy 39 02 265 0983

Japan 81 3 3471 7191

Korea 82 2 6300 4800

Mexico 52 55 5200 1860

© 2009 Waters Corporation. Waters, The Science of W hat’s Possible,

Sep-Pak and Nova-Pak are trademarks of Waters Corporation.

March 2009 WAT037506 Rev B KK-PDF

Waters Corporation

34 Maple Street

Milford, MA 01757 U.S.A.

T: 1 508 478 2000

F: 1 508 872 1990

www.waters.com

Waters Sep-Pak DNPH-Silica Cartridge

11

Loading...

Loading...