Page 1

[ CARE AND USE MANUAL ]

Quantitative Peptide Retention Standard

TABLE OF CONTENTS:

I. INTRODUCTION

II. STORAGE AND STABILITY

III. RECONSTITUTION OF THE PEPTIDE

RETENTION STANDARD

IV. EXAMPLE OF USING THE PEPTIDE

RETENTION STANDARD ON THE

ACQUIT Y U PLC

V. ORDERING INFORMATION

I. INT RO DUC TION

This standard was specifically designed and formulated as a simple peptide

mixture that provides a broad retention window for a variety for a variety of

peptide separation applications. It is an ideal reference material since the

peptides were designed to be stable and to not be prone to modification such

as oxidation.

This standard complements it’s qualitative counterpart, the MassPREP™

Peptide Standard which offers a versatility of various peptides but it not

quantitative. Each peptide in the Quantitative Peptide Retention Standard

is quantitated via amino acid analysis to provide greater accuracy to each

analysis, has been verified by mass identification and is highly pure (more

than 95% pure). Each standard is provided in a Waters TruView™ Maximum

Recovery Vial which simplifies the sample preparation process and allows

for direct injection once solubilized.

The standard consists of four neutral peptides with a single A280

chromophore and varying hydrophobicities and is formulated such that

the peptide components are present in equal abundance. See Table 1 for

specific peptide information.

Table 1: Peptide Mixture Components and Example Data Generated

from Figure 1

Peptide Retention Standard

Peak Area

Peptide MWmono RT (min)* (A

DGYGK

DTVGYGVK 837.4232 10.5 2572 25

DFVGYGVK 883.4440 13 2801 27

DFVGYGVKDFVGVGVK

280 nm chromophore (Y) highlighted

* See Figure 1 for retention time examples.

Applications of the standard can include, but are not limited to: evaluation

of columns and LC systems dedicated to peptide analysis as well as

monitoring performance and recovery across romatographic gradients.

538.2387

1684.8 825

2.6 2446 24

16.4 2437 24

) % Area

280

Page 2

[ CARE AND USE MANUAL ]

II. STORAGE AND STABILITY

Lyophilized peptides generally have excellent stabilities, often showing little or no degradation after a few years at -20 °C. Long-term

storage (> 1 year) should be at -80 °C desiccated, medium-term storage (1–12 months) should be at -20 °C desiccated, short-term

storage (< 1 month) may be at 4 °C. Once reconstituted the solution should be used immediately to avoid degradation of peptides which

would compromise the benefit of the standard having been quantitatively formulated.

III. RECONSTITUTION OF THE QUANTITATIVE PEPTIDE RETENTION STANDARD

This standard contains 20 nmoles of each peptide lyophilized. Reconstitute with 133.3 µL of either 0.1% aqueous formic acid or 0.1%

aqueous trifluoroacetic acid to produce a sample concentration of 150 pmol/µL (per peptide). Suggested injection volumes and sample

loads are outlined below.

Table 2: Recommended Mass Load for LC Column Evaluation

Reconstitution Volume Column ID Injection Volume Quantity of Peptide Loaded (each species)

133.3 µ L 4.6 mm 19.2 µL 2.9 nmol

133.3 µ L 2.1 mm 4.0 µL 600 pmol

133.3 µ L 1.0 mm 0.9 µL 140 pmol

IV. EXAMPLE OF USING THE QUANTITATIVE PEPTIDE RETENTION STANDARD

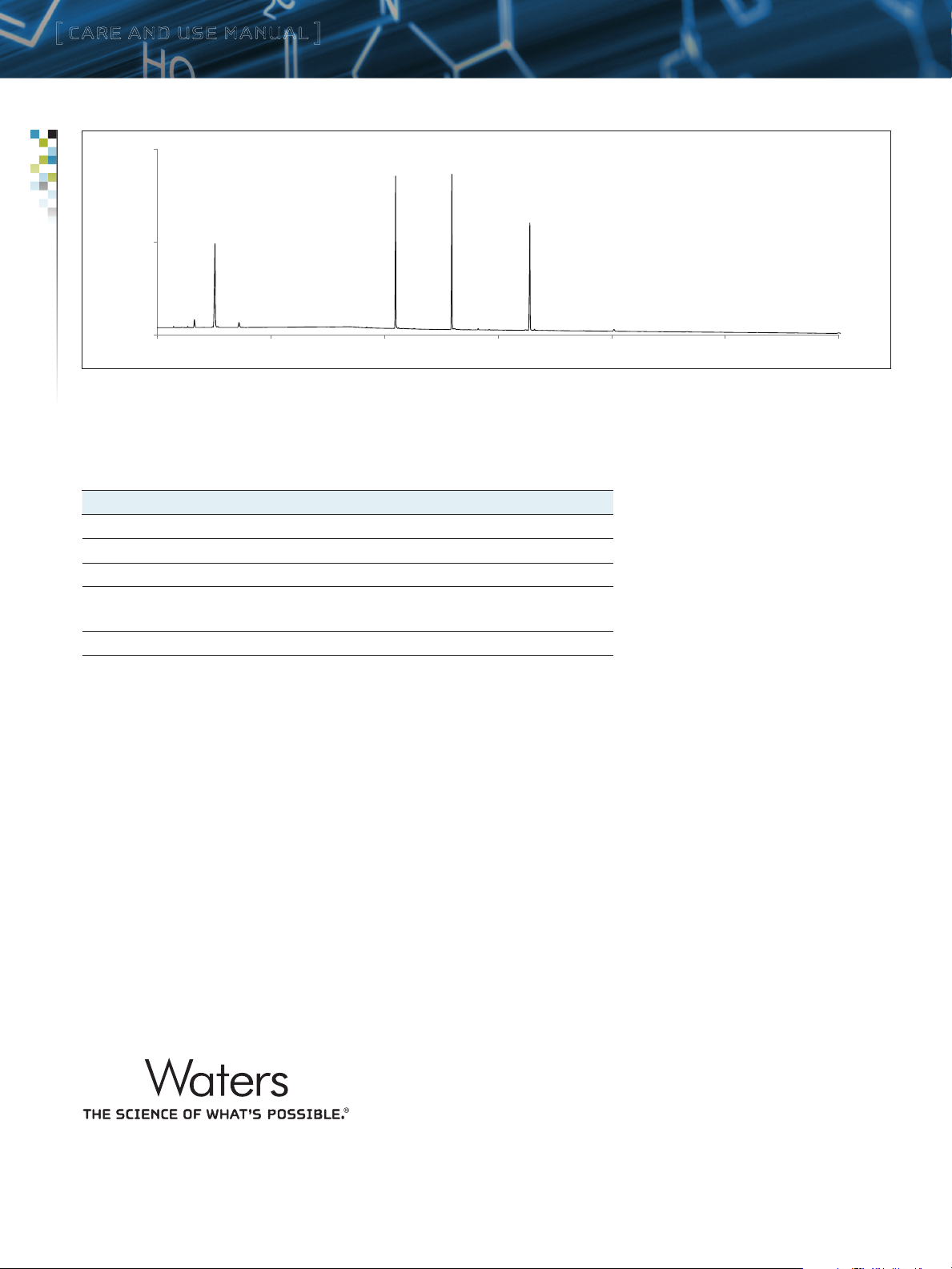

Below is a reference chromatogram with conditions to help provide an example of using the Quantitative Peptide Retention Standard.

Please note retention times are dependent on LC conditions, column and LC system. If the column size is different, the gradient/

injection volume can be scaled accordingly

System: ACQUITY UPLC® H-Class Bio

Column: ACQUITY UPLC CSH130 C18, 130Å, 1.7 µm, 2.1 x 150 mm

Mobile Phase A: Water with 0.1% FA (v/v)

Mobile Phase B: ACN with 0.1% FA (v/v)

Gradient: 0.5% B for 1 min, then to 50% B over 30 min

Flow Rate: 0.3 mL/min

Column Temp. 40 °C

Detector: UV @ 280 nm , 10 Hz

Software: Monoisotopic masses calculated with MassLynx® 4.1

2

Quantitative Peptide Retention Standard

Page 3

[ CARE AND USE MANUAL ]

0.12

DTVGYGVK

DFVGYGVK

DFVGYGVKDFVGVGVK

DGYGK

280

0.06

A

0

0510 15 20 25 30 min

Figure 1: UV chromatogram and measurements representative of the Quantitative Peptide Retention Standard as obtained with an ACQUITY U PLC CSH130 C18 column.

V. ORDERING INFORMATION

Description Qty Part Number

Quantitative Peptide Retention Standard 1 186006555

MassPREP Peptide Mix 1 186002337

MassPREP Peptide Mix 5 186002338

LCGC Certified Clear Glass, 12 x 32 mm, Screw Neck,

Max Recovery Vial

ACQUITY UPLC CSH130 C

, 130Å, 1.7 µm, 2.1 x 150 mm 1 186006938

18

100 186000327C

Waters, The Science of W hat’s Possible, ACQUITY UPLC, and MassLynx are registered trademarks

of Waters Corporation. MassPREP and TruView are trademarks of Waters Corporation.

©2014 Waters Corporation. Produced in the U.S.A. June 2014

720004786EN VW-PDF

Waters Corporation

34 Maple Street

Milford, MA 01757 U.S.A.

T: 1 508 478 2000

F: 1 508 872 1990

www.waters.com

Loading...

Loading...