Page 1

[ CARE AND USE MANUAL ]

PROTEIN-PAK SEC COLUMNS

I. INTRODUCTION

This Care and Use Manual contains information pertaining to the use of

the following Protein-Pak™ SEC Columns:

Protein-Pak 60 7.8 mm (i.d.) x 30 cm, Steel (P/N

WAT085250)

Recommended for use with biopolymers such as peptides, polypeptides,

steroids and small proteins. T he pore size distribution provides

excellent separation in the following molecular weight ranges: Native

Globular 1000-20,000 and Random Coil 600 - 8000. Shipped in

100 % m ethanol .

Protein-Pak 125 7.8 mm (i.d.) x 30 cm, Steel (P/N

WAT 084601)

Especially suited for separation of biopolymers such as proteins and

enzymes in the following molecular weight ranges: Native Globular

2000 - 80,000 and Random Coil 1000 - 30,000. Shipped in

100 % m ethanol .

Protein-Pak 300 SW 7.8 mm (i.d.) x 30 cm, Steel (P/N

WAT080013)

Protein-Pak 200 SW 8.0 mm (i.d.) x 30 cm, Glass (P/N

WAT 01178 6)

Protein-Pak 300 SW 8.0 mm (i.d.) x 30 cm, Glass (P/N

WAT011787)

CONTENTS

I. INTRODUCTION

II. PREPARATION FOR OPERATION

a. Steel Column Installation

b. Glass Column Installation

c. Solvent Requirements

d. Buffers

e. Protein Denaturants

f. Equilibration

g. Column Purge Volumes

III. CARE AND USE

a. Sample Preparation and Filtration

b. Precautions

c. Storage Consideratons

IV. TROUBLESHOOTING

a. Service and Applications Information

b. Column Efficency

c. Test Conditions

The columns of choice for use with larger biological active molecules

in the molecular weight range of Native Globular 10,000 - 400,000

and Random Coil 2000 - 150,000. Shipped in 0.05% sodium azide in

water solution.

Protein-Pak SEC Columns 1

Page 2

[ CARE AND USE MANUAL ]

maximum column eciency

Critical Distance to be determined by each

II. PREPARATION FOR OPERATION

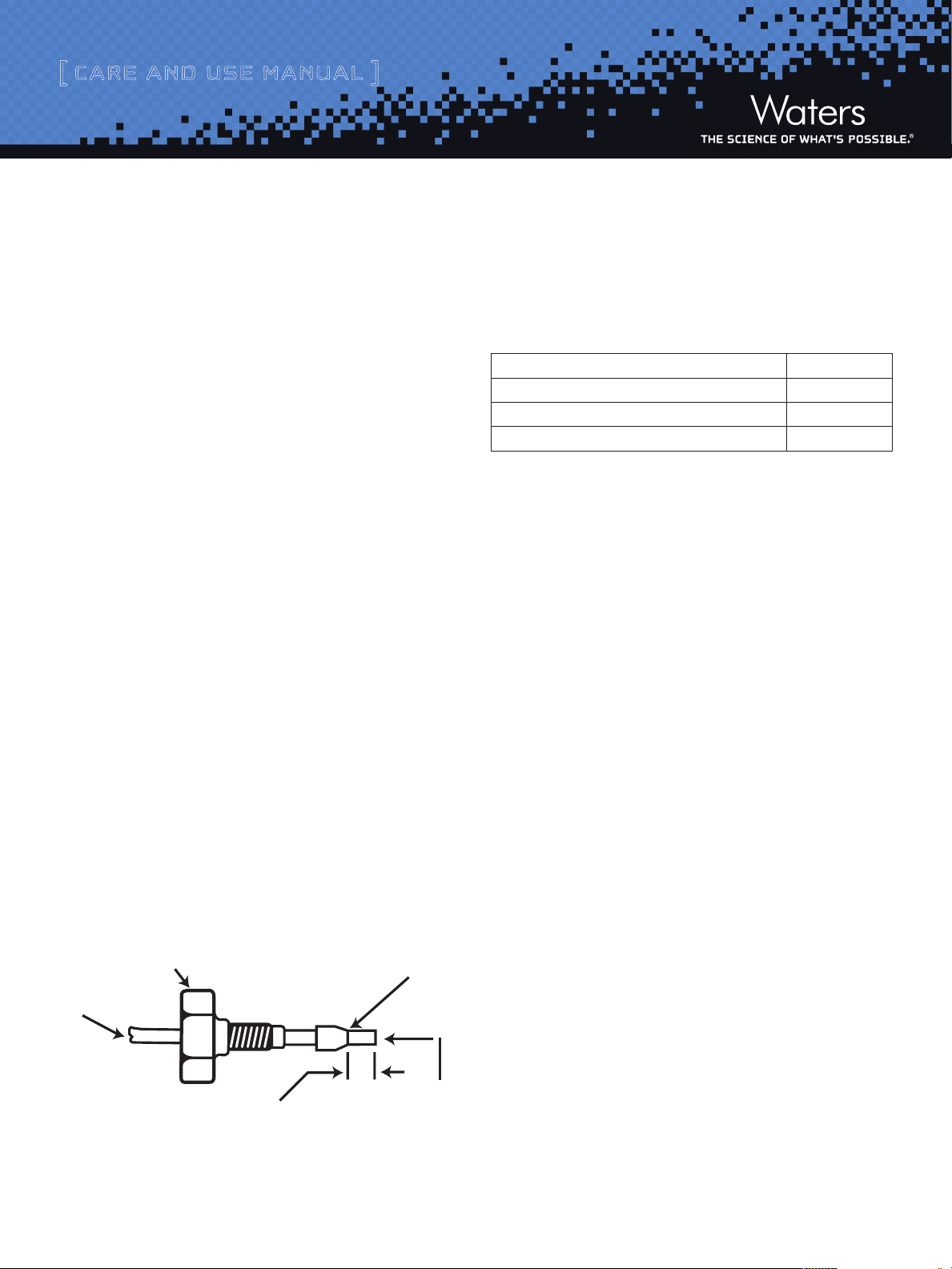

a. Steel Column Installation

Remove the end plugs from your colum with a 5/18” wrench and

save them for storage when the column is removed from the system.

The column outlet is indicated by an arrow on the label (showing the

direction solvent should flow). Tighten the fittings 1/4-to-1/2 turn.

DO NOT OVERTIGHTEN – THIS WILL DAMAGE THE FITTING SEAT.

A properly prepared and assembled compression fitting in good

conditions is all that is required.

Follow the next four steps of this procedure if tubing cutting is required

to connect a new steel column or to improve the end connections on your

existing fittings.

1. Using a file with a cutting edg, escribe the circumference of the tubing at

the desired break.

2. Grasp the tubing on both sides of the scribe mark with cloth covered pliers

(to prevent marring the tube surface), and gently work the tube back and

forth until it separates.

3. File the ends smooth and assemble as shown.

Note: Proper positioning of the fetrrule in the fitting seat will prevent

formation of unwanted dead volume which could result in sample mixing.

4. Slide the compression fitting, followed by the ferrule (large end of the

taper first) over the tube. Be certain to bottom the tube in the fitting seat

for which its use is intended to assure a leak-free connection.

Note: Attach a union in place of the column and flush the lines free of

microparticulates before attaching the column.

Figure 1: Ferrule and Compression Screw Assembly

Compression screw or nut

Tube

application (union, column tting, etc.)

End must be straight

and smooth to achieve

Ferrule

b. Glass Column Installation

Waters Protein-Pak 200 or 300 SW glass columns can be connected to

any HPLC or medium-pressure system remembering not to exceed 300 psi

backpressure with the installed glass SEC columns. T he following parts can

be used to adapt these columns to any of our standard Waters systems:

WAZ TO 1/4 UNF Adapter WAT089472

Compression Screw 1/8 o.d. 1/4 - 28 WAT08 8467

Reverse Ferrule 1/8 o.d. WAT088466

Tube Cut 0.125 x 0.009 x 120 WAT 088431

c. Solvent Requirements

Protein-Pak 60 and 125 columns are shipped containing an organic

solvent compatible with water-miscible solvents (such as methanol,

acetonitrile, etc.) The Protein-Pak 200 and 300 SW columns are shipped

in water containing 0.05% sodium azide, added as a bacteriostat. If

an immiscible solvent is to be used for analysis, make the changeover

gradually using at least one itermediate solvent (similar to changing over

solvents during analysis). When changing the organic concentration in

the mobile phase to reduce the flow rate. When adding organic solvents

to aqueous buffer solutions avoid salt precipitation.

d. Buffers

Protein-Pak columns are stable in normal salt buffer solutions such as

sodium sulfate, ammonium acetate, ammonium formate, phosphate

buffers, tris acetate and acetate buffers. Ionic strength equivalent to 0.1 M

minimizes the ionic interaction between the protein sample and the silica

stationary phase. Generally the salt concentrations in aqueous solutions

should be maintained below 0.5 M.

e. Protein Denaturants

Aqueous solutions of SDS, guanidine hydrochloride and urea are

compatible with the Protein-Pak columns although there is a tendency

to display shorter column life when compared to non-detergent

aqeuous solutions. We recommend dedicating columns used with these

solutions rather than changing back to other aqueous solutions with the

same column.

Protein-Pak SEC Columns 2

Page 3

[ CARE AND USE MANUAL ]

f. Equilibration

A necessary step to sucessful use of your new column is the inital

solvation (or wetting) of the packing. Purge the column with 5 - 10

column volumes of the stronger eluting component of the mobile phase

alone before a a final purge with the actual mobile phase. Equlibration

between the mobile phase and packing is established when a stable

baseline can be produced. If your result is unsatisfactory repeat the

equilibration process.

g. Column Purge Volumes

Column Size (mm x cm) Recommended Volumes (mL)

7.5 x 30 100

7.8 x 30 200

II. CARE AND USE

Liquid chromatography columns have a finite life influenced by their

care and use, number of injections, sample and solvent cleanliness,

frequency of solvent changeover and handling and storage procedures

among other factors. If a change is observed in the :

• Retention of a particular compound

• Resolution between two compounds

• Peak shape

Take immediate steps to determine the reason for the changes, and until

the determination is made, the results of any separations using the

column must not be relied upon. Follow generally accepted procedures

for quality control and methods development when using these columns.

Important Note: Before running the first analysis on your new column perform the test sample separation given in the test conditions section.

a. Sample Preparation and Filtration

Use HPLC grade solvents, filtered to remove microparticulate matter

above the 0.45 μm. This reduces the problem of plugged filters and

preserves column life. Vacuum filtration or sonification may be used to

remove dissolved gasses which could affect your solvent delivery system.

Always filter prepared samples to prevent excessive pressure buildup due

to particlate matter. Adequate sample cleanup (using Sep-Pak

designed for this purpose) prevents alteration of the column chemistry by

strongly adsorbing or precipitatin sample components.

®

cartridges

b. Precautions

Normal recommended pressure should not exceed 3500 psi for the

Protein-Pak SEC steel columns and no greater than 300 psi for glass SEC

columns. Maximum flow rate should not exceed: 1 mL/min

– For all silica-based packing materials, stay within a pH range of 2-8 (i.e.

avoid using concentrated acids or bases). For maximum column life stay

within the pH range: 3.5 - 6.5.

– Use Sentry™ Universal Guard Column Holder (WAT046910) and Protein-

Pak 125 Sentry Guard 2/pkg. (186000926) to protect your column from

contaiminants and extend column life.

– Try to dedicate more columns to specific applications. Constant switching

of samples and solvents will cause a more rapid column contamination

and loss of resolution.

– Filter all aqueous buffers. Avoid using turbid or cloudy buffers. Be sure that

any solutions containing buffers, salts, etc. are compatible with the wetted

surfaces of the column and equipment.

– Protect column from vibration, mechanical shock, and rapid changes in

pressure. Column packings are based on a highly porous and delicate silica

gel alignment. Any thermal, physical or chemical shock (such as changing

solvents rapidly or at high flow rates) can cause the particles to shift and

may result in a loss of efficiency.

Protein-Pak SEC Columns 3

®

– When using water, distill or treat with a Milli-Q

De-ionized water is not acceptable because it contains organi compounds

which alter column selectivity.

or equivalent system.

Page 4

[ CARE AND USE MANUAL ]

INJECT

lue of

– Avoid precipitation. DO NOT inject sample directly into the mobile

phase whenever possible. Dissolve (or dilute) samples in an appropri

ate volume of the mobile phase first. If other solvents must be used,

be sure that no precipitation occurs when they are injected into the

mobile phase.

– Protect the column from rapid changes in solvent composition. DO NOT

change the flow rate faster than 0.5 mL/min. increments.

-

C. STORAGE CONSIDERATONS

– DO NOT store column in water alone for more than three days, this practive

will promote microbial contaimination. Store this series of columns in a

0.05% sodium azide in water solution.

– DO NOT allow buffers or other potentially harmful materials to remain in

the system overnight when not being used. Flush and replace with 0.05%

sodium azide in water solution.

– Return the column to its box with the end caps firmly in place for

storage. Allowing steel columns to dry out can result in poor chro

matographic performance.

-

Problem Cause Solution

Excess pressure

buildup

Loss of

resolution, broad

peaks, low plate

counts

• Filters plugge

with Particulates

• Sample precipitates

on column (sample

not soluble in mobile

phase)

• Filters partially

plugged

• Contaminated

colum, insufficent

equilibration

• Column collapse

and void formation

• Clean in an ultrasonic

bath or replace.

• Always alter mobile

phases and samples.

• Slowly purge with a

strong mobile phase that

is both appropriate to

dis-solve the contaminate

and compatible with the

column.

• Replace or clean inlet

and outlet filters in an

ultrasonic bath.

b. Column Efficency

IV. TROUBLESHOOTING

a. Service and Applications Information

The Waters staff of trained and experienced Service Specialists

provides maintenance for Waters instruments on preventative and/or

corrective levels. Contact Waters Office at 1-800-252 HPLC or your

local Waters Representative for answers to specific chromatography

questions in methods development, applications, quality control, and

service related matters.

Waters measures the efficiency of the Protein-Pak 60 and 125

columns by using the 5 sigma method. Plate count as an expression of

effieciency, is determined by measuring the peak width at 4.4% of the

peak height method.

Figure 2: Half Height Method

N= Column Efficiency

V

= Elution time (min)

e

W 1/2= Half width va

h

sample peak (min) taken at

half height (1/2 h)

N = 5.54 x

V

e

W½

2

e

½h

Protein-Pak SEC Columns 4

Page 5

[ CARE AND USE MANUAL ]

INJECT

m)

Figure 3: 5 Sigma Method

N = Column efficiency

Vr = Elution volume (mL)

or distance from INJET (m

W 1/2= Volume at 4.4%

of peak height (mL) or peak

width at 4.4% (mm)

N = 25 x

V

r

W

2

c. Test Conditions

Columns are thoroughly testing in our quality control laboratories for adherence to our specifications. Since slight variations in your results will

occur depending on the equipment used, test your sample makeup and equipment settings and condition, perform the test sample run given here for

your new column and record the results (retention time and the settings used) before attempting the first analysis. Use these results for comparison

throughout the life of your column.

Detectors should run at 254 nm or 280 nm [UV ]; otherwise, use intstrument settings that produce an acceptable test peak [this may mean using a

lower sensitivity on UV detectors than normally practiced for a specific analysis].

Note: Be sure to record results and instrument settings (and configurations) to allow exact reproduction and comparison in the future.

Key

Mobile Phase Test Sample Peak

1 100% Methanol A 1,2 Dichlorobenzene

2 0.05% Sodium Azide B Ethylene glycol in water

Column name Part Number Mobile Phase Optimal Flow Rate

(mL /min)

Protein-Pak 60

7.8 mm x 30 cm

Prot e in -P a k 125

7.8 mm x 30 cm

Protein-Pak 300 SW

7.8 mm (i.d.) x 30 cm, Steel

Protein-Pak 200 SW

8.0 mm (i.d.) x 30 cm, Glass

Protein-Pak 300 SW

8.0 mm (i.d.) x 30 cm, Glass

WAT085250 1 0.5 A

WAT 0 8 4 6 01 1 0.5 A

WAT080013 2 0.5 B

WAT 01178 6 2 0.5 B

WAT 01178 7 2 0.5 B

Test Sample Peak

Protein-Pak SEC Columns 5

Page 6

[ CARE AND USE MANUAL ]

Sales Offices

Austria 43 1 877 18 07

Australia 61 2 9933 1777

Belgium and Luxembourg 32 2 726 1000

Brazil 55 11 4134 3788

Canada 1 800 252 4752

China 86 21 6156 2666

Czech Republic 420 2 617 11384

Denmark 45 46 59 8080

Finland 358 9 5659 6288

France 33 1 30 48 72 00

Germany 49 6196 400 600

Hong Kong 852 2964 1800

Hungary 36 1 350 5086

India 91 80 2837 1900

Ireland 353 1 448 1500

Israel 9723 3731391

Italy 39 02 265 0983

Japan 81 3 3471 7191

The Netherlands 31 76 508 7200

Norway 47 6 384 6050

Poland 48 22 101 5900

Portugal 351 21 893 61 77

Puerto Rico 1 787 747 8445

Russia/CIS 7 495 727 4490 / 290 9737

Singapore 65 6593 7100

Spain 34 93 600 9300

Sweden 46 8 555 115 00

Switzerland 41 56 676 7000

Taiwan 886 2 2501 9928

UK 44 208 238 6100

US 1 800 252 4752

Waters Corporation

34 Maple Street

Milford, MA 01757 U.S.A.

T: 508 478 2000

F: 508 872 1990

www.waters.com

Korea 82 2 6300 4800

Mexico 52 55 52 00 1860

©2013 Waters Corporation. Waters, The Science of W hat’s

Possible and Sep-Pak are registered trademarks of Waters

Corporation. Protein-Pak is a trademark of Waters Corporation.

All other trademarks are property of their respective owners.

September 2013 WAT020052 Rev G VW-PDF

Protein-Pak SEC Columns 6

Waters Corporation

34 Maple Street

Milford, MA 01757 U.S.A.

T: 1 508 478 2000

F: 1 508 872 1990

www.waters.com

Loading...

Loading...