Page 1

[ CARE AND USE MANUAL ]

columns

Protein-Pak Hi Res IEX Columns and Standards

CONTENTS

I. INTRODUCTION

II. CONFIGURING AN ACQUITY SYSTEM FOR

USE IN IEX PROTEIN SEPARATIONS

III. GETTING STARTED

a. eCord Installation

b. Column Connectors

c. Column Installation

d. Column Equilibration

e. Useful Functional Tests for

Benchmarking a New Column

IV. COLUMN SPECIFICATIONS AND USE

a. Specifications

b. Sample Preparation

c. Operating pH

d. Solvents

e. Pressure

f. Flow Rate

g. Temperature

I. INTRODUCTION

Thank you for choosing a Protein-Pak™ ion-exchange column.

Waters Protein-Pak Hi Res IEX family of columns were developed

to assist in the UPLC® characterization of recombinant proteins

and monoclonal antibodies found in many of today’s novel

biopharmaceutical therapeutics. T he non-porous, high-ligand

density particles overcome some of the high molecular weight

limitations present using traditional porous, IEX particles. In

addition, use of a multi-layered network of ion-exchange groups

(SP, CM, or Q) on non-porous particles assist the effective diffusion

and binding of charged proteins or other biomolecules onto the

particles to deliver relatively high sample loading capacities and

component resolution while minimizing column fouling.

The available ion-exchange chemistries include a strong-anion

and weak- and strong-cation exchangers (Table 1), all of which are

stable, over a wide pH range (3–10), high salt concentrations and

standard pressures (see Column Specifications and Use section) via

use of polymer-based particles. Only when the Protein-Pak Hi Res

IEX column series is combined with the ACQUITY UPLC® system

will the full performance benefits of this column be realized.

V. TROUBLESHOOTING

VI. COLUMN CLEANING, REGENERATION,

AND STORAGE

a. Cleaning and Regeneration

b. Storage

VI. INT RODUCING ECORD INTELLIGENT

CHIP TECHNOLOGY

a. Introduction

b. Installation

c. Manufacturing Information

d. Column Use Information

VIII. ORDERING INFORMATION

Table 1

Abbreviation Ion-Exchange Ligand

SP Sulfopropyl

CM Carboxymethyl

Q Quaternary ammonium

Page 2

[ CARE AND USE MANUAL ]

2 mm

II. CONFIGURING AN ACQUITY SYSTEM FOR

USE IN IEX PROTEIN SEPARATIONS

Although Waters Protein-Pak Hi Res IEX columns do not require

the high pressure capability of an ACQUITY UPLC system, the full

performance benefits of this column will only be realized with the

low system volume and low detector dispersion of the optimized

ACQUITY UPLC system. However, ion-exchange chromatography

may require modifications to an existing ACQUITY UPLC system.

Please refer to “Size Exclusion and Ion-Exchange Chromatography

of Proteins using the ACQUITY UPLC System”, (715002147A) for

specific recommendations that can be obtained at www.waters.

com/chemcu.

III. GETTING STARTED

An Analysis Report and an Inspection Data Sheet are generated

and available for each shipped Protein-Pak Hi Res IEX column.

The Analysis Report is specific to each batch of packing material

and includes the batch number and chromatographic separation

obtained using defined protein standards. This document is

available upon request http://www.waters.com/waters/form.

htm?id=10048430&ev=10048691&locale=en_US. The

Inspection Data Sheet is included with each shipment and is

specific to each individual column and contains the following

information: batch number, column serial number, plate count,

tailing factor, retention factor, and chromatographic separation

conditions. These data should be stored for future reference.

b1. The ACQUITY UPLC system utilizes tubing and gold plated

compression screws that have been designed to meet

stringent tolerance levels and to minimize extra column

volumes. The columns should be attached to the ACQUITY

UPLC injector with a column stabilizer.

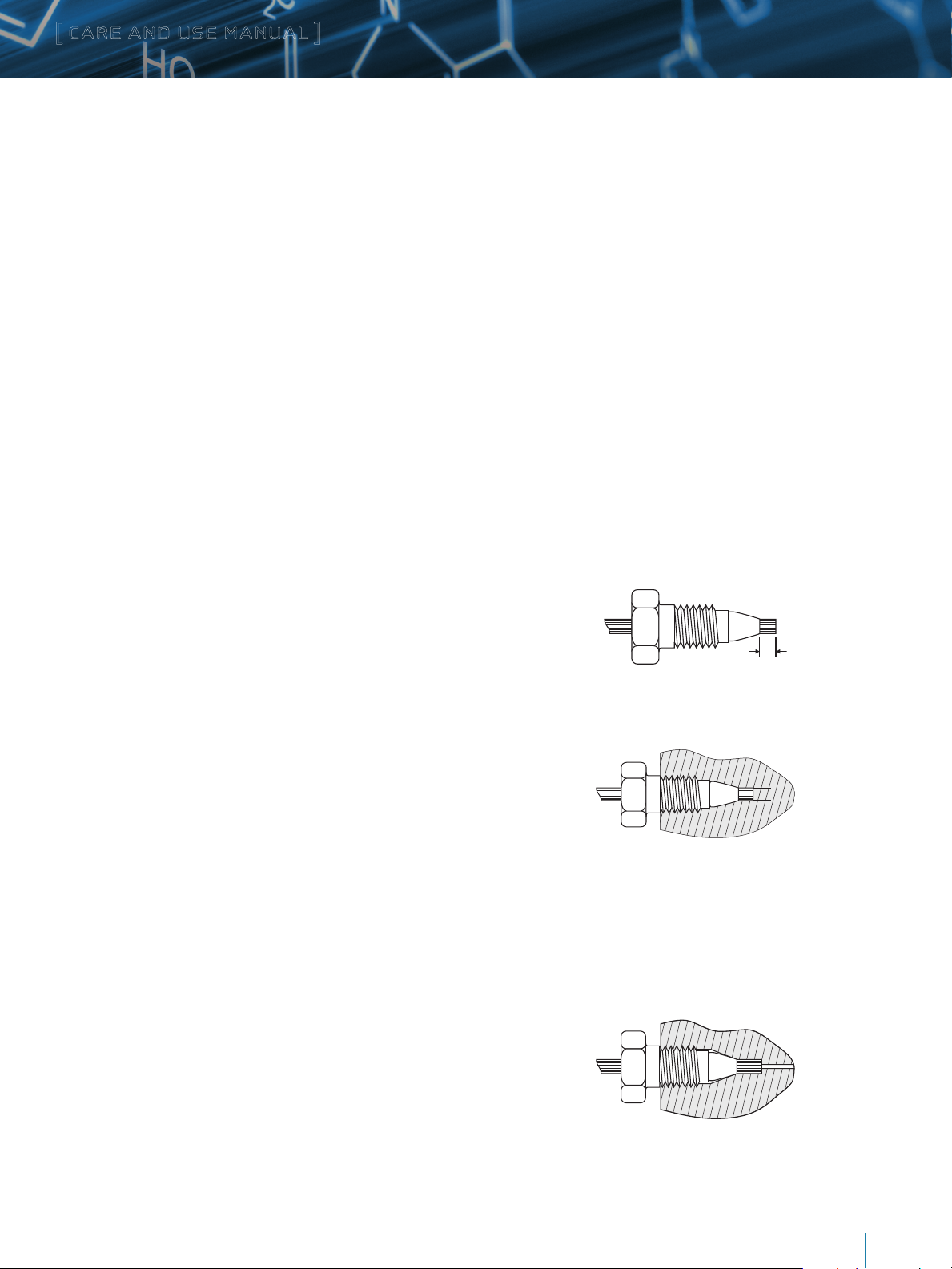

b2. Waters Protein-Pak Hi Res columns require end fittings that

have a 2 mm depth between the ferrule and the end of the

extending stainless steel tubing (Figure A) that must perfectly

seat to the end of the Protein-Pak Hi Res column. Connecting

a different style connector to a Waters Protein-Pak Hi Res

IEX column may leave a gap between the end of the stainless

steel tubing and the column that will result in undesired peak

broadening (Figure B).

To correct this problem, disassemble the finger-tight fitting of

the stabilizer and remake the connection (i.e., 2 mm depth) to the

Waters Protein-Pak Hi Res IEX column.

Figure A

Figure B

a. eCord Installation

The eCord™ button should be attached to the side of the Waters

ACQUITY UPLC column heater module. The eCord button is

magnetized and does not require specific orientation.

b. Column Connectors

There are two options for connecting the Protein-Pak Hi Res

column to an ACQUITY system. The first option is to use the

reusable fitting on the 150 mm and 100 mm column stabilizers

(sect b1). This fitting/tubing is supplied with ACQUITY UPLC

column heaters. A second alternative is to remove this fitting and

replace it with a non removable fitting (i.e. steel). If the second

option is employed, specific directions must be followed (sec b2).

In a proper tubing/column connection, the tubing touches the

bottom of the column end fitting with no void between them.

(Figure C).

Figure C

Protein-Pak Hi Res IEX Columns and Standards

2

Page 3

[ CARE AND USE MANUAL ]

c. Column Installation

Note: The flow rates given in the procedure below are for a Protein-

Pak Hi Res CM or SP, 7 µm, 4.6 mm i.d. column.

1. Purge the solvent delivery system of any organic or water-

immiscible mobile phases and connect the inlet end of the column

to the injector outlet. An arrow on the column identification label

indicates the correct direction of solvent flow.

2. Flush column with 100% aqueous buffer (line A1) by setting

the pump flow to 0.2 mL/min.

3. When the buffer is flowing freely from the column outlet attach

the column outlet to the detector. Monitor the system pressure

to ensure the column is within its pressure limitations.

4. Gradually increase the flow rate, by not more than 0.5mL/min

at a time (as described in step 2).

5. Once a stable backpressure has been achieved, proceed to the

next section.

d. Column Equilibration

Protein-Pak Hi Res columns are shipped in 20 mM sodium sulfate

with 0.05% sodium azide. It is important to ensure mobile-phase

compatibility before changing to a different mobile-phase system.

Equilibrate the column with a minimum of 10 column volumes of

the buffer to be used (refer to Table 2 for column volumes).

Table 2. Empty Column Volumes in mL

(multiply by 10 for flush solvent volumes).

Column Dimension Approximate Volume

4.6 x 100 mm 1.66 mL

e. Useful Functional Tests for Benchmarking a New Column

It may be useful to benchmark the column performance with

a sample that is representative of the intended application. A

separation of common proteins with an appropriate method is

suggested for your new column. Two standards were specially

designed for this purpose. The IEX Cation Test Standard is

specifically designed with proteins that resolve well on cation-

exchange columns. The IEX Anion Test Standard is specifically

designed with proteins that resolve well on anion-exchange

columns. This test can also be used to monitor the condition of

your column after extended use.

The following sets of conditions and chromatograms show

examples of using the IEX Standards for benchmarking and

monitoring column and system health. T he exact results observed

in any laboratory will depend on the instrument in use. Similar

results can only be expected with a Waters ACQUITY UPLC system.

These tests are valuable for monitoring the life of the column

and for troubleshooting separation difficulties that may arise.

Protein-Pak Hi Res Cation-Exchange Columns and Standards

Sample Diluent: 20 mM Sodium Phosphate Buffer, pH 6–7

The IEX Cation Test Standard is packaged in a Waters TruView

Max Recovery Vial (p/n 186005668cv) and is lyophilized for

prolonged storage and stability. The standard is shipped at room

temperature but it upon arrival, it is recommended to store this

standard at -20 ˚C.

Protein Sigma P/N Conc. mg/mL

Bovine Ribonuclease A R5500 4

Cytochrome C, bovine heart C2037 4

Chicken Lysozyme L6876 4

Column: Protein-Pak Hi Res CM, 4.6 x 100 mm,

or Protein-Pak Hi Res SP, 4.6 x 100 mm

Injection Volume: 10.0 μL

Flow Rate: 1 mL/min

Mobile Phase A: 20 mM sodium phosphate buffer, pH 6.6

Mobile Phase B: 20 mM sodium phosphate buffer,

0.5 M NaCl, pH 6.6

Weak Needle Wash: Mobile phase A

Strong Needle Wash: Mobile phase B

Seal Wash: 90/10 H20/MeOH

Temperature: 30 ˚C

Detection: 280 nm

Gradient:

Time %A %B Curve

1 100 0 6

34 40 60 6

36 40 60 6

38 100 0 6

55 100 0 6

Protein-Pak Hi Res IEX Columns and Standards

3

Page 4

[ CARE AND USE MANUAL ]

AU

0.040

0.050

0.060

0.070

0.080

0.090

0.030

0.020

0.010

0.000

8

Lysozyme

Ribonuclease A

Cytochrome C

10 12

14

16 18

20

22 24 min

Protein-Pak Hi Res CM Column

Protein-Pak Hi Res SP Column

0.080

0.070

0.060

0.050

AU

0.040

0.030

0.020

0.010

0.000

Cytochrome C

Ribonuclease A

810121416182022242628303234 min

Protein-Pak Hi Res Anion-Exchange Column and Standard

Sample Diluent: Lyophilized in 20 mM Tris Buffer, pH 8–9,

Reconstituted in 1ml 100% Milli-Q Water, vortex and

inspect for undisssolved solids.

Protein Sigma P/N Conc. mg/mL

Horse Myoglobin M188 2 0.5

Conalbumin from

Chicken Egg White

C0755 1.25

Soybean Trypsin Inhibitor T9128 2

Lysozyme

Column: Protein Pak Hi Res Q, 4.6 x 100 mm

Inj Vol: 10.0 µL

Flow Rate: 0.6 mL/min

Mobile Phase A (Acid): 100 mM TRIS HCl (aq)

Mobile Phase B (Base): 100 mM TRIS (aq)

Mobile Phase C (Salt): 1000 mM NaCl (aq)

Mobile Phase D (Aqueous): Water

Sample Manager Wash: 25 mM TRIS, 150 mM NaCl, pH 8.3

Sample Manager Purge: 25 mM TRIS, 150 mM NaCl, pH 8.3

Seal Wash: 90/10 H2O/MeOH

Column Temp.: 30 °C

Sample Manager Temp.: 4 °C

Detection: 280 nm

Auto•Blend Plus Gradient:

Time

(min)

Initial

2.0 0.6 9.0 6.0 0.0 6.0

15.0 0.6 9.0 6.0 500.0 6.0

18.0 0.6 9.0 6.0 500.0 6.0

19.0 0.6 9.0 6.0 0.0 6.0

20.0 0.6 9.0 6.0 0.0 6.0

Flow

(mL/min)

pH

pH

Curve

(mM )

0.6 9.0 6.0 0.0 6.0

Salt

Salt

Curve

Actual Gradient (with no Auto•Blend capability):

Time

Initial

2.0 0.6 3.3 16.7 0.0 80.0

15.0 0.6 3.3 16.7 50.0 30.0

18.0 0.6 3.3 16.7 50.0 30.0

19.0 0.6 3.3 16.7 0.0 80.0

20.0 0.6 3.3 16.7 0.0 80.0

Flow

(mL/min)

%A %B %C %D

0.6 3.3 16.7 0.0 80.0

Protein-Pak Hi Res Q Column

Myoglobin

Conalbumin*

*Contains IsoformA and B which could be resolved under various pH conditions)

TrypsinInhibitor

Protein-Pak Hi Res IEX Columns and Standards

4

Page 5

[ CARE AND USE MANUAL ]

IV. COLUMN SPECIFICATIONS AND USE

a. Specifications

Description

Protein-Pak

Hi Res Q

Ion Exchange Strong Anion Weak Cation Strong Cation

Functional Group

Matrix

Quaternary

ammonium

Hydrophilic

polymer

Particle Size (µm) 5 7 7

Pore Size:

i.d. x L (mm)

Non porous

4.6 x 100

Counter Ion Cl- Na+ Na+

pH Range 3–10 3 –10 3 –10

Small Ion Capacity

(µeq/g dry gel)

pK

a

270 100 23

10.5 4.9 2.3

1. A pproximate

Protein Binding

Capacity in mgs

per column (i.e.,

58 33

BSA for Hi Res Q

column; Lysozyme

for Hi Res CM and

Hi Res SP columns)

Flow Rates

2. Max Pressure

across column

0.3–0.6

mL/min

2175 p si

(15M P a )

Salt Concentration No limit No limit No limit

<50%. When

switching

from aqueous

Organic

Concentration

buffers to

organic, lower

flow rates to

<0.25 mL/

min.

Temperature (°C) 10–60 10– 60 10 – 60

1. For optimal resolution of complex samples, do not exceed 20% of the

column’s protein binding capacity.

2. See section e. pressure for details.

Protein-Pak

Hi Res CM

Protein-Pak

Hi Res SP

Carboxymethyl Sulfopropyl

Hydrophilic

polymer

Non porous

4.6 x 100

0.5–1.4

mL/min

1450 psi

(10Mpa)

<50%. When

switching

from aqueous

buffers to

organic, lower

flow rates to

<0.5 mL/min.

Hydrophilic

polymer

Non porous

4.6 x 100

25

0.5–1.4

mL/min

1450 psi

(10Mpa)

<50%. When

switching

from aqueous

buffers to

organic, lower

flow rates to

<0.5 mL/min.

To ensure the continued high performance of Protein-Pak Hi Res

IEX columns, follow these guidelines:

b. Sample Preparation

1. It is preferable to prepare the sample in the operating mobile

phase or a mobile phase that has a higher pH (anion exchange)

or lower pH (cation exchange) than the mobile phase to ensure

complete loading of the sample onto the column. The ionic

strength of the sample should also be lower or equivalent to

that of the starting buffer.

2. If the sample is not dissolved in the mobile phase, ensure that

the sample, solvent and mobile phases are miscible in order to

avoid sample and/or buffer precipitation.

c. Operating pH

The recommended operating pH range for Protein-Pak Hi Res

IEX columns is 3–10. A listing of commonly used buffers and

additives is given in Table 3. The column lifetime will vary

depending upon the operating temperature as well as the type

and concentration of buffer used.

Table 3. Buffers Commonly Used for Ion Exchange

Anion-Exchange Buffers

pH Range Additive/Buffer pKa (25 °C) Counter-ion Conc. (mM )

4.5–5.3 N-Methylpiperazine 4.75 Cl- 20

4.8–6.0 Piperazine 5.68 Cl-/HCOO- 20

5.8–7.0 bis-Tris 6.48 Cl- 20

6.4 –7.3 Bis-tris propane 6.80 Cl- 20

6.5–7.9 MOPS 7. 2 8 Cl- 20

7.3–8.2 Triethanolamine 7.76 Cl-/HCH3COO 20

7.5–8.8 Tris 8.06 Cl- 20

8.4–9.4 Diethanolamine 8.88 Cl- 20

9.0–10.0 Ethanolamine 9.50 Cl- 20

9.7–10.0 CAPS 10.40 Cl- 20

Cation-Exchange Buffers

pH Range Additive/Buffer pKa (25 °C) Counter-ion Conc. (mM )

3.0–4.3 Lactic acid 3.81 Na+ 20

3.3–4.3 Formic acid 3.75 Na+/Li+ 20

4.0– 5.7 Acetic acid 4.76 Na+/Li+ 20

4.6–6.6 Malonic acid 5.68 Na+/Li+ 20

5.1–7.1 MES 6.10 Na+/Li+ 20

5.5–7.7 Phosphate 7.20 Na+ 20

7.0–8.0 HEPES 7.5 5 Na+ or Li+ 20

7.8–8.8 BICINE 8.35 Na+ 20

a

Adapted from:

1. P Stanton, “Ion-Exchange Chromatography,” HPLC of Proteins and Peptide:

Methods and Protocols; Aguilar, M.-I. Ed; Method in Molecular Biology, Humana

Press, Totowa, NJ, Vol. 251, Ch 4.

2. “Buffer Reference Center,” Sigma –Aldrich, 2009. http://www.sigmaaldrich.

com/life-science/core-bior agents/biological-buffers/learning-center/bufferreference-center.html

Protein-Pak Hi Res IEX Columns and Standards

5

Page 6

[ CARE AND USE MANUAL ]

d. Solvents

To maintain maximum column performance, use high quality

chromatography grade solvents. Filter all aqueous buffers prior

to use. Solvents containing suspended particulate materials can

damage the fluidic components of the UPLC system and may clog

the inlet distribution frit of the column. This will result in higher

operating pressure and poor performance.

The maximum organic concentration must be <50%. When the

solvent is replaced by distilled or ion exchanged water, the flow

rate must be less than 0.25 mL/min for Protein-Pak Hi Res Q, 5

µm column or less than 0.5mL/min for Protein-Pak Hi Res CM or

SP, 7 µm columns.

e. Pressure

Protein-Pak Hi Res IEX columns can tolerate pressures across the

column of up to 2175 psi for Protein-Pak Hi Res Q, 5 µm column

and up to 1450 PSI for Protein-Pak Hi Res SP, 7 µm and Protein-

Pak Hi Res CM, 7 µm columns. These suggested limits are for the

pressure drop across the column. The actual recorded pressure on

an HPLC or UPLC system is a sum of the pressure generated from

solvent flow through the LC tubing and detector cell combined

to the pressure generated from solvent flow through the packed

IEX column. To determine the actual pressure drop across the

IEX column, subtract the above value from the system pressure

obtained (using the same eluent, flow, and temperature selected

for the IEX separation method) when a union is substituted in place

of the column on the LC System.

Note: Working at the extremes of pressure, pH and/or temperature

may result in shorter column lifetimes.

f. Flow Rate

Standard flow rate:

0.3–0.6 mL/min: Protein-Pak Hi Res Q, 5 µm column

0.5–1.4 mL/min: Protein-Pak Hi Res CM and SP, 7 µm columns

V. TROUBLESHOOTING

The first step in systematic troubleshooting is comparison of the

column, in its current state, to the column when it was functioning

properly. The functional tests with the protein mixture may reveal

subtle changes in surface chemistry that affect the application.

There are several common symptoms of change in the column.

1. An increase in pressure is often associated with lost

performance in the application. The first step in diagnosis is to

ensure that the elevated pressure resides in the column rather

than somewhere else in the system. This is determined by

measuring pressure with and without the column attached to the

instrument. If the system is occluded, the blockage should be

identified and removed. If the pressure increase resides in the

column, it is helpful to know whether the problem was associated

with a single injection or whether it occurred over a series of

injections. If the pressure gradually built up, it is possible that

the column can be cleaned as described in Section VI. For future

stability, it may be useful to incorporate a stronger regeneration

step in the method. If a single sample caused the pressure

increase, it likely reflects particulates or insoluble components,

such as lipids. Cleaning is still an option, but using the more

aggressive options. The sudden pressure increase suggests

that the user should consider some sample preparation, such as

filtration or high-speed centrifugation.

2. Loss of retention can reflect a change in the column surface

chemistry. Before proceeding with diagnostic or corrective

measures, check that the mobile phases have been correctly

prepared and the correct method has been selected. Then

repeat the functional or protein test. If the proteins show

loss of retention, the column may require replacement. If the

changes are small and reflected only for some proteins, one of

the cleaning procedures may be effective.

3. Change in peak shape, resolution, or relative retention of

peaks. Follow the same steps as for loss of retention (Symptom 2).

Under certain conditions (viscous buffers, low temperatures) the

maximum flow rate may have to be reduced so as to not exceed

the maximum column pressure limits.

g. Temperature

Temperatures between 10 ˚C–60 ˚C are recommended for

operating Protein-Pak Hi Res IEX columns.

4. Carryover and memory effects are defined as the appearance

of the constituents of one sample in the next gradient analysis.

First determine whether the column or the system is the

source of carryover. Define a gradient method that includes

an “internal gradient”. That is, the analytical gradient is

repeated within a single method. If the protein peaks appear

in both gradients, at the same time after start, the protein

came from the column in what is often described as a “memory

effect”. If the protein peaks only appear when an injection is

Protein-Pak Hi Res IEX Columns and Standards

6

Page 7

[ CARE AND USE MANUAL ]

made, they likely originate from adsorption to some system

component. In that case follow the instrument manufacturer’s

recommendations. Memory effects as a source of carryover

may be reduced or eliminated in several ways. First, raising the

temperature of the separation reduces the possibility of non-

specific protein adsorption. Second, memory effects may be

more pronounced with steep gradients. Keep the gradient slope

at 10 column volumes or greater. Third, memory effects may

be exacerbated by high flow rates. Reduce the flow rate by one

half while doubling the gradient time to maintain a constant

slope. Finally, apparent memory effects may actually reflect

the solubility of the protein in the mobile phase. Reducing the

amount injected may eliminate the effect.

Note: Useful general information on column troubleshooting

problems may be found in HPLC Columns Theory, Technology

and Practice, U.D. Neue, (Wiley-VCH, 1997), the Waters HPLC

Troubleshooting Guide (Literature code # 720000181EN) or visit

the Waters Corporation website for information on seminars

www.waters.com).

3. Flow reversal or back flushing is often suggested as part of a

cleaning procedure. This should be reserved as a last resort.

It may further damage the column or provide a short-lived

improvement in performance.

b. Storage

For overnight storage, the column can remain in the IEX separation

eluent while maintaining a low flow rate (e.g., 0.1 mL/min). For

long-term storage, replace the eluent at the suggested flow rate

shown below with filtered, high purity water containing 0.05%

sodium azide that will inhibit undesired microbial growth.

<0.25 mL/min for Protein-Pak Hi Res Q, 5 µm columns

<0.5 mL/min for Protein-Pak Hi Res CM and SP, 7 µm columns

Completely seal column to avoid evaporation and drying of the bed.

VII. INTRODUCING ECORD INTELLIGENT

CHIP TECHNOLOGY

VI. COLUMN CLEANING, REGENERATION

AND STORAGE

a. Cleaning and Regeneration

Changes in peak shape, peak splitting, shoulders on the peak,

shifts in retention, change in resolution, carryover, ghost peaks,

or increasing backpressure may indicate contamination of the

column. Choose a cleaning option that may be expected to

dissolve the suspected contaminant.

1. It may be useful to conduct cleaning procedures at one-half the

flow rate typically used with that column. In this way the

possibility of high pressure events is reduced.

2. Several different cleaning solutions may be injected to

strip strongly adsorbed material or particulates from the

column. Make the largest injection possible with the system

configuration. With such strong cleaning solutions, it is best to

disconnect the detector from the column and to direct the flow

to waste.

a. 0.1mol/L NaOH, or

b. 20 ~ 40% acetic acid, or

c. Solution containing aqueous organic solvent such as

methanol or acetonitrile

d. Solution containing a solubilizer such as urea and

non-ionic surfactants

a. Introduction

The eCord intelligent chip is a new technology that will provide

the history of a column’s maximum backpressure, maximum

temperature and the number of injections performed throughout its

lifetime. The eCord will be permanently attached to the column to

assure that the column’s performance history is maintained in the

event that the column is moved from one instrument to another.

Figure D. Waters eCord Intelligent Chip

Protein-Pak Hi Res IEX Columns and Standards

7

Page 8

[ CARE AND USE MANUAL ]

At the time of manufacture, tracking and quality control

information will be downloaded to the eCord. Storing this

information on the chip will eliminate the need for a paper

Certificate of Analysis. Once the user installs the column, the

software will automatically download key parameters into a

column history file stored on the chip. In this manual, we explain

how the eCord will provide a solution for easily tracking the

history of the columns, reduce the frustration of paperwork trails,

and give customers the reassurance that a well performing column

is installed onto their instruments.

Figure E. eCord Inserted into Side of Column Heater.

b. Installation

Install the column into the column heater. Plug the eCord into

the side of the column heater. Once the eCord is coupled to the

reader, the overall column usage information will be available

in the ACQUITY® console, allowing the user to access column

information on their desktop.

d. Column Use Information

The eCord chip provides the customer with column use data. T he

top of the screen identifies the column including chemistry type,

column dimensions and serial number. The overall column usage

information includes the total number of samples, total number

of injections, total sample sets, date of first injection, date of last

injection, maximum pressure, and temperature. The information

also details the column history by sample set including date

started, sample set name, user name, system name, number of

injections in the sample set, number of samples in the sample set,

maximum pressure, and temperature in the sample set and if the

column met basic system suitability requirements.

c. Manufacturing Information

The eCord chip provides the user with an overview of the bulk

material QC test results. The eCord chip provides the user with QC

test conditions and results on the column run by the manufacturer.

The information includes mobile phases, running conditions and

analytes used to test the columns. In addition, the QC results and

acceptance is placed onto the column.

Protein-Pak Hi Res IEX Columns and Standards

8

Page 9

[ CARE AND USE MANUAL ]

VIII. ORDERING INFORMATION

Product Description Part Number

Protein-Pak Hi Res CM, 7 µm, 4.6 x 100 mm 1860 0 4929

Protein-Pak Hi Res SP, 7 µm, 4.6 x 100 mm 18 6004930

Protein-Pak Hi Res Q, 5 µm, 4.6 x 100 mm 18600 4931

IEX Cation Test Standard 1860 06870

IEX Anion Test Standard 186006869

Note: Only when Protein-Pak Hi Res IEX columns are combined with the ACQUITY UPLC system are

the full performance benefits realized. See Waters service notes P/N 715002147A for ACQUITY UPLC

system configuration guidelines for ion-exchange chromatography.

Waters, The Science of W hat’s Possible, ACQUITY U PLC,

ACQUITY, and UPLC are registered trademarks of Waters

Corporaiton. Protein-Pak, TruView, and eCord are trademarks

of Waters Corporation. All other trademarks are the property

of their respective owners.

©2014 Waters Corporation. Produced in the U.S.A.

February 2014 Rev C 720003347EN K P-PDF

Waters Corporation

34 Maple Street

Milford, MA 01757 U.S.A.

T: 1 508 478 2000

F: 1 508 872 1990

www.waters.com

Loading...

Loading...