Page 1

[ CARE AND USE MANUAL ]

Preparative Chromatography Mix Standard

CONTENTS

I. INTRODUCTION

a. The Purpose of a QCRM

b. Determining your QCRM Criteria

c. What Affects your QCRM Result

II. STORAGE & STABILITY

III. USING THE PREPARATIVE CHROMATOGRAPHY MIX

IV. QCRM TESTING

V. TROUBLESHOOTING

VI. ORDERING INFORMATION

I. INTRODUCTION

The Quality Control Reference Material (QCRM) portfolio is a unique

collection of standards and mixtures. These products allow users to

evaluate and benchmark the chromatography system before analysis

of critical material. The products in the portfolio are all precisely

formulated based on the expertise of Waters scientist.

The preparative chromatography mix is 5 mg/mL each of Diclofenac

sodium salt, Diphenhydramine hydrochloride, and Flavone in DMSO.

This standard mix should be used to confirm the benchmark

performance of your Preparative/purification system. This particular

QCRM is a precisely formulated mix that includes a void marker,

neutral, acidic and basic compounds. These compounds were

vigorously tested and evaluated and chosen because they provide

the following advantages:

– Well-separated

– Easily visually identified

– Acceptable for use on a variety of column

Preparative Chromatography Mix

a. The Purpose of a QCRM:

Waters recommends to benchmark your chromatographic system with

a QCRM prior to system usage when there is confidenence your system

is in good working order. It is recommended to run and save the

initial results and continue to compare your QCRM results to the

previous benchmark any critical assay is run, and after any hardware,

column or mobile phase changes.

The QCRM benchmark result will be specific to the performance

of the system it is run on. All chromatographic systems have some

minor level of variability from run to run. Trending the benchmark

results over time will provide an understanding of system typical

variability. Trending of the same QCRM result on multiple systems

will provide the typical variability of those systems. Trending of the

same QCRM result on systems in laboratories in different locations

will provide the typical variability from across locations. Setting

specification for QCRM results of a system, multiple systems or

1

Page 2

[ CARE AND USE MANUAL ]

between laboratories should not be done without sufficient data

trending. Once variability is understood, QCRM results will help

determine the capability of the system to provide reliable results.

Determining your QCRM Criteria:

QCRM criteria should be determined based on specific requirements.

As mentioned above, specifications should not be set until the

variability of the system population is understood. The criteria and

specifications should allow it to be determined if the QCRM results

indicate that the system is functioning as expected or outside of

expectation. Typical criteria might include any of the following:

retention time reproducibility, peak area reproducibility, peak tailing

plate count, peak resolution, mass accuracy range, sensitivity

or response.

b. What affects your QCRM result:

The goal of the QCRM specifications and criteria will be to

indicate that the system is functioning as expected or outside

of expectation.

The system is comprised of many interdependent components

working together to produce results to an expected specification.

An issue with any one component can produce erroneous final

results. All components performing correctly will produce results

within an expected variability. Any changes or technical issues

within any one of the system components (hardware, software, or

chemical) may add variability to the QCRM result. Potential causes

of variability in QCRM results may include the following: mobile

phase preparation, column performance, tubing size, system

component performance (pump, injector, detector), temperature

control, data collection rate, integration.

Differences in any of the components mentioned can result in

system to system variability of results even when each system’s

components are functioning correctly.

II. STORAGE AND STABILITY:

The compounds are stable through the expiration date listed

as provided in 1 mL amber ampule before opening. This product

is for one time usage. The integrity of the standard can not be

guaranteed if stored after first use.

III. USING THE PREPARATIVE CHROMATOGRAPHY MIX

For preparative chromatographic analysis on a 19 x 50 mm column the

Preparative Chromatography Standard mix was injected at 10 µL. The

injected quantity should be scaled for other column diameters.

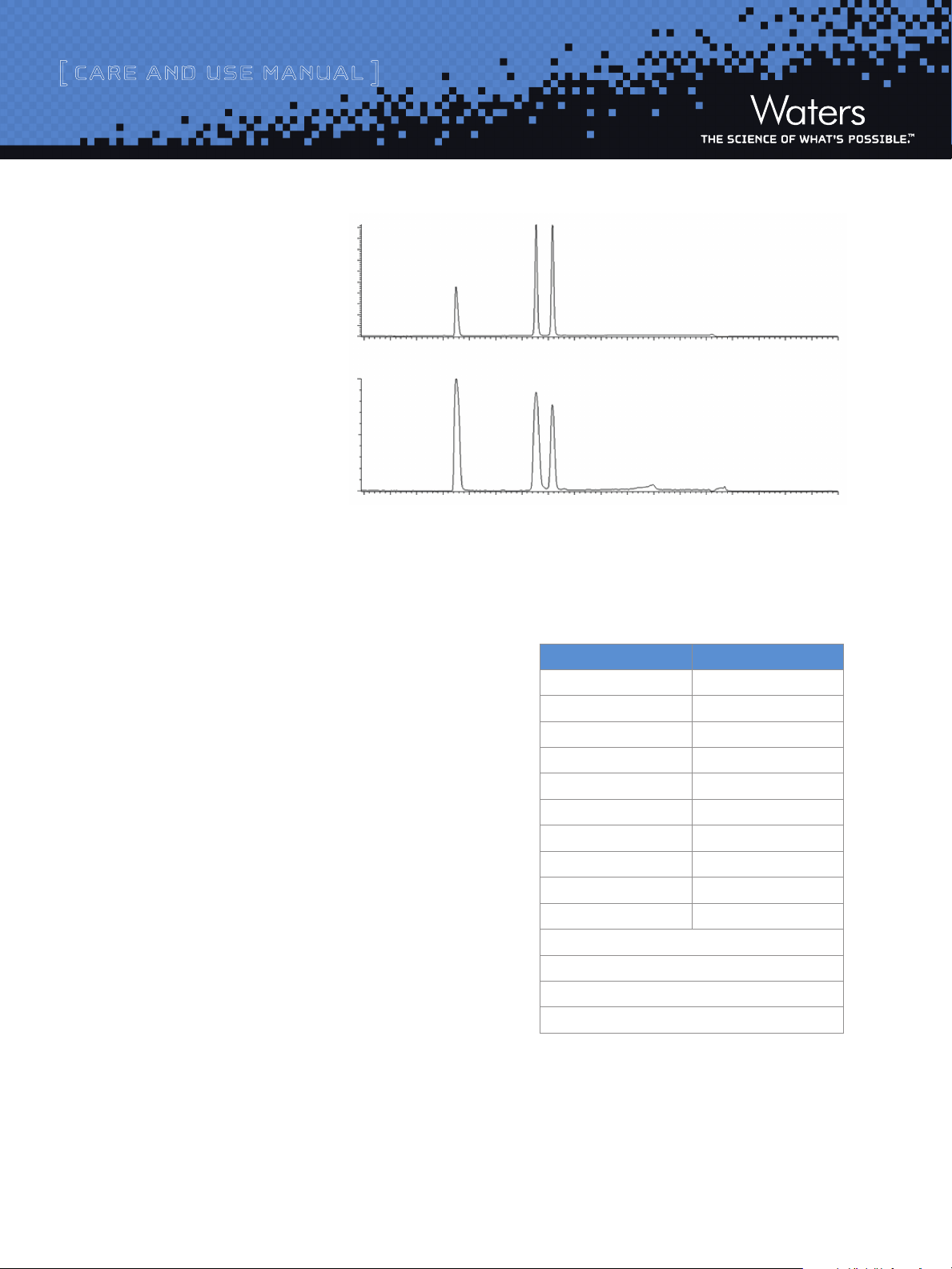

Sample chromatography for the Preparative Chromatography

Standard is shown in Figure 1. Note that the use of different column

stationary phases and/or column dimensions will have a effect on

the separation. On different column chemistries or dimensions, the

method may need to be modified or re-developed to obtain sufficient

resolution. To properly transfer the separation across column

dimensions, use the Prep Calculator. www.waters.com/prepcalculator.

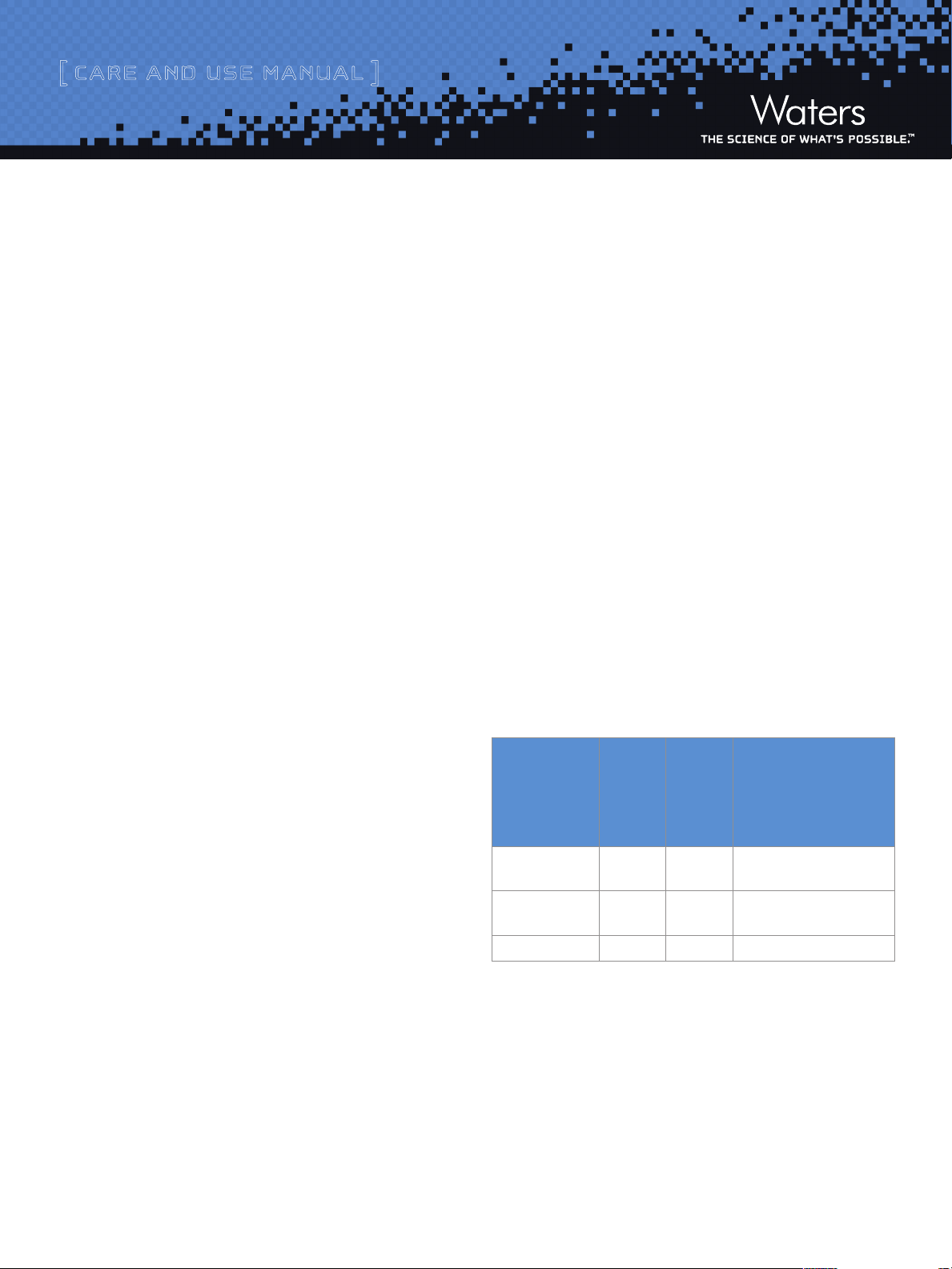

The table below indicated the approximate retention times obtained

for the compounds when using the specified chromatographic method

in Figure 1, as well as the m/z criteria for each compound.

Approximate RT (min)

Compound Type

Diclofenac

sodium salt

Diphenhydramine

hydrochloride

Flavone Neutral 223.07 4.3

Table 1: Preparative Mix UV and MS

Acid 296.02 4.6

Base 256.17 2.8

MS

(M+ H)

(XSelect™ CSH™ C18, 5 µm,

19 x 50 mm)

220 nm

Preparative Chromatography Mix 2

Page 3

[ CARE AND USE MANUAL ]

91

91

Figure 2 shows an example of the

chromatography obtained for the

preparative mix via UV and MS

when the method in Figure 1 is

using an XSelect™ CSH C18, 5 µm,

19 x 50 mm.

8.0e-1

6.0e-1

AU

4.0e-1

2.0e-1

0.0

12345678

99

%

-1

1

2345678

IV. QCRM TESTING

The use of reference standards for QCRM testing should allow the

analyst to track important instrument analytical parameters such as

peak width, peak area, retention time, and peak resolution. Each of

these important parameters can be tracked and evaluated using control

charts. The use of a high quality reference standard allows the analyst

to reliably measure and track these parameters.

QCRM testing should be performed on a regular basis for each

instrument/analyst combination or instrument per test method. The

data should be collected and entered into a control chart allowing

the analyst to evaluate the system performance over time. The use of

performance control charts has been a staple of analytical chemistry

quality control. The most common form of the control charting is to

track the analytical results and statistically analyze the data to a 99%

(3 standard deviations) or 95% confidence interval (2 standard

deviations) confidence interval around the mean of the data to

esta blish upper control limits (UCL) and lower control limits (LCL).

The initial criteria to establish a mean, standard deviation and

control limits involves analyzing a reference material a minimum

of 7 times to establish an initial estimate of precision and bias. This

provides the analyst with sufficient data to be statistically valid. The

analyses should be carried over the course of several days to provide

a more realistic view of the system variability. The frequency

of analyzing system performance will be dependent on the stability

of the analysis and the analytes. QCRM should always be evaluated

after maintenance has been performed, or when changes to the

system or analytical procedure have been made.

2

3

1

1. Diphenhydramine

2. Flavone

3. Diclofenac

220 nm

+

TIC; ES

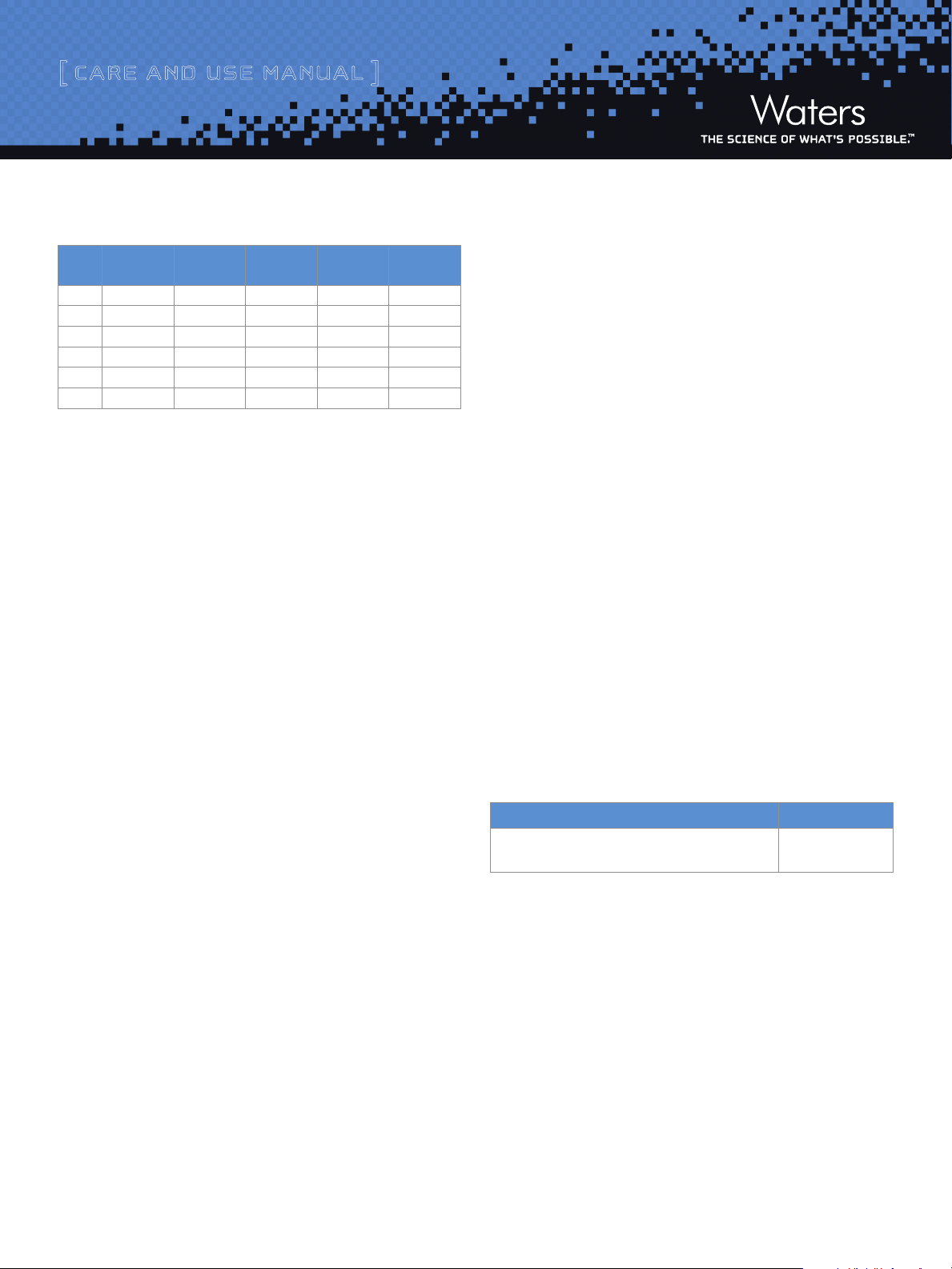

The example in Table 1 uses retention time monitoring to establish

a set of control limits for the purpose of monitoring on-going

system performance.

Table 1: Reference Standard Retention Time Data Example

Analysis Peak Retention Time (mins)

1 7.10

2 7.11

3 7.12

4 7.09

5 7.08

6 7.10

7 7.11

8 7.13

9 7.10

10 7.11

Mean 7.11

Standard Deviation 0.0136

LCL 7.08

UCL 7.13

The standard reference material was analyzed 10 times yielding

the above retention times. The mean retention time and standard

deviation were calculated and from this the UCL and LCL limits

were determined. The control limits represent a 95% confidence

interval (2 standard deviations) for the data. The control chart

in Figure 2 was then produced to establish that the instrument

retention times are in control.

0 min

0 min

Preparative Chromatography Mix 3

Page 4

[ CARE AND USE MANUAL ]

Figure 2: Retention Time Control Chart

1 Initial 25.00 95.0 5.0 Initial

2 0.10 25.00 95.0 5.0 6

3 6.10 25.00 5.0 95.0 6

4 7.10 25.00 5.0 95.0 6

5 7.20 25.00 95.0 5.0 6

6 10.10 25.00 95.0 5.0 6

Time

(min)

Flow

(mL/min)

A = 0.1% TFA in water

B = 0.1% TFA in acentonitrile

%A %B Curve

The establishment of control limits provides data as to the current

capabilities of the system. Control charting allows the quality

professional to compare instrument performance to the required

method specifications.

The process of continuous quality improvement can also be tracked

using control charts. When improvements are made to a method,

control charts allow you to see that the changes you have made are

effective and having the desired impact. The control chart will also

allow you to track trends over time. By observing the data trending

higher or lower over time, you can take preventative action prior to

having an out of specification result.

V. TROUBLESHOOTING:

The Preparative Chromatography Standard contains an acidic, basic

and neutral compound. Due to the vastly different properties of

stationary phases, not all compounds will behave similarly on each

column. For instance, basic compounds often have poor peak

shape on reversed-phase columns at neutral pH due to increased

interactions between the charged bases and silanols on the surface

of the stationary phase. For this reason, it is very important to

benchmark the performance of the Preparative Chromatography

Standard on a new column and functioning system. This will help

to identify whether poor peak shape issues are due to compound

interactions on the column, or failing column/system performance.

Failure to meet QCRM criteria will result in the need to troubleshoot

the system. Some chromatographic issues may be easily resolved,

for instance, a missing peak may simply be due to co-elution of

two peaks. However, most issues such as poor peaks shape, tailing

peaks, retention time shifts and poor peak response, to name a few,

may be due to a variety of causes that can be difficult to pinpoint.

For a detailed and comprehensive guide to troubleshooting, please

refer to the HPLC Troubleshooting Guide (WA20769) on the

Waters website.

Control charting can be employed for each QCRM criteria; peak

retention time, peak area, peak width, and peak resolution. Control

charts allow quality control professionals to establish statistically

significant criteria to monitor and control their HPLC analyses

thereby avoiding criteria that are too stringent or set arbitrarily.

Summary

The use of high quality reference standards specifically designed for

the system analysis, provide a controlled, consistent, and reliable

measure of system performance. Regular use of reference standards

and control charting the data provides improved monitoring of system

performance and system robustness, while at the same time

providing assurance that any results produced are high quality,

reliable, and reproducible.

References

1) Taylor, J.K., “Quality A ssurance of C hemical Measurements”, Lewis Publishers, 1987

2) Smith, G.M., “Statistic al Process C ontrol and Quality Improvement”, 3rd edition,

Prentice Hall, 1998

3) Ahuja, S. and Dong, M.W., “Handbook of Pharmaceutical Analysis by HP LC”, Elsevier

Inc., 2005

Preparative Chromatography Mix 4

VI. ORDERING INFORMATION

Description Part Number

Preparative/Purification Chromatography

Mix Standard

Thank you for choosing a QCRM from Waters. The standards are

manufactured in our ISO 9001 ISO 17025 facility. Each standard

is manufactured to ensure optimal reproducibility from lot to lot. A

Waters QCRM can be depended on for its’ accuracy. This removes

one variable from your system variability and provides you the most

dependable starting point for your testing.

If the QCRM box shows significant damage, notify the carrier and

your supplier at once and retain evidence of shipping damage so that

a claim can be made.

186006703

Page 5

[ CARE AND USE MANUAL ]

Related Products

XSelect Preparative Columns XBridge Preparative Columns

Description Part Number

XSelect CSH C18 OBD, 5 µm, 19 x 50 mm 186005420

XSelect CSH C18 OBD, 5 µm, OBD 19 x 100 mm 186005421

XSelect CSH C18 OBD, 5 µm, OBD 19 x 150 mm 186005422

XSelect CSH C18 OBD, 5 µm, OBD 19 x 250 mm 186005492

XSelect CSH C18 OBD, 5 µm, OBD 30 x 50 mm 186005423

XSelect CSH C18 OBD, 5 µm, OBD 30 x 75 mm 186005424

XSelect CSH C18 OBD, 5 µm, OBD 30 x 100 mm 186005425

XSelect CSH C18 OBD, 5 µm, OBD 30 x 150 mm 186005426

XSelect CSH C18 OBD, 5 µm, OBD 30 x 250 mm 186005493

XSelect CSH C18 OBD, 5 µm, OBD 50 x 50 mm 186005494

XSelect CSH C18 OBD, 5 µm, OBD 50 x 100 mm 186005495

XSelect CSH C18 OBD, 5 µm, OBD 50 x 150 mm 186005496

XSelect CSH C18 OBD, 5 µm, OBD 50 x 250 mm 186005497

XSelect CSH Fluoro-Phenyl OBD, 5 µm, 19 x 50 mm 186005433

XSelect CSH Fluoro-Phenyl OBD, 5 µm, OBD 19 x 100 mm 186005434

XSelect CSH Fluoro-Phenyl OBD, 5 µm, OBD 19 x 150 mm 186005435

XSelect CSH Fluoro-Phenyl OBD, 5 µm, OBD 19 x 250 mm 186005499

XSelect CSH Fluoro-Phenyl OBD, 5 µm, OBD 30 x 50 mm 186005436

XSelect CSH Fluoro-Phenyl OBD, 5 µm, OBD 30 x 75 mm 186005437

XSelect CSH Fluoro-Phenyl OBD, 5 µm, OBD 30 x 100 mm 186005438

XSelect CSH Fluoro-Phenyl OBD, 5 µm, OBD 30 x 150 mm 186005439

XSelect CSH Fluoro-Phenyl OBD, 5 µm, OBD 30 x 250 mm 186005500

XSelect CSH Fluoro-Phenyl OBD, 5 µm, OBD 50 x 50 mm 186005501

XSelect CSH Fluoro-Phenyl OBD, 5 µm, OBD 50 x 100 mm 186005502

XSelect CSH Fluoro-Phenyl OBD, 5 µm, OBD 50 x 150 mm 186005503

XSelect CSH Fluoro-Phenyl OBD, 5 µm, OBD 50 x 250 mm 186005504

XSelect CSH Phenyl-Hexyl OBD, 5 µm, 19 x 50 mm 186005446

XSelect CSH Phenyl-Hexyl OBD, 5 µm, OBD 19 x 100 mm 186005447

XSelect CSH Phenyl-Hexyl OBD, 5 µm, OBD 19 x 150 mm 186005448

XSelect CSH Phenyl-Hexyl OBD, 5 µm, OBD 19 x 250 mm 186005506

XSelect CSH Phenyl-Hexyl OBD, 5 µm, OBD 30 x 50 mm 186005520

XSelect CSH Phenyl-Hexyl OBD, 5 µm, OBD 30 x 75 mm 186005450

XSelect CSH Phenyl-Hexyl OBD, 5 µm, OBD 30 x 100 mm 186005451

XSelect CSH Phenyl-Hexyl OBD, 5 µm, OBD 30 x 150 mm 186005452

XSelect CSH Phenyl-Hexyl OBD, 5 µm, OBD 30 x 250 mm 186005507

XSelect CSH Phenyl-Hexyl OBD, 5 µm, OBD 50 x 50 mm 186005508

XSelect CSH Phenyl-Hexyl OBD, 5 µm, OBD 50 x 100 mm 186005509

XSelect CSH Phenyl-Hexyl OBD, 5 µm, OBD 50 x 150 mm 186005510

XSelect CSH Phenyl-Hexyl OBD, 5 µm, OBD 50 x 250 mm 186005511

Description Part Number

XBridge BEH C18 OBD, 5 µm, 19 x 50 mm 186002977

XBridge BEH C18 OBD, 5 µm, 19 x 100 mm 186002978

XBridge BEH C18 OBD, 5 µm, 19 x 150 mm 186002979

XBridge BEH C18 OBD, 5 µm,19 x 250 mm 186004021

XBridge BEH C18 OBD, 5 µm, 30 x 50 mm 186002980

XBridge BEH C18 OBD, 5 µm, 30 x 75 mm 186002981

XBridge BEH C18 OBD, 5 µm, 30 x 100 mm 186002982

XBridge BEH C18 OBD, 5 µm, 30 x 150 mm 186003284

XBridge BEH C18 OBD, 5 µm, 30 x 250 mm 186004025

XBridge BEH C18 OBD, 5 µm, 50 x 50 mm 186003933

XBridge BEH C18 OBD, 5 µm, 50 x 100 mm 186003937

XBridge BEH C18 OBD, 5 µm, 50 x 150 mm 186003929

XBridge BEH C18 OBD, 5 µm, 50 x 250 mm 186004107

XBridge BEH C18 OBD, 10 µm, 19 x 50 mm 186003893

XBridge BEH C18 OBD, 10 µm, 19 x 100 mm 186003901

XBridge BEH C18 OBD, 10 µm, 19 x 150 mm 186003894

XBridge BEH C18 OBD, 10 µm, 19 x 250 mm 186003895

XBridge BEH C18 OBD, 10 µm, 30 x 75 mm 186004711

XBridge BEH C18 OBD, 10 µm, 30 x 100 mm 186003930

XBridge BEH C18 OBD, 10 µm, 30 x 150 mm 186003896

XBridge BEH C18 OBD, 10 µm, 30 x 250 mm 186003897

XBridge BEH C18 OBD, 10 µm, 50 x 50 mm 186003898

XBridge BEH C18 OBD, 10 µm, 50 x 100 mm 186003902

XBridge BEH C18 OBD, 10 µm, 50 x 150 mm 186003899

XBridge BEH C18 OBD, 10 µm, 50 x 250 mm 186003900

Preparative Chromatography Mix 5

Page 6

[ CARE AND USE MANUAL ]

SunFire Preparative Columns SunFire Preparative Scouting Columns

Description Part Number

SunFire C18 OBD Prep Column, 100Å, 5 µm, 19 x 50 mm 186002566

SunFire C18 OBD Prep Column, 100Å, 5 µm, 19 x 100 mm 186002567

SunFire C18 OBD Prep Column, 100Å, 5 µm, 19 x 150 mm 186002568

SunFire C18 OBD Prep Column, 100Å, 5 µm, 19 x 250 mm 186004027

SunFire C18 OBD Prep Column, 100Å, 5 µm, 30 x 50 mm 186002570

SunFire C18 OBD Prep Column, 100Å, 5 µm, 30 x 75 mm 186002571

SunFire C18 OBD Prep Column, 100Å, 5 µm, 30 x 100 mm 186002572

SunFire C18 OBD Prep Column, 100Å, 5 µm, 30 x 150 mm 186002797

SunFire C18 OBD Prep Column, 100Å, 5 µm, 30 x 250 mm 186003969

SunFire C18 OBD Prep Column, 100Å, 5 µm, 50 x 50 mm 186002867

SunFire C18 OBD Prep Column, 100Å, 5 µm, 50 x 100 mm 186002869

SunFire C18 OBD Prep Column, 100Å, 5 µm, 50 x 150 mm 186003941

SunFire C18 OBD Prep Column, 100Å, 5 µm, 50 x 250 mm 186003970

SunFire C18 OBD Prep Column, 100Å, 10 µm, 19 x 150 mm 186002668

SunFire C18 OBD Prep Column, 100Å, 10 µm, 19 x 250 mm 186002669

SunFire C18 OBD Prep Column, 100Å, 10 µm, 30 x 50 mm 186003854

SunFire C18 OBD Prep Column, 100Å, 10 µm, 30 x 100 mm 186003971

SunFire C18 OBD Prep Column, 100Å, 10 µm, 30 x 150 mm 186002670

SunFire C18 OBD Prep Column, 100Å, 10 µm, 30 x 250 mm 186002671

SunFire C18 OBD Prep Column, 100Å, 10 µm, 50 x 50 mm 186002871

SunFire C18 OBD Prep Column, 100Å, 10 µm, 50 x 100 mm 186003972

SunFire C18 OBD Prep Column, 100Å, 10 µm, 50 x 150 mm 186002672

SunFire C18 OBD Prep Column, 100Å, 10 µm, 50 x 250 mm 186002673

SunFire C18 OBD Prep Column, 100Å, 10 µm, 100 x 250 mm 186003928

SunFire C18 Prep Column, 100Å, 5 µm, 10 x 50 mm 186002561

SunFire C18 Prep Column, 100Å, 5 µm, 10 x 100 mm 186002562

SunFire C18 Prep Column, 100Å, 5 µm, 10 x 150 mm 186002563

SunFire C18 Prep Column, 100Å, 5 µm, 10 x 250 mm 186002564

SunFire C18 Prep Column, 100Å, 5 µm, 19 x 50 mm 186002566

SunFire C18 Prep Column, 100Å, 5 µm, 19 x 100 mm 186002567

SunFire C18 Prep Column, 100Å, 5 µm, 19 x 150 mm 186002568

SunFire C18 Prep Column, 100Å, 5 µm, 19 x 250 mm 186004027

SunFire C18 Prep Column, 100Å, 5 µm, 30 x 50 mm 186002570

SunFire C18 Prep Column, 100Å, 5 µm, 30 x 75 mm 186002571

SunFire C18 Prep Column, 100Å, 5 µm, 30 x 100 mm 186002572

SunFire C18 Prep Column, 100Å, 5 µm, 30 x 150 mm 186002797

SunFire C18 Prep Column, 100Å, 5 µm, 30 x 250 mm 186003969

SunFire C18 Prep Column, 100Å, 5 µm, 50 x 50 mm 186002867

SunFire C18 Prep Column, 100Å, 5 µm, 50 x 100 mm 186002869

SunFire C18 Prep Column, 100Å, 5 µm, 50 x 150 mm 186003941

SunFire C18 Prep Column, 100Å, 5 µm, 50 x 250 mm 186003970

SunFire C18 Prep Column, 100Å, 10 µm, 10 x 50 mm 186003840

SunFire C18 Prep Column, 100Å, 10 µm, 10 x 150 mm 186002664

SunFire C18 Prep Column, 100Å, 10 µm, 10 x 250 mm 186002665

SunFire C18 Prep Column, 100Å, 10 µm, 19 x 150 mm 186002668

SunFire C18 Prep Column, 100Å, 10 µm, 19 x 250 mm 186002669

SunFire C18 Prep Column, 100Å, 10 µm, 30 x 50 mm 186003854

SunFire C18 Prep Column, 100Å, 10 µm, 30 x 100 mm 186003971

SunFire C18 Prep Column, 100Å, 10 µm, 30 x 150 mm 186002670

SunFire C18 Prep Column, 100Å, 10 µm, 30 x 250 mm 186002671

SunFire C18 Prep Column, 100Å, 10 µm, 50 x 50 mm 186002871

SunFire C18 Prep Column, 100Å, 10 µm, 50 x 100 mm 186003972

SunFire C18 Prep Column, 100Å, 10 µm, 50 x 150 mm 186002672

SunFire C18 Prep Column, 100Å, 10 µm, 50 x 250 mm 186002673

SunFire C18 Prep Column, 100Å, 10 µm, 100 x 250 mm 186003928

Description Part Number

SunFire C18 Column, 100Å, 10 µm, 4.6 x 150 mm 186003390

SunFire C18 Column, 100Å, 10 µm, 4.6 x 250 mm 186003391

SymmetryPrep Columns

Description Part Number

Symmetry C18 Prep Column, 100Å, 5 µm, 7.8 x 50 mm 186000208

Symmetry C18 Prep Column, 100Å, 5 µm, 7.8 x 100 mm 186000209

Symmetry C18 Prep Column, 100Å, 5 µm, 19 x 50 mm 186000210

Symmetry C18 Prep Column, 100Å, 5 µm, 19 x 100 mm 186000211

Symmetry C18 Prep Column, 100Å, 5 µm, 30 x 100 mm 186000236

Symmetry C18 Prep Column, 100Å, 7 µm, 7.8 x 150 mm WAT066288

Symmetry C18 Prep Column, 100Å, 7 µm, 7.8 x 300 mm WAT066235

Symmetry C18 Prep Column, 100Å, 7 µm, 19 x 150 mm WAT066240

Symmetry C18 Prep Column, 100Å, 7 µm, 19 x 300 mm WAT066245

Symmetry300 Columns

Description Part Number

Symmetry C18 Prep Column, 300Å, 5 µm, 19 x 50 mm 186001848

Symmetry C18 Prep Column, 300Å, 5 µm, 19 x 100 mm 186001849

Symmetry C18 Prep Column, 300Å, 5 µm, 19 x 150 mm 186001850

Preparative Chromatography Mix 6

Page 7

[ CARE AND USE MANUAL ]

Austria and European Export

(Central South Eastern Europe, CIS

and Middle East) 43 1 877 18 07

Australia 61 2 9933 1777

Belgium 32 2 726 1000

Brazil 55 11 4134 3788

Canada 1 800 252 4752

China 86 21 6156 2666

Czech Republic 420 2 617 11384

Denmark 45 46 59 8080

Finland 358 9 5659 6288

France 33 1 30 48 72 00

Germany 49 6196 400 600

Hong Kong 852 2964 1800

Hungary 36 1 350 5086

Norway 47 6 384 6050

Poland 48 22 101 5900

Puerto Rico 1 787 747 8445

Russia/CIS 7 495 727 4490/ 290 9737

Singapore 65 6593 7100

Spain 34 93 600 9300

Sweden 46 8 555 115 00

Switzerland 41 56 676 7000

Taiwan 886 2 2501 9928

United Kingdom 44 208 238 6100

All other countries:

Waters Corporation U.S.A.

1 508 478 2000

1 800 252 4752

www.waters.com

India 91 80 2837 1900

Ireland 353 1 448 1500

Italy 39 02 265 0983

Japan 81 3 3471 7191

Korea 82 2 6300 4800

Mexico 52 55 52 00 1860

The Netherlands 31 76 508 7200

©2013. Waters is a registered mark of Waters Corporation.

The Science of What's Possible, Sunfire, XBridge, XSelect

and CSH are trademarks of Waters Corporation. All other

trademarks are the property of their respective owners.

March 2013 720004429EN Rev B IH-PDF

Waters Corporation

34 Maple Street

Milford, MA 01757 U.S.A.

T: 1 508 478 2000

F: 1 508 872 1990

www.waters.com

Loading...

Loading...