Page 1

Prep 150 LC System

Quick Start

715003940 / Revision B

Copyright © Waters Corporation 2014

All rights reserved

Page 2

ii August 8, 2014, 715003940 Rev. B

Page 3

General Information

Copyright notice

© 2014 WATERS CORPORATION. PRINTED IN THE UNITED STATES OF

AMERICA AND IN IRELAND. ALL RIGHTS RESERVED. THIS DOCUMENT

OR PARTS THEREOF MAY NOT BE REPRODUCED IN ANY FORM WITHOUT

THE WRITTEN PERMISSION OF THE PUBLISHER.

The information in this document is subject to change without notice and should

not be construed as a commitment by Waters Corporation. Waters Corporation

assumes no responsibility for any errors that may appear in this document. This

document is believed to be complete and accurate at the time of publication. In no

event shall Waters Corporation be liable for incidental or consequential damages

in connection with, or arising from, its use. For the most recent revision of this

document, consult the Waters Web site (waters.com).

Trademarks

Waters and “THE SCIENCE OF WHAT’S POSSIBLE.” are registered trademarks

of Waters Corporation, and ChromScope is a trademark of Waters Corporation.

Other registered trademarks or trademarks are the sole property of their owners.

Customer comments

Waters’ Technical Communications organization invites you to report any errors

that you encounter in this document or to suggest ideas for otherwise improving

it. Help us better understand what you expect from our documentation so that we

can continuously improve its accuracy and usability.

We seriously consider every customer comment we receive. You can reach us at

tech_comm@waters.com.

Contacting Waters

Contact Waters® with enhancement requests or technical questions regarding the

use, transportation, removal, or disposal of any Waters product. You can reach us

via the Internet, telephone, or conventional mail.

August 8, 2014, 715003940 Rev. B iii

Page 4

Waters contact information:

Internet The Waters Web site includes contact information for Waters loca-

tions worldwide.

Visit www.waters.com

Telephone

and fax

Conventional

mail

From the USA or Canada, phone 800 252-HPLC, or fax 508 872

1990.

For other locations worldwide, phone and fax numbers appear in

the Waters Web site.

Waters Corporation

34 Maple Street

Milford, MA 01757

USA

Safety considerations

Some reagents and samples used with Waters instruments and devices can pose

chemical, biological, or radiological hazards (or any combination thereof). You

must know the potentially hazardous effects of all substances you work with.

Always follow Good Laboratory Practice, and consult your organization’s safety

representative for guidance.

FCC radiation emissions notice

Changes or modifications not expressly approved by the party responsible for

compliance, could void the users authority to operate the equipment. This device

complies with Part 15 of the FCC Rules. Operation is subject to the following two

conditions: (1) this device may not cause harmful interference, and (2) this device

must accept any interference received, including interference that may cause

undesired operation.

Canada spectrum management emissions notice

This class A digital product apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe A est conforme à la norme NMB-003.

Electrical power safety notice

Do not position the instrument so that it is difficult to operate the disconnecting

device.

iv August 8, 2014, 715003940 Rev. B

Page 5

Safety hazard symbol notice

Documentation needs to be consulted in all cases where the symbol is used to

find out the nature of the potential hazard and any actions which have to be

taken.

Equipment misuse notice

If the equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be impaired.

Safety advisories

Consult Appendix A for a comprehensive list of warning and caution advisories.

Operating the Prep 150 LC system

When operating the Prep 150 LC system, follow standard quality-control (QC)

procedures and the guidelines presented in this section.

Applicable symbols

Symbol Definition

Manufacturer

Date of manufacture

Authorized representative of the European Community

Confirms that a manufactured product complies with all applicable European Community directives

Australia EMC compliant

or

Confirms that a manufactured product complies with all applicable United States and Canadian safety requirements

Consult instructions for use

August 8, 2014, 715003940 Rev. B v

Page 6

Symbol Definition

Supply ratings

Electrical and electronic equipment with this symbol may

contain hazardous substances and should not be disposed of as

general waste.

For compliance with the Waste Electrical and Electronic Equipment Directive (WEEE) 2012/19/EU, contact Waters Corporation for the correct disposal and recycling instructions.

Safety information

Consult the operator's guides of the instruments or devices associated with this

system for information about how to safely operate and maintain them.

ISM classification

ISM Classification: ISM Group 1 Class B

This classification has been assigned in accordance with IEC CISPR 11 Industrial

Scientific and Medical (ISM) instruments requirements. Group 1 products apply to

intentionally generated and/or used conductively coupled radio-frequency energy

that is necessary for the internal functioning of the equipment. Class B products

are suitable for use in both commercial and residential locations and can be

directly connected to a low voltage, power-supply network.

EC authorized representative

Waters Corporation

Stamford Avenue

Altrincham Road

Wilmslow SK9 4AX UK

Telephone:

Fax:

Contact

+44-161-946-2400

+44-161-946-2480

Quality manager

vi August 8, 2014, 715003940 Rev. B

Page 7

Preface

This guide is part of the documentation set for the Waters Prep 150 LC system. It

provides you with basic information about the major tasks you can perform with

the Prep 150 LC system. For detailed information, refer to the Prep 150 LC

system's Online Information System that you can access by clicking Help in the

ChromScope software.

Audience and purpose

Waters designed the Prep 150 LC system for "walk-up" use by chemists who must

meet purification requirements. The system is particularly effective where rapid

preparative separations of complex mixtures are required to establish initial workflow criteria. It is not intended for use in diagnostic or biologically hazardous

applications.

Use the system to perform various sampling tasks in these environments:

l Pharmaceutical development

l Quality assurance and quality control

l Chemical materials

l Environmental sciences

l Academic laboratories

Documentation conventions

Instructions in this documentation adhere to the following conventions.

> Denotes the path for selecting menu commands, for moving from one

menu to another, or for performing a task.

Example: Click File > Open

< > Indicates that you must enter variable information, such as a path or

filename.

Example: Type open <filename>

August 8, 2014, 715003940 Rev. B vii

Page 8

Preface

viii August 8, 2014, 715003940 Rev. B

Page 9

Prep 150 LC System

This quick-start guide presents nine elementary procedures that provide a basic

knowledge of the Prep 150 LC system's operation and capabilities. Though relatively broad in scope, the guide offers enough instruction to allow purification of

product compounds and collection of fractions. With the information in this guide,

you can experiment with the system, learning for yourself minor details and variations on the prescribed practices. For more detailed information about each of the

procedures, open the online Help window in the ChromScope software, and browse

the list of topics there.

The nine procedures appear as individual chapters:

1 Start the system

2 Set up your work environment

3 Verify the system and module settings

4 Select and run a method-screening sample list

5 Create and load the run's methods and sample list

6 Start and monitor the run

7 Analyze the run's data

8 Report the results

9 Prepare the system for the next run or for shutting down

August 8, 2014, 715003940 Rev. B 9

Page 10

Prep 150 LC System

Start the system

To start the Prep 150 LC system and prepare it for operation, follow this procedure in conjunction with Good Laboratory Practice (GLP) guidelines and your laboratory's standard operating procedures.

Starting sequence:

To start the system and prepare it for operation:

1. Power-on the individual system modules by actuating the power switch on

each system module.

Important: If you are using the optional Prep Degasser with the 2545 QGM,

ensure the degasser is operating.

2. Power-on the ChromScope PC workstation.

Requirement: You must wait at least 30 seconds after powering-on the last

module before you start the ChromScope software and Waters Instrument

Console. Doing so is necessary for the components to communicate properly

with the software during startup.

3. From the Windows desktop, double-click the ChromScope shortcut .

Alternative: From the Windows Start menu, click All Programs, and click

ChromScope.

10 August 8, 2014, 715003940 Rev. B

Page 11

Requirement: Unless the system administrator has disabled the System

Secure function, you must be a registered user and provide your user name

and password, to start and log on to the ChromScope software.

4. Enter your user name and password, and then click Login, to start the

ChromScope software.

5. On the System Configuration Detector tab, click Lamp On.

Requirement: Allow the lamp to warm for a minimum of 30 minutes before

performing an injection, to stabilize its optics.

6. Inspect the column's tubing connections to ensure that the column or unions

are connected, leaving no open flows.

7. Inspect the gradient pump's solvent bottles for mobile phase and wash flows,

to ensure the volumes are adequate for your methods.

Preparing the solvent pump

When the solvent lines are dry, including for initial startup, or when changing

solvents, prime the pump's solvent and seal-wash flow paths, to remove any air

bubbles in the flow paths between each solvent bottle and pump. To prime the 2545

QGMor 2545 BGM, double-click the solvent pump in the ChromScope system

panel, and then refer to priming instructions in the 2535/2545/2555 Quaternary

Gradient Module Operator's Guide.

Start the system

Preparing the sample injector

You must prepare the sample injector according to its type, manual or 2707 Autosampler.

To prepare the manual injector:

1. With the column offline, flush the injector and sample loop with a suitable

solvent, to remove any trapped air or contaminants from the injection flow

path.

2. Prepare your sample for loading by inserting a syringe into the injector port.

To prepare the 2707 Autosampler:

1. Load samples, and ensure the wash-solvent bottle is full.

2. When the solvent line is dry, including for initial startup, or after changing

solvents or samples, on the System Configuration Autosampler tab, click

Needle Wash, to clean and purge any air bubbles from the syringe and buffer

tubing.

Tip: For best results, repeat the needle wash routine 2 or 3 times.

Preparing the fraction bed and waste container

You must prepare the WFC III module to collect fractions and waste during a purification run.

August 8, 2014, 715003940 Rev. B 11

Page 12

Prep 150 LC System

To prepare for fraction and waste collection:

1. Inspect the fraction collection tubes and collection bed layout, to verify the

module is ready to receive the run's fractions and waste.

2. Inspect the waste container, to ensure it can collect waste.

See also: Waters Fraction Collector III Operator's Guide.

Verifying operational readiness

Optionally, run an instrument method using the Monitor control, to set initial

conditions and verify the system's operational readiness.

Tip: You can view real-time status and plots in the ChromScope System Panel and

Current Run tabs, to monitor flow and detector baselines.

For more information, see these topics in the ChromScope online Help:

l Configure system and module settings

l Determine system status

l Maintain the 2545 Binary Gradient Module

l Create methods for controlling system functions

12 August 8, 2014, 715003940 Rev. B

Page 13

Set up your work environment

Set up your work environment

Before you begin using ChromScope software for the Prep 150 LC system to purify

product and collect fractions, you can customize the system according to your preferences. These customizations become part of your user profile. As such, they

appear whenever you log on to the system.

August 8, 2014, 715003940 Rev. B 13

Page 14

Prep 150 LC System

Task Description

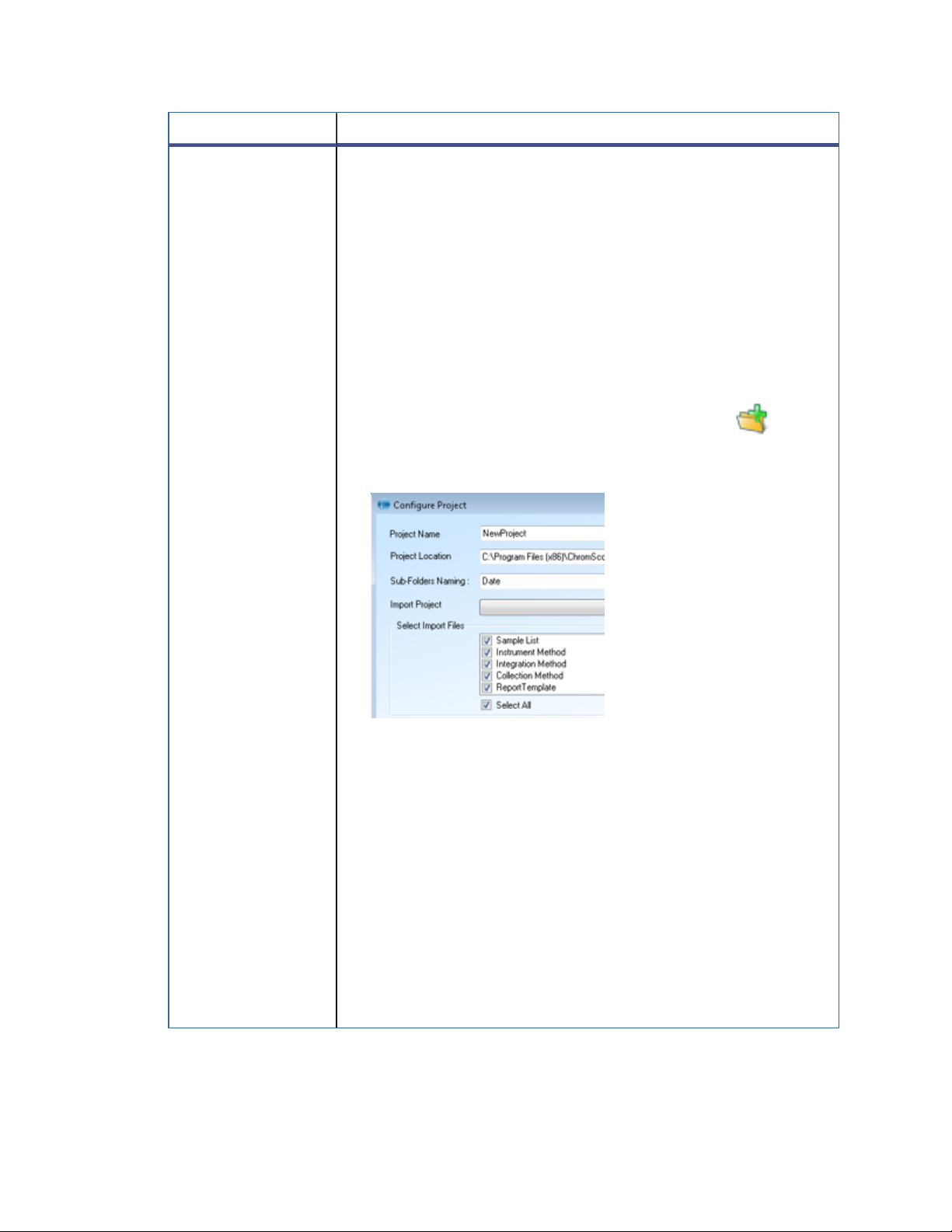

Set up your project

folder.

You can create a new project or work with existing projects.

When you create a new project in the system, a project folder

bearing the project name appears under the project's root

node. Inside the project folder, the ChromScope software

creates a subfolder structure to organize each file type that

exists in the project.

Alternative: Use the default project to get started, and then

add new projects later to organize your files.

To set up a new project:

1. Right-click the Project Folders node, and select Add New

Project.

Alternative: In the toolbar, click Add Project .

2. In the Configure Project dialog box, enter the project's

name and file location.

3. Select a subfolder naming convention from the list for

organizing the project's data-log files.

Restriction: After you create and save your new project,

you cannot change its subfolder naming convention.

4. To import the files from another project into your new

project, select the project from the list of available

projects, and then select the check boxes for the types of

files that you want to import.

Tip: Select "Select All" to import all of the project's files.

5. Click OK, to save your settings and create the new

project.

Result: The new project appears in the navigation tree,

under the Projects node.

14 August 8, 2014, 715003940 Rev. B

Page 15

Task Description

Set up your work environment

Decide how you

want to open and

work with the

acquisition data-log

files.

You can select from among three file-open modes (New Tab,

Current Tab, or Current Tab Overlay) according to how you

want to open and view data-log files. When you select a

mode, all data-log files you open remain open in that mode

until you select another mode.

Alternative: Accept the default file-open mode, New Tab, to

open each data-log file in a new tab in the ChromScope main

window.

The table below describes each of the three modes and its

effect on currently opened data-log files when you use it to

open a new data file.

Fileopen

mode

New

Tab

File tab caption

upon opening a

new data-log file

A new file (outer)

tab, which

Effect on currently

opened data-log files

All opened data-log

files remain open.

displays the file's

name, is created

for each data-log

file that you open.

Current

Tab

Current

Tab

Overlay

The data-log file is

opened in the

currently selected

tab, which

displays the file's

name.

The data-log file is

opened in the

currently selected

tab, which

displays the file's

The data-log file that

was previously opened

in the current tab is

closed. Other data-log

files opened in other

tabs remain open.

All opened data-log

files in the current tab

remain open. The tab

displays the name of

the last opened file.

name.

To set the file-open mode:

From the File menu, click File Open Mode > New Tab,

Current Tab, or Current Tab Overlay.

Alternative: From the toolbar, click New Tab , Current

Tab , or Current Tab Overlay .

Rules:

l For New Tab and Current Tab, the information in the

data grid pertains only to the single, opened data-log file.

August 8, 2014, 715003940 Rev. B 15

Page 16

Prep 150 LC System

Task Description

l For Current Tab Overlay, the information in the data

grid pertains to all of the data-log files opened in the

current tab.

Customize the

display of plots and

run data.

In the Display Options window, you can specify and save

your preferences for viewing chromatograms and their associated data in the data-log file's data grid. Use these preferences to show or hide various elements of the data-log file's

raw data, and to set preferences for how you want to display

pressure units.

Alternative: You can accept the default settings. Later, as

you gain familiarity with the system, you can change any of

the settings in the Display Options panel, to accommodate

your preferences.

To set display options:

1. From the Edit menu, click Display Options.

Alternative: In the toolbar, click Display Options.

2. In the Display Options window, edit the settings accord-

ing to your preferences.

3. Click OK, to save your display settings.

16 August 8, 2014, 715003940 Rev. B

Page 17

Task Description

Set up your work environment

Decide how to

configure and send

reports.

Import data from

other Waters

products.

You can configure and generate individual custom reports

using a predefined format, or set up batch processing to

process a group of data-log files sequentially. For batch

processing, you can also configure an option to automatically

distribute reports to a list of email recipients as a function

of a sample list's batch "run and report" queue. The reports

are based on the integration-method and report-template

settings in the sample list. For details, see the "Managing

Data and Reporting" section in the ChromScope online Help.

Alternative: After your run, open the data-log file, and from

the File menu, click "Print Quick Report to PDF" or "Print

Quick Report to Printer", to generate a predefined report of

your data.

You can import data-log files (*.tta) from a defined location

into a project's Data Files folder (or subfolder). This operation is useful for importing scouting-run information used

to set up the timing parameters for stacked-injection sample

lists.

Alternative: Use the system to generate your own scouting-

run data, or manually define your injection and collection

timing in the run's sample list and collection method.

To import data-log files:

1. In the navigation tree, right-click on the destination pro-

ject's Data Files node (or its subfolder), and select Import

Data Files.

2. Select the data-log files that you want to import from the

list, and click Open.

Result: The data-log files appear in the Project's Data

Files node (or its subfolder).

For more information, see these topics in the ChromScope online Help:

l Work with projects

l Work with views

l Configure your display preferences

l Generate and print a custom report

l Import and export data-log files

August 8, 2014, 715003940 Rev. B 17

Page 18

Prep 150 LC System

Verify the system and module settings

n Navigation tree > System Configuration > System Settings, Pump, Solvent Selector, Autosampler, and

Detector tabs

n Navigation tree > System Status > Collection Bed Status

To manage the system's operational readiness, you must define your preferences

for shutting down the system in response to certain operating conditions, and for

configuring the individual module's alert thresholds and usage settings. You must

also view a module's real-time device status for maintenance or diagnostic

purposes. You perform these actions using the tabs under the System Configuration and System Status nodes in the ChromScope software.

Alternative: To begin when using a standard Prep 150 LC manual or automated

system configuration, accept the software's default system configuration settings.

Later, as you gain familiarity with the system, you can change any of the settings

in the System Configuration tabs to accommodate your system modifications or

preferences.

Requirement: For fraction collection, before starting a purification run, you must

ensure that the collection bed and tube settings in the ChromScope Collection Bed

Status tab correlate to the bed layout and tube locations in the WFC III module's

collection bed.

18 August 8, 2014, 715003940 Rev. B

Page 19

Verify the system and module settings

To verify the system and module settings required for your configuration:

1. In the navigation tree, click the System Configuration node.

2. Click the tab for the system or module settings that you want to verify.

Tip: To set up your solvent levels and warning and alarm thresholds, click

the Solvent Selector tab, and configure the settings for each of your solvents.

3. Use the default values, or make any changes you require, and click Apply to

save your settings.

4. In the navigation tree, click the System Status node.

5. Click the Collection Bed Status tab, to configure the collection bed layout

and tube settings for the WFC III module's collection bed.

For more information, see these topics in the ChromScope online Help:

l Configure system and module settings

l Set up the collection bed in ChromScope

August 8, 2014, 715003940 Rev. B 19

Page 20

Prep 150 LC System

Select and run a method-screening sample list

To optimize collection of purified product, you must fine tune the purification chromatography on the system using a scouting run, and store the optimal settings in

a data-log file. To do so, you can select and run a method-screening sample list.

Later, you must build a purification sample list, using the integrated data from

plots in the scouting run's data-log file, to calculate and specify fraction-collection

and injection-timing settings. This technique is especially useful when you are

working with unknown samples or using the Sample List wizard to build stackedinjection sample lists for high-throughput purification.

Note: If the scouting-run data are already on the system's ChromScope work-

station, or if you are working with known samples and do not need to fine tune the

chromatography beforehand, skip this step.

To select and run a method-screening sample list:

1. Select a method-screening sample list, or create one using the Sample List

wizard, to help you fine tune the parameter settings used to isolate your

sample compounds.

20 August 8, 2014, 715003940 Rev. B

Page 21

Select and run a method-screening sample list

Create a method-screening sample list using the wizard:

2. If you are using an autosampler, specify the location of the samples in the

sample well-plate that you want to screen.

3. Select or create the instrument methods referenced in this method-screening

sample list, ensuring the appropriate order of change for the samples and

methods, which you select from separate lists.

Requirement: When you create the system's instrument methods, you must

specify and save the settings that control flow rate, detector wavelength, and

other critical run conditions.

Tip: To improve peak separation, try changing the solvent settings in the

instrument method. You can define the method's flow and composition functions as isocratic conditions or as gradient curves.

August 8, 2014, 715003940 Rev. B 21

Page 22

Prep 150 LC System

4. Load and run the method-screening sample list.

Tip: During the scouting run, after you identify the optimum conditions for

the run, to quit the remainder of the sample list, in the Main window, click

"Skip to the next sample list" . In the event that the queue is empty, the

system immediately switches to system-shutdown conditions.

5. Open and view the data-log file generated from the scouting run.

6. Analyze the data from the scouting run, and use it to confirm the optimum

conditions for separating your fractions.

Analyze the data from a scouting run:

For more information, see these topics in the ChromScope online Help:

l Create sample lists for acquiring data and collecting fractions

l Create sample lists using the Sample List wizard

l Work with integration

22 August 8, 2014, 715003940 Rev. B

Page 23

Create and load the run's methods and sample list

Create and load the run's methods and sample list

Before you can collect fractions or purified product using the system, you must

create the run's instrument methods, collection methods, and purification sample

list. You must then load the sample list into the sample list queue.

Create instrument and collection methods, and a sample list:

Alternative: Follow the procedure below to open and edit the default project's

instrument and collection methods and sample-list files, as needed. Save the edited

files, and then load the updated sample list into the sample list queue.

Requirements:

l To build stacked-injection sample lists that optimize throughput, you must

first create sequential or pooled collection methods using collection modes

that are time only or time with detector-signal threshold, slope threshold, or

both.

l Use the Sample List Purification wizard to easily build your stacked injec-

tions from a data file taken from a scouting run.

Rule: In the case of timed collection with overlapping windows, the start and stop

of the first time window always has precedence over that of the subsequent time

windows.

August 8, 2014, 715003940 Rev. B 23

Page 24

Prep 150 LC System

For an integration method, you can specify the quantitation and identification

parameters used to determine how you recognize and process a chromatogram's

peaks. Later you can edit the method, as needed, and add it to a sample list before

acquisition, or apply it to chromatograms after acquisition.

To create the run's methods and purification sample list:

1. Open an existing instrument method, or create a new one for the purification

run.

Tip: When specifying the method and sample-list settings, quantitate the

amounts of purified compound and solvent that you expect to recover during

the run, to avoid reaching the maximum capacity of the collection bed and

shutting down the system.

2. Edit the instrument-method settings, as needed, and then save your settings.

3. In the collection method for the run, specify the settings (detector signal or

slope thresholds, and/or timed collection) for directing fraction collection.

Tip: To quickly enter the timing settings in your collection method, do as

follows:

l Load the data-log file that contains the appropriate data from a scout-

ing run.

l Select and drag the overlaid plot that appears in the collection

method's absorbance plot to automatically enter the time settings.

Example showing collection start and stop times taken from scouting

run:

l Verify, and if necessary, edit the threshold settings that you want to

use in your method.

4. Save your collection-method settings.

5. In the sample list, specify your instrument method and collection method,

24 August 8, 2014, 715003940 Rev. B

Page 25

Create and load the run's methods and sample list

and then click the Sample List Wizard and Purification Sample List, to

specify your remaining settings.

Tips:

l To set up a "run and report" queue, you can define and assign an integ-

ration method and report template to the sample list's steps.

l To quickly define your purification sample list using the wizard, do as fol-

lows:

l Load the data-log file from your scouting run.

l Select and drag the second set of overlaid peaks on the plot to specify

the timing settings for stacked injections in the sample list's data

grid.

l Verify, and if necessary, edit the remaining settings in the Sample

List Wizard.

6. Click OK, to exit the wizard.

7. Edit the settings as required, and then save your sample list.

8. To load the sample list in the sample list queue so that you can run it, in

the sample list editor, click Add to Queue.

Result: The sample list appears in the sample list queue in the order that

you add it. You can add multiple sample lists in a particular order, and run

them sequentially in that order.

Tip: You can use the up and down controls in the sample list queue to

re-order the sample lists in the queue. To remove a sample list from the

queue, select it, and click remove .

For more information, see these topics in the ChromScope online Help:

l Create methods for controlling system functions

l Create methods for integrating peaks

l Create custom report templates

l Create methods for collecting fractions

l Create sample lists for acquiring data and collecting fractions

l Create sample lists using the Sample List wizard

l Load the sample lists

August 8, 2014, 715003940 Rev. B 25

Page 26

Prep 150 LC System

Start and monitor the run

You start the run, and monitor its conditions and fractions, to purify compounds of

interest and collect fractions.

Monitor a run:

To start the run and monitor its conditions and fractions:

1. With the purification run's sample list loaded at the top of the sample list

queue, click Start to start the run.

2. From the ChromScope Main window and System Panel, monitor the run, as

needed.

Tips:

l To extend the current run so that you can maintain system equilibration

while performing maintenance tasks, such as refilling solvents or emptying collection vessels, click Pause . When ready, you can restart operation by clicking Start .

l During the run, if you must ensure that the remainder of a peak clears

the column before the next timed injection occurs, click Pause . This

action maintains run conditions while delaying the next timed injection.

When ready, you can restart operation by clicking Start .

l During a purification run, to quit collection before the run ends, instead

of clicking Pause or Stop , you can click "Skip to the next sample

list" , to quit the remainder of the sample list. In the event that the

26 August 8, 2014, 715003940 Rev. B

Page 27

Start and monitor the run

queue is empty, the system immediately switches to system-shutdown

conditions.

l To manually collect fractions, also called emergency collection, from any

of the Current Run sub-tabs, specify a starting location in the collection

bed, and click Collection On.

l You can modify a sample list and method parameters during a puri-

fication run with on-the-fly-changes. To do so, select the line in the

sample list that you want to modify, or click on the appropriate method

tab on ChromScope's main page, and edit the settings as needed.

For more information, see these topics in the ChromScope online Help:

l Start and stop a run

l Manually inject samples

l Manually collect fractions

l Optimize fraction collection

l Modify a run

l Configure default update settings

l Enter on-the-fly updates

l Update a run's settings directly from the on-the-fly update panels

l Update a run's settings from the open current method or current sequence

August 8, 2014, 715003940 Rev. B 27

Page 28

Prep 150 LC System

Analyze the run's data

ChromScope software offers tools that quantitate the effectiveness of the methods,

instrumentation, and processes that are used to collect purified product.

Example chromatogram showing manual integration options:

To analyze the purification run's data:

1. Open the data-log file (in Current Tab or New Tab mode) for the run.

2. Choose peaks for manual integration, or use the Auto Integration function to

integrate them using an integration method.

3. Build calibration curves for the compounds of interest.

4. Use the information from the data-log file and calibration curves to determ-

ine the concentration of your compounds, and analyze the results of your

run.

Tip: On the basis of this information, you can evaluate the effectiveness of

your settings, instrumentation, and processes, for quality control purposes,

and determine what changes, if any, are needed to achieve best results.

28 August 8, 2014, 715003940 Rev. B

Page 29

Analyze the run's data

For more information, see these topics in the ChromScope online Help:

l Open and view data-log files

l Work with integration

l Work with calibration

l Test the purity of peaks detected by PDA

l Interpret PDA peak purity results

August 8, 2014, 715003940 Rev. B 29

Page 30

Prep 150 LC System

Report the results

For verification of your run's results, you must create a report from the integrated

data. To generate a basic, predefined report layout of your data, open the run's

data-log file, and from the File menu, click "Print Quick Report to PDF" or "Print

Quick Report to Printer".

Quick Report function:

Alternative: You can configure and generate individual custom reports using your

own predefined format, or set up batch processing to process a group of data-log

files sequentially. For batch processing, you can also configure an option to automatically distribute reports to a list of email recipients as a function of a sample

list's batch "run and report" queue. The reports are based on the integrationmethod and report-template settings in the sample list. For details, see the section

"Managing Data and Reporting" in the ChromScope online Help.

To print a quick report to a PDF file:

1. Open the data-log file.

2. Click the tab to display the chromatogram that you want to capture in the

report.

3. From the File menu, click Print Quick Report To PDF.

30 August 8, 2014, 715003940 Rev. B

Page 31

Report the results

Alternative: From the toolbar, click Print Quick Report To PDF .

4. In the PDF setting window, define a location in which to save the report, and

click OK.

5. In the Save As dialog box, name the PDF file, and click Save.

Rule: The message "Quick Report is not available on this Plot" appears if the

plot cannot be integrated.

To print a quick report to a printer:

Requirement: You must power-on a printer connected to the ChromScope work-

station.

1. Open the data-log file.

2. Click the tab to display the chromatogram that you want captured in the

report.

3. From the File menu, click Print Quick Report To Printer..., and select the

printer.

Alternative: From the toolbar, click Print Quick Report To Printer , to

print the report on the default printer.

Restriction: The message "Printer not available" appears when the printer is

not connected properly and powered-on.

For more information, see these topics in the ChromScope online Help:

l Configure auto report mail

l Create custom report templates

August 8, 2014, 715003940 Rev. B 31

Page 32

Prep 150 LC System

Prepare the system for the next run or for shutting down

Typically, you configure your purification sample lists and system inactivity

options to prepare the system for the next sample run or shutdown period.

System inactivity options:

l On the System Settings tab, before the sample list queue empties, select the

inactivity options (Stop system after x min. of inactivity and Turn Off lamp

after x min. of inactivity), and specify the duration settings so that when the

last run ends, the system maintains its current run conditions for the next

anticipated run before the system shuts down.

l Whenever possible, set up purification sample lists so that you complete the

run, and empty the sample list queue before you must empty fraction tubes,

refill or change solvents, and change to a new sample.

l If using buffers, thoroughly flush the system with distilled water before shut-

ting down the system.

l If using the manual injector, flush and clean the valve of the injector module

and the sample flow path after each run.

For more information, see these topics in the ChromScope online Help:

l Configure system and module settings

l Prepare the system for shutdown

l Optimize fraction collection

l Maintain the injector module

32 August 8, 2014, 715003940 Rev. B

Page 33

A Safety Advisories

Waters instruments and devices display hazard symbols that alert you to the

hidden dangers associated with a product’s operation and maintenance. The

symbols also appear in product manuals where they accompany statements

describing the hazards and advising how to avoid them. This appendix

presents the safety symbols and statements that apply to all of the products

that Waters offers.

Contents:

Warning symbols 33

Caution advisory 35

Warnings that apply to all Waters instruments and devices 35

Warnings that address the replacing of fuses 40

Electrical and handling symbols 42

Warning symbols

Warning symbols alert you to the risk of death, injury or seriously adverse

physiological reactions associated with an instrument’s use or misuse. Heed all

warnings when you install, repair, or operate any Waters instrument or device.

Waters accepts no liability in cases of injury or property damage resulting from

the failure of individuals to comply with any safety precaution when installing,

repairing, or operating any of its instruments or devices.

The following symbols warn of risks that can arise when you operate or maintain

a Waters instrument or device, or a component of an instrument or device. When

one of these symbols appear in a manual’s narrative sections or procedures, an

accompanying statement identifies the applicable risk and explains how to avoid

it.

August 8, 2014, 715003940 Rev. B 33

Page 34

A Safety Advisories

Warning: General risk of danger. When this symbol appears on an instru-

ment, consult the instrument’s user documentation for important safetyrelated information before you use the instrument.

Warning: Risk of burn injury from contacting hot surfaces.

Warning: Risk of electric shock.

Warning: Risk of fire.

Warning: Risk of sharp-point puncture injury.

Warning: Risk of hand crush injury.

Warning: Risk of exposure to ultraviolet radiation.

Warning: Risk of contacting corrosive substances.

Warning: Risk of exposure to a toxic substance.

Warning: Risk of personal exposure to laser radiation.

Warning: Risk of exposure to biological agents that can pose a serious

health threat.

Warning: Risk of tipping.

Warning: Risk of explosion.

Warning:Risk of eye injury.

Specific warnings

The following warnings (both symbols and text) can appear in the user manuals of

particular instruments and devices and on labels affixed to them or their component parts.

Burst warning

This warning applies to Waters instruments and devices fitted with nonmetallic

tubing.

34 August 8, 2014, 715003940 Rev. B

Page 35

Caution advisory

Warning: To avoid injury from bursting, nonmetallic tubing, heed these

precautions when working in the vicinity of such tubing when it is pressurized:

l Wear eye protection.

l Extinguish all nearby flames.

l Do not use tubing that is, or has been, stressed or kinked.

l Do not expose nonmetallic tubing to incompatible compounds like tet-

rahydrofuran (THF) and nitric or sulfuric acids.

l Be aware that some compounds, like methylene chloride and dimethyl

sulfoxide, can cause nonmetallic tubing to swell, significantly reducing

the pressure at which the tubing can rupture.

Biohazard and chemical hazard warning

This warning applies to Waters instruments and devices that can process biohazards, corrosive materials, or toxic materials.

Caution advisory

Caution advisories appear where an instrument or device can be subject to use or

misuse that can damage it or compromise a sample’s integrity. The exclamation

point symbol and its associated statement alert you to such risk.

Notice: To avoid damaging the instrument’s case, do not clean it with

abrasives or solvents.

Warning: To avoid personal contamination with biohazards,

toxic materials, or corrosive materials, you must understand

the hazards associated with their handling.

Guidelines prescribing the proper use and handling of such

materials appear in the latest edition of the National Research

Council's publication, Prudent Practices in the Laboratory:

Handling and Disposal of Chemicals.

Observe Good Laboratory Practice (GLP) at all times, particularly when working with hazardous materials, and consult the

safety representative for your organization regarding its protocols for handling such materials.

Warnings that apply to all Waters instruments and devices

When operating this device, follow standard quality-control procedures and the

equipment guidelines in this section.

August 8, 2014, 715003940 Rev. B 35

Page 36

A Safety Advisories

Attention: Changes or modifications to this unit not expressly

approved by the party responsible for compliance could void the

user’s authority to operate the equipment.

Important: Toute modification sur cette unité n’ayant pas été

expressément approuvée par l’autorité responsable de la conformité

à la réglementation peut annuler le droit de l’utilisateur à exploiter

l’équipement.

Achtung: Jedwede Änderungen oder Modifikationen an dem Gerät

ohne die ausdrückliche Genehmigung der für die ordnungsgemäße

Funktionstüchtigkeit verantwortlichen Personen kann zum Entzug

der Bedienungsbefugnis des Systems führen.

Avvertenza: qualsiasi modifica o alterazione apportata a questa

unità e non espressamente autorizzata dai responsabili per la

conformità fa decadere il diritto all'utilizzo dell'apparecchiatura da

parte dell'utente.

Atencion: cualquier cambio o modificación efectuado en esta unidad

que no haya sido expresamente aprobado por la parte responsable

del cumplimiento puede anular la autorización del usuario para

utilizar el equipo.

注 意 :未經有關法規認證部門允許對本設備進行的改變或修改,可能會使使用者喪

失操作該設備的權利。

注 意 : 未经有关法规认证部门明确允许对本设备进行的改变或改装,可能会使使用

者丧失操作该设备的合法性。

주 의 : 규정 준수를 책임지는 당사자의 명백한 승인 없이 이 장치를 개조 또는 변

경할 경우, 이 장치를 운용할 수 있는 사용자 권한의 효력을 상실할 수 있습니다.

注 意 :規制機関から明確な承認を受けずに本装置の変更や改造を行うと、本装置

のユーザーとしての承認が無効になる可能性があります。

36 August 8, 2014, 715003940 Rev. B

Page 37

Warnings that apply to all Waters instruments and devices

Warning: Use caution when working with any polymer tubing

under pressure:

l Always wear eye protection when near pressurized polymer

tubing.

l Extinguish all nearby flames.

l Do not use tubing that has been severely stressed or kinked.

l Do not use nonmetallic tubing with tetrahydrofuran (THF) or

concentrated nitric or sulfuric acids.

l Be aware that methylene chloride and dimethyl sulfoxide cause

nonmetallic tubing to swell, which greatly reduces the rupture

pressure of the tubing.

Attention: Manipulez les tubes en polymère sous pression avec

precaution:

l Portez systématiquement des lunettes de protection lorsque

vous vous trouvez à proximité de tubes en polymère pres-

surisés.

l Eteignez toute flamme se trouvant à proximité de l’instrument.

l Evitez d'utiliser des tubes sévèrement déformés ou endom-

magés.

l Evitez d'utiliser des tubes non métalliques avec du tétrahy-

drofurane (THF) ou de l'acide sulfurique ou nitrique concentré.

l Sachez que le chlorure de méthylène et le diméthylesulfoxyde

entraînent le gonflement des tuyaux non métalliques, ce qui

réduit considérablement leur pression de rupture.

Vorsicht: Bei der Arbeit mit Polymerschläuchen unter Druck ist

besondere Vorsicht angebracht:

l In der Nähe von unter Druck stehenden Polymerschläuchen

stets Schutzbrille tragen.

l Alle offenen Flammen in der Nähe löschen.

l Keine Schläuche verwenden, die stark geknickt oder über-

beansprucht sind.

l Nichtmetallische Schläuche nicht für Tetrahydrofuran (THF)

oder konzentrierte Salpeter- oder Schwefelsäure verwenden.

l Durch Methylenchlorid und Dimethylsulfoxid können nicht-

metallische Schläuche quellen; dadurch wird der Berstdruck

des Schlauches erheblich reduziert.

August 8, 2014, 715003940 Rev. B 37

Page 38

A Safety Advisories

Attenzione: fare attenzione quando si utilizzano tubi in materiale

polimerico sotto pressione:

l Indossare sempre occhiali da lavoro protettivi nei pressi di tubi

l Spegnere tutte le fiamme vive nell'ambiente circostante.

l Non utilizzare tubi eccessivamente logorati o piegati.

l Non utilizzare tubi non metallici con tetraidrofurano (THF) o

l Tenere presente che il cloruro di metilene e il dimetilsolfossido

Advertencia: se recomienda precaución cuando se trabaje con tubos

de polímero sometidos a presión:

l El usuario deberá protegerse siempre los ojos cuando trabaje

l Si hubiera alguna llama las proximidades.

l No se debe trabajar con tubos que se hayan doblado o sometido

l Es necesario utilizar tubos de metal cuando se trabaje con tet-

l Hay que tener en cuenta que el cloruro de metileno y el sulfóx-

警 告 :當在有壓力的情況下使用聚合物管線時,小心注意以下幾點。

l

l

l

l

l

di polimero pressurizzati.

acido solforico o nitrico concentrati.

provocano rigonfiamenti nei tubi non metallici, riducendo note-

volmente la pressione di rottura dei tubi stessi.

cerca de tubos de polímero sometidos a presión.

a altas presiones.

rahidrofurano (THF) o ácidos nítrico o sulfúrico concentrados.

ido de dimetilo dilatan los tubos no metálicos, lo que reduce la

presión de ruptura de los tubos.

當接近有壓力的聚合物管線時一定要戴防護眼鏡。

熄滅附近所有的火焰。

不要使用已經被壓癟或嚴重彎曲管線。

不要在非金屬管線中使用四氫呋喃或濃硝酸或濃硫酸。

要了解使用二氯甲烷及二甲基亞楓會導致非金屬管線膨脹,大大降低管線的耐

壓能力。

警 告 : 当有压力的情况下使用管线时,小心注意以下几点:

l

当接近有压力的聚合物管线时一定要戴防护眼镜。

l

熄灭附近所有的火焰。

l

不要使用已经被压瘪或严重弯曲的管线。

l

不要在非金属管线中使用四氢呋喃或浓硝酸或浓硫酸。

l

要了解使用二氯甲烷及二甲基亚枫会导致非金属管线膨胀,大大降低管线的耐

压能力。

38 August 8, 2014, 715003940 Rev. B

Page 39

Warnings that apply to all Waters instruments and devices

경 고 : 가압 폴리머 튜브로 작업할 경우에는 주의하십시오.

l

가압 폴리머 튜브 근처에서는 항상 보호 안경을 착용하십시오.

l

근처의 화기를 모두 끄십시오.

l

심하게 변형되거나 꼬인 튜브는 사용하지 마십시오.

l

비금속(Nonmetallic) 튜브를 테트라히드로푸란(Tetrahydrofuran: THF)

또는 농축 질산 또는 황산과 함께 사용하지 마십시오.

l

염화 메틸렌(Methylene chloride) 및 디메틸술폭시드(Dimethyl sulfox-

ide)는 비금속 튜브를 부풀려 튜브의 파열 압력을 크게 감소시킬 수 있으므로

유의하십시오.

警 告 :圧力のかかったポリマーチューブを扱うときは、注意してください。

l

加圧されたポリマーチューブの付近では、必ず保護メガネを着用してくださ

い。

l

近くにある火を消してください。

l

著しく変形した、または折れ曲がったチューブは使用しないでください。

l

非金属チューブには、テトラヒドロフラン(THF)や高濃度の硝酸または硫酸

などを流さないでください。

l

塩化メチレンやジメチルスルホキシドは、非金属チューブの膨張を引き起こ

す場合があり、その場合、チューブは極めて低い圧力で破裂します。

August 8, 2014, 715003940 Rev. B 39

Page 40

A Safety Advisories

Warning: The user shall be made aware that if the equipment is

used in a manner not specified by the manufacturer, the protection

provided by the equipment may be impaired.

Attention: L’utilisateur doit être informé que si le matériel est util-

isé d’une façon non spécifiée par le fabricant, la protection assurée

par le matériel risque d’être défectueuses.

Vorsicht: Der Benutzer wird darauf aufmerksam gemacht, dass bei

unsachgemäßer Verwenddung des Gerätes die eingebauten Sicherheitseinrichtungen unter Umständen nicht ordnungsgemäß funktionieren.

Attenzione: si rende noto all'utente che l'eventuale utilizzo dell'ap-

parecchiatura secondo modalità non previste dal produttore può

compromettere la protezione offerta dall'apparecchiatura.

Advertencia: el usuario deberá saber que si el equipo se utiliza de

forma distinta a la especificada por el fabricante, las medidas de

protección del equipo podrían ser insuficientes.

警 告 :使用者必須非常清楚如果設備不是按照製造廠商指定的方式使用,那麼該設

備所提供的保護將被消弱。

警 告 : 使用者必须非常清楚如果设备不是按照制造厂商指定的方式使用,那么该设

备所提供的保护将被削弱。

경 고 : 제조업체가 명시하지 않은 방식으로 장비를 사용할 경우 장비가 제공하는

보호 수단이 제대로 작동하지 않을 수 있다는 점을 사용자에게 반드시 인식시켜야

합니다.

警 告 : ユーザーは、製造元により指定されていない方法で機器を使用すると、

機器が提供している保証が無効になる可能性があることに注意して下さい。

Warnings that address the replacing of fuses

The following warnings pertain to instruments equipped with user-replaceable

fuses.

40 August 8, 2014, 715003940 Rev. B

Page 41

Warnings that address the replacing of fuses

If the fuse types and ratings appear on the instrument:

Warning: To protect against fire, replace fuses with those of the

type and rating printed on panels adjacent to instrument fuse

covers.

Attention: pour éviter tout risque d'incendie, remplacez toujours les

fusibles par d'autres du type et de la puissance indiqués sur le

panneau à proximité du couvercle de la boite à fusible de l'instrument.

Vorsicht: Zum Schutz gegen Feuer die Sicherungen nur mit Sicher-

ungen ersetzen, deren Typ und Nennwert auf den Tafeln neben den

Sicherungsabdeckungen des Geräts gedruckt sind.

Attenzione: per garantire protezione contro gli incendi, sostituire i

fusibili con altri dello stesso tipo aventi le caratteristiche indicate

sui pannelli adiacenti alla copertura fusibili dello strumento.

Advertencia: Para evitar incendios, sustituir los fusibles por aquel-

los del tipo y características impresos en los paneles adyacentes a

las cubiertas de los fusibles del instrumento.

警 告 : 為了避免火災,更換保險絲時,請使用與儀器保險絲蓋旁面板上所印刷之

相同類型與規格的保險絲。

警 告 : 为了避免火灾,应更换与仪器保险丝盖旁边面板上印刷的类型和规格相同的

保险丝。

경 고 : 화재의 위험을 막으려면 기기 퓨즈 커버에 가까운 패널에 인쇄된 것과 동일

한 타입 및 정격의 제품으로 퓨즈를 교체하십시오.

警 告 : 火災予防のために、ヒューズ交換では機器ヒューズカバー脇のパネルに

記載されているタイプおよび定格のヒューズをご使用ください。

August 8, 2014, 715003940 Rev. B 41

Page 42

A Safety Advisories

If the fuse types and ratings do not appear on the instrument:

Warning: To protect against fire, replace fuses with those of the

type and rating indicated in the “Replacing fuses” section of the

Maintenance Procedures chapter.

Attention: pour éviter tout risque d'incendie, remplacez toujours les

fusibles par d'autres du type et de la puissance indiqués dans la

rubrique "Remplacement des fusibles" du chapitre traitant des

procédures de maintenance.

Vorsicht: Zum Schutz gegen Feuer die Sicherungen nur mit Sicher-

ungen ersetzen, deren Typ und Nennwert im Abschnitt "Sicherungen ersetzen" des Kapitels "Wartungsverfahren" angegeben sind.

Attenzione: per garantire protezione contro gli incendi, sostituire i

fusibili con altri dello stesso tipo aventi le caratteristiche indicate

nel paragrafo "Sostituzione dei fusibili" del capitolo "Procedure di

manutenzione".

Advertencia: Para evitar incendios, sustituir los fusibles por aquel-

los del tipo y características indicados en la sección "Sustituir

fusibles".

警 告 : 為了避免火災,更換保險絲時,應使用「維護步驟」章節中「更換保險

絲」所指定之相同類型與規格的保險絲。

警 告 : 为了避免火灾,应更换“维护步骤”一章的“更换保险丝”一节中介绍的相同类

型和规格的保险丝。

경 고 : 화재의 위험을 막으려면 유지관리 절차 단원의 “퓨즈 교체” 절에 설명된 것

과 동일한 타입 및 정격의 제품으로 퓨즈를 교체하십시오.

警 告 : 火災予防のために、ヒューズ交換ではメンテナンス項目の「ヒューズの

交換」に記載されているタイプおよび定格のヒューズをご使用ください。

Electrical and handling symbols

Electrical symbols

The following electrical symbols and their associated statements can appear in

instrument manuals and on an instrument’s front or rear panels.

Electrical power on

Electrical power off

Standby

Direct current

42 August 8, 2014, 715003940 Rev. B

Page 43

Alternating current

Protective conductor terminal

Frame, chassis, terminal

Fuse

Handling symbols

The following handling symbols and their associated statements can appear on

labels affixed to the packaging in which instruments, devices, and component

parts are shipped.

Keep upright!

Keep dry!

Electrical and handling symbols

Fragile!

Use no hooks!

August 8, 2014, 715003940 Rev. B 43

Page 44

A Safety Advisories

44 August 8, 2014, 715003940 Rev. B

Loading...

Loading...