Page 1

[ Care and Use ManUal ]

Pico•Tag amino acid analysis column

I. IntroductIon

Waters exclusive bonding and packing processes, developed for the Pico•Tag®

Column (3.9 mm x 15 cm), P/N 88131, produce a durable, high efficiency

stationary phase ideally suited for the reverse-phase separation of phenyl-

thiocarbamyl amino acids. Our stringent quality control procedures result

in a column which, when used in conjunction with Waters Pico•Tag reagents,

eluents, and HPLC system is guaranteed to provide the speed, resolution, and

sensitivity needed for amino acid analysis.

This information provides the means to ensure that you derive the full benefit

of our research, manufacturing, and quality control. For additional information

on the complete method, refer to Section 4.4 of the Amino Acid Analysis

Manual, P/N 07124, or the Pico•Tag Amino Acid Analysis System Operator’s

Manual, P/N 88140.

WARNING: THE AMPULES OF PHENYLISOTHIOCYANATE WHICH ARE

CONTAINED IN THE PICO•TAG CHEMICAL PACKAGE REACT ON CONTACT WITH

STRONG ACIDS, EMITTING HIGHLY TOXIC CYANIDE FUMES AND/OR OXIDES

OF SULPHUR. CARE MUST BE TAKEN TO ASSURE THAT THESE AMPULES AND

CONTENTS ARE DISPOSED OF PROPERLY AND THAT THEY DO NOT COME INTO

CONTACT WITH ACIDS.

contents

I. IntroductIon

II. PrePArAtIon For oPerAtIon

a. Column Installation

b. Solvent Requirements

c. Equilibration

III. cAre And use

a. Sample and Eluent Preparation and Filtration

b. Precautions

c. Storage Considerations

d. Troubleshooting

e. Service and Applications Information

IV. column eFFIcIency

V. test condItIons

VI. recommended sPAre PArts (steel columns)

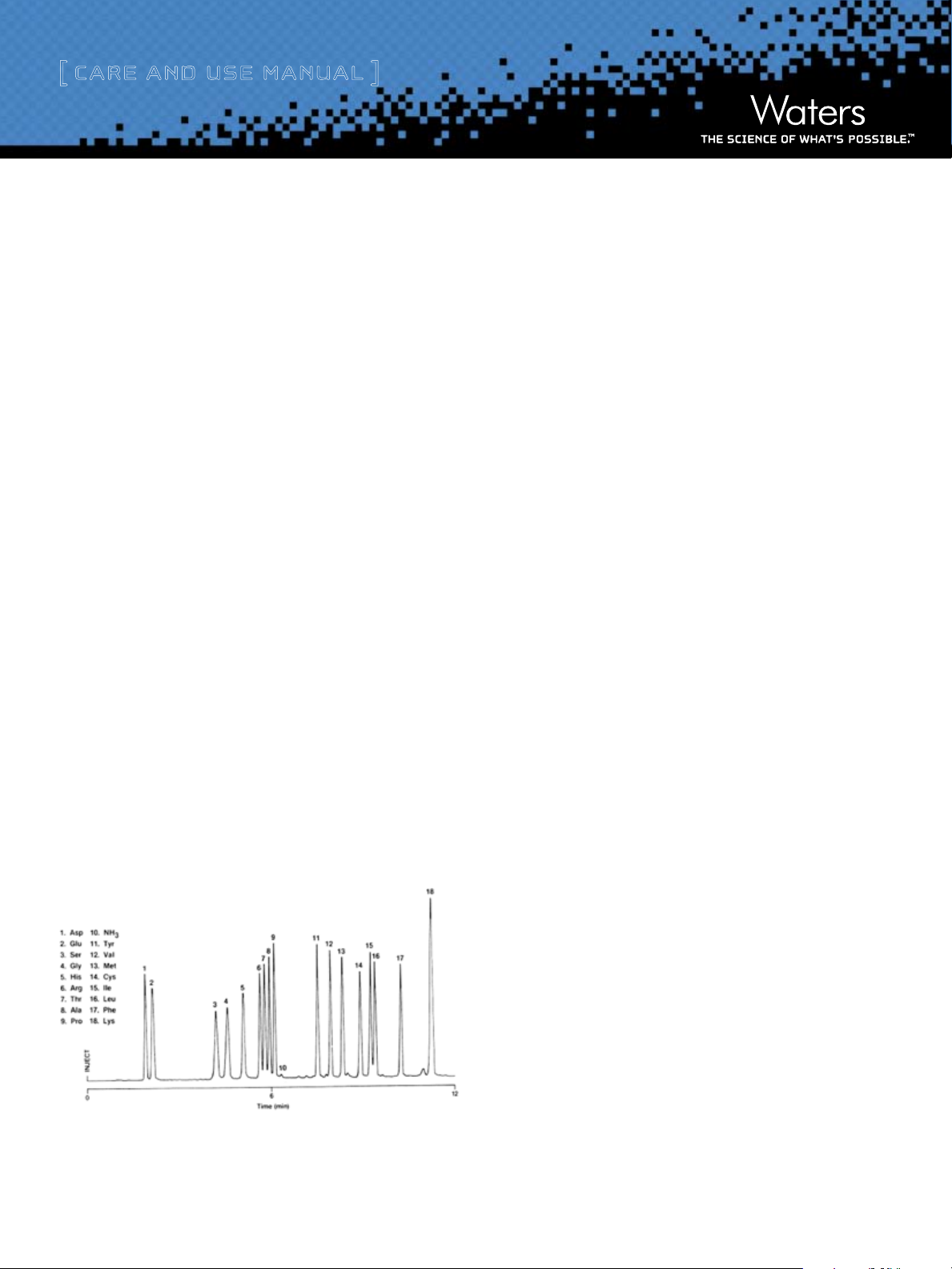

Figure 1. Pico•Tag Method Amino Acid Analysis 250 pmol of

Pierce H Standard

Pico•Tag Amino Acid Analysis Column 1

VII. WArrAnty

Page 2

[ Care and Use ManUal ]

II. PrePArAtIon For oPerAtIon

a. Column Installation

Remove the end plugs from your steel column with a 5/16” wrench and save

them for storage after the column has been removed from the system. The

column outlet is indicated by an arrow on the label (show-ing the direction

solvent should flow). Tighten the fittings 1/4-to-1/2 turn beyond finger tight.

DO NOT OVERTIGHTEN - THIS WILL DAMAGE THE FITTING SEAT. A properly

prepared and assembled com-pression fitting in good condition is all that

is required.

Follow the next four steps of this procedure if tubing cutting is required to

connect a new column or to improve the end connections on your existing

fittings.

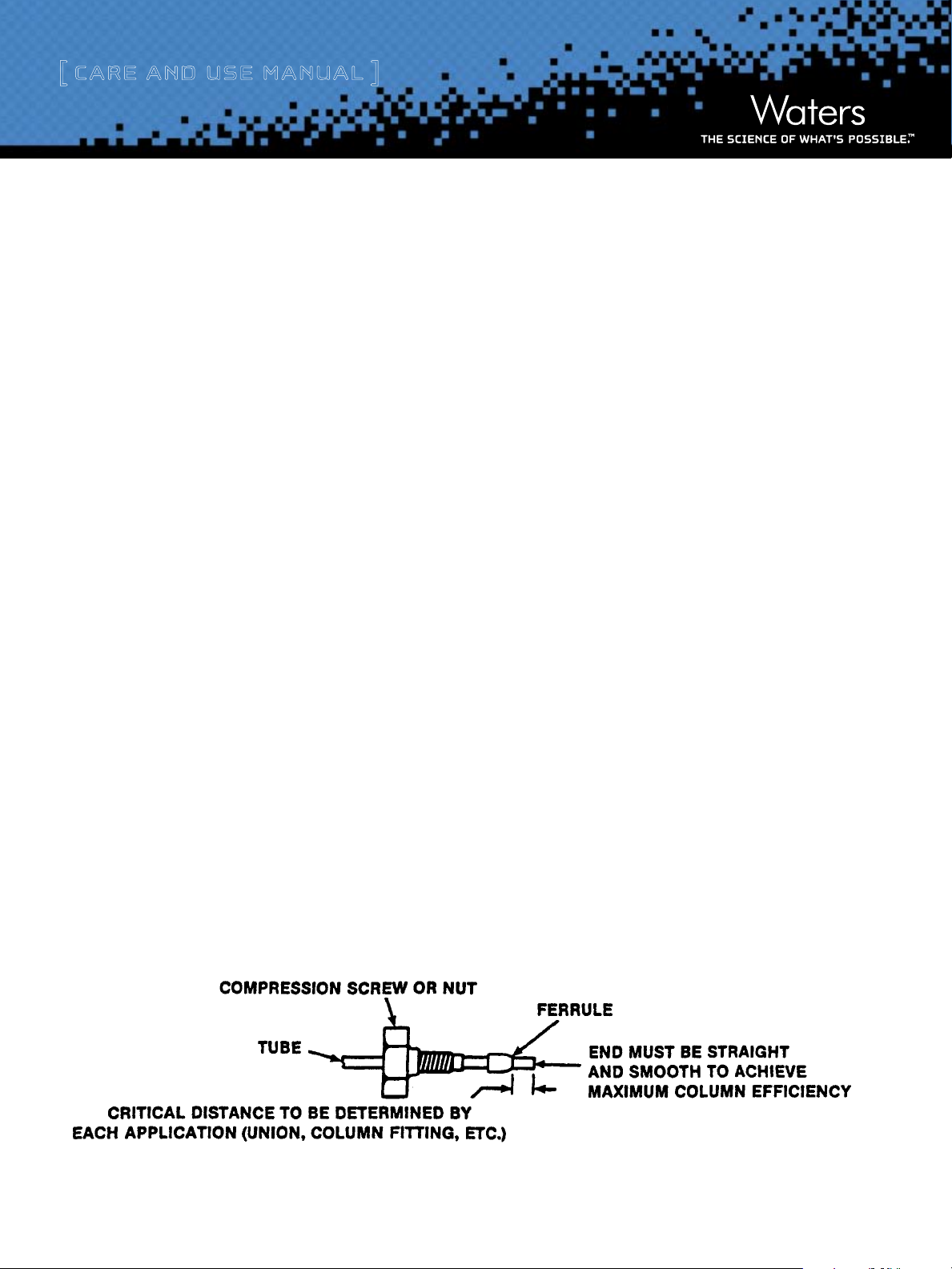

1. Using a file with a cutting edge (such as the file included in the Startup

Tool Kit, P/N 96146, supplied with each Waters Liquid C hromatography

System) scribe the circumference of the tubing at the desired break.

2. Grasp the tubing on both sides of the scribe mark with cloth-covered

pliers (to prevent marring the tube surface) and gently work the tube

back and forth until it separates.

3. File the ends smooth and assemble as shown.

b. Solvent Requirements

Your Pico•Tag column is shipped containing an aqueous/organic mixture

compatible with the Pico•Tag eluents. It is recommended that only Waters

Pico•Tag eluents be used with this column.

Waters Pico•Tag Eluent A (P/N 88108)

Waters Pico•Tag Eluent B (P/N 88112)

Waters Pico•Tag Diluent (P/N 88119)

c. Equilibration

A necessary step to successful use of your column is the initial solvation

(or wetting) of the packing. Install the column in a column heater and bring

temperature to 38 °C. Purge the column at 1 ml/min with Eluent B, then

equilibrate with Eluent A for fifteen minutes. Equilibration between the mobile

phase and packing is established when a stable baseline can be produced. If

your result is un-satisfactory repeat the equilibration process.

III. cAre And use

Liquid chromatography columns have a finite life influenced by their care and

use, number of injections, sample and solvent cleanliness, frequency of sol-

vent changeover, and handling and storage procedures among other factors. If

a change is observed in the:

4. Slide the compression fitting, followed by the ferrule (large end of the

taper first) over the tube. Be certain to bottom the tube in the fitting

seat for which its use is intended to assure a leak-free connection.

Note: Attach a union in place of the column and flush the lines free of

microparticulates before attaching the column

Figure 5: Ferrule and Compression Assembly

.

Retention of a particular compound resolution between two compounds peak

shape.

Take immediate steps to determine the reason for the changes, and until the

determination is made, the results of any separations using the column must

not be relied upon. Follow generally accepted pro-cedures for quality control

and methods development when using these columns.

Important Note: Before running the first analysis on your new column perform

the Test Sample Separation given in the Test Conditions Section.

Pico•Tag Amino Acid Analysis Column 2

Page 3

[ Care and Use ManUal ]

a. Sample and Eluent Preparation and Filtration

Use HPLC grade solvents, filtered to remove microparticulate matter above

0.45 µm. (Waters Pico•Tag prefiltered Eluents A [P/N 88]108 and B [P/N

88]112 are recommended.) This reduces the problem of plugged filters

and preserves column life. Vacuum filtration or sonification may be used to

remove dissolved gasses which could affect your solvent delivery system.

Always filter prepared samples to prevent excessive pressure buildup due to

particulate matter

• Adequate sample cleanup (using Sep-Pak

®

cartridges designed for this

purpose) prevents alteration of the column chemistry by strongly adsorbing

or precipitating sample components.

• Use of an in-line pre-column filter (P/N 84560), is recommended.

b. Precautions

Normal recommended pressure should not exceed 3500 psi.

• For all silica-based packing materials, stay within a pH range of 2-8

(i.e., avoid using concentrated acids or bases). Maximum column life

(pH): 3.5 - 6.5.

• Filter all aqueous buffers (Waters Pico•Tag eluents are prefiltered).

Avoid using turbid or cloudy buffers. Be sure that any solutions contain-

ing buffers, salts, etc. are compatible with the wetted surfaces of the

column and equipment.

• Protect column from vibration, mechanical shock, and rapid changes in

pressure. Column packings are based on a highly porous and delicate

silica gel alignment. Any thermal, physical or chemical shock (such as

changing solvents rapidly or at high flow rates) can cause the particles

to shift and may result in a loss of efficiency.

• When using water, distill or treat with a Milli-Q

De-ionized water is not ac-ceptable because it contains organic com-

pounds which alter column selectivity.

• Protect the column from rapid changes in solvent composition. DO NOT

change the flow rate faster than 0.5 ml/min increments.

®

or equivalent system.

c. Storage Considerations (more than 72 hours without use)

Leaving the column unused for less than 72 hours does not generally require

storage procedures.

• DO NOT store the column in water alone; this practice will promote

microbial contamination. Store the column in Pico•Tag Eluent B or in

10% organic in water mixture.

• DO NOT allow buffers or other potentially harmful materials to remain

in the system when not being used. Flush and replace with Eluent B or

10% organic in water mixture.

• Return the column to its box with the end plugs firmly in place for

storage. Allowing steel columns to dry out can result in poor chromato-

graphic performance.

d. Troubleshooting

Table 2: Typical Column Problems and Solutions

Problem Cause Solution

Excess pressure

buildup

Loss of resolution,

broad peaks, low

plate counts

• Filters plugged

with Particulates

• Sample precipi-

tates on column

(sample not

soluble in mobile

phase)

• Contaminated

column, insuffi-

cient equilibration

• Column col-

l a p s e a n d vo i d

formation

• Filters partially

plugged

• Clean in an ultrasonic bath

or replace.

• Always alter mobile phases

and samples.

• Slowly purge with a strong

mobile phase that is both

appropriate to dissolve the

contaminate and compat-

ible with the column.

• Slowly purge with very

strong solvent (refer to

Equilibration section)

• Since this may occur the

1st 2 weeks of use, Waters

will replace any column

with this defect. Refer to

warranty for details.

• Replace or clean inlet and

outlet filters.

Pico•Tag Amino Acid Analysis Column 3

e. Service and Applications Information

Waters staff of trained and experienced Service Specialists provides main-

tenance for Waters in-struments on preventative and/or corrective levels.

Contact Waters at 1-800-252-HPLC or your local Waters Representative for

answers to specific chromatography questions in areas such as methods devel-

opment, applications, quality control, and service related matters.

Page 4

[ Care and Use ManUal ]

IV. column eFFIcIency

Waters measures column efficiency by using the 5-sigma method. Plate count,

as an expression of efficiency, is determined by measuring the peak width at

4.4% of the peak height. Unlike half-peak height and tangent methods used by

other manufacturers, this stringent method takes into con-sideration naturally

occurring peak asymmetry.

Figure 3. Column Efficiency

V. test condItIons

Columns are thoroughly tested in our quality control laboratories for adher-

ence to our specifica-tions. Since slight variations in your results will occur

depending on the equipment used, test sam-ple makeup and equipment

settings and condition, perform the test sample run given here for your new

column and record the results (retention time and the settings used) before

attempting the first analysis. Use these results for comparison throughout the

life of your column.

NOTE: BE SURE TO RECORD RESULTS AND INSTRUMENT SETTINGS (AND

CONFIGURATIONS) TO ALLOW EXACT REPRODUCTION AND COMPARISON IN

THE FUTURE.

Test Sample: Acenaphthene (0.05% in acetonitrile)

Solvent: Pico•Tag Eluent B

Flow Rate: 1.0 ml/min

Chart Speed: 10 cm/min

Injection Volume: 15 µl

Detection: 254 nm @ 0.5 AUFS

VI. recommended sPAre PArts (steel columns)

Item P/N Quantity

Pico•Tag Reagent Kit 8 8123 1

Phenylisothiocyanate (PITC) 8 8120 1

Triethylamine (TEA) 8 8121 1

Protein Hydrolyzate Standards 8 8122 1

3.9 mm Filter Replacement Kit 84095 1

Filter Insert Assembly (only)* 84056 2

Retainers (only)* 84057 2

* Included as components of 3.9 mm Filter Replacement Kit

VII. WArrAnty

Waters warrants its quality manufactured columns in accordance with the

following terms and conditions. Waters will repack or replace the column (at

our discretion) at no cost if it fails to perform satisfactorily and Waters is noti-

fied within 90 days of receipt. Columns being returned must have prior Return

Authorization granted by Waters Customer Service Department. Approval is

subject to the following exclusions:

• Physical damage to the column due to misuse or abuse.

• Chemical damage to the packing material due to operating with incom-

patible solvents, buffers, or pH.

• Physical damage to the packing material due to operation at incorrect

temperatures or pressures.

• High internal pressure in the column due to improper solvent or sample

filtra-tion practices causing particulate buildup or precipitation in the

column or end fittings.

Pico•Tag Amino Acid Analysis Column 4

Page 5

[ Care and Use ManUal ]

Sales Offices:

Austria and European Export

(Central South Eastern Europe,

CIS and Middle East) 431 877 18 07

Australia 2 9933 1777

Belgium 32 2 726 1000

Brazil 55 11 5094 3788

Canada 800 252 4752

China 8621 6495 6999

CIS/Russia +7 495 3367000

Czech Republic 42 02 617 11384

Denmark 45 46 59 8080

Finland +358 9 5659 6288

France (33) 1 30 48 72 00

Germany 49 6196 400600

Hong Kong 852 29 64 1800

Hungary 36 1 350 5086

India and India Subcontinent

91 80 2 837 1900

Ireland 353 1 448 1500

Italy 39 02 274 211

Japan (81) 3 3471 7191

Korea (82) 2 820 2700

Mexico 5255 5200 1860

The Netherlands +31 (0)76-50 87 200

Norway 47 63 84 60 50

Poland (48) 22 833 4400

Puerto Rico 787 747 8445

Singapore 65 6273 1221

Spain 34 93 600 93 00

Sweden 46 8 555 11500

Switzerland 41 62 889 2030

Taiwan 886 2 2543 1898

United Kingdom 44 208 238 6100

©2007 Waters Corporation. Waters, The Science of W hat’s

Possible, Pico. Tag, and Sep-Pak are trademarks of Waters Corporation. Milli-Q is a trademark of Millipore Corporation.

November 2007 WAT088126 Rev 2 VW-PDF

Pico•Tag Amino Acid Analysis Column 5

Waters Corporation

34 Maple Street

Milford, MA 01757 U.S.A.

T: 1 508 478 2000

F: 1 508 872 1990

www.waters.com

Loading...

Loading...