Page 1

[ method guidelines ]

XBridge™ ost C18 Method guidelines

*ost: oligonuCleotide separation teChnology

XBridge™ OST C18 columns are based on Waters second generation of

hybrid-silica BEH Technology™ particles and can be effectively used

for the lab scale purification and analysis of detritylated synthetic

oligonucleotides using ion-pair, reversed-phase chromatography. This

document provides useful method guidelines for the effective use of

this column chemistry for this group of compounds.

Contents

I. PRINCIPLES OF OLIGONUCLEOTIDE SEPARATIONS

II. SAMPLE PREPARATION

III. RECOMMENDED MOBILE PHASES

IV. RECOMMENDED INJECTOR WASH SOLVENT

V. GENERAL CONSIDERATIONS IN DEVELOPING SEPARATIONS

VI. ANALYSIS OF MODIFIED OLIGONUCLEOTIDES

VII. PURIFICATION CONSIDERATIONS

Page 2

[ method guidelines ]

+

+

+

+

-

-

-

-

-

-

-

-

+

TEA

XBridge™ OST C

18

chain

PO group on Oligo chain

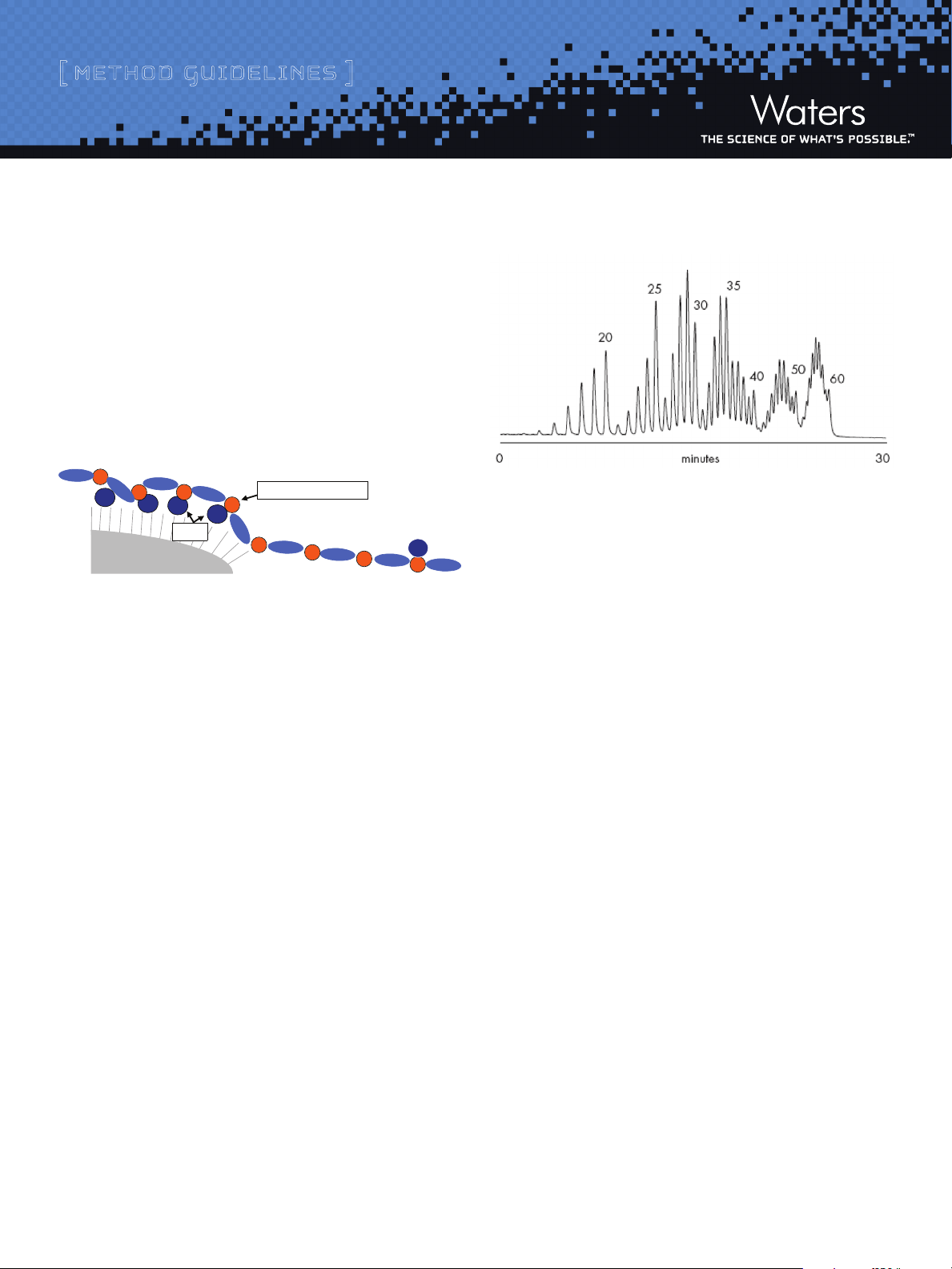

i. p rinCiples o F o l i gonu C l eotide s e parat ions

Separations of detritylated synthetic oligonucleotides on an XBridge™

O ST C18 column are based on ion-pair, reversed-phase chromatographic

principles (IP-RP-LC). As shown in Figure 1, the ion-pairing additive in

the mobile phase is adsorbed on a hydrophobic sorbent and provides

for charge-to-charge interactions with negative charges contained on

the oligonucleotide backbone (e.g., phosphate groups).

Figure 1: Proposed Mechanism of IP-RP-LC for Synthetic Oligonucleotide

Separations

As a result, an efficient charge-based (length-based) oligonucleotide

separation is achieved (Figure 2). Gradient elution using an acetonitrile

or methanol eluent displaces both ion-pairing agent and the oligonucleotides from the sorbent surface.

Figure 2: Separation of a 15 - 60mer Deoxythymidine Ladder on

XBridge™ OST C

18

HPLC system: Waters BioAlliance™ 2796, PDA Detector with micro UV cell

Sample Injected: Approximately 100 pmoles of a detritylated 15 – 60mer

oligonucleotide ladder diluted in

0.1 M TEAA

Column: Waters X Bridge™ OST C18, 2.5 µm (2.1 x 50 mm)

Mobile P hases: A: 0.1 M TEAA,

B: Acetonitrile / 0.1M TEAA, 20/80, v/v

Flow rate: 0.2 mL/min

Column Temp.: 60 ˚C

Gradient delay: 0.45 mL

Gradient: 40 to 62.5% B in 30 minutes (8-12.5% acetonitrile, 0.15%

acetonitrile per minute)

Detection: 260 nm, 5 scans per second

Separation selectivity and resolution decreases with increasing

oligonucleotide length (Figure 2) making the separation of long

oligonucleotides challenging. Modified oligonucleotides such as phosphorothioates and 2-O alkyl modified species are also more difficult

to analyze. Special mobile phase may be required (see Section III,

Recommended Mobile Phases).

Two commonly used ion-pairing agents for oligonucleotide applications

are triethyl ammonium and dimethylbutyl ammonium ions. The final pH of

these mobile phases containing either of these ion-pairing reagents is

adjusted by the addition of Acetic Acid, or in some cases, Hexafluoroisopropanol (HFIP). These mobile phases are volatile making them

suitable for LC-MS applications.

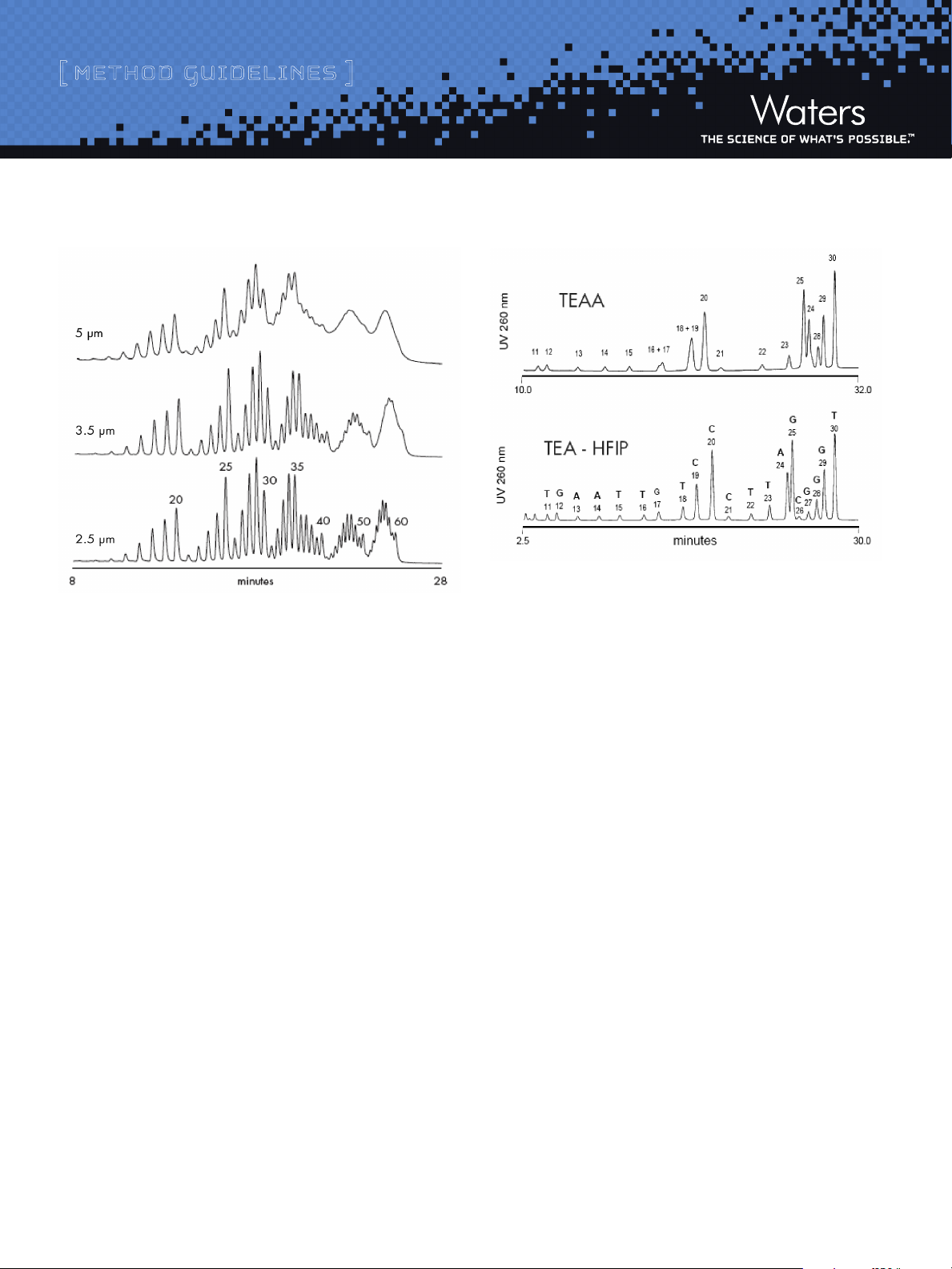

The ability to adequately resolve synthetic oligonucleotide mixtures

by ion-pair, reversed-phase chromatography is significantly affected

by the particle size of the material contained in an efficiently packed

column (see Figure 3). Consequently, XBridge™ OST C18 columns are

efficiently packed with 2.5 micron material to maximize detritylated

oligonucleotide component resolution. In order to improve oligonucleotide

separation efficiency and speed, elevated separation temperature (e.g.

60 ˚C) is recommended. Elevated temperature will also reduce operating

LC System back pressure.

2

Page 3

[ method guidelines ]

Figure 3: Effectiveness of Waters BEH Technology™ Hybrid-Silica C18

Particle Size on Deoxythymidine Ladder Separations

HPLC system: Waters BioAlliance™ 2796, PDA Detector with micro UV cell

Sample Injected: Approximately 100 pmoles of detritylated 15 – 60mer crude

oligonucleotide ladder diluted in 0.1 M TEAA

Column: Waters BEH Hybrid-Silica C18 particles (2.1 x 50 mm)

Mobile P hases: A: 0.1 M TEAA,

B: Acetonitrile / 0.1M TEAA, 20/80, v/v

Flow rate: 0.2 mL/min

Column Temp.: 60 ˚C

Gradient delay: 0.45 mL

Gradient: 40 to 62.5% B in 30 minutes (8-12.5% acetonitrile,

0.15% acetonitrile per minute)

Detection: 260 nm, 5 scans per second

In addition to ion-pairing, a hydrophobic reversed-phase mechanism

also takes place in the oligonucleotide separation. The residual interaction

of nucleobases has an impact on overall retention and separation

selectivity, especially when using Triethylammonium Acetate (TEAA)

ion-pairing mobile phases. Separation of N and N-1mers may be either

enhanced or suppressed by the sequence contribution. More potent

ion-pairing systems such as Triethylammonium ion with Hexafluoroisopropanol counter ion provide for more regular “charge-based”

separations (Figure 4).

Figure 4: Impact of Ion-pairing System on Separation of a 10-30mer

Heterooligonucleotide Ladder

HPLC system: Waters BioAlliance™ 2796, PDA Detector with micro UV cell

Sample: 20 mer: TCC C TA GCG T TG AAT TGT CC

25 mer: TC C CTA GCG TTG AAT TGT C CC TTA G

30 mer: TCC CTA GC G TTG AAT TGT CCC TTA GCG GGT

Ladder was prepared by hydrolyzing detritylated

20, 25, and 30mer oligonucleotides with a

3’-exonuclease

Column: Waters X Bridge™ OST C18, 2.5 µm (4.6 x 50 mm)

Mobile p hases: Upper chromatogram: 0.1 M TEAA with acetonitrile gradient; Lower

chromatogram: 16.3 mM T EA - 400 mM HFIP with methanol gradient

Flow rate: 1.0 mL/min

Column Temp.: 60 ˚C

Gradient delay: 0.45 mL

Detection: 260 nm, 5 scans per second

ii. saMple preparation

1. Dissolve the detritylated synthetic oligonucleotide sample in Mobile

Phase A (e.g., 0.1 M TEAA). For example, a 0.05 - 0.2 µmole scale

synthesis can be prepared in 0.1 mL of 0.1 M TEAA. Proportionately

larger or smaller volumes of 0.1M TEAA are required when dissolving

samples from different scale syntheses. Due to the nature of gradient

separations, relatively large volumes of sample (in low organic

strength eluent) can be injected and concentrated onto the head of

the column before beginning the gradient elution program.

2. Samples must be completely in solution and free of particulates

before injecting onto the column. Remove all particles from the

sample (Controlled Pore Glass Synthesis Support, etc.), which may

block the inlet column frit, increase the operating pressure, and

shorten the column life time. Sample contamination with high concentration of salts and/or detergents may also interfere with analysis.

3

Page 4

[ method guidelines ]

3. To remove particulates the sample may be filtered with a 0.2 μm

membrane. Be sure that the selected membrane is compatible and

does not dissolve with the selected Mobile Phase diluent. Contact

the membrane manufacturer with solvent compatibility questions.

An alternative method of particulate removal involves centrifugation

for 20 minutes at 8,000 rpm, followed by the transfer of the supernatant

liquid to an appropriate vial.

iii . reCo M M ended M o Bile p h ases

The most common ion-pair mobile phase for synthetic oligonucleotide

separations is based on Triethylammonium Acetate (TEAA). This

mobile phase can be prepared by titrating Glacial Acetic Acid aqueous

solution with Triethylamine (TEA).

Note: To maximize column life, it is ESSENTIAL that all prepared OST

Mobile Phases be ltered through a solvent compatible, 0.45 µm membrane and contained in bottles that are clean and particulate free.

TEAA

1L of 0.1 M TEAA may be prepared as follows:

advisable to use aqueous buffer consisting of 15 mM TEA and 400

mM HFIP (pH 7.9).

TEA-HFIP System 1

1L of 8.6 mM TEA / 100 mM HFIP is prepared as follows:

1) Perform work in a hood

2) Add 10.4 mL of HFIP (16.8 g) into 988.4 g of water and mix well.

3) Slowly add 1.2 mL of TEA.

4) The pH is approximately 8.3 +/- 0.1.

TEA-HFIP System 2

1 L of 15 mM TEA / 400 mM HFIP is prepared as follows:

1) Perform work in a hood

2) Add 41.56 mL (67.17 g) of HFIP into 956.36 g of water and mix well.

3) Slowly add 2.08 mL (1.52 g) of TEA.

4) The pH of final buffer is approximately 7.9 +/- 0.1.

1) Perform work in a hood.

2) Add 5.6 mL of glacial Acetic Acid into 950 mL of water and mix well.

3) Slowly add 13.86 mL of TEA.

4) The pH should be adjusted to pH 7 +/- 0.5 by careful addition

of Acetic Acid.

5) Adjust final volume to 1 L with water.

Alternatively, premixed TEAA can be used [(e.g., Sigma 1 M TEAA

(part no. 90357)]. Mix 100 mL with 900 mL of water to prepare 1 L of

0.1 M TEAA mobile phase.

Alternative ion-pairing reagents are recommended for improved separation of phosphorothioates or when performing LC-MS analyses. An

ion-pairing mobile phase based on Triethylamine (TEA) and Hexafluoroisopropanol (HFIP) as the buffering acid produces an efficient eluent

system for improved separations involving these application types.

As indicated below, two ion-pairing systems are useful.

For routine detritylated oligonucleotide applications, aqueous buffer

consisting of 8.6 mM TEA and 100 mM HFIP is effective. For applications

such as those involving the separation of G-rich oligonucleotides, it is

iV. reCoMMended inJeCtor Wash solVents

Between analyses, the HPLC system injector seals should be washed. A

90% Water / 10% Acetonitrile injector wash solvent is recommended.

V. general Consideration in deVeloping separations

Separation of detritylated synthetic oligonucleotides by ion-pair,

reversed-phase chromatography uses very shallow gradients. With

both TEAA and TEA-HFIP ion-pairing systems, a rate of strong eluent

change between 0.1-0.25 % Acetonitrile (or Methanol) per minute is

recommended. However, the formation of shallow gradients can place

performance demands on LC pumps and mixers that can compromise

the quality of the separation. Consequently, it is strongly advised

that Mobile Phase B formulation contain a premix blend of aqueous

and organic solvents (e.g., Mobile Phase A= 0.1 M TEAA and Mobile

Phase B = Acetonitrile / 0.1M TEAA, 20/80, v/v) to minimize potentially inadequate solvent mixing that can compromise component

resolution.

4

Page 5

[ method guidelines ]

As illustrated in Figures 5 through 7, these analyses were performed

with the following mobile phases:

Mobile Phase A: 0.1 M TEAA

Mobile Phase B: Acetonitrile (ACN) containing 0.1 M TEAA, 20:80 (v:v)

The 0.1% ACN / min gradient change from an initial 5 to 10% Acetonitrile

concentration over 50 minutes was programmed as specified in Table 1:

Table 1

Time % A % B Actual Acetonitrile (ACN) Concentration

0 min 75 25 5%

50 min 50 50 10%

Example:

For the initial 5% Acetonitrile concentration:

Initial %B = desired ACN % / Volume Fraction of ACN in Mobile Phase

B. So, initial %B = 5% / 0.2 = 25%

For the final 10% Acetonitrile concentration:

The organic solvent concentration at initial sample loading conditions

has to be well chosen. If the initial organic solvent strength is too

high, then some desired oligonucleotide sequences may be unretained.

In the other extreme, when the gradient starts with too low an organic

concentration, the analysis is excessively long without the benefit

of enhanced component resolution. A suitable gradient separation

method can be approximated from the oligonucleotide base (C, G, A,

and T) composition. The initial gradient is typically adjusted while

keeping the gradient slope constant.

Table 2: Suggested Gradient Conditions for Non-Standard Detritylated

Synthetic Oligonucleotide Sequences

Gradient 1

[Stan dard

oligonucleotides (1)]

Initial % ACN 7.0 0 % 5.25% 7.5 0 %

Final % ACN 10.75% 9.00% 12. 50 %

Gradient Length(4) 15 min 15m in 20min

Gradient 2

[Hig h GC content or s hort

oligonucleotides (2)]

Gradient 3

[Hig h AT content or long

oligonucleotides (3)]

1: Standard oligonucleotides: 10 – 30mers

Final %B = desired ACN % / Volume Fraction of ACN in Mobile Phase

B. So, final %B = 10% / 0.2 = 50%

With TEAA mobile phases, the unmodified oligonucleotides elute

within a 7-10 % ACN gradient window. However, C and G rich oligonucleotide sequences are generally less retained (i.e., elute within a

5-8% ACN gradient window) than A and T rich sequences (i.e., elute

within a 8-11% ACN gradient span). When using a shallow gradient,

the total length of analysis for an unknown sample sequence may be

excessive. Use of a fast scouting gradient with a 1% ACN per minute

change is recommended in such cases. Information gathered from this

scouting analysis can then be used to create a more appropriate and

time efficient set of gradient conditions for the particular sample.

Gradient slope has a direct impact on the achievable oligonucleotide

component resolution (along with the type of ion-pairing agent,

sequence, and oligonucleotide modification). Steeper gradients (e.g.,

1% ACN change per minute on a 4.6 x 50mm column at a 1.0 mL/min

flow) are recommended for labeled oligonucleotides or for short, 5-15

mer sequences. Separation of longer sequences are typically performed

using more shallow gradient slopes (e.g. 0.15% ACN change per minute

on a 4.6 x 50mm column at a 1.0 mL/min flow).

2: Short oligonucleotides: Less than 10mer

3: Long oligonucleotides: 30 – 60mers

4: Assuming use of a 2.1 x 50mm XBridge™ OST C18 column at a flow

of 0.2 mL/min and a separation temperature of 60 ˚C.

The retention of single and dual dye-labeled oligonucleotides is dictated

by the nature of label. For example, the retention of 25 mer oligonucleotide increases according to the type of label attached as follows:

no label<6FAM< <TAMRA<TET<HEX<Cy3.

Vi. analysis oF ModiFied oligonuCleotides

XBridge™ OST C18 columns are suitable for analysis of unmodified as

well as modified detritylated oligodeoxyribonucleotides and oligoribonucleotides. Phosphorothioate and 2’-O -alkyl modified oligonucleotides

can also be analyzed with IP-RP-HPLC method. However, these full

length oligonucleotide products are usually more difficult to resolve

from their shorter length failure sequences. The recommended ion-pair

system for phosphorothioate oligonucleotide analysis is TEA-HFIP (see

Recommended mobile phases). An example of a 25mer phosphorothioate

oligonucleotide analysis is shown in Figure 5.

5

Page 6

[ method guidelines ]

Figure 5: Analysis of a Digested 25mer Phosphorothioate Oligonucleotide

HPLC system: Waters BioAlliance™ 2796, PDA Detector with micro UV cell

Sample: Detritylated 25mer phosphorot hioate oligonucleotide mix

(CTC TCG CAC CCA TC T CTC TCC TTC T ) digested with 3’ exonuclease

Column: XBridge™ OST C18, 2.5 µm (2.1 x 50 mm)

Mobile p hase: A: 15 mM TEA with 400 mM HFIP

B: methanol

Flow rate: 0.2 mL/min

Column Temp.: 60 ˚C

Gradient delay: 0 mL

Gradient: 15 to 20% B in 20 minutes (0.25% methanol per minute)

Detection: 260 nm, 2 scans per second

Figure 6: Analysis of a 20mer Oligodeoxythymidine Crude Synthesis Mixture

HPLC system: Waters BioAlliance™ 2796, PDA Detector with micro UV cell

Sample: ~600 pmol of a detritylated 20mer, ~18 pmol of 19mer, ~4.5 pmol

of 17mer was injected on column.

Column: XBridge™ OST C18, 2.5 µm (2.1 x 50mm)

Mobile p hase: A: 0.1 M TE AA,

B: Acetonitrile / 0.1M TEAA, 20/80 (v/v)

Flow rate: 0.2 mL/min

Column Temp: 60 ˚C

Gradient Delay: 0 mL

Gradient: 35 to 50% B in 30 minutes (7-10% acetonitrile)

Detection: 260 nm, 2 scans per second

Peptide nucleic acids (PNA) can also be analyzed using XBridge™ OST C18

columns. The ion-pairing system recommended for analysis of PNA is

similar to those used for peptide analysis (0.1% Trifluoroacetic Acid

or Formic Acid).

UV detection of eluted oligonucleotide peaks is often performed at

260 nm. Injection of 50 pmol of detritylated oligonucleotide sample

on a 2.1 x 50mm XBridge™ OST C18 column yields relatively abundant

peaks. Limits of quantitation (LOQ) vary with the type of oligonucleotide,

LC system and detector; LOQ generated on Waters 2996 PDA detector

equipped with micro UV cell is approximately 1 pmol (2.1 x 50mm

XBridge™ OST C18). The Limit of detection (LOD) estimate is shown in

Figure 6.

Vii. puriFiCation Considerations

XBridge™ OST C18 columns are designed for laboratory scale oligonucleotide purifications and analyses. Sufficient amount of isolated

material suitable for molecular biology and other experiments can

be prepared in a single injection. For example, a 4.6 X 50 mm XBridge™

OST C18 column can suitably purify approximately 20-200 nmoles of

sample in a single injection. It is important to understand that column

overloading results in a peak broadening and that some earlier eluting

impurities may co-elute with the component of interest. With a proper

heart-cutting technique, a good purity of the target oligonucleotide

can be obtained without significant yield sacrifice (Figure 7).

Chromatographers frequently develop a separation on the analytical

scale before moving to preparative work. The steps required to optimize the analytical separation involve:

1) Selecting the appropriate column packing material and mobile phase.

2) Determining the optimal flow rate, gradient during and separation

temperature.

3) Determining the amount of material that can be satisfactorily

loaded and separated on the analytical scale column.

6

Page 7

[ method guidelines ]

Once the separation has been optimized, one begins preparing for the

preparative separation. The steps to successfully scale a separation

from an analytical to a preparative column, containing the same packing

material composition, are detailed below

Step A: Calculate the flow rate for use on the Preparative column.

Prep arative Column Flow Rate =

Analytic al Column Flow Rate x (Diameter of Prep Column)

(Diam eter of Anal Column)

2

2

Step B: To get similar chromatography, the gradient elution profile

should be created on both columns using the same number of column

volumes. When the analytical and preparative columns are of the

same length, as is recommended for this application, then the gradient

duration should be the same.

Note: This assumes use of the same ow rate linear velocity for both

runs as calculated above. For preparative runs, it is also important to

note that an initial gradient delay is required to allow the entire sample

to load onto the head of the column prior to beginning chromatography.

* XBridge™ OST C18 Custom Column

** Values are only approximate and vary depending on detritylated

oligonucleotide length, base composition, and “heart-cutting” fraction

collection method used

Figure 7 shows the separation of 90 nmoles of a detritylated 30 mer

deoxythymidine crude reaction mixture on a 4.6 x 50mm XBridge

OST C18 column. The collection interval is suggested by the lines. Due

to partial column overloading, the N -1, N -2... impurities are partially

displaced and elute earlier than expected. With the proper hearth-cutting

technique, 95-98% purity is typically achieved for 15-35 mer oligonucleotides at this purification scale.

Figure 7: Purication of a Detritylated 30mer Deoxythymidine Sample

™

Step C: The last calculation involves determining how much sample

can be loaded on the preparative column. This calculation compares

the relative volumes of the two columns assuming that both columns

are the same length as recommended for this application.

Preparative Column Sample Load =

Previously Determined Analytical Column Sample Load x (Diameter of Prep Column)2

(Diameter of Anal Column)

2

Table 3: XBridge™ OST C18 Column Selection Guide for Detritylated

Oligonucleotide Purication

Column (mm) Approx Mass Load (µmoles)** Flow Rate (mL/min)

2.1 x 50 0.04 0.2

4.6 x 50 0.20 1.0

10.0 x 50 1.0 0 4.5

19.0 x 50* 4.00 16. 0

30.0 x 50* 9.00 40.0

50.0 x 50* 25.00 110 . 0

HPLC system: Waters BioAlliance™ 2796, PDA Detector with micro UV cell

Sample: Crude detritylated 30mer oligothymidine, 200 nmole dissolved in

100 µl of mobile p hase A, 45 µl was injected on column

Column: XBridge™ OST C18, 2.5 µm (4.6 x 50mm)

Mobile p hase: A: 0.1M TEAA with 400 mM HFIP

B: Acetonitrile/0.1M TEAA, 20/80 (v/v)

Flow rate: 1.0 mL/min

Column Temp.: 60 ˚C

Gradient delay: 0 mL (compensated)

Gradient: 35 to 65% B in 24 minutes (7-13% ACN, 0.25% ACN per minute)

Detection: 260 nm, 2 scans per second

Table 4: Ordering Information

Description Particle Size Pore Size Dimension Part No.

XBridge™ OST C18 2.5 μm 135 Å 2.1 x 50 mm 186003952

XBridge™ OST C18 2.5 μm 135 Å 4.6 x 50 mm 186003953

XBridge™ OST C18 2.5 μm 135 Å 10.0 x 50 mm 186003954

Custom

XBridge™ OST C

18

-- -- -- 186003955

7

Page 8

[ method guidelines ]

sales oFFiC es

Australia

Waters Australia Pty. Limited

Tel: 2 9933 1777

Fax: 2 9898 1455

Austria and European Export

(Central South Eastern Europe,

CIS and Middle East)

Tel: 431 877 18 07

Fax: 431 877 18 08

Belgium

Waters S.A.-N.V.

Tel: 32 2 726 1000

Fax: 32 2 726 1100

Brazil

Waters Technology

Tel: 55 11 5094 3788

Fax: 55 11 5093 6413

Canada

Waters Limited

Tel: 800 252 4752

Fax: 905 678 9237

China

Waters Technologies

(Shanghai) Limited

Tel: 8621 6495 6999

Fax: 8621 6495 1999

CIS/Russia

Tel: +7 495 727 4490

Fax: +7 495 336 7000

Czech Republic

Tel: 42 02 617 11384

Fax: 42 02 617 11386

Denmark

Waters A/S

Tel: 45 46 59 8080

Fax: 45 46 59 8585

Finland

Waters Finland

Tel: (09) 5659 6288

Fax: (09) 5659 6282

France

Waters S.A

Tel: (33) 1 30 48 72 00

Fax: (33) 1 30 48 72 01

Germany

Waters GmbH

Tel: 49 6196 400600

Fax: 49 6196 4006010

Hungary

Tel: 36 1 350 5086

Fax: 36 1 350 5087

Hong Kong

Waters China Ltd.

Tel: 852 29 64 1800

Fax: 852 25 49 6802

India

Waters India Pvt. Ltd.

Tel: 91 80 2 837 1900

Fax: 91 80 2 839 2157

Ireland

Waters Chromatography

Ireland Ltd.

Tel: 353 1 448 1500

Fax: 353 1 448 1510

Italy

Waters S.P.A.

Tel: 39 02 274 211

Fax: 39 02 250 1827

Japan

Nihon Waters K.K.

Tel: (81) 3 3471 7191

Fax: (81) 3 3471 7118

Korea

Waters Korea Limited,

Tel: (82) 2 820 2700

Fax: (82) 2 820 2730

Mexico

Waters S.A. DE C.V.

Tel: 5255 5200 1860

Fax: 5255 5524 9376

The Netherlands

Waters Chromatography B.V.

Tel: +31 (0)76-50 87 200

Fax: +31 (0)76-50 87 280

Norway

Waters AS

Tel: 47 63 84 60 50

Fax: 47 63 84 60 51

Poland

Tel: (48) 22 833 4400

Fax: (48) 22 833 0987

Puerto Rico

Waters Technologies Corporation

Tel: 787 747 8445

Fax: 787 747 8448

Singapore

Waters Asia Ltd.

Tel: 65 6273 1221

Fax: 65 6273 6116

Spain

Waters Cromatografía, S.A.

Tel: 34 93 600 93 00

Fax: 34 93 600 93 60

Sweden

Waters Sverige AB

Tel: 46 8 555 11500

Fax: 46 8 555 11550

Switzerland

Waters AG

Tel: 41 62 889 2030

Fax: 41 62 889 2059

Taiwan

Tel: 886 2 2543 1898

Fax: 886 2 2543 1918

United Kingdom

Waters U.K. Ltd.

Tel: 44 208 238 6100

Fax: 44 208 207 7070

All Other Countries

Waters Corporation

34 Maple Street

Milford, MA 01757 USA

Tel: 508 478 2000

800 252 4752

Fax: 508 872 1990

http://www.waters.com

Waters, XBridge, BEH Technology and BioAlliance are trademarks of

Waters Corporation.

©2008 Waters Corporation.

April 2008 715001476 Rev B SC

Waters Corporation

34 Maple Street

Milford, MA 01757 U.S.A.

T: 1 508 478 2000

F: 1 508 872 1990

www.waters.com

Loading...

Loading...