Page 1

[ Care and Use ManUal ]

nanoEasE trappinG columns

i. introduction:

Waters NanoEase Trapping Columns are robust devices that can effectively

separate complex samples and remove buffers and high concentrations of

salts. For the latest on Life Science Chemistries, go to:

www.waters.com/lifesciences.

ii. nanoEasE trap column prEparation

1. It is recommended that the trap column be washed and conditioned

with a suitable solvent before use. This can be accomplished using

a suitable syringe to flush solvent through the column. If a syringe

is used for this purpose, it is recommended that a syringe with an

inert teflon plunger and glass body be used to avoid contami-

nation. Syringes with rubber plungers or plastic bodies should

not be used. Alternatively, the trap column can be placed on the

HPLC system and washed with suitable solvent at a flow rate of

10-40 µL/min for several minutes prior to use.

®

2. If using a 10-port valve, use UpChurch

part # F-285X) in eac h adjacent port of the 10-port valve, due to

the clearance width of the trap column.

long nuts (UpChurch

contEnts

i. introduction

ii. nanoEasE trap column prEparation

iii. GEnEral GuidElinEs for column usE

iv. ordErinG information

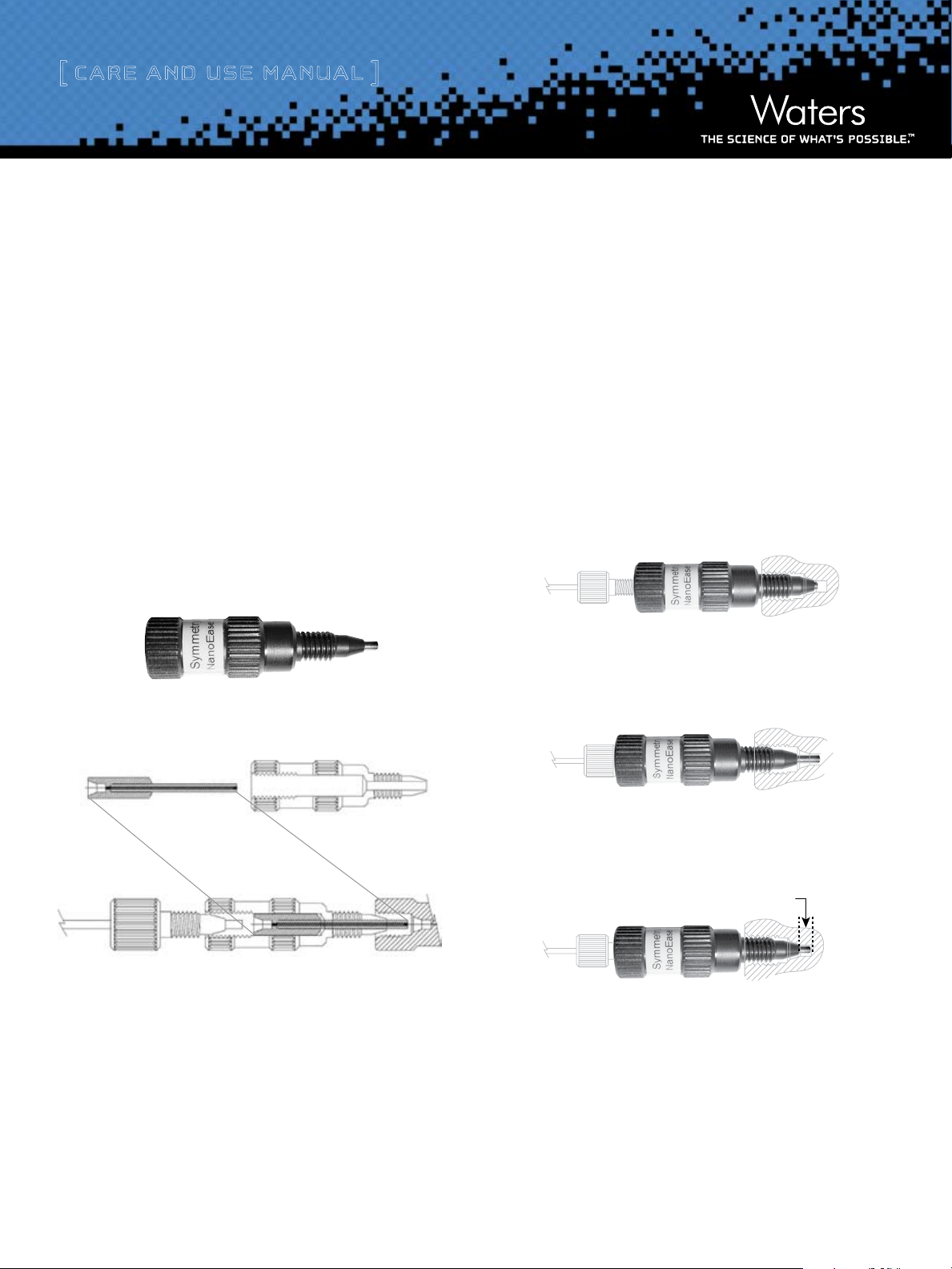

3. The trap column works with the black 10-32 outer fitting with

white label (Figures 1a and 1b), which secures the stainless steel

®

tu be and the tan P EEK

switching valve.

NanoEase Trapping Columns 1

(column insert part) pie ce ( Figure 2) to the

Page 2

[ Care and Use ManUal ]

4. To secure the column into a multi-port valve, care must be taken

to get the face of the stainless steel barrel seated properly into

the port without introducing dead volume between the frit at the

end of the stainless steel barrel and the valve port. The stainless

steel barrel must not protrude too far past the end of the black

fitting, otherwise there will not be enough threads of the fitting

protruding into the valve port to make a proper seal. Consult Fig-

ures to see how to properly seal the trap into the valve port and

connect the desired tubing. The following steps are suggested:

a) First make sure that the trap column insert (Figure 2) is

inside the black fitting (Figure 1b).

b) Screw in a column-blanking plug into the top of the black

fitting (Figure 3) until the stainless steel barrel protrudes

from the end of the fitting approximately between 2 and 3

mm (Figure C). It may be necessary to use your finger (use

a glove to avoid contamination of the trap) to push against

the end of the stainless steel barrel so that the other end of

the insert is set against the column-blanking plug and the

stainless steel barrel protrudes from the end of the black

fitting at the proper depth. Adjust the position of the col-

umn-blanking plug if necessary.

a. Illustration of adjusting the length of the stainless

steel barrel

Figure A. Incorrect. Results in dead volume between valve port and trap column

Figure 1a

Figure 3

Figure 2

Figure 1b

Figure B. Incorrect. Note these are insufficient number of threads to seal trap

column to valve

2-3 mm

Figure C. Correct.

NanoEase Trapping Columns 2

Page 3

[ Care and Use ManUal ]

NanoEase

trap column

25 mm i.d. fused silica tubing

to nanoLC

column

3

1

10

9

8

7

6

5

4

2

waste

10-Port

Va lve

auxiliary

pump

A/S

valve

nanoLC gradient

10-32 fitting with

fused silica sleeve

25 mm i.d. fused silica tubing

to nanoLC

column

3

1

10

9

8

7

6

5

4

2

waste

10-Port

Va lve

auxiliary

pump

A/S

valve

nanoLC gradient

10-32 fitting with

fused silica sleeve

NanoEase

trap column

c) Grip the outside of black fitting (Figure 1a and 1b) and care-

fully screw it into the valve port to seal the trap into the

valve, while being careful not to rotate the column-blanking

plug.

d) Check to see that the black fitting is tightly sealed into the

valve, but do not overtighten it.

e) Secure the tubing to form the “sample loop” (fused silica, or

60 mm i.d. tan PEEK) into the top of the trap column with an

appropriate fitting (see Figure 3).

5. For Nano LC applications using 75 μm analytical columns, dead

volume can be minimized when using a multi-port valve by

placing the trap column at the closest end to the inlet of the

analytical column. Figures 4 and 5 show the plumbing diagram of

such a configuration for the wash and elute cycles using a 10-port

switching valve.

6. Connect up the HPLC System and start flow through the

NanoEase Trap Column. Check for leaks and tighten the fittings

if necessary.

iii. GEnEral GuidElinEs for column usE

Typical Separation Flow Rates: 1-40 µL/min

®

Typical Loading Flow Rate: 15 µL/min for 4 minutes (with Waters CapL

Stream Select Module)

Loading Capacity: 2-5 µg maximum for the RP; 4-8 µg maximum for the SCX

(will vary depending on sample)

Storage Recommendations: Long term storage in acetronitrile for the RP;

Storage in aqueous solvent is adequate for SCX (e.g. HPLC grade water with

acetronitrile).

Typical Column Lifetime: Varies depending on sample and care of column,

but excess of 100 injections is possible.

and

Figure 4. Loading and wash step Figure 5. Elution step

NanoEase Trapping Columns 3

Page 4

[ Care and Use ManUal ]

iv. ordErinG information

Description Particle Size Dimension Part No.

Symmetry300

Atlantis

SCX 300

Symmetry

0.18 i.d. Custom Trap Column 5/pack Custom 0.18 x 23.5 mm 186002687

0.50 i.d. Custom Trap Column 5/pack Custom 0.50 x 23.5 mm 186002806

Sales Offices:

™

C18 Trap Column 5/pack 5 μm 0.18 x 23.5 mm 186002622

®

dC18 Trap Column 5/pack 5 μm 0.18 x 23.5 mm 186002574

®

Trap Column 5/pack 5 μm 0.50 x 23.5 mm 186002623

®

C18 Trap Column 5/pack 5 μm 0.18 x 23.5 mm 186002808

Austria and European Export

(Central South Eastern Europe,

CIS and Middle East) 431 877 18 07

Australia 2 9933 1777

Belgium 32 2 726 1000

Brazil 55 11 5094 3788

Canada 800 252 4752

China 8621 6495 6999

CIS/Russia +7 495 3367000

Czech Republic 42 02 617 11384

Denmark 45 46 59 8080

Finland +358 9 5659 6288

France (33) 1 30 48 72 00

Germany 49 6196 400600

Hong Kong 852 29 64 1800

Hungary 36 1 350 5086

India and India Subcontinent

91 80 2 837 1900

Ireland 353 1 448 1500

Italy 39 02 274 211

Japan (81) 3 3471 7191

Korea (82) 2 820 2700

Mexico 5255 5200 1860

The Netherlands +31 (0)76-50 87 200

Norway 47 63 84 60 50

Poland (48) 22 833 4400

Puerto Rico 787 747 8445

Singapore 65 6273 1221

Spain 34 93 600 93 00

Sweden 46 8 555 11500

Switzerland 41 62 889 2030

Taiwan 886 2 2543 1898

United Kingdom 44 208 238 6100

©2007 Waters Corporation, Waters, The Science of W hat’s Possible, CapLC, Symmetry, Atlantis, Symmetry300, SCX 300 and

NanoEASE are trademarks of Waters Corporation. UpC hurch is a

trademark of Upc hurch Scientific®, a Unit of IDEX® Corporation. PEEK is a trademark of Victrex plc.

Printed in the U.S.A. 11/2007 715001556 Rev B VW-P DF

Nanoease Trapping Columns 4

Waters Corporation

34 Maple Street

Milford, MA 01757 U.S.A.

T: 1 508 478 2000

F: 1 508 872 1990

www.waters.com

Loading...

Loading...