Page 1

W a ters Micromass

ZQ Detector

Operator’s Guide

34 Maple Street

Milford, MA 01757

71500044702, Revision B

Page 2

NOTICE

The information in this document is subject to change without notice and should not be

construed as a commitment by Waters Corporation. Waters Corporation assumes no

responsibility for any errors that may appear in this document. This document is believed

to be complete and a c cu rate at th e time o f p u blication. In no event shall Water s

Corporation be liable for incidental or consequential damages in connec tion with, or

arising from, the use of this document.

© 2002 WATERS CORPORATION. PRINTED IN THE UNITED STATES OF AMERICA.

ALL RIGHTS RESERVED. THIS D OCUMENT OR PARTS THEREOF MAY NOT BE

REPRODUCED IN ANY FORM WITHOUT THE WRITTEN PERMISSION OF THE

PUBLISHER.

Alliance, Micromass, and Waters are registered trademarks, and Empower, ESCi,

MassLynx, and SAT/IN are trademarks of Waters Corporation.

Microsoft, Windows, and Windows NT are registered trademarks of Microsoft Corporation.

All other trademarks or registered trademarks are the sole property of their respective

owners.

Page 3

When you use the instrument, follow generally accepted procedures for quality

Note:

control and methods development.

If you observe a change in the retention of a particular compound, in the resolution

between two compounds, or in peak shape, immediately determine the reason for the

changes. Until you determine the cause of a change, do not rely on the separation results.

The Installation Category (Overvoltage Category) for this instrument is Level II. The

Note:

Level II Category pertains to equipment that receives its electrical power from a local level,

such as an electrical wall outlet.

STOP

Atención:

responsible for compliance could void the user’s authority to operate the equipment.

Importan t :

par l’autorité responsable de la conformité à la réglementation peut annuler le droit de

l’utilisateur à exploiter l’équi pem ent .

Achtun g :

ausdrückliche Genehmigung der für die ordnungsgemäße Fun ktion stüchtigkeit

verantwortlichen Personen kann zum Entzug der Bedienungsbefugnis des Systems

führen.

Avvertenza:

espressamente approvate da un ente responsabile per la conformità annulleranno

l’autorità dell’utente ad operare l’apparecchiatura.

Atención:

expresamente aprobado por la parte responsable del cumplimiento puede anular la

autorización del usuario para utilizar el equip o.

Changes or modifications to this unit not expressly approved by the party

Toute modification sur cette unité n’ayant pas été expressément approuvée

Jedwede Änderungen oder Modifikationen an dem Gerät ohne die

eventuali modifiche o alterazioni apportate a questa unità e non

cualquier cambio o modificación efectuado en esta unidad que no haya sido

Page 4

Caution:

Use caution when working with any polymer tubing under pressure:

• Always wear eye protection when near pressurized polymer tubing.

• Extinguish all nearby flames.

• Do not use Tef zel tubing tha t has been severely stressed or kinked.

• Do not use Tefz el tubing with tetrahydrofuran (THF) or concentrated nitric or

sulfuric acids.

• Be aware that methylene chloride and dimethyl sulfoxide cause Tefzel tubing to

swell, which greatly reduces the rupture pressure of the tubing.

Attention :

Soyez très prudent en travaillant avec des tuyaux de polymères sous

pression :

• Portez toujours des lunettes de protection quand vous vous trouvez à proximité de

tuyaux de polymères.

• Eteignez toutes les flammes se trouvant à proximité.

• N'utilisez pas de tuyau de T efzel fortement abîmé ou déformé.

• N'utilisez pas de tuyau de Tefzel avec de l'acide sulfurique ou nitrique, ou du

tétrahydrofurane (THF).

• Sachez que le chlorure de méthylène et le sulfoxyde de diméthyle peuvent

provoquer le gonflement des tuyaux de Tefzel, diminuant ainsi fortement leur

pression de rupture.

Vorsicht:

Bei der Arbeit mit Polymerschläuchen unter Druck ist besondere Vorsicht

angebracht:

• In der Nähe von unter Druck stehenden Polymerschläuchen stets Schutzbrille

tragen.

• Alle offenen Flammen in der Nähe löschen.

• Keine T e fzel-Schläuche verwenden, die stark geknickt oder überbeansprucht sind.

• Tef zel-S chläuche nicht für Tetrahydrofuran (THF) oder konzentrierte Salpeteroder Schwefelsäure verwenden.

• Durch Methylenchlorid und Dimethylsulfoxid können Tefzel-Schläuche quellen;

dadurch wird der Berstdruck des Schlauches erheblich reduziert.

Page 5

Precauzio ne :

prestare attenzione durante le operazioni con i tubi di polimero sotto

pressione:

• Indossare sempre occhiali da lavoro protettivi nei pressi di tubi di polimero

pressurizzati.

• Estinguere ogni fonte di ignizione circostante.

• Non utilizzare tubi Tefzel soggetti a sollecitazioni eccessive o incurvati.

• Non utilizzare tubi Tefzel contenenti tetraidrofurano (THF) o acido solforico o

nitrico concentrato.

• Tenere presente che il cloruro di metilene e il dimetilsolfossido provocano

rigonfiamento nei tubi Tefzel, che riducono notevolmente il limite di pressione di

rottura dei tubi stessi.

Advertencia:

manipular con precaución los tubos de polímero bajo presión:

• Protegerse siempre los ojos en las proximidades de tubos de polímero bajo

presión.

• Apagar todas las llamas que estén a proximidad.

• No utilizar tubos Tef zel que hayan sufri do tensiones extrem as o hayan sido

doblados.

• No utilizar tubos Tefzel con tetrahidrofurano (THF) o ácidos nítrico o sulfúrico

concentrados.

• No olvidar que el cloruro de metileno y el óxido de azufre dimetilo dilatan los tubos

Tefzel, lo que reduce en gran medida la presión de ruptura de los tubos.

Page 6

Page 7

Caution:

The user shall be made aware that if the equipment is used in a manner not

specified by the manufacturer, the protection provided by the equipment may be

impaired.

Attention :

L’utilisateur doit être informé que si le matériel est utilisé d’une façon non

spécifiée par le fabricant, la protection assurée par le matériel risque d’être

défectueuses.

Vorsicht:

Der Benutzer wird darauf aufmerksam gemacht, dass bei unsachgemäßer

Verwenddung des Gerätes unter Umständen nicht ordnungsgemäß funktionieren.

Precau zion e :

l’utente deve essere al corrente del fatto che, se l’apparecchiatura viene

usta in un modo specificato dal produttore, la protezione fornita dall’apparecchiatura

potrà essere invalidata.

Adver tenc ia:

el usuario deberá saber que si el equipo se utiliza de forma distinta a la

especificada por el fabricante, las medidas de protección del equipo podrían ser

insuficientes.

Page 8

Caution:

rating.

To protect against fire hazard, replace fuses with those of the same type and

Attention :

Remplacez toujours les fusibles par d’autres du même type et de la même

puissance afin d’éviter tout risque d’incendie.

Vorsicht:

Zum Schutz gegen Feuergefahr die Sicherungen nur mit Sicherungen des

gleichen Typs und Nennwertes ersetzen.

Precauzio ne :

per una buona protezione contro i rischi di incendio, sostituire i fusibili con

altri dello stesso tipo e amperaggio.

Advertencia:

sustituya los fusibles por otros del mismo tipo y características para evitar

el riesgo de incendio.

Page 9

Caution:

To avoid possible electrical shock, disconnect the power cord before servicing

the instrument.

Attent i on :

Afin d’éviter toute possibilité de commotion électrique, débranchez le cordon

d’alimentation de la prise avant d’effectuer la maintenance de l’instrument.

Vorsicht:

Zur Vermeidung von Stromschlägen sollte das Gerät vor der Wartung vom

Netz getrennt werden.

Precauzio ne :

per evitare il rischio di scossa elettrica, scollegare il cavo di alimentazione

prima di svolgere la manutenzione dello strumento.

Precaución:

para evitar descargas eléctricas, desenchufe el cable de alimentación del

instrumento antes de realizar cualquier reparación.

Page 10

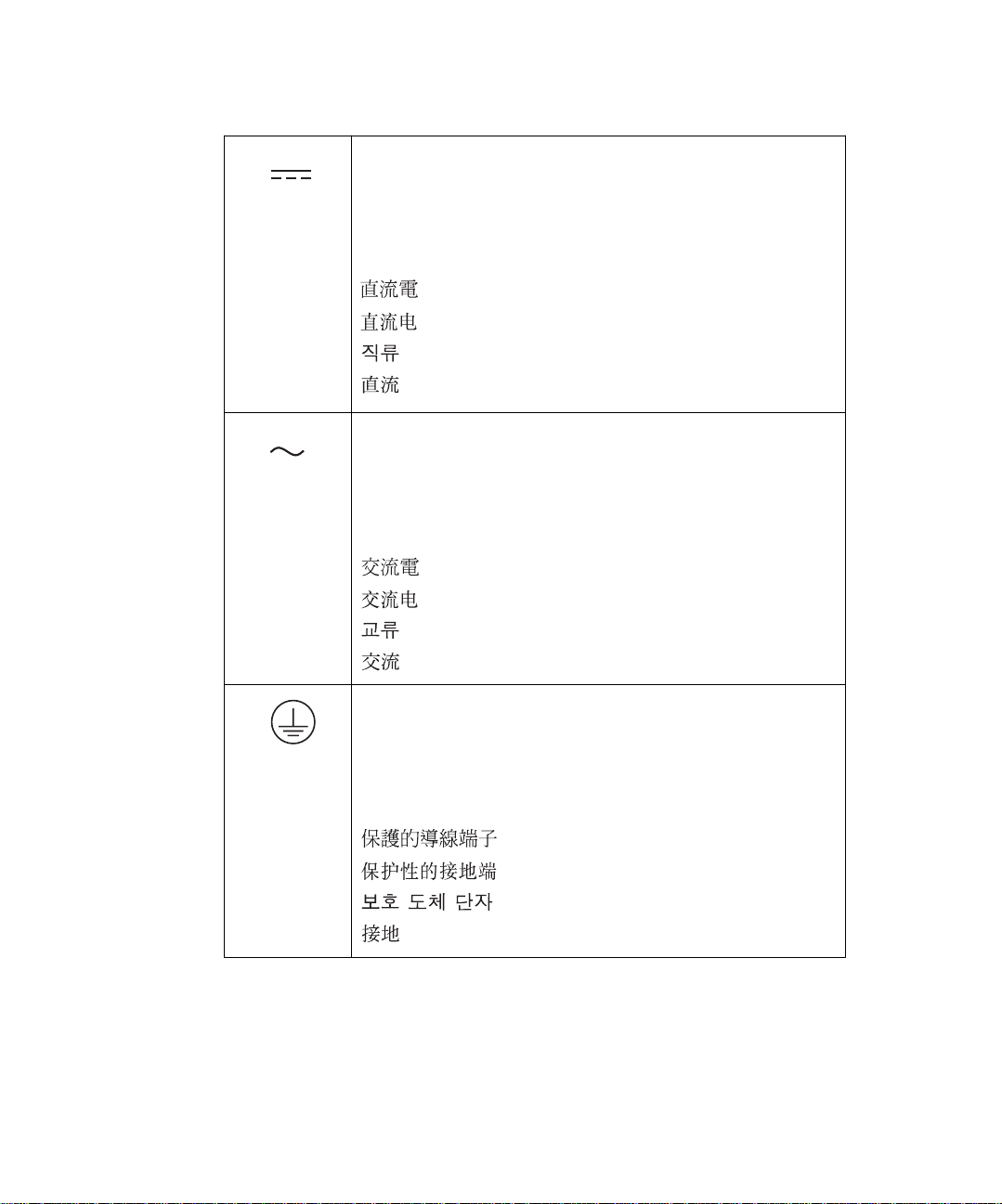

Commonly Used Symbols

Direct current

Courant continu

Gleichstrom

Corrente continua

Corriente continua

Alternating current

Courant alternatif

Wechselstrom

Corrente alternata

Corriente alterna

Protective conductor terminal

Borne du conducteur de protection

Schutzleiteranschluss

Ter m ina le di conduttore con protezione

Borne del conductor de tierra

Page 11

Commonly Used Symbols (Continued )

Frame or chassis terminal

Borne du cadre ou du châssis

Rahmen- oder Chassisanschluss

Ter m ina le di struttura o telaio

Borne de la estructura o del chasis

Caution or refer to manual

Attention ou reportez-vous au guide

Vorsicht, oder lesen Sie das Handbuch

Prestare attenzione o fare riferimento alla guida

Actúe con precaución o consulte la guía

Caution, hot surface or high temperature

Attention, surface chaude ou température élevée

Vorsicht, heiße Oberfläche oder hohe T emperatur

Precauzione, superficie calda o elevata temperatura

Precaución, superficie caliente o temperatura elevada

Page 12

Commonly Used Symbols (Continued )

Caution, risk of electric shock (high voltage)

Attention, risque de commot ion électri que (haut e tension )

Vorsicht, Elektroschockgefahr (Hochspannung)

Precauzione, rischio di scossa elettrica (alta tensione)

Precaución, peligro de descarga eléctrica (alta tensión)

Caution, risk of needle-stick puncture

Attention, risques de perforation de la taille d’une aigui lle

Vorsicht, Gefahr einer Spritzenpunktierung

Precauzione, rischio di puntura con ago

Precaución, riesgo de punción con aguja

Caution, ultraviolet light

UV

Attention, rayonnement ultrviolet

Vorsicht, Ultraviolettes Licht

Precauzione, luce ultravioletta

Precaución, emisiones de luz ultravioleta

Page 13

Commonly Used Symbols (Continued )

Fuse

Fusible

Sicherung

Fusibile

Fusible

1

0

Electrical power on

Sous tension

Netzschalter ein

Alimentazione elettrica attivata

Alimentación eléctrica conectada

Electrical power off

Hors tension

Netzschalter aus

Alimentazione elettrica disat tivata

Alimentación eléctrica desconectada

Page 14

Waters Micromass ZQ Detector Information

Intended Use

Waters designed the Waters® Micromass® ZQ™ Detector to with an HPLC system to

determine mass-to-charge ratio (m/z) for a wide range of analytes.

Biological Hazard

When you analyze physiological fluids, take all necessary precautions and treat all

specimens as potentially infectious. Precautions are outlined in “CDC Guidelines on

Specimen Handling,” CDC – NIH Manual, 1984.

Calibration

Follow the calibration methods set forth in this guide, using pure standards. The

concentration range should cover the entire range of quality-control samples, typical and

atypical specimens.

Quality Control

Routinely run three quality-control samples. Quality-control samples should represent

subnormal, nor m al, and above-norm al levels of a compound. Ensure that quality-control

sample results are within an acceptable range, and ev aluate precision from day to day and

run to run. Data collected when quality-control samples are out of range may not be valid.

Page 15

Table of Contents

Preface ....................................................................................... 23

Chapter 1

Overview ........ .............. .............. ............... ......... ............... .............. . 27

1.1 About the Micromass ZQ Detector........................................ 27

1.2 Theory and Principles of Operation ...................................... 28

1.3 MassLynx 4.0 Software......................................................... 29

Chapter 2

Installing .......................................................................................... 30

2.1 Site Selection and Power Requirements............................... 31

2.2 Unpacking and Inspecting..................................................... 32

2.3 Installing the Detector ........................................................... 33

2.3.1 Installing the Rotary Pump ........................................ 33

2.3.2 Installing the Oil Return Connection Kit..................... 34

2.3.3 Connecting the Nitrogen Supply and Exhaust........... 35

2.3.4 Connecting the Rheodyne Injector (for Manual

Injections).................................................................. 37

2.3.5 Installing the ESI Probe............................................. 38

2.3.6 Connecting the Workstation....................................... 39

2.3.7 Preparing the Syrin ge an d Syringe Pump ................. 40

Table of Contents 15

Page 16

Chapter 3

Tuning ............................................................................................ 41

3.1 Opening MassLynx and Starting the Instrument................... 41

3.2 Tuning in ESI Mode............................................................... 43

3.2.1 Specif ying Parameter Settin gs on the ES+

Source Page....................... ..... .... ..... ..... ................... . 44

3.2.2 Specif ying Parameter Settin gs on the

Analyser Page ........................................................... 46

3.3 Tuning in APCI Mode ............................................................ 47

3.3.1 Preparing the Source for APCI Operation ................. 48

3.3.2 Installing the Tee Fitting............................................. 49

3.3.3 Specifying Parameters on the APCI+ Source

Page.......................................................................... 49

3.4 Readbacks............................................................................ 52

Chapter 4

Calibrating ....................................................................................... 54

4.1 Setting Up the Calibration File.............................................. 54

4.2 Setting Calibration Parameters ............................................. 55

4.2.1 Tune Window Setting s ............. .... .................... .... ..... . 55

4.2.2 Instrum en t Thresh old Settin gs Dialog Box ...... .... ..... . 58

4.2.3 Automatic Calibration Check Dialog Box ................... 59

4.2.4 Calibration Parameters Dialog Box............................ 60

4.2.5 Mass Measure Dialog Box......................................... 62

4.2.6 Automatic Calibration Dialog Box .............................. 63

4.2.7 Calibration Acquisition Dialog Box............................. 64

Table of Contents 16

Page 17

Chapter 5

Maintaining ...................................................................................... 73

5.1 Considerations...................................................................... 73

5.2 Routine Maintenance............................................................ 75

5.2.1 Checking the Rotary Pump Oil .................................. 75

5.2.2 Replacing the Pump Oil............................................. 75

5.2.3 Gas-Ballasting the Rotary Pump............................... 78

5.2.4 Replacing the Oil Mist Filter....................................... 79

5.2.5 Cleaning the Source Assembly.................................. 80

5.2.6 Cleaning the APCI Probe Tip..................................... 91

5.2. 7 Cleaning and Replacing th e Corona Discharge

Needle....................................................................... 91

5.3 Replacing Parts..................................................................... 92

5.3.1 Replacing the Ion Block Cartridge Heater................. 92

5.3.2 Replacing the Stainless Steel Capillary..................... 93

5.3.3 Replacing the ESI Probe Tip ..................................... 95

5.3.4 Replacing the APCI Fused Silica Capillary and

Filter Pad.................. ..... ..... ..... ................... ..... .... ..... . 96

5.3.5 Replacing the APCI Probe Heater............................. 98

Chapter 6

Troubleshooting ............................................................................... 99

6.1 Safety and Handling.............................................................. 99

6.2 Component Hardware Troubleshooting............................... 101

6.3 Inspecting the APCI Probe.................................................. 107

Table of Contents 17

Page 18

Appendix A

Using the ESCi Multi-Mode Ionization Source................................ 108

A.1 Preparing for Oper ation . ..... ..... ................... ..... ..... ..... ........ 108

A.1.1 Installing the Corona Discharge Needle.................. 108

A.1.2 Setting Up MassLynx .............................................. 110

A.2 Daidzein Test ... ..... ..... .... ..... ..... ..... ................... ..... ..... .... .... 117

A.2.1 Test Conditions ...................................................... 118

A.2.2 Signal-to-Noise Ratio .............................................. 118

Appendix B

Specifications ................................................................................. 119

B.1 ZQ Detector Specifications ................................................ 119

B.2 ESCi Multi-Mode Ionization Source Specifications ........... 121

Appendix C

Accessories and Spare Parts ......................................................... 122

Index ..................................................................................... 129

Table of Contents 18

Page 19

List of Figures

2-1 Installing the Detector....................................................................30

2-2 Pump Oil Level...............................................................................33

2-3 Fitting the Gas Ballast and Hose adaptors to the Rotary Pump.... 35

2-4 ZQ Detector Rear Panel ................................................................36

2-5 Nitrogen Stud.................................................................................36

2-6 Drying Gas Exhaust Bottle ............................................................37

2-7 Rheodyne Injector........... ......... ......... .......... ......... ..........................38

2-8 ESI Probe in Situ...........................................................................39

2-9 Syringe Pump................................................................................40

3-1 MassLynx Login Dialog Box...........................................................41

3-2 MassLynx Main Window................................................................ 42

3-3 Tune Window Displaying the ES+ Source Page ............................ 43

3-4 Syringe Selection Dialog Box ........................................................45

3-5 Tune Window Displaying the Analyser Page..................................47

3-6 Combined Flow into the Tee..........................................................49

3-7 Tune Window Displaying the APCI+ Source Page.........................50

3-8 Readbacks Dialog Box................................ ...................................52

3-9 Diagnostics Page Readbacks........................................................53

4-1 Calibration Window........................................................................54

4-2 Open Dialog Box............................................................................55

4-3 Tune Window Displaying the ES+ Source Page ............................ 57

4-4 Tune Window Displaying Analyser Page Parameters....................58

4-5 Instrument Threshold Settings Dialog Box ....................................59

4-6 Automatic Calibration Check Dialog Box.......................................59

4-7 Calibration Pa rameters Dialog Box................................................60

4-8 Mass Measure Dialog Box.............................................................62

4-9 Automatic Calibration Dialog Box ..................................................63

4-10 Calibration Acquisition Setup Dialog Box ......................................65

List of Figures 19

Page 20

4-11 Display Calibration Graphs Dialog Box..........................................67

4-12 Calibrate Window Showing ZQ-4000 Calibration Graphs..............69

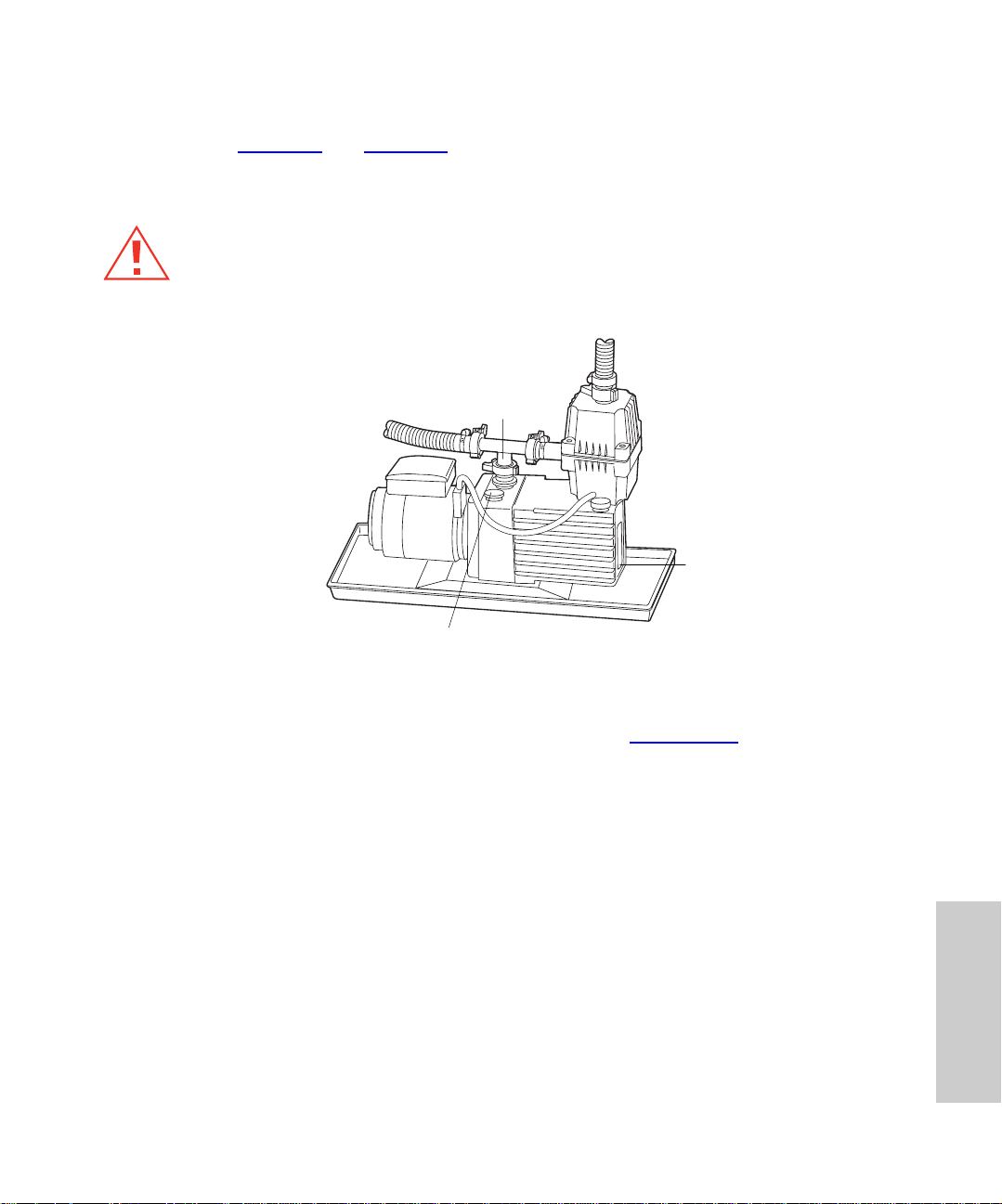

5-1 Rotary Pump Assembly Fitted with Oil Mist Filter..........................76

5-2 Rotary Pump Oil Filler Plug, Drain Plug, and Sight Glass.............77

5-3 Isolation Valve................................................................................79

5-4 Oil Mist Filter Assembly.................................................................80

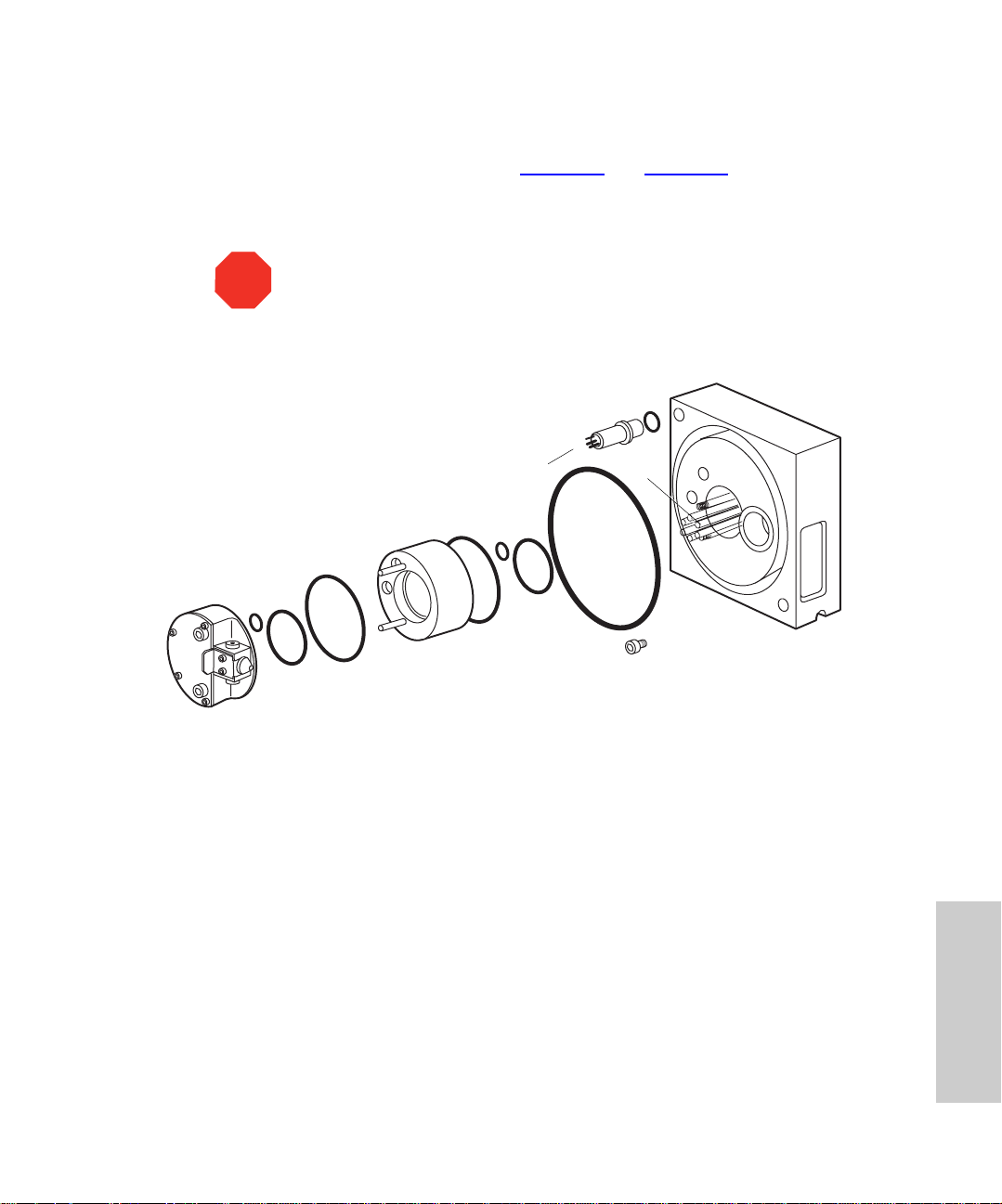

5-5 Pumping Block Assembly..............................................................82

5-6 Ion Block Assembly .......................................................................83

5-7 Probe Assembly in Position on the Source ....................................84

5-8 ZQ Detector Front View.................................................................85

5-9 Source Showing the Corona Discharge Needle............................86

5-10 Ion Block........................................................................................86

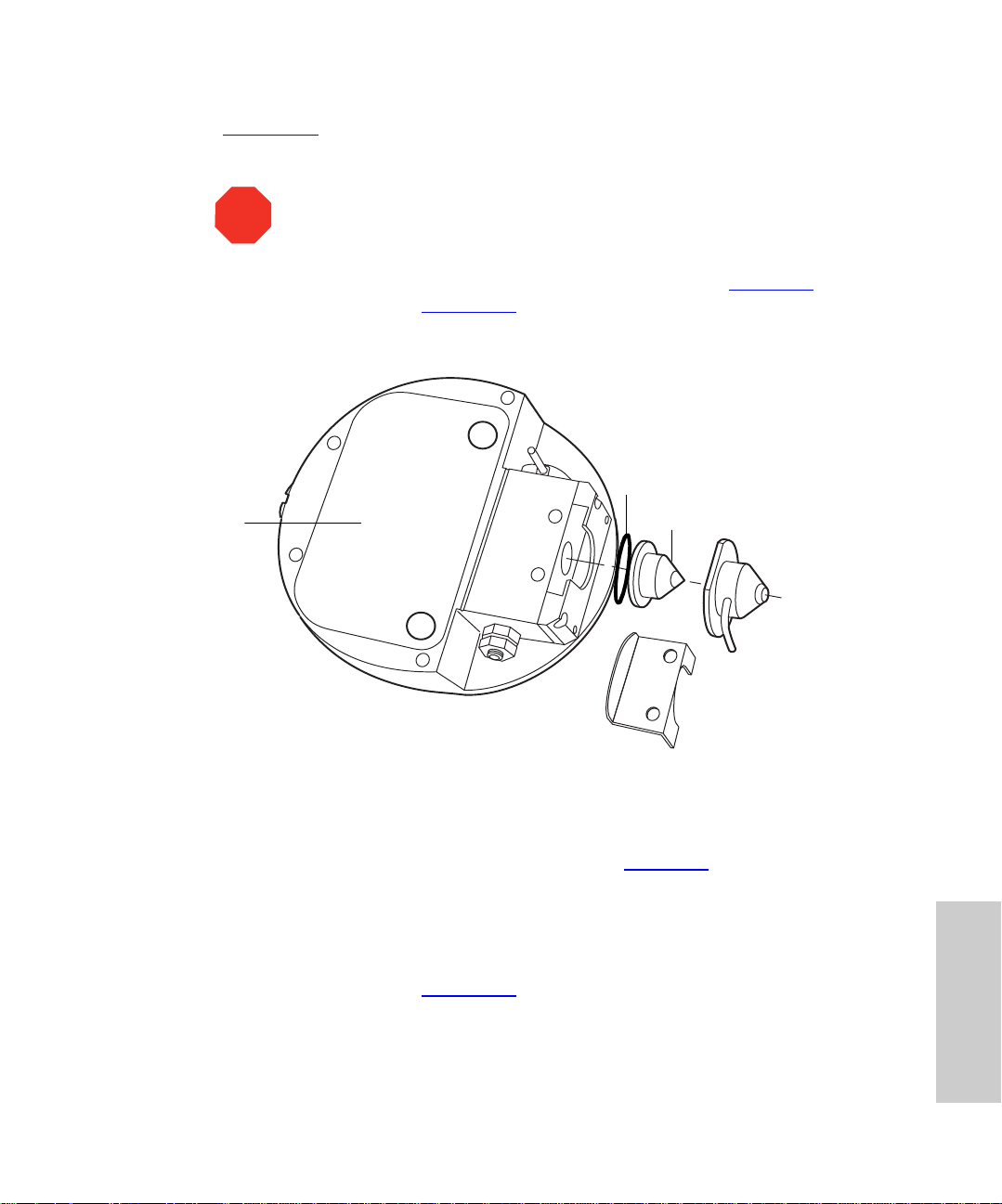

5-11 Sample Cone and Cone Gas Nozzle.............................................87

5-12 Ion Block Rear View ......................................................................88

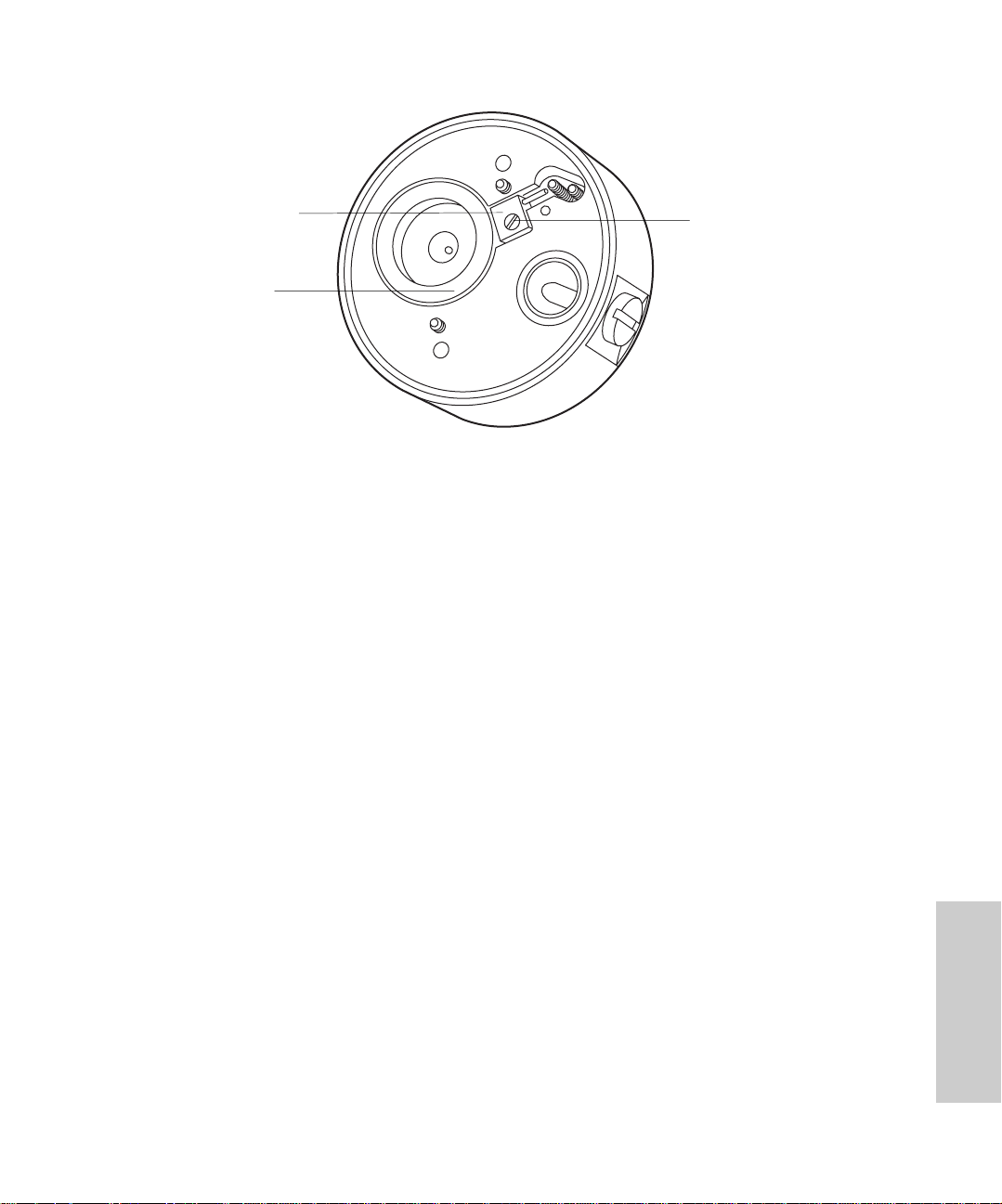

5-13 Hexapole Assembly.......................................................................89

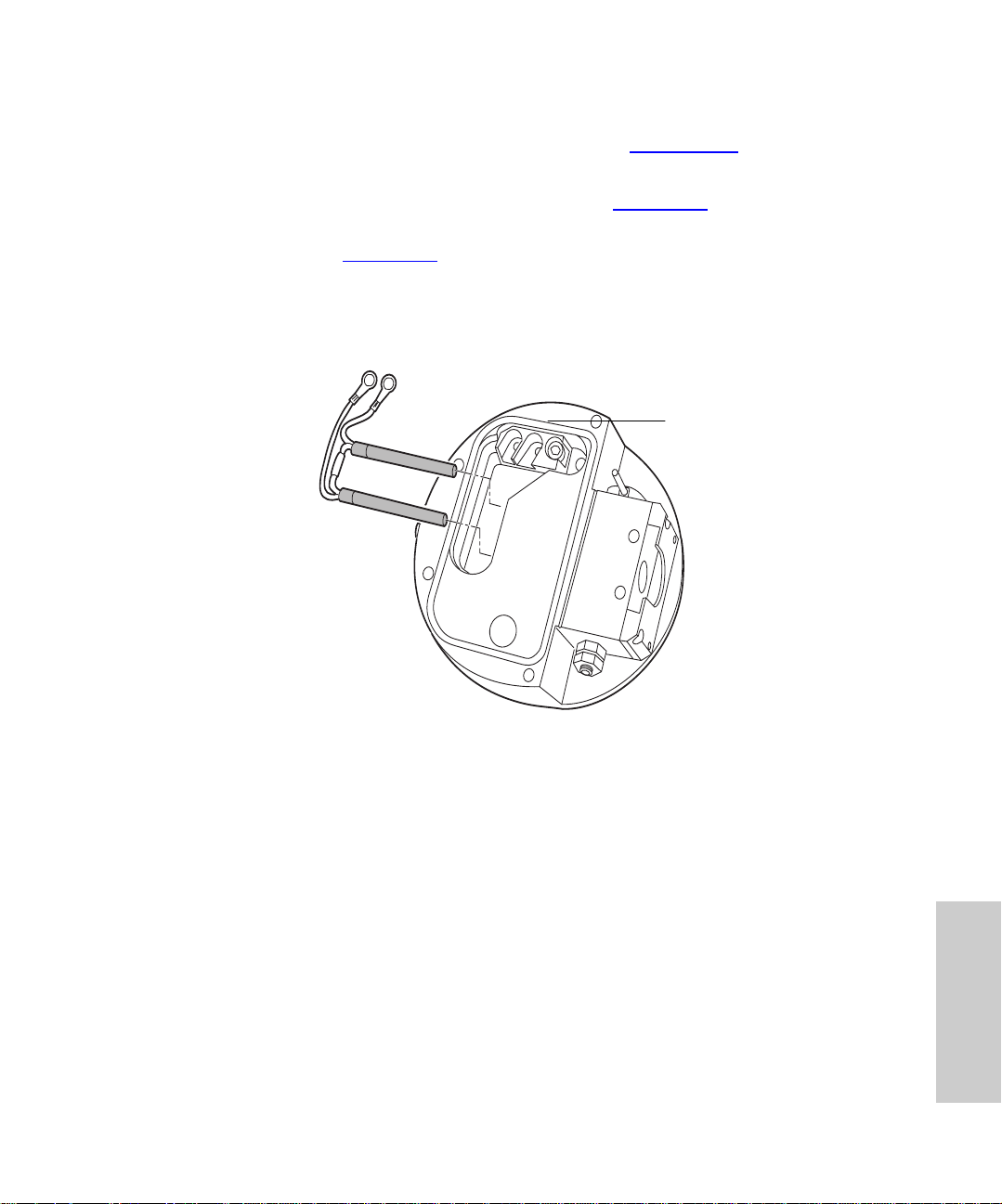

5-14 Ion Block Cartridge Heater............................................................92

5-15 Replacing the Heater Car tridge.....................................................93

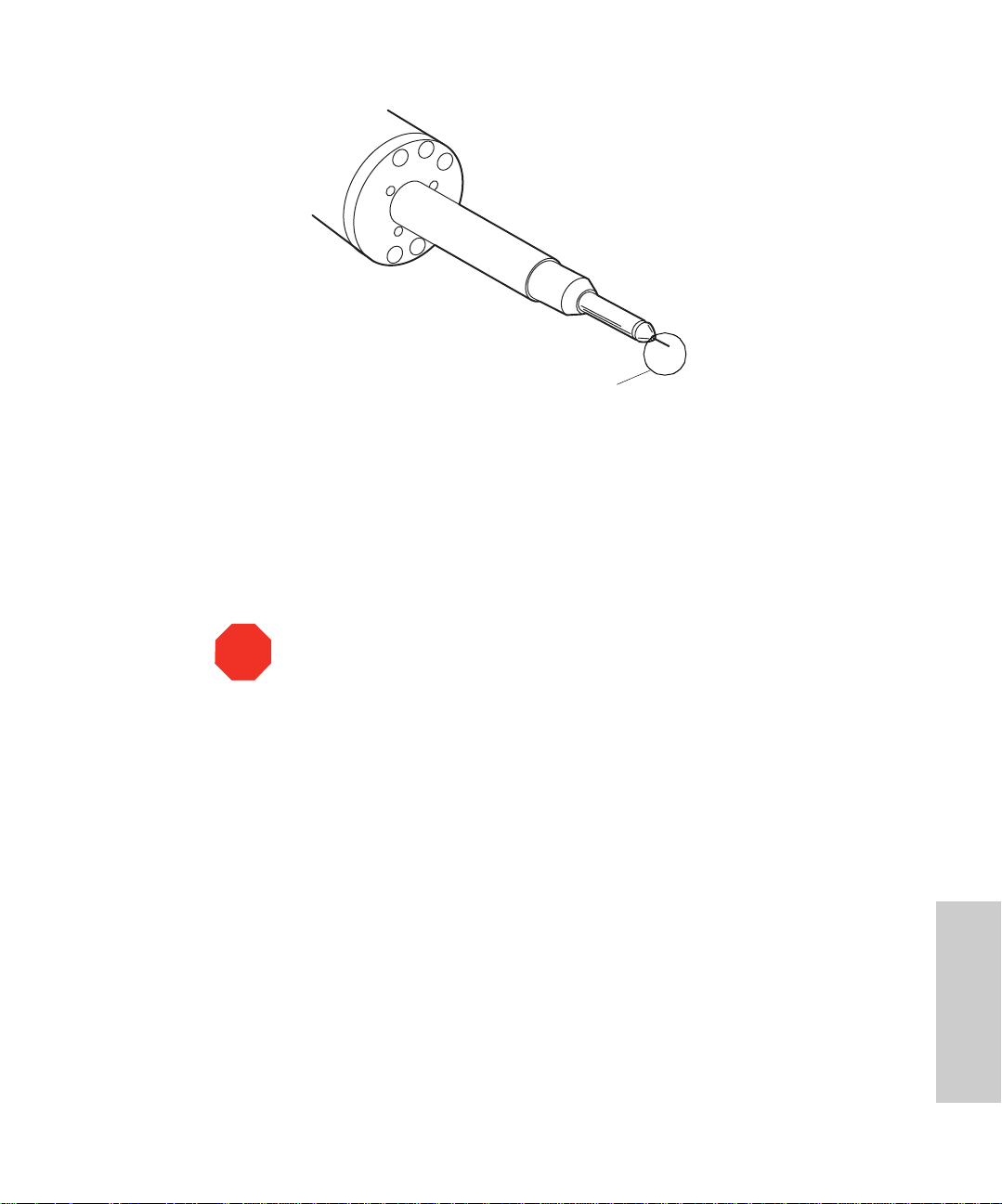

5-16 ESI Probe Tip with Capillary Protruding 0.5 mm...........................95

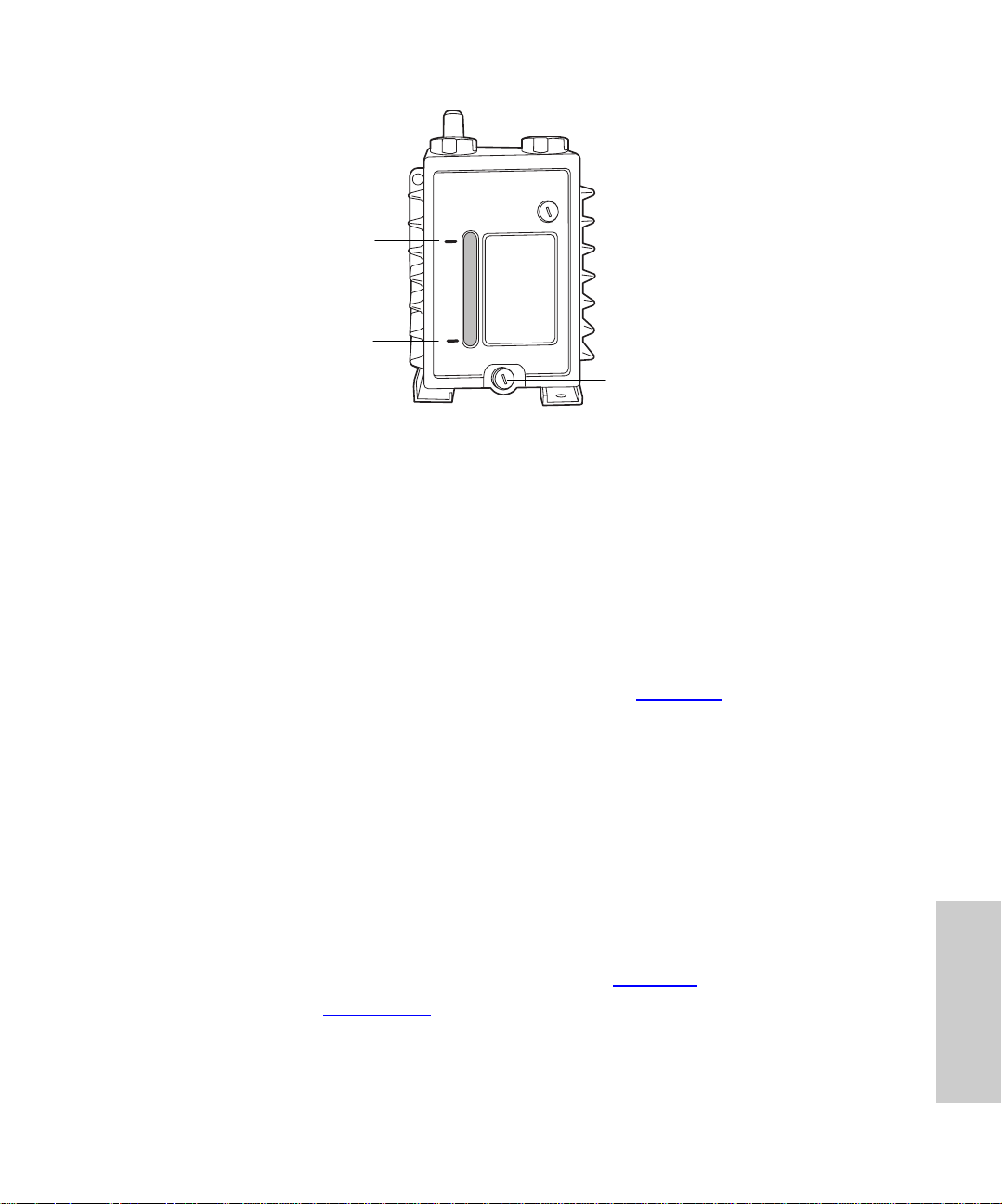

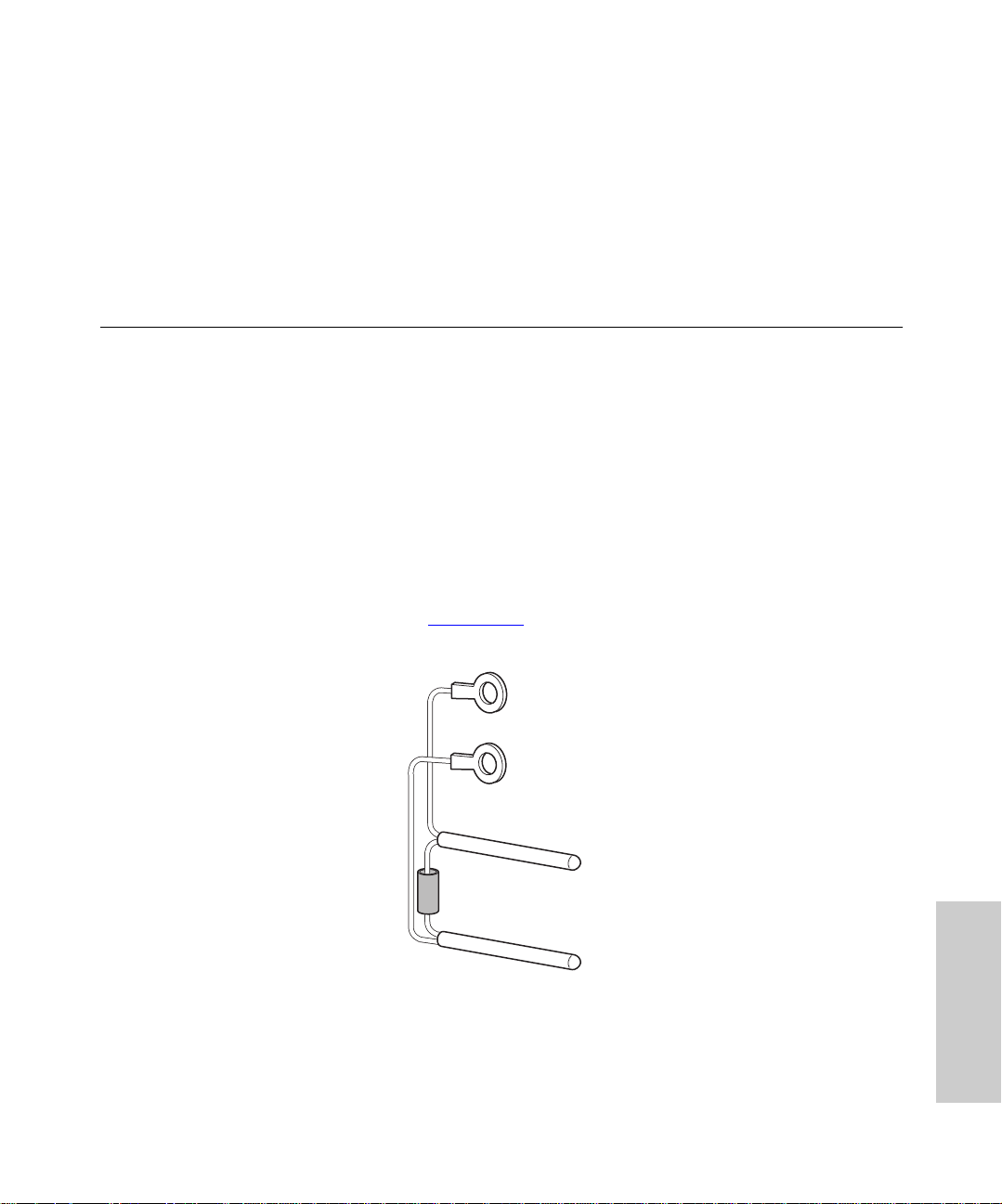

A-1 ZQ Mass Detector, Front View ...................................................109

A-2 Installing the Corona Needle ...................................................... 110

A-3 Tune Window ..............................................................................110

A-4 Tune Window Showing Options List with ESCi Mode Selected .111

A-5 Tune Window, Diagnostics Page ................................................112

A-6 Selecting the ESCi+ or ESCi- Ionization Mode ...........................112

A-7 Selecting the Ion Mode in the MassLynx Peak Editor ................ 113

A-8 Tune Window as it Appears During ESCi Operation ..................114

A-9 Function List Editor Window (Blank) ...........................................115

A-10 Function:n MS Scan Dialog Box ................................................. 115

A-11 Function List Editor Window Showing Specified Functions ........116

A-12 ESCi Mode Disabled ...................................................................117

A-13 Daidzein (m/z = 255.2 [M + H] and 253.2 [M – H]) ..................... 117

List of Figures 20

Page 21

List of Tables

2-1 Installation Site Requirements ......................................................31

3-1 ES+ Source Page Parameters ......................................................43

3-2 Source and Desolvation Temperature Settings........................ 44

3-3 Analyser Page Parameters...................................................... 46

3-4 APCI+ Source Page Parameters ............................................. 49

4-1 Recommended Calibration Acquisitions Setup Parameters ......... 65

4-2 Calibration Failure Troubleshooting ......................................... 69

5-1 Maintenance Schedule .................................................................74

6-1 Hardware Troub lesh ooting .................................. ......... ............... 101

A-1 HPLC Conditions ........................................................................118

A-2 MS Conditions ............................................................................ 118

B-1 ZQ Detector Operational Specifications .....................................119

B-2 ZQ Detector Environmental Specifications................................. 120

B-3 ZQ Detector Dimensions ............................................................ 120

B-4 ZQ Detector Electrical Specifications......................................... 120

B-5 ESCi Environmental Specifications............................................ 121

B-6 ESCi Electrical Specifications..................................................... 121

C-1 Fuses .......................................................................................... 122

C-2 Probe Components..................................................................... 122

C-3 Vacuum Components................................................................. 123

C-4 Valves and Flow Meters ............................................................. 124

C-5 Kits........................................... ..................................... .......... .... 125

C-6 Power Supplies........................................................................... 125

List of Tables 21

Page 22

C-7 Source and Analyser Components............................................. 126

C-8 Washers, Screws, and Nuts....................................................... 127

C-9 Miscellaneous Components........................................................ 128

List of Tables 22

Page 23

Preface

The Waters Micromass ZQ Detector Operator’s Guide descr ibe s procedures for

unpacking, installing, using, mai nta ining, and troubleshooting the Waters

ZQ™ Detector. Its appendixes ex pl ain how to use the optional ESCi™ Multi-Mode

Ionization Source, and list instrument specifications, accessories, and spare part s.

This guide is intended for individuals who need to install, operate, maintain, and/or

troubleshoot the Micromass

ZQ Detector.

®

Organization

This guide contains the following:

Chapter 1

Chapter 2

liquid line, gas, signal, and other hardware connections.

Chapter 3

calibrate it.

Chapter 4

in MassLynx™.

Chapter 5

Chapter 6

Appendix A

describes the instrument, including its features and options.

describes how to unpack and install the instrument and how to make power ,

describes how to configure the instrument, start it operating, and tune and

describes how to set up a calibration file and specify calibration parameters

explains routine maintenance procedures.

describes troubleshooting procedures.

explains how to use the ESCi Multi-Mode Ionization Source option.

Micromass®

Appendix B

Appendix C

presents instrument specifications.

lists recommended and optional accessories and spare parts.

Related Documentation

Waters Licenses, Warranties, and Support: Provides software license and warranty

information, describes training and extended support, and tells how Waters handles

shipments, damages, claims, and returns.

Online Documentation

MassLynx Help

dialog boxes f or the base software and software options. Also includes reference

information and procedures for performing all tasks required to use MassLynx software.

Included as part of the MassLynx software.

: Describes all MassLynx windows, menus, menu selections, and

23

Page 24

Printed Doc um entation for Base Product

MassLynx User’ s Guide

MassLynx Interfacing Guide

MassLynx Security User’s Guide

MassLynx 4.0 Guide to Inlet Control

MassLynx 4.0 Guide to ZQ Data Acquisition

Wate rs Micro mass ZQ wit h MassLynx v4.0 Software a nd Instrument Verification

Procedure

Related Adobe Acrobat Reader Documentation

For detailed information about using Adobe® Acrobat® Reader, see the Adobe Acrobat

Reader Online Guide. This guide covers procedures such as viewing, navigating, and

printing electronic documentation from Adobe Acro bat Reader.

Printing This Electro nic Docu men t

Adobe Acrobat Reader lets you easily print pages, page ranges, or the entire document by

selecting File > Print. For optimum print quantity, Waters recommends that you specify a

PostScript

resolution.

®

printer driver for your printer. Ideally, use a printer that supports 600 dpi print

Documentation Conventions

The following conventions can be used in this guide:

Convention Usage

Purple

Italic Italic indicates information that you supply such as variables. It also

Courier

Courier Bold

Purple text indicates user action such as keys to press, menu selections, and commands. For example, “Click Next to go to the next

page.”

indicates emphasis and document titles. For example, “Replace

file_name with the actual name of your file.”

Courier indicates examples of source code and system output. For

example, “The SVRMGR> prompt appears.”

Courier bold indicates characters that you type or ke ys you press in

examples of source code. For example, “At the LSNRCTL> prompt ,

enter set password oracle to access Oracle.”

24

Page 25

Convention Usage

Underlined Blue I ndi cates hypert ext cross-references to a specific chapter, section,

subsection, or sidehead. Clicking this topic using the hand symbol

brings you to this topic within the document. Right-clicking and

selecting Go Back from the shortcut menu returns you to the origi-

nating topic. For example, “Monitoring Readbacks are described in

Section 3.4,

Keys T he word key refers to a computer key on the keypad or keyboard.

Screen keys ref er to the ke ys on the instrument located immediately

below the screen. For example, “The A/B screen key on the 2414

Detector displays the selected channel.”

… Three periods indicate that more of the same type of item can

optionally follow. For e xample, “You can store filename1, filename2,

… in each folder.”

>

Notes

Notes call out information that is helpful to the operator. For example:

Record your result before you proceed to the next step.

Note:

A right arrow between menu options indicates you should choose

each option in sequence. For example, “Select File > Exit” means

you should select File from the menu bar, then select Exit from the

File menu.

Readbacks”

Attentions

Attentions provide information about preventing damage to the system or equipment. For

example:

To avoid damaging the detector flow cell, do not touch the flow cell

STOP

Attention:

window.

25

Page 26

Cautions

Cautions provide information essential to the safety of the operator. For example:

Caution:

To avoid burns, turn off the lamp at least 30 minutes before removing it for

replacement or adjustment.

Caution:

To avoid electrical shock and injury, unplug the power cord before

performing maintenance procedures.

Caution:

To avoid chemical or electrical hazards, observe safe laboratory practices

when operating the system.

26

Page 27

Chapter 1 Ov erview

This chapter describes the Waters® Micromass® ZQ™ Detector, its features and options.

1.1 About the Micromass ZQ Detector

The ZQ Detector is a quadrupole mass analyser that can determine the mass-to-charge

ratio (m/z) of diverse analytes. An HPLC system, or syringe pump, delivers liquid sample

to the instrument’s analyser source. There the sample molecules ionize by means of one

of two ionization modes: electrospray (ESI) or atmospheric pressure chem ical ionization

(APCI). In ESI mode, sample molecules ionize in solution before they reach the source.

On entering the ev acuated source, they begin a desolvation process. In APCI mode, an

electrical discharge inside the source ionizes the sample molecules whereupon they

undergo desolvation.

The ions ultimately reach the quadrupole, which separates them according to their

mass-to-charge ratios. A photomultiplier then detects the mass-separated ions, amplifies

their signals, and sends the mass information to the data syst em.

Probes

An electrospray ionization (ESI) probe or an atmospheric pressure chemical ionization

(APCI) probe introduces the sample to the ion source.

1

Sample Inlet

Either of two methods deliver solvent and sample to the installed probe:

• An HPLC system – Delivers the eluent from an HPLC analysis.

• A built-in syringe pump – Delivers standard solutions or infusions of unknown

samples.

Vacuum System

An external rotary (roughing) pump and an internal split flow turbomolecular pump

combine to create the source vacuum. The turbomolecular pump evacuates the analyser

and ion transfer region.

Vacuum leaks and electrical or vacuum pump failures cause vacuum loss, which

protective interlocks guard against. The system monitors turbomolecular pump speed and

About the Micromass ZQ Detector 27

Page 28

continuously measures vacuum pressure with a built-in Pirani gauge. The gauge also

serves as a switch, discontinuing detector operation when it senses vacuum loss.

A vacuum isolation valve isolates the source from the mass analyser, allo wing routine

source maintenance without venting.

Mass Analyser (Quadrupole)

The mass analyser separates ions by mass-to-charge ratio (m/z).

Data System

The data system collects information from the mass analyser and includes these

components:

• MassLynx™ 4.0 software

• An external workstation

• An embedded PC

MassLynx software controls the workstation-based data system and mass detector

through the detector’s embedded PC. Using MassLynx, you tune the instrument, set up

and run the HPLC system, and acquire and process data. When they are part of the

system, the software also controls the autosampler and the divert and injector valves.

The workstation uses a Windows NT

environment and allows full user interaction with the keyboard or mouse. A network link

communicates between the workstation and the detector’s embedded PC.

®

, Windows® 2000, or Windows XP color graphical

1

MassLynx acquires and stores data from conventional LC detectors simultaneously with

data the mass detector acquires. It can also acquire data from selected systems, like

Waters 996/2996 Photodiode Array Detectors. Consult the MassLynx 4.0 Guide to Inlet

Control for details about MassLynx.

1.2 Theory and Principles of Operation

Electrospray Ionization (ESI)

In ESI, a high electrical voltage charges the eluent as it emerges from a nebulizer,

producing an aerosol of charged droplets. As the solvent evaporates, the droplets shrink,

developing a charge dense enough to eject ions from their s urfaces (ion evaporation). The

mass analyser then sorts the singly or multiply charged ions by mass-to-charge m/z ratio.

The analyser source can accommodate eluent flows of up to 1 mL/min. You can enhance

performance by reducing the rate of eluent flow at the ion source.

Overview 28

Page 29

Atmospheric Pressure Chemical Ionization (APCI)

A heated nebulizer vaporizes the sample. The sample ions then merge with solvent ions in

the atmospheric source, enabling proton transfers between the solvent and sample ions.

APCI generally produces both protonated and deprotonated molecular ions from the

sample. For positive ions, this ionization occurs by means of a proton transfer mechanism.

For negative ions, the mechanism is proton abstraction.

1.3 MassLynx 4.0 Software

MassLynx 4.0 software permits these major operations:

• Configuring the instrument

• Creating HPLC inlet and MS methods that define operating parameters for a run

• Tuning and calibrating the mass detector

• Running samples

• Monitoring the run

• Acquiring data

• Processing data

• Reviewing data

• Printing data

1

See the MassLynx 4.0 Guide to Inlet Control and MassLynx Help for more information on

installing and using MassLynx software.

MassLynx 4.0 Software 29

Page 30

Chapter 2 Installing

This chapter describes how to unpack and install your Waters Micromass ZQ Detector.

Figure 2-1

summarizes these procedures.

Installation

Begins

Select and Prepare

Appropriate Site

Unpack and Inspect

Install Rotary Pump

Install Oil Retur n

Connection Kit

Connect N2 and

Exhaust

Connect Rheodyne

Injector Tubing

Install

ESI Probe

Connect

Workstation

Set Up

Syringe Pump

2

Figure 2-1 Installing the Detector

Installation

Complete

30

Page 31

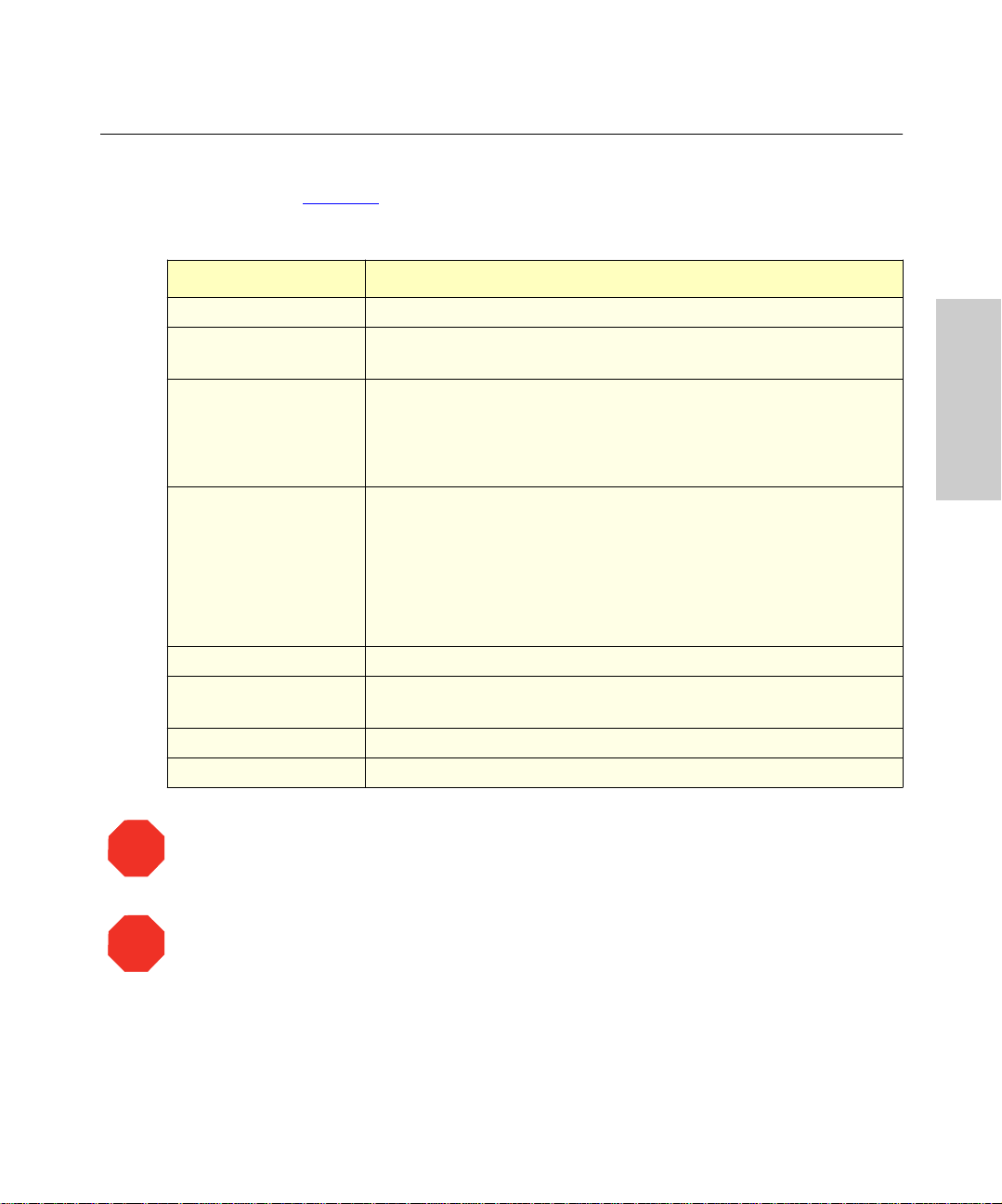

2.1 Site Selection and Power Requirements

Install the detector on a stable, level, and appropriately clean surface that meets the

specifications in Table 2-1

Table 2-1 Installation Site Requirements

Factor Requirement

Temperature range 15 to 28 °C (59 t o 82.4 °F)

Relative humidity

range

Bench space Width: 15.2 in. (38.1 cm)

Clearance Rear: 4.75 in. (120 mm)

Power requirements Grounded AC, 230 V, 50/60 Hz

Electromagnetic fields No nearby source of electromagnetic noise, such as NMR

Static electricity Negligible

Vibration Negligible

.

20 to 80%, noncondensing

Depth: 26 in. (66.1 cm)

Height: 23 in. (57.2 cm)

Weight: 210 lb. (95.3 kg)

Right side: 20 in. (0.5 m) to allow for service access.

Movable equipment can be located as close as 4.75 in.

Note:

(120 mm).

Left side: 0.0 in./mm

Top: 11 in. (28 cm)

systems or magnetic sector mass spectrometers

2

STOP

STOP

Attention:

top, sides, and rear of the instrument.

Attention:

before installing the instrument. Read ings of less than 208 VAC indicate the need for a

step-up transformer.

To avoid overheating the instrument, allow the prescribed clearances at the

To avoid damaging the instrument, measure the voltage at the 230 VAC outlet

Installing 31

Page 32

2.2 Unpacking and Inspecting

The Waters Micromass ZQ system is shipped in several cartons. Among them, they

contain these items:

• Micromass ZQ Detector with Startup Kit

• Rotary pump

• MassLynx wo rk stati o n

• MassLynx 4.0 documentation set

• Waters Micromass ZQ Detector Operator’s Guide

Required Material

Utility knife or scissors

Procedure

1. Note any tipping or shock indicators on the cart ons that shipping might have

triggered. Also, inspect the carton for damage.

2. Cut and remove the straps that secure the large carton.

3. Lift the carton off the pallet.

4. Remove foam packing material from the top of the instrument.

5. Remove the Star tup Kit, and set it aside.

6. Lift the detector from the foam support on the pallet and carefully set the unit down

on a bench.

Caution:

and place it on the bench.

The instrument should overhang the bench top by several inches to allow the

Note:

waste tube, which extends from the lower-right corner, a straight descent to the

liquid waste container.

7. Che ck the Star tup Kit contents against the accompa nying parts list to confirm that

all items are included.

8. O pen the carton containing the rotary pump, then remove the packing material and

Star tup Kit.

9. Care fully remove the rotary pump, and set it temporarily down on a level surface.

At least four people must lift the instrument from its shipping pallet

2

Unpacking and Inspecting 32

Page 33

Contacting Waters Technical Service

Inspect all items for damage. Immediately report any shipping damage to both the carrier

and Waters. Nort h American customers who report damage should cont act Waters

Technical Ser v ice at 800 252-4752. All others should call their local Waters subsidiary or

Waters corporate headquarters in Milford, Massachusetts (U.S.A.).

2.3 Installing the Detector

This section describes how to install the Waters Micromass ZQ 2000 and ZQ 4000

Detectors.

2.3.1 Installing the Rotary Pump

2

Attention:

STOP

1. Place the rotary pump on the floor, within 5 feet of the instrument. Place the PTFE

2. Fill the pump with oil:

starting it.

drip tray beneath the pump.

a. Rem ove the fille r plu g.

b. Pour oil into the pump until the level reaches the MAX mark on the bezel at the

oil-level sight glass. If the level exceeds the MAX mark, remove the drain plug,

and let the excess oil drain (Figure 2-2

c. After a few minutes, recheck the oil. If the level is now below the MAX mark, add

the appropriate amount of oil.

d. Refit the oil filler plug. Finger tighten it. Do not overtighten it.

The rotary pump is shipped without oil. You mus t f ill it wi th o il before

).

Oil Fi ller Plug

MAX

MIN

Figure 2-2 Pump Oil Level

Installing 33

Page 34

Use Ultragrade 19 or Inland Q45 oil only. Refer to the manufacturer’s manual

Note:

for more information about filling the pump with oil.

3. Attach the NW 25 tee, included in the Start up Kit, to the inlet of the rotary pump

using the NW25 center ring and clamp (Figure 5-1

4. Attach a length of 1-inch ID vacuum hose to each open por t on the NW25 tee. Use

the NW25 flanges, center rings, and clamps provided in the Startup Kit.

5. Con nect the opposit e ends of the two lengths of vacuum hose to the two straight

NW25 vacuum ports on the detector’s rear panel. Use NW25 flanges, center rings,

clamps, and elbows, as necessary.

6. Remove the nozzle fitting on the pump exhaust port, and replace it with the NW25

flange and O-ring from the Startup Kit.

Ensure the NW25 flange is tight. Pump vibration can loosen it, causing oil to

Note:

leak.

7. Con nect the oil mist filter assembly to the pump exhaust port. Use an NW25 center

ring and clamp.

8. Con nect an NW25 nozzle fitting to the oil mist filter assembly. Use an NW25 center

ring and clamp.

9. Con nect the 12-mm clear PVC exhaust tubing to the NW25 nozzle fitting. Secure

the tubing with a hose clamp.

10. R ou te the open end of the exhaust tubing to a suitable exhaust vent.

11. Remove the drain plug and bonded seal from the oil mist filter housing. Save the

drain plug for future use.

12. Connect the female end of the rotary pump power cord to the connector on the

rotary pump relay box. Connect the male end of the power cord to the rotary pump

connector on the instrument’s rear panel.

13. T urn the power switch to On.

).

2

The pump will not start at this time. It is controlled by the system software.

Note:

2.3.2 Installing the Oil Return Connection Kit

The oil return connection kit collects excess oil from the oil mist filter housing and returns it

to the rotary pump oil reservoir.

1. Insta ll the drain adaptor and bonded seal onto the oil mist filter drain port

(Figure 2-3

).

Installing the Detector 34

Page 35

1. E1/E2M Pump

2. Filters

3. Wire Mesh

4. Circlip

5. O-Ring

6. Gas Ballast Adaptor

7. Bonded Seal

8. Hose Adaptor

9. Bonded Seal

10. Banjo Bolt

Figure 2-3 Fitting the Gas Ballast and Hose adaptors to the Rotary Pump

2. Remove the circlip , wire mesh, and filters from the gas ballast inlet on the pump.

3. Insert the gas ballast adaptor and O-ring into the gas ballast inlet por t on the pump.

4. Connect the hose adaptor to the gas ballast adaptor. Use t he banjo bolt and the two

bonded seals.

5. Estimate how much fle xible oil return tubing you need to loosely connect the oil mist

filter housing’s drain port to the pump’s inlet port. When fitted, the tube must be free

of kinks or tight bends.

6. Cut the tubing, ensuring the cut ends are burr-free and square.

7. Lu bri cate the restrictor with oil, then inser t it into one end of the tube.

8. Connect one end to the drain adaptor on the oil mist filter housing, and the other end

to the hose adaptor.

9. Secure the ends of the tube with hose clips.

2

2.3.3 Connecting the Nitrogen Supply and Exhaust

1. Con nect one end of a length of the 6-mm PTFE tubing to the N2 In port on the rear

of the instrument (Figure 2-4

).

Installing 35

Page 36

N2 In Port

N

Rotary Pump

Po wer Connection

Figure 2-4 ZQ Detector Rear Panel

2. At tach a nitrogen regulator to the nitrogen supply, and install the 6-mm stud

(Figure 2-5

) into the regulator outlet.

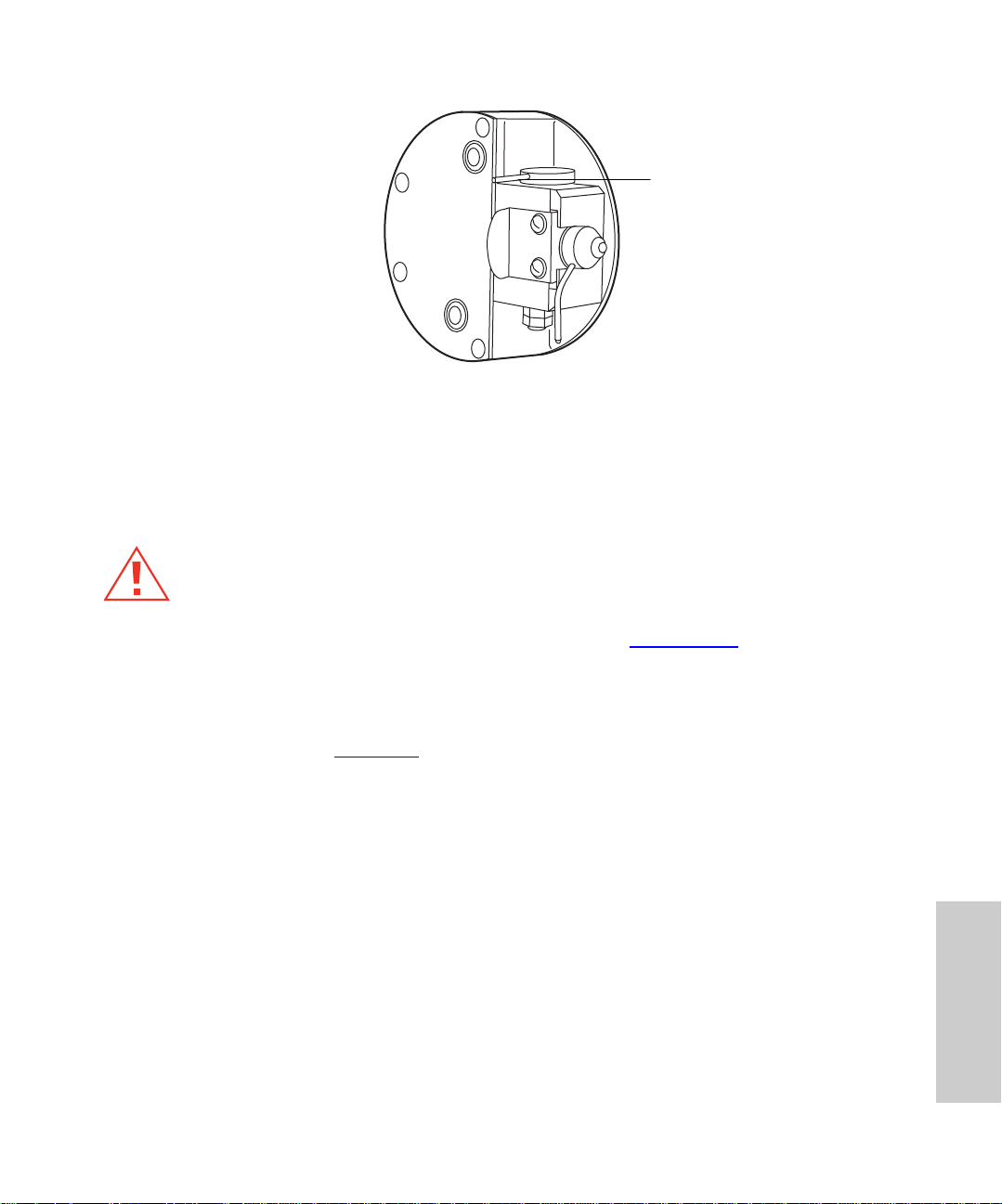

Figure 2-5 Nitrogen Stud

2

Vacuum Ports

Exhaust

2

3. Con nect the free end of the 6-mm PTFE tubing to the 6-mm stud.

4. Locate the drying gas exhaust bottle (Figure2-6

5. Cut a length of 10-mm tubing long enough to connect the instrument to the drying

gas exhaust bottle. Connect one end of the tubing to the exhaust por t on the rear

panel. Connect the other end to one of two ports on the dryin g gas exhaust bottle.

6. Cut a second length of 10-mm tubing long enough to connect the dr ying gas

exhaust bottle to the exhaust vent. Insert one end of the tubing into the remaining

port on the dr yin g gas exhaust bottle. Route the other end to the exhaust vent.

) in an accessible area.

Installing the Detector 36

Page 37

Figure 2-6 Drying Gas Exha ust Bottle

2

Attention:

STOP

7. Route the PTFE waste tubing from the detector’s lower-right corner to a suitable

liquid waste container.

nitrogen, the other for the rotary pump. Vent them to atmosphere through

separate exhaust lines. Oil mist can seriously damage the instrum ent when

the nitrogen exhaust line connects with the rotary pump exhaust line. Your

warranty does not cover damage caused by routing exhaust lines incorrectly.

The instrument requires two separate exhaust systems, one for

2.3.4 Connecting the Rheodyne Injector (for Manual Injections)

Refer to Figure 2-7 for this pr ocedure .

1. Con nect the PTFE waste tube to injector por t 5.

2. Insta ll the needle port fitting onto injector port 6.

3. Connect the 10-µL injection loop between injector ports 1 and 4.

4. Connect the LC system tubing to injector port 2.

Installing 37

Page 38

2

3

(To Source)

4

Figure 2-7 Rheodyne Injector

2.3.5 Installing the ESI Probe

1

6

2

5

Refer to Figure 2-8 for this proced ure .

1. Connect the PTFE tubing from the probe adjustment flange to the desolvation gas

port on the front panel.

2. Remove the protective sleev e, if fitted, from the electrospray probe tip.

3. Slide the probe into the hole in the probe adjustor plate until the probe body rests on

the probe adjustment flange. The probe identification contacts must touch the

screws on the probe adjustment flange.

4. Secure the probe with the two knurled thumbscrews.

5. Connect the 4-mm PTFE tubing from the probe to the nebulizer gas port.

6. Con nec t the electr ic al lea d from the probe to the capillary connector on the front

panel.

Installing the Detector 38

Page 39

Desolvati on Ga s Port

Source Cable

Nebulizer Gas Port

Probe Adjustor

Probe Cable

Knurled Thumbscrews (2)

Probe

Flange

Source Cover Clip

Figure 2-8 ESI Pr obe in S itu

2.3.6 Connecting the Workstation

Waters ships the workstation with preinstalled MassLynx software. Before connecting the

workstation to the instrument, set it up according to its accompanying instructions. You

should locate the workstation within 16 feet (5 meters) of the instrument.

1. Co nnect one end of the network cable to the appropriate port on the rear panel of

the detector.

2. Co nnect the other end of the network cable to the port labele d ZQ on the

workstation rear panel.

Probe Adjustor Plate

Source Cover

Source Cover Clip

2

Caution:

installation procedures in the previous sections.

Do not connect the instrument’s power supply cord until you complete the

Installing 39

Page 40

To connect the instrument to the power source:

1. Sele ct the correct power cord for your location.

2. Connect the female end of the power cord t o the power port on the rear panel of the

instrument.

2.3.7 Preparing the Syringe and Syringe Pump

This section refers to the 250-µL Hamilton syringe, various syringe fittings, and the API

Setup Solution (polypropylene glycol/reserpine/cyclodextrin) found in the Startup Kit.

1. Flush the syringe three times with methanol or a volume-to-volume mixture of 70%

methanol : 30% water .

2. Lo ad the syrin ge with the setup solution, and connect the Rheodyne 9013 needle

port fitting to the PEEK

3. Clip the ground cable (with the plug-in clip), located on the lower-right side of the

front panel, into the syringe needle.

union, finger tightening it.

2

Caution:

4. Fit the syringe into the syringe pum p, and set the syringe stop accordingly

(Figure 2-9

).

Caution:

certain syringe types from breaking. Nevertheless, as added protection

against syringe breakage, you should set the syringe stop adjustor. This

prevents the syringe plunger from traveling its full stroke inside the syringe

barrel, reducing the potential for breakage.

To avoid electrical shock, always ground the needle.

The syringe pump includes a positive syringe stop to prevent

Needle Port

Syringe

Syringe Stop Adjustor

Figure 2-9 Syringe Pump

TP01745

Installing the Detector 40

Page 41

Chapter 3 Tuning

Tuning involves adjusting source settings, analyser settings, and gas flows to produce

optimal peak intensities.

After you tune, calibrate the instrument in electrospray (ESI) mode, even if you intend to

operate it in APCI mode. See Section 3.3.3

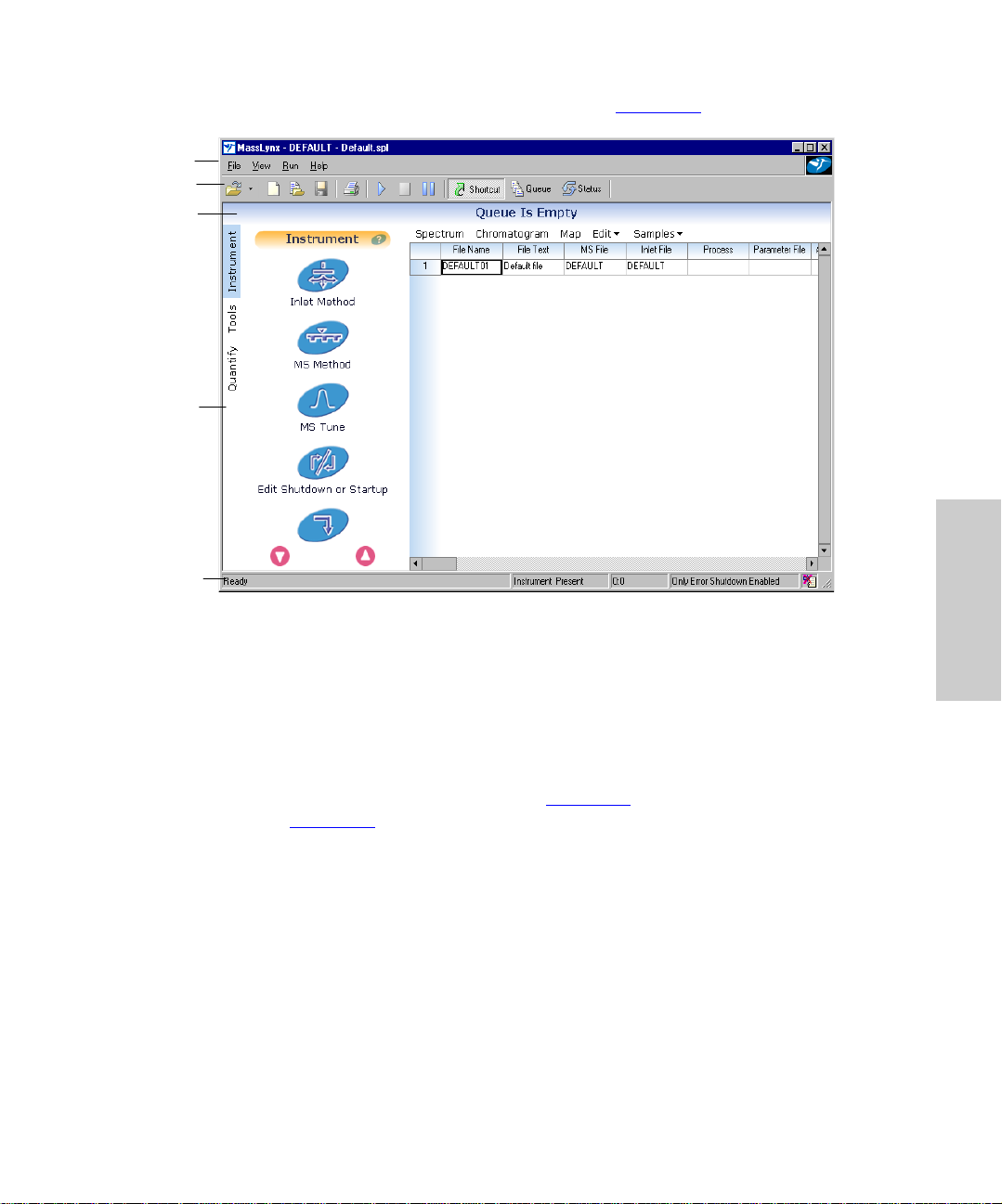

3.1 Opening MassLynx and Starting the Instrument

1. Dou ble-click the MassLynx V4.0 desktop icon to open the application. The

MassLynx Login dialog box appears (Figure 3-1

for details about tuning in APCI mode.

).

3

Figure 3-1 MassLynx Login Dialog Box

2. Compl ete the Logon Name, Password, and Domain fields .

The Login dialog box appears only when you enable MassLynx security. Otherwise,

Note:

the MassLynx Main window (Figure 3-2

desktop icon. See the MassLynx Secu rity User’s Guide (version 4.0) for details about

enabling MassLynx security.

) appears after you click the MassLynx V4.0

Opening MassLynx and Starting the Instrume nt 41

Page 42

3. Click OK. The MassLynx Main window appears (Figure 3-2).

Menu Bar

Toolbar

Information Bar

Shortcut Bar

Status Bar

3

Figure 3-2 MassLynx Main Window

After initiating, the Main window displays “Instrument Present” in the status

Note:

bar.

4. The shortcut bar should appear in the MassLynx Main window, and “Instrument”

should appear at its top. If it fails to appear, click Shortcut, in the toolbar, to open it.

Then click Instrument, at the left edge of the shortcut bar.

5. Select MS Tune from the Main window (Figure 3-2

window (Figure 3-3

).

) shortcut bar to open the Tun e

Tuning 42

Page 43

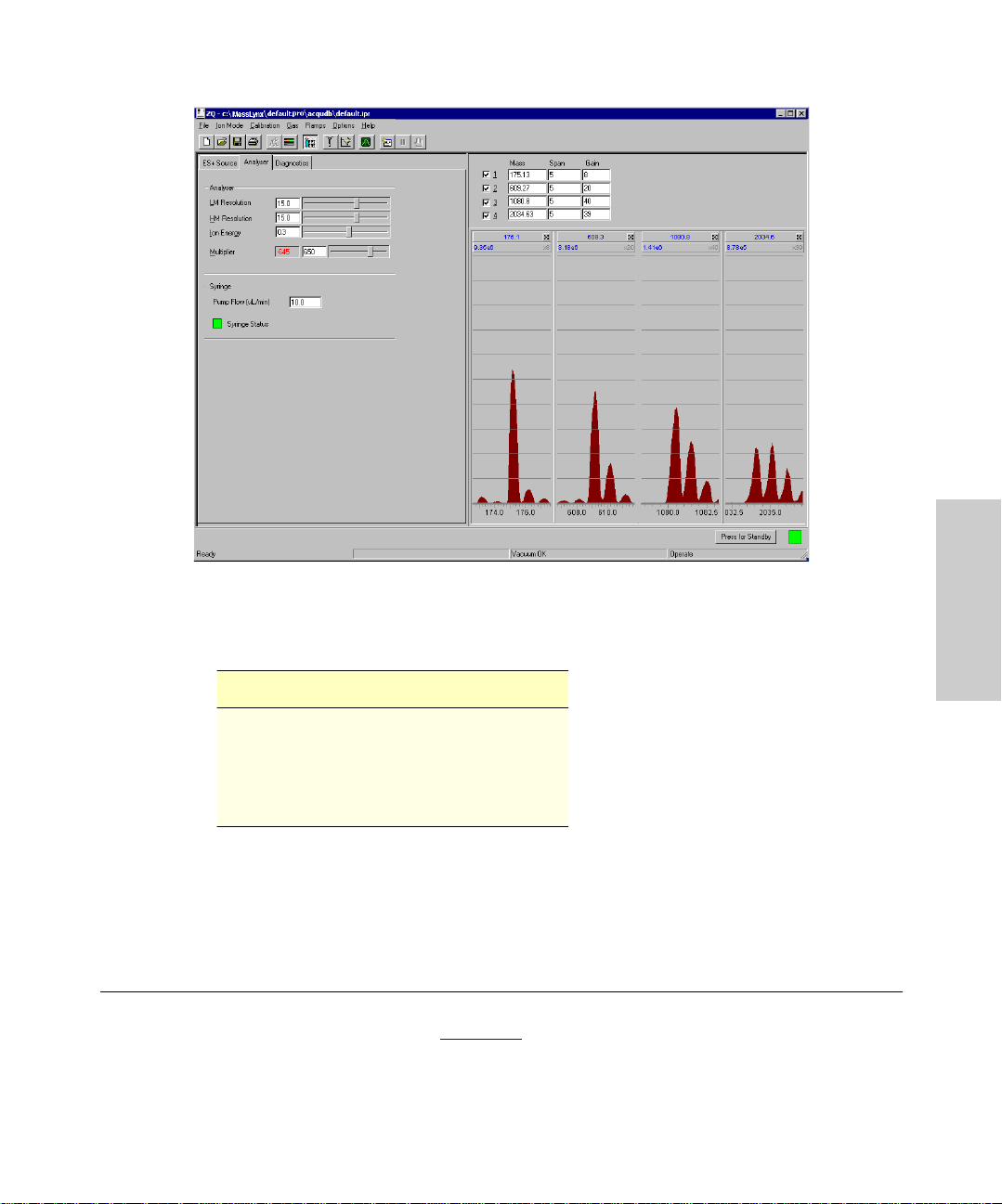

Figure 3-3 Tune Window Displaying the ES+ Source Page

3.2 Tuning in ESI Mode

Table 3-1 describes the Tune window’s ES+ Source page parameters.

The voltage parameters shown in this table optimize sensitivity and s tab ility. The

Note:

temperature and flow rate parameters control the extent of solvent evaporation and adduct

formation.

Table 3-1 ES+ Source Page Parameters

Parameter Description

Capillary voltage Enhances or suppresses ion density by supplying excess charge

to droplets. Optimal voltages: 2 to 4 kV for positive ions and 2 to

3 kV for negative ions.

Cone voltage Helps draw ions into the first vacuum region (20 to 70 V optimal).

Extractor voltage Focuses ions toward the hexapole RF lens (3 to 10 V optimal).

Increasing voltage can induce fragmentation.

RF Lens voltage Focuses ions toward the center of the quadrupole (~0.5 V).

3

Tuning in ESI Mode 43

Page 44

Table 3-1 ES+ Source Page Parameters (Continued)

Parameter Description

Source temperature See Table 3-2.

Desolvation

temperature

Desolvation gas flow Optimizes gas flow depends on mobile phase composition and

Cone gas flow Helps reduce adduct ions and keep the sample cone clean (50

See Table 3-2.

flow rate (>100 L/hr).

to150 L/hr).

Source and Desolvation Temperatures

The Source and Desolvation temperature settings control desolvation for a specified flow

rate. Table 3-2

Table 3-2 Source and Desolvation Temperature Settings

gives temperature ranges for specific flow rates.

HPLC Flow

Rate (µL/hr)

<100 80 to 100 100 to 350

100 to 250 100 to 130 350 to 400

250 to 1000 130 to 150 400 to 450

Source Temperature oC Desolvation Temperature oC

3.2.1 Specifying Parameter Settings on the ES+ Source Page

1. Click (API Gas) in the Tune window to toggle the nitrogen flow to On.

Attention:

STOP

2. Make sure the instrument is operating, noting whether peak activity appears in the

Tune window’s Peak Display area (Figure 3-3

(indicated by no peaks), click Press for Operate.

supply once it has been shut off. Otherwise, the sudden inrush of gas can

damage the flow meter.

You must toggle API gas to Off before reopening the nitrogen

). If the instrument is not operating

3

Tuning 44

Page 45

3. Click the ES+ Sou rce ta b, and specify these suggested star ting parameters in the

corresponding fields of the ES+ Source page.

Parameter Suggested V alue

Capillary (kV) 3.5

Cone (V) 60

Extractor (V) 3

RF Lens (V) 0.5

Source Temp (oC) 80

Desolvation Gas Flow (L/hr) 300

Desolvation Temp (oC) 150

Cone Gas Flow (L/hr) 50

Attention:

STOP

4. Sele ct all four Peak Editor fields, and enter these mass assignment values.

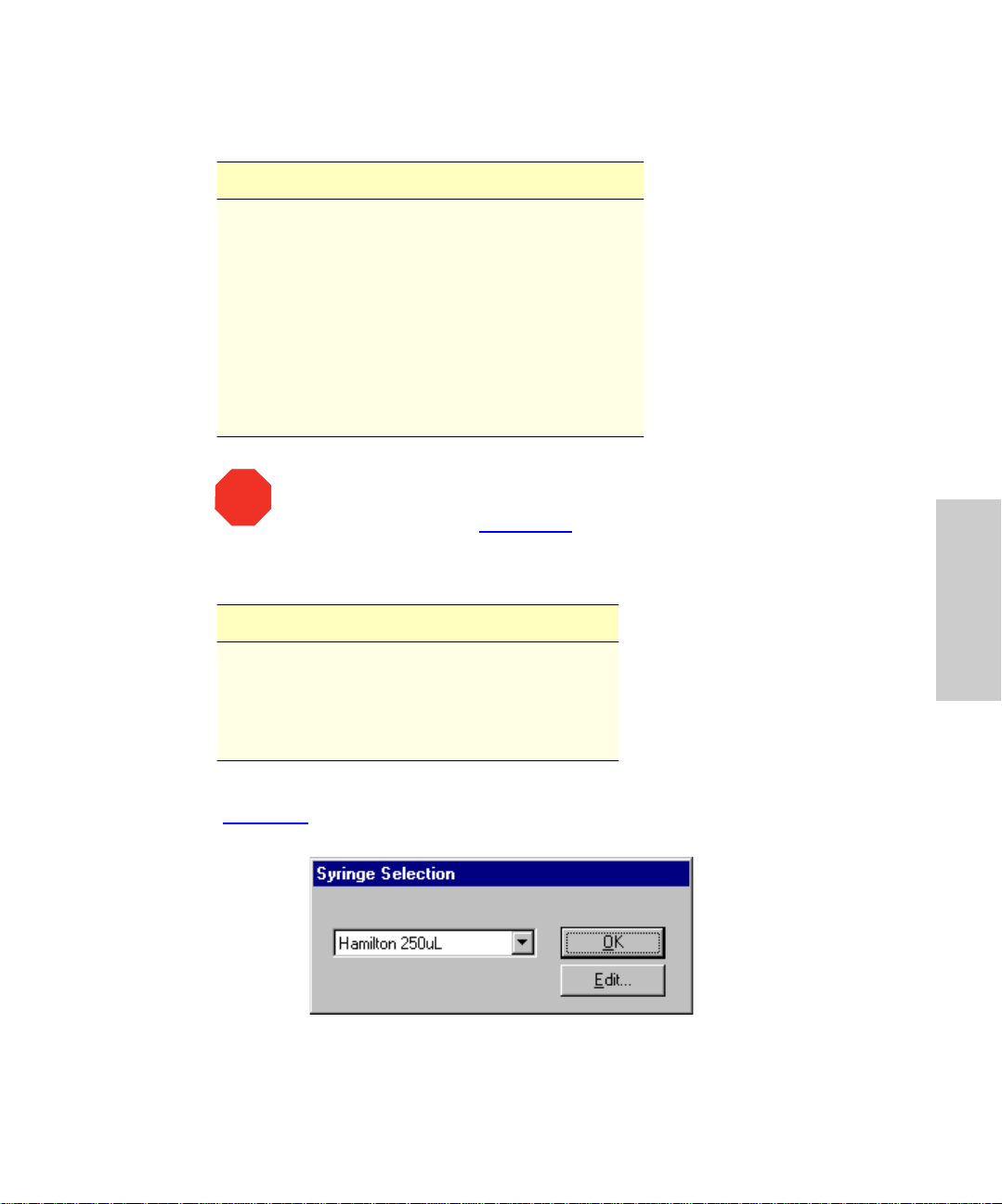

5. Select Options > Syringe Type. The Syringe Selection dialog box appears

(Figure 3-4

gas flow, desolvation temperature, and cone gas flow reach their setpoints

before proceeding. See Section 3.4

Mass Span Gain

175.1 5 10

609.3 5 10

1080.8 5 10

2034.6 5 10

).

Monitor readbacks, letting the source temperature, desolvation

for details about monitoring readbacks.

3

Figure 3-4 Syringe Selection Dialog Box

Tuning in ESI Mode 45

Page 46

6. Ensure th e drop-down list displays Hamilton 250uL, then click OK.

7. Set the syringe pump to deliver 10 µL/min by entering that rate in the Pump Flow

field of the Analyser page (Figure 3-5

8. C l ick (Syringe pump) to infuse the startup s olution into the source.

9. Click the Analyser tab, and ensure the syringe pump flow rate is 10 µL/min.

10. Turn the probe adjustor (see Figure 2-8

peak intensities.

11. A dju st the capillar y, cone, extractor, and RF lens voltages to optimize peak

intensities.

).

) in one direction or the other to optimize

3.2.2 Specifying Parameter Settings on the Analyser Page

Analyser settings optimize mass peak resolution. With span settings at 5, the bases of

mass peaks as they appear on the Tune window Analyser page should measure 1 da.

The parameters LM Resolution, HM Resolution, and Ion Energy optimize resolution.

Note:

Table 3-3 describes the Tune window’s Analyser page parameters.

Table 3-3 Analyser Page Parameters

Parameter Description

LM Resolution

HM Resolution

Ion Energy (V) Decreases resolution. Set between –1 and 3 V, as low as

Multip lie r (V) Modifies gain (attenuation). Settings between 400 and 450

1. Click the Analyser tab. The Tune window Analyser page appears (Fi gure 3-5

Affect mass peak concentration. Usually, 15, an arbitrary

unit, yields adequate mass resolution. Increasing the value

lowers sensitivity; decreasing it enhances sensitivity.

possible without reducing peak intensity.

yield a suitable signal-to-noise balance.

3

).

Tuning 46

Page 47

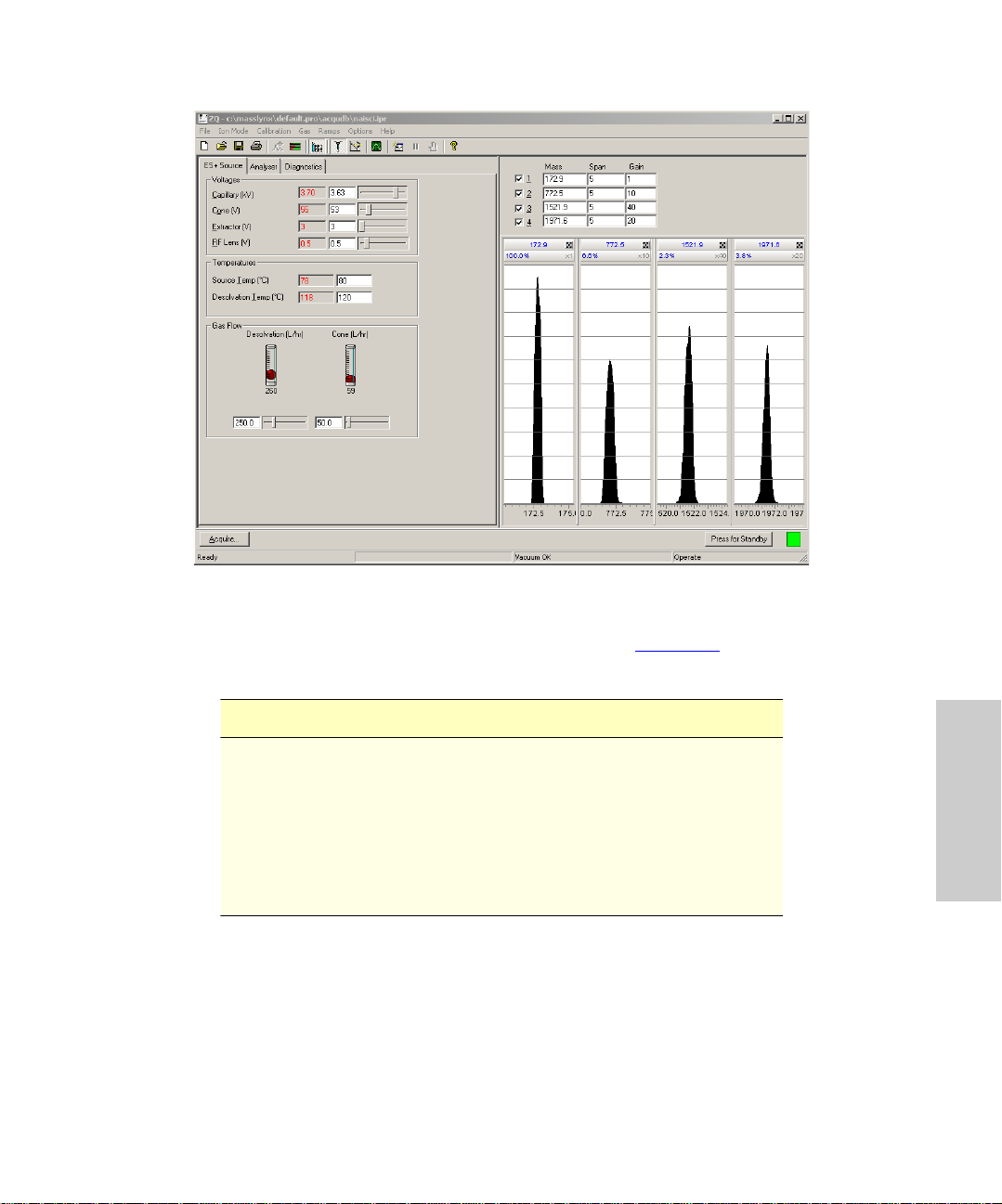

Figure 3-5 Tune Window Displaying the Analyser Page

2. Specify these suggest ed starting parameters in the Analyser page fields.

Parameter Suggested V alue

LM Resolution 15

HM Resolution 15

Ion Energy 0.3

Multiplier 650

If you change HM and/or LM Resolution after calibrating the instrument, you should

Note:

recalibrate. Otherwise, any data the instrument acquires could fall outside the calibration

mass ran ge.

3.3 Tuning in APCI Mode

After you tune and calibrate (see Chapter 4 for calibration information) in ESI mode, you

may tune for APCI operation. This entails preparing the source, installing a tee fitting

upstream of the probe, and specifying APCI parameters.

3

Tuning in APCI Mode 47

Page 48

3.3. 1 Prepa ring the Source for APCI Operation

To prepare the source for APCI tuning when the instrument is in ESI mode:

1. Prepare t he syr inge according to the procedure in Section 2.3.7

Setup Solution from the Start up K it.

2. Click Press for Standby on the lower right of the Tune window.

3. Disconnect the nebulizer gas line and both electrical connections from the front

panel.

4. Remove the ESI probe.

5. Insert the APCI probe into the source, tightening the two thumbscrews.

6. Con nect the APCI nebulizer and desolvation gas lines at the front panel.

7. O pen the source enclosure cover.

Caution:

temperature, even with the source enclosure removed.

8. Remove the blanking plug from the corona pin mounting contact, and fit the corona

discharge pin (Figure 5-9

the sample cone.

9. Close the source enclosure cover.

10. Connect the electrical lead to the Source/Probe receptacle on the front panel.

11. C lick Press for Operate.

The source is now ready for APCI operation.

The ion source block is hot. It can reach 150 °C, maintaining its set

). Align the tip of the corona discharge pin with the tip of

, loading it with API

3

STOP

Attention:

and the probe inserted.

Do not start the liquid flow until the gas flow and probe heater are switched on

Tuning 48

Page 49

3.3.2 Installing the Tee Fitting

To optimize APCI peaks, temporarily install a tee fitting to merge the sample flow from the

syringe pump with the solvent flow from an HPLC pump. The combined sample/solvent

stream flows into the probe (Figure 3-6

).

Syringe Pump

Flow

Combined Flow

into Probe

Figure 3-6 Combined Flow into the Tee

1. Connect the HPLC pump tubing to injector port 2 (see Figure 2-7

2. Con nec t the capillary from the syringe pum p to one of the tee’s three ports.

3. Con nect a 1/16-in. OD × 0.007 in. ID × 1 M tube between injector por t 3 and a

second tee port.

4. Connect another 1/16-in. OD × 0.007 in. ID × 1 M tube from APCI probe to the tee’s

third port.

HPLC Pump Flow

From Injector Port 3

3.3. 3 Specifying Parameters on t he APCI+ S ource Page

Table 3-4 describes the APCI+ Source page parameters.

Table 3-4 APCI+ Source Page Parameters

Parameter Description

Corona Affects sensitivity. The amount of current required depends on

the polarity of both the compound and mobile phase.

Optimize when mobile phase is present.

APcI Probe Temp Affects sensitivity. Start at 650 oC and reduce in 50o steps,

allowing time for stabilization to take place before reading.

Optimize while mobile phase is flowing.

Desolvation Gas flow rate usually affects signal intensity only marginally.

Nevertheless, adjusting it can suppress chemical background

noise.

Cone Gas Gas flow rate can minimize formation of solvent adducts.

for port positions).

3

Tuning in APCI Mode 49

Page 50

1. Select Ion Mode > APC I+ from the Tune window (Figure 3-3). The APCI+ Source

page appears (Figure 3-7

Figure 3-7 Tune Window Displaying the APCI+ Source Page

).

3

2. C l ick (API Gas) in the Tune window to toggle the nitrogen flow to On.

Attention:

STOP

Note:

operational mode. To remedy this, click

supply once it has been shut off. Otherwise, the sudden inrush of gas can

damage the flow meter.

If you do not observe any peak activity, the instrument may not be in

You must toggle API gas to Off before reopening the nitrogen

Press for Operate

.

Tuning 50

Page 51

3. Specify these suggest ed parameters in the APCI + Sourc e page fields.

Parameter Suggested V alue

Corona (µA) 0.1

Cone (V) 48

Extractor (V) 3

RF Lens (V) 0.0

Source Temp (oC) 120

Desolvation Gas Flow (L/hr) 300

APcI Probe Temp (oC) 500

Cone Gas Flow (L/hr) 50

Attention:

STOP

4. Sele ct all four Peak Editor fields, and enter these mass assignment values.

5. Start the LC pump, specifying a 1 mL/min flow rate.

6. C l ick (Syringe pump) to infuse the star tup solution into the source.

7. Click the Analyser tab, and ensure the syringe pump flow rate is 10 µL/min.

Turn the probe adjustor (see Figure 2-8

intensities.

flow, desolvation temperature, and cone gas flow reach their setpoints. See

Section 3.4

Mass Span Gain

175.1 5 10

609.3 5 10

1080.8 5 10

2034.6 5 10

Before proceeding, let the source temperature, desolvation gas

for information about monitoring readbacks.

) in either direction to optimize peak

3

Tuning in APCI Mode 51

Page 52

3.4 Readbacks

Readbacks report current instrument performance in most of the parameters whose

values you specify on the Tune window’s pages. They appear as red numerals in read-only

fields. These fields are adjacent to those that contain the parameters’ set values. Monitor

readbacks to determine whether the instrument performs to your parameter settings.

MassLynx provides readbacks on all Tune window pages. You can, howev er, prevent them

from appearing on the Source and Analyser pages or limit their display to those that are

out of range.

1. Select Options > Readbacks to open the Readbacks dialog box (Figure 3-8

Figure 3-8 Readbacks Dialog Box

2. Evaluate readbacks, including those on the Diagnostics page (Figure 3-9

Source and Analyser page readbacks should match the parameter values you

specify.

Some readbacks serve a broad diagnostic purp os e and therefore do not

Note:

necessarily mirror their set values. For example, a voltage readback can vary from

its set value when the instrument’s proper operation does not depend on that

voltage. In such a case, whether voltage is at all present is the more critical

measure.

). Most

).

3

Tuning 52

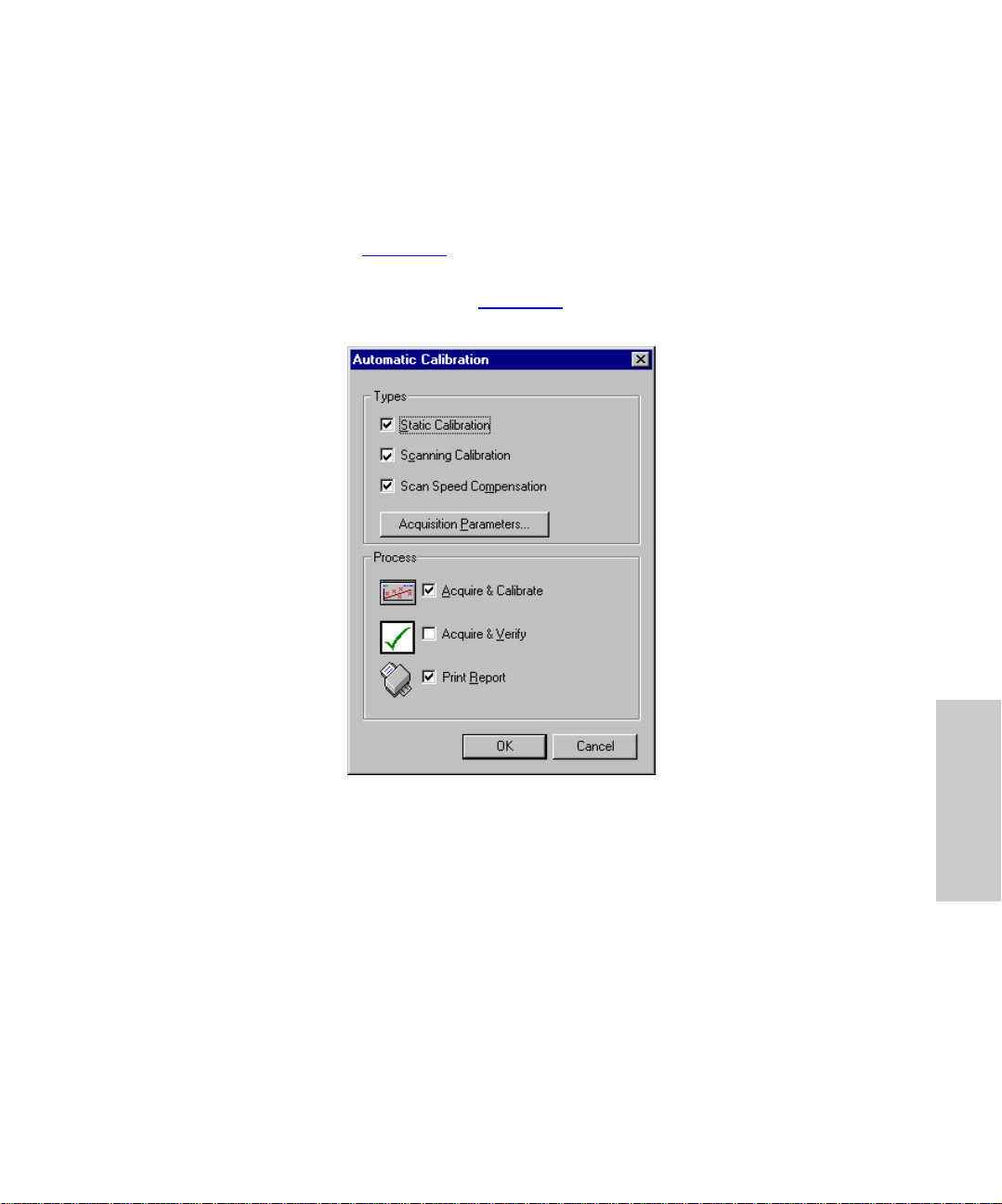

Page 53

Figure 3-9 Diagnostics Page Readbacks

3. Let the ion beam stabilize for 3 to 5 minutes.

4. Monitor for mass peaks, which should appear at approximately the mass values you

specified on the ES+ Source or APCI+ Source page.

3

Readbacks 53

Page 54

Chapter 4 Calibrating

Calibrating the mass scale entails setting up a calibration file and specifying calibration

parameters in MassLynx.

4.1 Setting Up the Calibration File

Before calibrating, you must remove the current calibration file and select a reference file:

1. Select Calibration > Calibrate Instrument from the Tune window (Figure 3-3

Reference File

List

2. Select NaICs2 from the reference file list to choose the reference file, if your ZQ

Calibration window appears (Figure 4-1

Figure 4-1 Calibration Window

Mass Detector is a 2000 model. Select NaICs4 if it is a 4000 model.

).

). The

4

Setting Up the Calibration File 54

Page 55

3. Select File > Open. The Open dialog box appears (Figure 4-2).

Figure 4-2 Open Dialog Box

4. Select Uncal.cal, and click Open. The Calibration window reappears.

5. Make sure the phrase “No calibration” follows the three calibration types: Static,

Scanning, and Scan Speed Compens ation.

4.2 Setting Calibration Parameters

The rest of this chapter describes how to specify calibration parameters in these windows

and dialog boxes:

• Tune window

• Instrumen t Threshold Settings dialo g box

• Automatic Calibration Check dialog box

• Calibration Parameters dialog box

• Mass Measure dialog box

• Automatic Calibration dialog box

• Calibration Acquisition Setup dialog box

4.2.1 Tune Window Settings

1. Follow the syringe preparation procedure in Section 2.3.7, this time loading the

syringe with sodium cesium iodide solution (from the API Test Kit).

2. Click (Syringe pump) in the Tune wind ow to infuse the solution into the source.

4

Calibrating 55

Page 56

3. Enter these sugges ted initial reference solution values in Tune window’s Peak

Editor.

Row Mass (ZQ 2000) Mass (ZQ 4000) Span Gain

1 172.9 172.9 5 8

2 772.5 1521.9 5 20

3 1521.9 2271.4 5 40

4 1971.6 3470.5 5 39

These settings are offered as reference points only and, once adopted, might

Note:

require adjusting.

4. Sele ct rows 1 to 4 in the Peak Editor. This specifies four mass peaks in the Tune

window’s Peak Display area (see Figure 3-3

5. Click the ES+ Sou rce ta b, and enter these suggested parameters in the

corresponding fields of the ES+ Source page (Figure 4-3

Parameter Suggested Value

Capillary (kV) 3.5

Cone (V) 50

Extractor (V) 3

RF Lens (V) 0.5

Source Temp erature (oC) 80

Desolvation Gas Flow Rate (L/hr) 250

Desolvation Temperature (oC) 120

Cone Gas Flow (L/hr) 50

).

).

4

Caution:

the source.

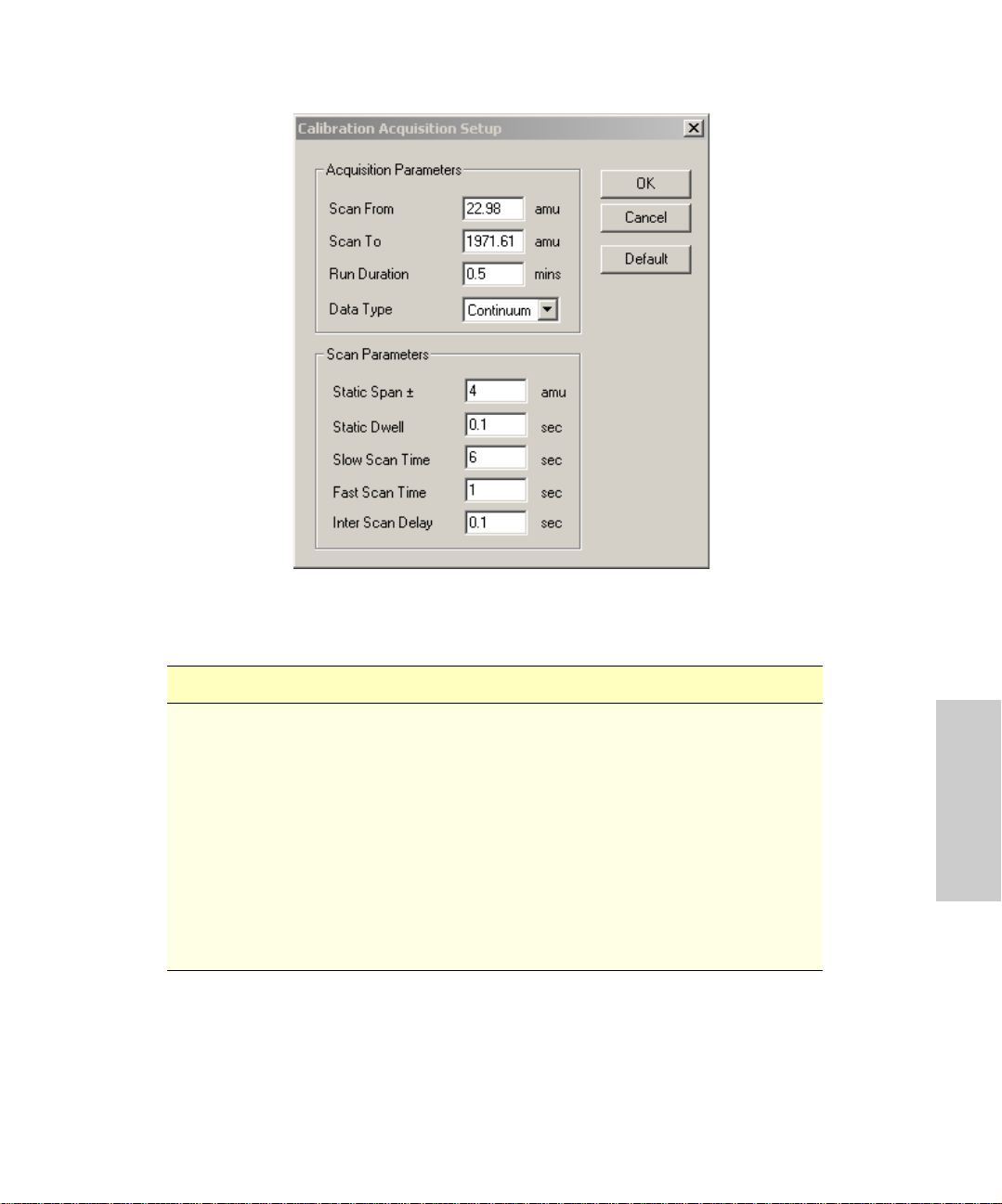

Fail ure to flow desolvation gas during ESI operation can damage

Setting Calibration Parameters 56

Page 57

Figure 4-3 Tune Window Displaying the ES+ Source Page

6. Click the Analyser tab to open the Analyser page (Figure 4-4

suggested parameters in the corresponding fields.

Parameter Suggested Value

LM resolution 15

HM resolution 15

Ion energy (V) 0.5

Multip lie r (V) 600

Cone Gas Flow Rate (L/hr) 50

Syringe Pump Flow Rate (µL/min) 5

), and enter these

4

Calibrating 57

Page 58

Figure 4-4 Tune Window Displaying Analyser Page Parameters

7. Max imize the signal intensity of the four mass peaks in the Tune window Peak

Display:

a. Turn the probe adjustor knob (Figure 2-8

relative to the sample cone orifice.

b. Adjust the source parameters from the T une window’s ES+ Source page. These

include Capillary, Extractor, RF Lens, and Cone voltages, as well as desolvation

and cone gas flows.

8. Adjust the slide adjustors for LM ( low mass) Resolution, HM (high mass) Resolution,

and Ion Energy on the Tune window’s Analyser page (Figure 3-5

full-width-at-half-height measurement of 0.4 to 0.6 da.

Make sure you can see all ions and that none are saturated on a gain of 1X.

Note:

) to adjust the orientation of the probe

4.2.2 Instrument Threshold Settings Dialog Box

This dialog box contains parameters that control how the system preprocesses data

before sending the data to a host computer.

4

) to obtain a

Setting Calibration Parameters 58

Page 59

For most low mass-range calibrations, the instrument acquires calibration data in

continuum mode. The continuum-data parameter settings in the Instrument Threshold

Settings dialog box ensure appropriate scanning speeds.

1. Select Options > Set Instrument Threshold from the Tune window. The

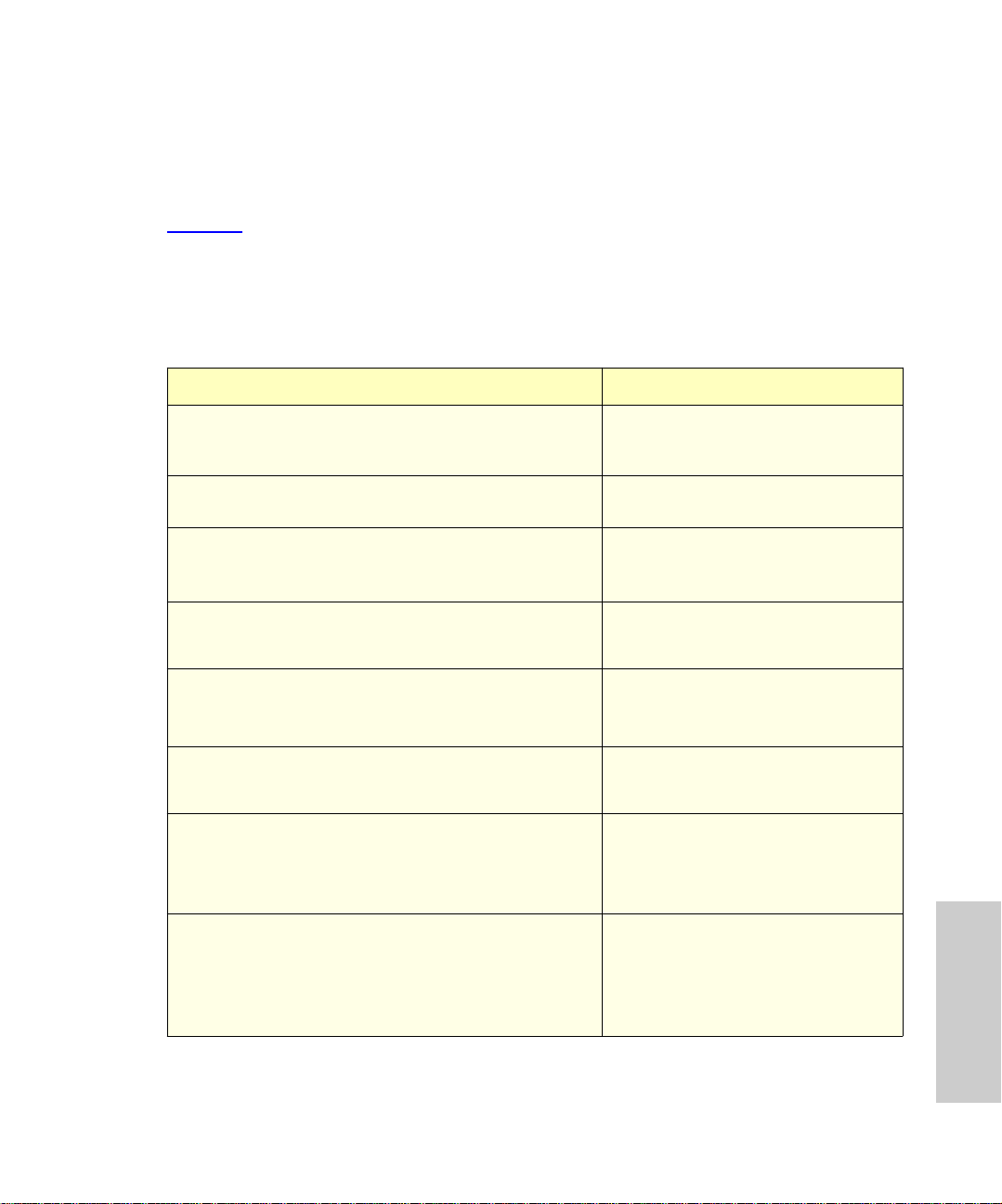

Instrument Threshold Settings dialog box appears (Figure 4-5

2. Acc ept the default settings by clicking OK.

Figure 4-5 Instrument Threshold Settings Dialog Box

).

4.2.3 Automatic Calibration Check Dialog Box

Select Edit > Au toCal Check Pa r ameter s from the Calibration window (Figure 4-1). The

Automatic Calibration Check dialog box appears (Figure 4-6

Figure 4-6 Automatic Calibration Check Dialog Box

Parameters

Missed Reference Peaks – Specifies the maximum number of unmatched consecutive

peaks you allow between the reference spectrum and the acquired calibration spectrum.

).

4

Calibrating 59

Page 60

The calibration fails when the number of unmatched peaks exceeds the maximum you

specify. The default value, 2, in most cases suffices.

Maximum Std Deviation – For each pair of matched peaks, MassLynx calculates the

difference between the measured mass in the acquired calibration file and the true mass

in the reference file. The calibration fails when the standard deviation for a set of mass

differences exceeds the maximum standard deviation you specify. Decreasing the value

imposes a more stringent limit. Increasing it makes the requirement easier to meet, though

you should normally avoid setting values greater than 0.20, the default value.

Apply Span Correction – Enabling this option ensures correct mass assignment, even

when the mass scale differs from the one the instrument was calibrated with.

You should not enable this option when the mass range of interest is less than 1000

Note:

da and includes the subrange 0 to 150 da.

Check Acquisition Calibration Ranges – Waters recommends you enable this option,

which displays messages alerting you when the instrument attempts to acquire data

outside the calibrated ranges for mass and scan speed.

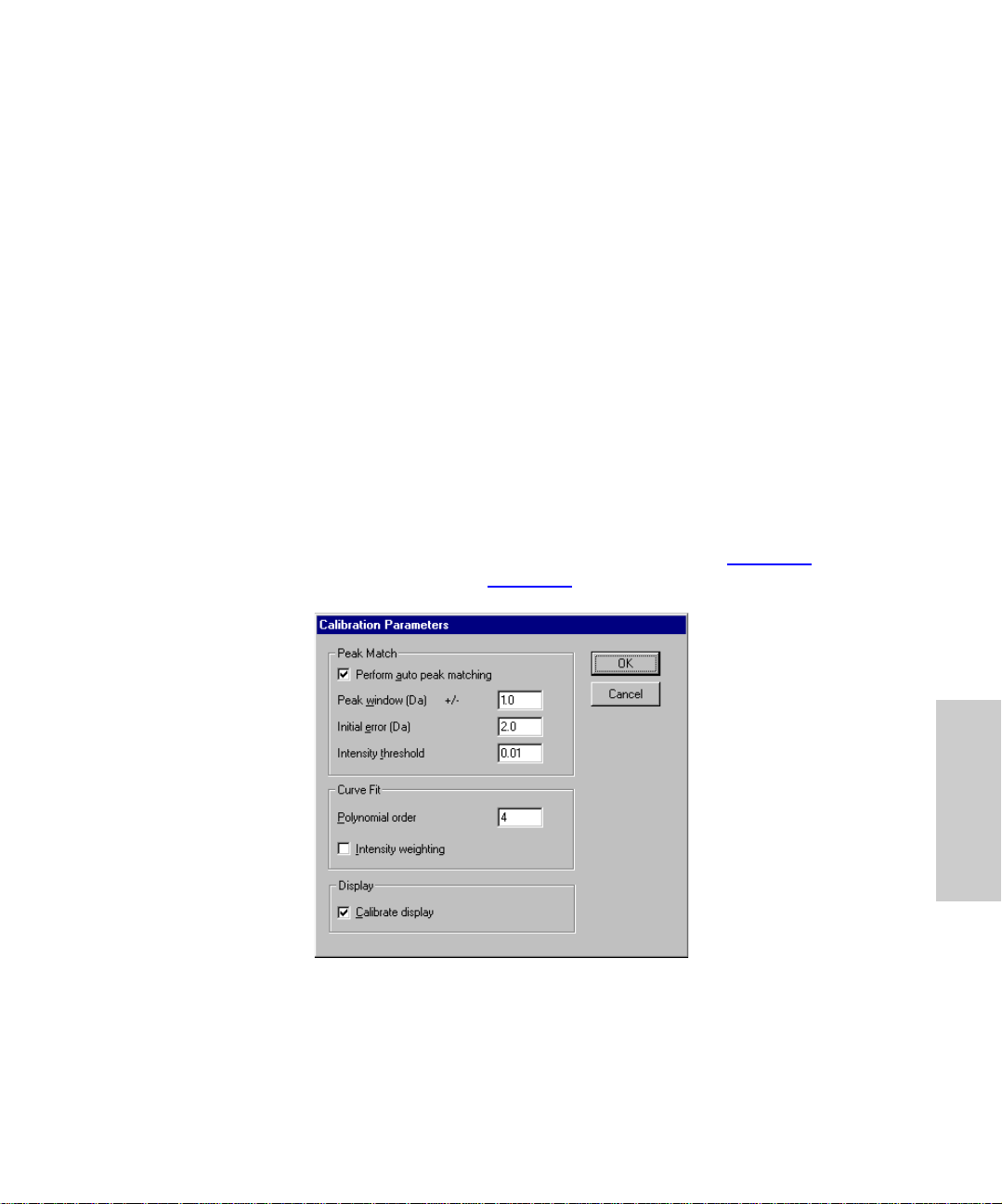

4.2.4 Calibration Parameters Dialog Box

Select Edit > Calibration Parameters from the Calibration window (Figure 4-1) to open

the Calibration Parameters dialog box (Figure 4-7

).

Figure 4-7 Calibration Parameters Dialog Box

Setting Calibration Parameters 60

4

Page 61

Parameters

Perform auto peak matching – When enabled, matches peaks in the reference fil e to

those in the acquired file.

Peak window – Speci fies the maximum mas s difference between the reference peaks

and the expected position of corresponding peaks in the acquired spectrum. Normal

operating range is 0.3 to 1.5 da.

Initial error – Specifies the maximum mass difference you will allow between the first

reference peak the software chooses (for its position at or near the center of the calibration

range) and the peak it corresponds to in the acquired spectrum.

Increasing Peak window and Initial Error values may result in incorrect peak

Note:

matching.

Intensity threshold – Specifies the lower intensity limit of peaks that form the calibration

curve. The threshold is expressed as a percentage of the most intense peak of the

acquired spectrum. Norm al operating range is 0 to 5%.

MassLynx does not use any peaks in the acquired spectrum that fall below the

Note:

Intensity threshold parameter.

Polynomial order – Once MassLynx matches each peak in the reference spectrum to one

in the acquired spectrum, it calculates the mass difference (the acquired mass less the

reference mass) for each peak pair. It then plots these differences as points on a graph

and fits a smooth curve through the points. This parameter, set to values 0 to 5,

determines the type of cur ve MassLynx draws:

• Polynomial order = 0 – a horizontal baseline

• Polynomial order = 1 – a linear curve

• Polynomial order = 2 – a quadratic curve

• Polynomial order = 3 – a cubic curve

• Polynomial order = 4 – a fourth-order curve

• Polynomial order = 5 – a fifth-order curve

Waters suggests a polynomial order of 2 for cali brations that use sodium cesium iodide as

the reference solution and where the calibrated mass range starts below 100 da and

extends through 650 da. Use

of the mass scale (600 to 1000+ da) and for calibrating with widely spaced reference

peaks.

Intensity weighting – Weights the curve toward points that represent the more intense

acquired peaks. Thus each point’s weight equals the square root of the acquired peak’s

intensity.

polynomial order 4

for the wide mass ranges at the high end

Calibrating 61

4

Page 62

Calibrate display – Lets you calibrate the raw data peaks in the upper graph of the

Calibration report. As you select each peak, the display recalibrates , bringing the other

spectral masses into line.

4.2.5 Mass Measure Dialog Box

Mass measure parameters contr ol co nversion of raw continuum data to centroid data,

which the calibrati on process require s. You must therefore specify them before calibra ting

in ESI mode.

If you use centroid data for calibration, you need not specify mass measure

Note:

parameters.

Select Edit > Calibrate Quad Mass Measure Parameters from the Calibration window

(Figure 4-1

). The Mass Measure dialog box appears (Figure 4-8).

Figure 4-8 Mass Measure Dialog Box

Setting Calibration Parameters 62

4

Page 63

4.2.6 Automatic Calibration Dialog Box

You should perform all three types of calibration: static, scanning, and scan speed

compensation. This lets you subsequently use any data acquisition mode. It also lets you

change mass ranges and scan speeds while maintaining correct mass assignment .

1. Select Calibratio n > C a librat e In strume nt from the Tune window. The Calibration

window appears (Figure 4-1

2. Select Calibrate > Start Acquisition from the Calibration window. The Automatic

Calibration dialog box appears (F igure 4-9

).

).

Figure 4-9 Automatic Calibration Dialog Box

3. Specify the type or types of calibration you intend to perform: Static, Scanning,

and/or Scan Speed.

For a complete calibration, select

Note:

and

Scan Speed Compensation

select

Acquire & Calibrate

and

Print Report

Static Calibration, Scanning Calibration

in t he Types area. Then, in the Process area,

.

Considerations

Though Waters suggests you perform all three types of calibration, you can nevertheless

specify one, or any combination, of calibration types. Beware, however, that doing so

invokes the fol lo wing limitations:

• Specify Static to calibrate only for acquisitions where the quadrupole “parks” at a

single mass (for example, SIR acquisitions).

Calibrating 63

4

,

Page 64

• Specify Scanning to calibrate only for scanning acquisitions. This limits acquisitions

to the same mass range and scan speed you specified in the calibration.

• Specify Scan Speed Compensation to calibrate only for scanning acquisitions over

the same mass range and at the same scan speed you specified in the calibration.