Page 1

[ CARE AND USE MANUAL ]

MassPREP On-Line Desalting Cartridge

CONTENTS

I. INTRODUCTION

II. INSTALLING THE MASSP REP ON-LINE

DESALTING CART RIDGE INTO T HE SENTRY

2.1 X 10 MM GUARD COLUMN HOLDER

III. RECOMMENDED LC/MS SYSTEM CONFIGURATION

TO MINIMIZE MS SOURCE CONTAMINATION

IV. SUGGEST ED METHOD FOR MASS ANALYSIS

USING MASSPREP ON-LINE DESALTING

CARTRIDGE

a. Instrumentation

b. Separation Method

V. GUIDELINES FOR USE AND

TROUBLESHOOTING

VI. MISCELLANEOUS

I. INTRODUCTION

Mass spectrometry is a powerful tool for intact protein analysis.

However, the quality of analyses can be compromised by salts in

the sample that interfere with ionization and/or form adducts with

the investigated proteins. It is therefore important to remove or

significantly minimize the introduction of extraneous salt ions

into the mass analyzer. The use of on-line, desalting devices can

efficiently perform this function with minimal sample handling.

Waters MassPREP™ On-line Desalting Cartridges (2.1 x 10 mm,

P/N 186002785) contain a polymer-based, reversed-phase

packing material that can be used to effectively desalt protein

samples prior to mass spectrometry. (Note: The purchase and use

of Waters Sentry™ 2.1 x 10 mm Guard Column Holder Kit (P/N

WAT097958) is required for this application as shown in Figure 1.)

The phenyl phase material contained in these on-line devices

successfully “traps” proteins allowing the salts to be washed

to waste prior to elution of the desalted protein into the mass

spectrometer. With an optimized LC/MS method, cycle times as low

as 3 minutes are achievable. These on-line devices, when used with

an appropriate HPLC System injector and injector wash solution,

can be used for the sequential analyses of different samples (See

Figures 2 and 3).

This Care and Use manual provides suggested methods for the

successfully use of this product. For the latest list of MassPREP,

BioSuite™ or NanoEase™ column offerings, go to www.waters.com/

lifesciences.

II. INSTALLING THE MASSPREP ON-LINE

DESALTING CART RIDGE INTO T HE SENTRY

2.1 X 10 MM GUARD COLUMN HOLDER

1. Unscrew the two halves of the Sentry 2.1 x 10 mm Guard

Column Holder.

2. Remove the old MassPREP On-line Desalting Cartridge, if

present.

Page 2

[ CARE AND USE MANUAL ]

3. Install the new MassPREP On-line Desalting Cartridge, noting

the flow arrow direction on the device. This should match the

flow arrow direction on the analytical column.

4. Reassemble the Sentry 2.1 x 10 mm Guard Column Holder.

Hand-tighten only.

5. Connect the 2.1 x 10 mm Guard Column Holder containing

the MassPREP On-line Desalting Cartridge onto HPLC or

LC/MS System using appropriate connectors (e.g., PEEK™

tubing and connectors). Prior to use, the MassPREP On-line

Desalting Cartridge reversed-phase packing material must

be “wet” with organic solvent prior to equilibration with 95%

Eluent A/5% Eluent B. This can be accomplished by running

a “blank injection” (i.e., buffer injection followed by running

the separations gradient) or by washing the column with a

minimum of five column volumes of 50% Eluent B followed by

a ten column volume equilibration at 95% Eluent A/5% Eluent

B prior to sample injection. While equilibrating, check the

holder and all connections for leaks.

III. RECOMMENDED LC/MS SYSTEM

CONFIGURATION TO MINIMIZE MS SOURCE

CONTAMINATION

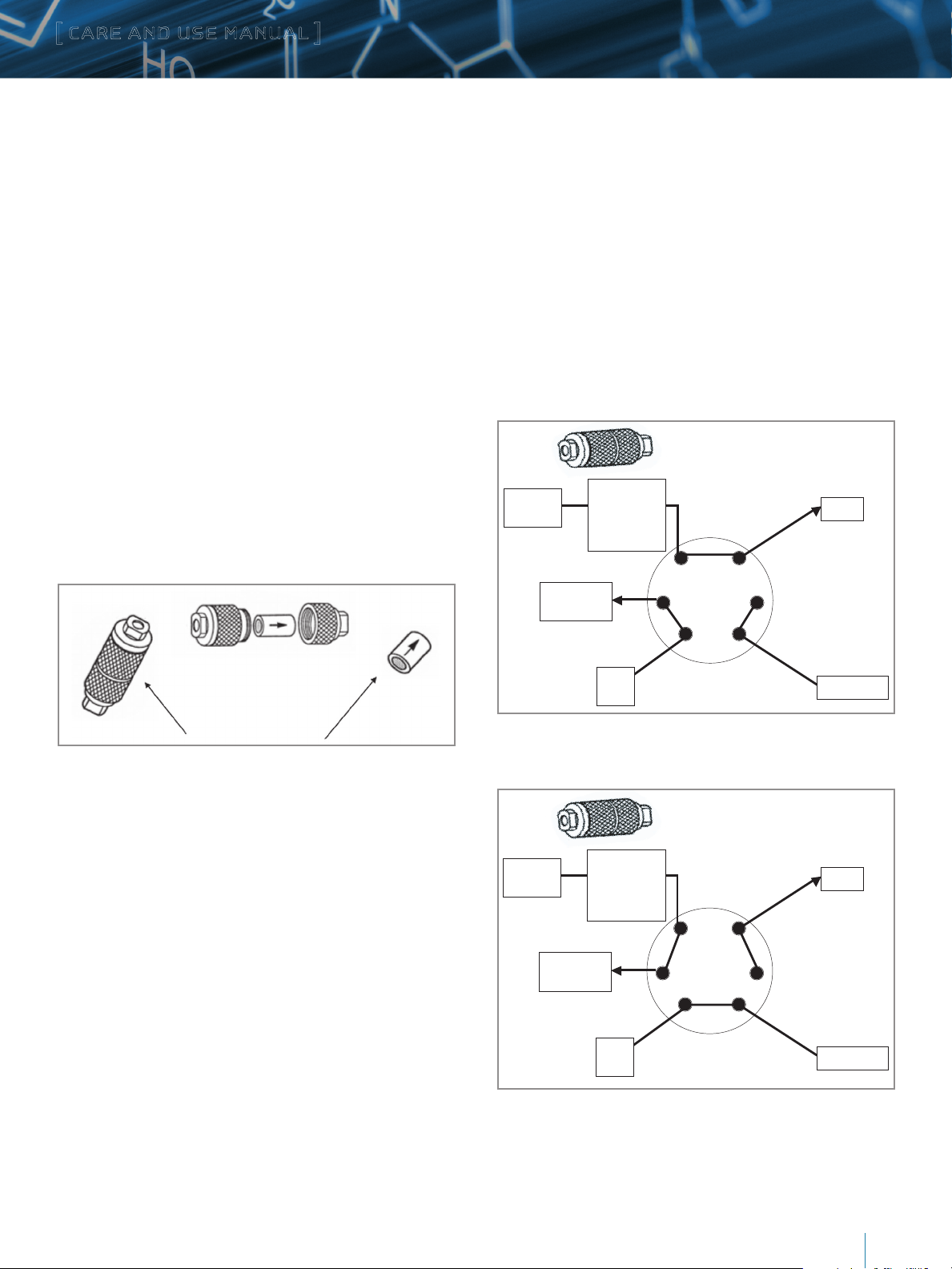

The presence of non-volatile salts (e.g., NaCl) can suppress protein

ionization and foul the ionization source of the mass spectometer.

It is therefore important to remove or significantly minimize the

introduction of these compounds into the mass analyzer. Figure

2 details an LC/MS configuration that can effectively be used to

load sample onto the column and elute salt to waste prior to valve

switching and protein elution into the mass analyzer.

Position 1: Sample Loading and Salt Elution to Waste

Spectrometer

MassPREP

On-Line

Desalting

Cartridge

Waste

1

2

3

6

5

4

Gradient

HPLC

Mass

Figure 1: Sentry Guard Holder (P/N WAT097958) and MassPREP On-line

Desalting Cartridge (P/N 186002785).

HPLC

Pump

Recirculation

Position 2: Sample Elution to Mass Spec

Spectrometer

MassPREP

On-Line

Desalting

Cartridge

HPLC

Pump

Waste

1

2

6

5

4

3

Recirculation

Gradient

HPLC

Mass

Figure 2: LC/MS Valve Switching Configuration for use with MassPREP

On-line Desalting Cartridge.

MassPREP On-Line Desalting Cartridge

2

Page 3

[ CARE AND USE MANUAL ]

IV. SUGGEST ED METHOD FOR MASS ANALYSIS

USING MASSPREP ON-LINE DESALTING CART RIDGE

(Considerations to Minimize Protein Carryover

Between Injections):

HPLC injector design, composition of injector wash solution, and

number of injector wash cycles between injections are some of the

factors that can effectively minimize protein carryover between

sample analyses. Waters MassPREP On-line Desalting Cartridges,

when used with an appropriately performing HPLC System and

injector wash protocol, can be used for the sequential analyses of

different samples due to the lack of protein carryover from prior

injections. Figure 3 shows the mass analyses results obtained

from buffer blank and intact protein injections [bovine serum

albumin (BSA) and IgG monoclonal antibody (mAb)] processed

through the MassPREP On-line Desalting Cartridge using the

Waters instrumentation and separation method detailed below:

a. Instrumentation

HPLC System: Alliance® 2796 Separations Module

Needle Wash

Solution Composition: H20 (35%) / Isopropanol (5%)

Acetonitrile (60%)

Number of Needle Washes: Single

Needle Wash Time: 15 sec needle exterior/3 sec inject port

b. Separation method:

Eluent A: H20 with 0.1% Formic Acid

Eluent B: Acetonitrile with 0.1% Formic Acid

Flow: 0.4 mL/minute

Initial Column Conditioning:

Prior to use, the MassPREP On-line Desalting Cartridge reversed

phase packing material must be “wet” with organic solvent prior

to equilibration with 95% Eluent A/5% Eluent B. This can be

accomplished by running a “blank injection” (i.e., buffer injection

followed by running the separations gradient) or by washing the

cartridge with a minimum of five column volumes of 50% Eluent

B followed by a ten cartridge volume equilibration at 95% Eluent

A/5% Eluent B prior to sample injection.

Sample Loading/Salt Elution:

Load sample onto cartridge while delivering 95% Eluent A/5%

Eluent B. The protein sample will bind to the cartridge while the

contaminating salt passes through unretained to waste.

Sample Elution to Mass Spec:

At approximatly. 0.5 min, begin increase Eluent B concentration

from 5 to 80% in 1.5 min. Hold at 80% B for an additional 1.0 min

to allow protein to completely elute from cartridge into MS system.

Mass Spectrometer: Q-tof

Ionization mode: ES +

Capillary voltage: 3300

Cone voltages: 30 for BSA mass analysis 35 for

mAb mass analysis

Source temp: 150 °C

Desolvation temp: 350 °C

Gas flow: 500 L/Hr

Cone gas: 50 L/Hr

Column re-equilibration:

At approximately 3.0 min, re-equilibration cartridge with ten

cartridge volumes of 95% Eluent A/5% Eluent B prior to next

sample injection.

MassPREP On-Line Desalting Cartridge

3

Page 4

[ CARE AND USE MANUAL ]

Injection 100_blank

100

%

0

Injection 99_MAb

100

%

0

100

Injection

%

0

100

Injection

%

0

0.10 0.20 0.30 0.40 0.50 0.60 0.70 0.80 0.90 1.00 1.10 1.20 1.30 1.40 1.50 1.60 1.70 1.80 1.90 2.00

Time

100

%

0

100

%

0

100

%

0

100

%

Injection 100 blank

Injection 99 MAb

Injection 98 BSA

Injection 97 blank

0

1000 1200 1400 1600 1800 2000 2200 2400 2600 2800 3000 3200 3400 3600 3800

m/z

Figure 3: Results from final 4 injections on MassPREP On-line Desalting Cartridge from a 100 injection overnight sequence noting absence of protein

carryover between injections. Test series consisted of repetitive injections of PBS, IgG monoclonal antibody (mAb) and BSA.

MassPREP On-Line Desalting Cartridge

4

Page 5

[ CARE AND USE MANUAL ]

V. GUIDELINES FOR USE AND T ROUBLESHOOTING

1. The amount of intact protein to load onto a MassPREP On-line Desalting Cartridge to obtain

acceptable mass analysis results depends upon a number of variables. These include the

type of mass analyzer used, the ionization efficiency of analyzed protein and MS source, the

potential ionization suppression effect of ion-pairing reagents used in the separation eluent

(e.g., TFA), etc. In general, between 1 and 5 µg of injected protein such as BSA or an IgG

monoclonal antibody should yield good mass detector signal and excellent protein recovery

from the MassPREP On-line Desalting Cartridge. Proportionately less material should be

injected when analyzing smaller molecular weight proteins to prevent overloading the On-line

Desalting Cartridge and or mass detector.

2. The maximum recommended operating pressure for MassPREP On-Line Desalting Cartridge,

when configured WITHOUT pre-column tubing, is approximately 150 psi. Use of pressure

generating tubing immediately before the MassPREP On-Line Desalting Cartridge is required

to generate sufficient UPLC System back pressure for proper functioning. Thus, the total

reported UPLC System backpressure generated when BOTH the pre-column tubing and

MassPREP On-Line Desalting Cartridge are configured for an application is approximately

5700 psi at a flow of 0.5 mL/min with a 5% ACN/0.1% FA eluent.

3. Results obtained with Waters MassPREP On-line Desalting Cartridges can vary depending

upon the physical characteristics of the analyzed proteins as well as on the performance

characteristics of the HPLC (or LC/MS System), injector, and injector wash protocol used.

VI. MISCELLANEOUS

Recommended Storage:

For overnight storage, continuously flush the cartridge with the mobile phase at slow flow (e.g.,

0.1 – 0.2 mL/min). If the cartridge is not to be used for several days, store the cartridge in 50%

acetonitrile (CH3CN) without any eluent additives such as formic acid or TFA. Do not store the

MassPREP On-line Desalting Cartridges in buffered eluents. Completely seal the stored column to

avoid evaporation and drying of the bed.

Waters Corporation, Waters. The Science of W hat’s Possible, and Alliance are registered trademarks of Waters Corporation. MassPRE P, Sentry,

BioSuite, NanoEase, and Q-Tof micro are trademarks of Waters Corporation. All ot her trademarks are property of their respective owners.

©2014 Waters Corporation. Produced in the U.S.A. June 2014 715001026EN Rev C. KP-PDF

Waters Corporation

34 Maple Street

Milford, MA 01757 U.S.A.

T: 1 508 478 2000

F: 1 508 872 1990

www.waters.com

Loading...

Loading...