Page 1

[ CARE AND USE MANUAL ]

MassPREP Micro Desalting Column

CONTENTS

I. INTRODUCTION

II. CONNEC TING THE MASSPREP MICRO

DESALTING COLUMN WITH T HE CHOSEN

LC SYSTEM

III. LC/MS SYSTEM CONFIGURATION TO

MINIMIZE MS SOURCE CONTAMINATION

IV. USING MASSP REP MICRO DESALTING

COLUMN TO MINIMIZE PROTEIN CARRYOVER

BETWEEN INJECTIONS

V. GUIDELINES FOR USE

VI. RECOMMENDED STORAGE

I. INTRODUCTION

Mass spectrometry is a powerful tool for intact protein analysis.

However, the quality of analyses can be compromised by salts in

the sample that interfere with ionization and/or form adducts with

the investigated proteins. It is, therefore, important to remove or

significantly minimize the introduction of extraneous salt ions into

the mass spectrometer. The use of on-line, desalting devices can

efficiently perform this function with minimal sample handling.

Waters MassPREP™ Micro Desalting Columns (2.1 x 5 mm, P/N

186004032) contain a polymer-based, reversed-phase packing

material (20 µm particle size, 1000 Å pore size) that can be used

to effectively desalt protein samples prior to mass spectrometry.

The phenyl phase material contained in these on-line devices

successfully retains proteins allowing the salts to be washed

to waste prior to elution of the desalted protein into the mass

spectrometer. With an optimized LC/MS method, cycle times as low

as 4 minutes are achievable. These on-line devices, when used with

an appropriate LC system injector and injector wash solution, can

be used for the sequential analyses of different samples.

II. CONNECTING THE MASSP REP MICRO DESALTING

COLUMN WITH T HE CHOSEN LC SYSTEM

The MassPREP Micro Desalting Column can be used with an

appropriately performing LC system to perform the desalting

functions so long as proper fittings/tubings are used to make

connections. However, optimized performances are achieved

only when the cartridge is connected to a Waters ACQUITY or

nanoACQUITY UPLC system. For the use of the cartridge with

ACQUITY or nanoACQUITY, pre-assembled tubing kits (Intact Mass

Tubing Kit, p/n 205000548) are provided to connect the column to

the UPLC systems and mass spectrometer.

There are two configurations to connect the cartridge into the LC

fluidic path. The inlet of the cartridge can be directly screwed onto

the Valco® UPLC injection valve with no tubing connection.

Page 2

[ CARE AND USE MANUAL ]

This configuration would leave the cartridge operating at room

temperature. The other configuration is to screw the cartridge

into one end of the included union connector. The connection of

proper tubing to the other end of the union connector would allow

the cartridge to be placed into a column heater to control the

desalting temperature.

III. LC/MS SYST EM CONFIGURATION TO

MINIMIZE MS SOURCE CONTAMINATION

Non-volatile salts (e.g., NaCl) can suppress protein ionization

and foul the ionization source of the mass spectrometer. It

is, therefore, important to avoid the introduction of these

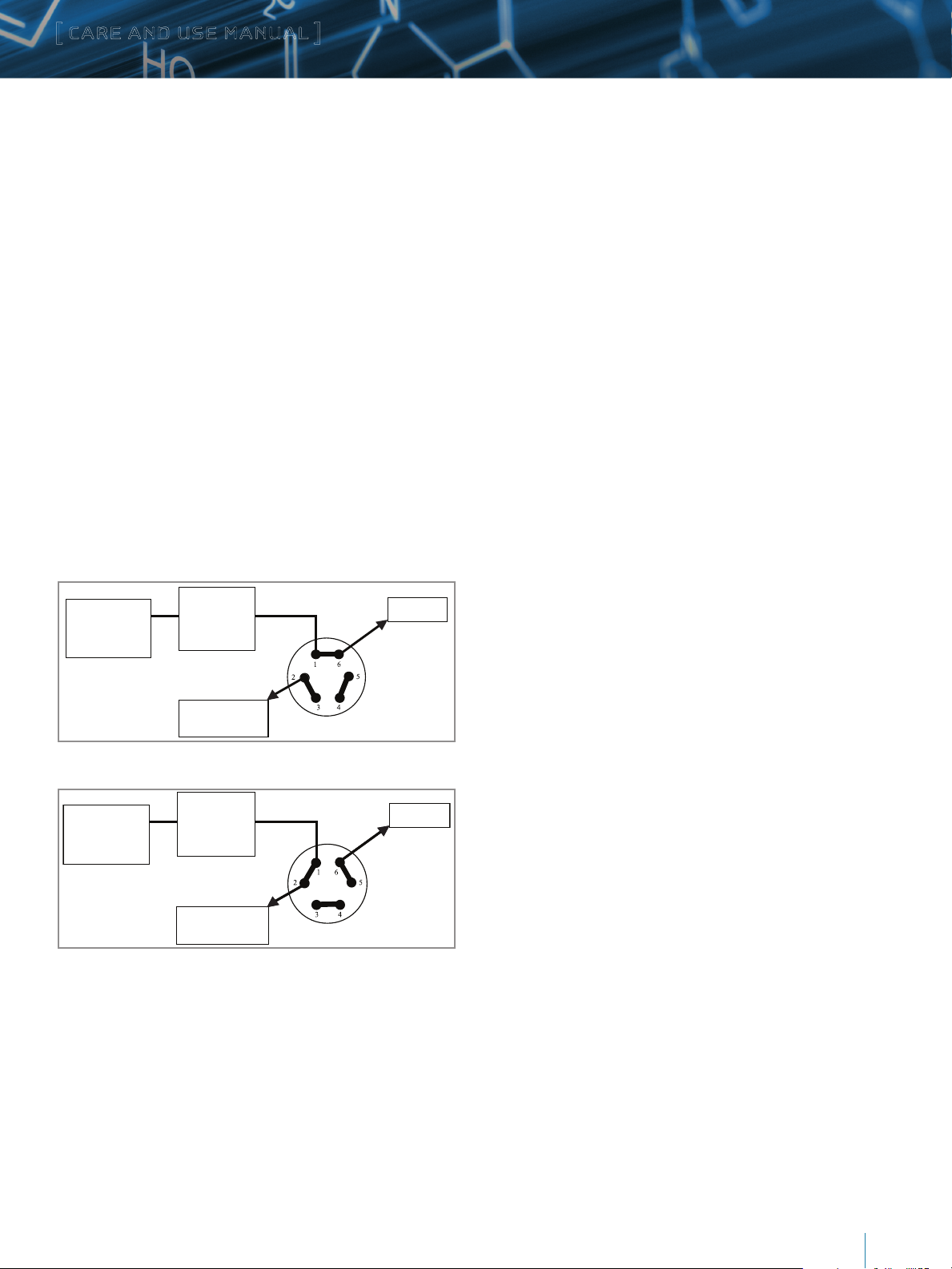

compounds into the mass spectrometer. Figure 1 details an LC/MS

configuration that can effectively be used to load sample onto the

column and elute salt to waste prior to valve switching and protein

elution into the mass spectrometer.

Position 1: Sample Loading and Salt Elution to Waste

MassPREP

Gradient

UPLC/HPLC

System

Micro

Desalting

Column

Mass

Spectrometer

Position 2: Sample Elution to Mass Spectrometer

MassPREP

Gradient

UPLC/HPLC

System

Figure 1. LC/MS Valve Switching Configuration for Use of MassPREP

Micro Desalting.

Micro

Desalting

Column

Mass

Spectrometer

Waste

Waste

IV. USING MASSPREP MICRO DESALTING

COLUMN TO MINIMIZE PROTEIN CARRYOVER

BETWEEN INJECTIONS

LC injector design, composition of injector wash solution, and

number of injector wash cycles between injections are some of the

factors that can effectively minimize protein carryover between

sample analyses. Waters MassPREP Micro Desalting Column, when

used with an appropriately performing UPLC/HPLC system and

injector wash protocol, can be used for the sequential analyses

of different samples due to the removal of protein carryover from

prior injections.

V. GUIDELINES FOR USE

1. Initial Column Conditioning. Prior to use, the MassPREP Micro

Desalting Column reversed-phase packing material must be

“wet” with organic solvent prior to equilibration with 95%

Eluent A / 5% Eluent B (e.g., Eluent A = 0.1% formic acid in

MS grade H20 and Eluent B = 100% Acetonitrile). This can

be accomplished by running a “blank injection” (i.e., Eluent A

injection followed by running the separation gradient) or by

washing the column with a minimum of five column volumes

(~20 µL) of 50% Eluent B followed by a ten column volume

equilibration at 95% Eluent A / 5% Eluent B prior to sample

injection.

2. The maximum recommended operating pressure for MassPREP

On-Line Desalting Cartridge, when configured WITHOUT

pre-column tubing, is approximately 150 psi. Use of pressure

generating tubing immediately before the MassPREP On-Line

Desalting Cartridge is required to generate sufficient UPLC

System back pressure for proper functioning. Thus, the total

reported UPLC System backpressure generated when BOTH the

pre-column tubing and MassPREP On-Line Desalting Cartridge

are configured for an application is approximately 5700 psi at

a flow of 0.5 mL/min with a 5% ACN/0.1% FA eluent.

3. Results obtained with Waters MassPREP Micro Desalting

Columns can vary depending upon the physical characteristics

of the analyzed proteins as well as on the performance

characteristics of the HPLC (or UPLC/MS System), injector, and

injector wash protocol used.

MassPREP Micro Desalting Column

2

Page 3

[ CARE AND USE MANUAL ]

VI. RECOMMENDED STORAGE

For overnight storage, continuously flush the column with the mobile phase at slow flow

(e.g., 50 µL/min for ACQUITY® System). If the column will not be used for several days,

store the column in 50% acetonitrile without any eluent additives such as formic acid or

TFA. Do not store the MassPREP Micro Desalting Columns in buffered eluents. Completely

seal the stored column to avoid evaporation and drying of the bed.

Waters Corporation. Waters, The Science of W hat’s Possible, ACQUITY UPLC, nanoACQUITY UPLC, and ACQUITY are registered trademarks

of Waters Corporation. MassPR EP is a trademark of of Waters Corporation. All other trademarks are property of their respective owners.

©2014 Waters Corporation. Produced in the U.S.A. June 2014 715001616EN KP-PDF

Waters Corporation

34 Maple Street

Milford, MA 01757 U.S.A.

T: 1 508 478 2000

F: 1 508 872 1990

www.waters.com

Loading...

Loading...