Page 1

[ CARE AND USE MANUAL ]

iKey Separation Device

CONTENTS

I. INTRODUCTION

II. iKEY FEATURES

a. Analytical iKey

b. Accessory iKeys

c. iKey Component Description

III. CONNECTING THE iKEY TO THE

ionKEY SOURCE

IV. iKEY USAGE

a. Sample Preparation

b. Mobile Phases

c. pH Range

d. Pressure

e. Temperature

V. REMOVING THE iKEY FROM THE

ionKEY/MS SYSTEM

VI. CARING FOR THE iKEY

a. Cleaning and Regeneration

b. Storage

c. Good Practices

I. INTRODUCTION

The Waters iKey™ Separation Device is a high-pressure,

microfluidic device that provides UPLC® separations with

the ionKey/MS™ System. The iKey eliminates manual fitting

connections and minimizes the potential for manual variability

and extra-column dispersion.

The iKey contains a ceramic substrate produced using a modified,

co-fired ceramic manufacturing process which contains an

analytical separation channel packed with stationary phase, an

electrospray emitter, a column heater, and an integrated memory

device. The integrated memory maintains the number of injections,

maximum backpressure, and number of sample sets run. A circuit

in the iKey senses and controls temperature as well.

The iKey is manufactured to exacting specifications, providing

outstanding peak symmetry for maximum sensitivity and

accurate quantitation. Each iKey is individually tested to

ensure that it passes stringent quality control requirements.

Compared to conventional chromatographic systems, successful

day-to-day performance of the ionKey/MS System requires

certain considerations. This document provides several essential

recommendations for the successful use of the iKey. The iKey

is the only analytical consumable device compatible with

ionKey/MS System.

VII. TROUBLESHOOTING iKEY PERFORMANCE

VIII. ORDERING INFORMATION

Page 2

[ CARE AND USE MANUAL ]

II. iKEY FEATURES

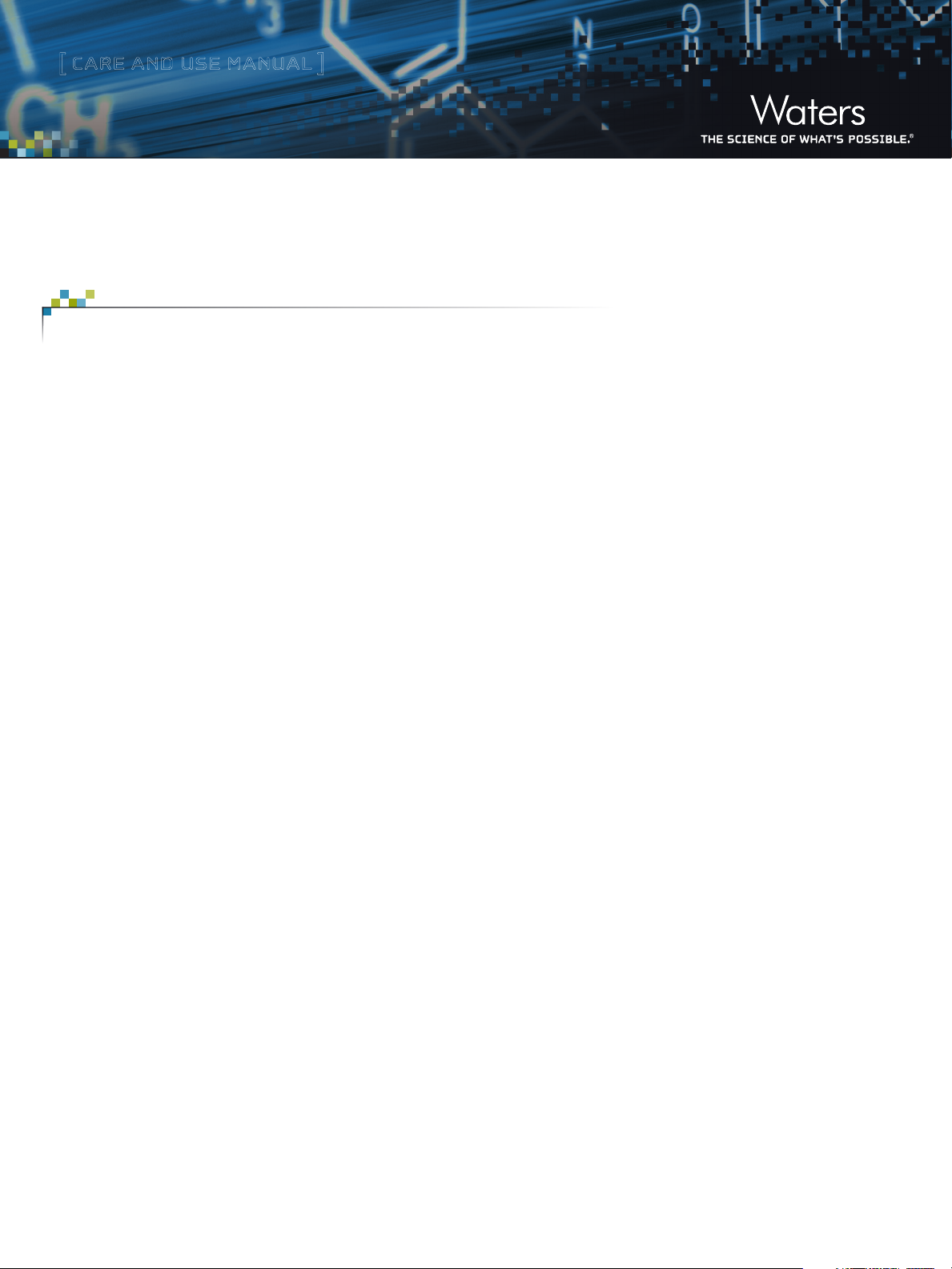

a. Analytical iKey

This iKey has a 150 µm x 50 mm or 150 μm x 100 mm analytical separation channel available with a variety of packing materials.

An electrospray emitter is located at the end of the channel. A sheath is provided to protect the iKey and its emitter from damage

during handling.

Left side of the iKey

Electrospray connection contact Electronic connections Fluidic ports (4)

Electrospray

emitter tip

Right side of the iKey

Fluidic path diagram

Emitter connection port

NanoFlow gas port

Notes label

Flow channel to emitter (50 mm shown, 100 mm iKey also available)

Identification label

Orientation rib

Injection inlet port

Auxiliary port (inactive)

Infusion port (inactive)

Outlet port (inactive)

iKey

2

Page 3

[ CARE AND USE MANUAL ]

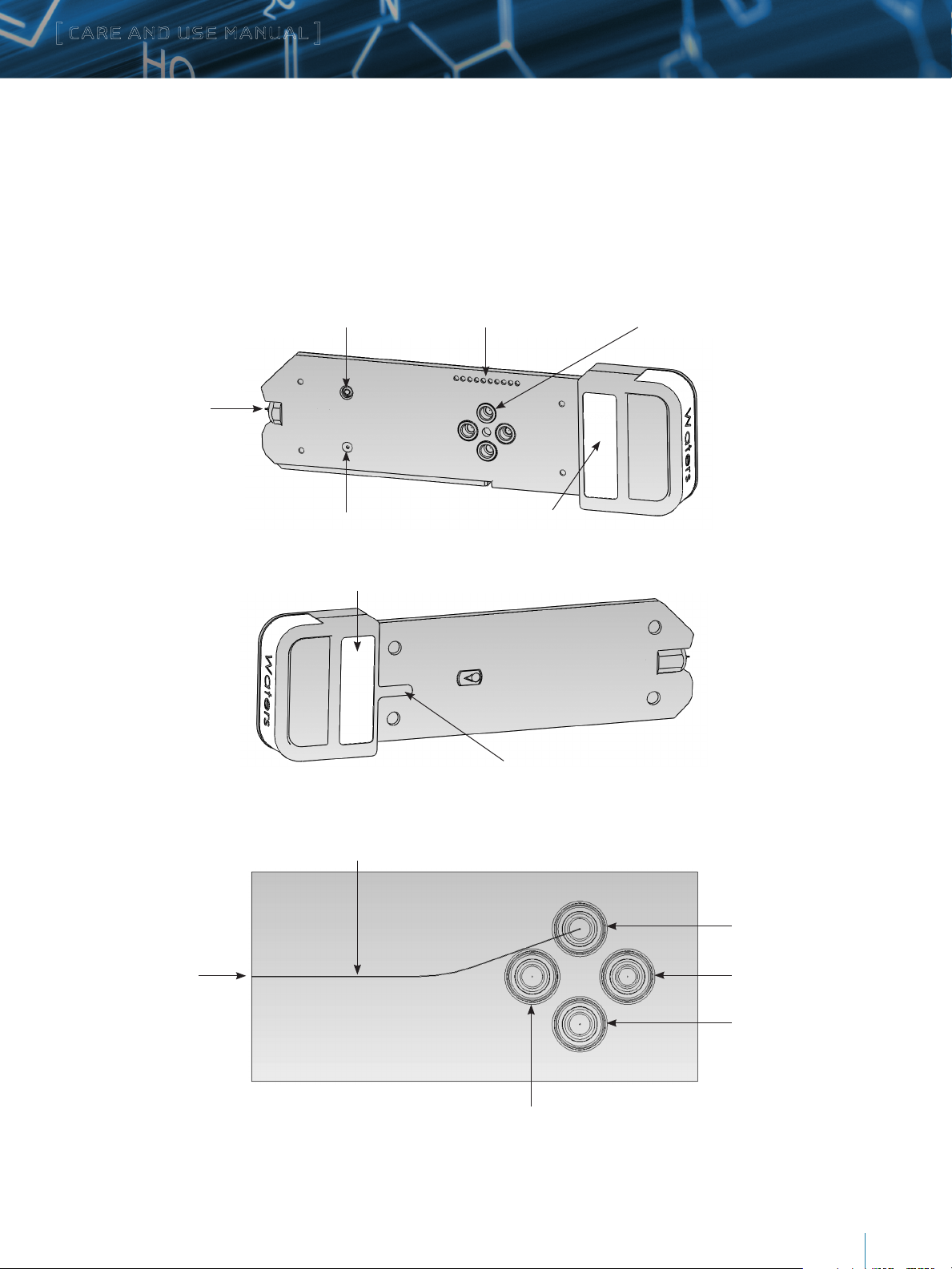

b. Accessory iKeys

Flow Injection iKey: This iKey has no packing material. It enables one to inject a sample from the sample manager directly to the emitter

on the iKey without any chromatographic separation. Flow path is identical to the 50 mm Analytical iKey.

Infusion iKey: This iKey enables calibrant infusion from the ionKey/MS fluidics. Additionally, it can also be used to divert flow to waste

for solvent changeovers and idle flow conditions, when liquid flow into the source is not desired.

Flow channel to emitter Flow channel to waste

Injection inlet port

Auxiliary port (inactive)

Outlet port to waste

Infusion port

Diagnostic iKey: This iKey has no flow channels. It provides a seal at the inlet fitting of the ionKey™ source for testing the fluidic integrity

of the system.

c. iKey Component Description

Component Description

Auxiliary fluidic port Used for alternative system arrangements.

Infusion port Connects to the MS fluidics.

Electronic connections Electronic connections for the heater and EEPROM device.

Electrospray connection contact Electrospray potential is applied to the iKey emitter through a conductive pad.

Electrospray emitter tip The emitter is housed within the iKey. Electrospray occurs when liquid within the emitter is charged

by a high-voltage connection.

Identification label Identifies the specifications for the iKey.

Injection inlet port Receives the injections and mobile phase flow from the system.

NanoFlow gas inlet Connects to a supply of nitrogen from the mass spectrometer. The gas pressure is set in the mass

spectrometer’s tune window.

iKey

3

Page 4

[ CARE AND USE MANUAL ]

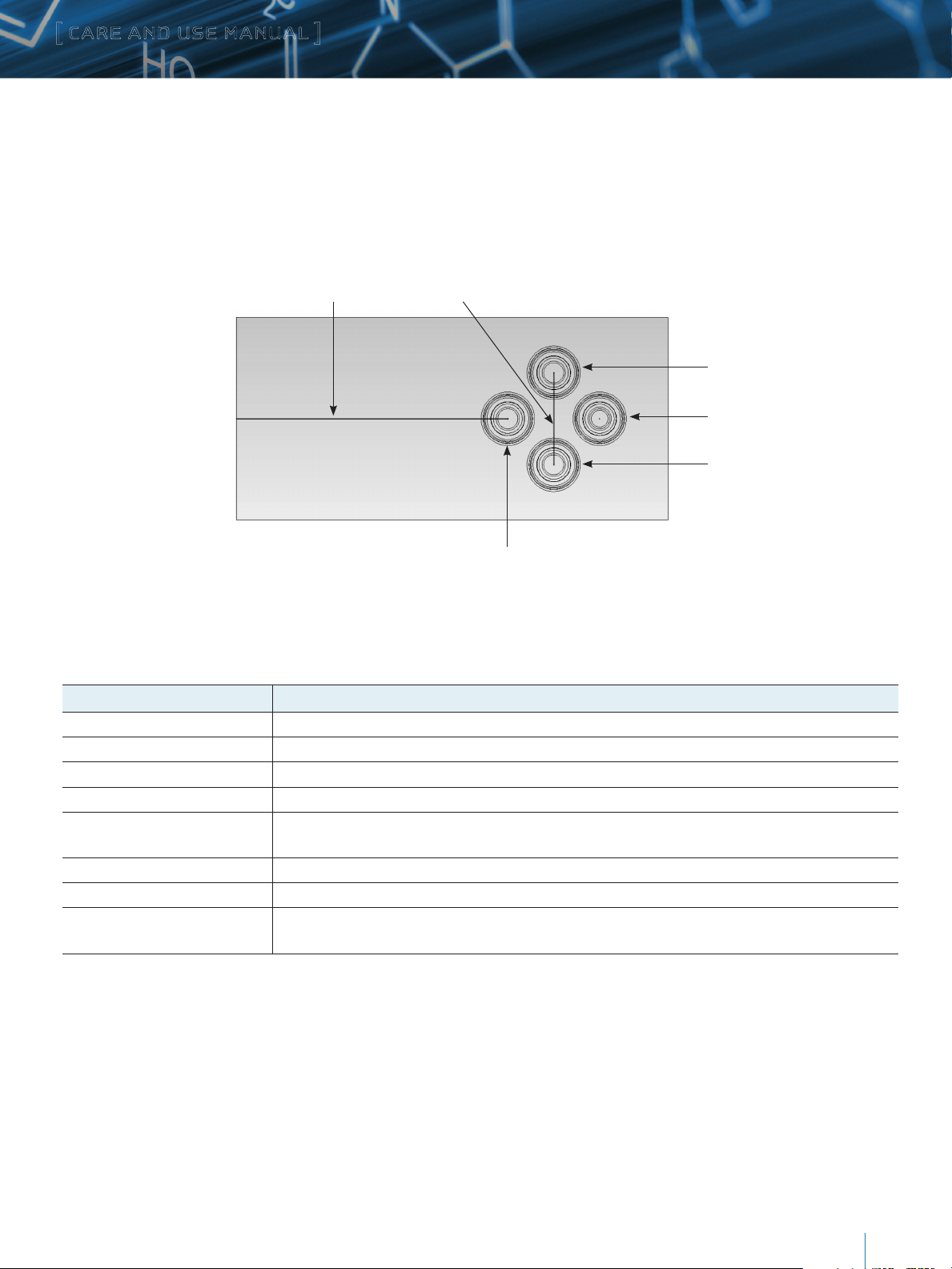

III. CONNECTING THE iKEY TO THE ionKEY SOURCE

These procedures outline the steps necessary to connect your iKey into the ionKey source. Connecting your iKey properly is essential

for operation.

To insert the iKey in the ionKey source:

1. Ensure the lever is vertical, and the unlock

indicator is in the 12 o’clock position.

2. Remove the iKey from the protective sheath.

Unlock indicator in 12 o’clock position

Lever in vertical position

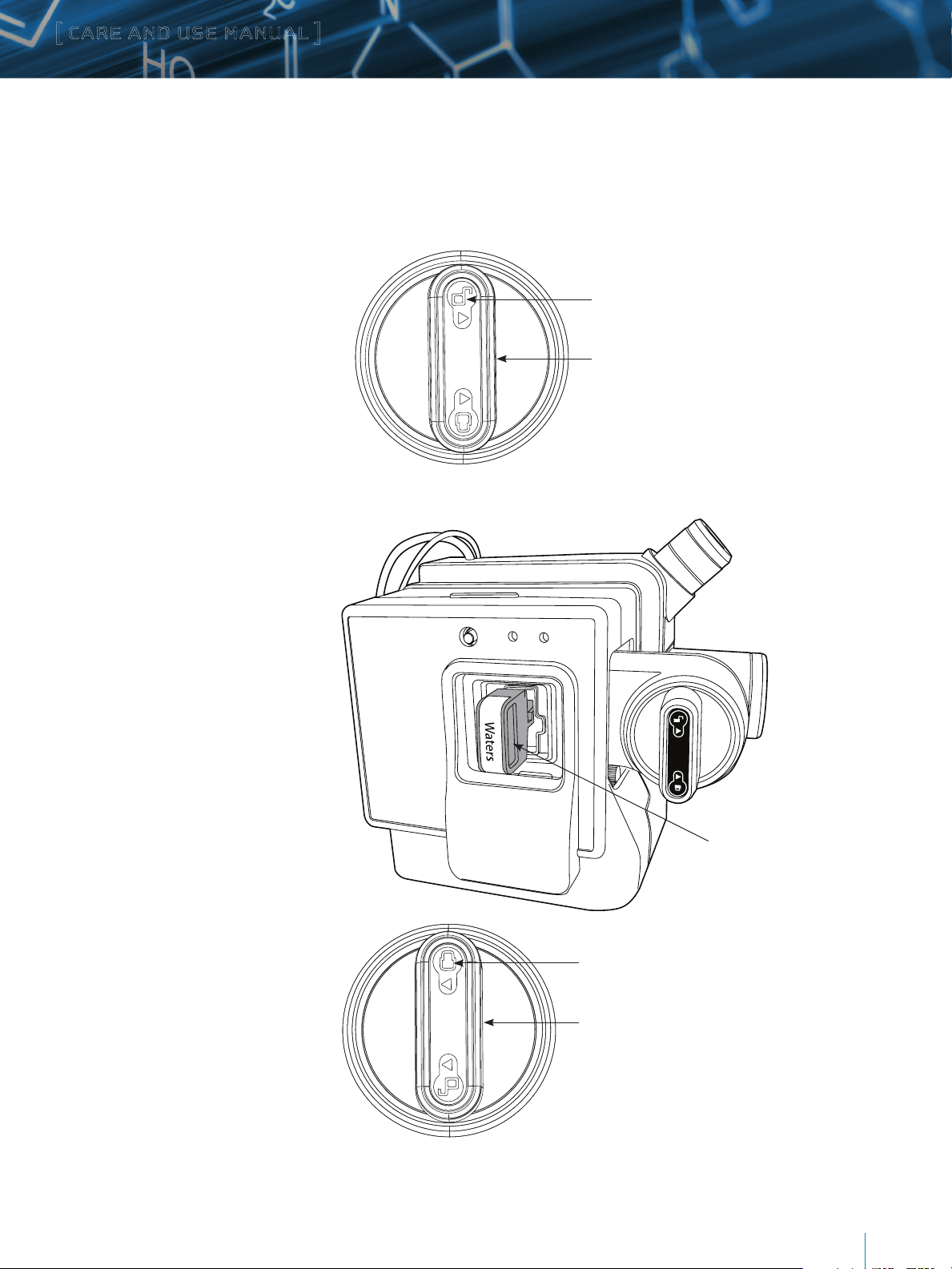

3. Insert the iKey fully in the ionKey

source’s docking port with sufficient

force until it reaches a hard stop and

the base of the iKey handle is nearly

flush with the face plate on the source.

The green STATUS LED on the source

will flash indicating that the iKey is

inserted but not clamped.

4. Rotate the lever counterclockwise

180 degrees until the lock indicator

is in the 12 o’clock position. Doing so

locks the iKey in place and engages the

fluid, gas, and electronic connections.

Once clamped, the high-voltage

electrospray ionization (ESI) is

connected for electrospray, and

pressurization and temperature

control are active.

STOP F LOW

STATU S PRESSURE

iKey

Lock indicator in 12 o’clock position

Lever in vertical position

iKey

4

Page 5

[ CARE AND USE MANUAL ]

IV. iKEY USAGE

To ensure the continued high performance of your iKey Separation Device, please follow these guidelines:

a. Sample Preparation

1) Samples containing hundreds of nanograms of undigested protein (and higher) per injection have been shown to limit or shorten

iKey lifetimes.

Therefore, it is essential that proper sample preparation protocols are followed. For example, below are examples of recommended

protocols for preparing plasma:

Shaded green = Readily adaptable to ionKey/MS Shaded purple = Requires more careful consideration

Sample Preparation

Protein precipitation

>2:1 AC N: H2O

Liquid/liquid extraction

Digestion Proteins are broken into smaller pieces that no longer present an issue.

Affinity

Solid-phase extraction

Filter Filters will not remove protein that is in solution.

Centrifugation Centrifugation will not remove protein that’s in solution, unless it’s been crashed with PPT.

Dilution It depends on the dilution ratio, and the diluent. In general small aqueous dilutions will not remove protein.

This method effectively removes the majority of protein from solution, pay attention to final organic content.

This method effectively extracts the analyte leaving the protein behind, pay attention to final

organic content.

Small amounts of specific proteins are extracted from the sample for analysis This can be an effective way

of preparing samples by removing residual protein.

This is an issue when the analyte has similar properties to proteins. E.g. The methods used to isolate

larger peptides often leave significant protein content in the final extract. If solid-phase extraction is the

sole sample preparation technique, multidimensional chromatography (i.e., trap and back-flush elution)

is required.

Sample Type

Urine

Bile

Microsomes

Plasma

Organic Extracts High amounts of organic affect the performance of any column, this effect is greater with small dimensions.

2) The use of multidimensional chromatography, specifically a trap and back-flush elution strategy, can provide further sample cleanup

and facilitate injections of higher organic strength injection solvents without experiencing analyte breakthrough. This multidimensional

chromatographic strategy is required when solid-phase extraction is the sole sample preparation technique (i.e., no additional

sample preparation technique is used to remove large amounts of undigested protein).

3) It is preferable to prepare the sample in the initial mobile phase conditions or a weaker solvent for the best peak shape and sensitivity.

4) If the sample is not prepared in the mobile phase, ensure that the sample, solvent, and mobile phases are miscible in order to avoid

sample and/or buffer precipitation.

Typically low protein content and does not require organic additive to crash proteins. Dilution and

centrifugation is recommended.

Typically low protein content and does not require organic additive to crash proteins. Dilution and

centrifugation is recommended.

Microsomal incubations contain proteins. Pay close attention to sample preparation to ensure that

minimal protein remains in the final sample extract.

Plasma typically contains high concentrations of protein. Pay close attention to sample preparation

to ensure that minimal protein remains in the final sample extract. Injecting a large amount of undigested

proteins onto the iKey will result in compromised performance and shorter lifetimes.

iKey

5

Page 6

[ CARE AND USE MANUAL ]

5) Consider filtering samples with a 0.2 µm membrane to remove particulates. If the sample is dissolved in a solvent that contains an

organic modifier (e.g., acetonitrile, methanol, etc.) ensure that the membrane/filter material is compatible with the solvents in use.

Alternatively, centrifuge the sample for 20 minutes at 8000 RPM, followed by the transfer of the supernatant to an appropriate

Waters TruView LCMS Certified Vial could be considered.

6) Below are two examples of commonly used sample preparation protocols:

Protein precipitation (PPT)*

a. Add acetonitrile to plasma at a ratio of 2:1 (acetonitrile: plasma).

b. Vortex (mix) for one minute.

c. Centrifuge at 5000 relative centrifugal force (RCF) for five minutes.

d. Remove supernatant.

e. Perform solid-phase extraction (SPE) cleanup (optional).*

f. Pipette into Waters TruView™ LCMS Certified Vial (e.g., part number 186005663CV).

Liquid/Liquid Extraction (LLE)*

1. Add hexane to plasma at a ratio of 10:1 (hexane:plasma).

2. Vortex (mix) for one minute.

3. Centrifuge at 5000 relative centrifugal force (RCF) for five minutes.

4. Remove supernatant and evaporate to dryness.

5. Reconstitute (e.g., initial gradient conditions solvents).

6. Centrifuge at 5000 relative centrifugal force (RCF) for five minutes (optional).

7. Perform solid phase extraction (SPE) cleanup (optional).*

8. Remove supernatant and pipet into Waters TruView LCMS Certified Vial (e.g., part number 186005663CV).

*Additional sample cleanup steps using Oasis

sensitivity, and reduced matrix effects.

®

or Sep-Pak® SPE devices can provide cleaner samples, improved selectivity, higher

iKey

6

Page 7

[ CARE AND USE MANUAL ]

b. Mobile Phases

To maintain and ensure maximum iKey performance, use high quality chromatography solvents. Use only filtered and degassed mobile

phases. Filter all aqueous buffers prior to use through a 0.2 μm filter. Solvents containing suspended particulate materials will generally

clog the iKey ceramic substrate (analogous to clogging the inlet frit of an LC column). This may result in higher backpressure or distorted

peak shape. A table of recommended buffers is listed below:

Additive/Buffer pKa Buffer Range

Acetic Acid 4.76 Volatile Yes

Formic Acid 3.75 Volatile Yes

Acetate

(NH4CH2COOH)

Formate

(NH4COOH)

Additionally, the iKey lifetime will vary depending upon the operative temperature and pressure as well the type and concentration of

additive/buffer used.

4.76 3.76 – 5.76 Volatile Yes

3.75 2.75 – 4.75 Volatile Yes

Vola t ility (±1

pH unit)

Used for

Mass Spec

Comments

Maximum buffering obtained when used with

ammonium acetate salt. Used in 0.1–1.0% range.

Maximum buffering obtained when used with

ammonium formate salt. Used in 0.1–1.0% range.

Used in the 1–10 mM range. Note that sodium or

potassium salts are not volatile.

Used in the 1–10 mM range. Note that sodium or

potassium salts are not volatile.

c. pH Range

The recommended operating range for iKey is 1 to 7.

d. Pressure

iKeys can be operated at pressures up to 10000 psi (690 bar). Infusion and flow injection iKeys can be operated at at pressures up to

8000 psi (550 bar).

e. Temperature

Temperatures can be used to enhance selectivity, lower solvent viscosity, and increase mass transfer rates. When operating near the upper

pH limit for iKey, lower temperatures are recommended for higher iKey lifetime. iKey temperature limits are shown below:

Component Description

Ethylene bridged hybrid (BEH) 90 °C

Charged surface hybrid (CSH) 80 °C

High strength silica (HSS) 45 °C

Note: Working in combinations of extreme pH, temperature and pressure may result in reduced iKey lifetime.

iKey

7

Page 8

[ CARE AND USE MANUAL ]

V. REMOVING THE iKEY FROM THE ionKEY SOURCE

CAUTION: Opening the locking lever on the ionKey system without first stopping flow and decompressing the fluidic pressure

can damage the iKey.

1. Stop the solvent flow and decompress the fluidic pressure on the iKey using one of these methods.

a. Press the STOP FLOW button on the front of the source.

b. In the Console, select Sample Manager from the system tree, and then click > Maintain > Remove iKey.

2. Make sure the mobile phase flow is completely stopped and that the system pressure has decompressed below 100 psi. If the solvent

is flowing, the PRESSURE LED is steady green. The PRESSURE LED blinks green as the system is decompressing. Wait until the light is

turned off completely. If an ikey is removed without first decompressing the system, a “Removed under pressure” error message will

appear, indicating potential damage to the iKey.

3. Rotate the lever clockwise 180 degrees to the vertical position with the unlock indicator in the 12 o’clock position.

Unlock indicator in 12 o’clock position

Lever in vertical position

4. Pull the iKey from the docking port.

5. Place the iKey in the protective sheath.

WARNING: The electrospray emitter at the front end of the iKey contains a very small metal tip. Like a needle, it can pierce skin.

WARNING: If the iKey had been run at high temperature, the metal rings near the fluidic ports on the side may be hot.

Avoid touching them.

VI. CARING FOR THE iKEY

a. Cleaning and Regeneration

Changes in peak shape, peak splitting, shouldering peaks, shifts in retention, change in resolution or increasing backpressure may

indicate iKey contamination. Flush with a neat organic solvent to remove the non-polar contaminant(s), taking care not to precipitate any

buffered mobile phase components. If this flushing procedure does not solve the problem, purge the iKey with the following cleaning and

regeneration procedures.

Use a cleaning routine that matches the properties of the samples and stationary phase type and will solubilize the suspected contaminate.

Flush with 20 iKey volumes of solvent at an intermediate temperature of 40 °C. Return to the initial mobile phase conditions by reversing

the sequence.

Purge the iKey with a sequence of progressively more non-polar solvents (e.g., water, methanol, acetonitrile, isopropanol, etc.). If iKey

performance has not improved after regeneration/cleaning procedures, contact your local Waters representative for additional support.

If iKey performance has not improved after regeneration/cleaning procedures, contact your local Waters representative for

additional support.

iKey

8

Page 9

[ CARE AND USE MANUAL ]

b. Storage

For periods longer than four days, store the reversed-phase iKey in 100% acetonitrile. Do not store iKeys in buffered eluents. If the mobile

phase contained a buffer salt, flush the reversed-phase iKey with 10 iKey volumes of HPLC grade water followed by 10 iKey volumes of

acetonitrile. Failure to perform this intermediate step could result in precipitation of the buffer salt in the column when 100% acetonitrile

is introduced. Completely seal the iKey to avoid solvent evaporation and drying out of the chromatographic bed.

Note: If an iKey has been run with a formate-containing mobile phase (e.g., ammonium formate, formic acid, etc.) and is purged with 100%

acetonitrile, slightly longer equilibration times may be necessary when the iKey is re-installed and re-wetted with that same formate-

containing mobile phase.

VII. TROUBLESHOOTING iKEY PERFORMANCE

The table below lists symptoms, causes, and solutions for troubleshooting the iKey.

Symptom Cause Solution

Excessive baseline noise The emitter tip has residue on it Rinse the emitter tip in isopropanol.

Poor LC quality such as

retention time shift, or peak

width variance

The iKey does not fit into the

ionKey source’s docking port

Fluid leak

The iKey is upside down

Use the Fluidic Integrity Test within the Console

software in combination with the Diagnostic iKey

to find and identify leaking components.

Remove and orient the iKey so that the four ports

are on the left side.

a. Tips for Maximizing iKey Lifetimes

To maximize iKey lifetime, pay close attention to:

Water quality (including water purification systems);

Solvent quality;

Mobile phase preparation, storage and age;

Sample, buffer and mobile phase solubilities;

Sample quality and preparation.

When problems arise, systematically troubleshoot potential causes one variable at a time in a systematic fashion.

Always remember to:

Discourage bacterial growth by minimizing the use of 100% aqueous mobile phases where possible;

Discard and re-prepare aqueous mobile phase every 24 to 48 hours (if 100% aqueous mobile phase is required);

Routinely maintain your water purification system to ensure it is functioning properly;

Only use ultra-pure water (18 MOhm-cm) and highest quality solvent possible;

Consider improving sample preparation (e.g., solid-phase extraction, filtration, centrifugation, etc.) when possible.

Avoid when possible:

100% aqueous mobile phases;

HPLC-grade bottled water;

“Topping off” your mobile phases.

iKey

9

Page 10

[ CARE AND USE MANUAL ]

Don’t assume the iKey is to blame:

Investigate cause of iKey failure;

Monitor backpressure;

Examine mobile phase age, bacterial contamination, mobile phase precipitation, etc.;

Examine sample quality;

Examine injection solvent strength.

Do not prepare excessive amounts of mobile phase:

To reduce the chances of mobile phase contamination or degradation, prepare enough mobile phase to last for 3–4 days.

Alternatively, store excess bulk quantities in a refrigerated environment.

b. Troubleshooting Questions

What is the age of your 100% aqueous mobile phase?

Is the mobile phase filtered through a 0.2 µm membrane?

Was the mobile phase prepared fresh or topped off?

Is the water source of adequate quality?

When was the last time the water system was serviced or was the bottle of water unopened?

Is bacterial growth a possibility?

If a neat standard is prepared in the initial mobile phase conditions and injected, are the problems still observed?

If the sample is additionally filtered/purified (i.e., SPE, filtration, etc.) is the problem still observed?

Has the quality of the samples changed over time?

c. Good Practices

Do not operate at pressures that exceed 10000 psi (690 bar).

Do not apply electrospray potential to the emitter for an extended period of time without mobile phase flow.

Do not immerse in liquid.

Do not touch any part of the iKey other than the handle.

Do not freeze.

Flush with acetonitrile and store at room temperature when not in use.

Use the iKey sheath to protect device when not in use.

Do not bend or pull the capillary connection tubing at the ionKey source coupling.

Avoid excess voltage (>4.0 kV) which can erode emitter over time.

iKey

10

Page 11

[ CARE AND USE MANUAL ]

VIII. ORDERING INFORMATION

Product Description Part Number

iKey, Peptide BEH C

iKey, BEH C

18

iKey, Peptide CSH C

iKey, CSH C

iKey, BEH C

18

18

iKey, Peptide BEH C

iKey, BEH C

18

iKey, Infusion 186007049

iKey, Diagnostic 186007050

iKey, Injection 186007051

* QC tested with a Peptide Standard Mix.

,

130Å, 1.7 µm, 150 µm x 50 mm* 186006764

18

,

130Å, 1.7 µm, 150 µm x 50 mm 186007256

,

130Å, 1.7 µm, 150 µm x 50 mm* 186007257

18

,

130Å, 1.7 µm, 150 µm x 50 mm 186007244

,

300Å, 1.7 µm, 150 µm x 50 mm 186006969

,

130Å, 1.7 µm, 150 µm x 100 mm* 186006766

18

,

130Å, 1.7 µm, 150 µm x 100 mm 186007258

Please go to at www.waters.com/ikey for a complete list of iKey Separation Devices.

Waters, The Science of W hat’s Possible , UPLC, Oasis, and Sep-Pak are registered trademarks of Waters Corporation.

TruView, iKey, ionKey/MS, and ionKey are trademarks of Waters Corporation.

©2014 Waters Corporation. Produced in the U.S.A. March 2014 20004897EN TC-PDF

Waters Corporation

34 Maple Street

Milford, MA 01757 U.S.A.

T: 1 508 478 2000

F: 1 508 872 1990

www.waters.com

Loading...

Loading...