Page 1

[ Care and Use ManUal ]

IC-pak Column and guard Column

I. IntroduCtIon

Waters IC-Pak™ anion (A) and cation (C) columns are designed for use

in Ion Chromatography (IC) applications to separate ions.

a. Anion Columns

The stainless steel anion columns separate and quantify many

anions, such as F-, CI-, NO

-

, Br-, NO

2

ppb levels. Table 1 lists the characteristics of IC-Pak anion columns.

Table 1: Anion Column Characteristics

Anion Column Dimensions Particle Size Capacity

IC-Pak A 4.6 x 50 mm 10 µm 30 ± 3 µeq/mL

IC-Pak A HC

(High Capacity)

IC-Pak A HR

(High Resolution)

4.6 x 150 mm 10 µm 30 ± 3 µeq/mL

4.6 x 75 mm 6 µm 30 ± 3 µeq/mL

The packing material is a polymethacrylate resin with a quaternary

ammonium functional group. The columns are shipped in 1.3 mM

gluconic acid/1.3 mM boric acid (pH 8.5).

-

, HPO

3

2-

, and SO

4

2-

anions at

4

Contents

I. IntroduCtIon

II. InstallatIon

III. eluent and sample guIdelInes

IV. operatIon

V. Care and maIntenanCe

VI. orderIng InformatIon

VII. Warranty/serVICe

b. Cation Columns

The non-metallic cation columns separate and quantify Li+, Na+,

+

NH

, K+, Mg2+, Ca2+, Sr2+ and Ba2+ cations at ppb levels. T he Waters

4

cation guard column, placed in the solvent stream before the

sample injector, is used only to aid monovalent cation detection by

removing polyvalent cations from the solvent stream.

Table 2 lists the characteristics of IC-Pak cation and cation guard

columns.

IC-Pak Column and Guard Column 1

Page 2

[ Care and Use ManUal ]

COMPRESSION SCREW OR NUT

T

UBE

FERRULE

END MUST BE STRAIGHT

AND SMOOTH TO ACHIEVE

MAXIMUM COLUMN EFFICIENCY

CRITICAL DISTANCE TO BE DETERMINED BY

THE UNION OR COLUMN FITTING, ETC.

Table 2: Cation Column Characteristics

Cation Column Dimensions Particle Size Capacity

IC-Pak C 4.6 x 50 mm 10 µm 12.0 ± 0.2 µeg/mL

Guard 4.6 x 50 mm n/a 2.0 ± 0.2 meg/mL

The packing material is a styrene divinylbenzene resin with a

sulfonic acid functional group. The columns are shipped in 2 mM

nitric acid.

II. InstallatIon

Before attaching the column in the flow path:

1. Directly connect the HPLC injector to the detector by replacing the old

column with a zero-dead-volume union.

2. Flush the lines free of microparticulates and previous solvents. Flush

the injector loop if applicable.

3. Remove the union.

4. Install the column.

To prepare a new tubing/ferrule connection:

1. Scribe the circumference of the tubing at the desired break using either

a file with a cutting edge or a tube cutter.

2. Grasp the tubing on both sides of the scribe mark with cloth-covered

pliers (to prevent marring the tube surface), and gently work the tube

back and forth until it separates.

Note: Ensure that the tubing end is straight, open, and free of burrs.

3. Slide the compression fitting, followed by the ferrule (large end of the

taper first) over the tube.

Note: Properly bottom the tubing in the fitting seat. Otherwise, dead

volume could result in sample band spreading.

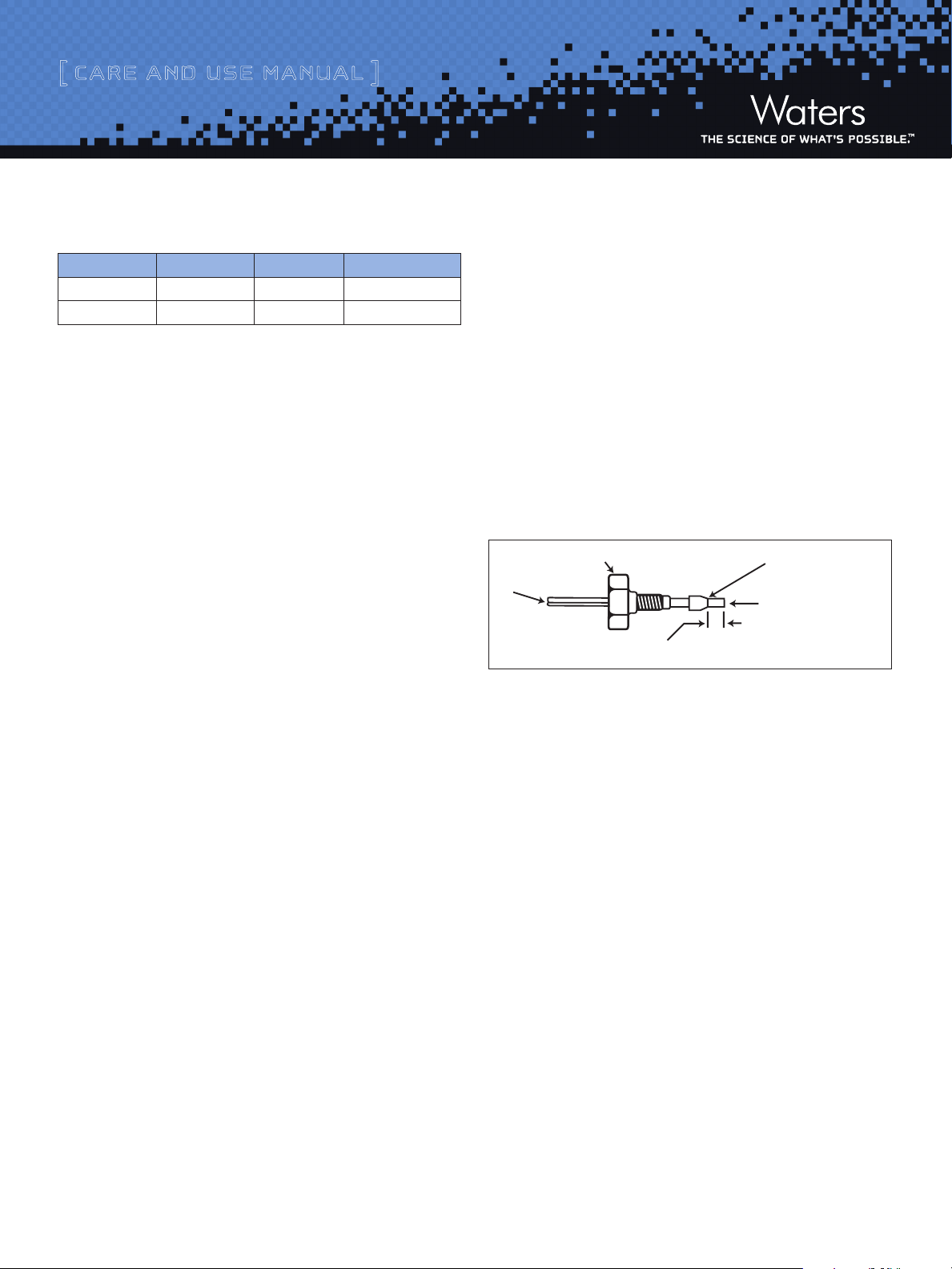

Figure 1: Ferrule and Compression Assembly (Stainless Steel Column)

a. Installing a Stainless Steel Column

Remove the end plugs from the column and save them for use when

the column is removed from the system and stored. The column

outlet is indicated by an arrow on the label (showing the direction

solvent should flow).

To install the column, thread the inlet and outlet fittings into the

column until finger tight, and then tighten the fittings 1/4-to-1/2

turn. Do not over-tighten. Over-tightening will damage the

connection. A properly prepared and assembled compression fitting

in good condition is all that is required.

Prepare a new tubing/ferrule connection (Figure 1) when a new

column is connected or when a damaged compression screw or worn

ferrule are removed.

Note: The tubing distance beyond the ferrule may differ for different

column types. Re-size the tubing to the correct distance by replacing

the ferrule.

IC-Pak Column and Guard Column 2

b. Installing Non-Metallic Columns

Remove the end plugs from your column and save them for use when

the column is removed from the system and stored. The column

outlet is indicated by an arrow on the label (showing the direction

solvent should flow).

To install the column, thread the inlet and outlet fittings into the

column until finger tight, and then tighten the fittings 1/4-to-1/2

turn. Use caution with non-metallic columns. Over-tightening these

fittings may cause damage which results in a leaking connection.

A properly prepared and assembled compression fitting in good

condition is all that is required.

Page 3

[ Care and Use ManUal ]

COMPRESSION SCREW

.021-inch (i.d.)

TEFZEL TUBING

TEFLON® FACE

BEVEL

FERRULE

STAINLESS STEEL

FAC E

FROM SOLVENT

RESERVOIR

PUMP

Inj

OPTIONAL

GUARD-PAK

AND HOLDER

IC-PAK

A

COLUMN

DETECTOR

TO WASTE

HIGH SENSITIVITY

NOISE FILTER

PUMP

Inj

HIGH SENSITIVITY

NOISE FILTER

ELUENT

EDTA/ HNO

3

GUARD COLUMN Inj

IC-PAK C

430/431

PUMP

Inj

HIGH SENSITIVITY

NOISE FILTER

ELUENT

EDA/ HNO

3

Inj

IC-PAK C

430/431

To replace a fitting:

1. Use a sharp razor blade to make a long tapering cut in the tubing as

shown in Figure 2. Alternately, if tubing is not in short supply, stretch

the tubing (after warming over low heat) between two sets of pliers and

cut the tube at thinnest point. The resulting taper will slip through the

fittings more easily.

2. Pass the tubing through the compression screw and ferrule. Be sure the

stainless steel side of the ferrule is facing the screw. Pull the tubing

with pliers to ensure the bevel or taper is completely past the ferrule.

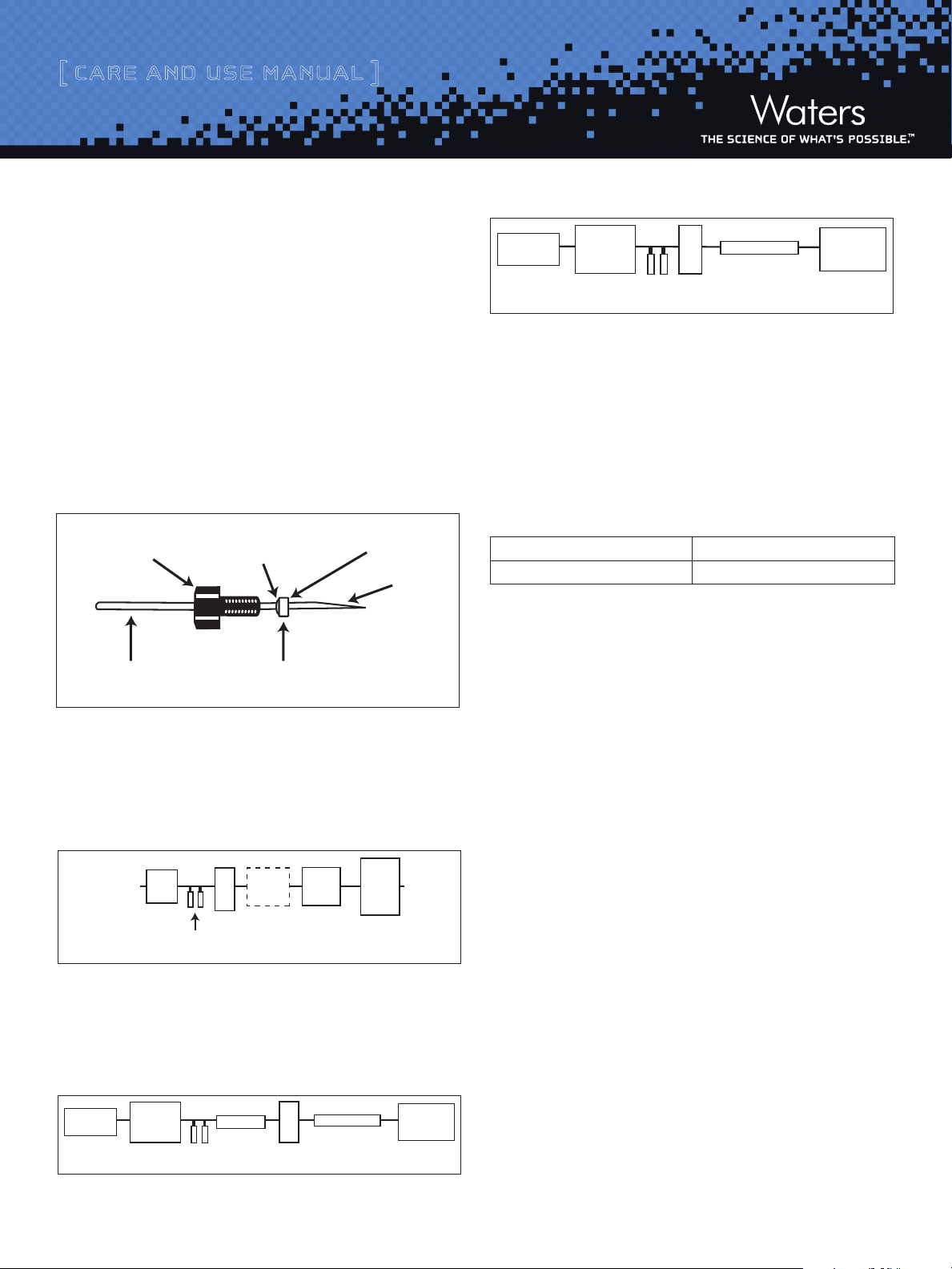

Figure 5: IC Systems for Divalent Cation Analysis

III. eluent and sample guIdelInes

a. Preparing the Eluent Requirements

3. Hold the ferrule with a second set of pliers and give the tubing a half

twist to lock the ferrule. Cut the tubing flush with the end of the ferrule.

Figure 2: Ferrule and Compression Assembly (Non-Metallic Column)

c. Configuring the Column In the System

Install stainless steel or non-metallic anion columns relative to the

other major components as shown in Figure 3.

Water-miscible organic solvents, which may be used as modifiers to

reduce hydrophobic interaction between sample and packing, must

not exceed the concentrations listed below.

IC-Pak A Columns 12% acetonitrile in water

IC-Pak C and Guard Columns 10% acetonitrile in water

Note: Organic solvent concentration should not exceed 20%. It is

possible, however, to use organic solvents up to 50% concentration

by gradual introduction via gradient method. Perform solvent

changeovers at 0.1 mL/min over 6 hours. Dedicate column to use in

the organic concentrations over 20%.

Use high performance liquid chromatography (HPLC) grade solvents

that have been filtered to remove microparticulate matter greater

than 0.45 µm in size. Filtering will ensure optimum long-term

performance of the column. Vacuum filtration, sonication, or sparging

may be used to remove dissolved gas which could affect results.

Before filtering or clarifying any solvents, flush the filters with

100 mL of the eluent. Discard the filtered eluent. Surfactants used to

treat some filters may otherwise affect analysis.

Figure 3: IC System for Anion Analysis

Install cation columns with a guard column for detecting monovalent

cations (Figure 4) or without a guard column for polyvalent cations

(Figure 5).

Figure 4: IC Systems for Monovalent Cation Analysis

IC-Pak Column and Guard Column 3

An in-line filter may be used to remove particulates in the solvent

and contaminants which the 0.45 µm filter does not remove.

Note: Do not use tetrahydrofuran (THF) or methanol with IC-Pak A columns.

Page 4

[ Care and Use ManUal ]

Solvents Containing Salts

Changeover between an organic solvent and water containing

salts should be performed gradually using 18 megohm water as

the intermediate solvent. Use care when adding organic solvents

to aqueous buffer solutions as salt precipitation may occur. As a

general rule, do not exceed salt concentrations of 0.1 M.

High pH Mobile Phase

If a high pH mobile phase (greater than 9) is to be used, a soda-

lime or AscariteTM absorbing trap is recommended. Otherwise, CO2

absorption from air contact with the reservoir may cause changes

in pH and ionic strength and impair reproducibility. Sparging with

helium is another recommended method to avoid this problem.

Equilibration

The shipping solvent maintains equilibrium. Flush the newly

attached column with fresh mobile phase before performing the first

separation.

Preparing Eluent for Efficiency Testing

b. Lithium Borate/Gluconate Eluent

All reagents should be of the highest purity available. To prepare

Lithium Borate/Gluconate concentrate:

1. To a one liter volumetric flask add:

34 g boric acid (H3BO3)

23.5 mL d-gluconic acid*

8.6 g lithium hydroxide monohydrate

* The compound d-gluconic acid is available as a 50 wt. percent aqueous

solution (Aldrich or Eastman Kodak).

Note: Sep-Pak® C18 clean-up of this reagent is recommended. Clean-up is

complete when a clear solution is obtained.

2. Add approximately 500 mL of Milli-Q® water and mix thoroughly until

dissolved. Then add 250 mL glycerin.

3. Fill to the mark with Milli-Q water and mix thoroughly. Concentrate

may be stored for up to six months before requiring replacement.

To prepare Lithium Borate Gluconate Eluent, conductivity 240 µS:

For general use and for efficiency testing (Section IV, b.), prepare

the eluent specified in Table 3.

Column Name Eluent Section

Table 3: Eluents for Efficiency Testing

IC-Pak A

IC-Pak A HC

IC-Pak A HR

IC-Pak C (Monovalent) EDTA/Nitric Acid Section III, d)

IC-Pak C (Divalent) EDA/Nitric Acid Section III, e)

*Sodium borate gluconate may be used in place of lithium borate

gluconate if desired. The chromatographic effects of the two eluents

are essentially identical.

Lithium Borate/Gluconate or

Sodium Borate/Gluconate*

Section III. b)

Section III, c)

1. Place approximately 500 mL of Milli-Q water into a one liter

volumetric flask. To this add:

20 mL borate gluconate concentrate

20 mL n-butanol

120 mL acetonitrile

2. Fill the flask to the mark with Milli-Q water and mix thoroughly. Filter

through a 0.22 µm GHP membrane.

c. Sodium Borate/Gluconate Eluent

All reagents should be of the highest purity available. To prepare

Sodium Borate/Gluconate concentrate:

1. To a one liter volumetric flask add:

16 g sodium gluconate

18 g boric acid

25 g sodium tetraborate decahydrate

2. Add approximately 500 mL of Milli-Q water and mix thoroughly until

dissolved. Then add 250 mL glycerin.

IC-Pak Column and Guard Column 4

Page 5

[ Care and Use ManUal ]

3. Fill to the mark with Milli-Q water and mix thoroughly. Concentrate

may be stored for up to six months before requiring replacement.

To prepare Sodium Borate/Gluconate Eluent, conductivity 270 RS:

1. Place approximately 500 mL of Milli-Q water into a one liter volumet-

ric flask. To this add:

20 mL borate gluconate concentrate 20 mL n-butanol

120 mL acetonitrile

2. Fill the flask to the mark with Milli-Q water and mix thoroughly. Filter

through a 0.22 µm GHP membrane.

d. Monovalent Cation Eluent

All reagents should be of the highest purity available.

1. To approximately 500 mL of Milli-Q water, add 120 ELL of concen-

trated nitric acid (Ultrex® grade).

2. Accurately weigh 18.6 mg of disodium EDTA and add this to the nitric

acid solution.

3. Dilute the solution to one liter with Milli-Q water.

4. Filter particulate matter from the solution with one of the following Pall

Life Science membranes (refer to Section VI for part numbers):

Aqueous replacement filters, GHP (0.45 µm, 47 mm)

f. Sample Preparation and Filtration

Filter prepared samples using a GHP membrane filter to prevent

excessive pressure buildup due to particulate matter. Rinse the filter

with 10 mL of 18 megohm water then filter the first few drops of

sample through the filter to waste.

IV. operatIon

a. Chromatography Guidelines

Liquid chromatography columns have a finite life which is directly

related to the care and use they receive. Column life is reduced

by contamination from samples and solvents, frequent solvent

changeovers, and improper handling and storage.

If changes in the peak shape, retention of a particular compound,

or resolution between two compounds occurs, take immediate

steps to determine the reason for the changes. Until the cause is

determined, do not rely on the results of the analyses.

Follow generally accepted procedures for quality control and

methods development when using these columns.

Note: Before running the first analysis on the new column, perform

the test sample separation given in the Efficiency Testing section.

GHP filters (0.22 µm, 47 mm)

5. Degas the eluent.

e. Divalent Cation Eluent

All reagents should be of the highest purity available.

1. To prepare the stock HNO3 solution, add 2.00 mL Ultrex HNO3 (ni tri c

acid) to a 100 mL volumetric flask and dilute to the mark with Milli-Q

water. Store in a refrigerator for no longer than six months.

2. To a one liter volumetric flask filled with approximately 500 mL of

deionized water, add 35 µL anhydrous ethylene diamine (EDA).

3. Add 3.25 mL of stock HNO3 prepared in Step 1 above.

4. Fill to the mark with Milli-Q water and mix thoroughly.

5. Filter particulate matter from eluent with GHP filters, (0.45 µm, 47

mm, refer to Section VI for part number).

IC-Pak Column and Guard Column 5

Precautions

Maximum pressure should not exceed:

IC-Pak A, IC-Pak C and Guard Column 6.7 MPa (67 atm or 1000 psi)

IC-Pak A HR 13 MPa (130 atm or 2000 psi)

IC-Pak A HC 20 MPa (200 atm or 3000 psi)

Recommended Flow Rate:

IC-Pak A 1.2 mL/min

IC-Pak A HC 2.0 mL/min*

IC-Pak A HR 1.0 mL/min

IC-Pak C 1.2 mL/min

pH Range for all columns: 1-12

Page 6

[ Care and Use ManUal ]

Temperature:

Normal operation 25 °C

Limits 10 °C - 50 °C

* Do not exceed a flow rate of 1.0 mL/min for the IC-Pak A HR

column. Flow rates higher than this may damage the column and will

void the warranty.

General Considerations:

• Sodiumsilicateleachingfromglassvialswillcauseartifactswhen

analyzing anions or cations. Plastic containers should be used for all

solutions.

• Dedicatecolumnstooneeluentonly,ifpossible.Multipleeluent

changes may result in shortened column life. Dedicated columns should

be used for either monovalent or divalent cation analysis.

• Filterallaqueousbuffers.Donotuseturbidorcloudybuffers.

• RemovealiquotsfromthesamplecontainerforpHreadings,andthen

dispose of the contaminated aliquots.

• UseapHmetertomeasurethepHofeluents.

b. Efficiency Testing

Waters columns are tested for adherence to Waters specifications.

Slight variations in results will occur depending on:

• Equipmentused

• Testsamplemakeup

• Equipmentsettingsandconditions

Perform an initial efficiency test before attempting the first analysis.

Run the test sample using the calibration standards detailed in the

following pages and record the results (retention time and the set-

tings used).

The initial efficiency test is performed by:

1. Preparing the eluent (Section III, a)

2. Preparing the calibration standards (Section IV, b to Section IV, d)

3. Running the calibration standard and determining column efficiency

(Section IV, e)

If problems occur during normal operation of the column, repeat the

conditions for the initial efficiency test and compare the results. Dif-

ferences in the results may indicate the source of the problem.

• Protectcolumnsfromvibration,mechanicalshock,andrapidchanges

in pressure, flow rate or solvent composition. Any thermal, physical or

chemical shock (such as changing solvents rapidly or at high flow rates)

can cause a loss of efficiency.

• Whenusingwater,treatwithaMilli-Qwatersystemcapableofdeliver-

ing 18 megohm water. Neither deionized water nor HPLC grade bottled

water is acceptable because each may contain organic compounds

which alter column selectivity.

• DONOTinjectconcentratedsamplesdirectlyintotheeluent.Direct

injection may cause precipitation of the salts in the sample. Dissolve

(or dilute) samples in an appropriate volume of the eluent first. If other

solvents must be used, be sure no precipitation occurs upon injection

into the eluent. Always filter samples before use.

• Highlyconcentratedsamples(greaterthan100ppmperion)mayyield

poor peak shape due to overloading the column. Dilute the sample

before injection. When analyzing an unknown, prepare a 1:100 dilution

as a first step in optimizing the method.

c. Anion Calibration Standard Preparation

1. To prepare individual 1000 ppm (mg/L) stock standards, refer to Table

4 for the weight of salt required. Select the highest purity salt available,

weigh the specified amount, and add to a 1 liter volumetric flask.

Table 4: Salt Weight for Anion Stock Solution Preparation

Anion (expressed as

compound listed)

-

F

-

CI

-

Br

-

NO

3

-2

HP0

4

-2

SO

4

Compound Weight in grams

NaF 2.2101

NaCl 1.6485

NaBr 1.2877

NaNO

KH2PO

Na2SO

3

4

4

1.3708

1.4179

1.4787

IC-Pak Column and Guard Column 6

Page 7

[ Care and Use ManUal ]

The following sample equation shows how these weights were

determined:

1 g CI -/L x 58.44 g NaCl/35.45 g Cl - x 1 L = 1.6485 g NaCl

2. Fill the flask to the mark with 18 megohm water. Store the stock

solutions in clean plasticware for up to one month.

3. Prepare a working standard containing all seven anions by combining

volumes of the stock standards as follows in a 100 mL volumetric

flask:

Table 5: Stock Standard Volumes

Anion Stock

Volume (µL)

Solution

Fluoride 100

Chloride 200

Nitrite 400

Bromide 400

Nitrate 400

Phosphate 600

Sulfate 400

Fill the flask to the mark with 18 megohm water. Table 6 contains the

species concentrations in the working standard.

Table 6: Anion Working Standard Concentrations

1. To prepare individual 1000 ppm (mg/L) stock standards, refer to Table

7 for the weight of salt required. Select the highest purity salt available

(atomic absorption standards if possible), weigh the specified amount,

and add to a 1 liter volumetric flask.

Table 7: Salt Weight for Cation Stock Solution Preparation

Cation (expressed

Compound Weight in grams

as compound listed)

+

NH

Na

Li

+

+

4

LiOH•H2O 6.0476

NaCl 2.5421

NH4CI 2.9640

KCI 1.9067

+2

Mg

Ca

Sr

Ba

+2

+2

+2

Mg(N03)2•6H20 10.5466

Ca(N0)2•4H20 5.8919

Sr(N03)2•4H2O 3.2377

BaCl2•2H2O 1.7786

The following sample equation shows how these weights were

determined:

1 g K+/L x 74.553 g KCI/39.100 g K+ x 1 L = 1.9067 g KCI

2. Fill the flask to the mark with 18 megohm water.

3. Store the stock solutions in clean plasticware for up to one month.

Anion Stock

ppm

Solution

Fluoride 1

Chloride 2

Nitrite 4

Bromide 4

Nitrate 4

Phosphate 6

Sulfate 4

d. Cation Calibration Standard Preparation

Cation standard concentrates may be purchased from most major

chemical suppliers. Use the highest purity solutions available. A

number of anionic species can cause the precipitation of alkali

and alkaline earth metals. Consult solubility tables to avoid these

species. Also, avoid hygroscopic salts.

IC-Pak Column and Guard Column 7

4. Prepare a working standard for monovalent or divalent cations. Take

volumes of the stock standards as follows and combine in a 100 mL

volumetric flask.

For monovalent cation use the following volume of the appropriate

stock solutions:

Lithium 10 µL

Sodium 50 µL

Ammonium 100 µL

Potassium 100 µL

For divalent cation use the following volume of the appropriate

stock solutions:

Magnesium 200 µL

Calcium 400 µL

Strontium 600 µL

Barium 1600 µL

Page 8

[ Care and Use ManUal ]

IN JEC T

W½

½h

h

= Column Eciency (plates)

= Volume to peak apex (µL)

= Volume of peak at ½ peak height (µL)

N

VR

W ½

N = 5.54 x

2

5. Fill the flask to the mark with 18 megohm water. Tables 8 and 9

contain the species concentrations in the monovalent and divalent

cation working standards.

Table 8: Monovalent Cation Working Standard Concentrations

Monovalent Cation

ppm

Stock Solution

Lithium 0.1

Sodium 0.5

Ammonium 1.0

Potassium 1.0

Table 9: Divalent Cation Working Standard Concentrations

Divalent Cation

ppm

Stock Solution

Magnesium 2

Calcium 4

Strontium 6

Barium 16

f. Calculating Efficiency

Refer to Figure 6 for the appropriate peak to measure for your anion

or cation column. Use the equation in the figure below to compute

column efficiency for comparison to the value in the table.

Figure 6: Half Height Method Test Calculations

e. Running the Calibration Standard and Determining

Column Efficiency

Refer to Table 10 for the parameters to run the calibration standard.

Table 10: Calibration Standard Parameters

Column

Name

IC-Pak A 1.2 Anion 800 sulfate

IC-Pak C 1.2 Cation 1100 sodium

IC-Pak A HC 2.0 Anion 1500 sulfate

IC-Pak A HR 1.0** Anion 2500 sulfate

* By half-height method on a low dispersion Waters ion

chromatograph

** Do not exceed a flow rate of 1.0 mL/min for the IC-Pak A HR

column. Flow rates higher than this may damage the column and void

the warranty.

IC-Pak Column and Guard Column 8

Optimal Flow

Rate (mL/min)

Test Sample Efficiency

(Plates)*

Peak for Plate

Measurement

Page 9

[ Care and Use ManUal ]

V. Care and maIntenanCe

a. Troubleshooting

Table 11: Column Problems and Solutions

Symptom Conditions Corrective Action

Excess pressure buildup Filters plugged with

Loss of resolution,

broad peaks, low plate

counts

particulates. Check for

injector and pump seal

shedding

Sample precipitates

on column (sample no

soluble in eluent)

Clogged tubing Unclog or replace tub-

Polyvalent electrolyte

accumulation

Failing injector Repair injector.

Contaminated column Slowly purge with

Insufficient equilibration Continue equilibration.

Incorrect 0.040-inch

stainless steel tubing

0.1 mL/min with eluent.

in-line precolumn filter

purge (below 1 mL/min)

IC-Pak C – Slowly purge

Back flush column at

Always filter eluents

and samples. Use an

between the pump and

injector.

Black flush column at

0.1 mL/min with elu-

ent. Use a solvent that

is compatible with the

sample.

ing.

IC-Pak A – Slowly

with 100 mL of the

following solution:

In a 1 liter volumetric

flask combine 50 mL

eluent concentrate,

120 mL Acetonitrile,

and 20 mL Butanol.

Fill to the mark with

18 megohm water and

filter.

(below 1 mL/min) with

50 mL of 100 mM

strong solvent.

0.009-inch stainless

-

HNO

3

Install correct

steel tubing.

b. Column Storage

Remove columns not in use for over 72 hours and store:

• AnioncolumnsinBorateGluconateEluent

• Cationcolumnsintheeluentusedforanalysis(eitherEDTA/HNO3 or

EDA/HNO3)

Eluent may be left in the columns with the columns connected to the

system for short-term storage.

When storing columns:

• DONOTstorecolumnsinwater.Topreventgrowthofbacteriastorethe

columns in the eluent being used. Fill the column with eluent, replace

the end plugs, and return the column to its box.

• DONOTallowthecolumntodryout.Allowingthecolumnpackingto

dry out can result in poor chromatographic performance. Eluent may

be left in the columns with the columns connected to the system for

short-term storage.

• Storeat15°Cto35°C.Freezingduringstoragewillcauseperfor-

mance degradation.

c. Cation Guard Column Preparation and Regeneration

Monovalent cation analysis may require frequent changing

or regeneration of the guard column due to interference from

polyvalent cations. Change or regenerate the column when:

• k’changesorthereisanoticeabledecreaseinretentiontime

(greater than 15%)

• Fusedpeaksareseen

• Resolutionisabnormal

Changing or regeneration of the guard column may be frequent,

depending on the particular analysis. Monovalent detection using a

sample matrix containing heavy metals may load the column easily.

To regenerate the column, flush the column with 200 mL 0.1 M HNO3

at a flow rate of 1.2 mL/min.

IC-Pak Column and Guard Column 9

Page 10

[ Care and Use ManUal ]

VI. orderIng InformatIon

Table 12: Recommended Spare Parts

Item Part Number Quantity

IC-Pak A Column – 0.46 x 5.0 cm WAT007355 1

IC-Pak A HC Column – 0.46 x 15.0 cm WAT026770 1

IC-Pak A HR Column – 0.46 x 7.5 cm WAT026765 1

IC-Pak C Column – 0.46 x 5.0 cm WAT007354 1

Cation Guard Column – 0.46 x 5.0 cm WAT007356 1

Compression Screws and Ferrules

(for anion column only)

Sample Clarification Kit (Aqueous) WAT026865 1

Filters:

Solvent Clarification Kit w/pump and Filters

(110 V. 60 Hz)

Acrodisc GHP 25 mm, 0.45 µm WAT200514 100/box

Solvent Filters GHP 47 mm, 0.22 µm 186003527 100/box

In-Line Precolumn Filter WAT084560

Guard-PakTM Precolumn Module:

Module (no cartridges) WAT088141 1

IC-Pak Anion Guard-Pak Inserts WAT010551 5/box

IC-Pak Anion Concentrator Inserts WAT007358 5/box

IC-Pak Cation Concentrator Inserts WAT010565 5/box

Sep-Pak C18 Cartridges WAT051910 50/box

Sep-Pak C18 Plus Cartridges WAT011191 50/box

Polypropylene Vials 12 mm x 32 mm 186004112 100/box

WAT025604 5/box

WAT085113 1

Sales Offices:

Austria and European Export

(Central South Eastern Europe,

CIS and Middle East) 431 877 18 07

Australia 2 9933 1777

Belgium 32 2 726 1000

Brazil 55 11 5094 3788

Canada 800 252 4752

China 8621 6495 6999

CIS/Russia +7 495 3367000

Czech Republic 42 02 617 11384

Denmark 45 46 59 8080

Finland +358 9 5659 6288

France (33) 1 30 48 72 00

Germany 49 6196 400600

Hong Kong 852 29 64 1800

Hungary 36 1 350 5086

India and India Subcontinent

91 80 2 837 1900

Ireland 353 1 448 1500

Italy 39 02 274 211

Japan (81) 3 3471 7191

Korea (82) 2 820 2700

Mexico 5255 5200 1860

The Netherlands +31 (0)76-50 87 200

Norway 47 63 84 60 50

Poland (48) 22 833 4400

Puerto Rico 787 747 8445

Singapore 65 6273 1221

Spain 34 93 600 93 00

Sweden 46 8 555 11500

Switzerland 41 62 889 2030

Taiwan 886 2 2543 1898

United Kingdom 44 208 238 6100

©2008 Waters Corporation, Waters. The Science of What’s

Possible. IC-Pak, Sep-Pak, WISP and Guard-Pak are trademarks of

Waters Corporation. Milli-Q, Ascarite, Durapore, Millex, Ultrex

and MilliTrap are trademarks if Millipore Corporation.

May 2008 WAT091064 Rev C VW-PDF

IC-Pak Column and Guard Column 10

Waters Corporation

34 Maple Street

Milford, MA 01757 U.S.A.

T: 1 508 478 2000

F: 1 508 872 1990

www.waters.com

Loading...

Loading...