Page 1

[ Care and Use ManUal ]

WAters IC-PAk C M/d CoLuMn

I. IntroduCtIon

This manual describes procedures for using the Waters IC-Pak™ C M/D

Ion Chromatography separation of monovalent and divalent cations.

Please take a few moments to read this manual carefully. Follow its

recommendations to obtain reproducible chromatography and column

stability.

a. Waters IC-Pak C M/D Column Description

Waters IC-Pak C M/D column is designed for ion chromatography

applications. Use the M/D column to simultaneously analyze

monovalent and divalent cations isocratically. The column separates

and allows quantitation of Li

+

, Na+, NH

+

, +*, Mg

4

+

’ Ca+, Sr

2

+

, and Ba

2

+

2

cations at ppb levels.

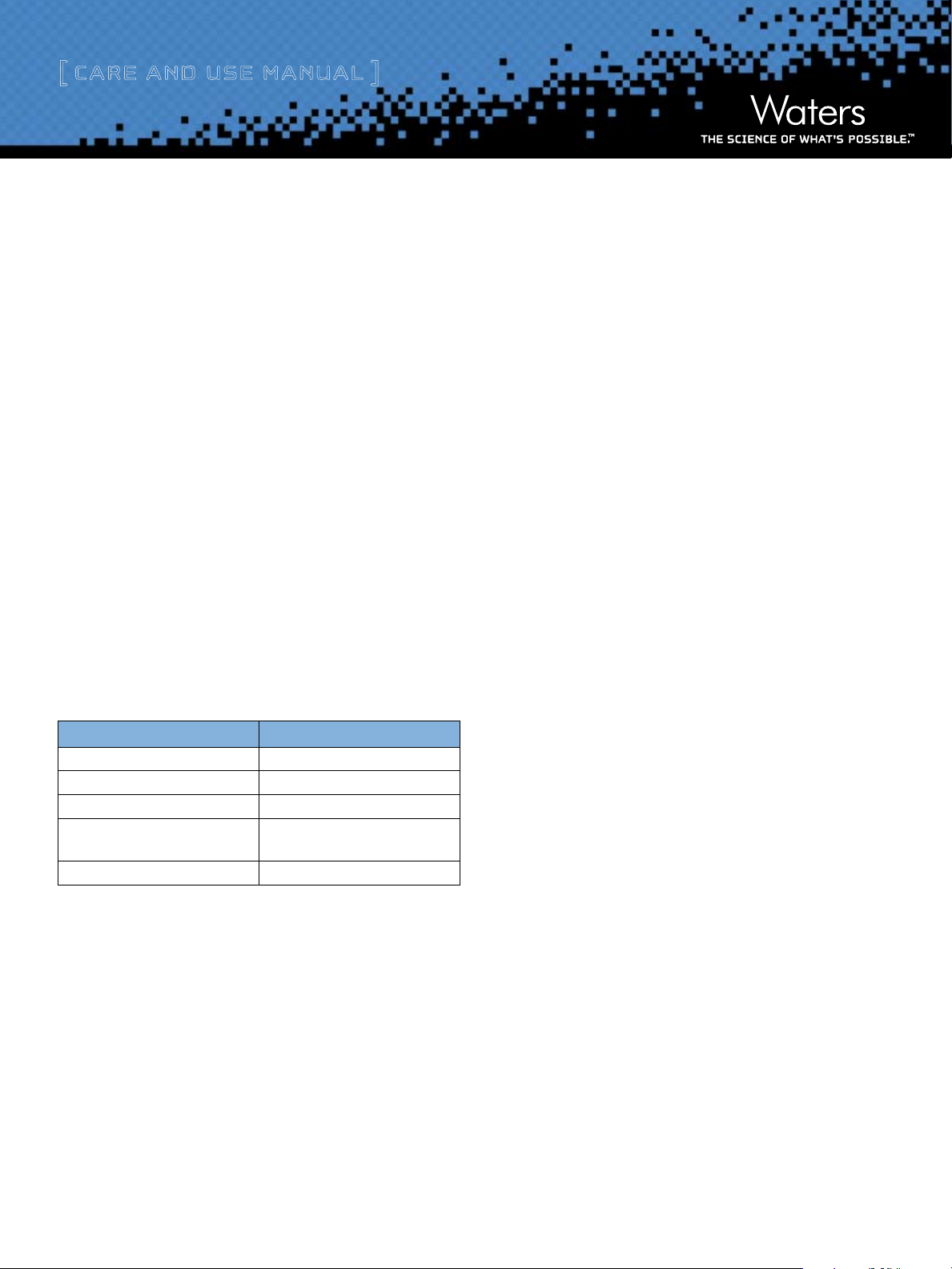

b. Specifications

Column IC-Pak C M/D

Dimensions 3.9 x 150 mm

Particle size 5 µm

Capacity 1.5 ± 0.2 meq/g

Packing material Silica base coated with polybutadi-

ene/maleic acid copolymer

Shipped in 20/80 (v/v} acetonitrile/water

Contents

I. IntroduCtIon

a. Waters IC-Pak C M/D Column Description

b. Specifications

II. InstALLInG tHe CoLuMn

a. Preparing the Ion Exchange System

b. Installing the Column

c. Equilibrating the Column

III. PrePArInG MoBILe PHAse And sAMPLes

a. Preparing the Mobile Phase

b. Preparing the Sample Preparing

IV. usInG tHe CoLuMn

a. Chromatography Guidelines

b. Efficiency Testing

V. CAre & MAIntenAnCe

a. Storing the Column

b. Troubleshooting

VI. orderInG InForMAtIon

Waters IC-Pak C M/D Column 1

Page 2

[ Care and Use ManUal ]

Compression Screw or Nut

Ferrule

0.009-inch ID Tubing

(0.23 mm)

II. InstALLInG tHe CoLuMn

a. Preparing the Ion-Exchange System

To prepare the system, you need two 3/8-inch wrenches and a zero

dead-volume union. Before installing the column in the flow path:

1. Directly connect the injector to the detector by replacing the old column

with a zero dead-volume union.

2. Flush the lines and the detector of microparticulates and previous sol-

vents. Use fresh eluent at a flow rate of 1.0 mL/min. Flush the injector

loop if applicable.

3. Remove the union.

4. Install the column between the injector and detector (see Section II. b).

b. Installing the Column

Remove the end plugs from the column and save them for use when

you store the column. To install the column:

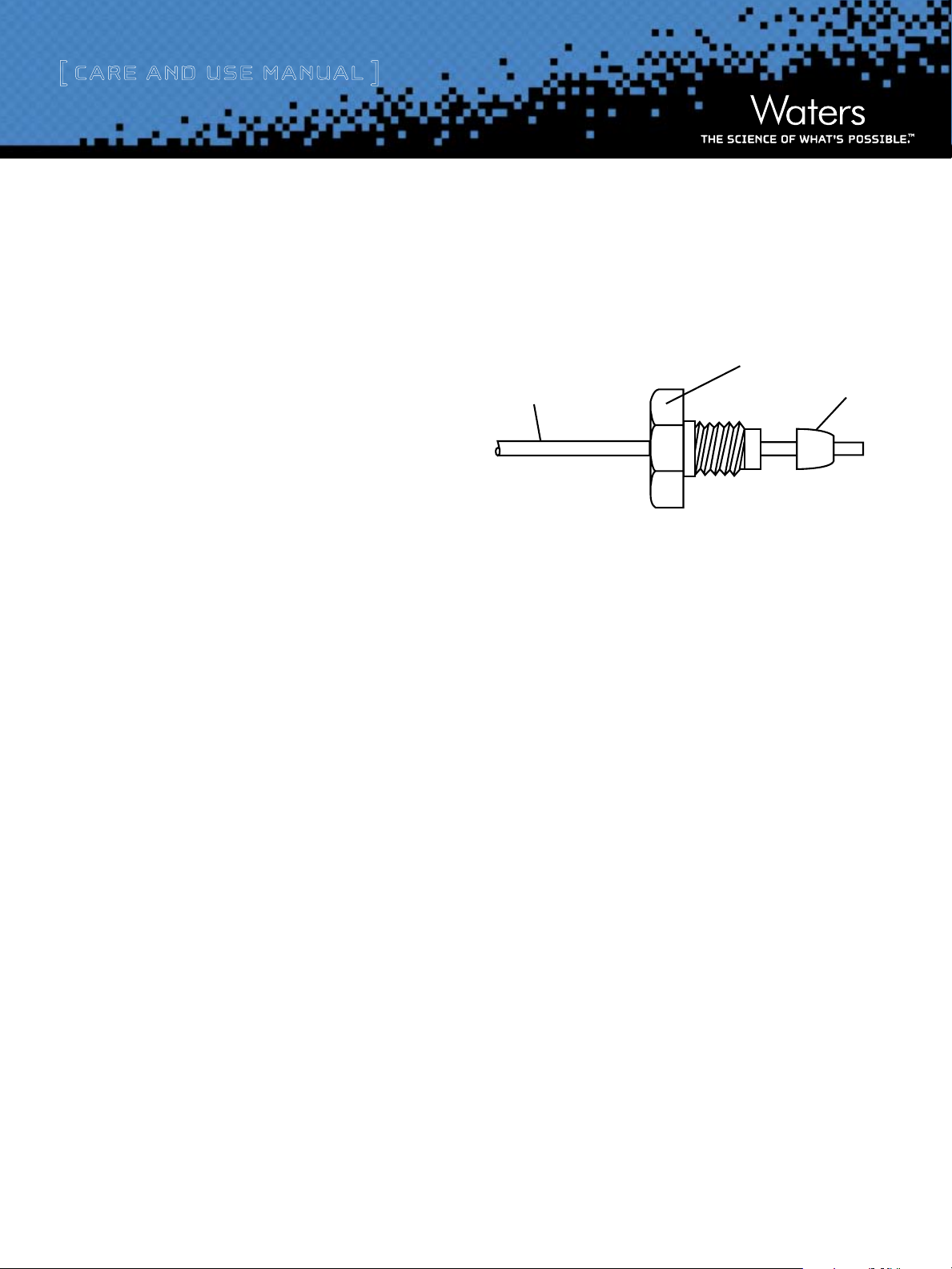

3. Slide the compression fitting, followed by the ferrule (large end of the

taper first) over the tube.

Note: Properly bottom the tubing in the fitting seat. Otherwise, dead

volume could result in sample bond spreading.

Figure 1: Ferrule and Compression Screw Assembly

c. Equilibrating the Column

1. Precondition new columns by flushing with 100% acetonitrile for 30

minutes at 0.5 mL/min.

1. Thread the inlet and outlet fittings into the column until finger-tight.

An arrow on the label indicates the direction of flow.

2. Use the wrenches to tighten the fittings 1 /4 to 1 /2 turn. Do not

overtighten. Overtightening damages the connection.

3. Prepare a new tubing-ferrule connection (Figure 1) when connecting a

new column or when removing a damaged compression screw or worn

ferrule.

Note: The tubing distance beyond the ferrule may differ for each

column type. Resize the tubing to the correct distance by replacing

the ferrule.

Preparing a New Connection

To prepare a new tubing-ferrule connection:

1. Scribe the circumference of the tubing at the desired break using either

a file with a cutting edge or a tube cutter.

2. Grasp the tubing on both sides of the scribe mark with cloth-covered

pliers (to prevent marring the tube surface), and gently work the tube

back and forth until it separates.

Note: Ensure that tubing end is straight, open, and free of burrs.

2. Flush the column with mobile phase for 5 minutes at 0.5 mL/min,

and them for 30 minutes at 1.0 mL/min before performing the first

separation.

III. PrePArInG MoBILe PHAse And sAMPLes

a. Preparing the Mobile Phase

Chemical requirements

The IC-Pak C M/D uses 0.1 mM EDTA/3.0 mM HNO3 as a mobile

phase. Store mobile phase at room temperature for up to one month.

• ACSReagentgradeorequivalentqualityfree-acidEDTA

• Qualitynitricacid

• Quality18megohmwater

• Plasticwaretoprepareandstoreallmobilephases,standards,and

samples

Waters IC-Pak C M/D Column 2

Page 3

[ Care and Use ManUal ]

Filtration

Before filtering the mobile phase, flush the filters with 100 mL of mobile

phase. Discard the filtered mobile phase. Filter and degas mobile phases

®

with a compatible Millex

of the column.

Use an in-line precolumn filter to remove particulates in the mobile phase

and contaminants which the 0.45 µm filter does not remove.

0.45 µ filter for optimum long-term performance

Glass Containers

Sodium leaching from glass viols causes artifacts when analyzing cations.

Use plastic containers for all solutions.

Organic Mobile Phases

Samples containing organic amines may exhibit hydrophobic interaction

between the mobile phase and packing. You may use a water-miscible

organic mobile phase, such as acetonitrile, as a modifier to reduce this.

Do not use methanol; over time it causes a significant decrease in cation

8

retention time. Pretreat the sample with a C1

remove hydrophobic compounds.

Sep-Pak® cartridge to

Changeover to Mobile Phases Containing Salts

Perform changeover between on organic solvent and water containing

salts gradually to avoid salt precipitation. Use 18 megohm water as the

intermediate solvent. Do not exceed salt concentrations of 0.1 M.

Preparing the Mobile Phase

b. Preparing the Sample Preparing

Sample cleanup with Sep-Pak cartridges prevents alteration of the column

chemistry by strongly adsorbing or precipitating sample components. Pass

the first few drops of sample to waste.

Filter prepared samples with a microporous filter to prevent excessive

pressure buildup due to particulate matter. Rinse the filter with 10 mL of

18 megohm water. Pass the first few drops of Sample through the filter

to waste.

IV. usInG tHe CoLuMn

a. Chromatography Guidelines

The life of a column is directly related to its care and use. Contamination

from samples and mobile phases and improper handling and storage

reduce column life.

Note: Before running the first analysis on the new column, perform the test

sample separation given in Section IV. b, Efficiency Testing.

Physical Limits

Maximum Pressure 27 MPa (27 atm or 4000 psi)

Flow Rote 1 m min

pH Range 2 to 7

Temperature:

Normal operation

Limits

25 °C

≤ 50 °C (do not freeze column)

1. Put800mLofMilli-Q™waterintoaone-litervolumetricflask.

2. Add 0.0292 g EDTA, free acid (reagent grade). Stir or place in ultra-

sonic bath for 15 minutes.

3. Add 189 µL Nitric Acid (Ultrex).

4. DilutethesolutiontooneliterwithMilli-Qwaterandmixthoroughly.

5. Filter any undissolved EDTA from the solution and degas with one

of the following Millipore membranes (refer to Section ??? for part

numbers):

Aqueous Replacement Filters (0.45 µm, 47 mm)

®

Durapore

Waters IC-Pak C M/D Column 3

Filters (0.22 µm, 47 mm)

Page 4

[ Care and Use ManUal ]

General considerations

• Filterallaqueousbuffers.Donotuseturbidorcloudybuffers.

• Donotreusealiquotstakenfromthesamplecontainer;disposeof

them.

• Protectthecolumnfromvibration,mechanicalshock,andrapid

changes in pressure, flow rate or mobile phase composition. Any

thermal, physical or chemical shock (such as changing mobile phases

rapidly) can cause a loss of efficiency.

• Whenusingwater,treatitwithawatersystemcapableofdelivering

18 megohm water. Neither deionized water nor HPLC-grade bottled

water are acceptable because they may contain organic compounds

which alter column selectivity.

• Highlyconcentratedsamples(greaterthan10ppmperion)can

overload the packing material, resulting in poor peak shape. Dilute

the sample before injection. W hen analyzing an unknown, start with a

1:100 dilution.

• DO NOT inject concentrated samples directly into the mobile phase.

Direct injection may cause precipitation of the salts in the sample.

Dissolve (or dilute) samples in an appropriate volume of the mobile

phase first. If you must use other solvents, watch for precipitation upon

injection into the eluent. Always filter samples before use.

Preparing Mobile Phase

The IC-Pak C M/D column uses 0.1 mM EDTA/3.0 mM HNO3 as a

mobile phase. See phase Section III. a, Preparing the Mobile Phase,

for procedures for mobile phase preparation.

Guidelines for the Calibration Standard

Standard concentrates are available from most major chemical

suppliers. Use reagent-grade or analytical standard-grade

solutions. Several anionic species can cause the precipitation of

alkali and alkaline earth metals. Consult solubility tables to avoid

these species. Avoid hygroscopic salts. Select the highest purity

salt available. Certain atomic absorption standards are made

from ammonium salts and must not be used to prepare calibration

standard.

Preparing Individual 1000 ppm Stock Standards

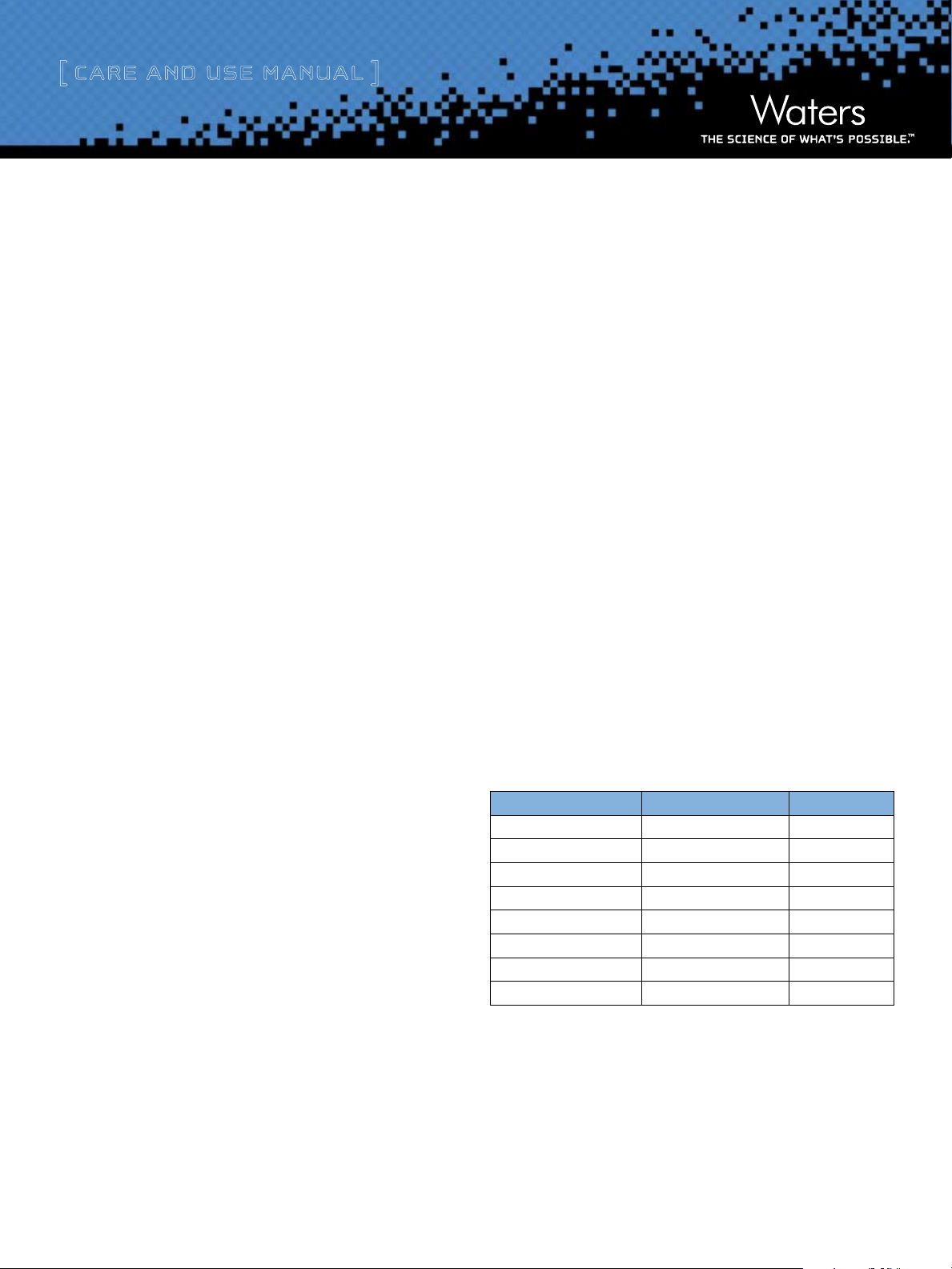

1. Weigh the specified amount of salt (refer to Table 1).

2. Add the salt to a plastic 1 liter volumetric flask.

3. Fill the flask to the mark with 18 megohm water.

4. Store the stock solutions in clean plasticware at room temperature for

up to 6 months.

Table 1: Salt Weight for Stock Solution Preparation

b. Efficiency Testing

Perform on efficiency test before attempting the first analysis.

Run the test sample using the calibration standards detailed in the

following pages. Record the retention time and the settings used

There are four parts to performing the efficiency test:

1. Preparing the mobile phase

2. Preparing the stock calibration standards

3. Running the calibration (working) standard

4. Calculating column efficiency

If you experience problems during normal operation, repeat the

conditions for the initial efficiency test and compare the results.

Differences may indicate a problem with the column.

Waters IC-Pak C M/D Column 4

Cation Compound Weight (g)

+

(Lithium) UOH•H20 6.0476

Li

+

(Sodium) NaCI 2.5421

No

+

(Ammonium) NH4CI 2.9640

NH

4

+

(Potassium) KCI 1.9067

K

+

(Magnesium) Mg(NO3)2•6H20 10.5466

Mg

2

+

(Calcium) Ca(N03)2•4H20 5.8919

Ca

2

+

(Strontium) Sr(NO3)2•4H20 3.2377

Sr

2

+

(Barium) BaCl2•2H20 1.7786

Ba

2

The following equation is an example of how these weights were

determined:

+

/L x 74.553 g KCI/39.100 g K+ x 1 L = 1.9067 g KCI

1 g K

Page 5

[ Care and Use ManUal ]

T

R

Inject

W

1/2

1/2h

h

Column eciency (plates)

Time to peak apex (minutes)

Width of peak at 1/2 peak height (minutes)

N = 5.54 x

2

Time (minutes)

0510 15 20 25

15.0 µS

1

2

3

4

5

6

7

8

1. Lithium

2. Sodium

3. Ammonium

4. Potassium

0.25 ppm

1.0 ppm

1.0 ppm

3.0 ppm

5. Magnesium

6. Calcium

7. Strontium

8. Barium

2.0 ppm

3.0 ppm

5.0 ppm

5.0 ppm

To prepare 1 liter of working standard:

1. Measure the appropriate quantity of stock standard (refer to Table 2).

2. Add the stock standard to a plastic 1000 ml volumetric flask.

3. Fill the flask to the mark with 18 megohm water. Table 2 shows

the concentrations for the monovalent and divalent cation working

standards.

4. Store working standards in clean plasticware at room temperature for

up to one month.

Table 2: Working Standard Solutions and Final Concentrations

Cation Use This Volume of

Stock Standard

+

Li

(Lithium) 0.250 ml 0.25

+

(Sodium) 1.000 ml 1.00

Na

+

NH4

Ammonium) 1.000 ml 1.00

+

(Potassium) 3.000 ml 3.00

K

+

agnesium) 2.000 ml 2.00

Mg

2

+

(Calcium 3.000 ml 3.00

Ca

2

+

(Strontium 5.000 ml 5.00

Sr

2

+

(Barium) 5.000 ml 5.00

Ba

To Yield This Concentration of

Working Standard (ppm)

Calculating Efficiency

Use the potassium peak (#4) to measure your column efficiency

with the half-height method equation in Figure 3.

Figure 3: Half-Height Method Test Calculations

V. CAre & MAIntenAnCe

Determining Column Efficiency

Use a flow rate of 1.0 ml/min. The peak for potassium should yield

>2,000 plates by the half-height method on a low dispersion Waters

ion chromatograph.

Figure 2 shows the conditions and resulting chromatogram for

monovalent and divalent cation standards.

Figure 2: IC-Pak C M/D Standard Cation Chromatogram

Waters IC-Pak C M/D Column 5

a. Storing the Column

For short-term storage, leave the mobile phase in the column with

the column connected to the system.

If the column will not be used for more than 72 hours, store it in

20/80 acetonitrile/water (v/v).

When storing columns:

DO NOT store the column in methanol or methanol-containing

Conditions

Column IC-Pak C M/D

Eluent 0.1 mM EDTA/

3 mM HNO3

Detector Waters 431

Flow Rate 1.0 mL/min

Injection

Volume

Conductivity

100 µL

solutions. Over time, methanol causes significant decreases in

cation retention times. To prevent growth of bacteria, fill with 20/80

acetonitrile/water (v/v), replace the end plugs, and return the column

to its box.

DO NOT allow the column to dry out. Allowing the column packing to

dry out can result in poor chromatographic performance.

Store at 15 °C to 35 °C. Freezing during storage degrades

performance.

Page 6

[ Care and Use ManUal ]

b. Troubleshooting

Table 3: Column Problems and Solutions

Symptom Conditions Corrective Action

Excess pressure

buildup

Filters plugged with

particulates. Check for

Replace filter.

injector and pump seal

shedding.

Clogged tubing Unclog or replace tubing.

Failing injector Repair the injector.

Sample precipitates

on column

Sample not soluble in

eluent

Backflush column with

mobile phase for 30 minutes at 0.1 mL/min.

Use a compatible mobile

phase.

Loss of resolution,

broad peaks, low

plate counts

Insufficient equilibration Continue equilibration

Incorrect diameter stainless steel tubing

Install 0.0009-inch stainless steel tubing.

Contaminated column Flush column with 100%

acetonitrile at 0.5 mL/min

for 30 minutes.

VI. orderInG InForMAtIon

Sales Offices:

Austria and European Export

(Central South Eastern Europe,

CIS and Middle East) 431 877 18 07

Australia 2 9933 1777

Belgium 32 2 726 1000

Brazil 55 11 5094 3788

Canada 800 252 4752

China 8621 6495 6999

CIS/Russia +7 495 3367000

Czech Republic 42 02 617 11384

Denmark 45 46 59 8080

Finland +358 9 5659 6288

France (33) 1 30 48 72 00

Germany 49 6196 400600

Hong Kong 852 29 64 1800

Hungary 36 1 350 5086

India and India Subcontinent

91 80 2 837 1900

Ireland 353 1 448 1500

Italy 39 02 274 211

Japan (81) 3 3471 7191

Korea (82) 2 820 2700

Mexico 5255 5200 1860

The Netherlands +31 (0)76-50 87 200

Norway 47 63 84 60 50

Poland (48) 22 833 4400

Puerto Rico 787 747 8445

Singapore 65 6273 1221

Spain 34 93 600 93 00

Sweden 46 8 555 11500

Switzerland 41 62 889 2030

Taiwan 886 2 2543 1898

United Kingdom 44 208 238 6100

To order these parts, contact the nearest subsidiary (see back cover).

Table 4: Spare Parts and Accessories

Part Number

IC-Pak C M/D Column, 3.9 x 150 mm WAT036570

Replacement frit for 3.9 mm column WAT015931

IC-Pak C M/D Guard-Pak™ Inserts, 10/pkg WAT098801

© 2007 Waters Corporation. Waters, The Science of W hat’s Possible, IC-Pak, Sep-Pak, and Guard-Pak are trademarks of Waters

Corporation. Millex, Milli-Q, and Durapore are trademarks of

Millipore Corporation.

November 2007 WAT036549 Rev 4 VW-P DF

Waters IC-Pak C M/D Column 6

Waters Corporation

34 Maple Street

Milford, MA 01757 U.S.A.

T: 1 508 478 2000

F: 1 508 872 1990

www.waters.com

Loading...

Loading...