Waters High Strength Silica Columns User Manual

[ Care and Use ManUal ]

HIGH stRenGtH sILICa HPLC CoLUMns

Contents

I. IntRoDUCtIon

II. ConeCtInG tHe CoLUMn to tHe HPLC sYsteM

III. WateRs sMaLL PaRtICLe sIze (3.5 �M) CoLUMns

– Fast CHRoMatoGRaPHY

IV. CoLUMn eqUILIbRatIon

V. CoLUMn InstaLLatIon PRoCeDURe

VI. CoLUMn PeRFoRManCe VaLIDatIon

VII. InItIaL CoLUMn eFICIenCY DeteRMInatIon

VIII. CoLUMn UsaGe

IX. CoLUMn CLeanInG, ReGeneRatInG anD stoRaGe

X. tRoUbLesHootInG

I. IntRoDUCtIon

Thank you for choosing a High Strength Silica (HSS) HPLC column.

The manufacture of HSS HPLC columns begins with ultrapure

reagents to control the chemical composition and purity of the

final product. HSS HPLC columns are manufactured in a cGMP,

ISO 9001:2000 certified plant with each step being conducted

within narrow tolerances. Every column is individually tested and

Certificates of Batch Analysis and a Performance Chromatogram are

provided with each column.

HSS HPLC columns are based on the same particle technology and

chemistries as ACQUITY UPLC HSS columns, thus enabling seamless

transferability between HPLC and UPLC separations.

™

Waters recommends the use of Sentry

column lifetime and protect the column from contaminants.

guard columns to maximize

HSS HPLC C olumns

1

[ Care and Use ManUal ]

II. CONNECTING THE COLUMN TO THE HPLC SYSTEM

a. Column Connection

Handle the column with care. Do not drop or hit the column on a hard

surface as this may disturb the bed and affect its performance.

1. Correct connection of 1/16 inch outer diameter stainless steel

tubing leading to and from the column is essential for high-

quality chromatographic results.

2. An arrow on the column identification label indicates correct

direction of solvent flow.

3. When using standard stainless steel compression screw fittings,

it is important to ensure proper fit of the 1/16 inch outer

diameter stainless steel tubing. When tightening or loosening the

compression screw, place a 5/16 inch wrench on the compression

screw and a 3/8 inch wrench on the hex head of the column

endfitting.

Caution: If one of the wrenches is placed on the column flat

during this process, the endfitting will be loosened and leak.

Under-tightening compression screws or using worn ferrules can

lead to solvent leaking. Care should be taken to check all column

connections for leaks to avoid exposure to solvents and the

hazards associated with such exposure including risks to health

and electrical

connections.

4. If a leak occurs between the stainless steel compression screw fit-

ting and the column endfitting, a new compression screw fitting,

tubing and ferrule must be assembled.

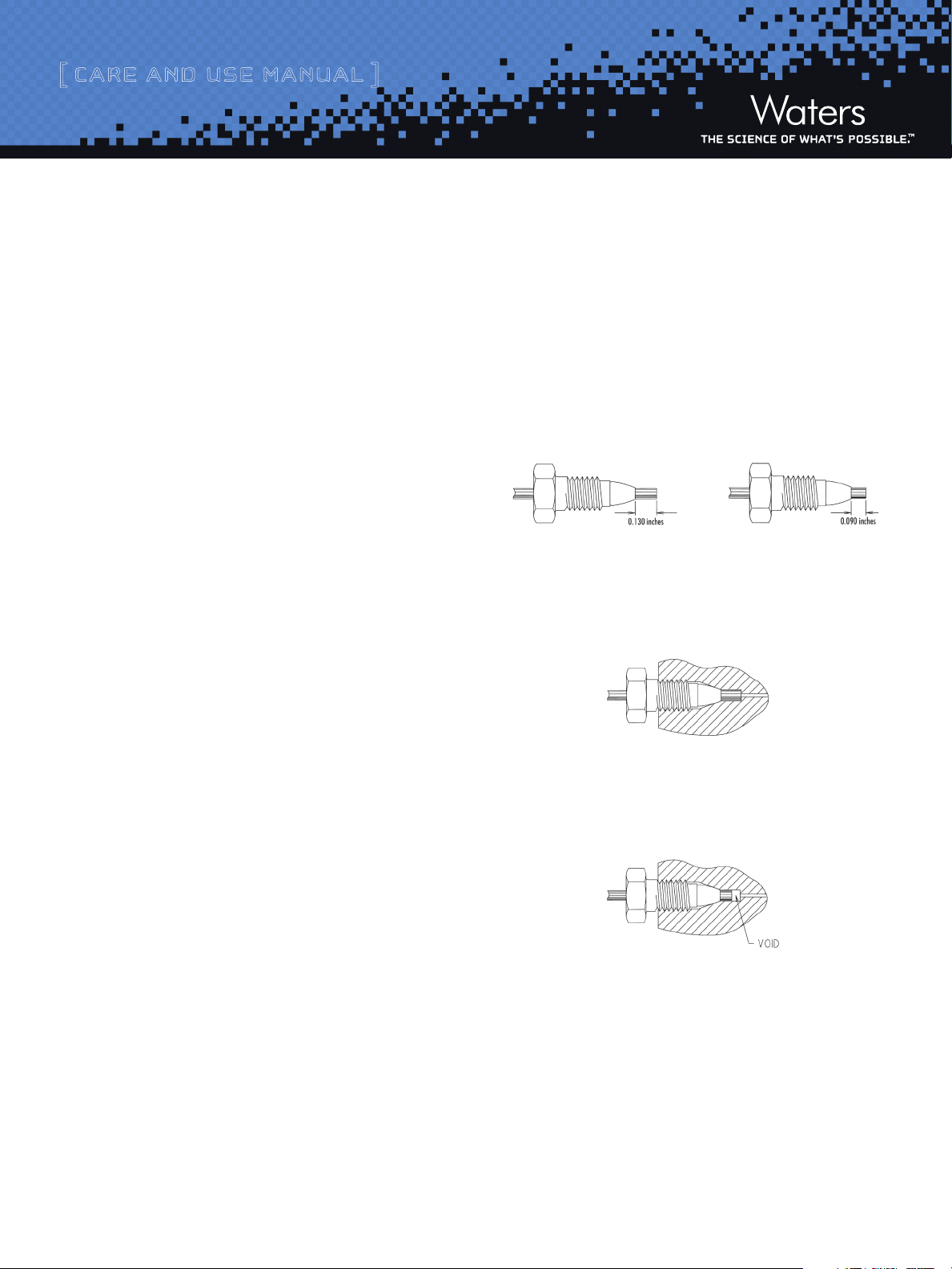

ferrule. If a non-Waters style column is presently being used, it is

critical that ferrule depth be reset for optimal performance prior to

installing a HSS HPLC column. In a proper tubing/column connection

(Figure 2), the tubing touches the bottom of the column endfitting,

with no void between them.

Attention: A void will occur if tubing with a Parker ferrule is con-

nected to a Waters style endfitting (Figure 3). This will dramatically

reduce the efficiency of the column and cause peak shape distortion.

Figure 1: Waters and Parker Ferrule Types

Waters Ferrule Setting Parker Ferrule Setting

Figure 2: Proper Tubing/Column Connection

Tubing touches the bottom of the column endfitting, with no void

between them.

Attention: A void will occur if tubing with a Parker ferrule is con-

nected to a Waters style endfitting (Figure 3). This will dramatically

reduce the efficiency of the column and cause peak shape distortion.

Figure 3: Parker Ferrule in a Waters Style Endfitting

It is important to realize that extra column peak broadening can

destroy a successful separation. The choice of appropriate column con-

nectors and system tubing is discussed in detail below.

b. Column Connectors and System Tubing Considerations

Due to the absence of an industry standard, various column man

facturers have employed different types of chromatographic column

connectors. The chromatographic performance of the separation can

be negatively affected if the style of the column endfittings does not

match the existing tubing ferrule setting. This section explains the

differences between Waters style and Parker style ferrules and endfit-

tings (Figure 1). Each endfitting style varies in the required length

of the tubing protruding from the ferrule. The HSS HPLC column is

equipped with Waters style endfittings, which require a 0.130 inch

HSS HPLC C olumns

To fix this problem: Cut the end of the tubing with the ferrule, place a

new ferrule on the tubing and make a new connection. Before tighten-

ing the screw, make sure that the tubing bottoms out in the endfitting

of the column.

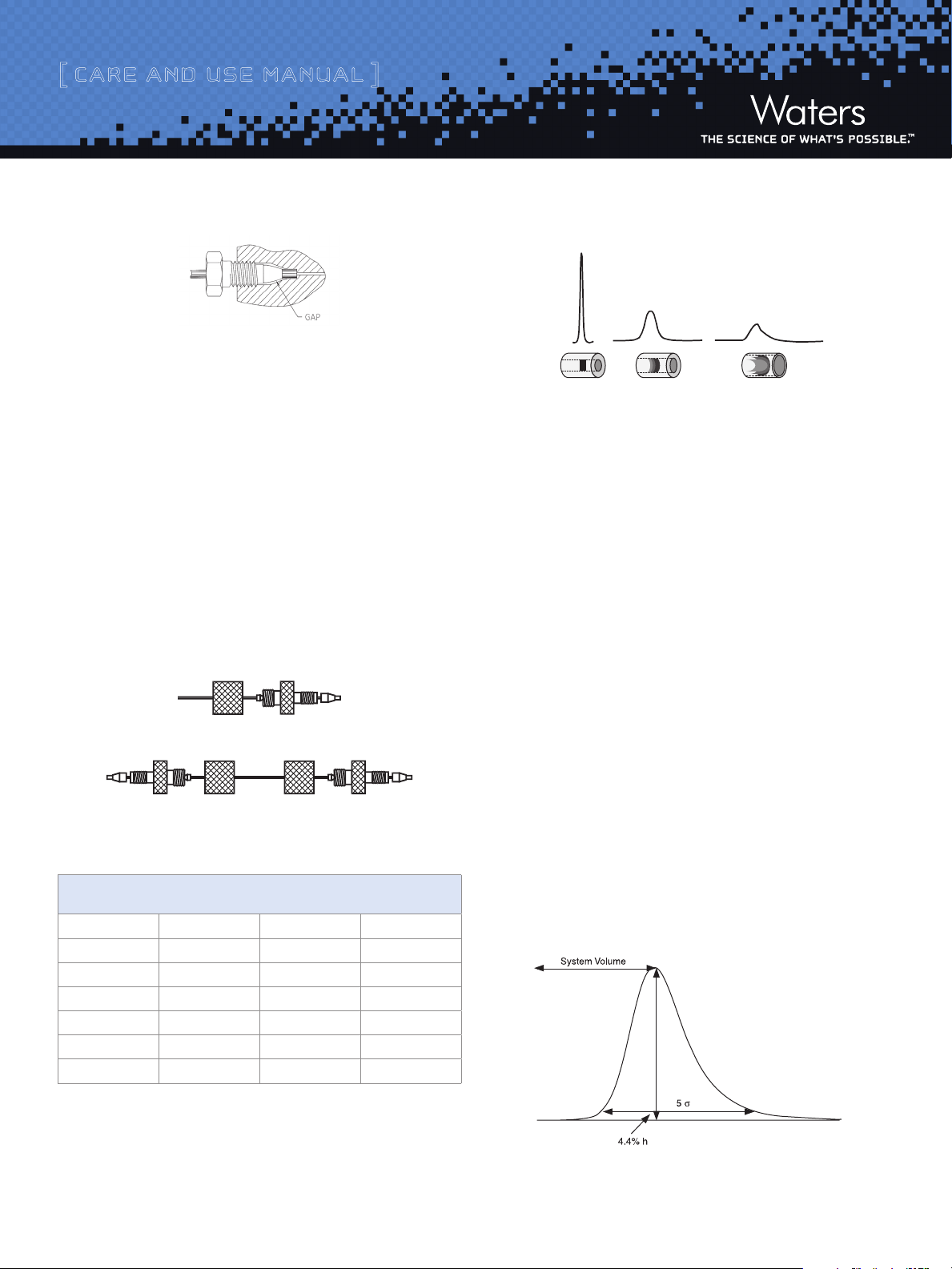

Conversely, if tubing with a Waters ferrule is connected to a column

with Parker style endfitting, the end of the tubing will bottom out

before the ferrule reaches its proper sealing position. This will leave a

gap and create a leak (Figure 4).

Caution: The connection will leak if a Waters ferrule is connected to a

column with a Parker style endfitting.

2

[ Care and Use ManUal ]

Diluted/Distorted Sample Band

0.005 inches

0.020 inches

0.040 inches

Figure 4: Waters Ferrule in a Parker Style Endfitting

There are two ways to fix the problem:

1. Tighten the screw a bit more. The ferrule moves forward, and

reaches the sealing surface. Do not overtighten since this may

break the screw.

2. Cut the tubing, replace the ferrule and make a new connection.

Alternatively, replace the conventional compression screw fitting with

™

an all-in-one PEEK

fitting (Waters Part Number PSL613315) that

allows resetting of the ferrule depth. Another approach is to use a

™

Thermo Hypersil

Keystone, Inc. SLIPFREE® connector to ensure the

correct fit. The fingertight SLIPFREE connectors automatically adjust to fit

all compression screw type fittings without the use of tools (Figure 5).

Figure 5: Single and Double SLIPFREE Connectors

Figure 6: Effect of Connecting Tubing on System

d. Measuring System Bandspread Volume

This test should be performed on an HPLC system with a single wave-

length UV detector (not a Photodiode Array (PDA)).

1. Disconnect column from system and replace with a zero dead

volume union.

2. Set flow rate to 1 mL/min.

3. Dilute a test mix in mobile phase to give a detector sensitivity

0.5-1.0 AUFS (system start up test mix can be used which

contains uracil, ethyl and propyl parabens; Waters Part Number

WAT034544).

Table 1. Waters Part Numbers for SLIPFREE Connectors

SLIPFREE Type and

Tubing Length

0.005” 0.010” 0.020”

Single 6 cm PSL 618000 PSL 618006 PSL 618012

Single 10 cm PSL 618002 PSL 618008 PSL 618014

Single 20 cm PSL 618004 P SL 618010 PSL 618016

Double 6 cm PSL 618001 PSL 618007 PSL 618013

Double 10 cm P SL 618003 PSL 618009 PSL 618015

Double 20 cm P SL 618005 PSL 618001 PSL 618017

c. Band Spreading Minimization

Internal tubing diameter influences system band spreading and peak

shape. Larger tubing diameters cause excessive peak broadening and

lower sensitivity (Figure 6).

Tubing Internal Diameter

4. Inject 2 to 5 μL of this solution.

5. Using 5 sigma method measure the peak width at 4.4% of peak

height:

Band Spreading (μL) = Peak Width (min) x Flow Rate (μL/min)

= 0.1 min x 1000 μL/min

= 100 μL

Figure 7: Determination of System Bandspread Volume

Using 5-Sigma Method

In a typical HPLC system, the Bandspread Volume should be 100 μL ± 30 μL .

HSS HPLC C olumns

3

Loading...

Loading...